Tooling for processing intelligent carbon skateboard with multi-point limit clamping and its application method

A technology of carbon skateboard and limit position, which is applied in the direction of workpiece clamping device and manufacturing tools, can solve the problems of not being able to use carbon skateboards of different sizes at the same time, the damage of the carbon skateboard body, and affecting the processing effect, so as to improve stability and work Efficiency, ease of disassembly and assembly, and increased convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

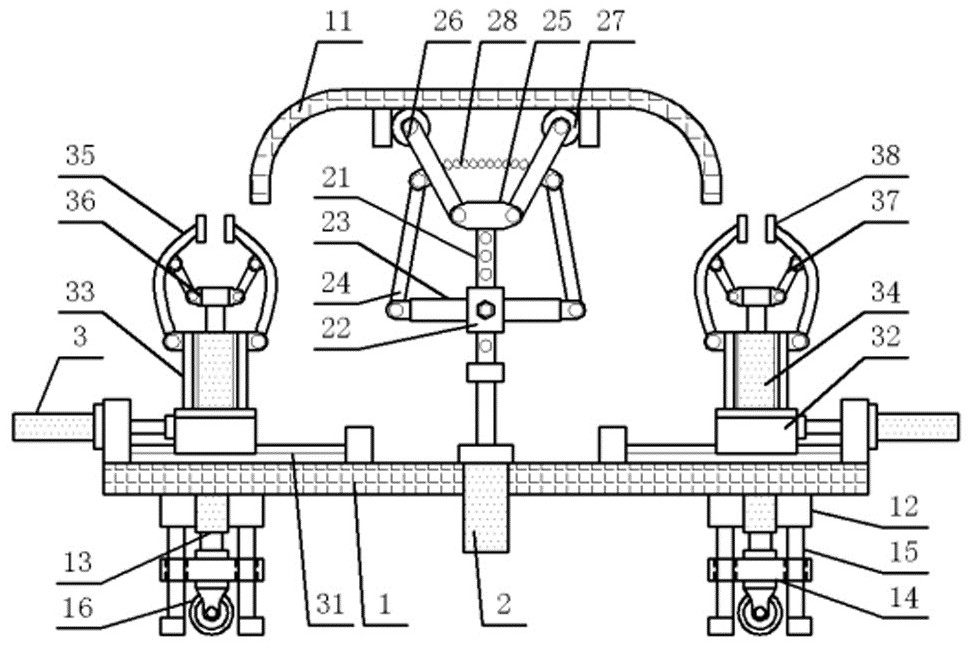

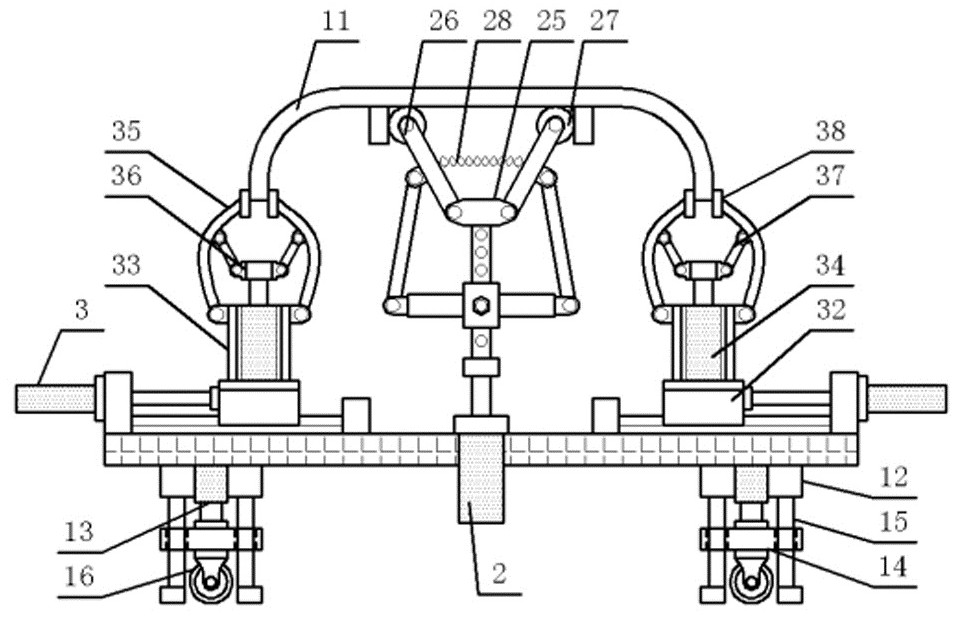

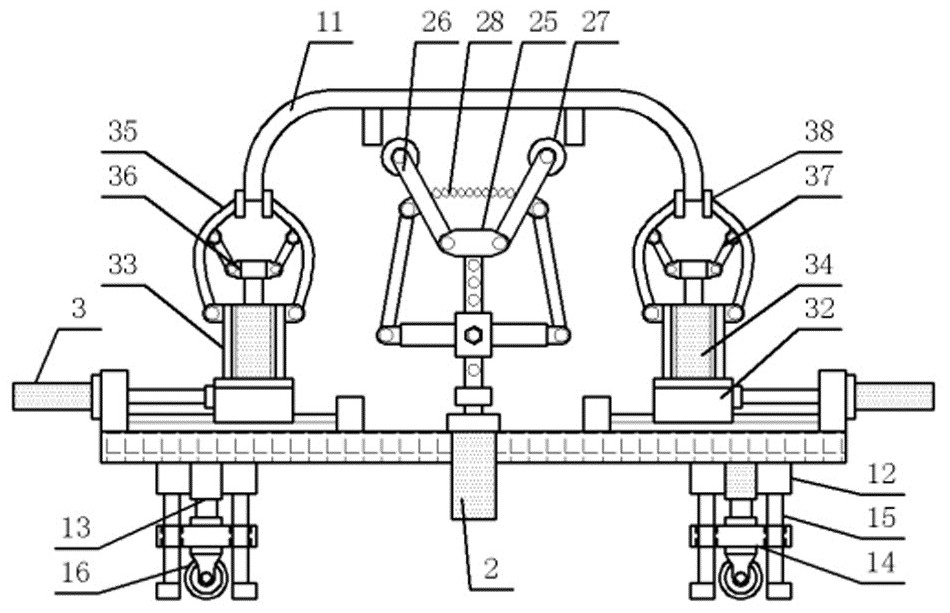

[0033] Embodiment 1: see Figure 1-5, the tooling for processing smart carbon skateboards with multi-point limit clamping, including a bottom plate 1, the bottom plate 1 is a rectangular long plate placed horizontally and horizontally, and a carbon skateboard with an opening facing downwards is arranged horizontally above the top surface of the bottom plate 1 11. The four corners of the bottom surface of the bottom plate 1 are provided with a base 12, and the bottom surface of each base 12 is recessed with a first telescopic cylinder groove with the opening facing downward, and each of the first telescopic cylinder grooves is equipped with an output The first telescopic cylinder 13 with the end facing down, the model of the first telescopic cylinder 13 is FESP25, each telescopic cylinder of the first telescopic cylinder 13 is movably connected with the roller 16 through a sliding assembly; the center of the top surface of the bottom plate 1 is depressed There is a second teles...

Embodiment 2

[0039] Example 2: see Figure 6 , in this embodiment, the present invention also proposes a method for using a tooling for intelligent carbon skateboard processing with multi-point limit clamping, including the following steps:

[0040] Step 1, the first telescopic cylinder 13, the second telescopic cylinder 2, the sliding telescopic cylinder 3, and the third telescopic cylinder 34 are all powered on respectively;

[0041] Step 2, control the first telescopic cylinder 13 to drive the roller 16 up and down, the telescopic cylinder of the first telescopic cylinder 13 drives the limiting plate 14 through the first connecting block, and the sliding hole on the limiting plate 14 moves up and down along the first sliding rod 15 , and then drive the roller 16 up and down, and push the tooling to move to the designated position according to the processing position;

[0042] Step 3, according to the width of the two inner buckles of the carbon skateboard 11, lock the sliding cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com