Novel anti-rotation sealed connector

A connector and sealing type technology, which is applied in the direction of connection, parts of the connection device, contact parts, etc., can solve the problems of high risk of axial displacement and torsion resistance, high failure rate of connectors, shrinkage or expansion leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

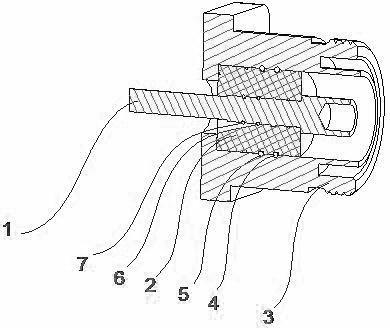

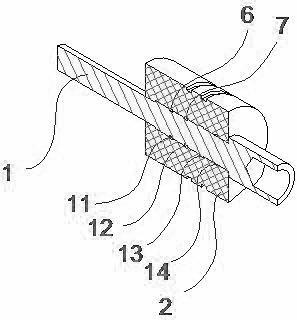

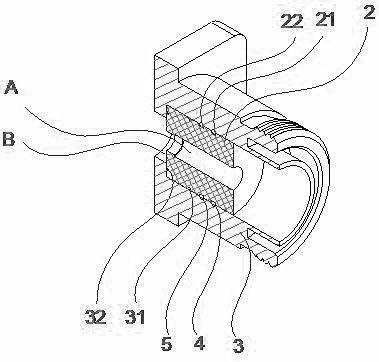

[0014] As shown in the figure, a new type of anti-rotation sealed connector, the connector includes an outer conductor 3, a channel aB is provided in the outer conductor 3, an insulator 2 is installed in the channel aB, and an insulator 2 is installed in the insulator 2 There is a channel bA in which the inner conductor 1 is accommodated.

[0015] The inner conductor 1 is provided with a sealing groove a11 and a sealing groove b12 on the outer diameter, and the sealing ring a6 and the sealing ring b7 can be pressed into the channel bA by snapping into the sealing groove a11 and the sealing groove b12, Deformation and rebound, so that the inner conductor a and the insulator b meet the effect of water sealing. The insulator 2 is provided with a sealing groove c21 and a sealing groove d22 on the outer diameter. The sealing ring c4 and the sealing ring d5 can be snapped in The sealing groove c21 and the sealing groove d22 are pressed into the channel aB.

[0016] The outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com