Continuous coating machine and continuous coating method with continuous coating machine

A coating machine and coating technology, applied in the field of coating machine equipment and coating, continuous coating machine, and continuous coating, can solve the problems of low production efficiency, long time consumption, and large energy consumption, and achieve Increased production efficiency, shorter time consumption, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

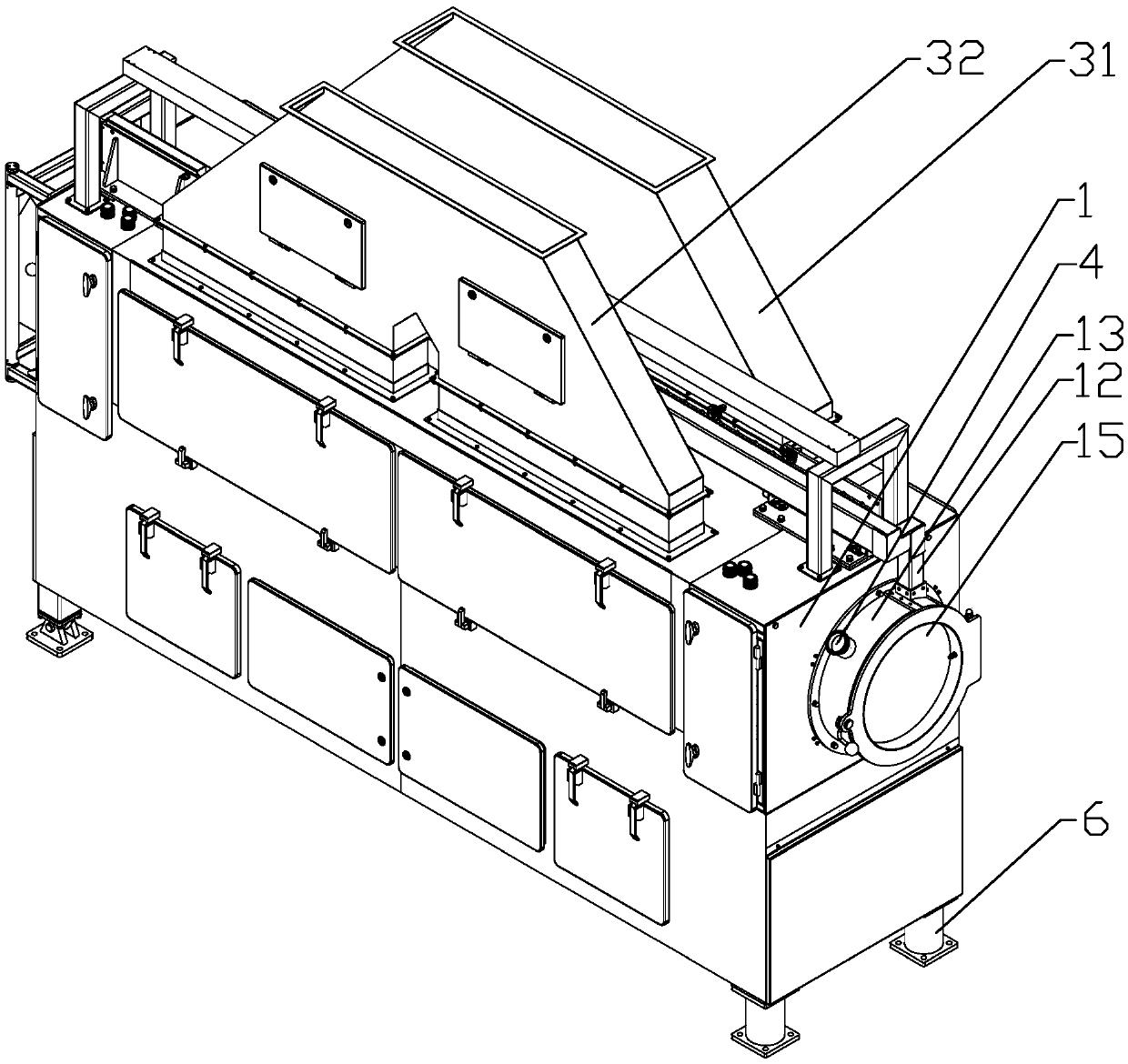

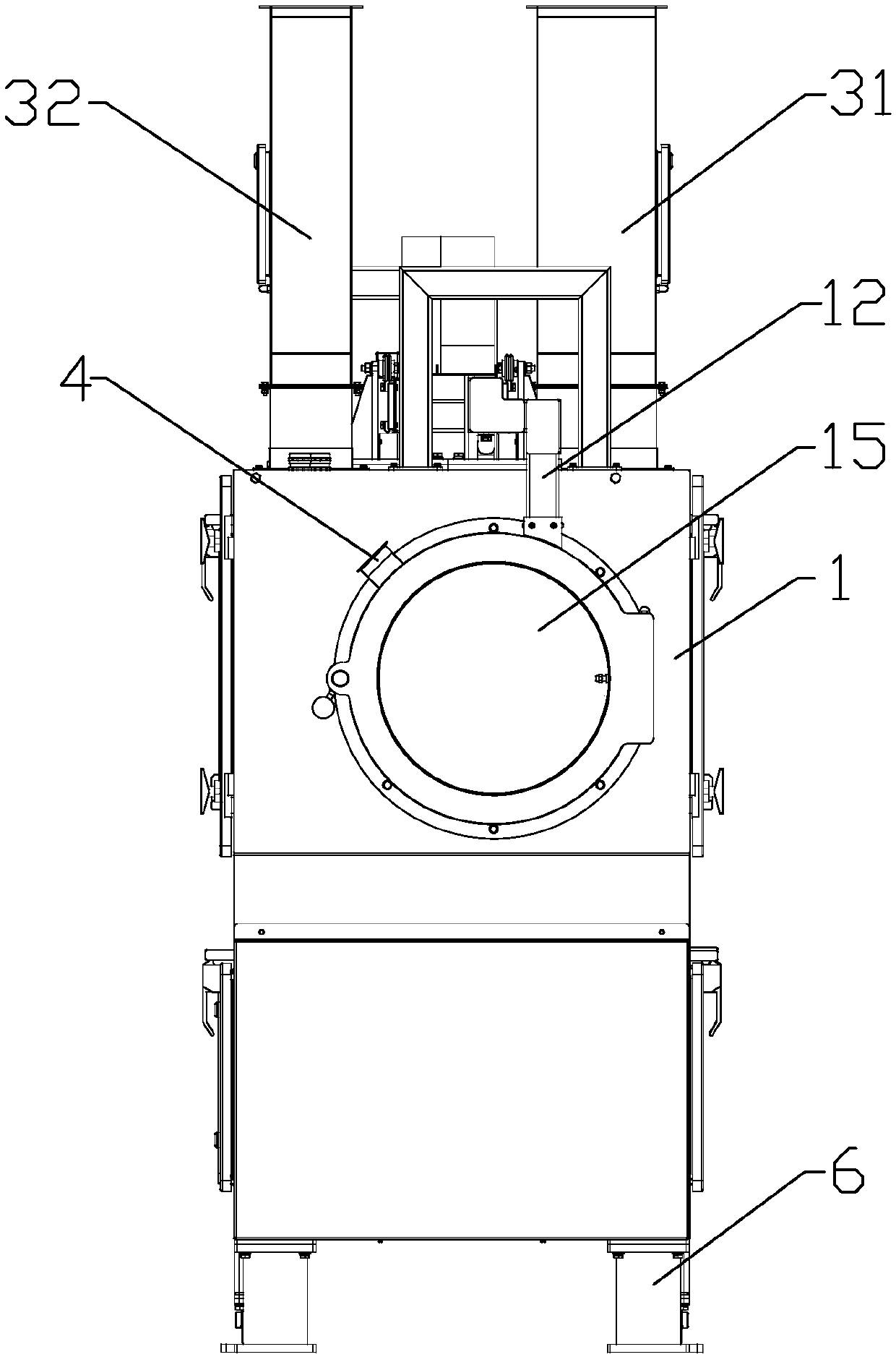

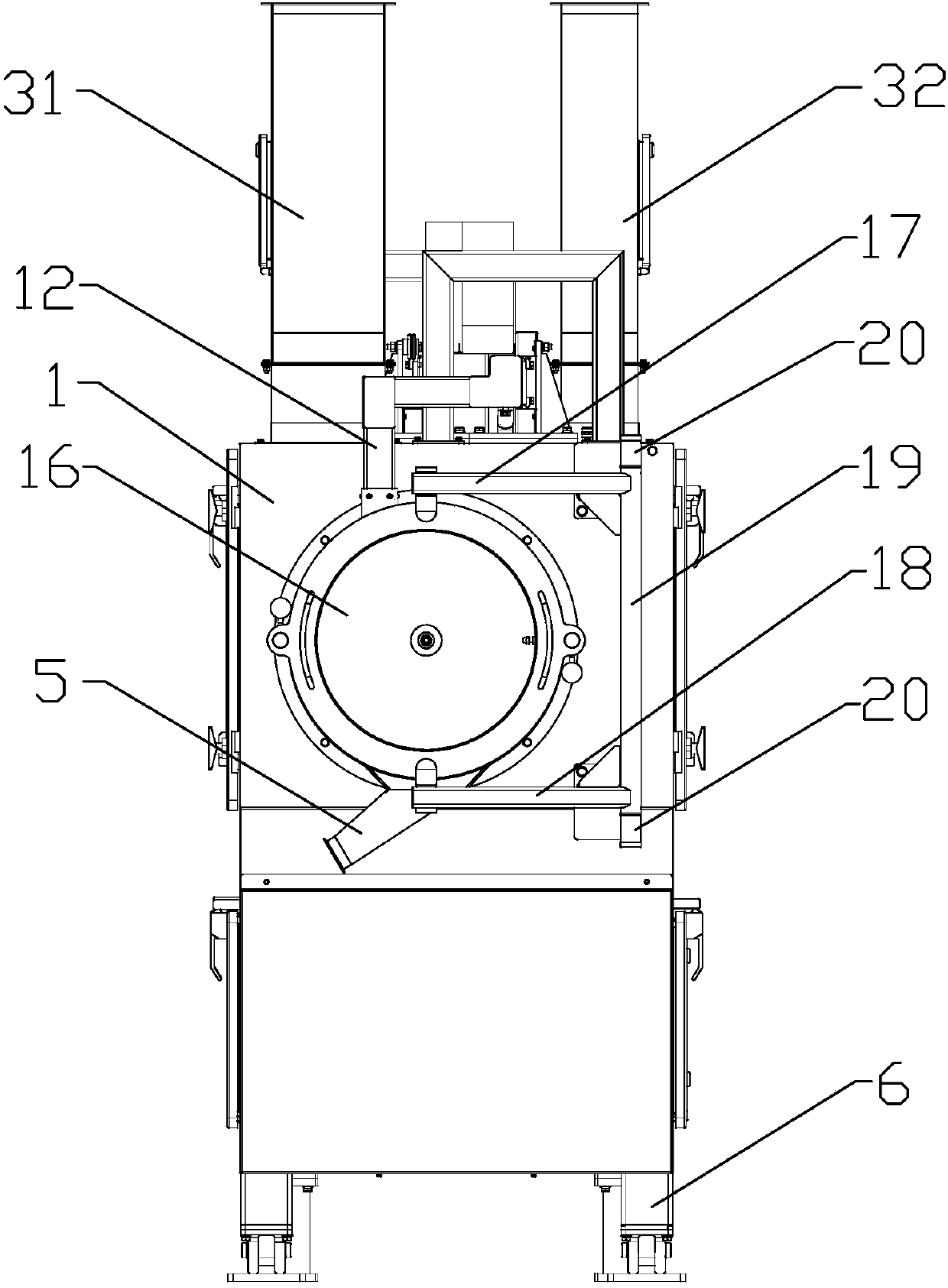

[0053] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, a continuous coating machine of this embodiment, including a machine body 1, a coating drum 2, and a motor 3 that drives the coating drum to rotate along the axis, between the motor and the coating drum The transmission mode of the coating can be belt transmission, gear transmission or other suitable transmission modes. Usually, the rotation direction of the coating drum is clockwise during coating production. Continuous coating machine also comprises feed pipe 4, discharge pipe 5, support leg 6 and cylinder 7, and described coating drum is the elongated cylindrical shape of two ends opening, and generally, the length of described coating drum is not Less than 1.6m, diameter not less than 0.27m. The coating drum is horizontally and rotatably sealed and installed in the body, the wall of the coating drum is densely covered with through holes, and the front end of the body is provided ...

specific Embodiment approach 2

[0057] Specific implementation mode two: combination Figure 4 , Figure 8 , Figure 9 and Figure 10 To illustrate this embodiment, the continuous coating machine of this embodiment also includes a plurality of feeders 8, which are elongated and generally slightly shorter than the coating drum. The cross-section is semicircular, and the feeder is fixedly installed on the inner wall of the coating drum along the axial direction of the coating drum, and the arc-shaped outer arc surface of the feeder points to the coating drum The axis, usually the number of the auger is six, evenly distributed along the radial direction of the coating drum. The setting of the feeder helps to turn over the material during the rotation of the coating drum, so that the material can fully contact with the spray liquid of the spray gun, and improve the coating effect and coating efficiency. The design of the shape of the feeder, The material to be lifted or shifted can slide or roll smoothly on ...

specific Embodiment approach 3

[0058] Specific implementation mode three: combination Figure 1-Figure 4 Illustrate this embodiment, the continuous coating machine of this embodiment also includes spray gun mounting frame 9 and spray gun 10, and described spray gun mounting frame is from the front end and / or rear end of described machine body along the axial direction of described coating drum. Stretching into the coating drum from outside to inside, a plurality of spray guns are installed at equal intervals from front to back on the spray gun mounting frame, and the spray gun mounting frame is divided into a plurality of sequentially connected and identical spray gun areas from front to back, At least one spray gun is included in each spray gun area, and each spray gun is controlled independently. The liquid is usually in the shape of a cone, so that the drug can be sprayed to the surface of the material more uniformly, and the coating effect can be better achieved. Generally, the spray gun installation f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com