Chain conveying belt

A technology of conveyor belts and chains, applied in the field of conveyor belts, can solve the problems of sheet falling, increase labor intensity and labor cost, increase equipment cost, etc., and achieve the effect of convenient width adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

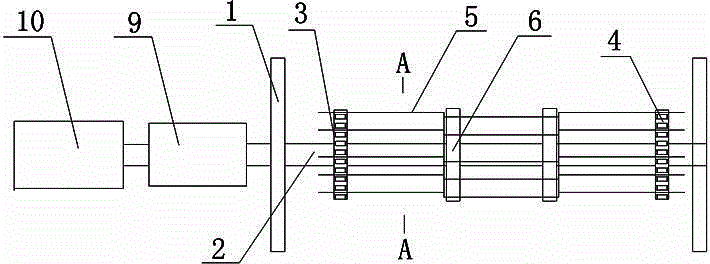

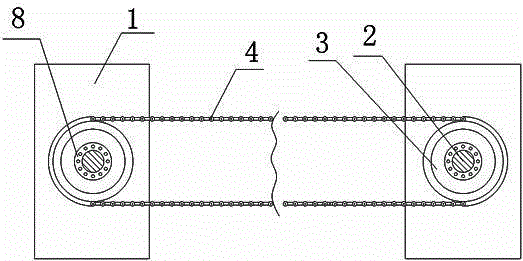

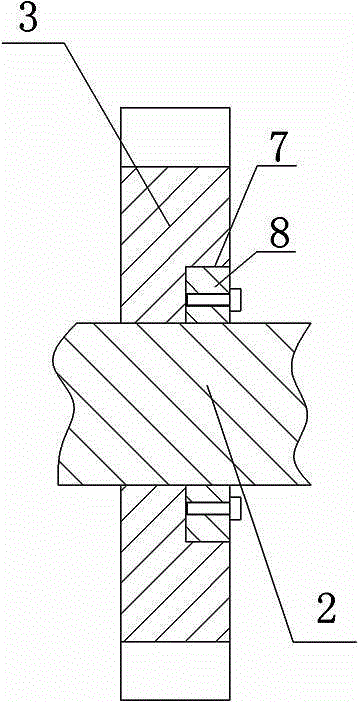

[0013] Such as figure 1 and figure 2 Shown, a kind of chain conveyer belt, it comprises frame 1, power transmission shaft 2, primary sprocket 3, chain 4, conveyer belt 5, secondary sprocket 6 and the transmission mechanism that drives transmission shaft 2 to rotate, and the transmission mechanism of described transmission shaft 2 The two ends are connected in the frame 1 by bearings, and the secondary sprockets 6 are two and symmetrically fixedly installed in the middle part of the transmission shaft 2, as image 3 As shown, there are two main sprockets 3 and one end surface of the main sprocket 3 is provided with an expansion step 7, an expansion sleeve 8 is installed in the expansion step 7, and the main sprockets 3 are installed on the drive shaft 2 respectively. The two ends of the drive belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com