Anti-loose structure for large-sized motor rotator

A high-speed motor and anti-loosening technology, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., to achieve the effect of preventing radial deformation and axial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

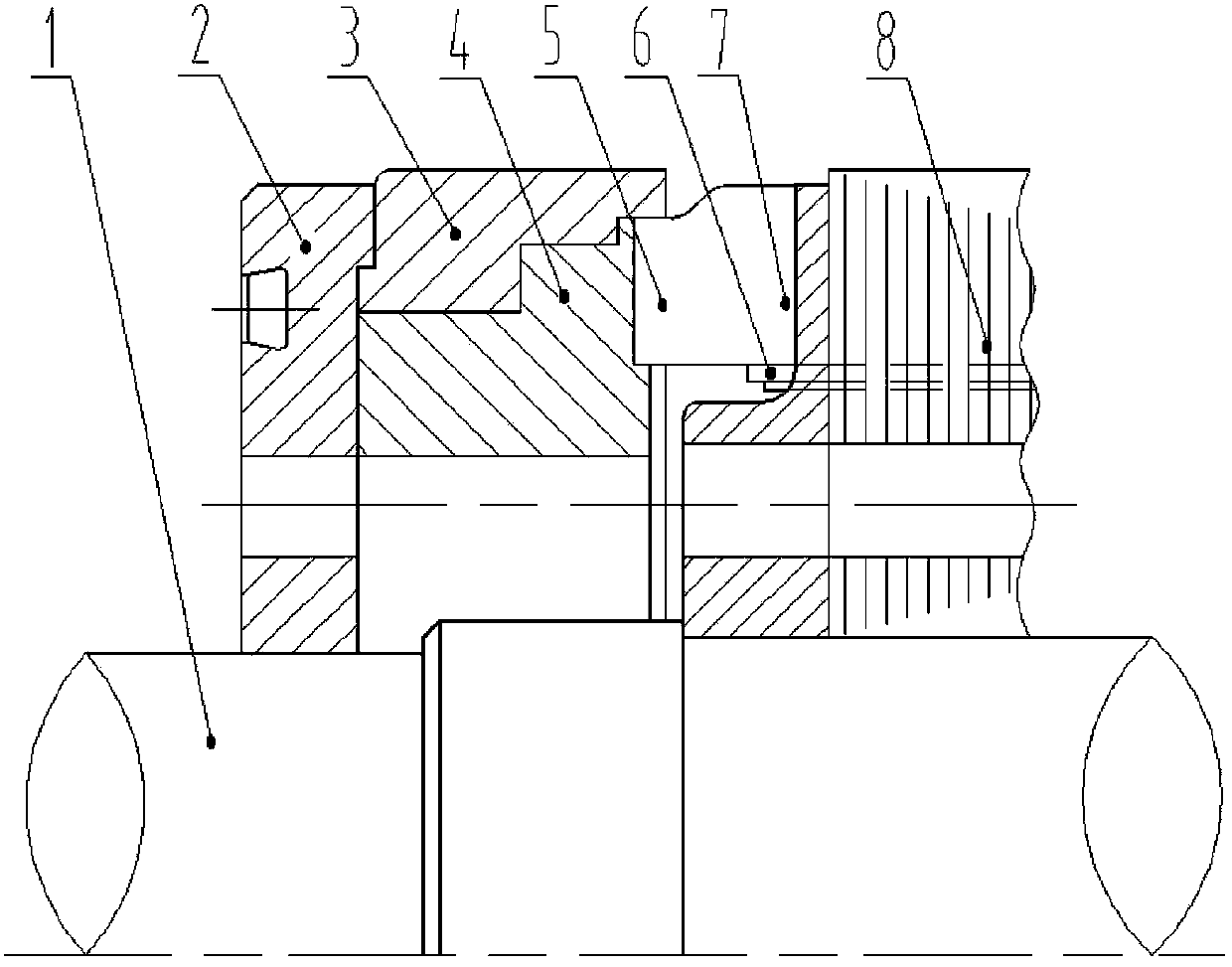

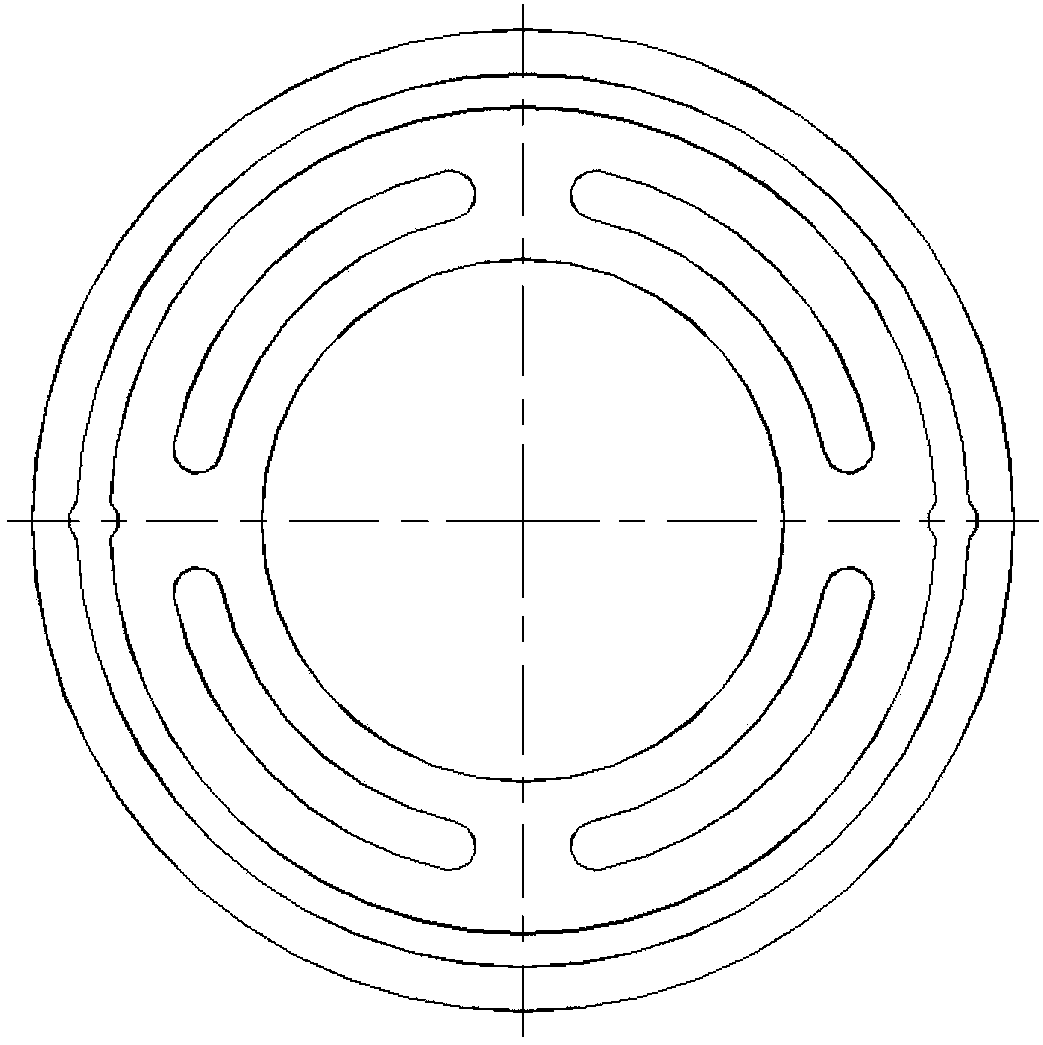

[0009] as attached figure 1 As shown, a specific embodiment of the anti-loosening structure of the large-scale high-speed motor rotor of the present invention includes a rotating shaft (1), a balance ring (2), a retaining ring (3), an end ring (4), and a rotor guide bar (5), Slot bottom wedge key (6), rotor pressure ring (7), rotor core (8). Among them, the rotor guide bar (5) penetrates into the rotor core (8) and drives into the groove bottom wedge key (6) at the bottom of the groove to wedge tightly and weld firmly to prevent the rotor guide bar (5) from radially loosening in the groove.

[0010] After the end ring (4) is welded to the rotor guide bar (5), after the outer edge of the end ring is processed to a certain size, the high-strength alloy steel retaining ring (3) is shrunk onto the end ring (4) to prevent The radial deformation of the end ring and the end of the guide bar due to centrifugal force when the motor rotates at high speed. The balance ring (2) is shrun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com