Method for preparing silicon/carbon composite material with magnesiothermic reduction process

A technology of silicon-carbon composite materials and composite materials, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of easily changing the morphology of porous silicon and affecting the excellent performance of composite materials, and achieve the best capacity to withstand volume strain, ion The effect of short diffusion path and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of silicon-carbon composite materials

[0036] Use a planetary ball mill to mix diatomite, polyvinylidene fluoride and methylpyrrolidone solvent at a mass ratio of 4:1:1, the mass ratio of the ball to material is about 5:1, the speed is 400 rpm, and the ball milling time is 4 hours. A silica / polyvinylidene fluoride homogeneous material was obtained. The obtained silica / polyvinylidene fluoride homogenate material is placed in an oven for drying.

[0037] After taking it out, mix the composite material and magnesium powder according to the ratio of 1:1. The mixture was placed in a tube furnace, heated to 700 °C at a rate of 5 °C / min in an argon atmosphere, kept for 4 hours, and naturally cooled to room temperature; pickled with hydrochloric acid, then deionized water and ethanol were used to Washed 3 times, dried in a vacuum oven at 100° C. for 5 hours to obtain a silicon-carbon composite material.

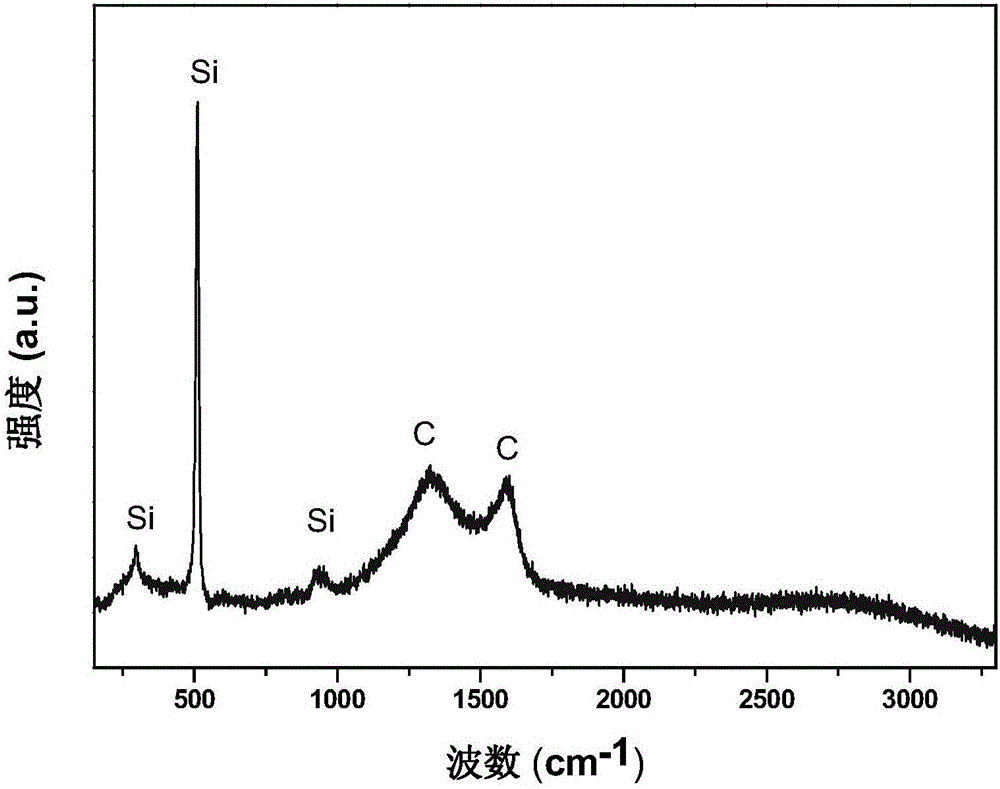

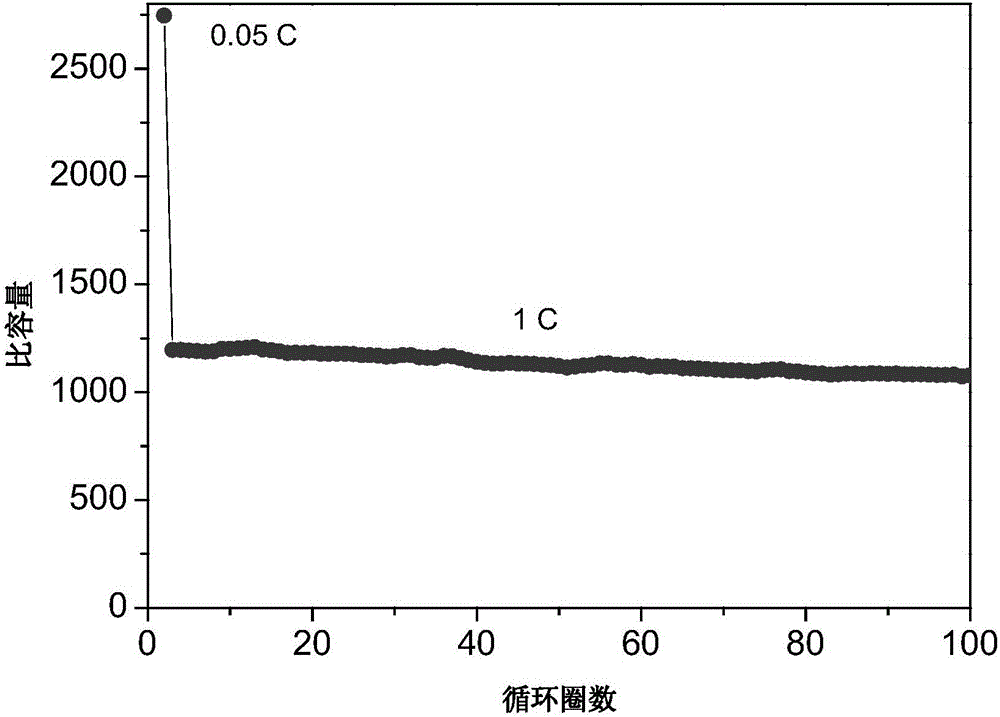

[0038] The prepared silicon-carbon composite material ...

Embodiment 2

[0044] 1. Preparation of silicon-carbon composite materials

[0045] Use a planetary ball mill to evenly mix mesoporous silica, polypyrrole and pyridine solvent with a mass ratio of 6:1:1, the mass ratio of the ball to material is about 4:1, the speed is 700 rpm, and the ball milling time is 6 hours. A silica / polypyrrole homogeneous material was obtained. The obtained silica / polypyrrole homogenate material is dried in an oven.

[0046] After taking it out, mix the materials according to the ratio of composite material and magnesium powder at 1:1. The mixture was placed in a tube furnace, heated to 700°C at a heating rate of 5°C / min in a nitrogen atmosphere, kept for 5 hours, and cooled to room temperature naturally; pickled with hydrochloric acid, then washed with deionized water and ethanol respectively 3 times, and dried in a vacuum oven at 120° C. for 3 hours to obtain a silicon-carbon composite material.

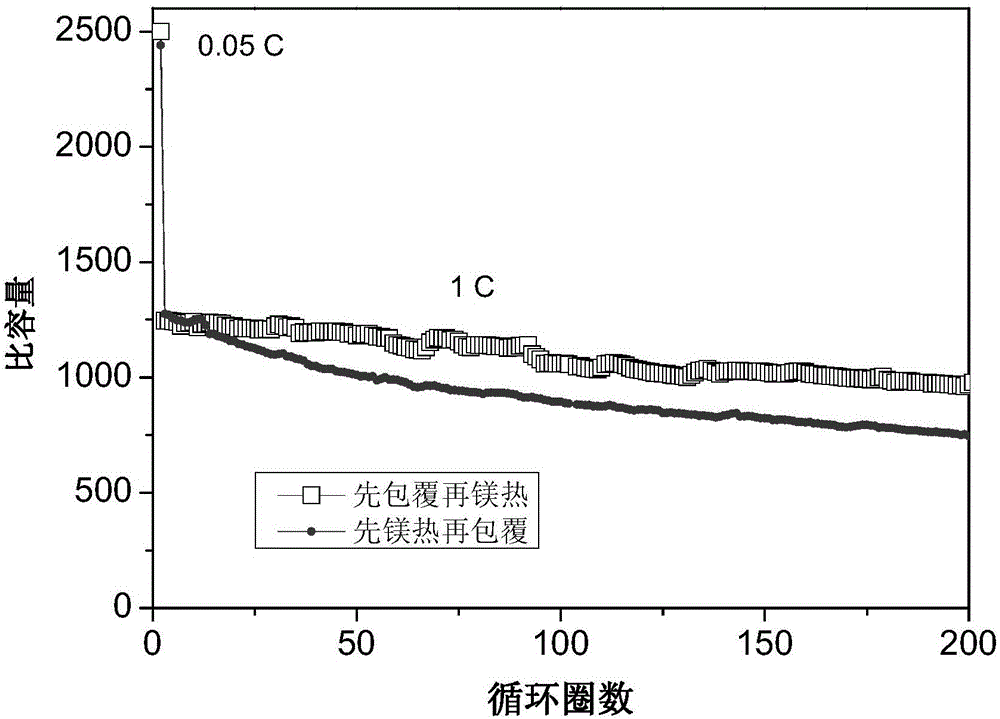

[0047] 2. Preparation of silicon-carbon composite negative elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com