Packing machine membrane arrangement equipment

A packaging machine and equipment technology, applied in the field of packaging machine film release equipment, can solve the problems that affect the efficiency and quality of film release, time-consuming and laborious replacement of packaging film, heavy packaging film weight, etc., to improve film release efficiency and ensure continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

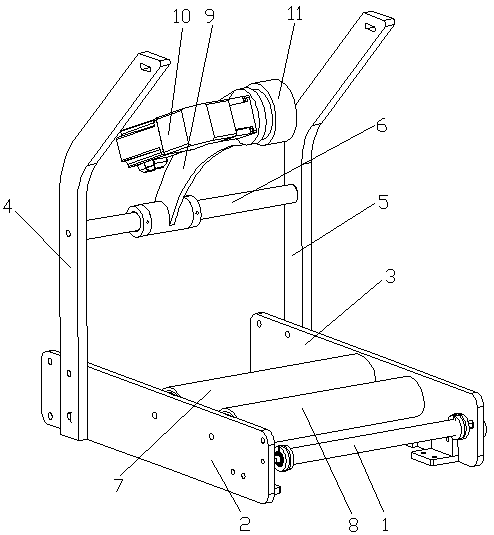

Embodiment 1

[0044] The film release equipment of the packaging machine includes a support and a film passing roller 1. The support includes a first seat plate 2, a second seat plate 3, a first support plate 4, a second support plate 5 and a first support plate connected to the first support plate. 4 and the fulcrum shaft 6 between the second support plate 5, the first support plate 4 is fixed on the first seat plate 2, the second support plate 5 is fixed on the second seat plate 3, and one end of the film passing roller 1 It is connected with the first seat plate 2, and the other end is connected with the second seat plate 3, and the first idler roller 7 and the second idler roller 8 are arranged side by side between the first seat plate 2 and the second seat plate 3, and the A swing arm 9 is hinged on the fulcrum shaft 6, a servo motor 10 is fixed on the swing arm 9, and an active rubberized wheel 11 is connected to the servo motor 10.

[0045] This embodiment is the most basic implement...

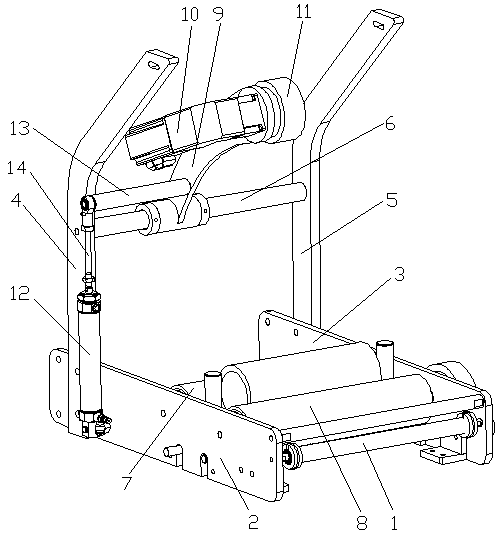

Embodiment 2

[0047] The film release equipment of the packaging machine includes a support and a film passing roller 1. The support includes a first seat plate 2, a second seat plate 3, a first support plate 4, a second support plate 5 and a first support plate connected to the first support plate. 4 and the fulcrum shaft 6 between the second support plate 5, the first support plate 4 is fixed on the first seat plate 2, the second support plate 5 is fixed on the second seat plate 3, and one end of the film passing roller 1 It is connected with the first seat plate 2, and the other end is connected with the second seat plate 3, and the first idler roller 7 and the second idler roller 8 are arranged side by side between the first seat plate 2 and the second seat plate 3, and the A swing arm 9 is hinged on the fulcrum shaft 6, a servo motor 10 is fixed on the swing arm 9, and an active rubberized wheel 11 is connected to the servo motor 10.

[0048] A cylinder 12 is hinged on the first seat p...

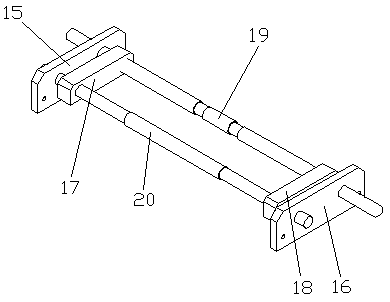

Embodiment 3

[0051] The film release equipment of the packaging machine includes a support and a film passing roller 1. The support includes a first seat plate 2, a second seat plate 3, a first support plate 4, a second support plate 5 and a first support plate connected to the first support plate. 4 and the fulcrum shaft 6 between the second support plate 5, the first support plate 4 is fixed on the first seat plate 2, the second support plate 5 is fixed on the second seat plate 3, and one end of the film passing roller 1 It is connected with the first seat plate 2, and the other end is connected with the second seat plate 3, and the first idler roller 7 and the second idler roller 8 are arranged side by side between the first seat plate 2 and the second seat plate 3, and the A swing arm 9 is hinged on the fulcrum shaft 6, a servo motor 10 is fixed on the swing arm 9, and an active rubberized wheel 11 is connected to the servo motor 10.

[0052] A cylinder 12 is hinged on the first seat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com