Patents

Literature

181results about How to "Prevent axial displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

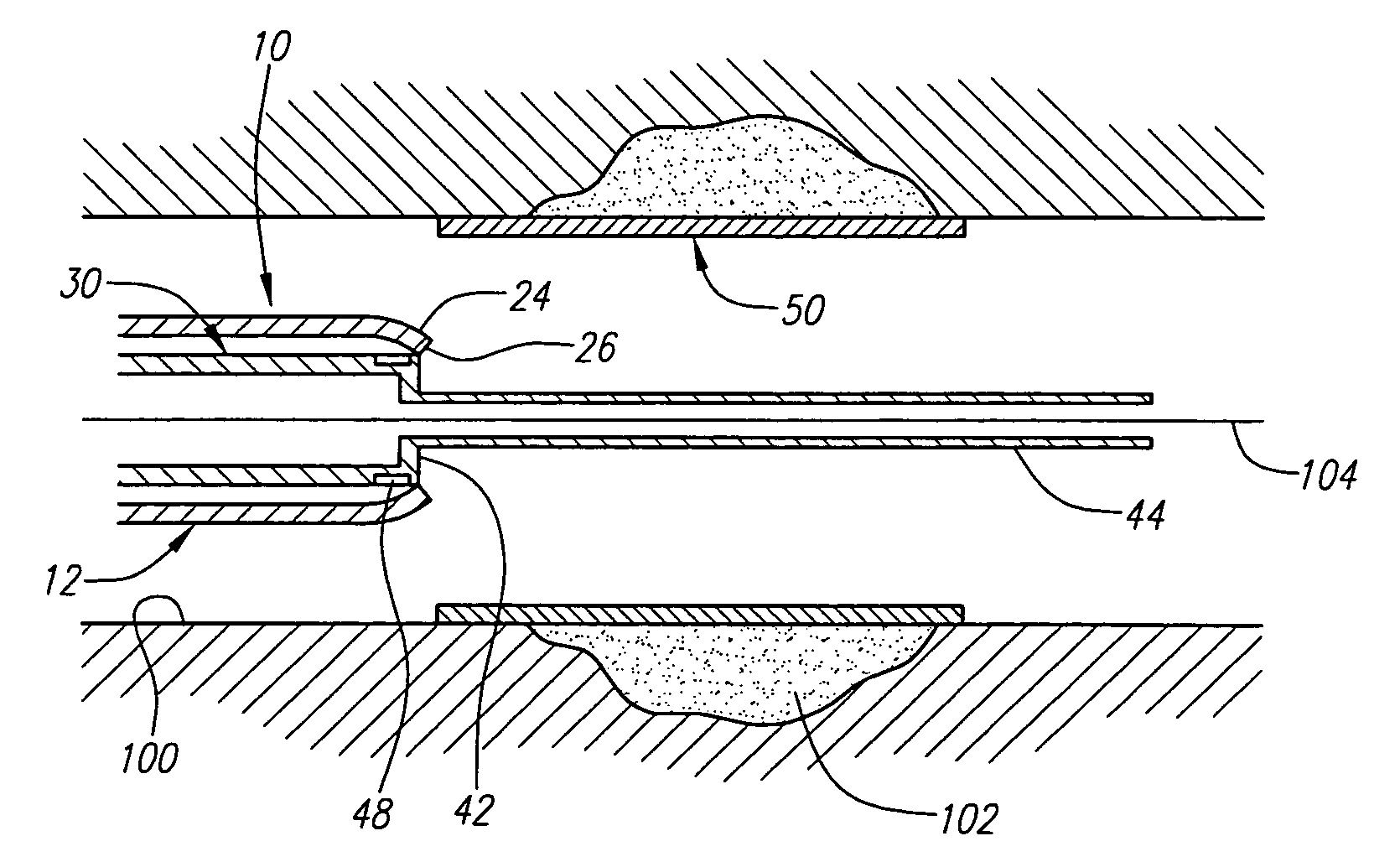

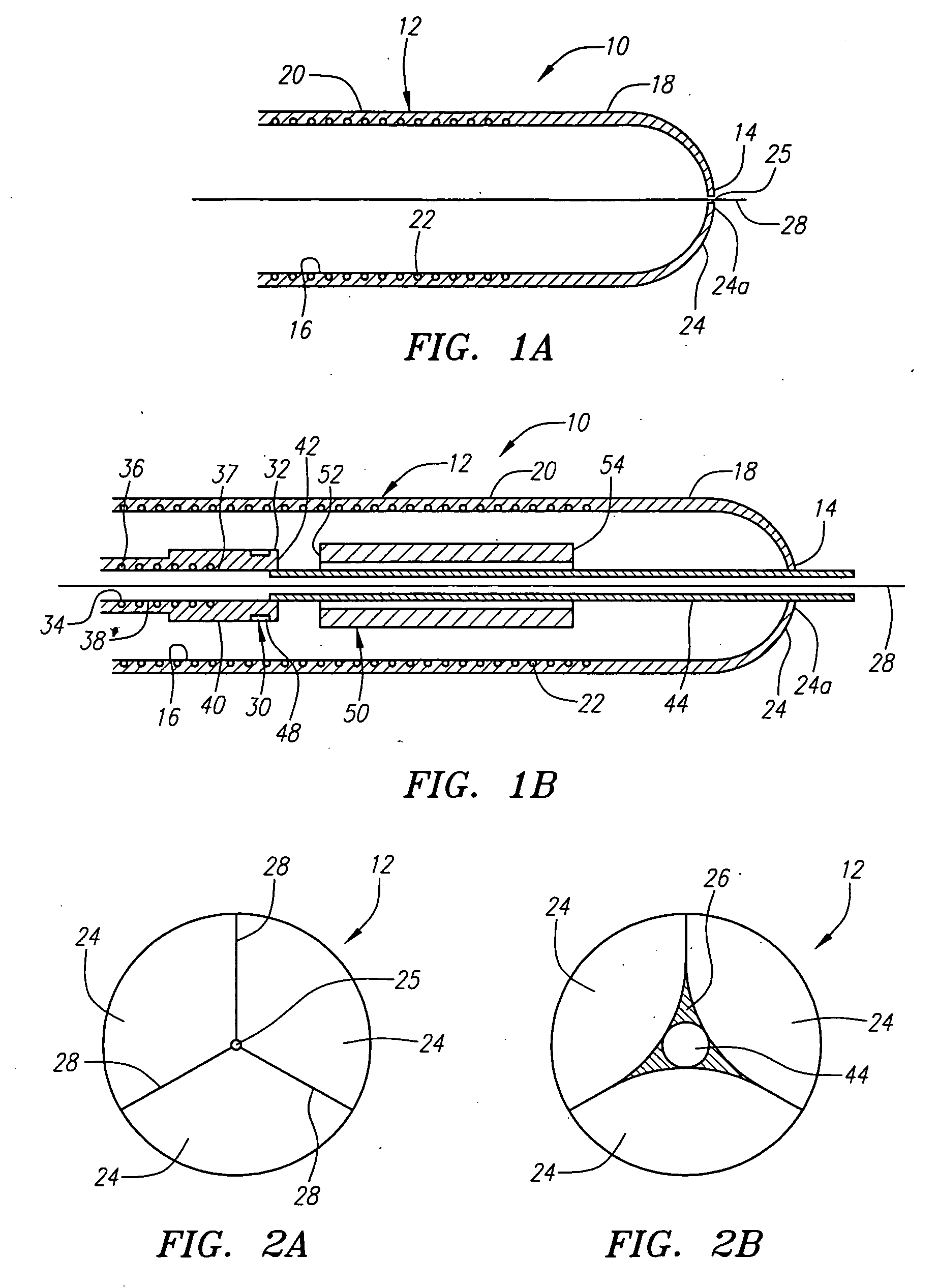

Apparatus for delivering endoluminal prostheses and methods of making and using them

Owner:ENDOTEX INTERVENTIONAL SYST

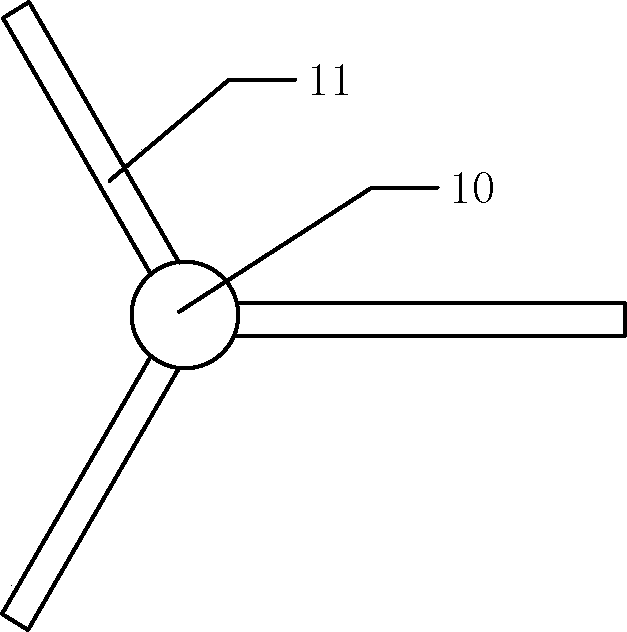

Rotating shaft angle position sensing device and sensing system

ActiveCN104180752APrevent axial displacementAvoid vibrationUsing electrical meansElectric signalMagnet device

The invention provides a sensor for sensing an angle position of a rotating shaft and a sensing system, wherein a magnet conductive block is fixedly arranged on the rotating shaft and can rotate along with rotation of the rotating shaft. The sensor comprises a magnet device and a Hall effect sensing component. The Hall effect sensing component is used for sensing the angle position of the rotating shaft. When the magnet conductive block rotates along with the rotating shaft, a magnetic field which is generated by the magnet device is changed. The Hall effect sensing component generates an electric signal along with magnetic field change. The electric signal indicates the angle position of the rotating shaft. Because built-in U-shaped back magnet technology is adopted for the sensor of the invention, sensing precision of the sensor is greatly improved. Therefore a precision requirement for measuring the angle position of the rotating shaft can be satisfied through using a single IC chip which is provided with one Hall effect sensing component.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

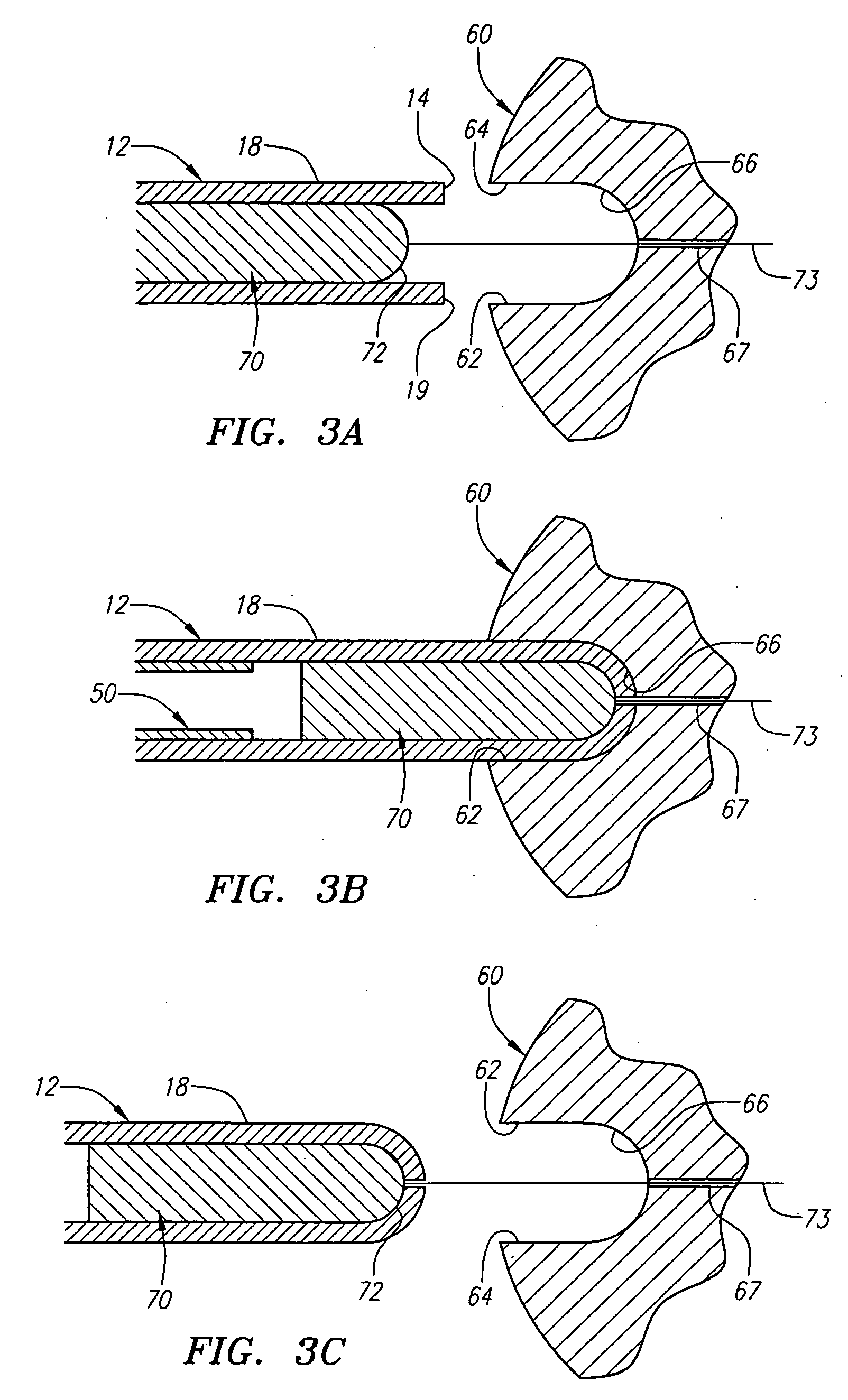

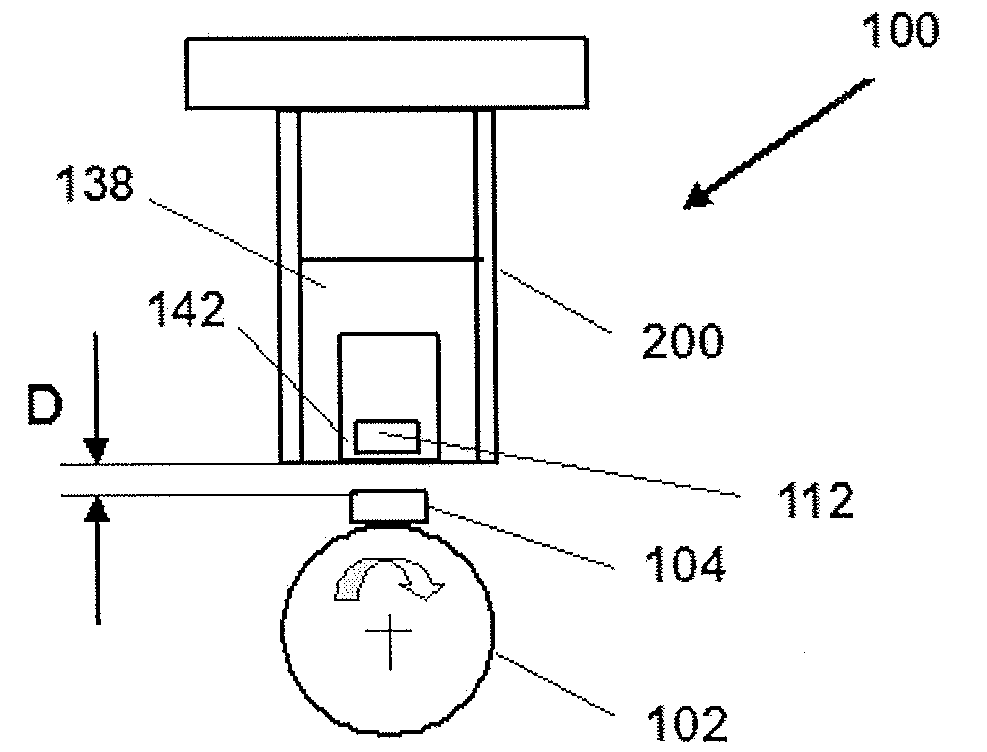

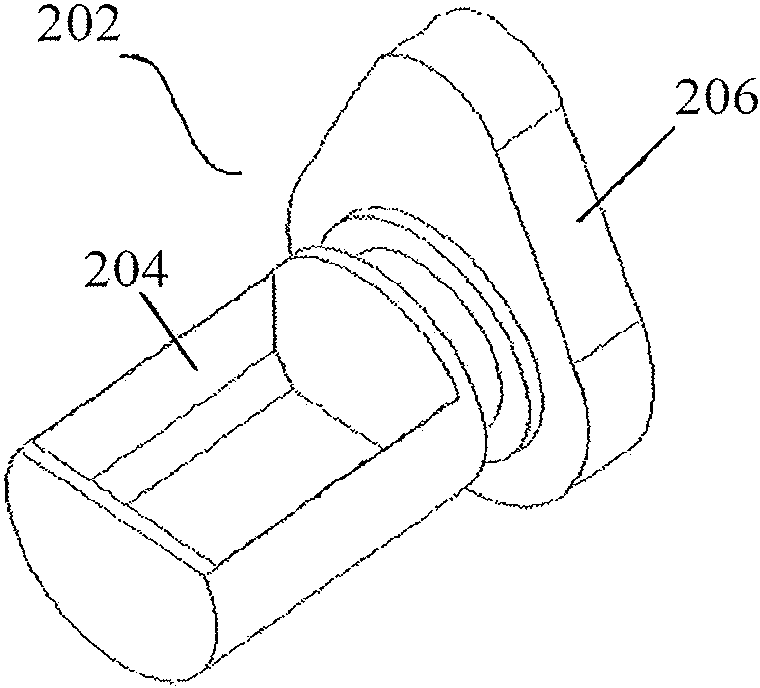

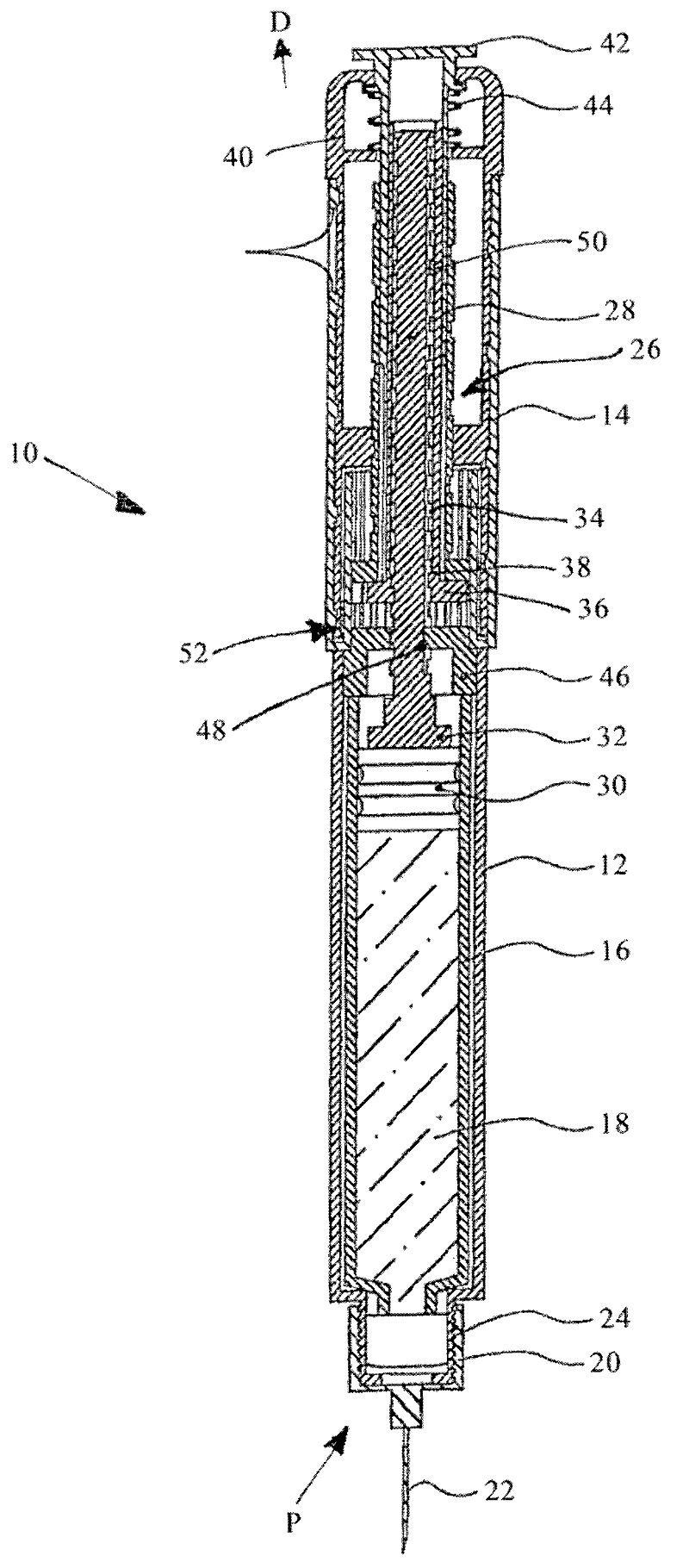

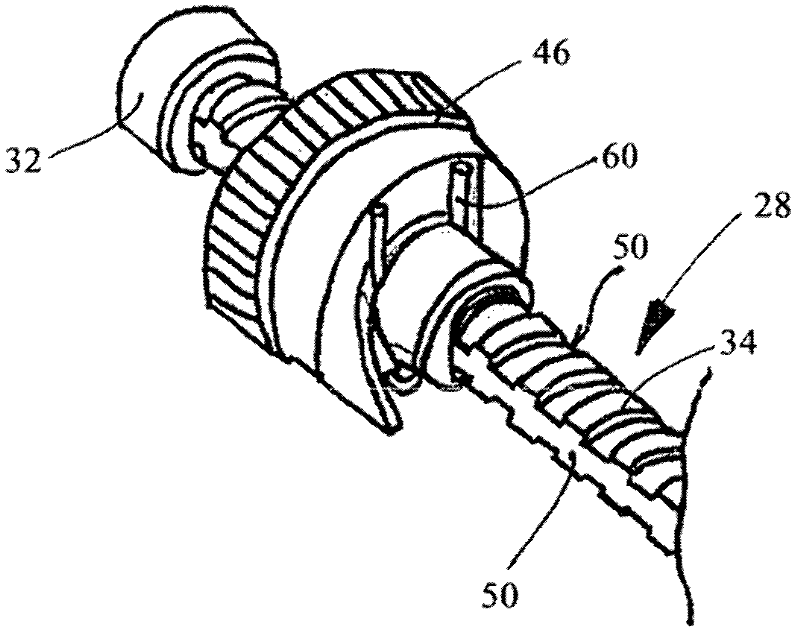

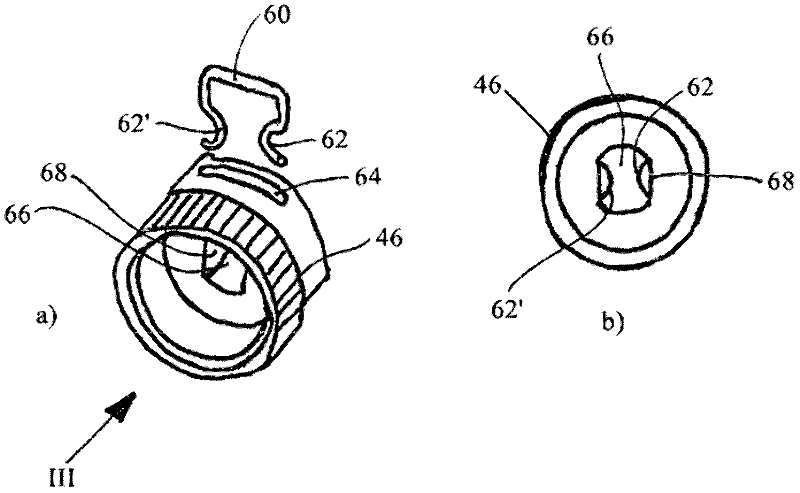

Injection device with holding means to prevent unintentional movements of piston rod

ActiveCN102238974AImprove the display effectAvoid formingAmpoule syringesMedical devicesAxial displacementEngineering

The invention relates to a injection device, comprising a housing being adapted to receive in its proximal housing portion a container with an injection fluid and to receive in its distal housing portion a dose setting and injection mechanism, wherein the mechanism includes a piston rod (28) being axially displaceable with respect to the housing for dispensing injection fluid from the container, wherein the piston rod (28) has an outer thread (34) and is arranged torque proof with respect to the housing, dose setting means comprising a threaded element, which threaded element has an inner thread being in engagement with the outer thread (34) of the piston rod (28), is designed so that its axial position relative to the housing is changeable and is rotatable relative to the piston rod (28) and relative to the housing during setting of an injection dose, wherein the dose setting means are designed such that the threaded element is held in torque proof manner relative to the piston rod (28) and to the housing during the injection of the beforehand set injection dose in such a manner that the threaded element and the piston rod (28) are axially displaceable together with respect to the housing, wherein the mechanism (26) further comprises holding means (60; 160) being in contact with the piston rod (28) and being designed such that the axial displacement of the piston rod (28) can be substantially immobilized during use of the device except for the dispensing of the injection dose. It is proposed according to the invention that the holding means (60; 160) are axially fixed with respect to the housing.

Owner:SANOFI AVENTIS DEUT GMBH

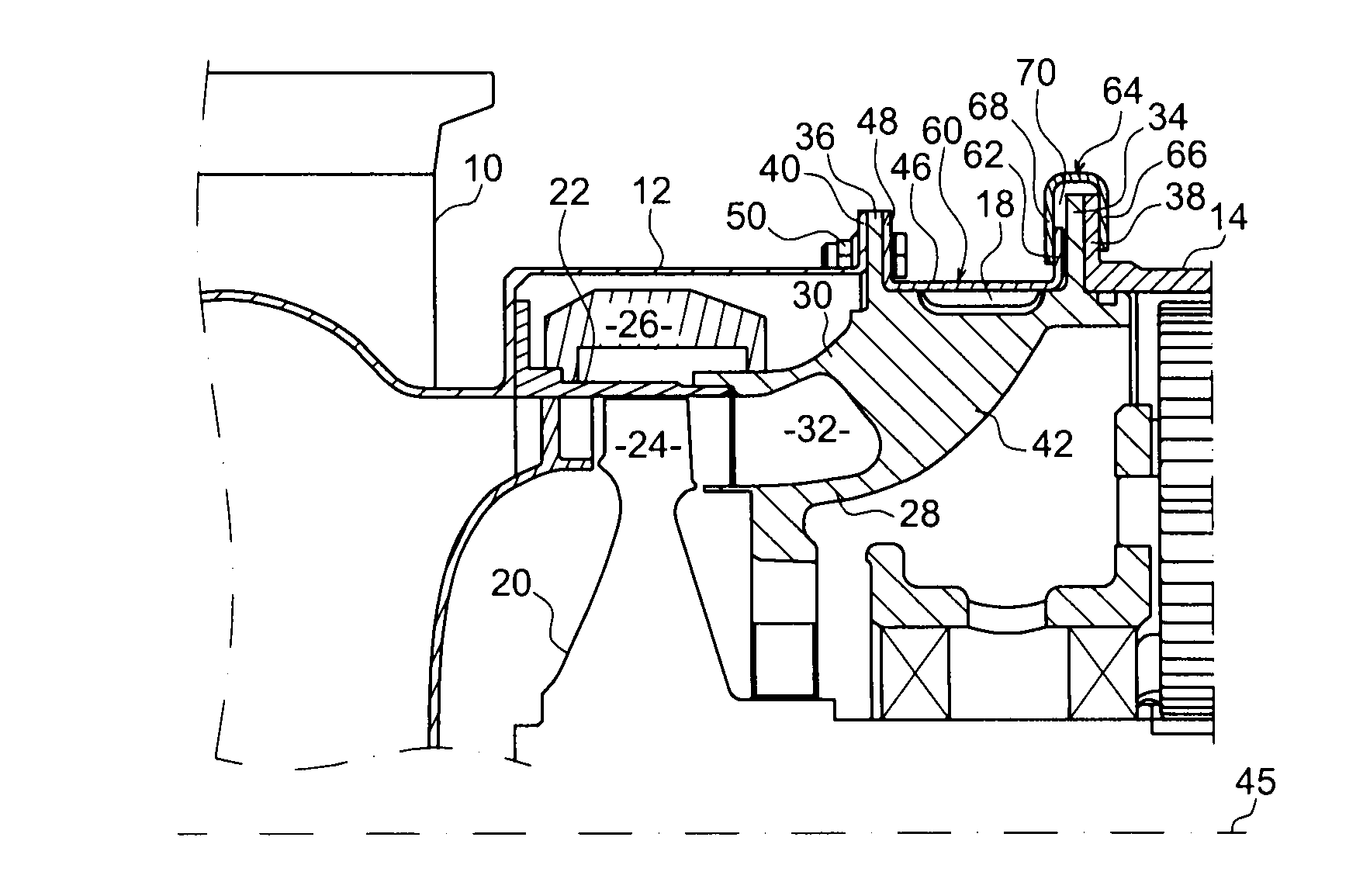

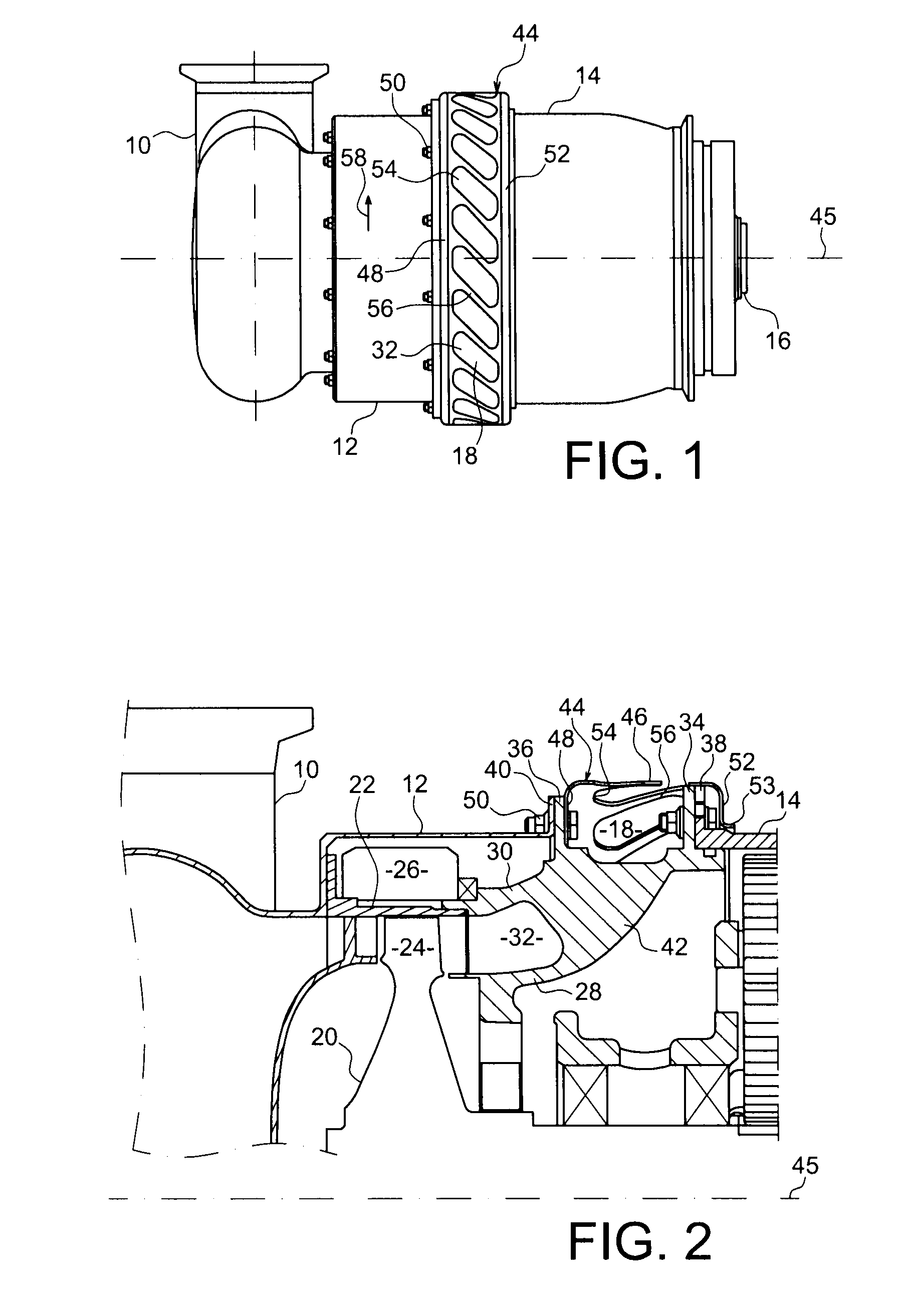

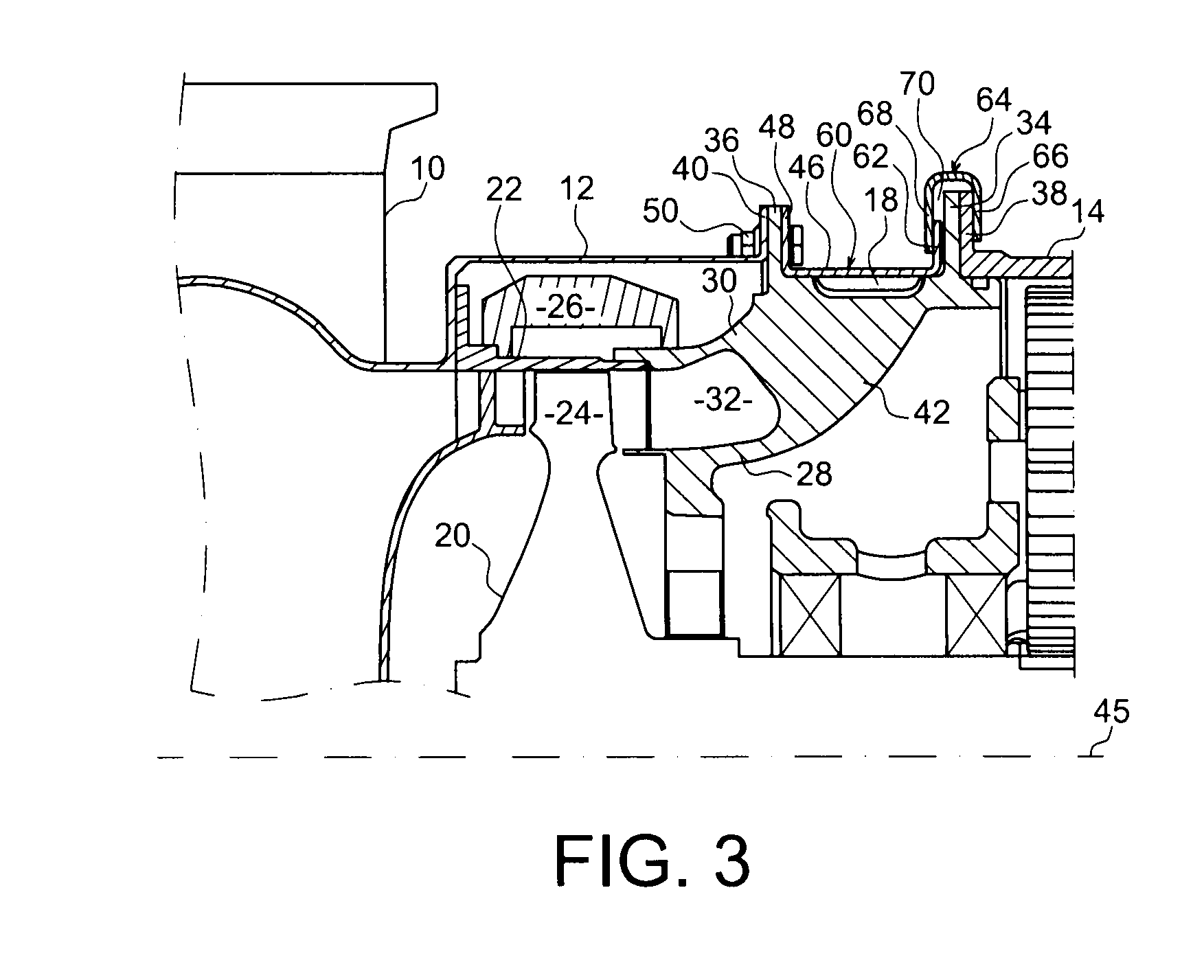

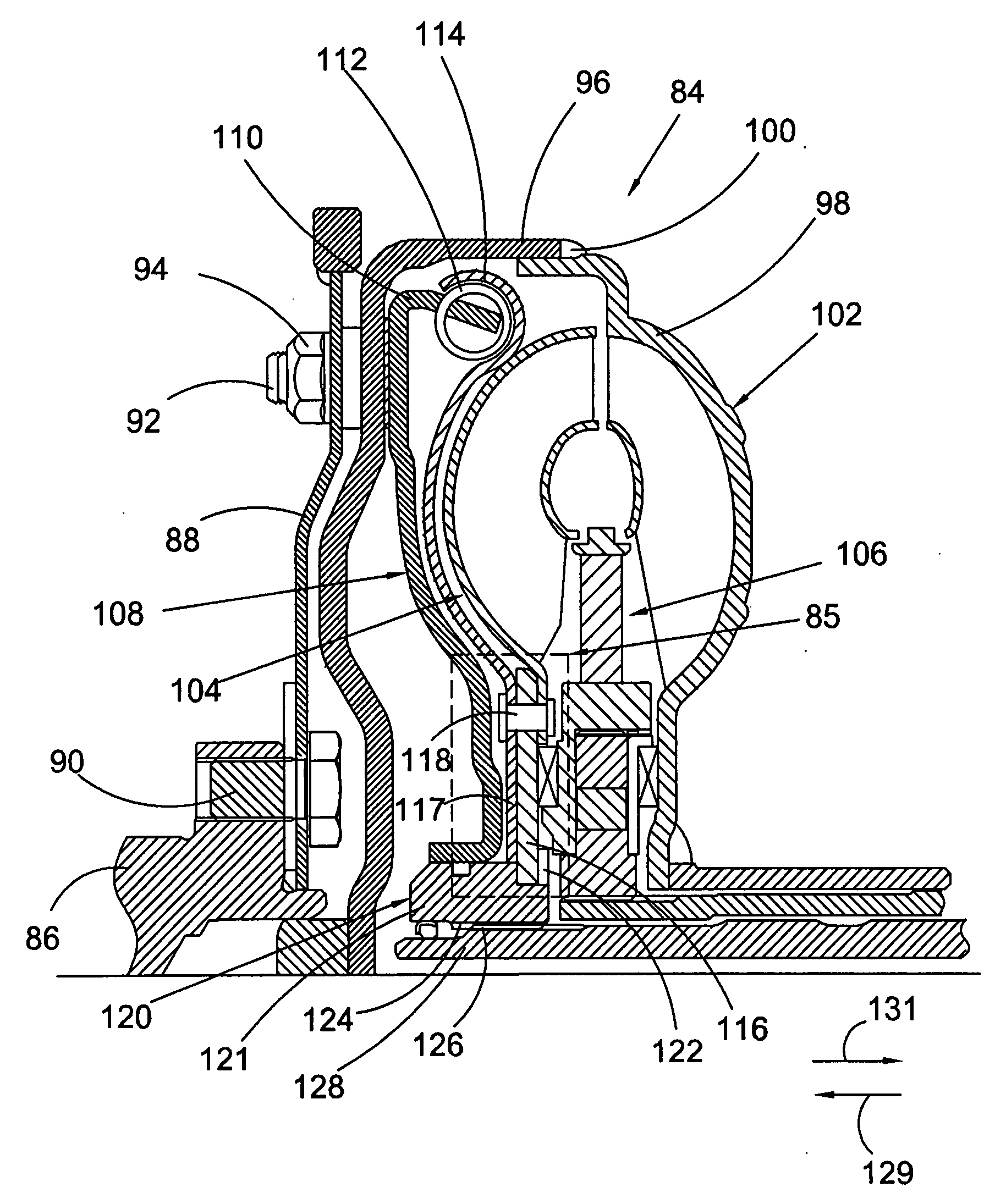

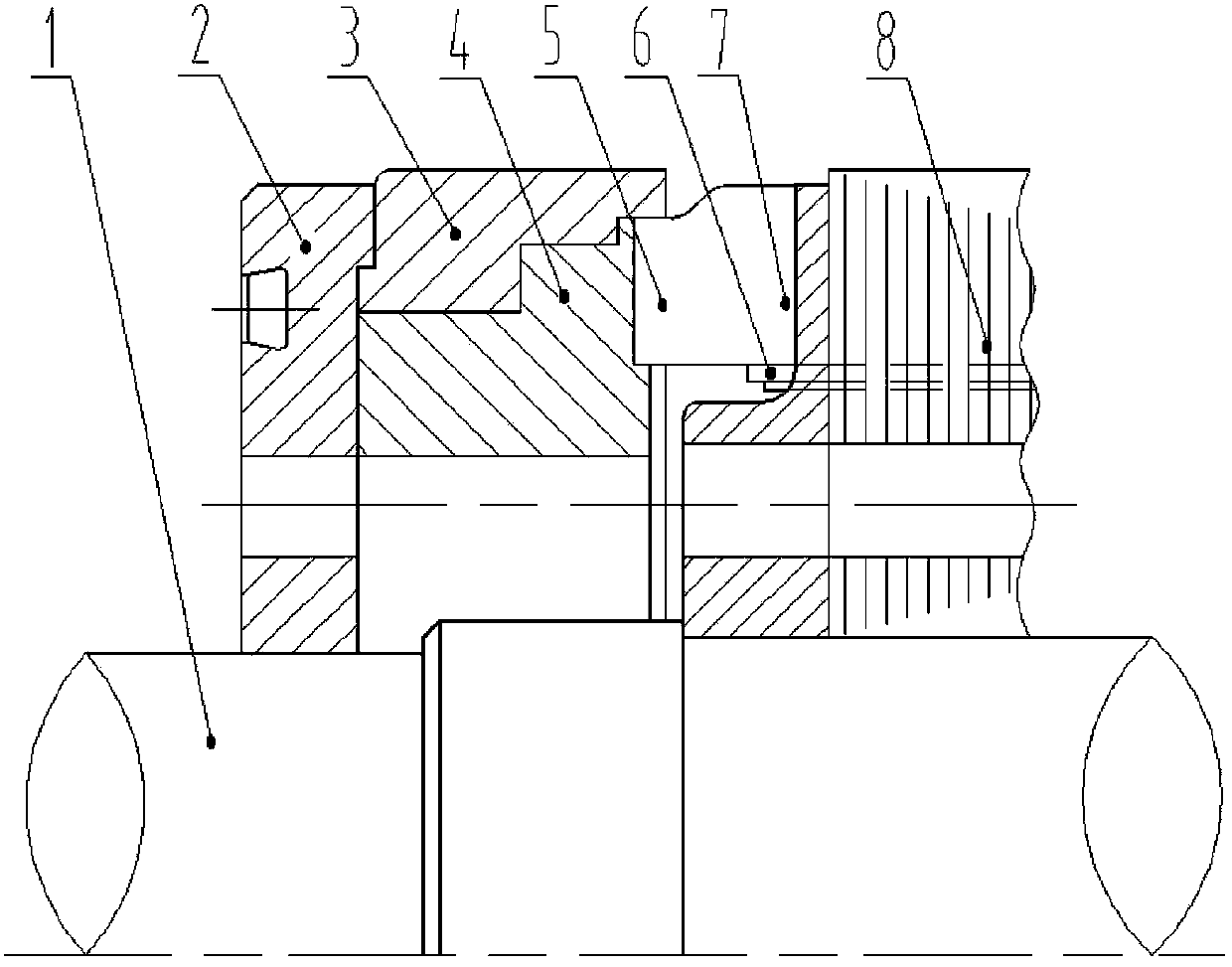

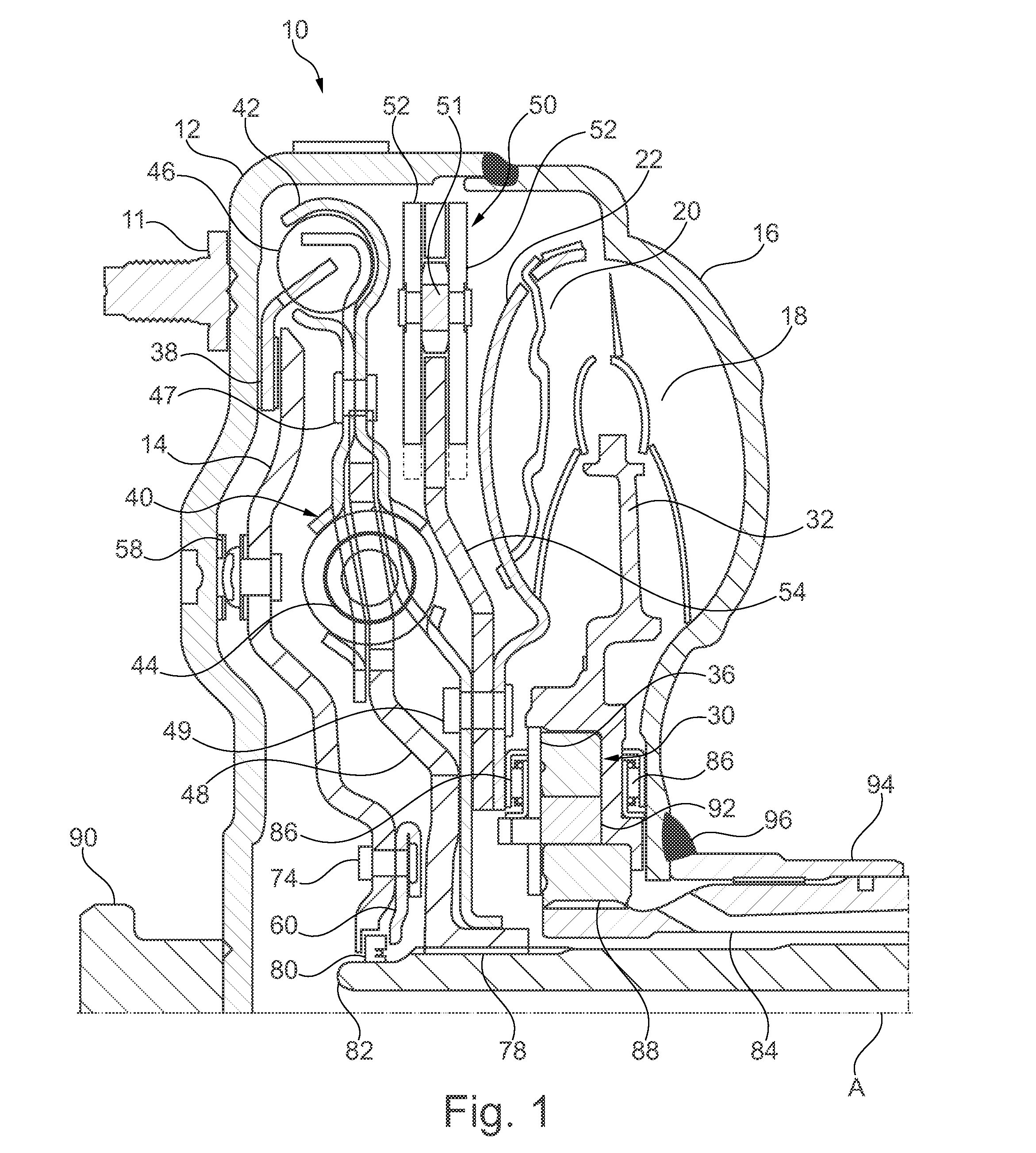

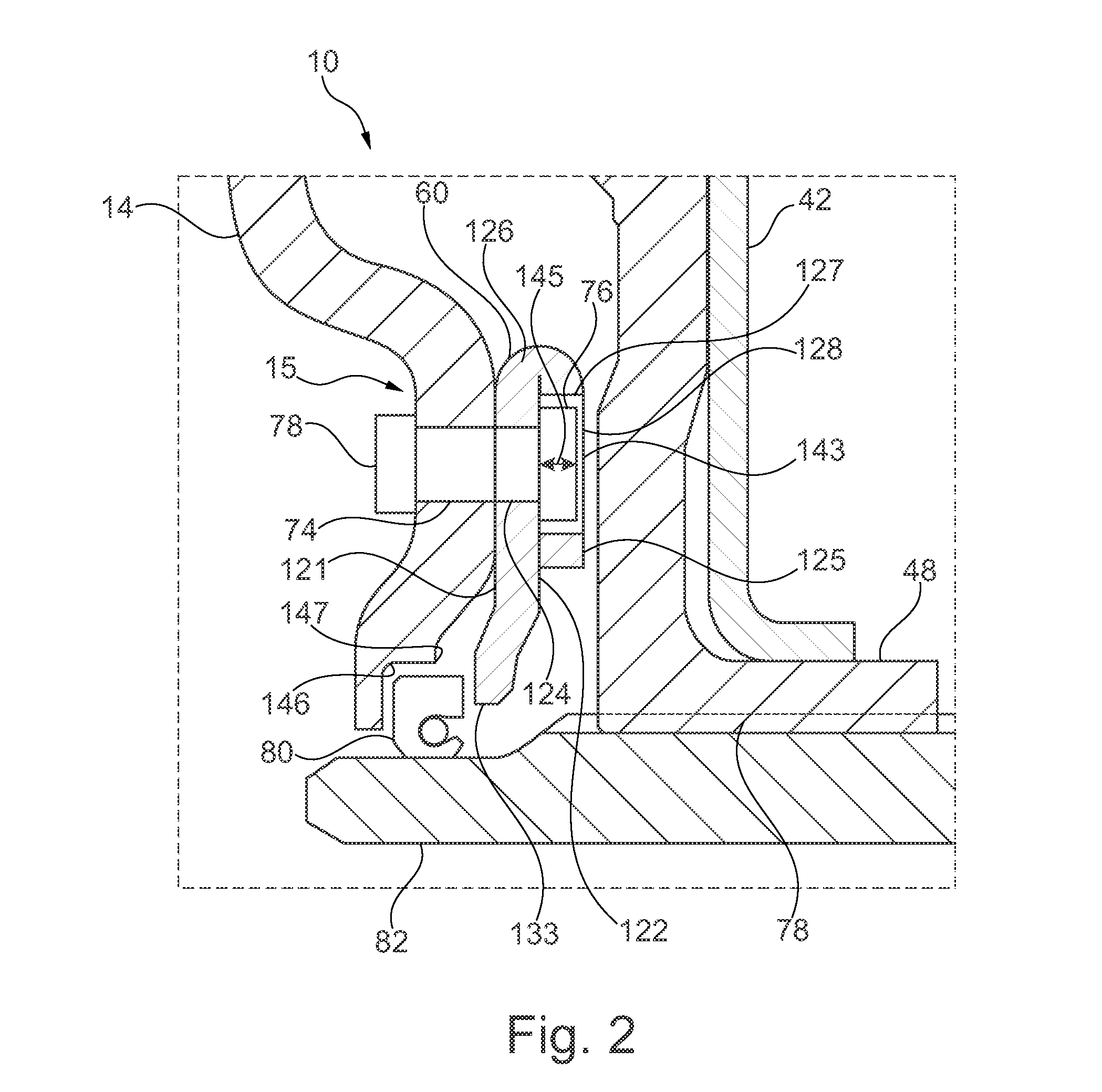

Compressed air starter for turbomachine

ActiveUS20100192594A1Light weightPrevent axial displacementPump componentsTurbine/propulsion engine ignitionFront and back endsCompressed air

Air starter for turbomachine, comprising a forward casing (12), an aft casing (14), an annular exhaust flow path (32) opening up between an aft end of the forward casing and a forward end of the aft casing, and a cylindrical outlet mesh (44) of the exhaust flow path (32) the forward and aft ends of which comprise means (48, 52) of axially retaining the forward casing (12) and the aft casing (14) respectively to the mesh (44), wherein at least said means (52) of axially retaining one (14) of the casings to the mesh (44) enable a relative rotation of the mesh (44) and this casing (14).

Owner:SAFRAN POWER UNITS

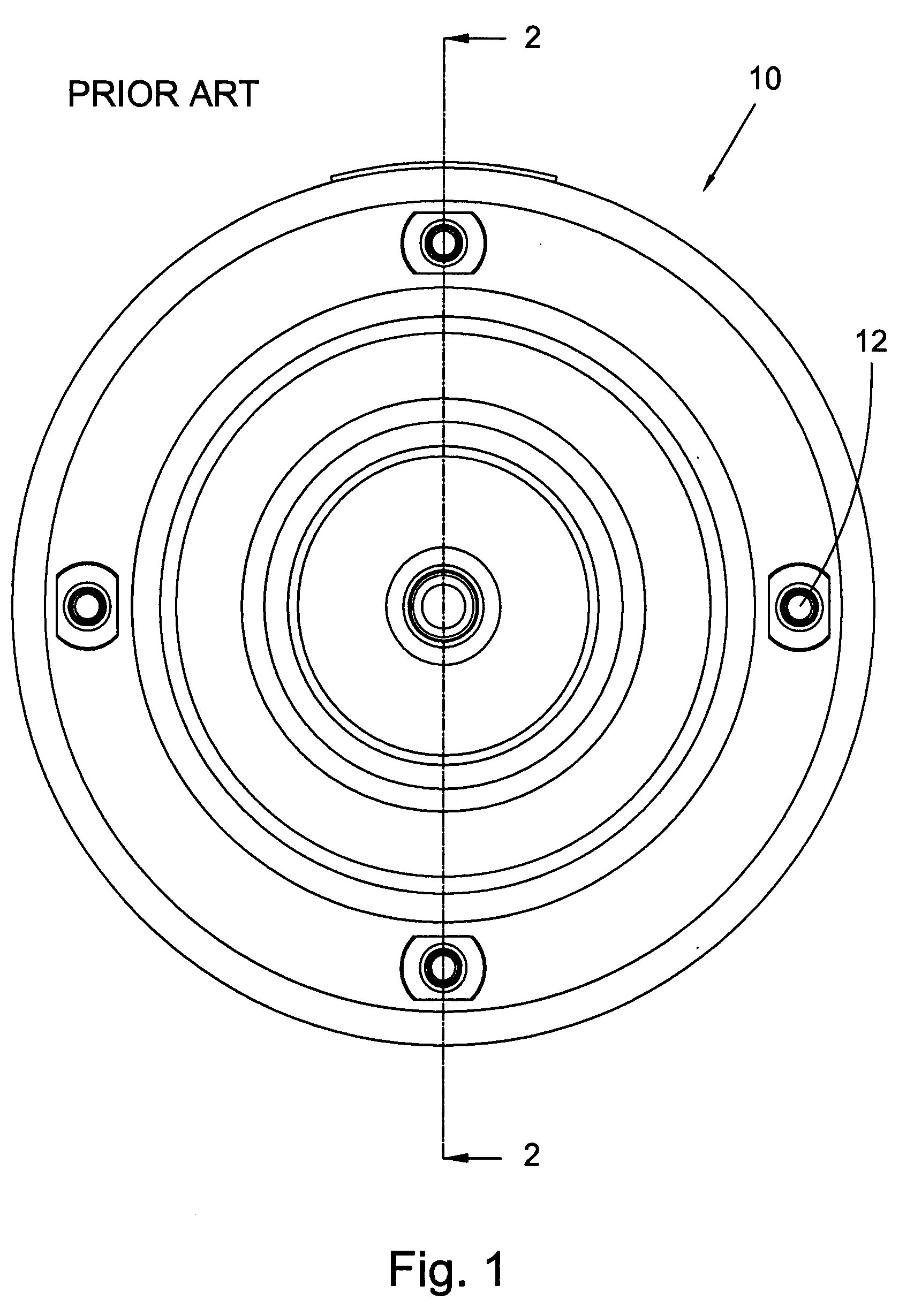

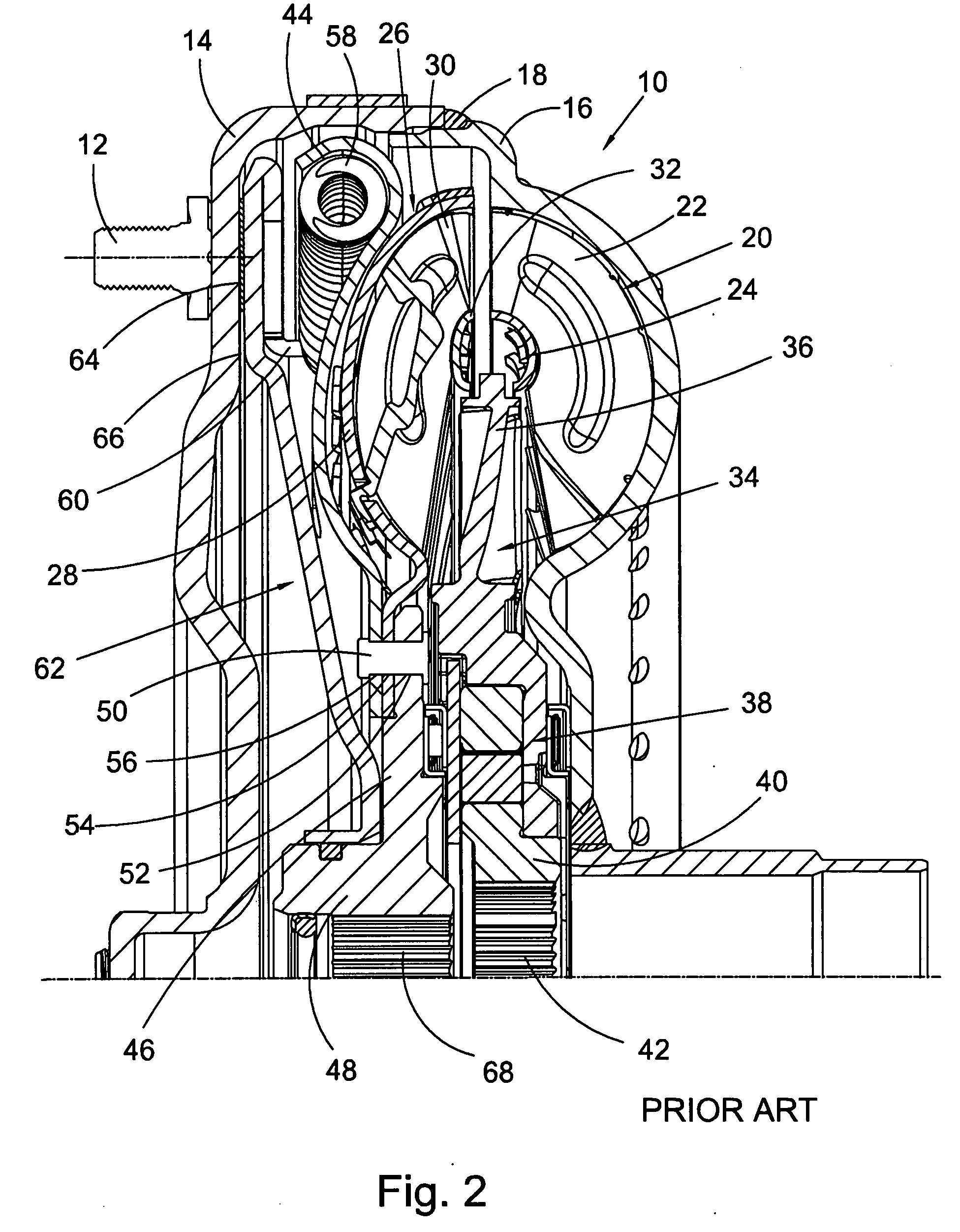

Apparatus for joining components to a hub

InactiveUS20070256905A1Reduce the total massEasy to assembleYielding couplingRotary clutchesEngineeringTurbine

The present invention broadly includes a hub assembly for a torque converter having a hub arranged to rotationally connect to a transmission input shaft and includes first and second radial surfaces, a first plate rotationally connected to a turbine, rotationally connected to the hub, and fixed in a first axial direction by the first surface and a second plate rotationally connected to the first plate and fixed in a second axial direction, opposite the first direction, by the second surface. The hub assembly may include a hub having at least one radially disposed protrusion, the protrusion includes the second radial surface, and the first plate is rotationally connected to the protrusion. The hub may further include a body with a first diameter and the protrusion with a second diameter greater than the first diameter. The first and second radial surfaces may be arranged to axially fix a turbine with respect to the hub, or the first and second radial surfaces may be coplanar. The first plate may be in contact with the first radial surface, or the second plate may be in contact with the second radial surface.

Owner:SCHAEFFLER TECH AG & CO KG

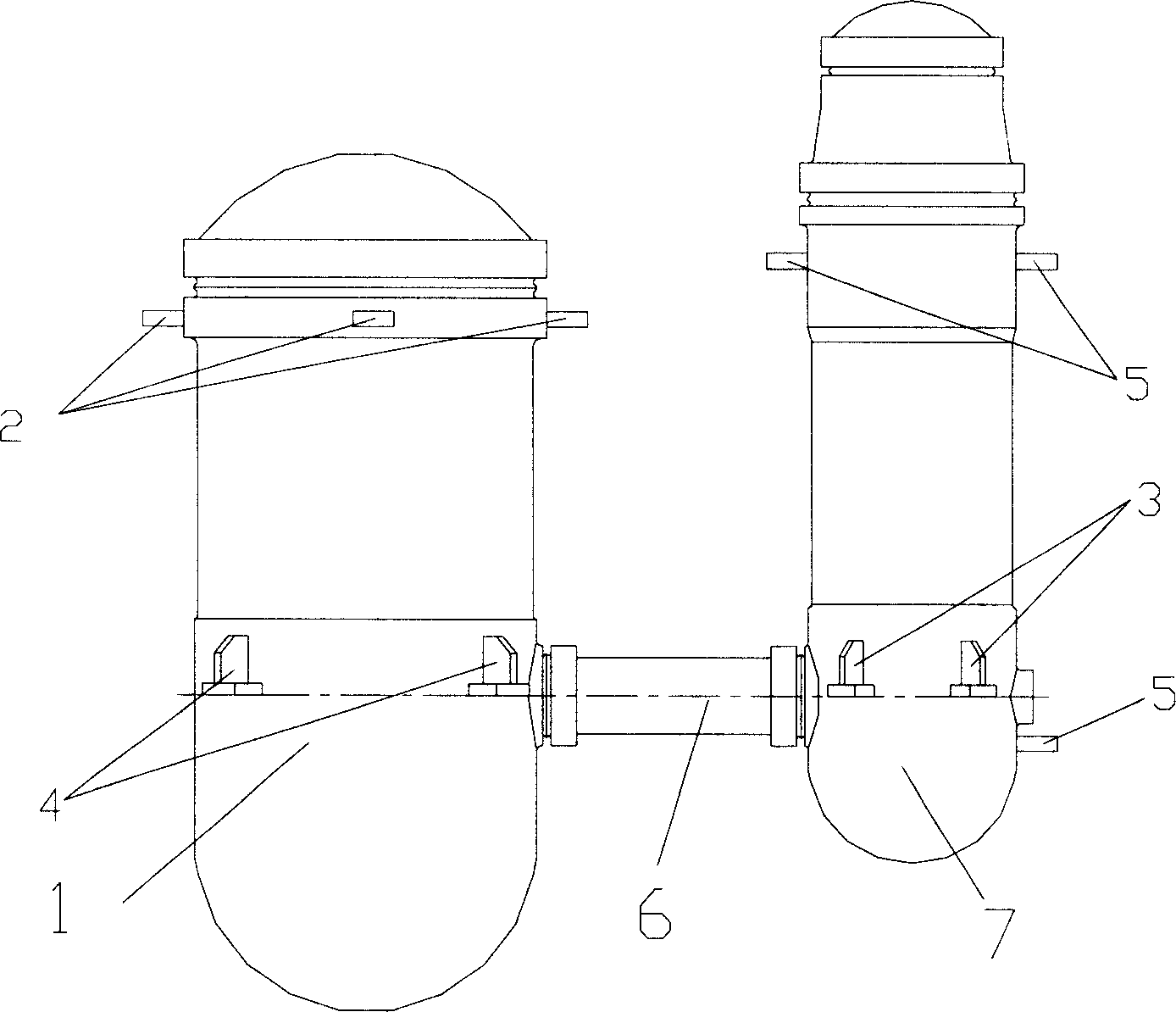

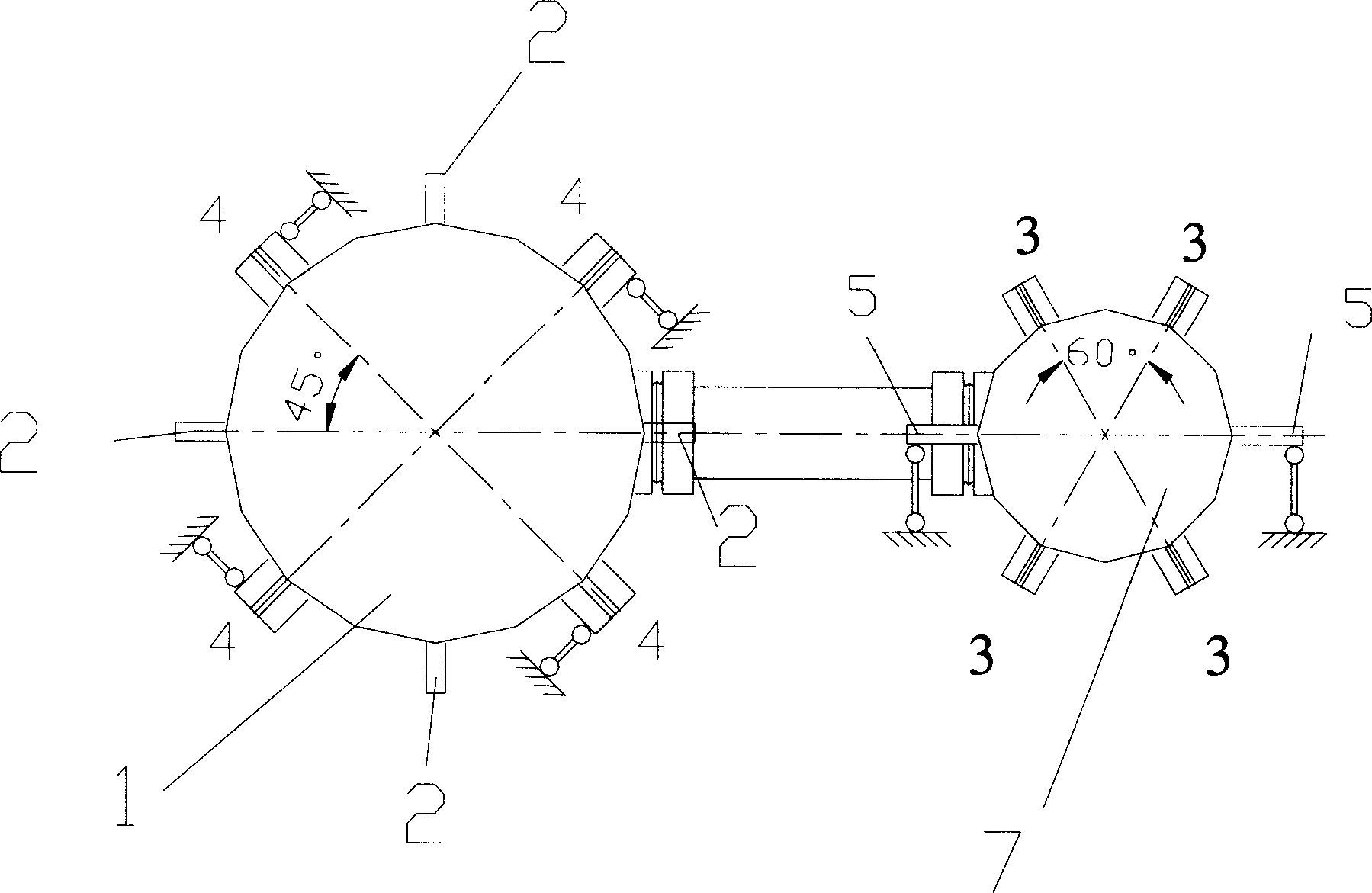

Damper-free support system for modular high temperature air-cooled pile pressure casing

ActiveCN1641797AFlexible rotationPrevent rotationNuclear energy generationContainmentEarthquake resistantMain bearing

The invention relates to a non-damper supporting system of module-type high temperature air-cooled reactor pressure vessel that is belonged to device technology field. The invention is used to solve the antimony between the unreliability of big damper and the high reliability of actor. The invention supplies a safe and reliable machine to take place of damper supporting system. It includes the first main bearing bracing, the second main bearing bracing, the first side direction bracing and the second side direction. Using the invention, the effective bearing and earthquake-resistant behavior would be ensured, and the fabrication cost is low.

Owner:TSINGHUA UNIV

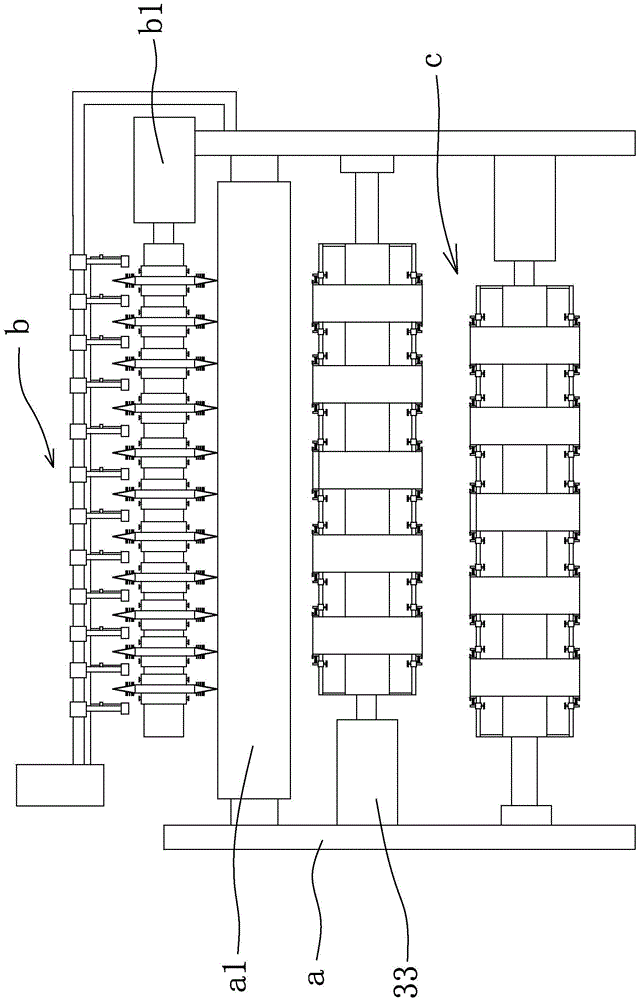

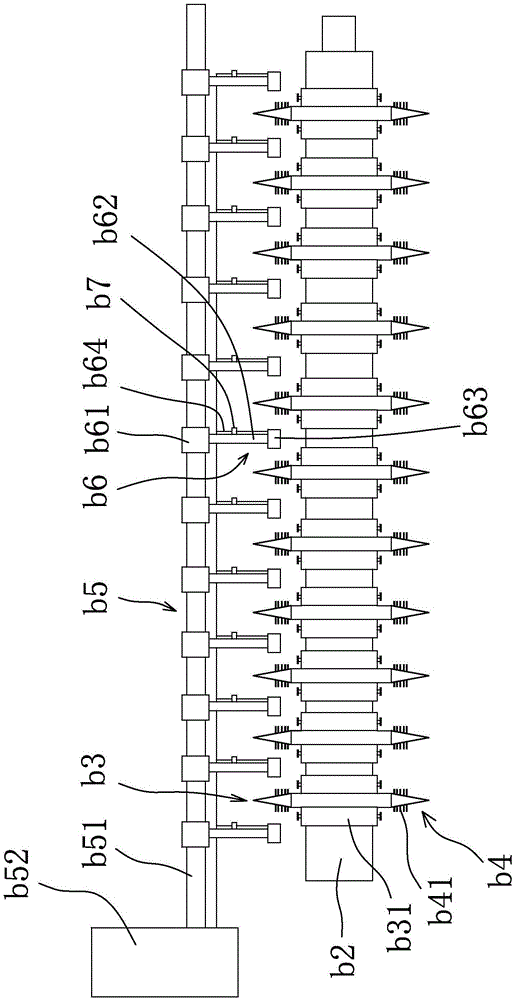

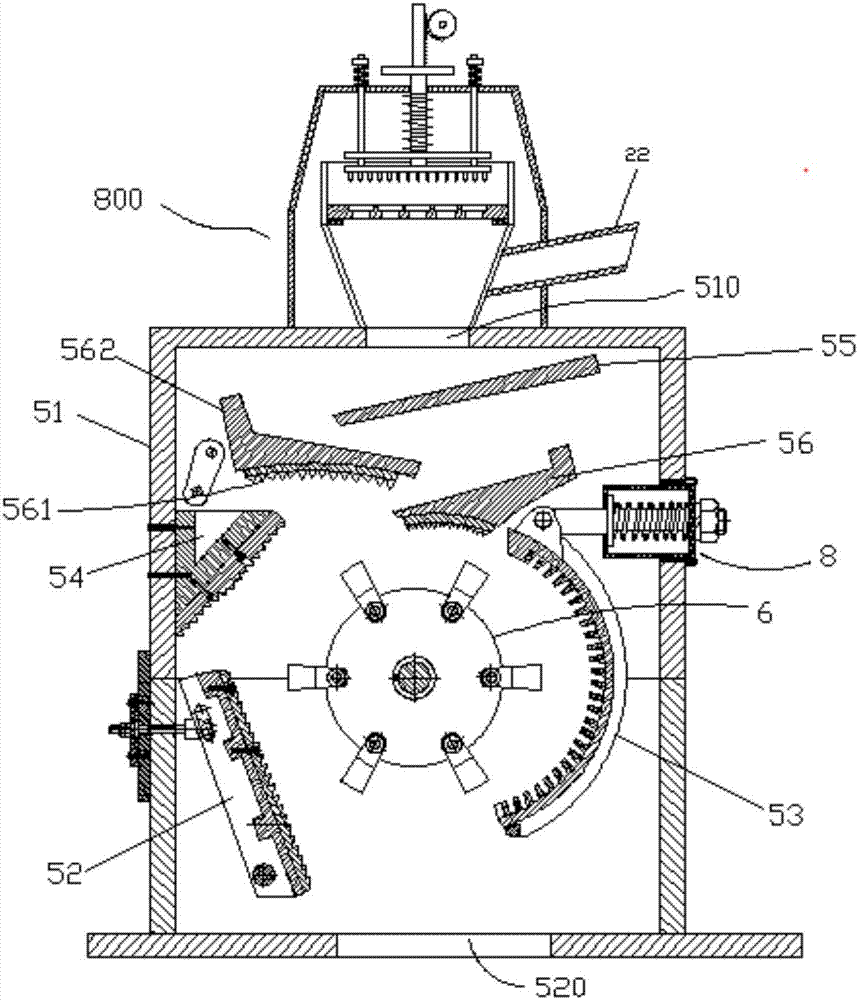

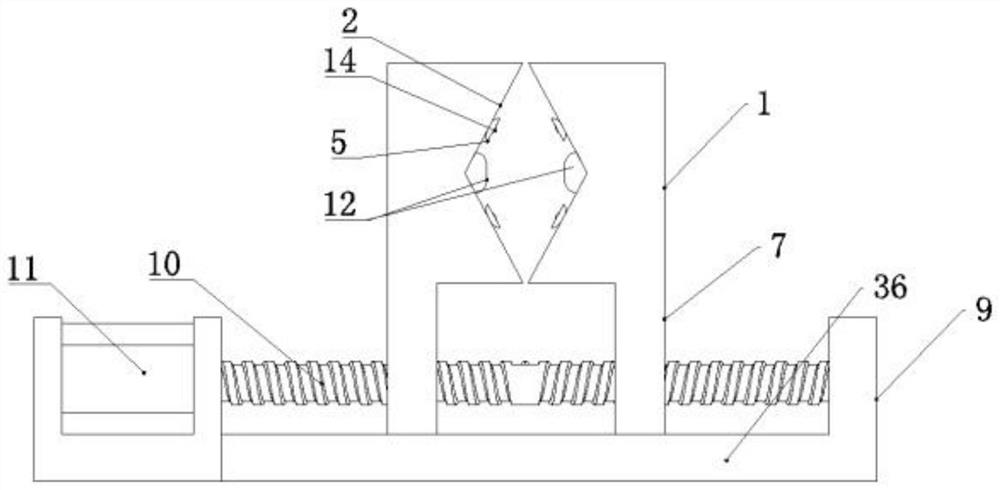

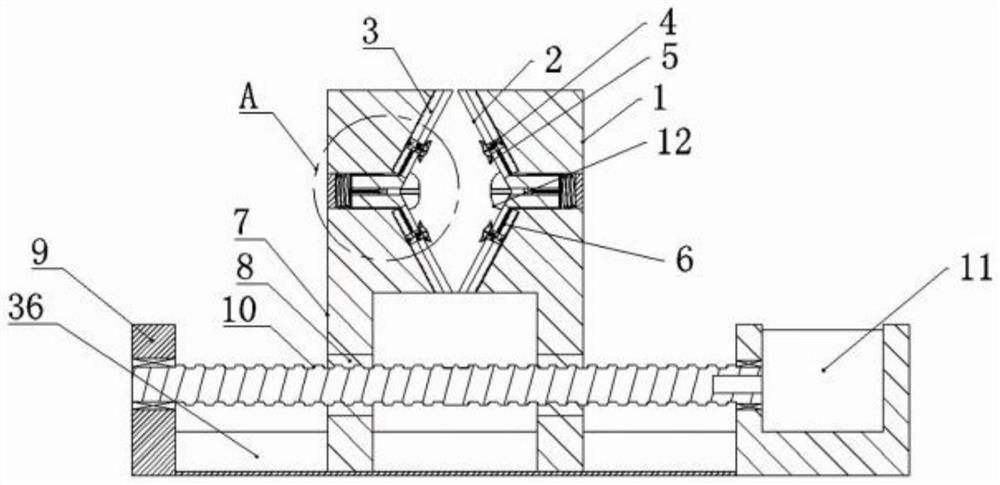

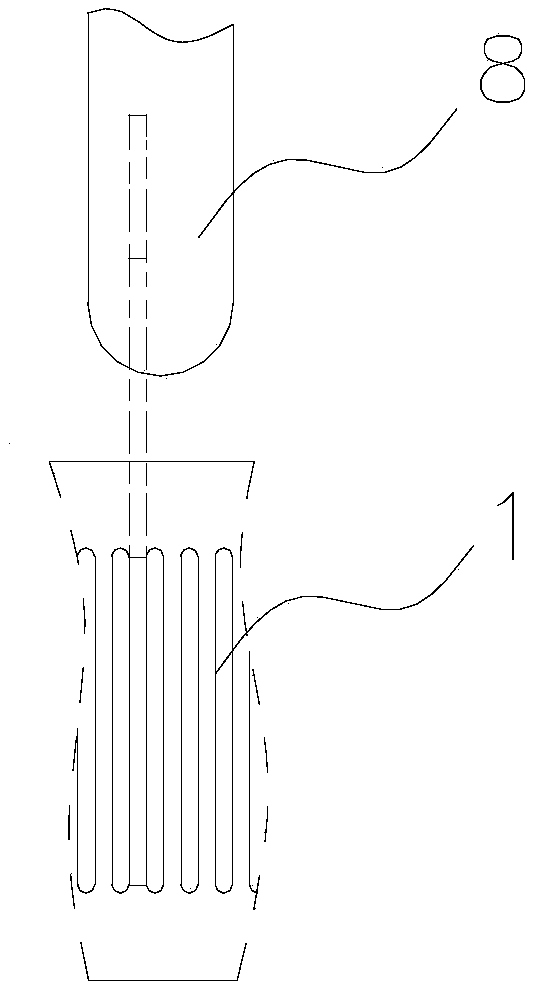

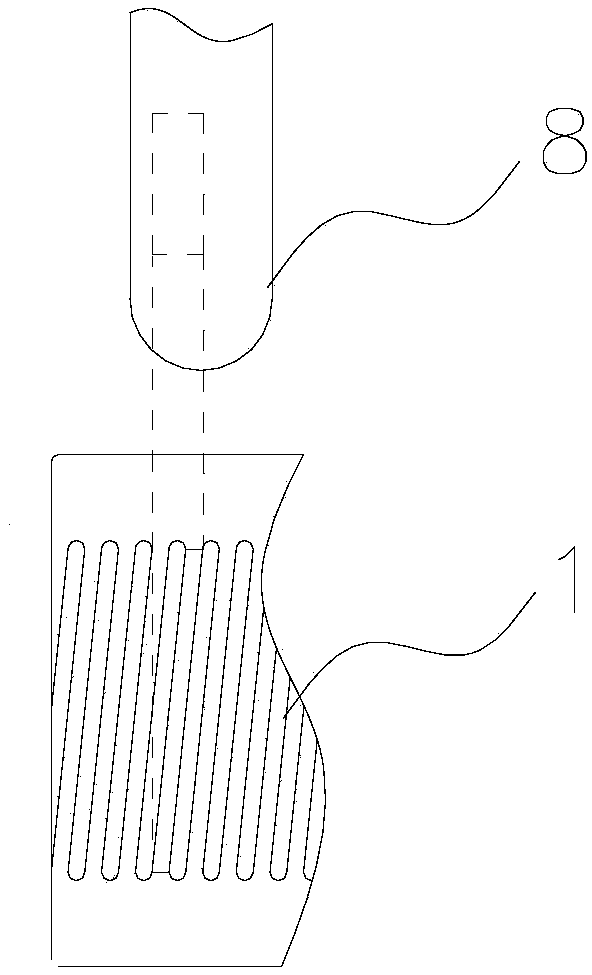

Efficient thin film slitting machine

InactiveCN105600565AQuality improvementGuaranteed stabilityArticle deliveryWebs handlingEngineeringLocking mechanism

The invention provides an efficient thin film slitting machine. The efficient thin film slitting machine comprises a rack, wherein a feeding roller is arranged on the rack; a slitting blade mechanism for slitting a thin film wound on the feeding roller is arranged above the feeding roller; the thin film, which is slit by the slitting blade mechanism, is wound on a winding mechanism; the winding mechanism comprises at least two rollers which are connected with a first driving mechanism; the two rollers are provided with tensioning mechanisms which are arranged in sequence in a staggered manner; each tensioning mechanism comprises at least one tensioning assembly; each tensioning assembly is connected with a tensioning part which sleeves a winding barrel; an elastic sealing assembly is arranged between each tensioning part and the corresponding roller; each tensioning part is provided with fastening devices which are located at the two sides of the corresponding winding barrel and can be used for tightly clamping the winding barrel; the position between the two fastening devices can be adjusted; locking mechanisms are arranged on the fastening devices. The efficient thin film slitting machine has the advantage of good slitting effect.

Owner:ZHEJIANG OUTE ELECTRONICS TECH CO LTD

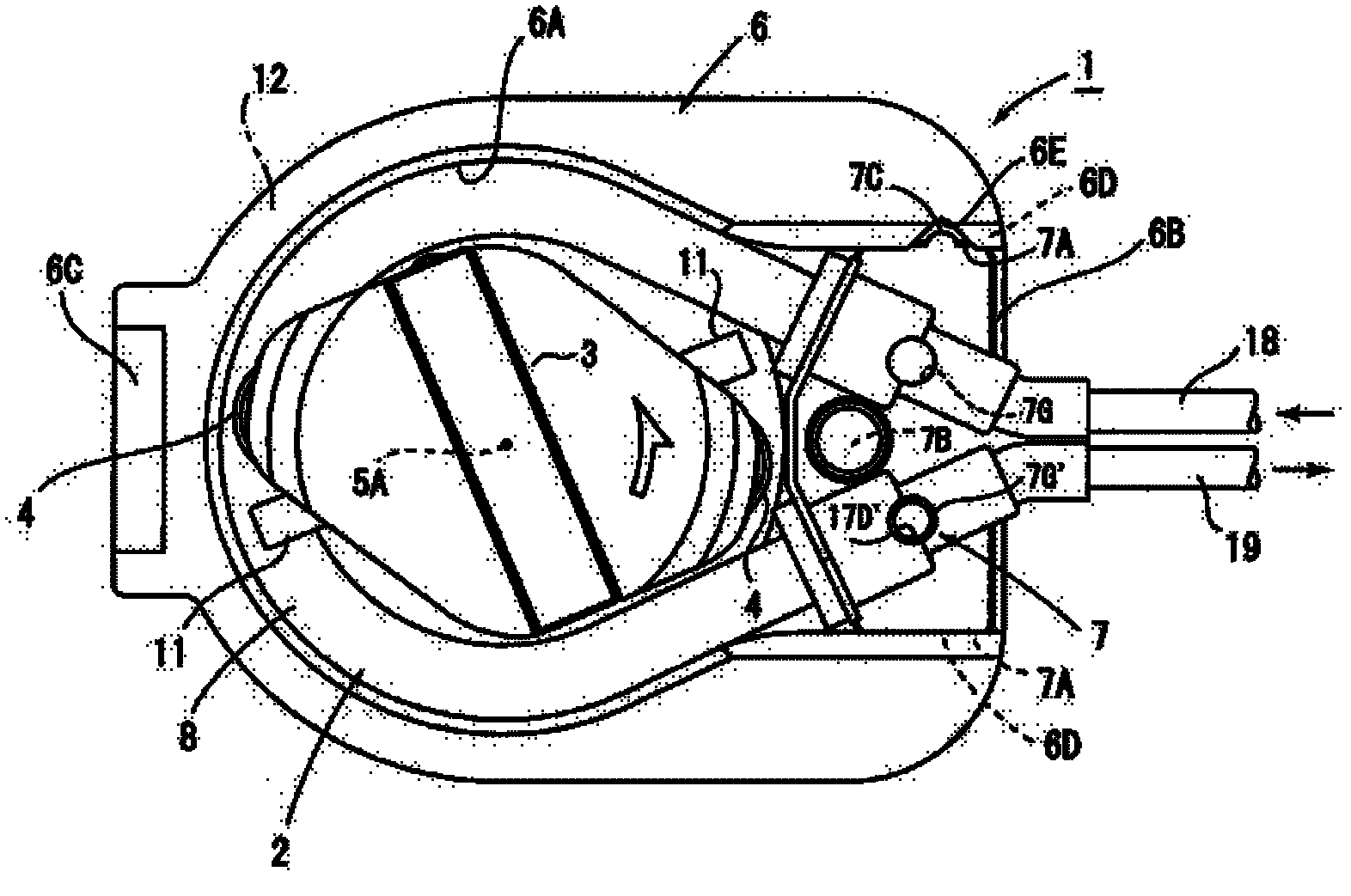

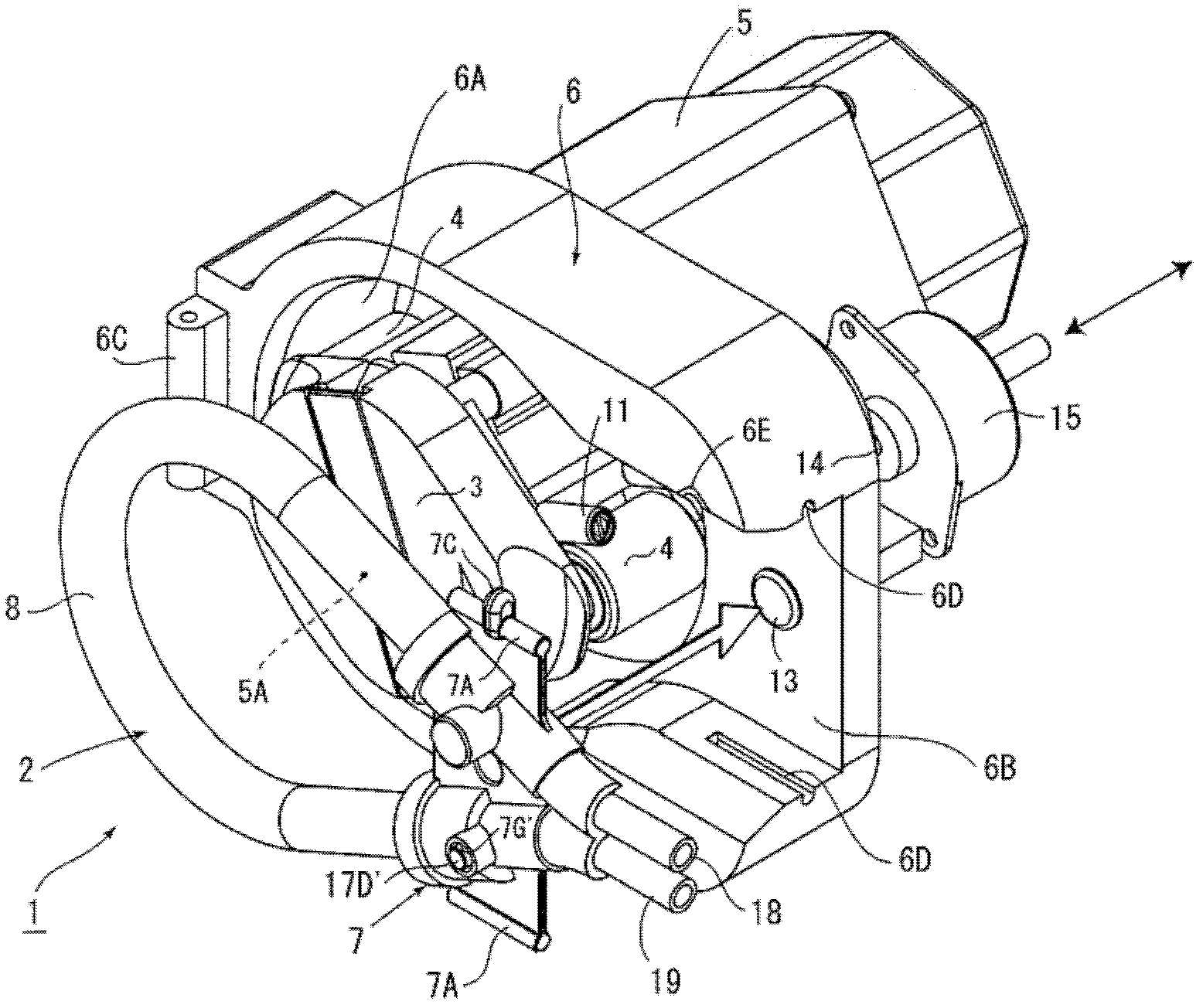

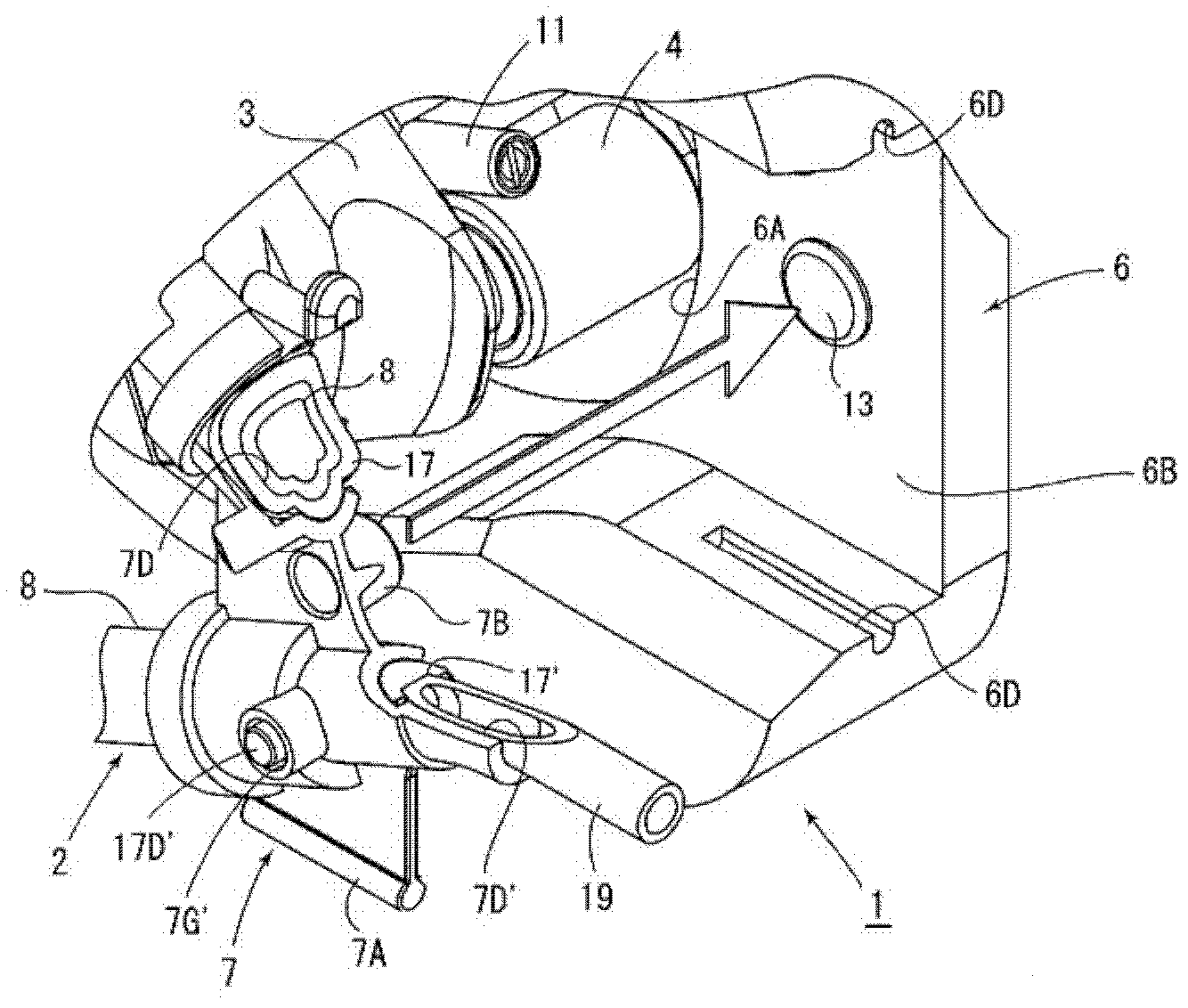

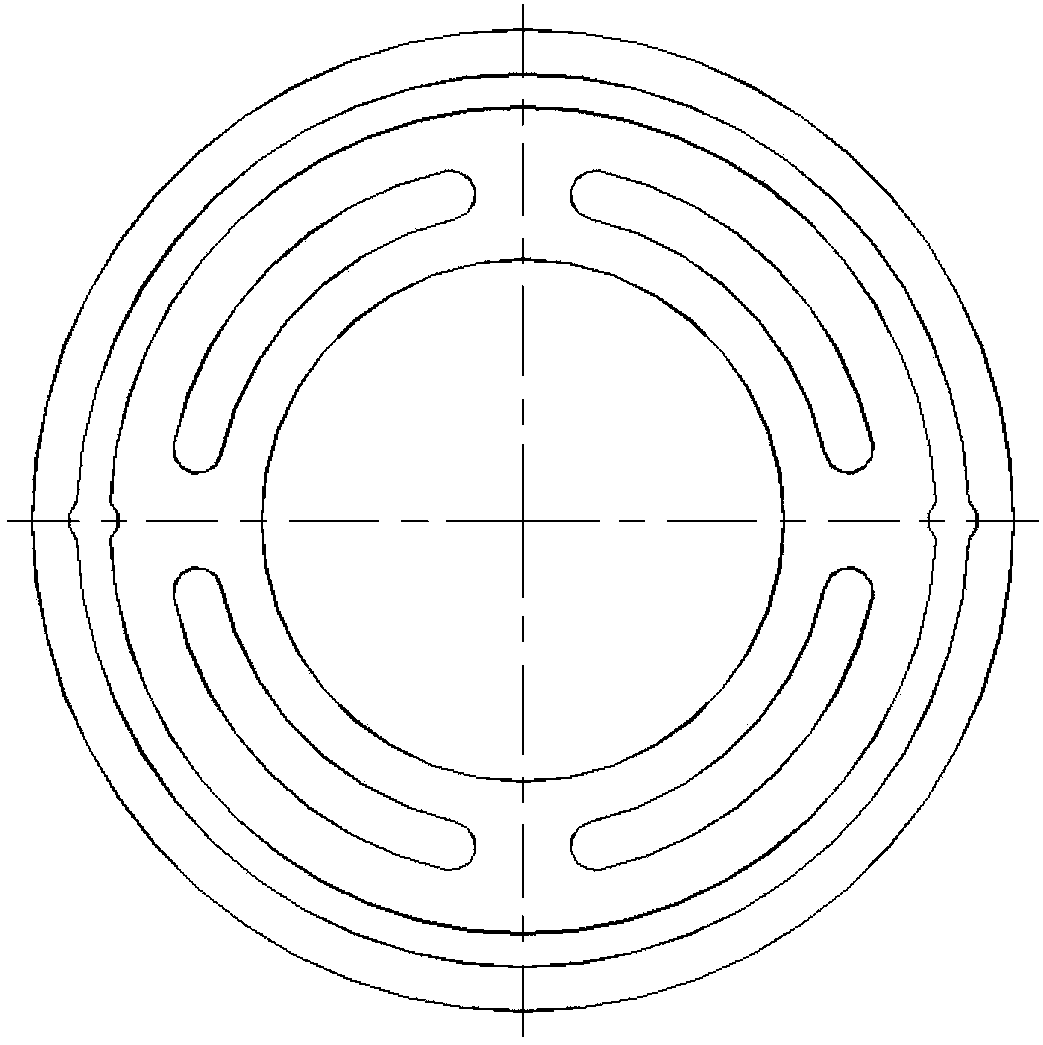

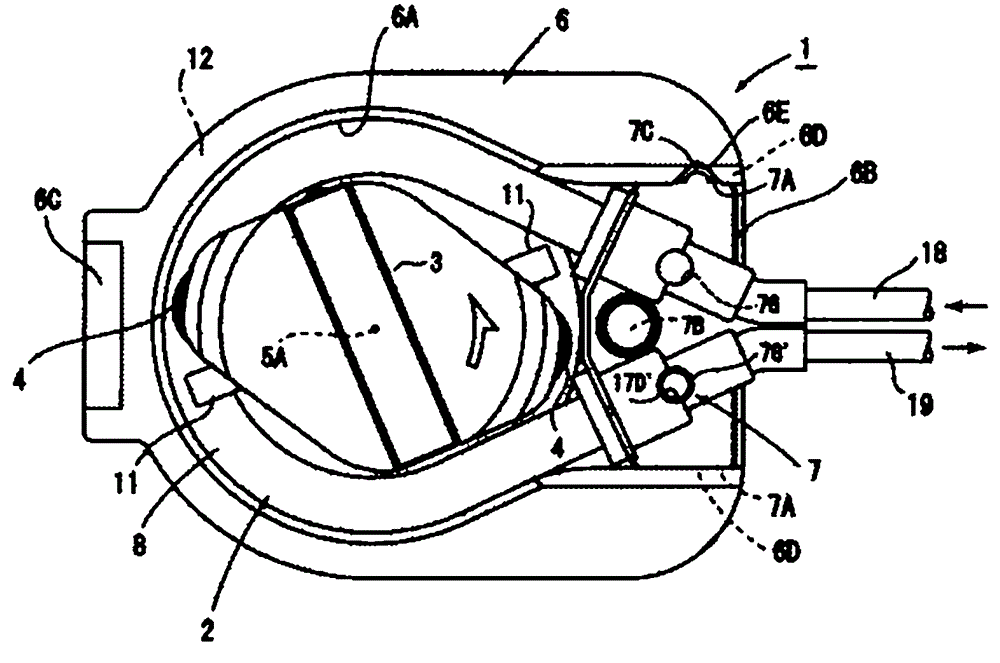

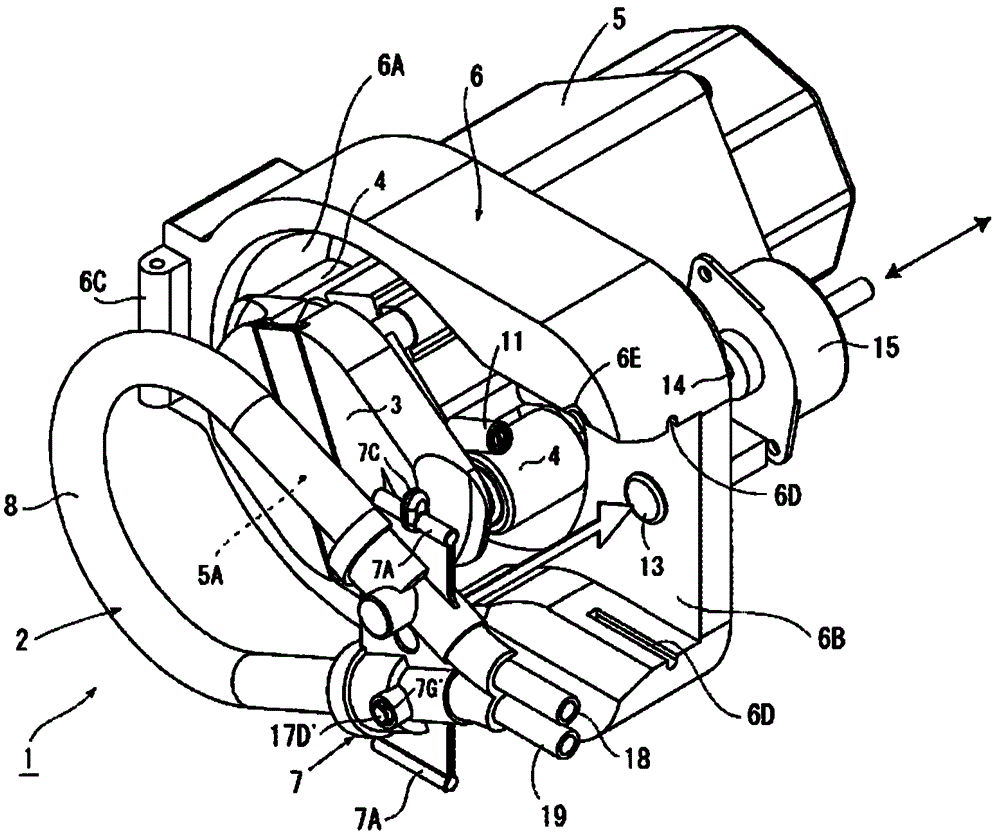

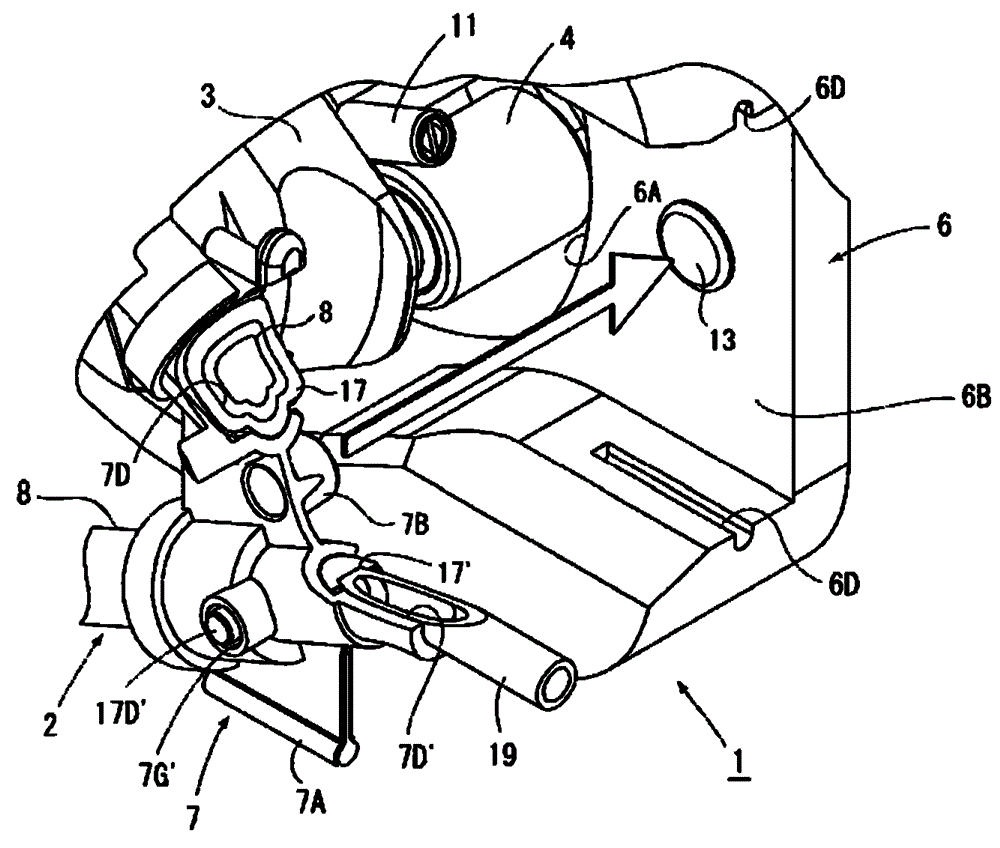

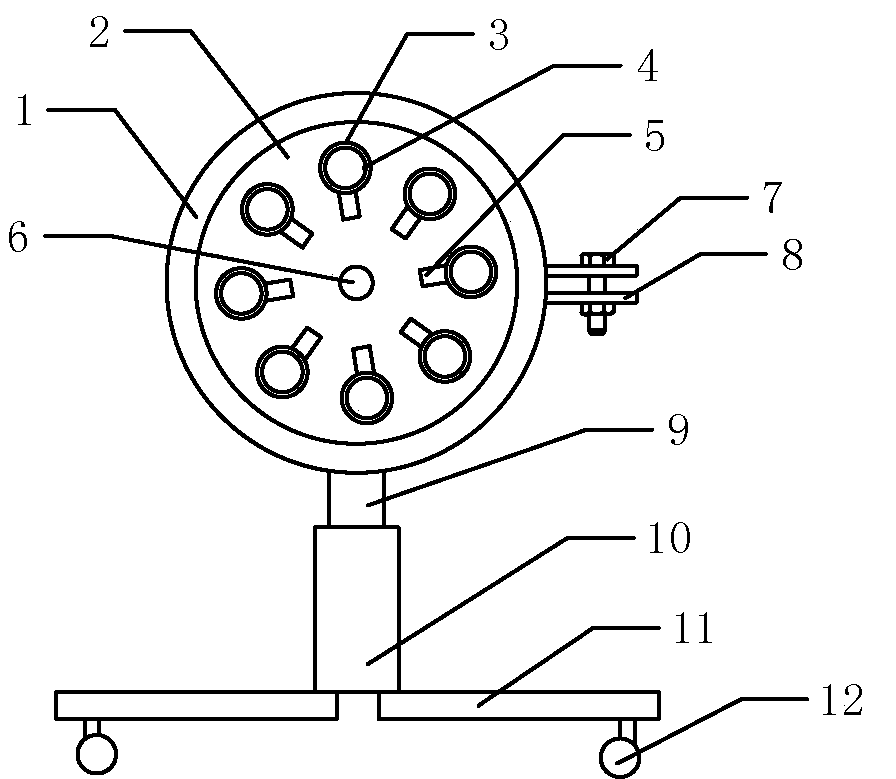

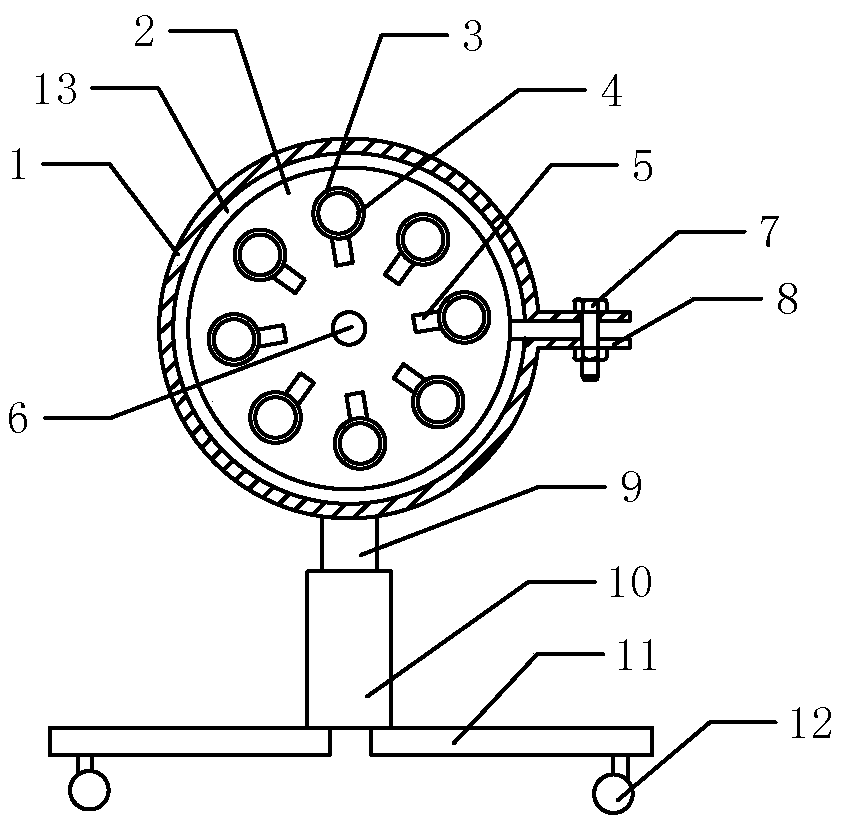

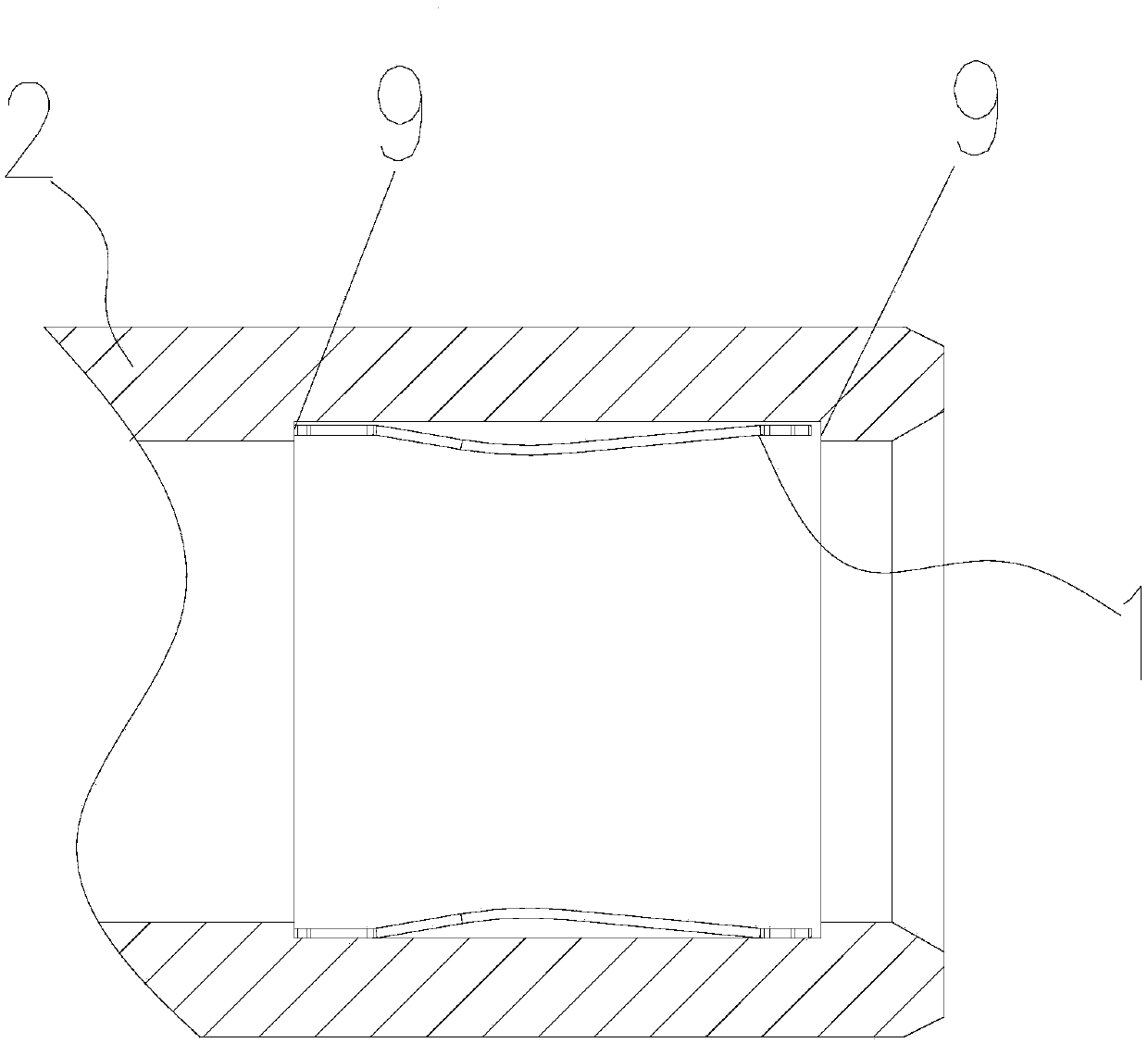

Tube pump

ActiveCN102317629ASimple structureEasy to install and disassembleFlexible member pumpsDialysis systemsElectrical and Electronics engineeringMental detachment

A duct 2 in a tube pump 1 includes a looped large-diameter tube 8, a supply tube 18 connected to an end of the large-diameter tube 8 via a supply-side connector 17, and a discharge tube 19 connected to the other end of the large-diameter tube 8 via a discharge-side connector 17'. The holder 7 includes a pair of stepped engagement recess portions 7D and 7D' that are engageable with outer surfaces of the respective connectors 17 and 17'. The connectors 17 and 17' are held by the stepped engagement recess portions 7D and 7D' of the holder 7, and the holder 7 in such a state is attached to a notch portion 6B of the housing 6. The tube pump 1 enabling easy attachment / detachment of the duct 2 to / from the housing 6 can be provided.

Owner:NIPRO CORP +1

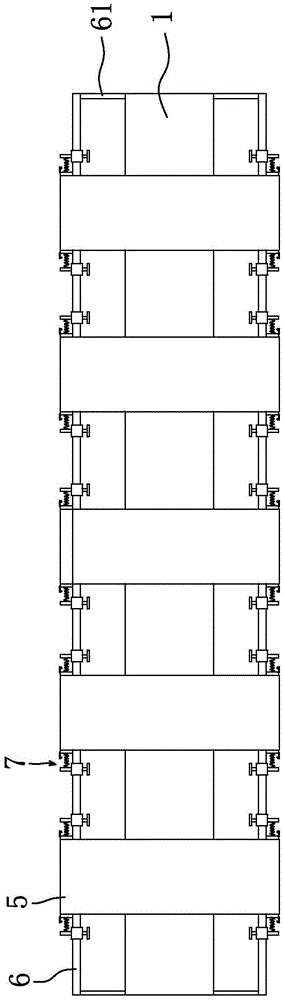

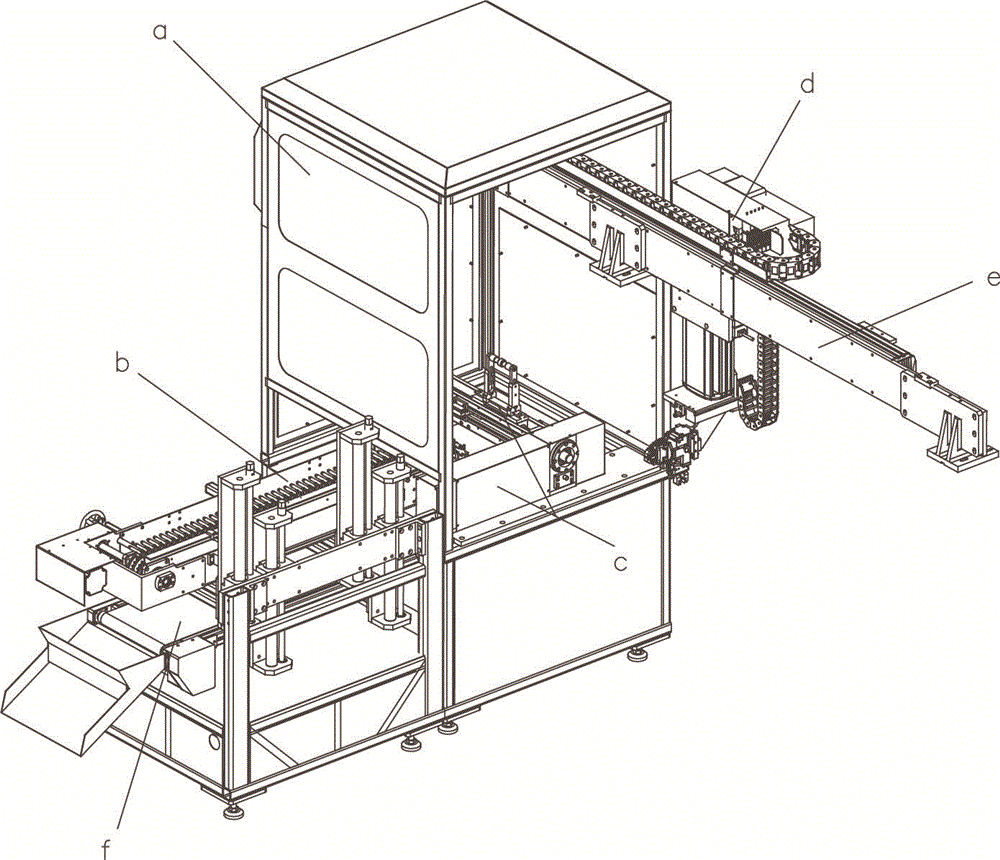

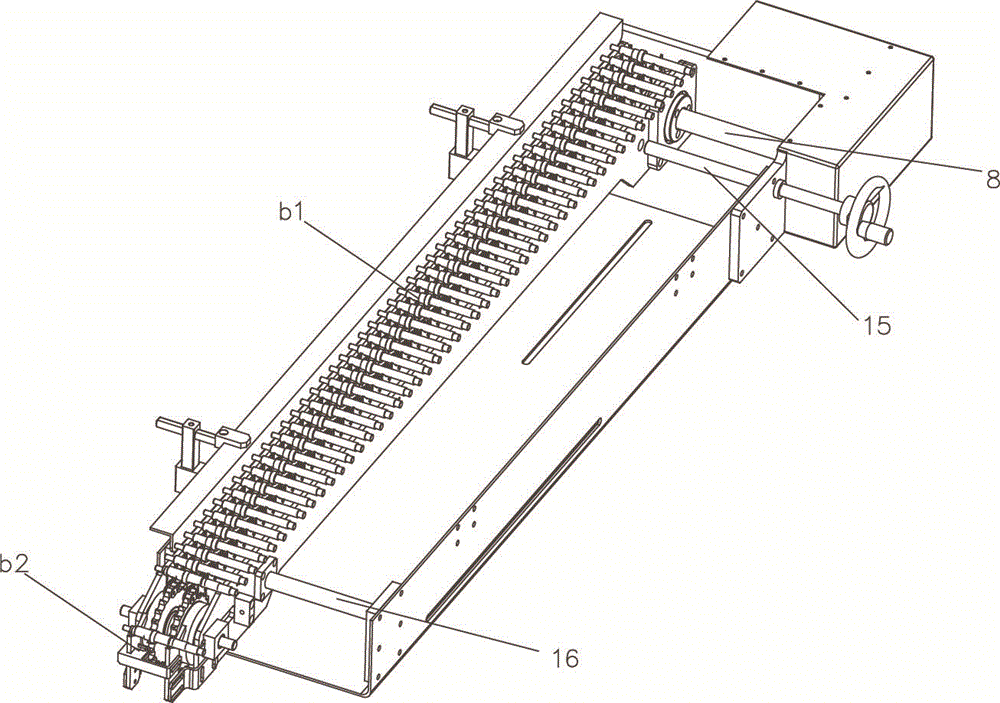

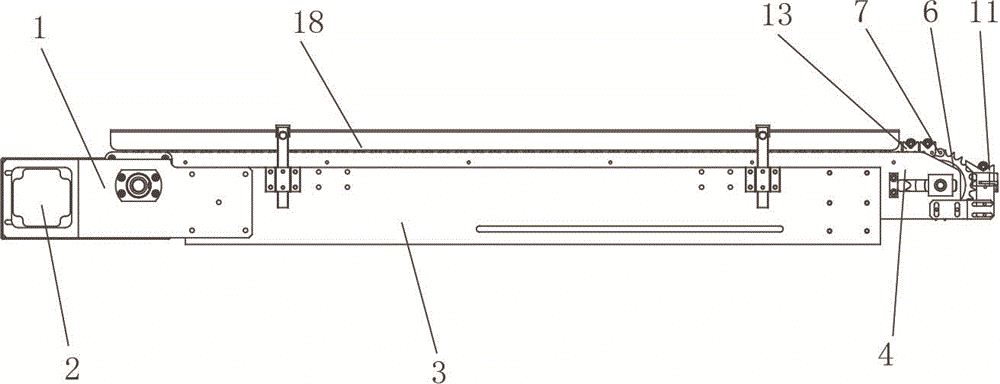

Intermittent chain wheel conveyor line

InactiveCN104526444APrevent axial displacementAdjustable tightnessMetal working apparatusGear-cutting machinesSprocketEngineering

The invention discloses an intermittent chain wheel conveyor line. The intermittent chain wheel conveyor line comprises an aluminum supporting frame, a stepping motor, a bottom groove plate, two chain wheel assemblies arranged side by side and a chain wheel supporting plate arranged on the side edges of the chain wheel assemblies. The chain wheel supporting plate is provided with a main wheel hole, a sliding bar hole and an adjusting groove. The main wheel hole and a driving chain wheel are erected on the aluminum supporting frame through a rotating shaft. The rotating shaft is connected with the stepping motor through a synchronous belt. A chain wheel fetching frame is arranged at the front end of the adjusting groove and comprises a fixing piece, a vertically arranged V-shaped positioning block and a clamping piece. The intermittent chain wheel conveyor line has the following advantages that as the chain wheel fetching frame is arranged, subsequent chain wheel fetching and clamping procedures can be facilitated, the chain wheel assemblies will not be touched in the clamping process, and therefore shaft parts are prevented from being overturned; as a supporting piece is arranged, the shaft parts can be placed on the supporting piece, and steps on the shaft parts can be clamped through the supporting piece, axial displacement is prevented, and the effect of initial positioning is achieved.

Owner:宁波沃特美逊机器人科技有限公司

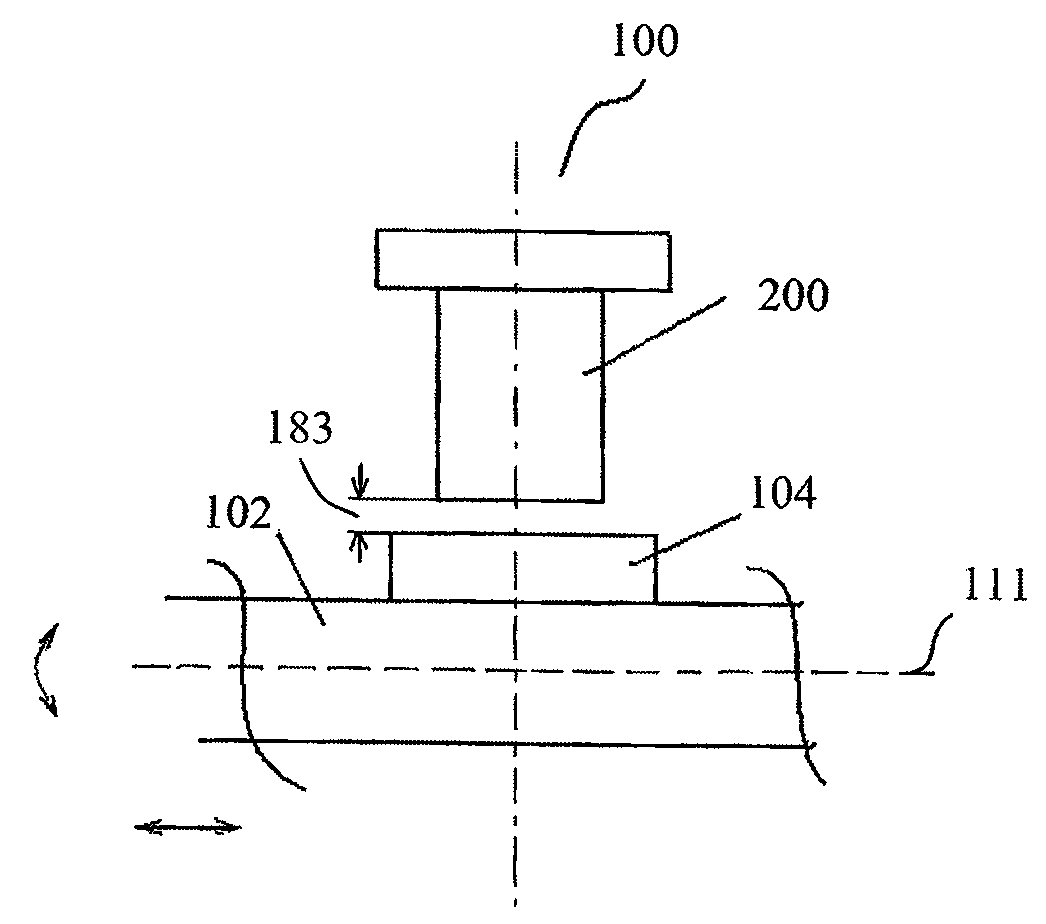

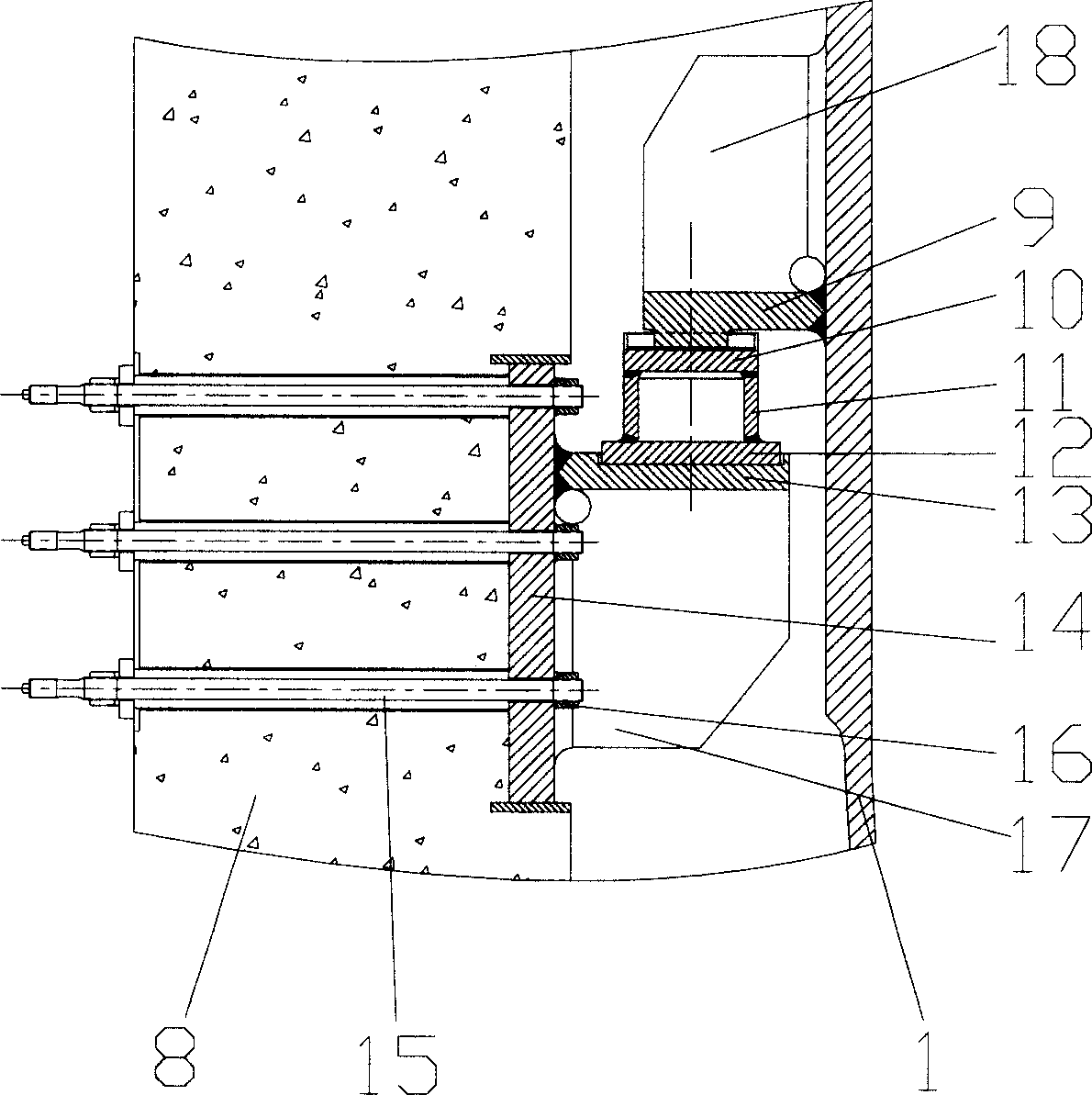

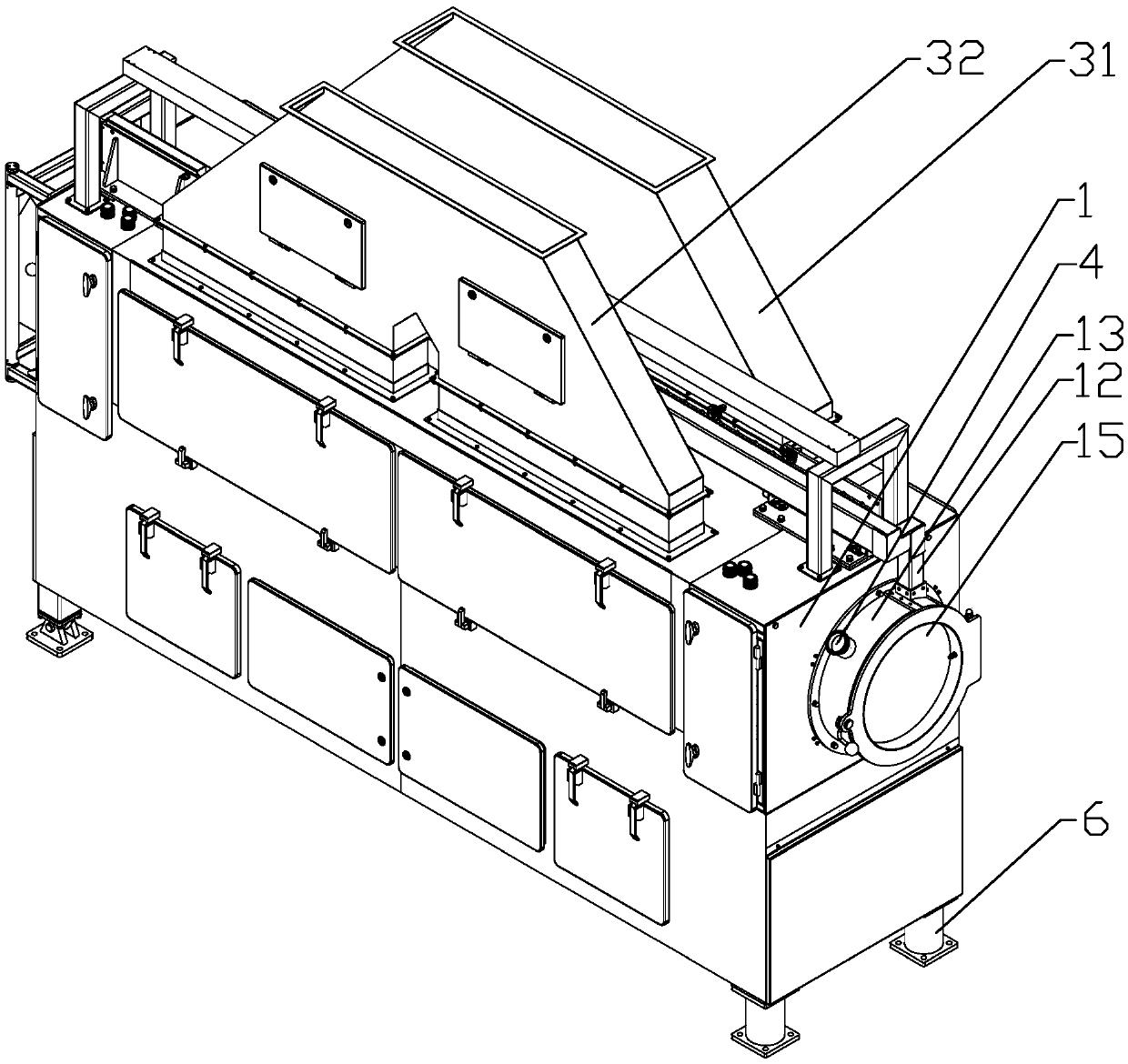

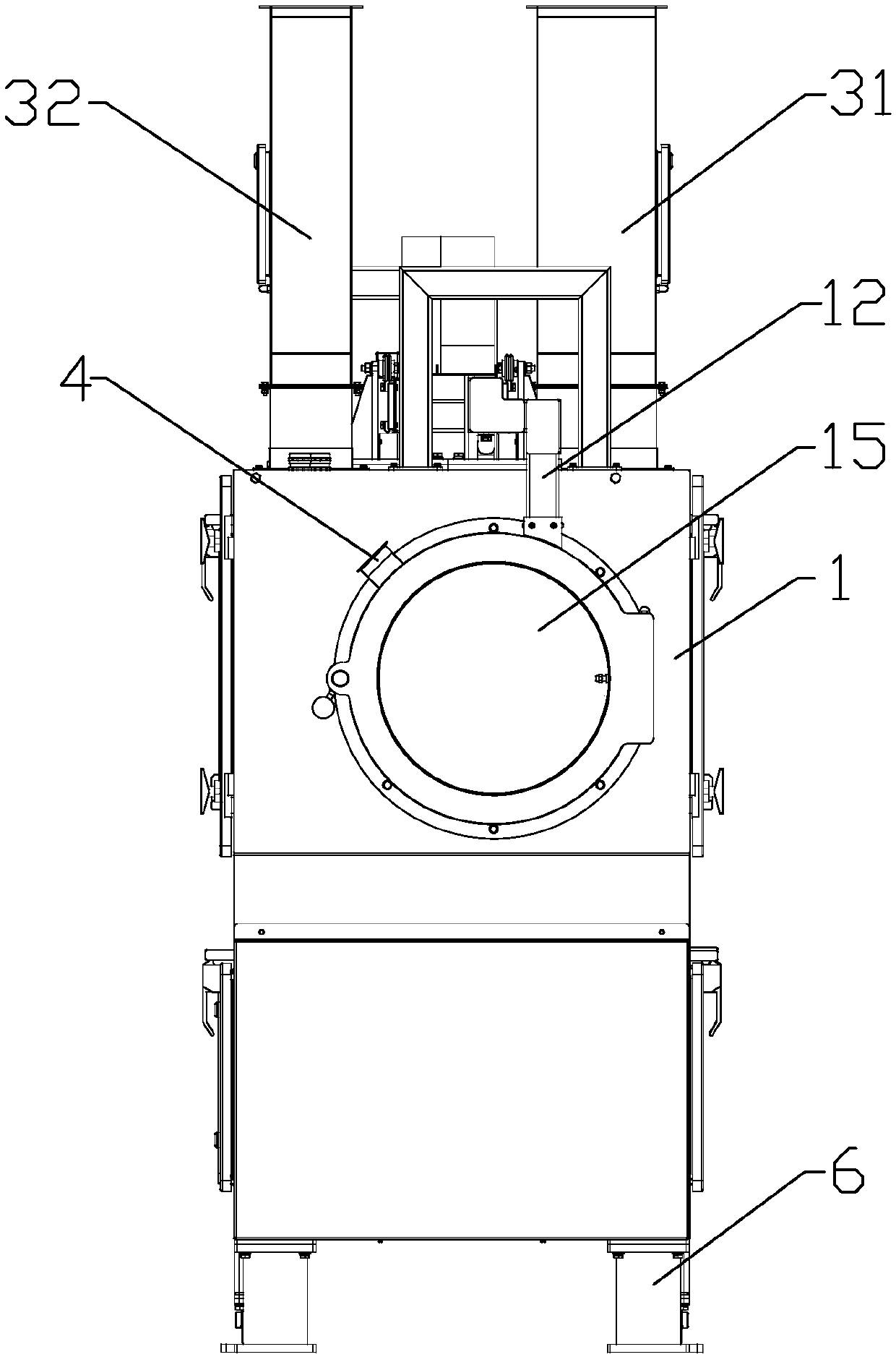

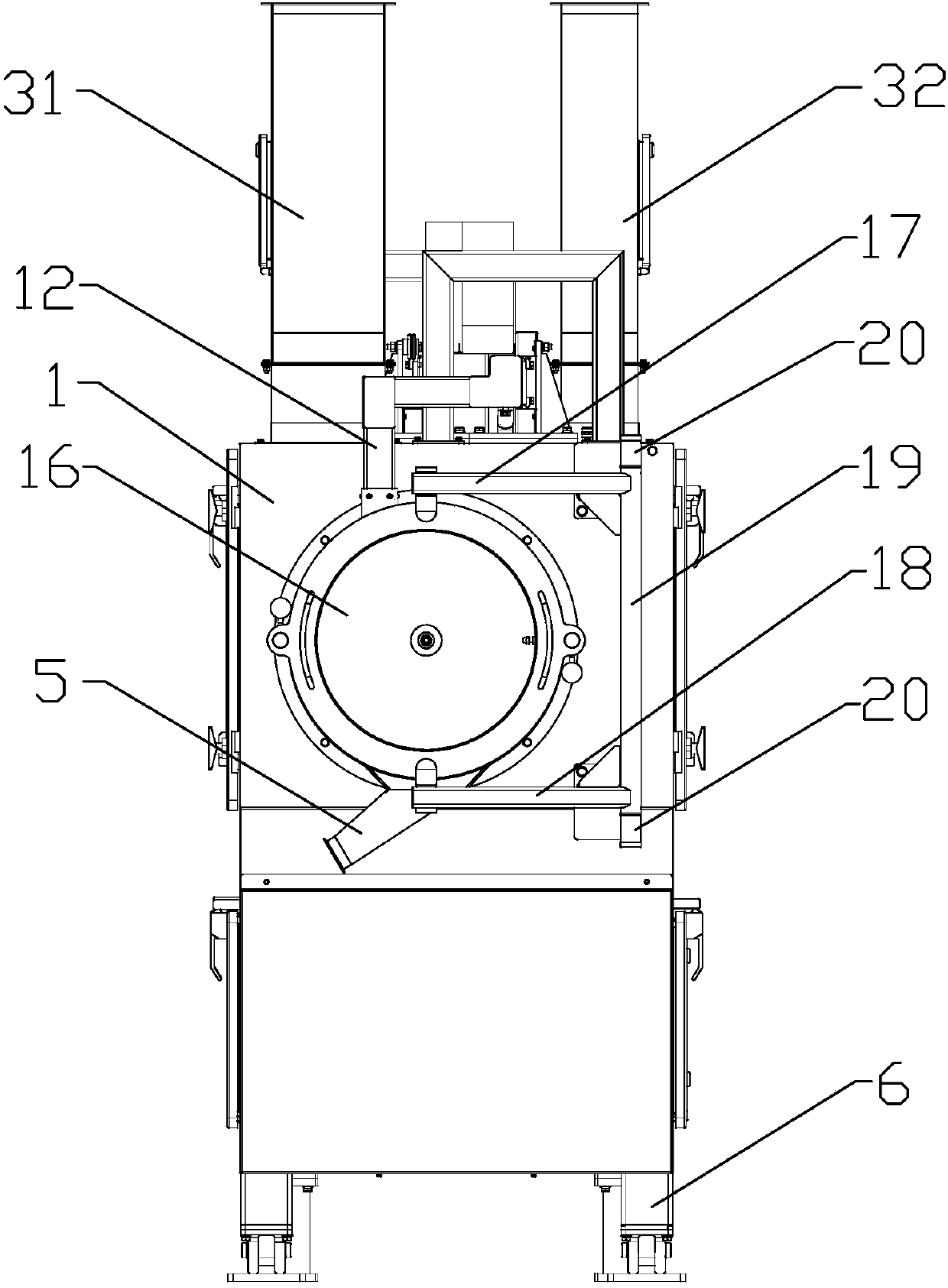

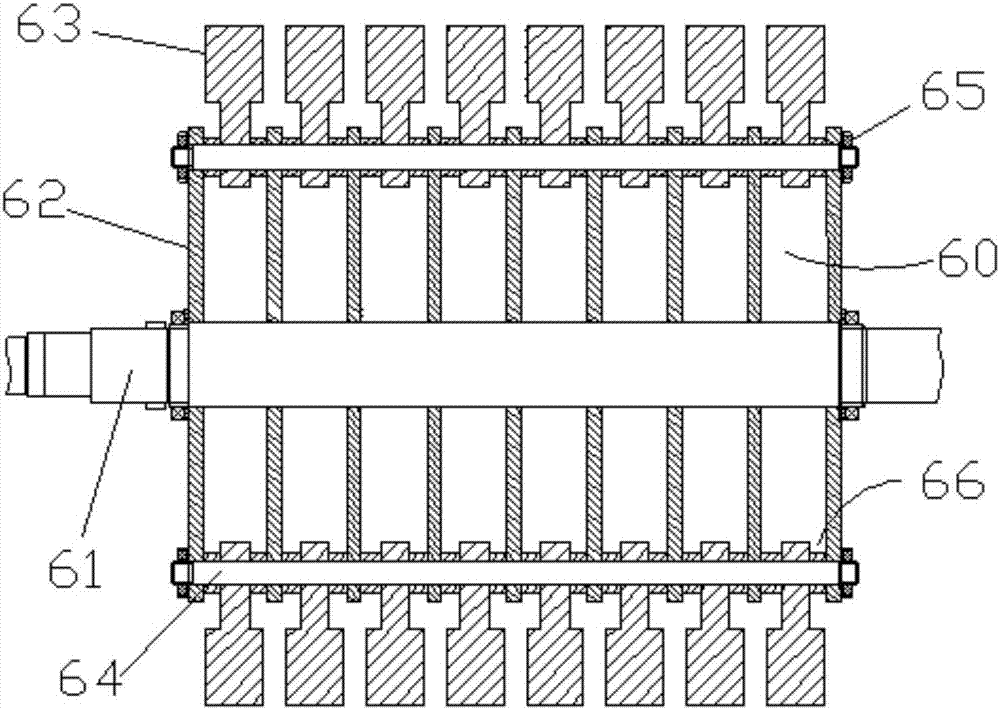

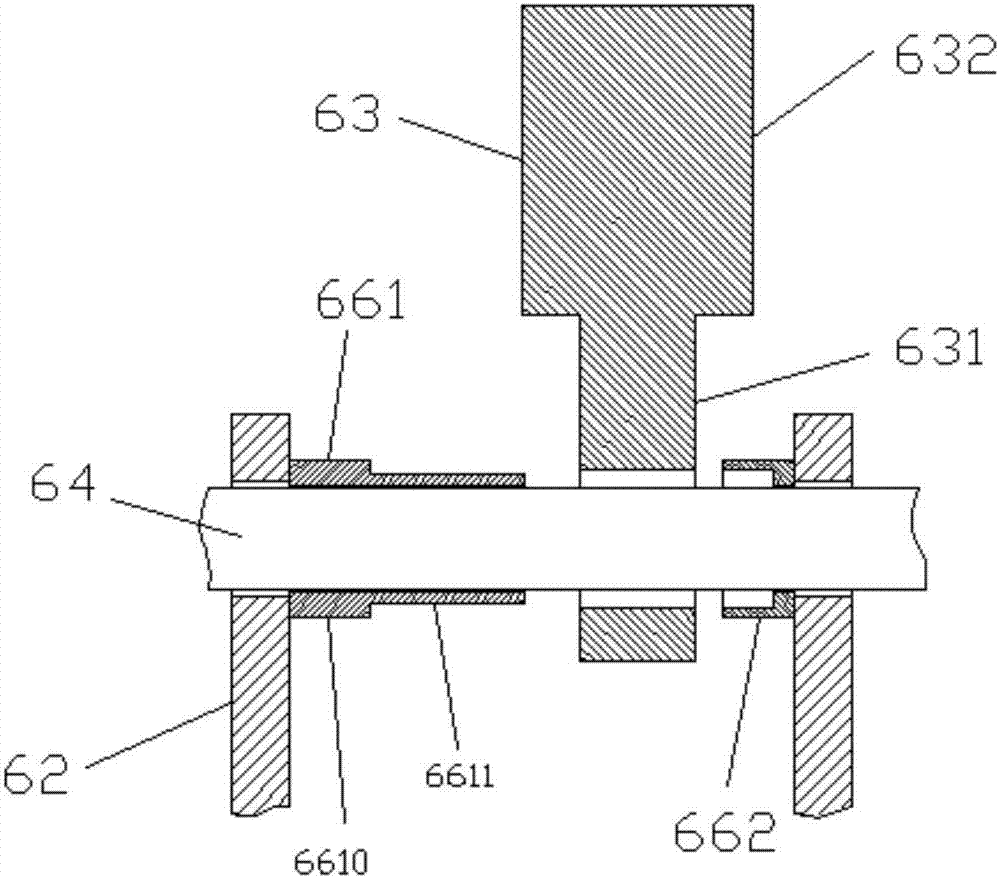

Continuous coating machine and continuous coating method with continuous coating machine

ActiveCN107744167AShort timeReduce energy consumptionPharmaceutical product form changeFood coatingProcess engineeringMechanical engineering

The invention provides a continuous coating machine and a continuous coating method with the continuous coating machine, and relates to a coating machine and a coating method. In order to solve the problems that when a conventional coating machine is used for coating production of massive materials, the time consumption is high, the energy consumption is high, and the production efficiency is nothigh, the invention provides the continuous coating machine. A coating roller is a slab-sided cylinder with two opened ends, and is horizontally mounted in a machine body in a rotating and sealing manner, and through holes are densely distributed in the wall of the coating roller; a feed pipe is arranged at the front end of the machine body, and a discharge pipe is arranged at the rear end of themachine body; and support legs are mounted at four corners of the bottom end of the machine body, and an air cylinder capable of controlling the lifting of the machine body and the coating roller is vertically mounted in two support legs at the front end of the machine body. The coating roller is used for continuously feeding and discharging materials, in the process that the materials advance tothe outlet of the coating roller from the inlet of the coating roller, the coating is completed, and continuous coating production of the massive materials is realized; and besides, the production energy consumption is rationalized, zero consumption during production is realized, and the continuous coating machine is used for coating the materials.

Owner:NANO PHARM TECH MACHINERY EQUIP

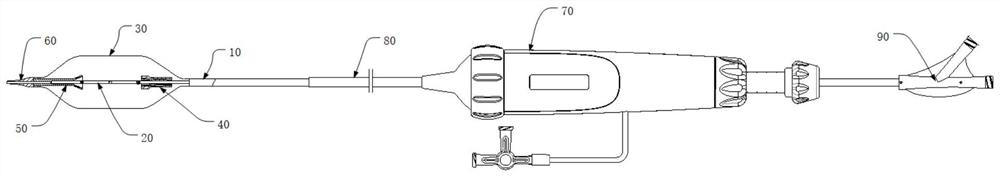

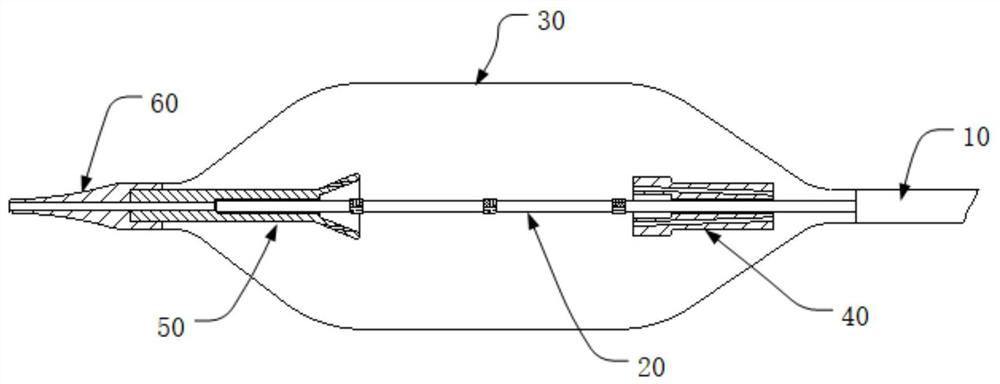

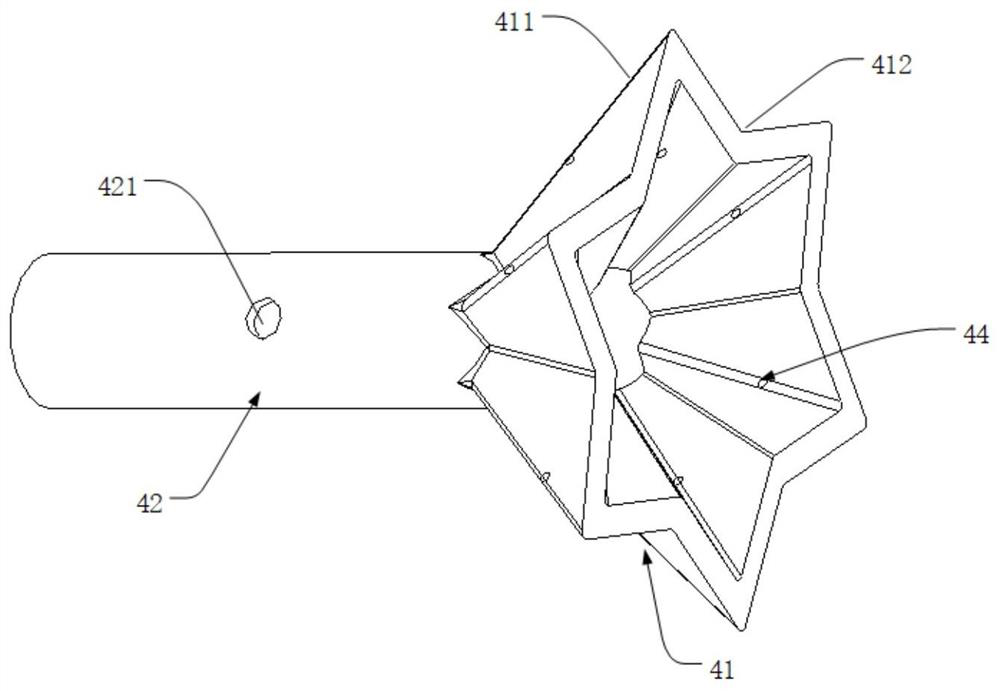

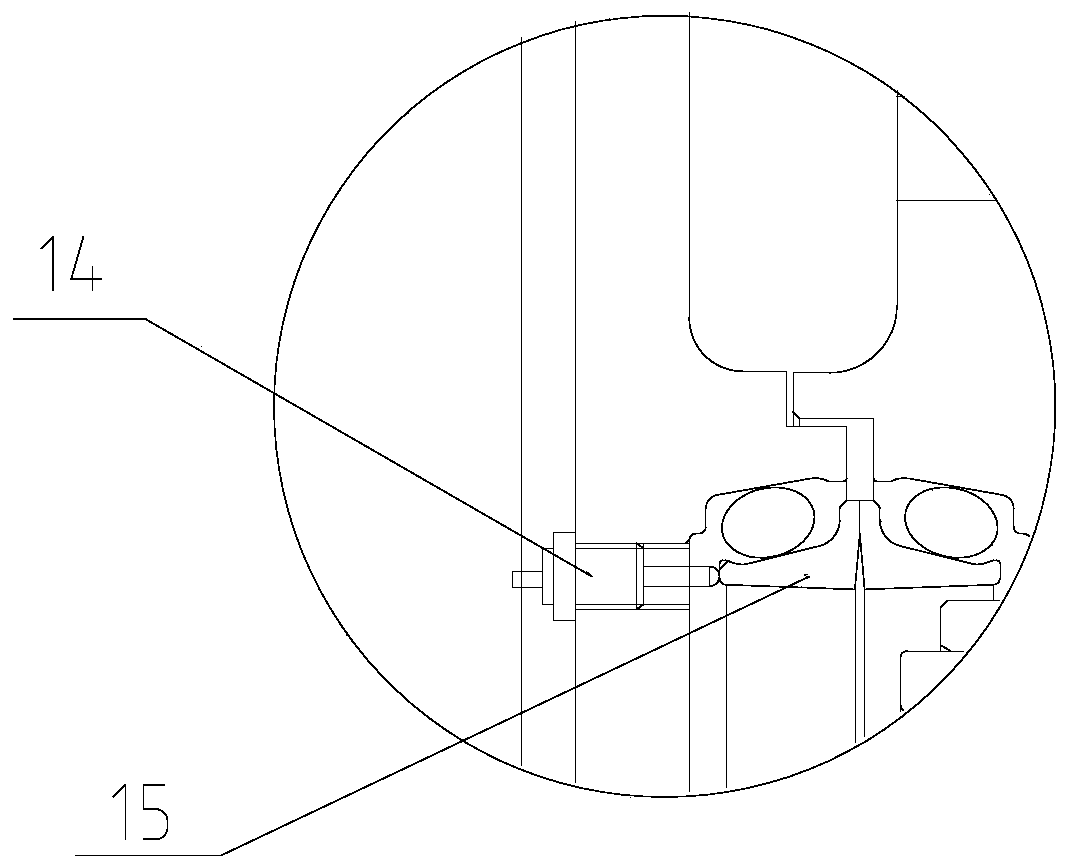

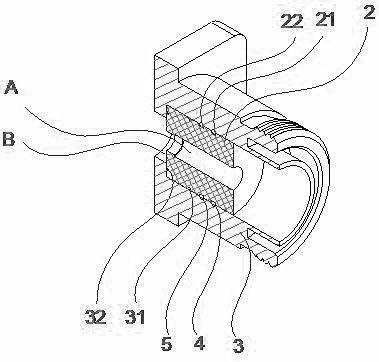

Prosthetic valve delivery system

The invention provides an artificial valve conveying system which comprises an outer tube, an inner tube, an expandable balloon, a first blocking piece and a second blocking piece, each of the first blocking piece and the second blocking piece comprises a fixing part and a locking part, each locking part is of a circumferentially-closed annular structure, each fixing part is connected with the inner tube, and each locking part is of a circumferentially-closed annular structure. A first fluid channel or a second fluid channel is arranged on the side wall of the first stopper; the side wall of the second stopper is provided with a first fluid channel; the first fluid channel penetrates through the stop part in the axial direction of the inner pipe; the second fluid channel penetrates from one end, far away from the fixed part, of the stop part of the first stopper to one end, far away from the stop part, of the fixed part of the first stopper in the axial direction of the inner pipe; and the end parts of the two stop parts can axially limit the artificial valve. According to the invention, the expansion medium can flow more smoothly at the initial expansion stage of the expandable balloon, so that the interventional therapy can be quickly carried out, and the artificial valve can be better prevented from axial displacement in the expansion process of the expandable balloon.

Owner:SHANGHAI NEWMED MEDICAL CO LTD

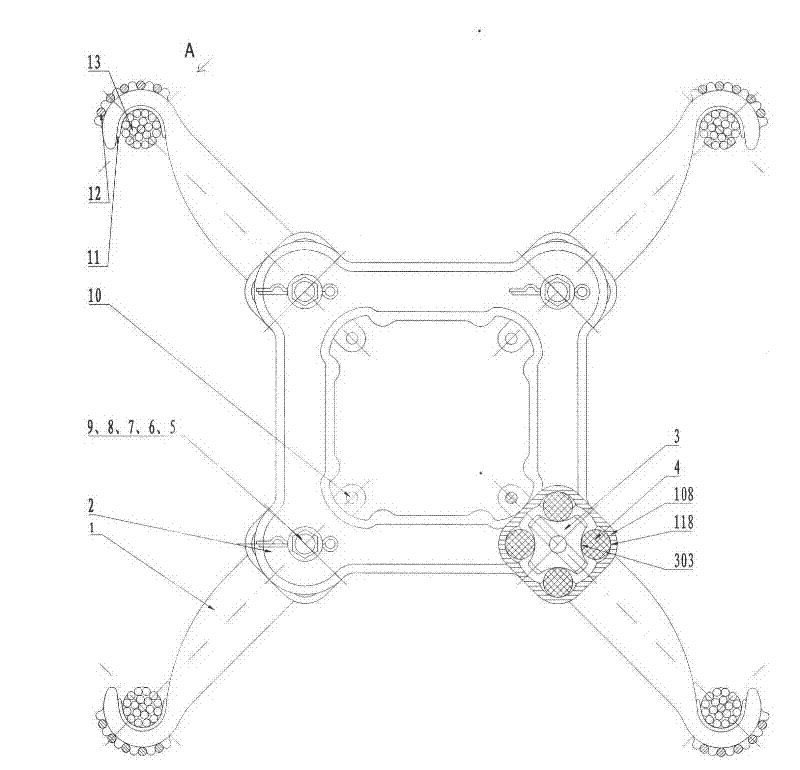

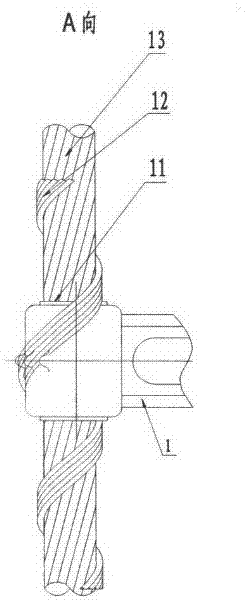

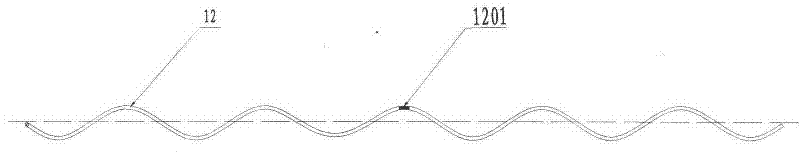

A pre-twisted anti-skid damping spacer

InactiveCN102290765APrevent axial displacementPrevent cascadingMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsYarnEngineering

The invention relates to a pre-twisted anti-slip damping spacer bar. It includes a bracket and a wire clip, the wire clip is arranged at the end corner of the bracket for connecting the split wire, and the wire clip also includes a pre-twisted wire; the head end of the wire clip used to connect the split wire is hook-shaped, The back of the hook is provided with a positioning structure for positioning the pre-twisted wire; the tail end of the clamp is connected to the corner of the bracket through a damping and limiting device. The invention can be installed by bare hands, has the advantages of convenient installation, good reliability and easy control of installation quality.

Owner:江苏华厦电力成套设备有限公司

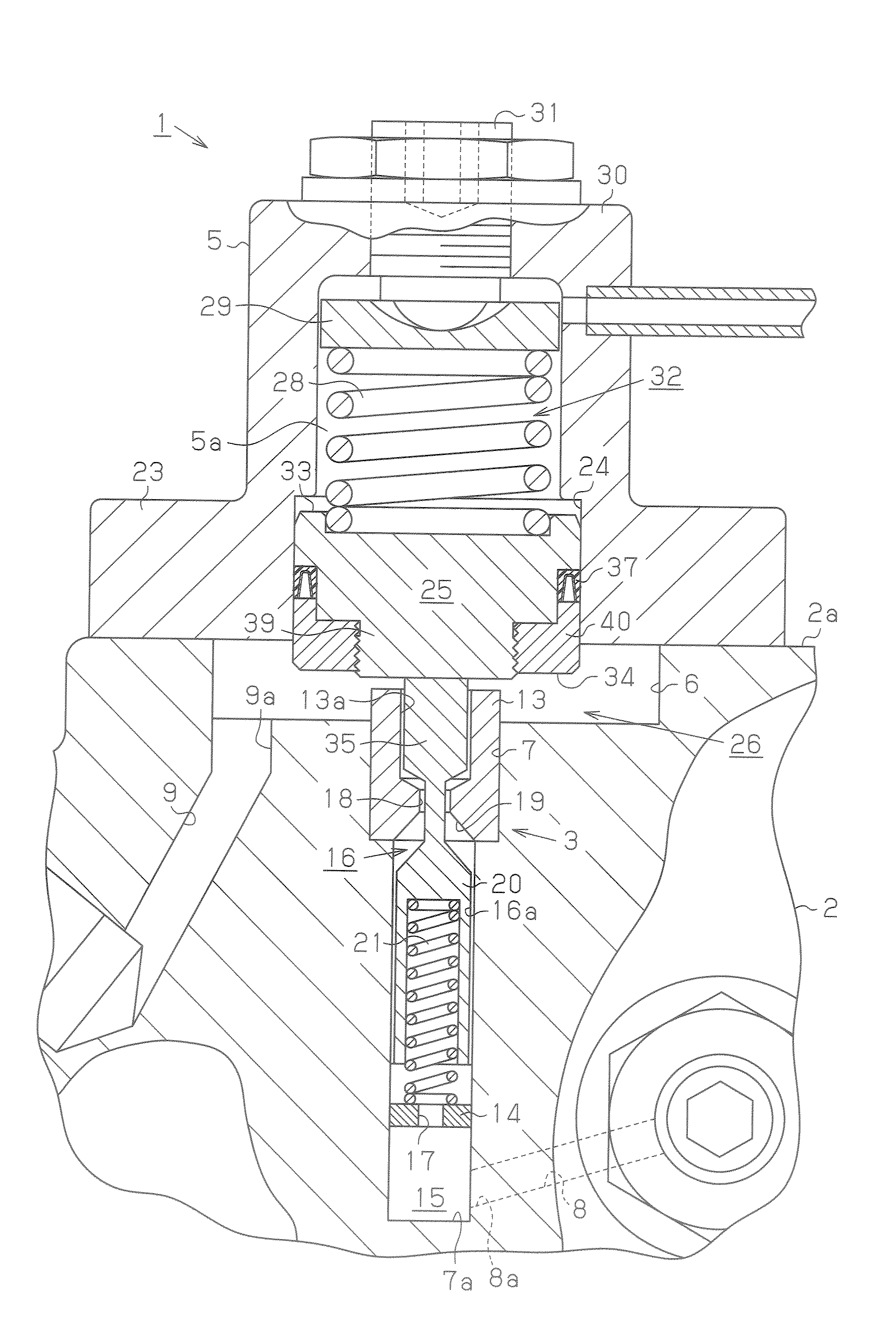

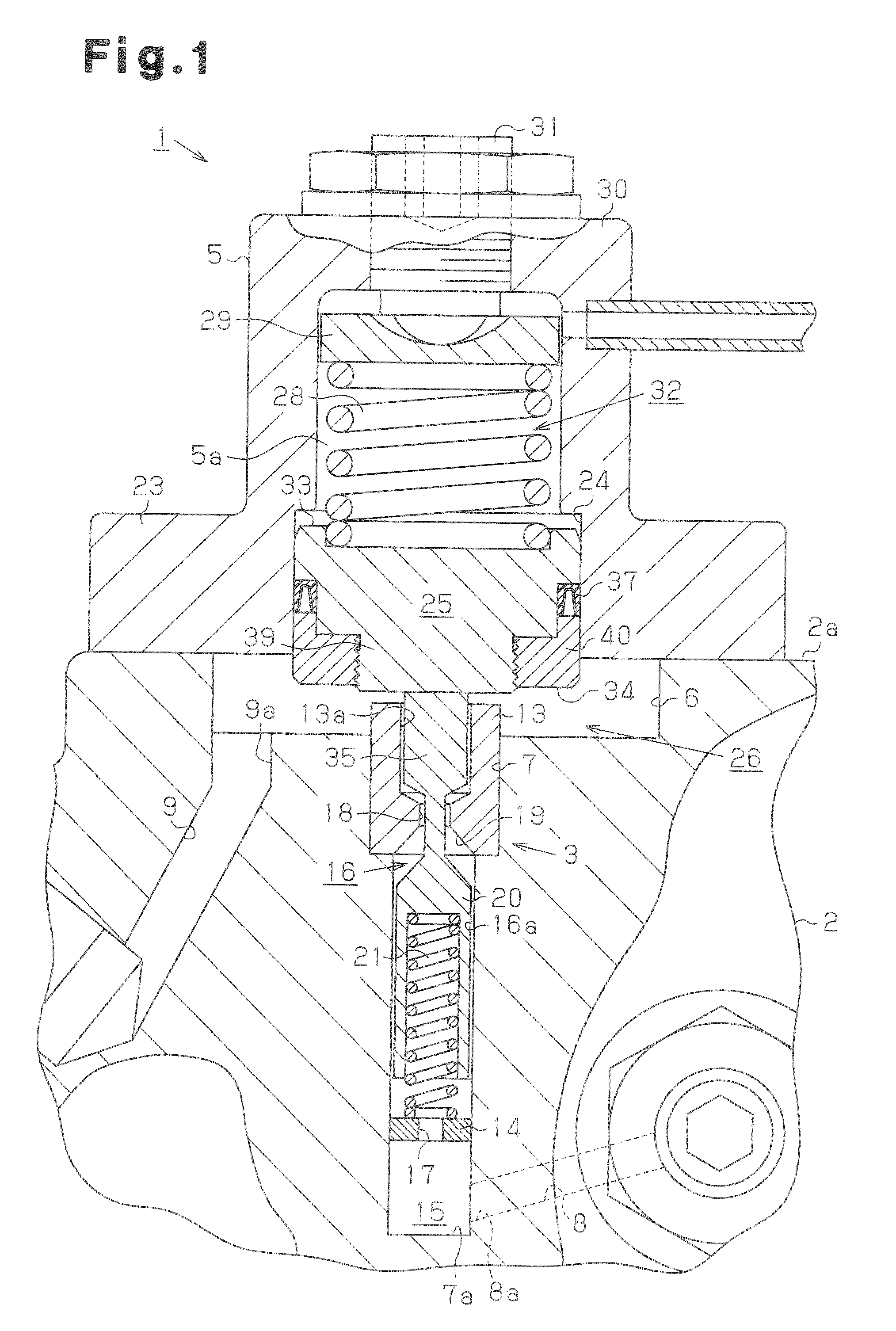

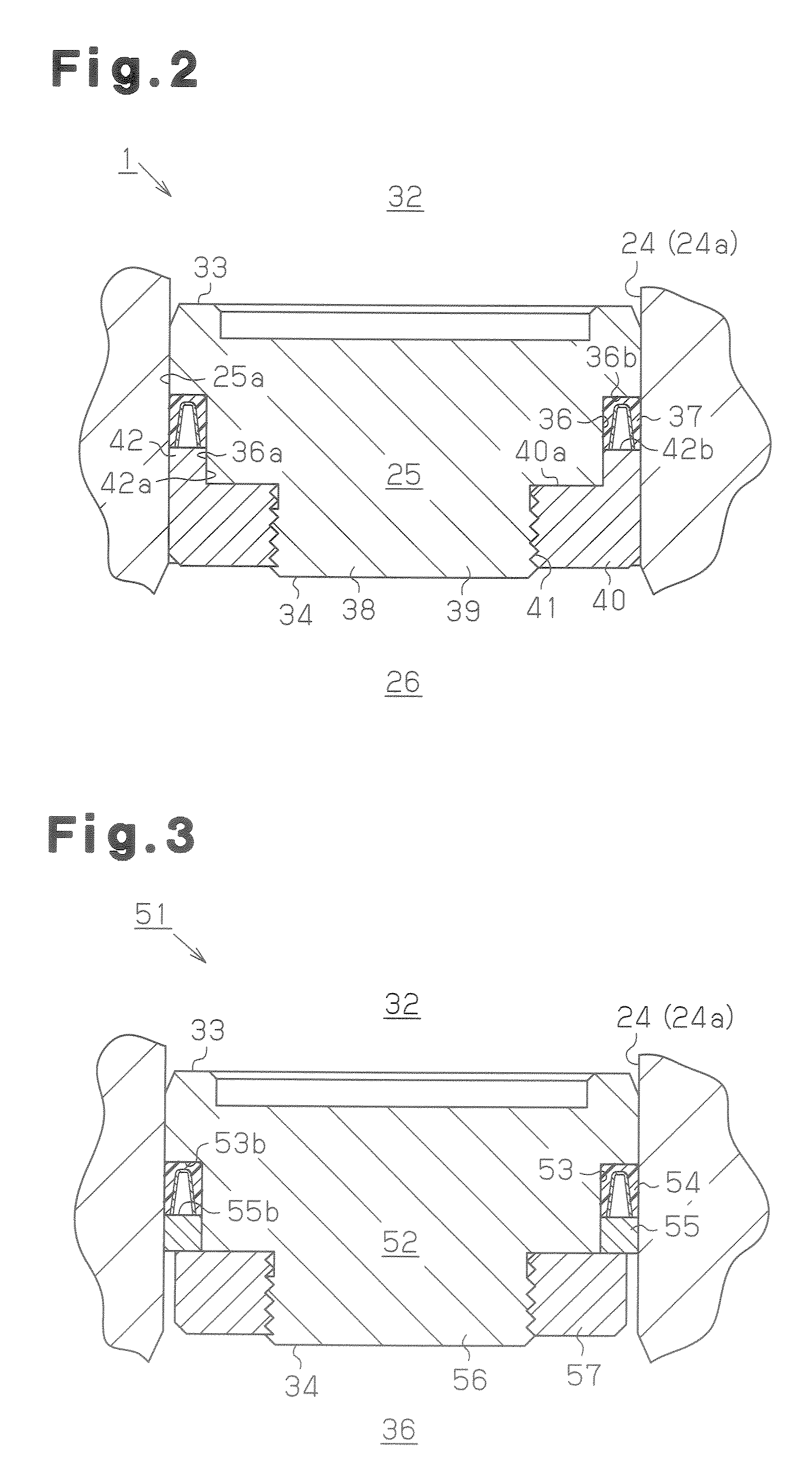

Pressure-Reducing Valve

InactiveUS20080105840A1Highly accurate pressure regulationAvoid displacementPiston ringsPlungersEngineeringLip seal

An annular mating portion extends from a fastening surface of a fastening nut. The mating portion has an inner diameter set to be substantially equal to an outer diameter of the portion of a piston in which an accommodating groove is formed. In a state in which the mating portion is inserted into the accommodating groove and an inner circumferential surface of the mating portion slides in contact with a circumferential wall of the accommodating groove, the fastening nut is mated with a threaded portion and a lip seal is held between the mating portion and the accommodating groove. This fixes the lip seal to the piston.

Owner:JTEKT CORP

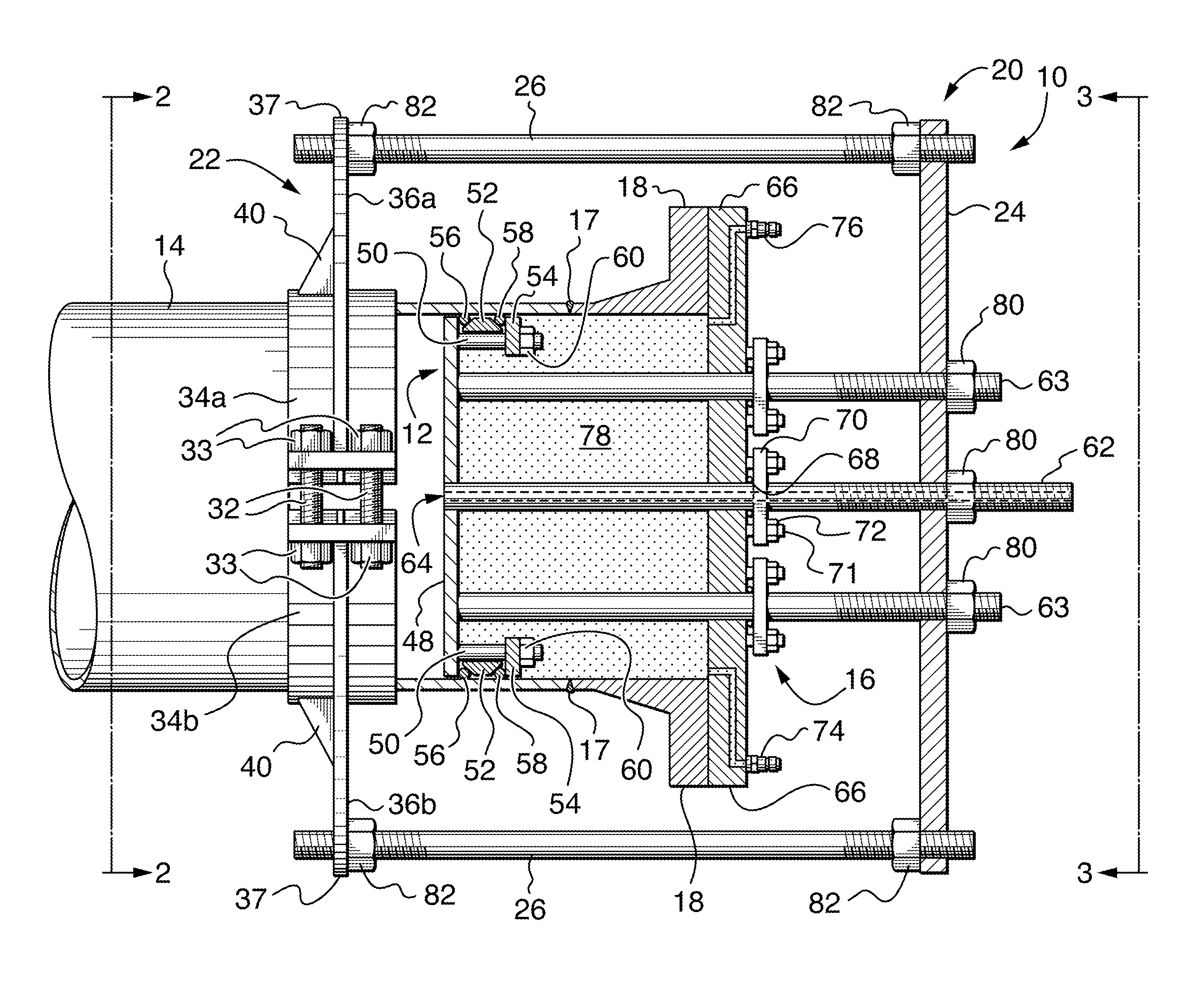

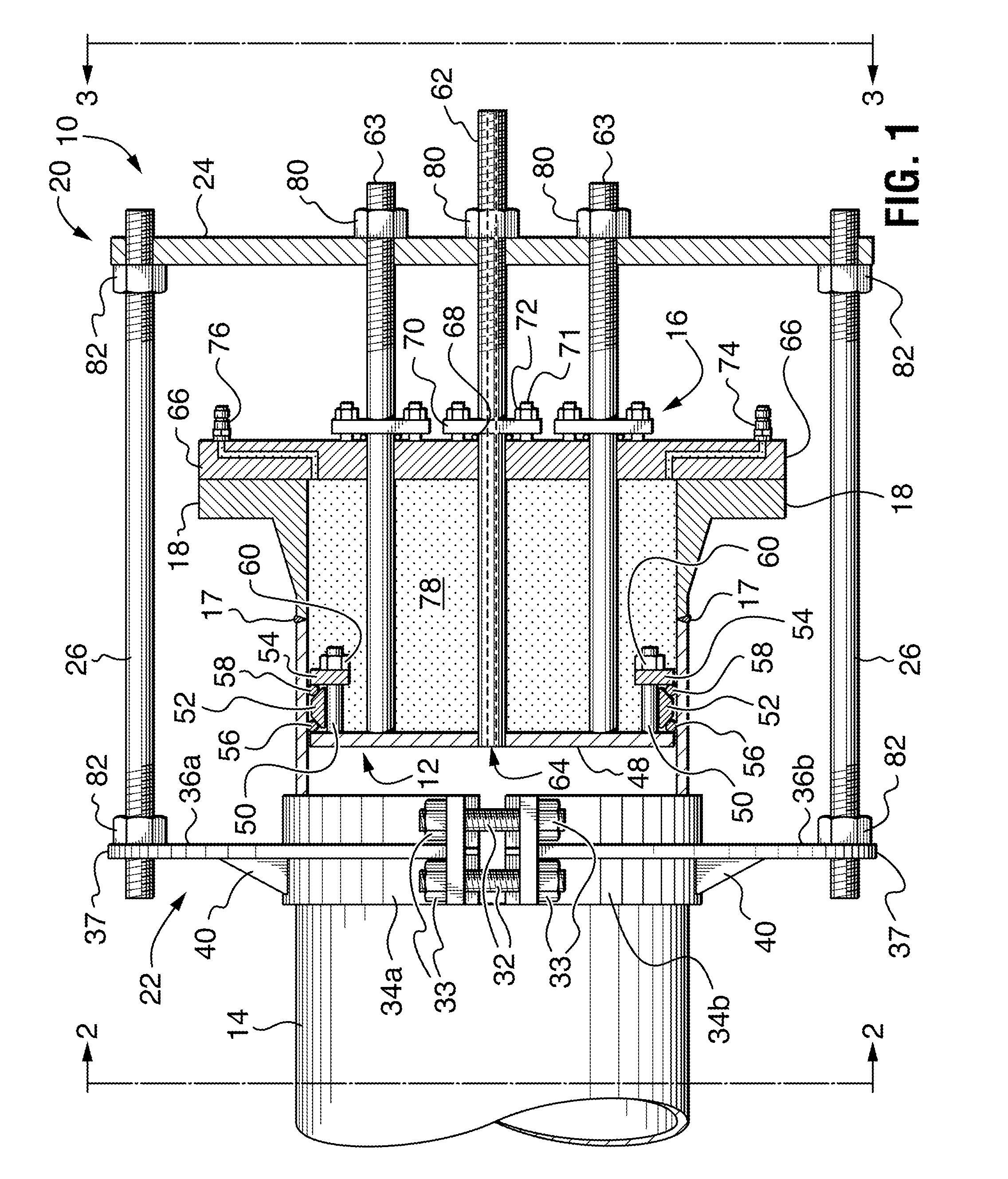

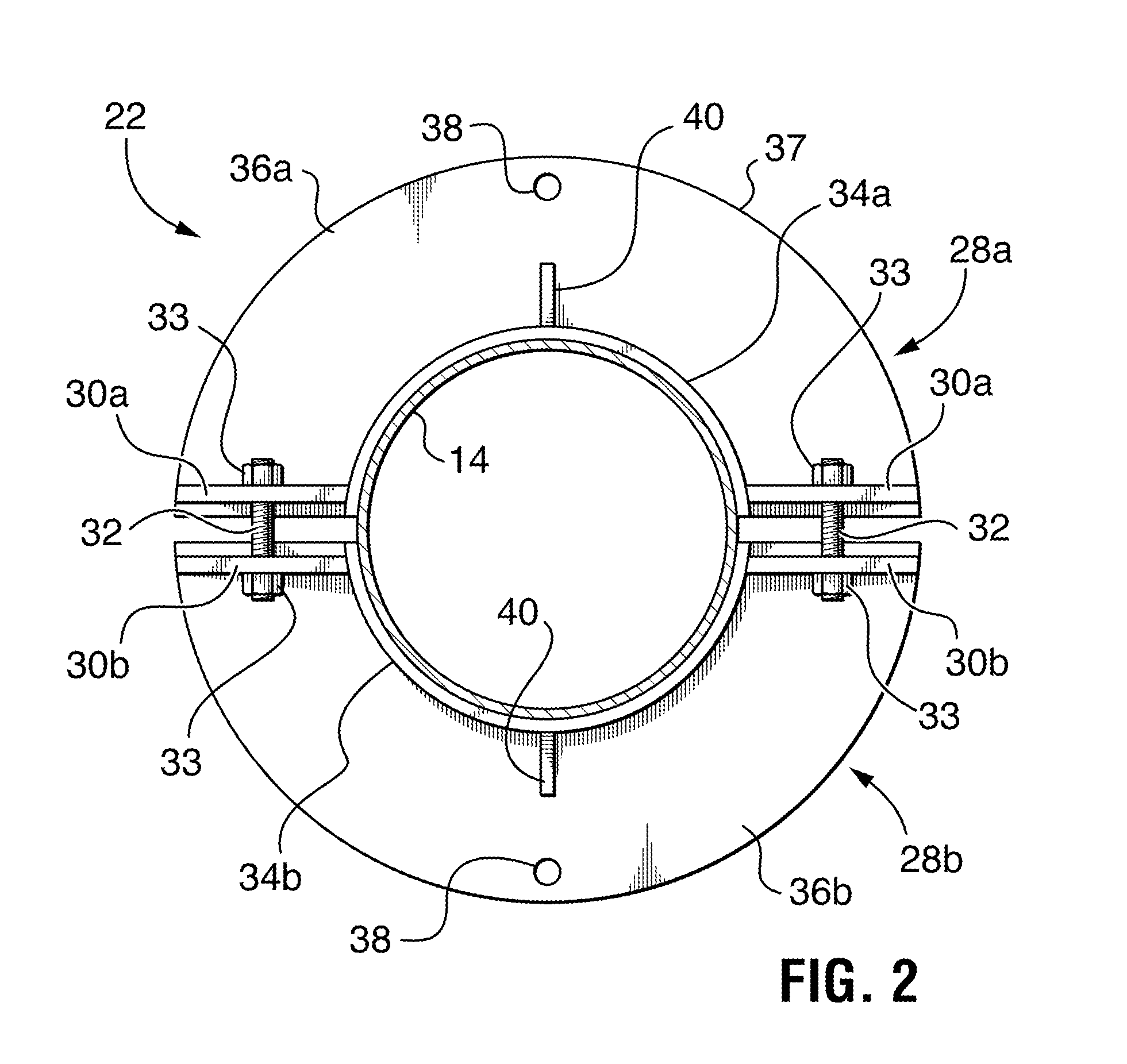

Apparatus and Method for Isolating or Testing a Pipe Segment with Axial Reinforcement

InactiveUS20100186484A1Prevent axial displacementAvoid displacementDetection of fluid at leakage pointMeasurement of fluid loss/gain rateEngineeringTest procedures

An apparatus and method for testing the integrity of a weld securing a flange to the end of a pipe comprises a testing assembly and a reinforcement assembly. The testing assembly comprises a first sealing means positioned within the pipe and a second sealing means secured against the flange face to form a sealed region within the pipe with the region overlapping the weld. The reinforcement assembly comprises a circumferential clamp secured to the outer wall of the pipe and an anchor plate positioned opposite the flange. The first sealing means is connected to the anchor plate to prevent relative movement there-between. The anchor plate is connected to the clamp to prevent relative movement there-between. The weld test procedure comprises installing the apparatus, filling and pressurizing the sealed space and monitoring the pressure created therein. The reinforcement assembly prevents the first sealing member from being separated and allows a weld test to be performed without a compressive force being applied on the weld. The invention also provides a reinforced tool and method for isolating an end segment of a pipe.

Owner:CAR BER INVESTMENTS INC

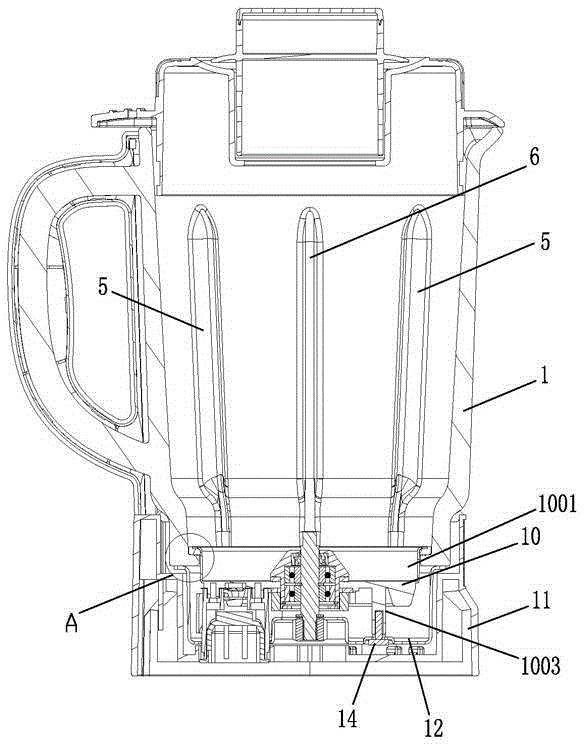

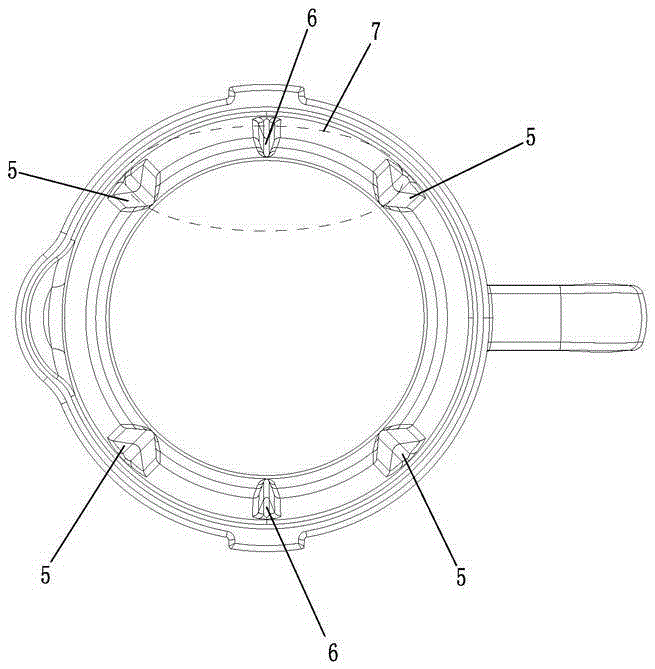

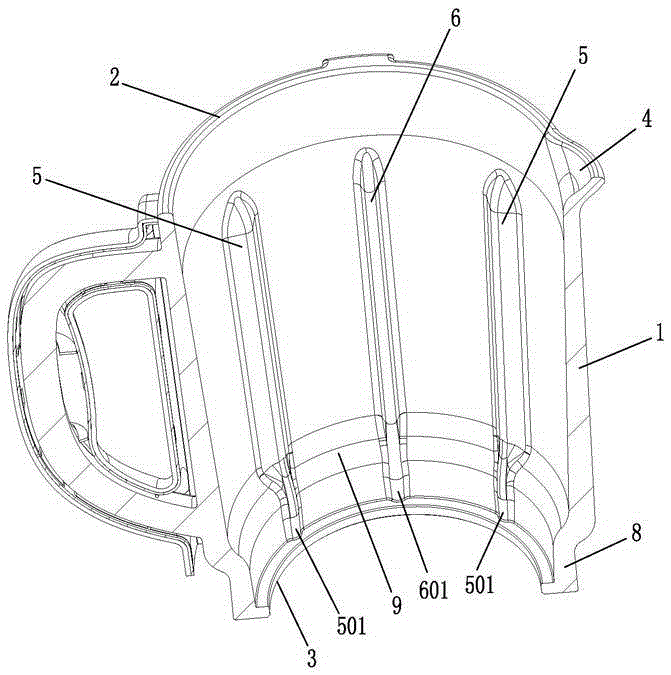

Novel food processer

Owner:广东昌盛电器有限公司

Sampling device

PendingCN107607346ANot mixedGuarantee the precision requirements of procurementWithdrawing sample devicesComputer science

Owner:HUNAN SUNDY SCI & TECH DEV

Internal combustion engine

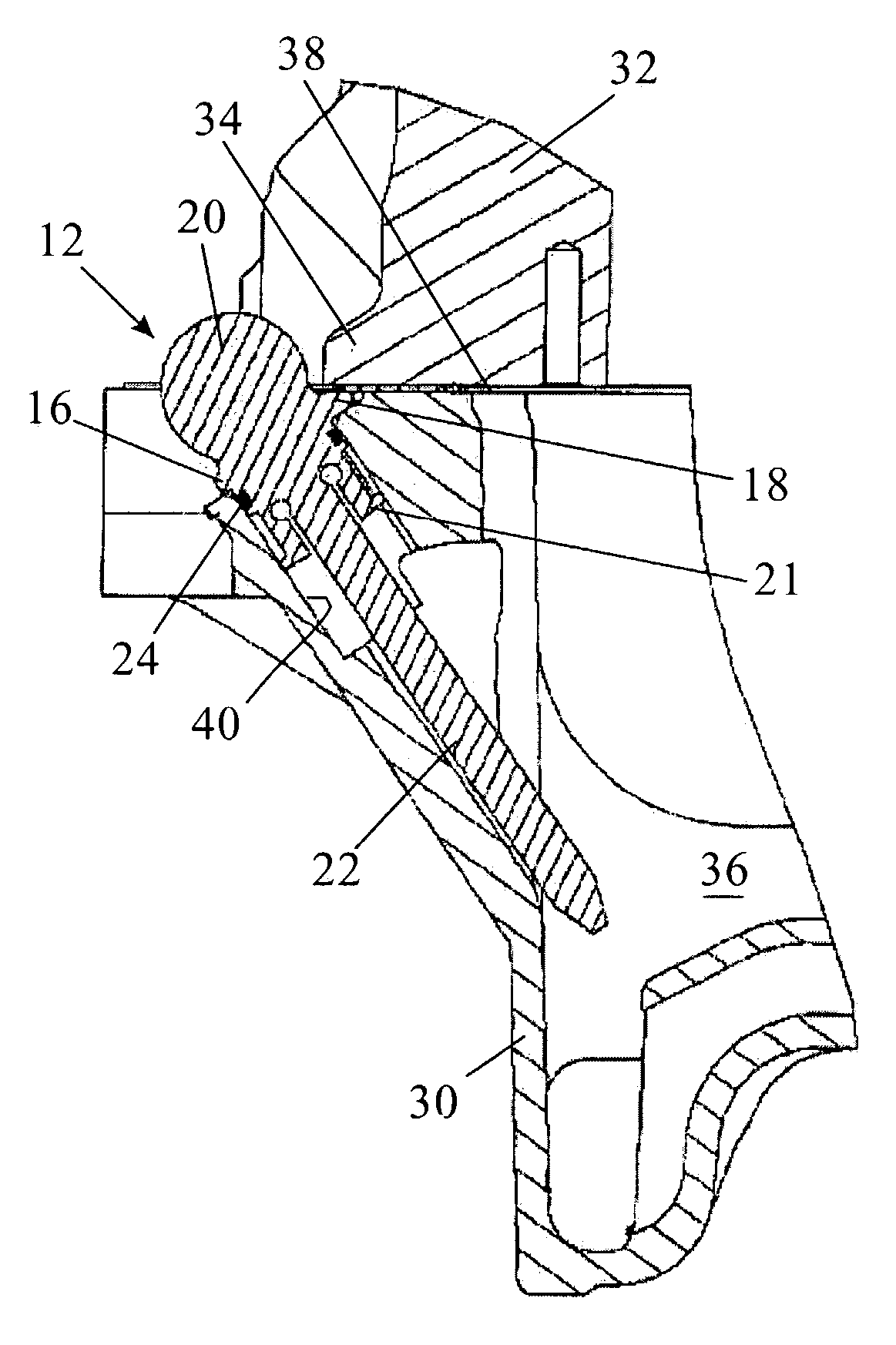

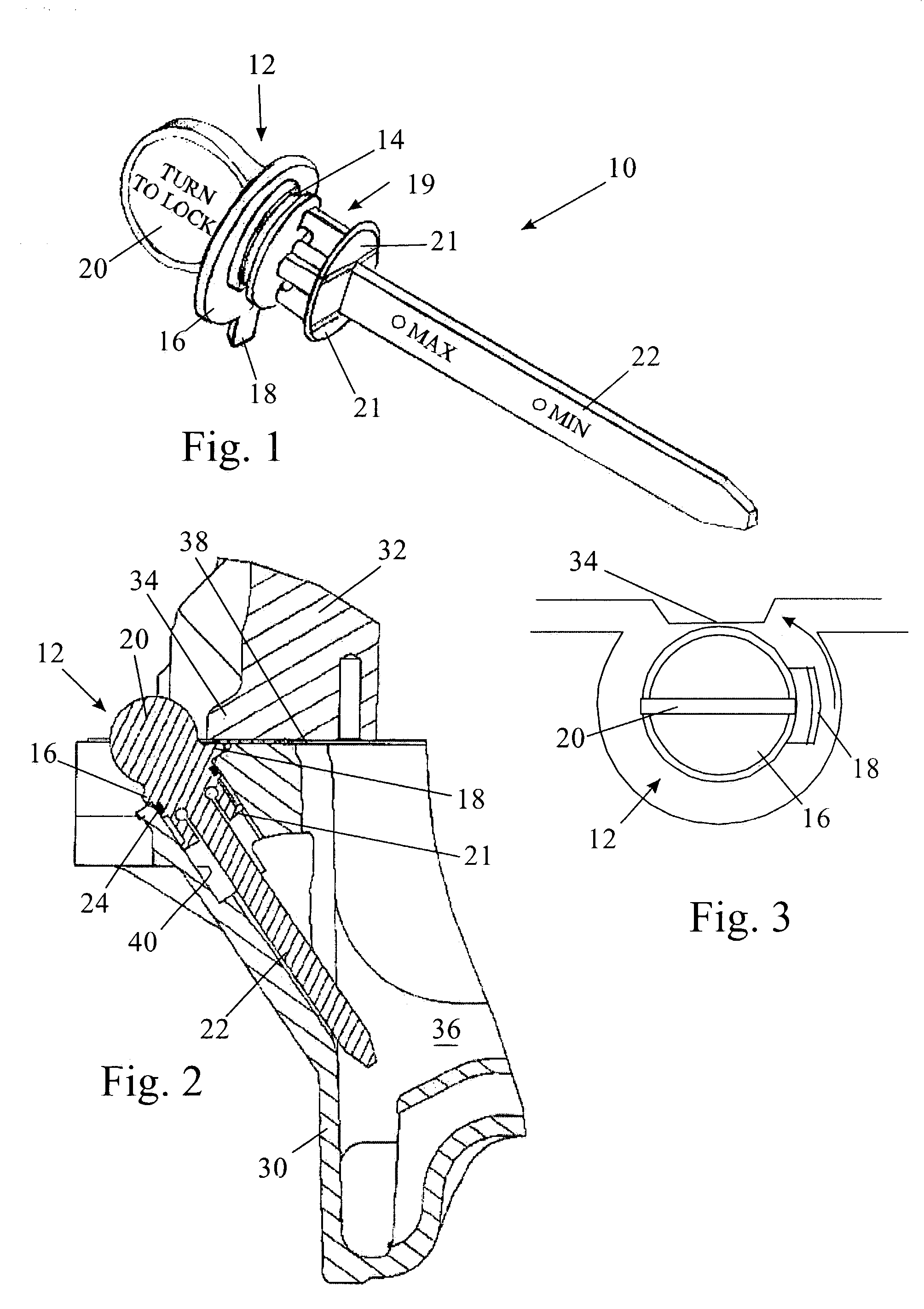

ActiveUS7100744B2Place safePrevent axial displacementLevel indicators by dip membersUsing mechanical meansAxial displacementEngineering

An engine is described having a hole for a dipstick which is closed by a cap from which the dipstick depends. The engine body is formed with an overhanging lip adjacent the mouth of the hole, and the cap comprises a spigot rotatably received in the mouth of the hole and a flange extending radially outwards from the spigot to cover the mouth of the hole. The flange is non-circular so that by rotation of the cap relative to the hole, a radially projecting portion of the edge of the flange may be selectively engaged beneath the overhanging lip to prevent axial displacement of the cap and the dipstick relative to the engine body.

Owner:CUMMINS ENGINE CO LTD

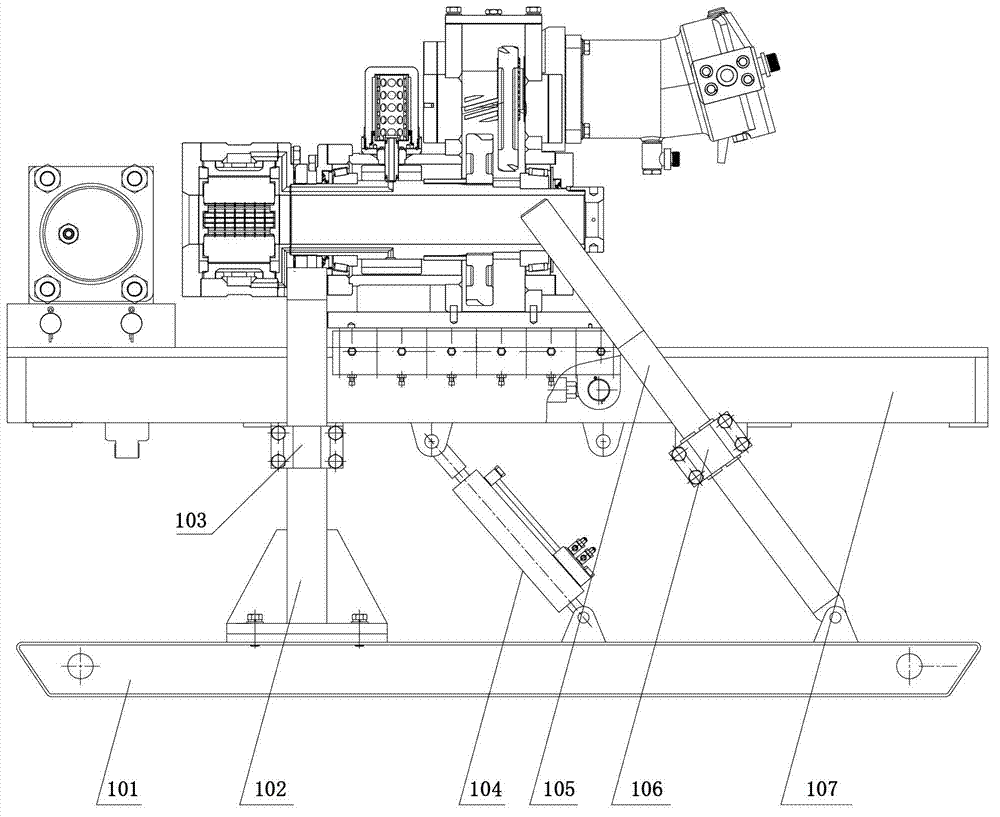

Travel reducer test system

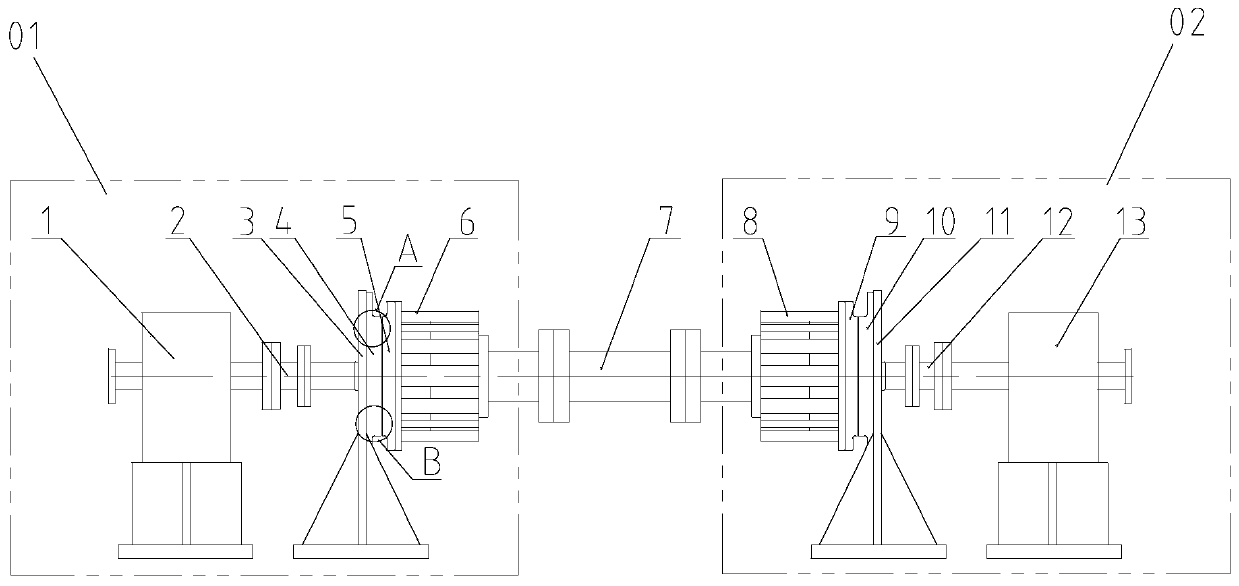

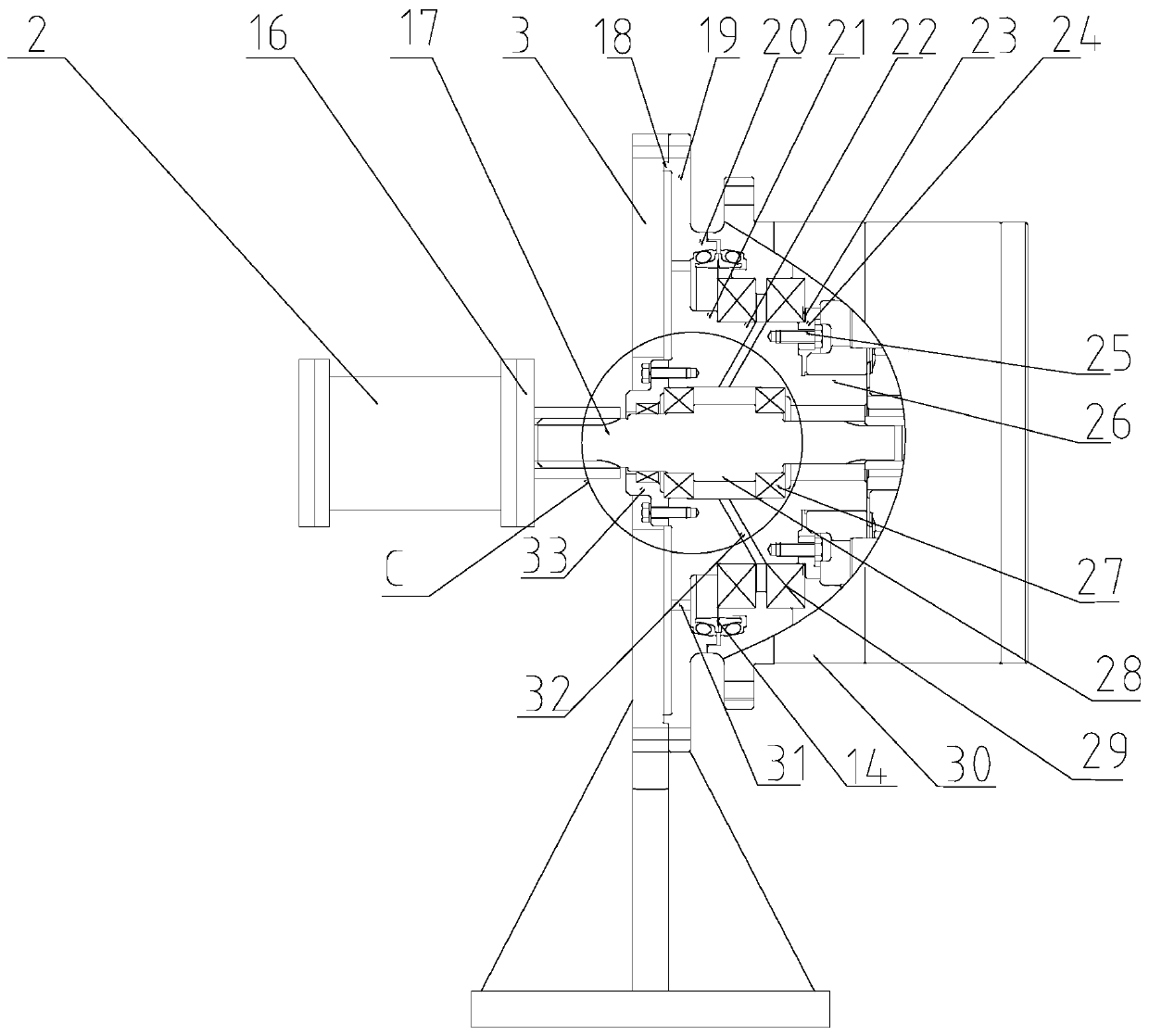

ActiveCN110333069AReduce investmentReduce energy consumptionThermometer detailsMachine gearing/transmission testingCouplingClosed loop

The invention provides a travel reducer test system, solving the problem that the existing travel reducer test system is high in cost, large in occupied space and low in efficiency. The test system comprises a test platform, a third coupler, a main test unit and an accompanying test unit; the main test unit and the accompanying test unit are arranged in a mirrored manner via the third coupler; themain test unit comprises a loading motor, a first coupler, a first loading tool, a main travel reducer to be tested and a first transition connection tray connected in sequence; the accompanying testunit comprises a load motor, a second coupler, a second loading tool, an accompanying travel reducer to be tested and a second transition connection tray connected in sequence; the first loading toolis used for achieving dynamic loading performed by the loading motor on the main travel reducer to be tested; the second loading tool is used for achieving dynamic loading performed by the load motoron the accompanying test unit; the loading motor and the load motor are separately connected with the output end and the input end of the test platform, and thus the test platform, the main test unitand the accompanying test unit are formed into a closed loop connection.

Owner:SHAANXI FAST AUTO DRIVE GROUP CO LTD

Glass breaking device

InactiveCN107233963APrevent flying outAvoid accidental injuryGrain treatmentsWood splinterEngineering

The invention discloses a crushing device for crushing glass, which comprises a crushing shell, which is provided with a feed port and a discharge port, and also includes a strip-shaped counterattack plate, an arc counterattack plate, a counterattack block, and a first counterattack block. A material guide baffle, a second material guide baffle, a rotor and a crushing mechanism, the rotor is rotatably connected in the crushing shell, the strip counterattack plate and the counterattack block are arranged on the left side of the rotor, and the arc counterattack plate is arranged on the side of the rotor On the right side, a first material guide baffle and two second material guide baffles are layered up and down below the feed inlet, and the crushing mechanism is fixed on the outer wall of the crushing shell. The invention can effectively prevent broken glass chips from flying out from the feeding port, and avoid accidentally injuring people; after the large pieces of glass are broken, they will directly enter the crushing shell, with high efficiency. The plate is crushed, and at the same time, it can be used for large and small glass blocks, and the use effect is good. The limit unit can effectively prevent the axial displacement of the hammer head.

Owner:NANJING CHAOYANG GLASS CO LTD

Anti-loose structure for large-sized motor rotator

InactiveCN103427516APrevent radial deformationPrevent axial displacementMagnetic circuit rotating partsAxial displacementElectric machine

The invention discloses an anti-loose structure for a large-sized high speed (more than 1500 revolutions per minute) motor rotor. According to the principle, a high intensity alloy steel protective ring which is designed is sleeved at the outer edge of a rotor end ring in a thermal mode; the outer end of the protective ring achieves axial positioning through a balanced ring which is sleeved on a shaft in a thermal mode and prevents radial displacement of the protective ring through a spigot of the balanced ring; a taper key (6) is embedded at the groove bottom to be tightly wedged after a rotor conducting bar (5) penetrating into a rotor core (8) and the rotor conducting bar is firmly welded to prevent the rotor conducting bar (5) from generating radial looseness inside a groove; certain gaps are reserved between the end ring (4) and a rotor pressing ring (7) to be used for ventilation and heat dissipation. The anti-loose structure for the large-sized high speed motor rotor has the advantages of preventing the conducting bar end portion and the end ring from performing radial deformation caused by centrifugal force, preventing the conducting bar and the end ring from performing axial displacement caused by conducting bar looseness and avoiding breakage bar, open weld and end ring deformation accidents from happening.

Owner:李贤明

Fixing roller

ActiveCN1831675AIncreased durabilityPrevent circular motionElectrographic process apparatusSilicone ElastomersBiomedical engineering

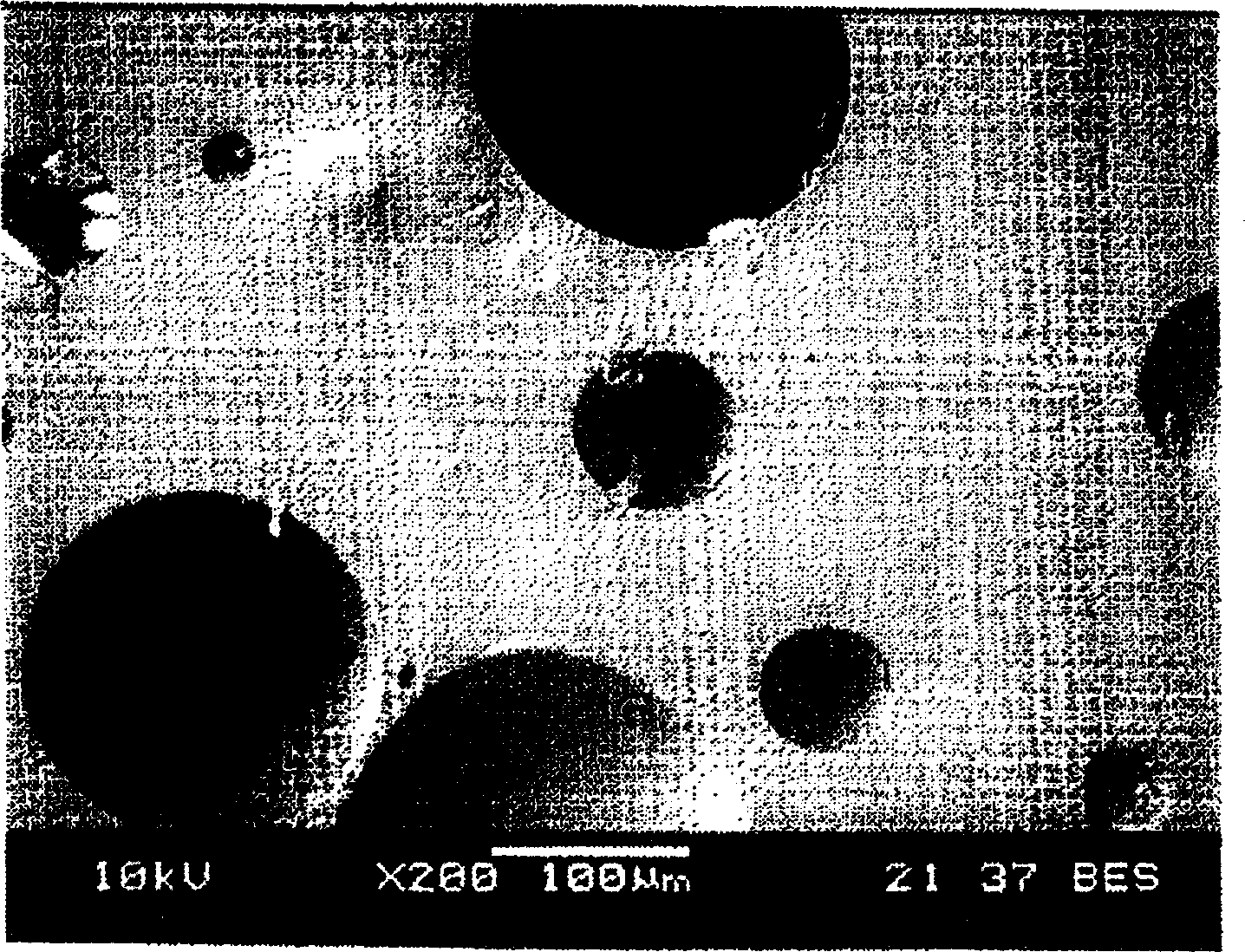

Disclosed is a fixing roller which comprises a core 16 , a porous material layer 22 disposed in surrounding relation to an outer peripheral surface of the core 16 , and a thin-walled metal sleeve 26 covering an outer peripheral surface of the porous material layer 22 . The porous material layer 22 comprises a closed cell-type silicone elastomer. The present invention provides a fixing roller capable of ensuring enhanced durability and maintaining a usable state over long periods under the condition of being actually driven and rotated.

Owner:SYNZTEC

Automobile circular shaft part clamping tool

PendingCN114211425ARealize the clamping effectAchieve releaseWork holdersPositioning apparatusMotor vehicle partControl theory

The invention relates to the technical field of automobile part production auxiliary equipment, and discloses an automobile circular shaft part clamping tool which comprises two V-shaped clamping blocks capable of getting close to each other or getting away from each other, the two V-shaped clamping blocks get close to each other or getting away from each other is controlled by a driving mechanism, and the V-shaped clamping faces of the V-shaped clamping blocks are provided with two adsorption pieces which are in point contact with circular shaft parts all the time. An elastic adsorption body elastically abutting against the surface of the circular shaft part is arranged in the concave center of the V-shaped clamping face in a protruding mode, the adsorption piece comprises a suction cup and a first air bag arranged in the center of the suction cup in an expanding mode, and an adsorption pipe is arranged in the center of the elastic adsorption body. A linkage mechanism for driving the negative pressure of the adsorption pipe to be increased after the first air bag is extruded is arranged in the V-shaped clamping block, a desorption mechanism for supplementing air to the first air bag is arranged on the adsorption piece, and a reset mechanism for driving the first air bag to reset and the adsorption pipe to recover the normal pressure is arranged in the V-shaped clamping block. The clamping firmness can be obviously improved, and discharging is convenient and fast.

Owner:郭传渠

Tube pump

ActiveCN102317629BSimple structureEasy to install and disassembleFlexible member pumpsDialysis systemsEngineeringGuide tube

The conduit (2) of the hose pump (1) has: a loop-shaped large-diameter hose (8); a supply hose (18) connected to the end of the large-diameter hose (8) One end; the discharge hose (19), which is connected to the other end of the large diameter hose (8) by a discharge side connector (17'). The bracket (7) has a pair of stepped engaging recesses (7D, 7D') capable of engaging with the outer surfaces of the two connectors (17, 17'). The two connectors (17, 17') are held by the stepped engagement recesses (7D, 7D') of the bracket (7), and the bracket (7) in this state is mounted on the cutout (6B) of the housing (6). . It is possible to provide a hose pump (1) in which the conduit (2) is easily attached to and detached from the housing (6).

Owner:NIPRO CORP +1

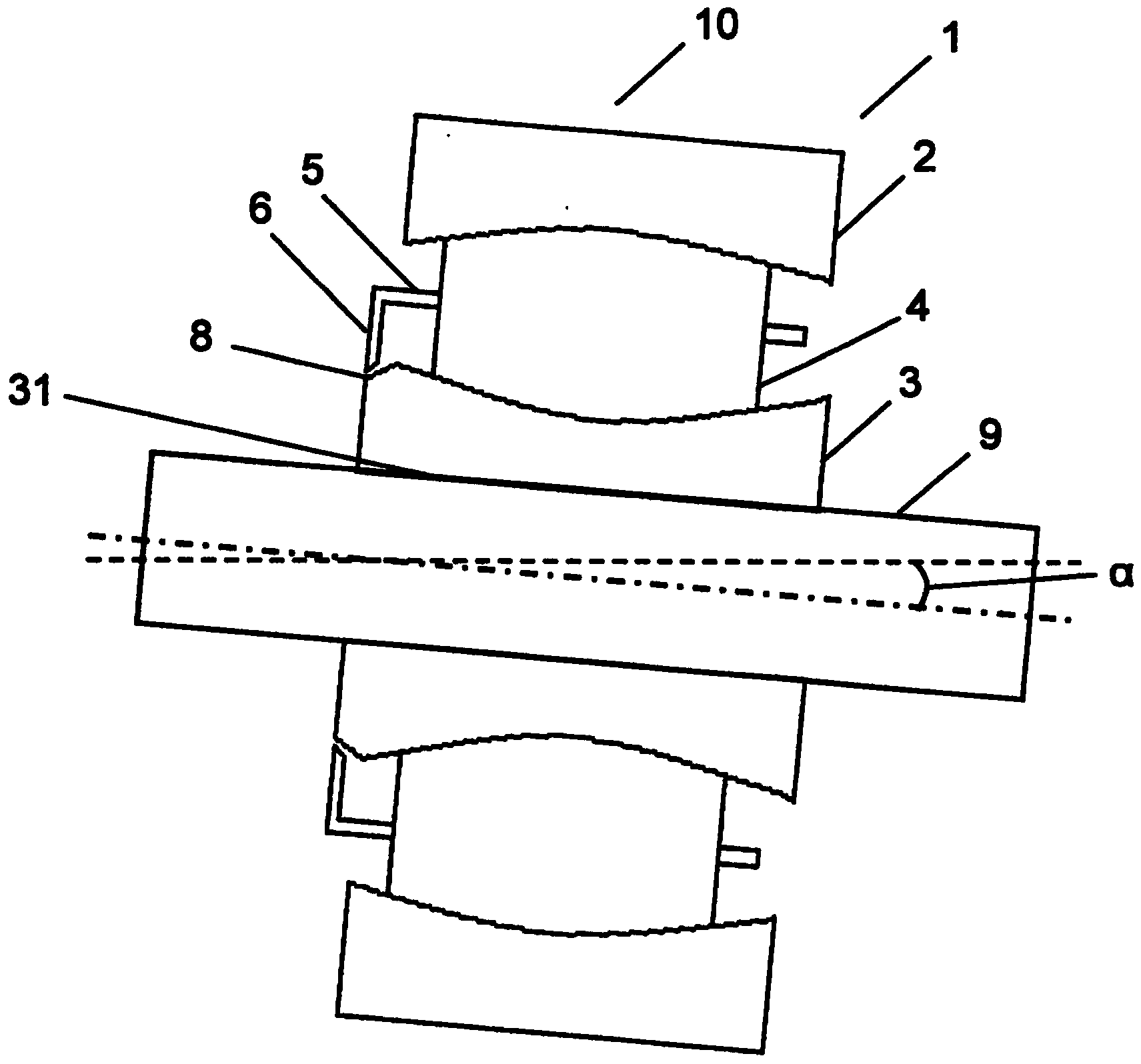

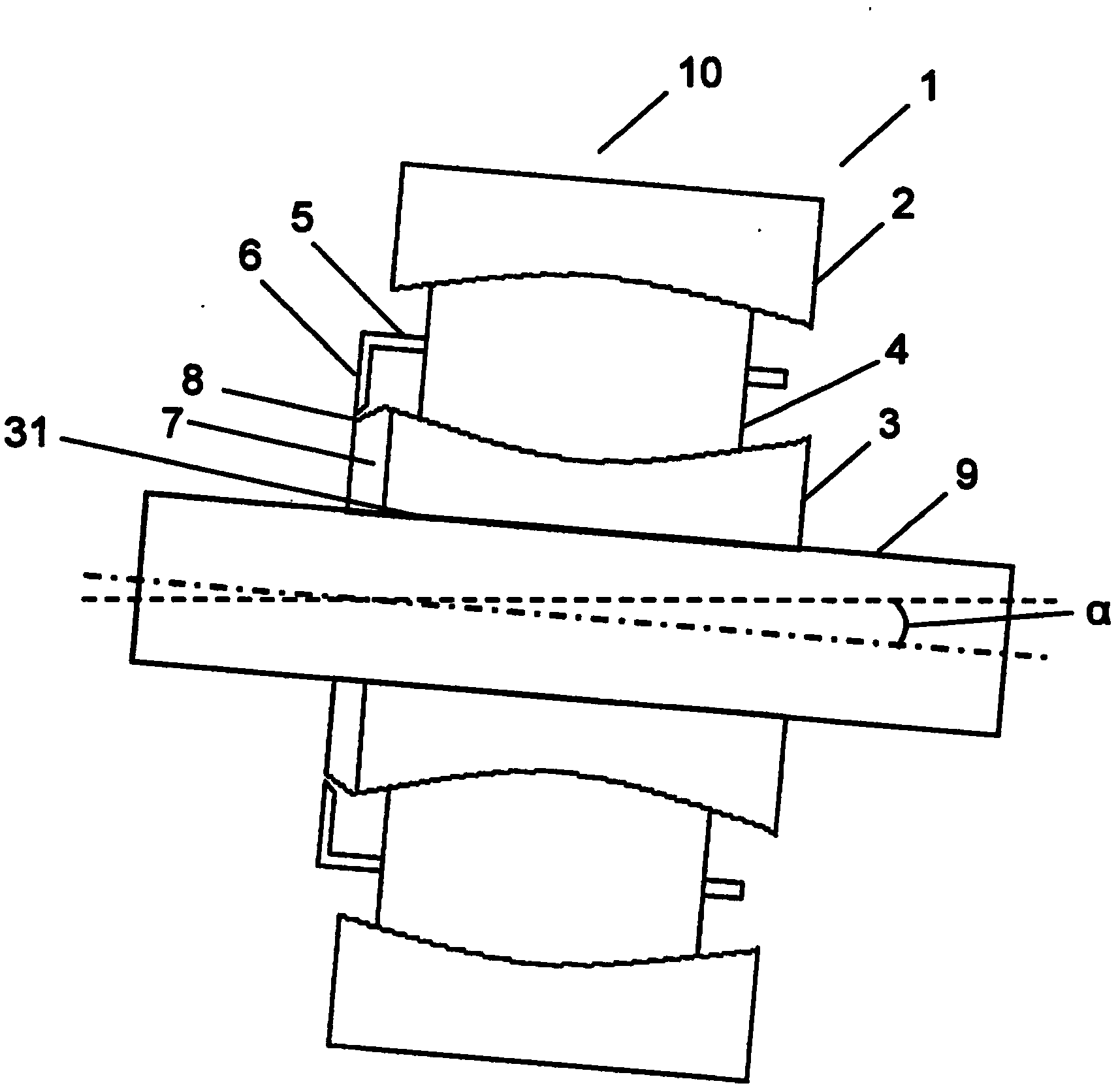

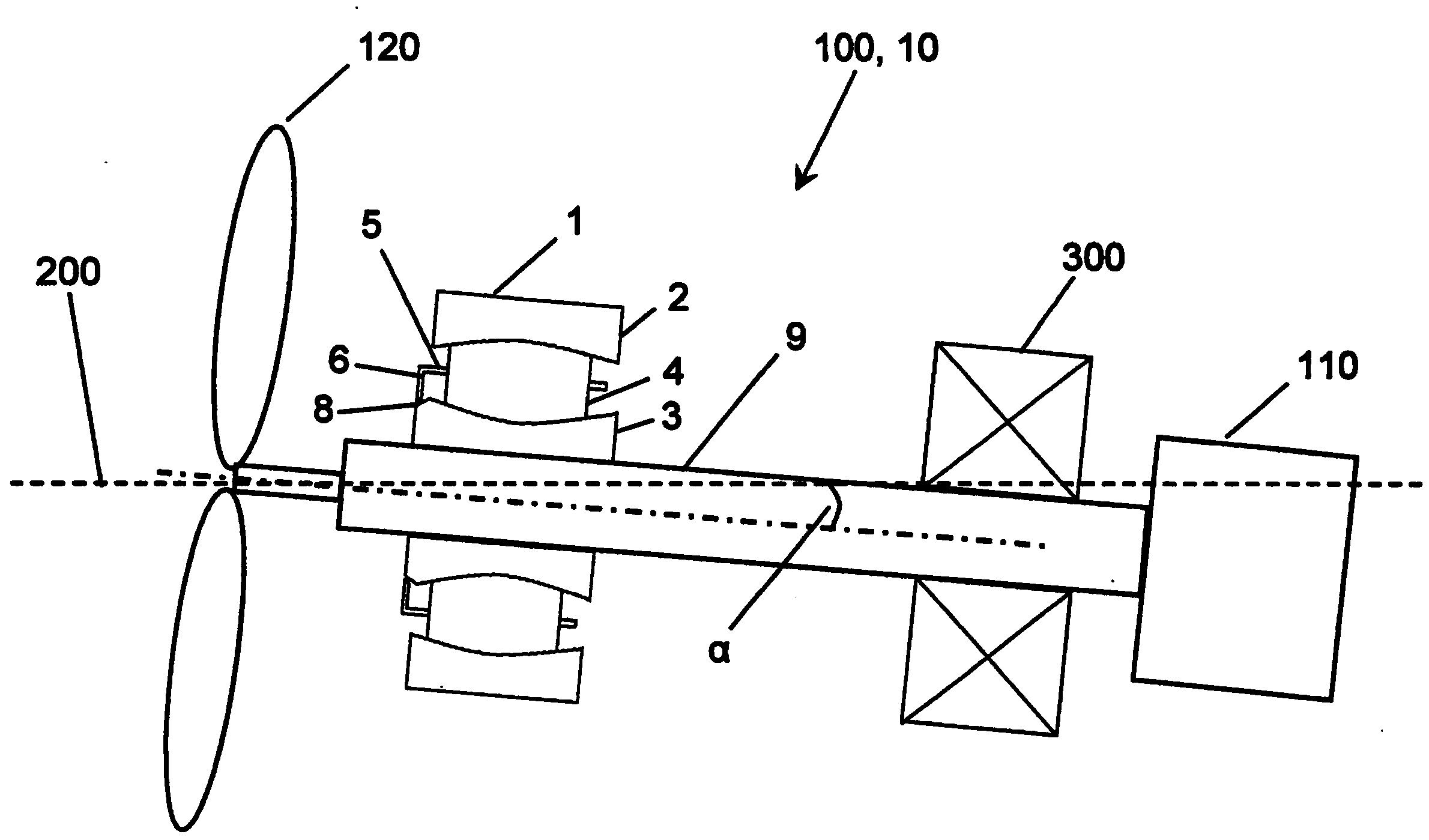

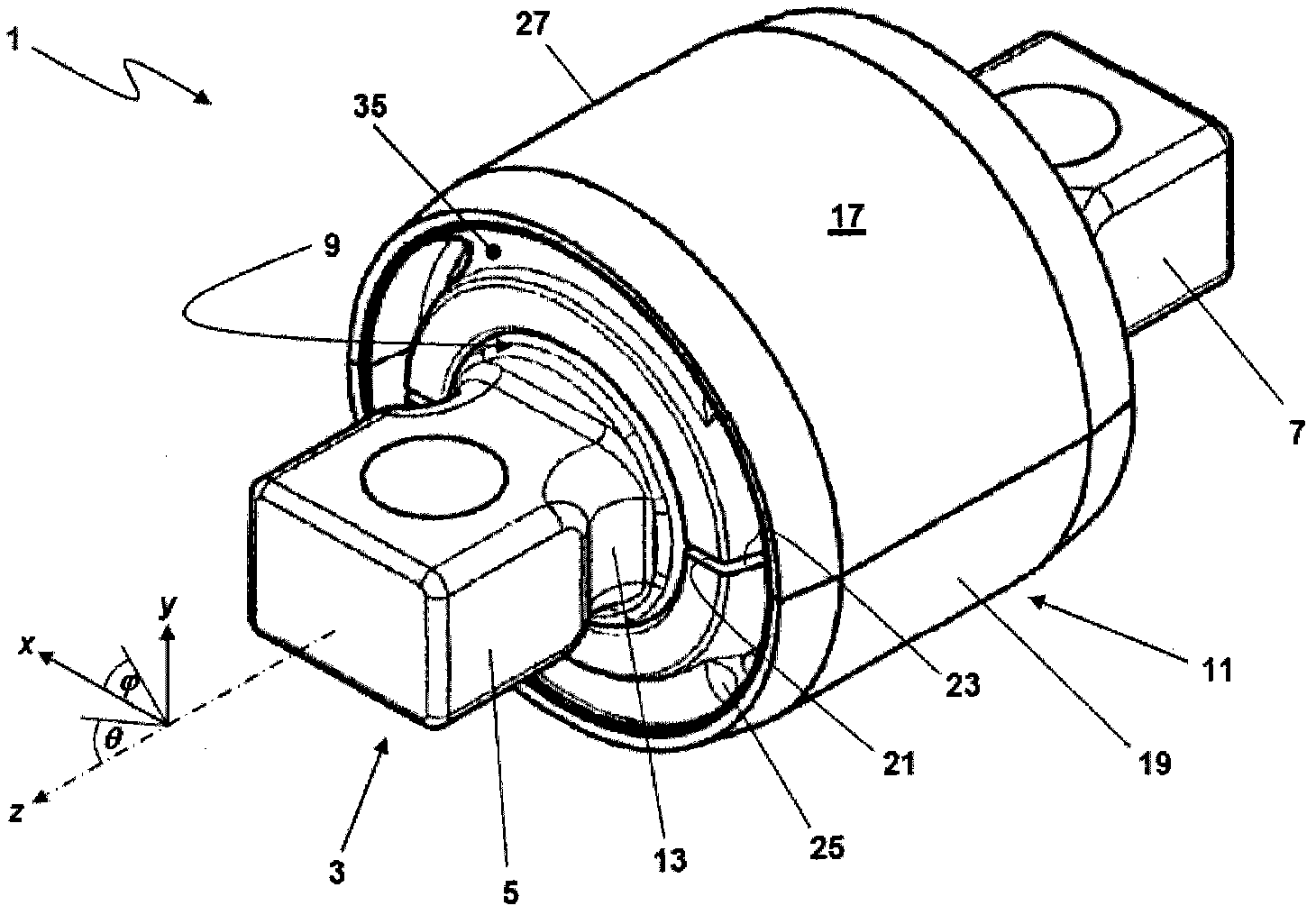

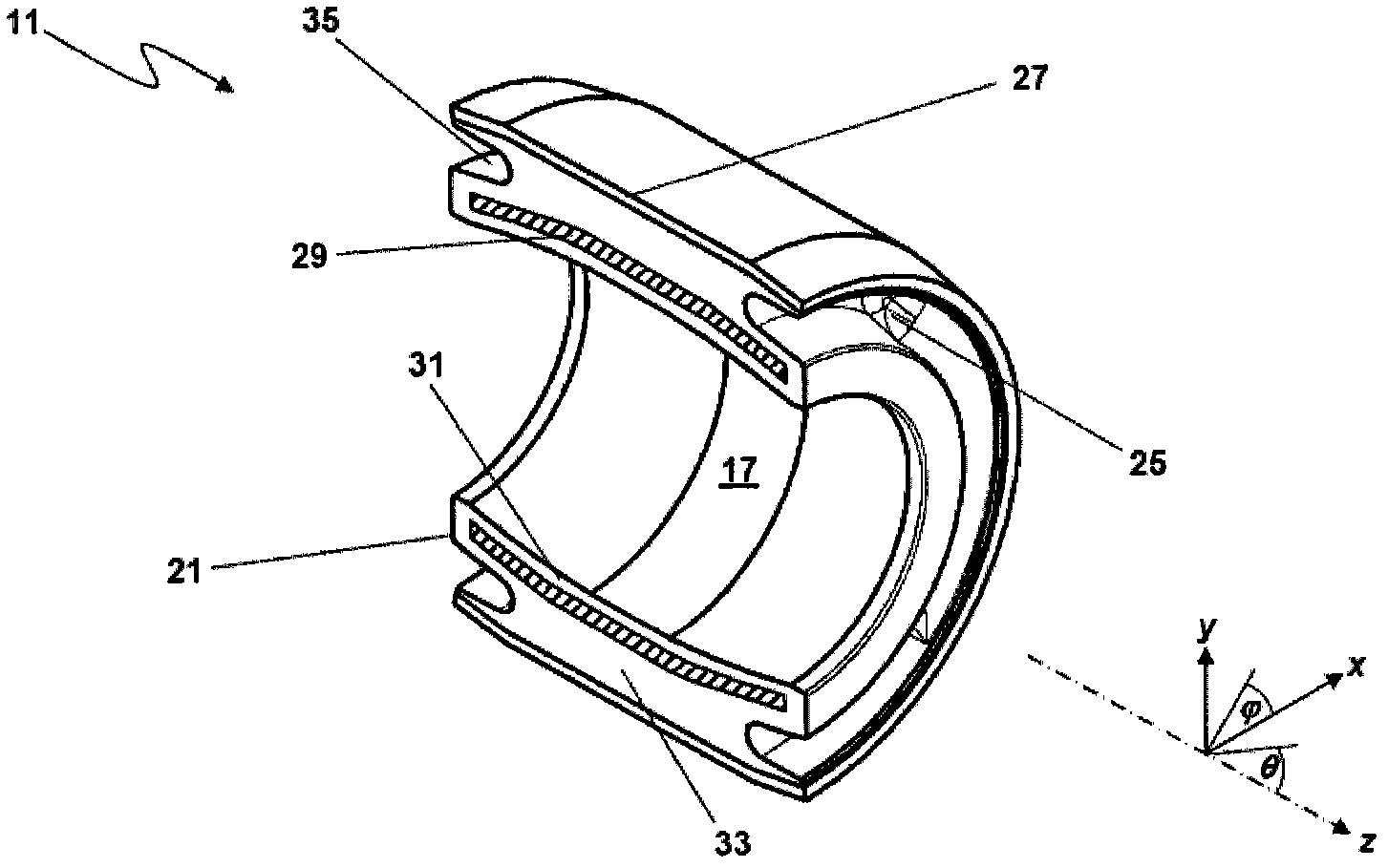

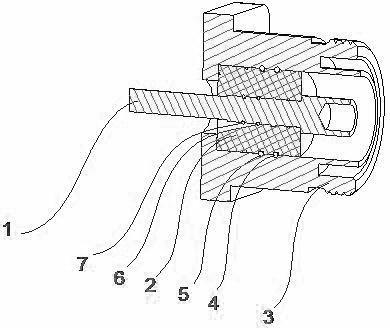

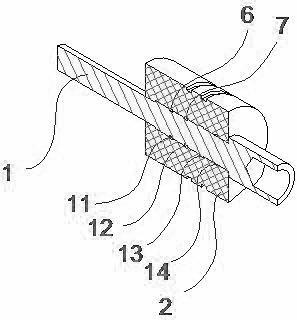

Bearing arrangement

ActiveCN104254698APrevent axial displacementReduce skewRoller bearingsBearing assemblyEngineeringAxial force

The invention regards a bearing arrangement (10), comprising a rolling bearing (1), wherein the rolling bearing (1) comprises an inner ring (3), an outer ring (2) and rolling elements (4) interposed between the inner (3) and outer (2) ring. Furthermore, the bearing 1 comprises a cage (5) for holding and separating the rolling elements (4), wherein said inner ring (3) presents an inner circumferential surface (31). A shaft (9) is also present, wherein the rolling bearing (1) is mounted on the shaft (9) via the inner circumferential surface (31) of the inner ring (3). The shaft (9) during operation is meant to oscillate in its axial direction, or is positioned in an angle a being (90 - y) degrees, wherein y is between 0 and 89, or the rolling elements (4) during operation are exposed of an axial force F, and the cage (5) presents means (6) for axially guiding the rolling elements (4) against at least one of the inner ring (3), the outer ring (2) or a separate element (7) located outside the rolling bearing (1). In addition, the invention concerns a wind turbine main shaft arrangement.

Owner:AB SKF

Cable pulling device

ActiveCN104348117APrevent fallbackAvoid confusionApparatus for laying cablesCable trayPetroleum engineering

The invention discloses a cable pulling device, which comprises a fixing device and a cable pulling disc, wherein the fixing device comprises a fixing frame and a fixing ring, the fixing frame comprises a base and a support rod, the support rod is positioned at the center of the base, and is connected with the base by thread, the fixing ring is fixedly connected with the upper end of the support rod, the fixing ring is in a circle shape and is provided with a notch, locking blocks are respectively arranged at the two sides of the notch of the fixing ring, a locking bolt is arranged between the two locking blocks, the fixing ring is provided with a clamping groove along the circumferential direction, and is an elastic clamping groove, the cable pulling disc is positioned in the clamping groove and is abutted against the clamping groove, a group of cable pulling holes are formed in the cable pulling disc, a binding belt is arranged in the inner wall of each cable pulling hole, and a hanging ring is arranged at the center of the cable pulling disc. The cable pulling device overcomes the technical defects of disordering of cables and difficult operation of cable connecting equipment in the cable pulling process in a cable tray, and has the advantages that the disordering of the cables is avoided and the operation of the cable connecting equipment is easy when the cable is pulled in the cable tray.

Owner:CHONGQING RUIPU CABLE

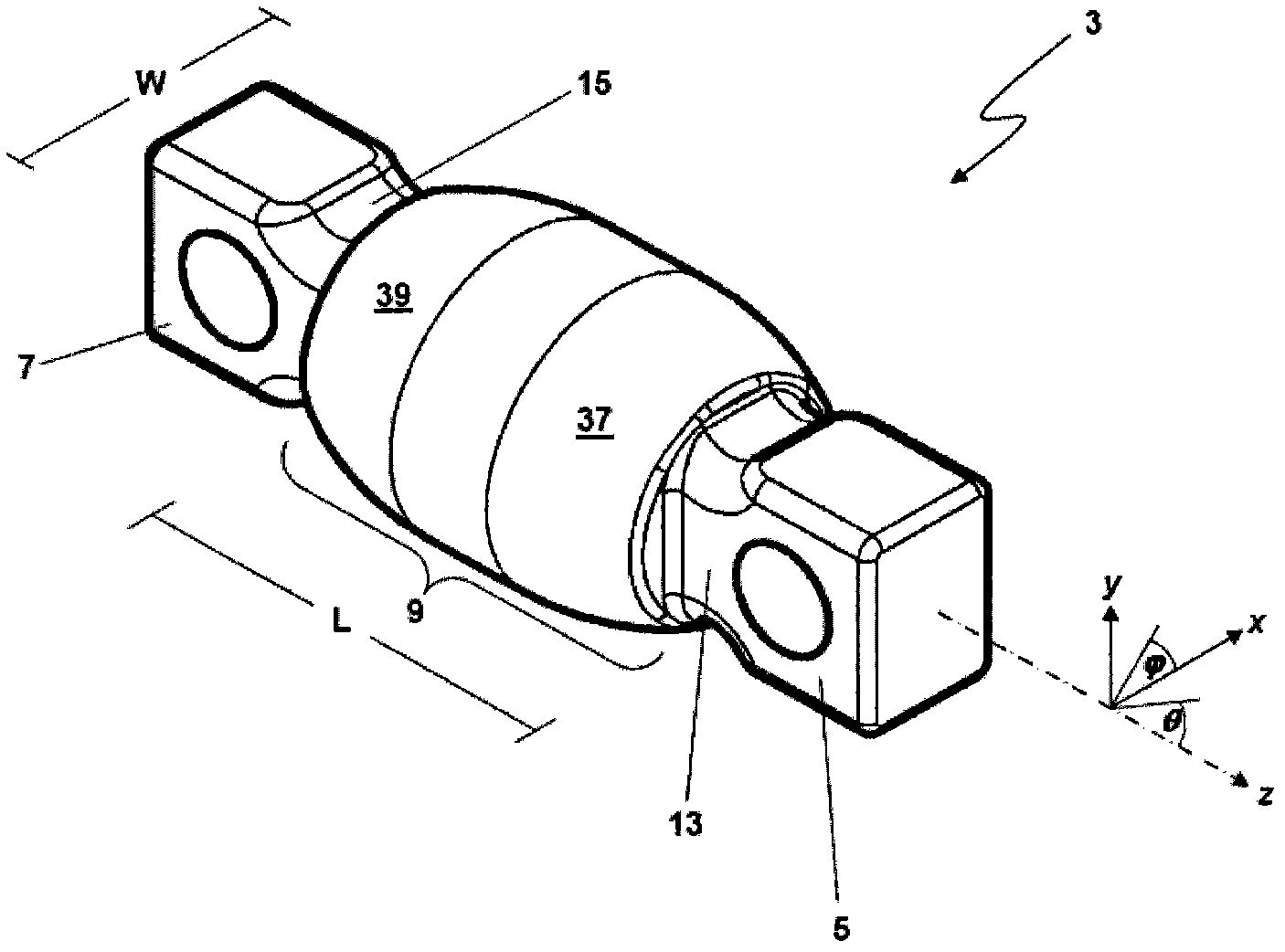

Reaction rod arrangement

ActiveCN101990504ALow production costLow installation costSpringsPivotal connectionsElastomerRigid core

The present invention refers to a reaction rod arrangement, in particular a V-stay suspension, for a vehicle including a bushing (1), wherein the bushing (1) comprises a rigid core member (3) having a bearing portion (9) and defining a longitudinal axis (z), and an elastomer body (11) being arranged on at least a portion of the radially outer surface of the bearing portion (9), characterised in that the bearing portion (9) comprises a first and a second tapering portion (37, 39), wherein the first tapering portion (37) tapers towards one axial end of the bearing portion (9) and the second tapering portion (39) tapers towards the other opposite axial end of the bearing portion (9), wherein the axial extension of the bearing portion (9) is larger than its maximal radial extension with respect to the longitudinal axis (z), and wherein the elastomer body (11) is movably arranged on the bearing portion (9) such that the elastomer body (11) is able to perform a rotational movement about thelongitudinal axis (z) relative to the rigid core member (3) and a tilting movement about an axis perpendicular to the longitudinal axis (z) relative to the rigid core member (3).

Owner:孔斯贝格汽车公司

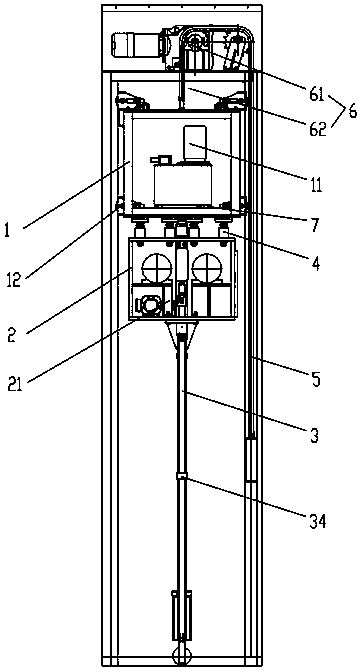

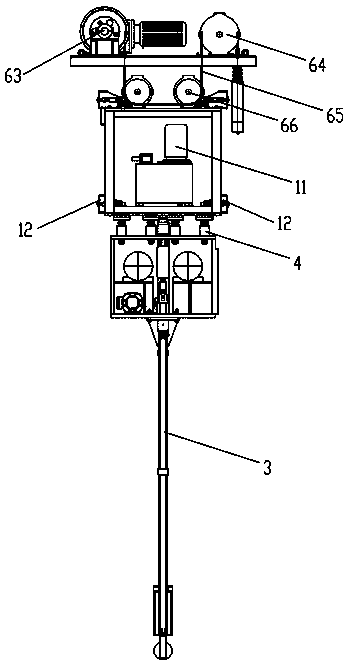

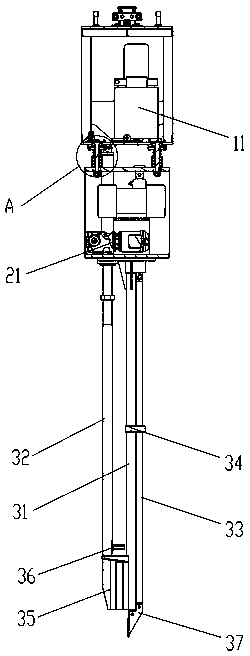

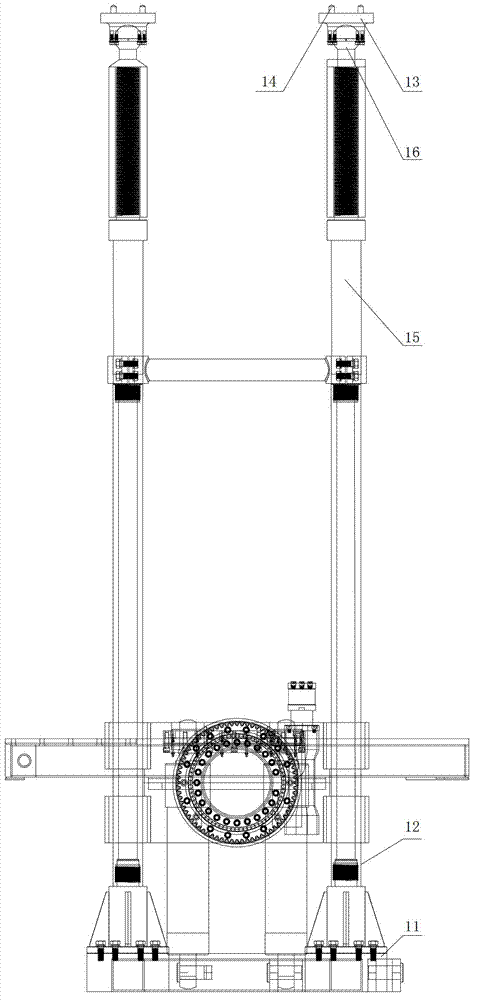

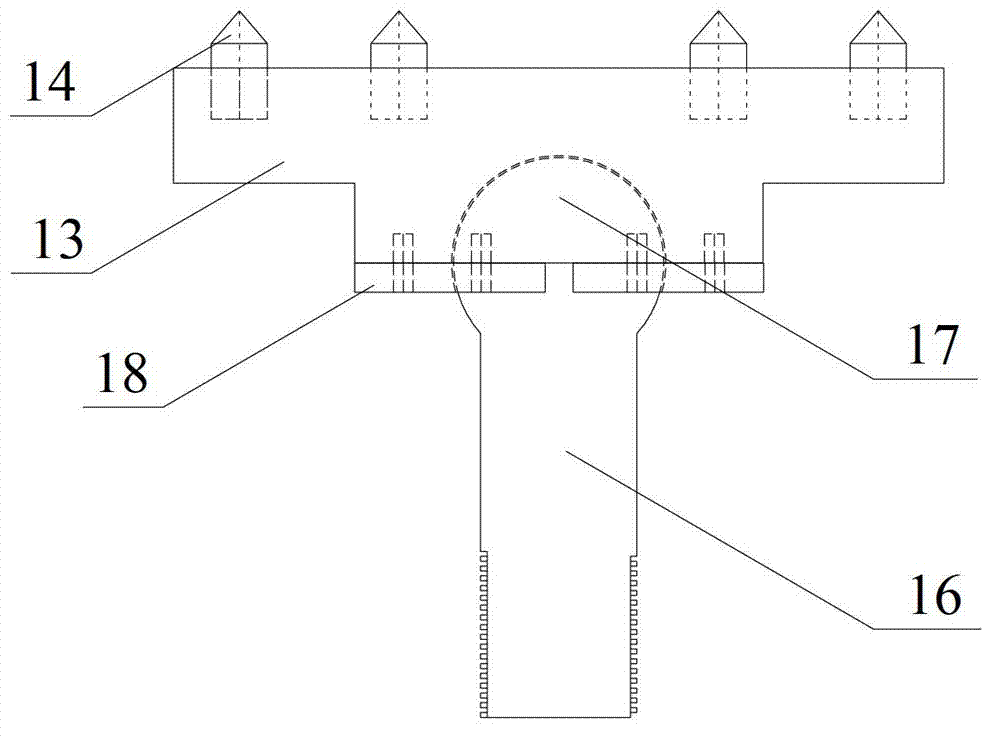

Underground drill rig and supporting device thereof

The invention discloses an underground drill rig and a supporting device thereof. The supporting device comprises a base, a stand column, a driving device, a connection component and a column cap, the stand column is arranged on the base, the driving device is arranged at the top end of the stand column, the connection component is driven by the driving device to perform extension and retraction movement along the axial direction of the stand column, and the column cap is spherically hinged at the top end of the connection component. By means of the supporting device of the underground drill rig, stability of the underground drill rig during operation can be effectively improved.

Owner:CHONGQING PINGSHAN MINING ELECTROMECHANICAL EQUIP

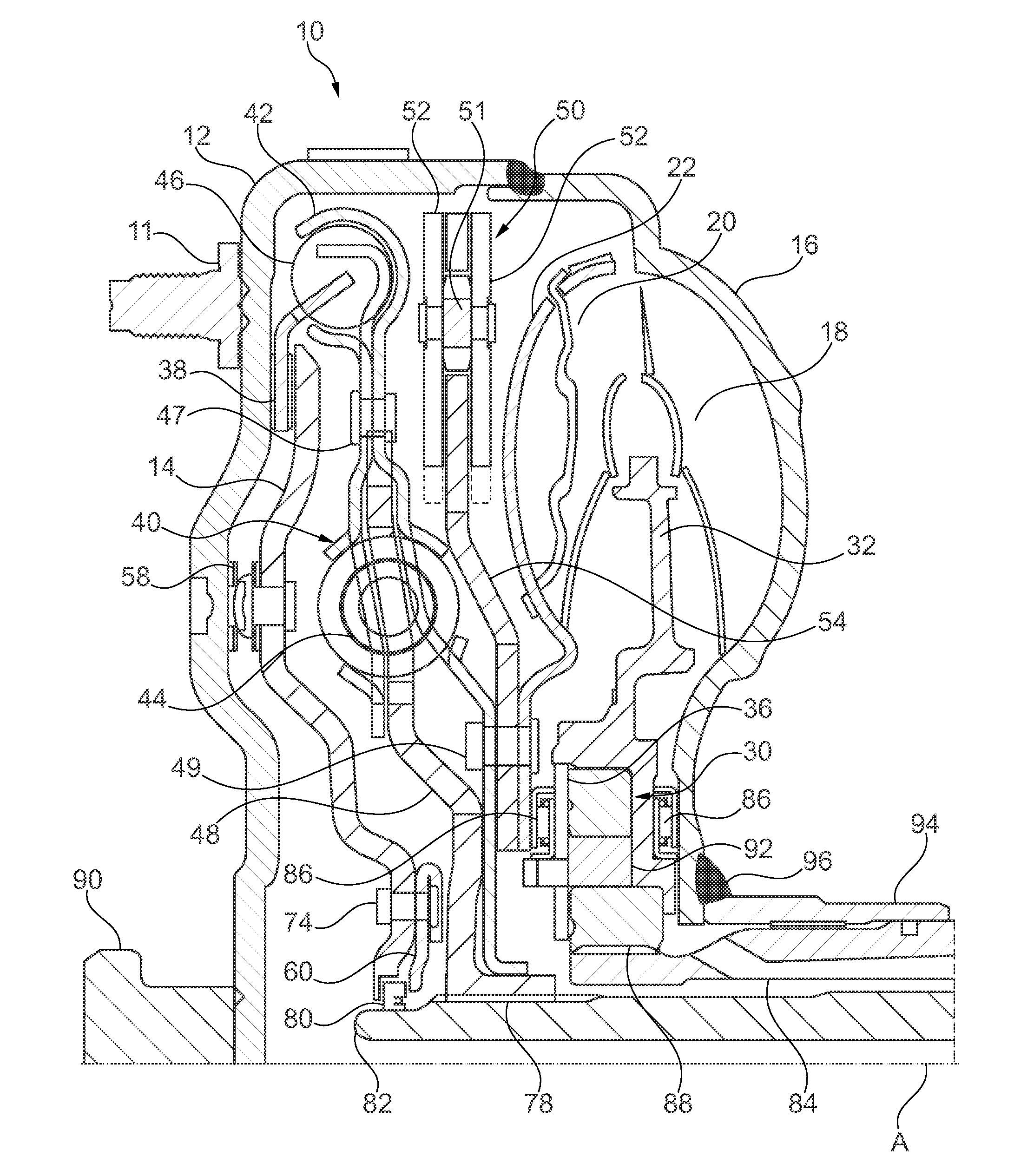

Folded seal retention plate with thrust surface

ActiveUS20150247538A1Prevent axial displacementEngine sealsRotary clutchesMechanical engineeringTorque converter

A seal retention plate for a torque converter, the plate comprising: an annular body portion having a first surface; a second surface opposite the first surface; an interior portion having at least one first hole; at least one radially outer tab extending from the interior portion and folded to contact the second surface so as to provide a thrust surface; and a center opening.

Owner:SCHAEFFLER TECH AG & CO KG

Novel anti-rotation sealed connector

InactiveCN102509923AEffective positioningEffective sealing fitCoupling contact membersCouplings bases/casesElectrical conductorKnurling

The invention discloses a novel anti-rotation sealed connector which comprises an inner conductor, an outer conductor and an insulator, wherein grooves are respectively radially arranged on the inner conductor, the outer conductor and the insulator, seal rings can be clamped into the grooves for completing sealing, anti-rotation barb and a fixed barb a are arranged on the outer diameter of the inner conductor, an anti-displacement barb is arranged on the outer diameter of a channel a, a fixed barb b is arranged on the bottom end surface of the channel a, and straight knurling is processed on the surfaces of the inner diameter and the outer diameter of the inner conductor as well as the inner diameter of the outer conductor, so that anti-rotation and sealing effects can be achieved and sealing performance can be thoroughly improved.

Owner:CHANGZHOU WUJIN FENGSHI COMM EQUIP

Crown spring mounting structure with good restriction and convenient disassembly

InactiveCN109638511AEasy charging connectionAvoid axial displacement and circumferential displacementSecuring/insulating coupling contact membersCoupling contact membersEngineeringAxial displacement

The invention belongs to the technical field of electric connectors and particularly relates to a crown spring mounting structure with good restriction and convenient disassembly. The crown spring mounting structure includes a crown spring and a sleeve. Elastic folding plates are uniformly distributed on the outer circumferential surfaces of the two ends of the crown spring. A plurality of throughholes are uniformly arranged on the cylinder surfaces of the two ends of the sleeve. The elastic folding plates are disposed in the through holes and have opposite folding directions. The free ends of the elastic folding plates are abutted against the walls of the through holes. The crown spring mounting structure has the beneficial effects that the axial displacement and the circumferential displacement of the crown spring in the sleeve can be avoided, the connection structure of the crown spring and the sleeve is firmly installed, which is convenient for charging connection; regardless of the diameter of the crown spring, the crown spring is convenient to disassemble and convenient to be taken out of the sleeve, thereby contributing to the maintenance of the crown spring; when the crownspring is maintained, the replacement of the connection structure of the sleeve and the crown spring can be avoided and the maintenance cost is saved.

Owner:JIANGSU WANBANG DEHE NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com