Efficient thin film slitting machine

A strip cutting machine and film technology, applied in the direction of winding strips, thin material processing, sending objects, etc., can solve the problems of poor cutting effect of the slitting device and affect product quality, so as to improve work efficiency, improve quality, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

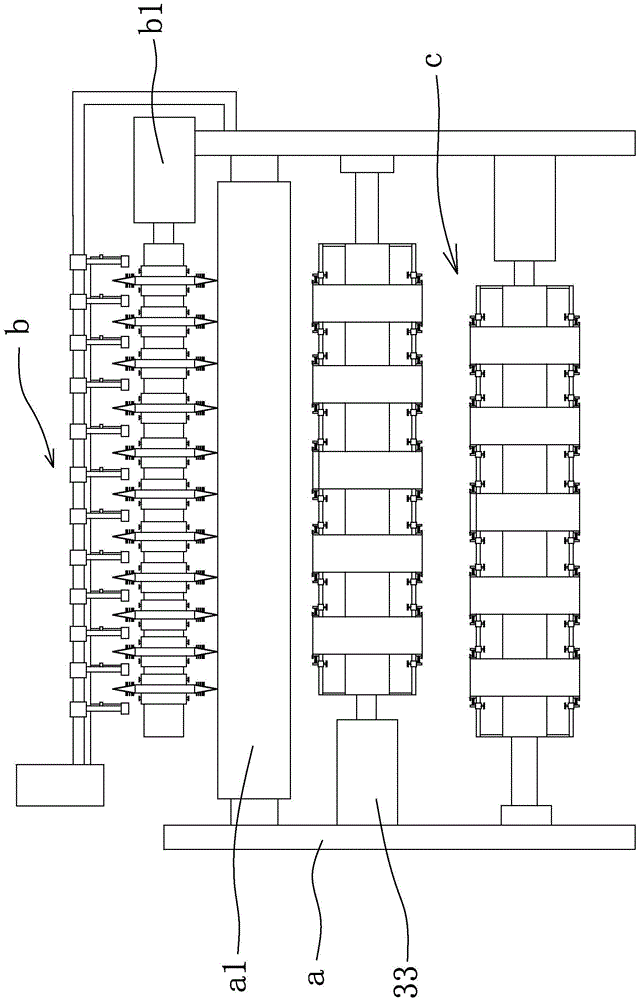

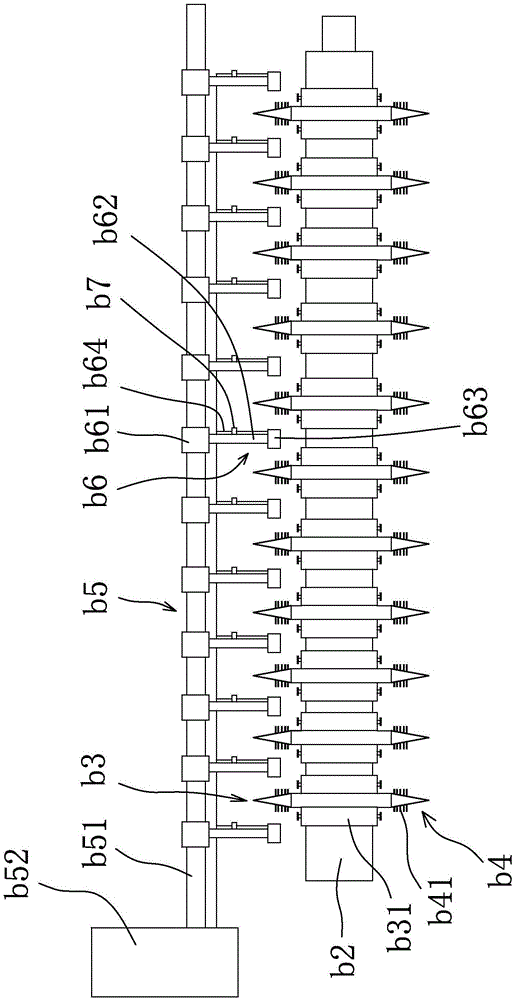

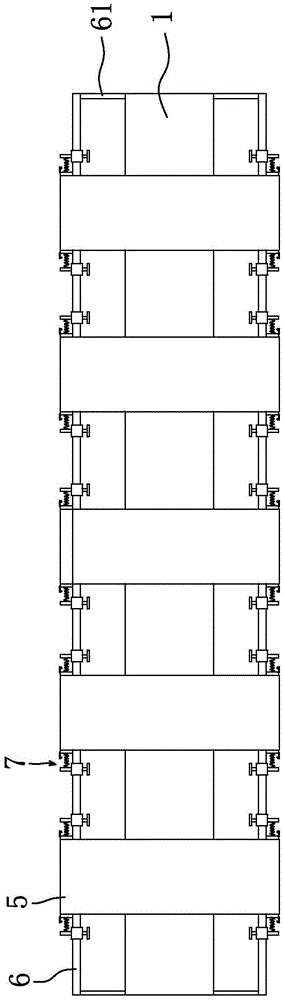

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Shown, this scheme comprises frame a, is provided with feeding roller a1 on the frame a, is provided with the strip cutting blade mechanism b that is used for slitting the film rolled on the feeding roller a1 above the feeding roller a1, through the strip cutting blade mechanism b The slit film is wound to the winding mechanism c, the winding mechanism c includes at least two roller bodies 1 connected to the first driving mechanism 33, the two roller bodies 1 are provided with tensioning mechanisms 3 that are sequentially staggered, The tensioning mechanism 3 includes at least one tensioning assembly 31, the tensioning assembly 31 is connected with a tensioning member 6 for sheathing the reel 5, an elastic sealing assembly 61 is arranged between the tensioning member 6 and the roller body 1, and The tightening member 6 is provided with fastening devices 7 which are located on both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com