High-voltage circuit breaker and nozzle thereof

A technology for high-voltage circuit breakers and spouts, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of inconvenient processing and installation of spouts, prevent axial movement, avoid secondary deformation, and simplify The effect of tooling design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

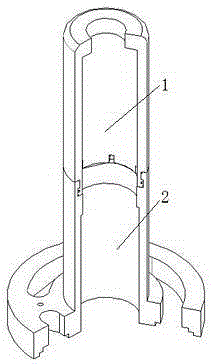

[0023] Examples of high voltage circuit breakers:

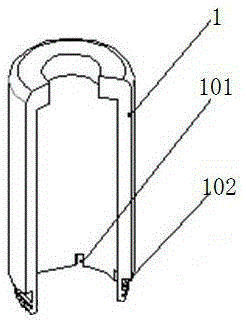

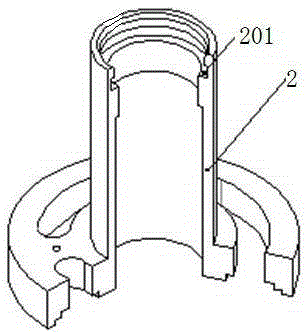

[0024] High voltage circuit breaker structure such as Figure 1~3 As shown, including the spout 1 and the flange 2, the lower end surface of the spout 1 is provided with two notches 101 extending in the axial direction, and the two notches 101 equally divide the cross section of the spout 1. For the radially stretchable elastic contact fingers of the spout 1, two annular flanges 102 are processed on the outer surface of the elastic contact fingers. The flange 2 has a connecting cylinder that matches the shape of the spout 1, and on the inner surface of the connecting cylinder Two annular grooves 201 matched with the annular flange 102 are processed.

[0025] In other embodiments, on the premise of ensuring that the pressure of the elastic contact fingers against the flange is sufficient, a plurality of gaps may also be formed on the lower end surface of the spout, and the distances between the gaps may also be different.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com