Rotating shaft angle position sensing device and sensing system

A technology of angular position and sensing system, which is applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems affecting the sensing accuracy and sensitivity of sensing circuits, the change of magnetic field strength of interfering magnets, and the adverse effects of assembly tolerances, etc., to achieve Improve sensing accuracy and sensitivity, eliminate signal asynchrony, and extend the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made to specific embodiments, examples of which are illustrated in the accompanying drawings. In the detailed description of particular embodiments, directional terms such as "top", "bottom", "above", "below", "left", "right", etc. are used with reference to the directions described in the drawings. Since components of embodiments of the present invention may be arranged in many different orientations, directional terms are used for purposes of illustration and are not limiting in any way. Wherever possible, the same or similar numerals and symbols are used throughout the drawings to refer to the same or like parts.

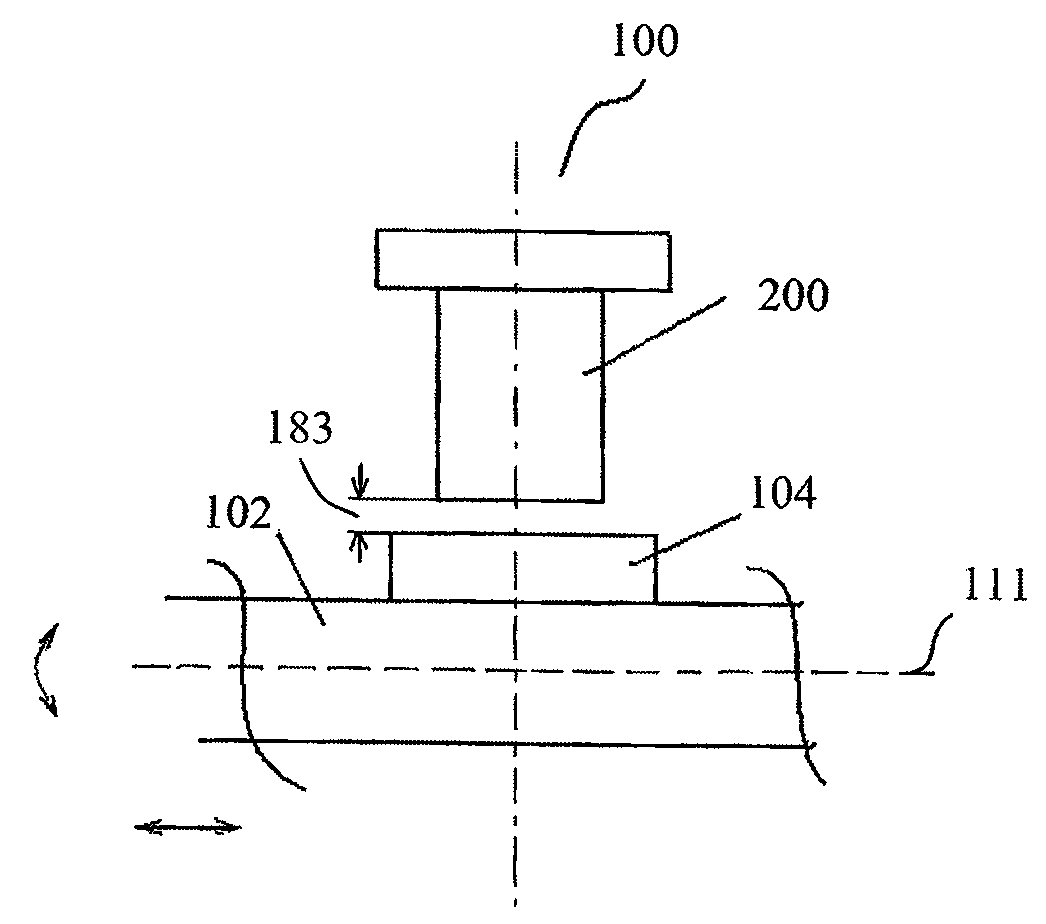

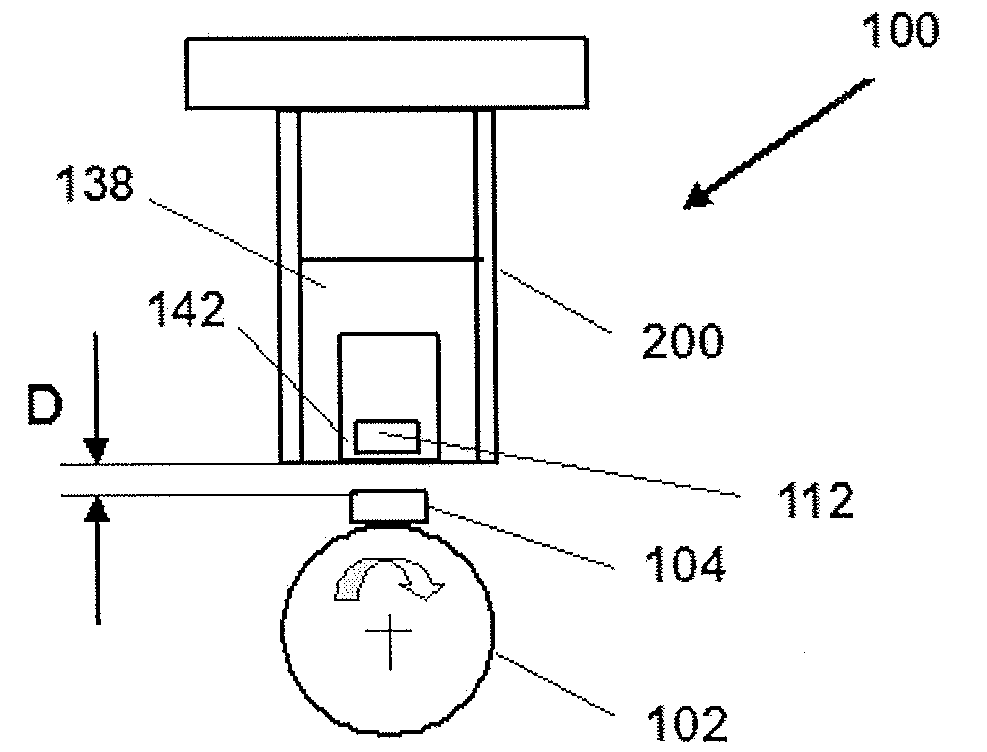

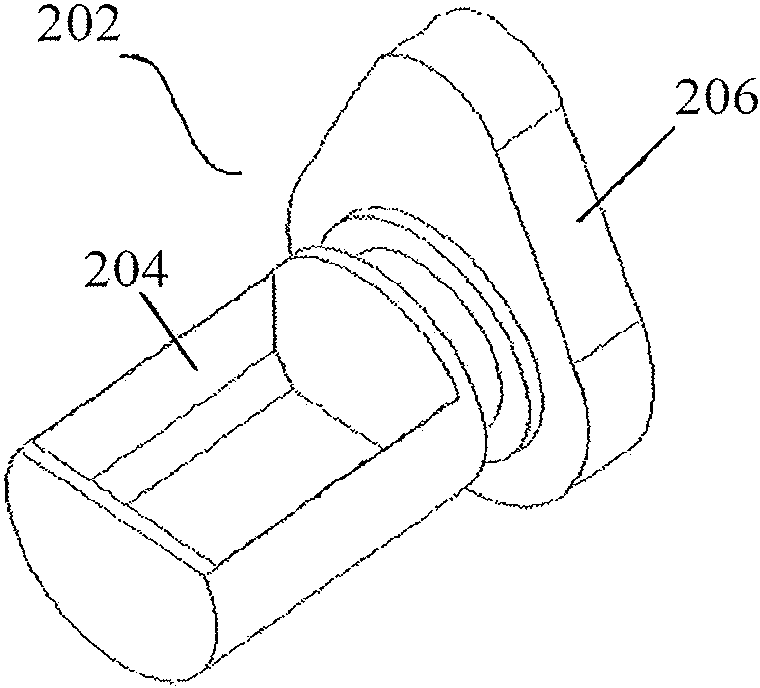

[0037] Figures 1A-1BA sensing system 100 for sensing the angular position of the rotating shaft 102 according to the present invention and a schematic installation diagram of the sensing system 100 relative to the rotating shaft 102 and the magnetic block 104 are described.

[0038] Such as Figure 1A As shown, the angular position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com