Patents

Literature

36results about How to "Avoid secondary deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat insulating and preserving ceramic composite plate with decorative properties

ActiveCN102877614AReduce construction costWith thermal insulationCovering/liningsClaywaresCeramic compositeInsulation layer

The invention discloses a method for producing a heat insulating and preserving ceramic composite plate with decorative properties, comprising the following steps: preparing the powder of a decorative layer; preparing the powder of a heat insulating and preserving layer; loading the powder in a ceramic sagger in the secondary distribution way; sintering in a roller kiln in one time without drying and moulding by a ceramic pressing machine; demoulding, polishing and finishing the decorative surface, and determining the thickness and shape of the heat insulating and preserving surface by mechanical dry cutting. By the joint reaction of the ultrafine foaming agent, the dolomite, the diatomaceous earth and the polishing slag at high temperature, the heat insulating and preserving plate filled with tiny closed pores can be formed. The product has high strength, strong penetration resistance and lower thermal conductivity than the existing ceramic heat preserving material and has the characteristics of low production energy consumption, good decorative effect and prominent heat preservation, heat insulation and sound insulation effects.

Owner:FOSHAN RONGZHOU NO 2 BUILDING CERAMICS FACTORY

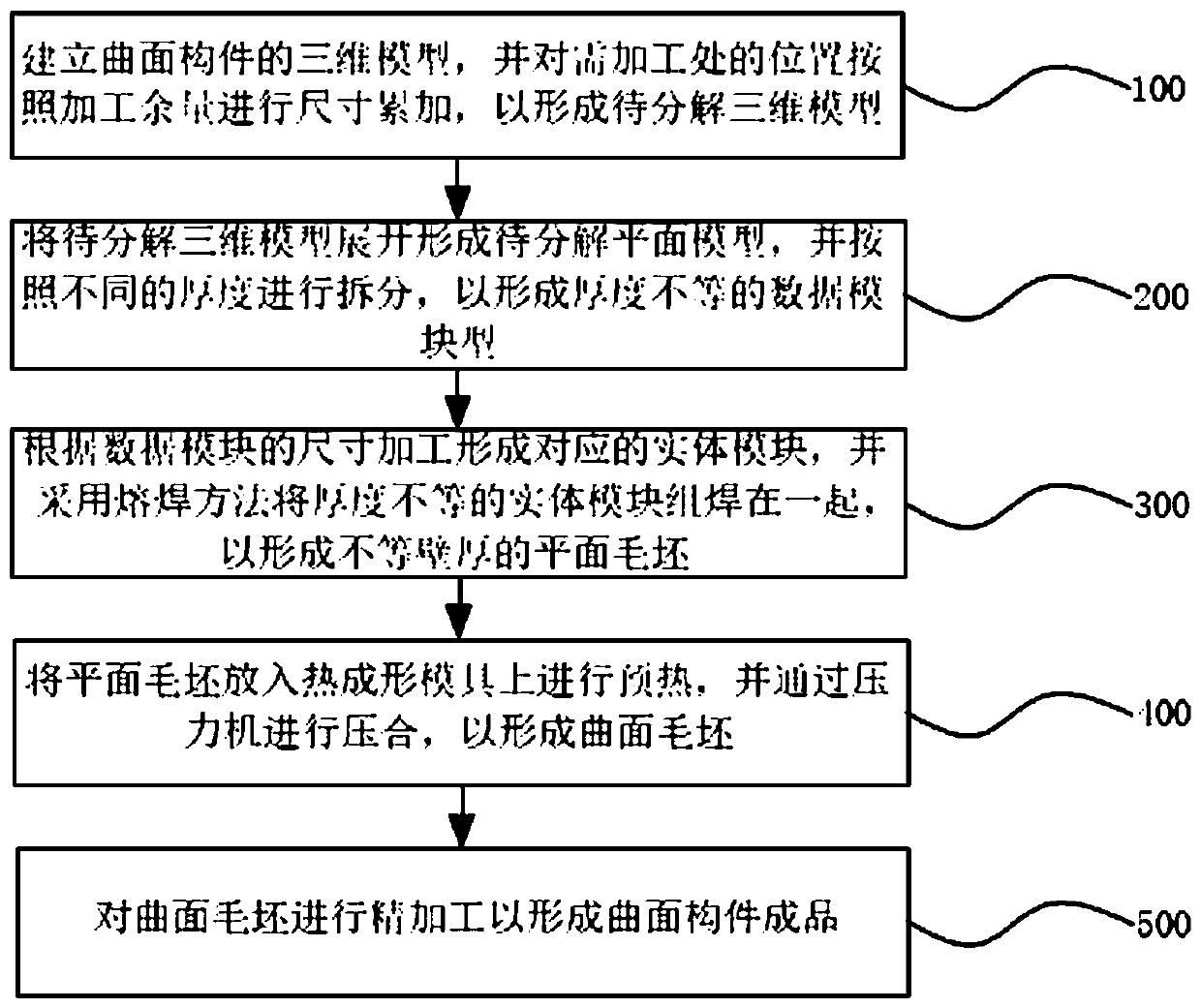

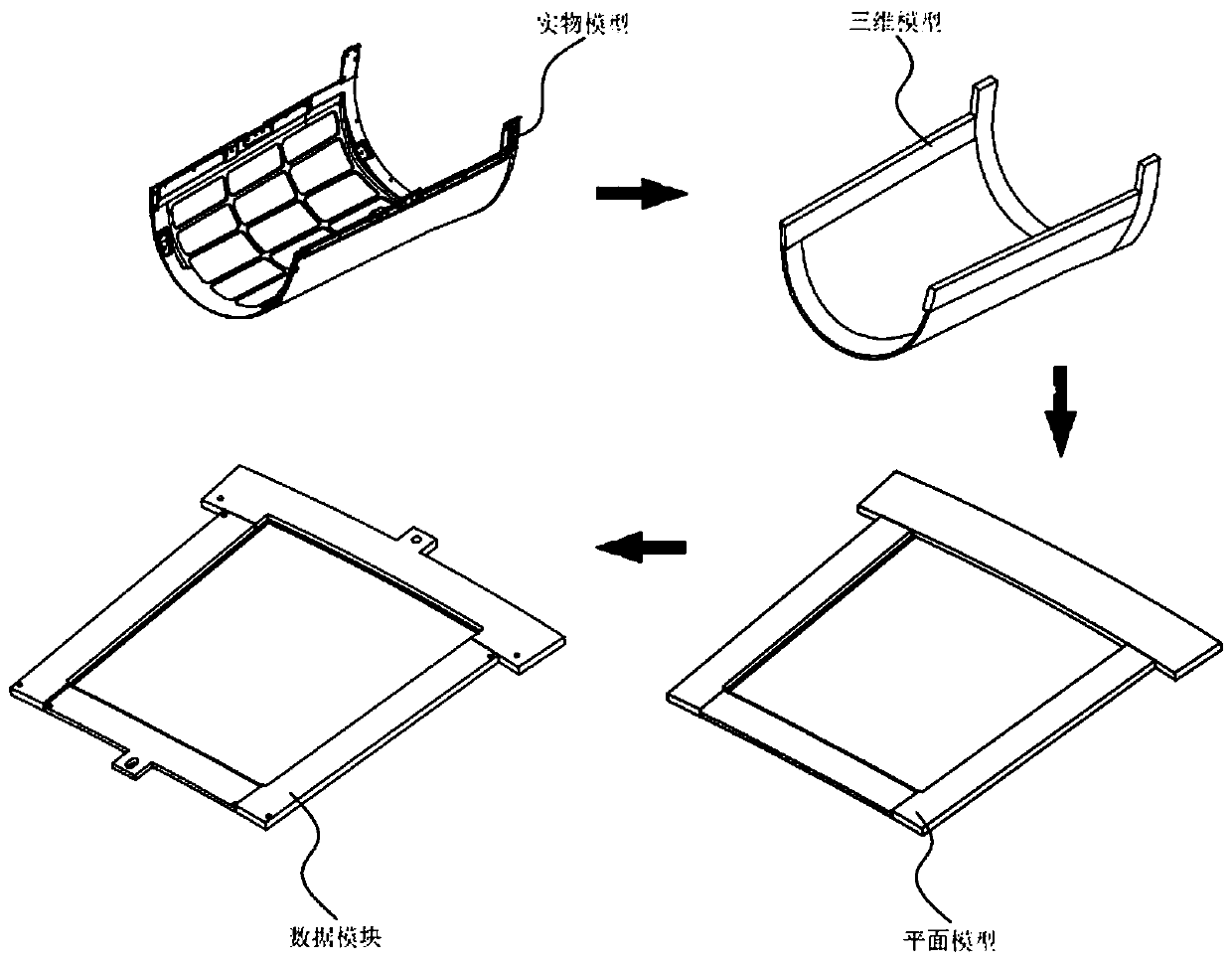

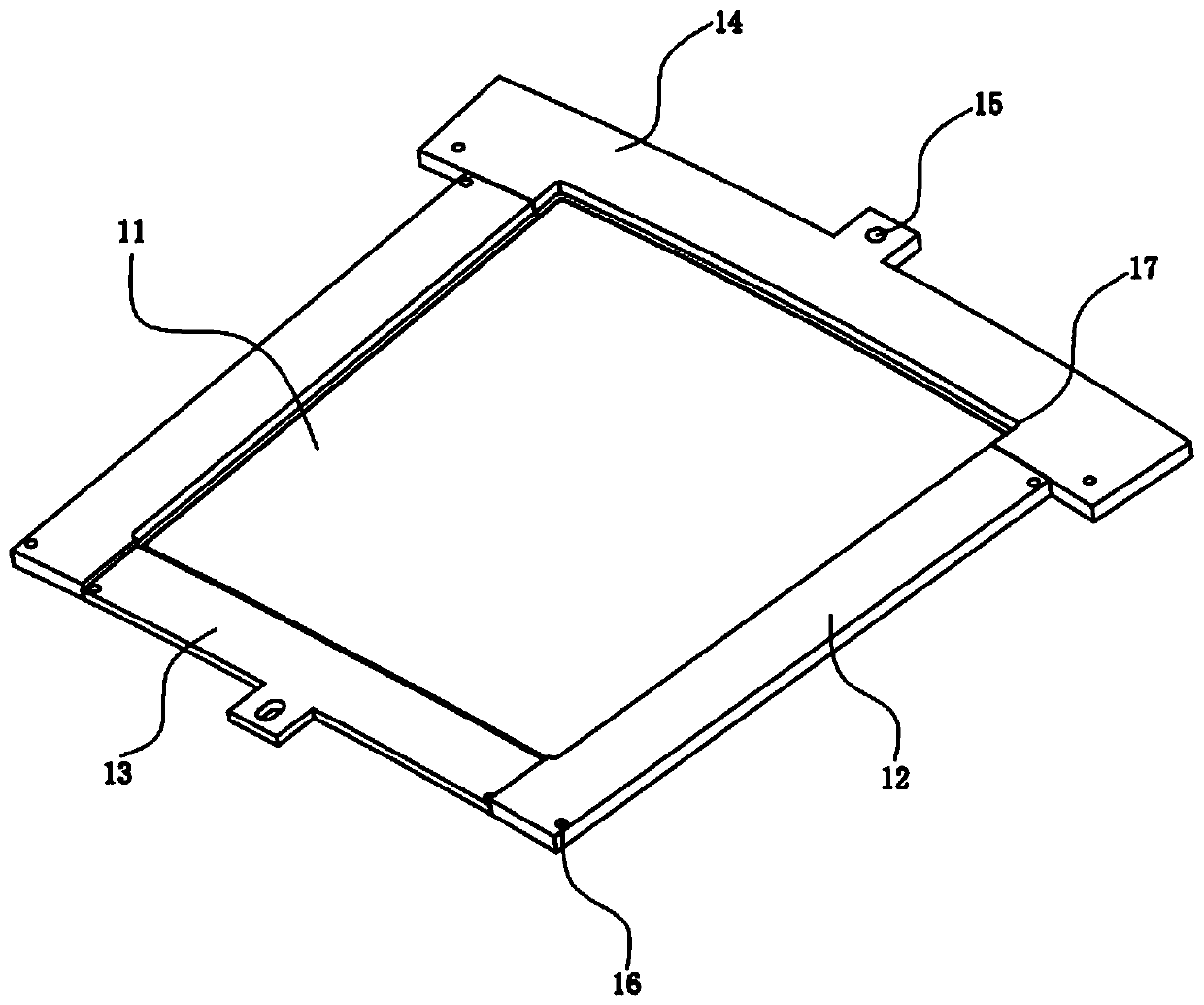

Manufacturing method of unequal-wall-thickness curved surface part

ActiveCN110625344AShorten the development process routeReduce development costsSpecial data processing applications3D modellingThree dimensional modelMachine press

The invention discloses a manufacturing method of an unequal-wall-thickness curved surface part. The method comprises the steps that a three-dimensional model of the curved surface part is built, theposition required to be machined is subjected to size accumulation according to the machining allowance, and a three-dimensional model to be decomposed is formed; the three-dimensional model to be decomposed is unfolded to form a plane model to be decomposed, according to different thicknesses, dismounting is carried out, and data modules with uneven thicknesses can be formed; according to the size of the data modules, corresponding solid modules are formed through machining, a fusion welding method is adopted for installing and assembling the solid modules with the unequal thicknesses, and anunequal-wall-thickness plane workblank is formed; the plane workblank is put on a hot forming mold to be preheated, press fitting is carried out through a press machine, and a curved surface workblank is formed; and the curved surface workblank is subjected to finish machining to form a curved surface part finished product. Through one-time thermal forming, forming of the unequal-wall-thickness curved surface part can be achieved, the development process of the part is shortened, the development cost is reduced, the thermal forming has the effect of removing stress, and the heat treatment isnot needed.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

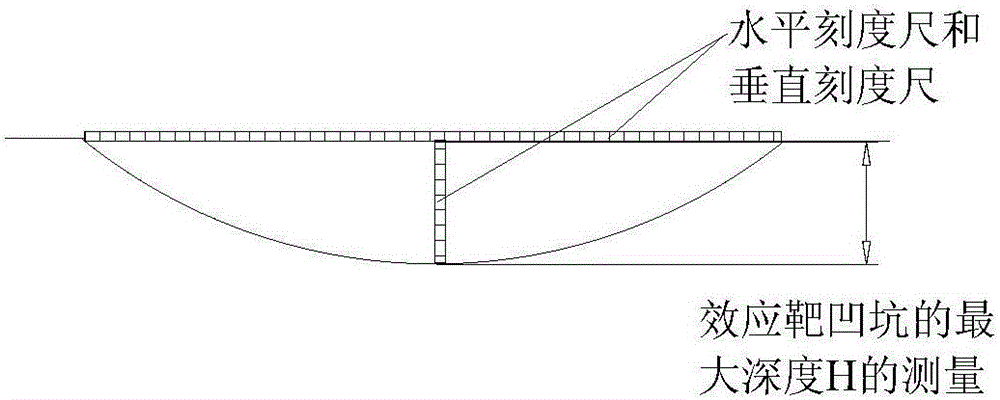

Method for measuring deformation of effect target with laser

ActiveCN105157597AMeet measurement needsEasy to operateUsing optical meansContainer/cavity capacity measurementLaser rangingMeasurement device

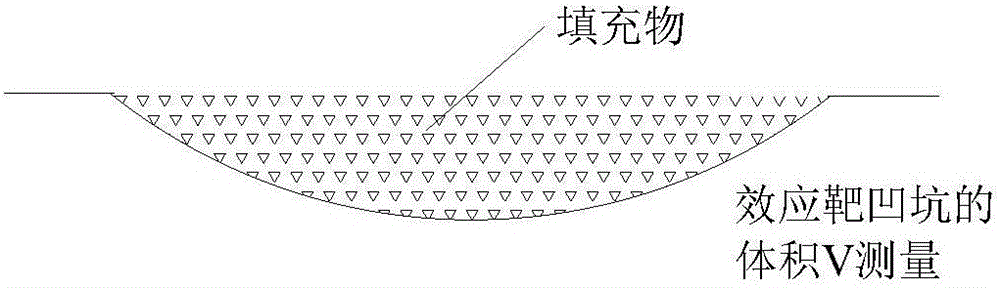

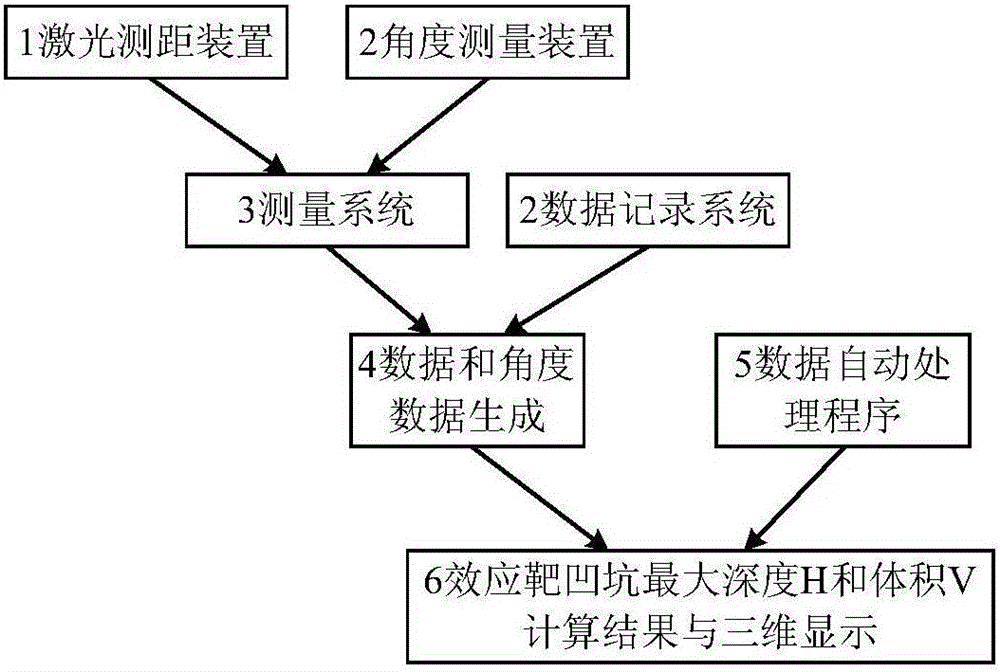

The invention discloses a method for measuring deformation of an effect target with a laser, relates to the field of damage experiment testing, and solves problems that a conventional measurement method is low in efficiency, large in operation error and poor in measurement stability. The method combines the laser measurement technology and the data analysis means, and can measure the deformation parameters of the effect target rapidly and accurately. A measurement device comprises a measurement system (3), a data recording system (4) and a data automatic processing program (5). Firstly, a laser range finding device (1) and a angle measurement device (2) of the measurement system (3) obtain geometric parameters of a deformed part of the effect target, then the data automatic processing program (5) reads the geometric parameters from the data recording system (4) and performs calculation, so as to obtain the deformation parameters of the effect target-the maximum depth H and the size V of a concave pit and to generate three-dimensional graphic display of the deformed concave pit.

Owner:XIAN MODERN CHEM RES INST

Forging method of aluminum or aluminum alloy

InactiveCN102836939AAvoid secondary deformationHigh precisionDomestic articlesHeating/cooling devicesTemperature controlStructure property

The invention provides a forging method of aluminum or aluminum alloy, which comprises the following steps that blanks of the aluminum or the aluminum alloy is provided; a forging mould which comprises an upper mould and a lower mould is provided, and each of the upper mould and the lower mould is provided with an independent heating device and temperature control equipment; the blank of the aluminum or the aluminum alloy are placed in the forging mould for forging; and the temperature difference between the upper mould and the lower mould is 100-350 DEG C in the forging process. An aluminum or aluminum alloy forged piece manufactured by the method is good in structure property and high in precision and yield, so that the method is suitable for industrialized production.

Owner:FIH PRECISION ELECTRONICS LANG FANG CO LTD

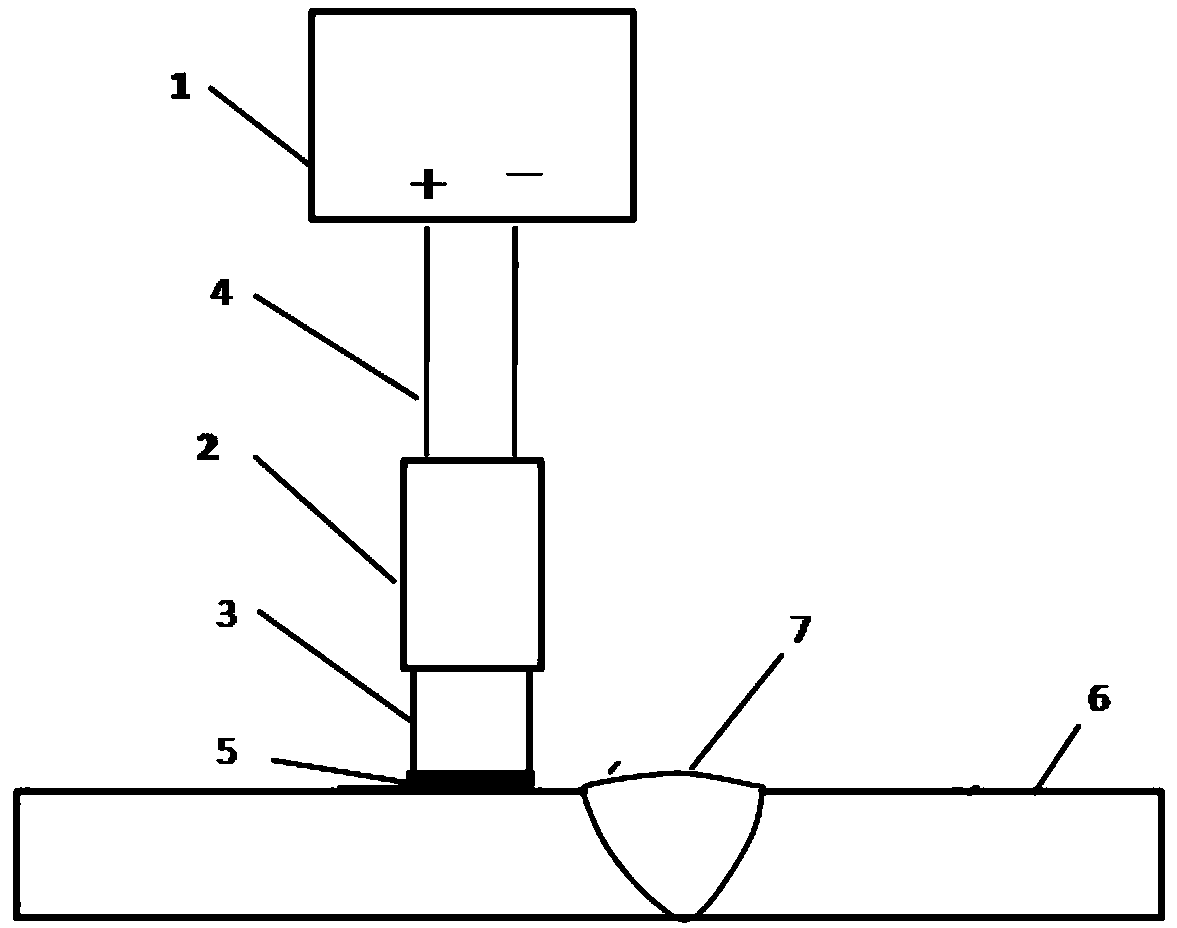

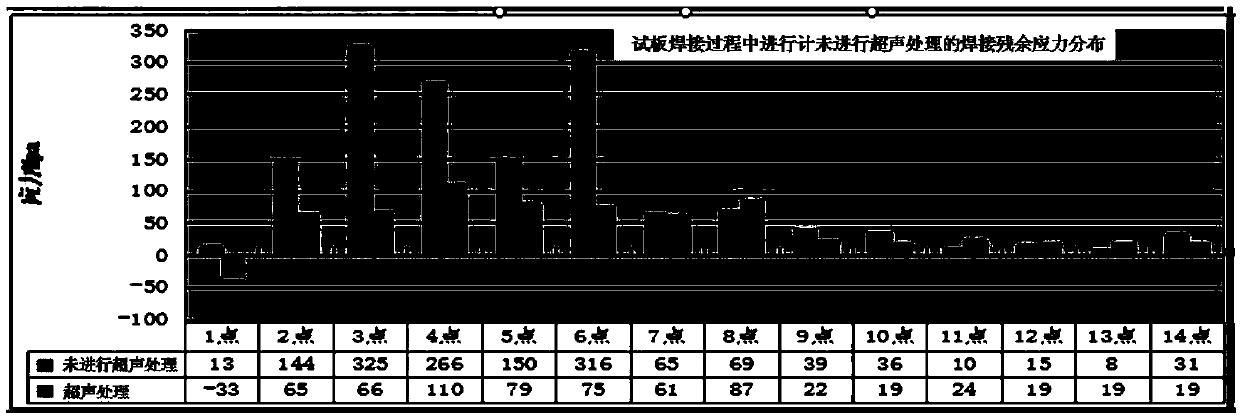

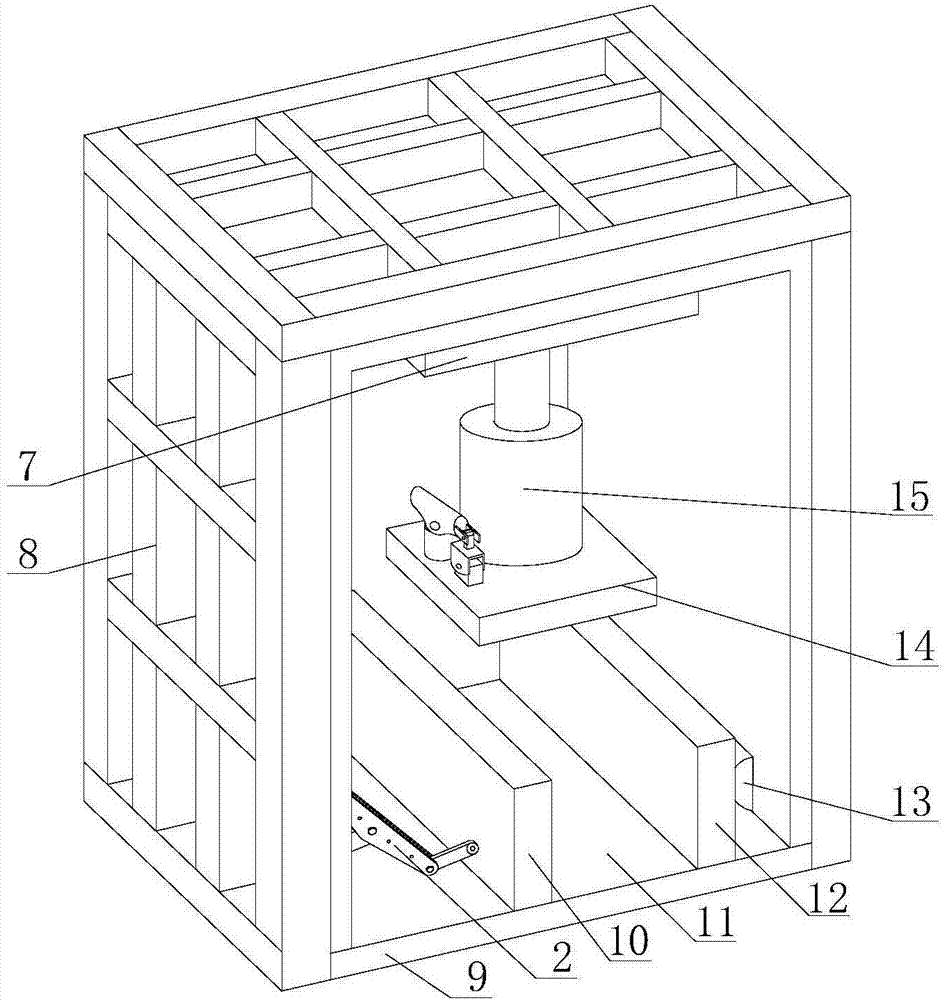

Welding deformation control method based on high-energy ultrasonic treatment

InactiveCN109570793ALower yield strengthFacilitated releaseWelding apparatusStress distributionStress concentration

The invention specifically relates to a welding deformation control method based on high-energy ultrasonic treatment. The welding deformation control method based on the high-energy ultrasonic treatment comprises the following steps that (1) an ultrasonic transducer is arranged at a appropriate position of a workpiece to be welded; (2) the ultrasonic transducer and an ultrasonic power supply are connected; (3) ultrasonic processing parameters are set; (4) the workpiece is welded; and (5) ultrasonic processing is conducted, specifically, a joint is still in a high temperature state after weldedmetal solidified, the ultrasonic power supply is started to drive the ultrasonic transducer, and ultrasonic energy is injected into the workpiece welded joint and a heat affected zone, and work is stopped until set processing time. According to the welding deformation control method based on high-energy ultrasonic treatment, the existing welding technology and process of the product is not changed, the equipment is simple, the technology is concise, the welding deformation can be effectively controlled by adjusting three parameters of an ultrasonic frequency, power and processing time, and meanwhile stress concentration can be eliminated and even stress distribution is lowered.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Hydraulic drive efficient correction leveling assembly for silicon steel column

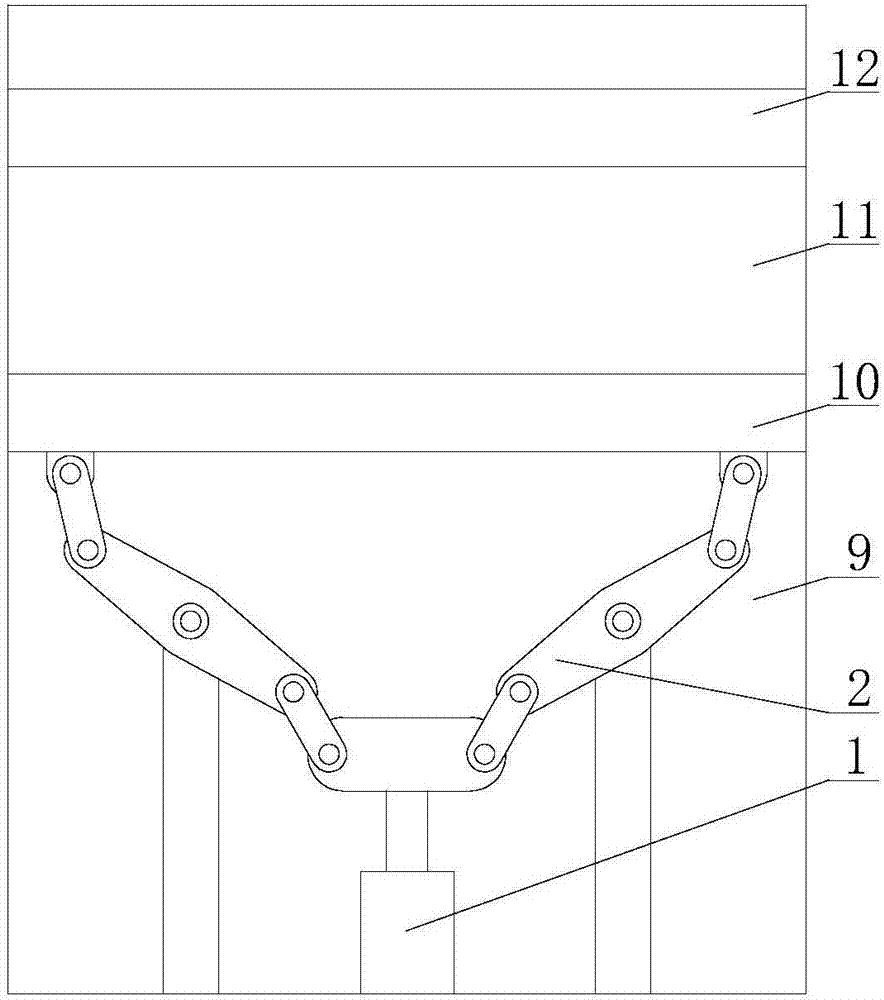

InactiveCN106862314ASimple structureControl the transfer status at any timeHydraulic cylinderDrive shaft

The invention relates to a silicon steel column hydraulic high-efficiency correction leveling assembly, which belongs to the technical field of silicon steel column processing, and aims to provide a silicon steel column hydraulic high-efficiency correction leveling assembly with good correction effect and high correction efficiency. It includes a square frame body, the inner bottom surface of the square frame body is provided with a first splint and a second splint, and a silicon steel column correction and leveling channel with adjustable spacing is formed between the first splint and the second splint; The inner bottom surface of the square frame is provided with a horizontal correction device for horizontal correction and leveling of the silicon steel column, and the inner top surface of the square frame is provided with a vertical correction device for vertical correction and leveling of the silicon steel column The level correction device includes a hydraulic cylinder, the end of the drive shaft of the hydraulic cylinder is connected with a push mechanism, and the push mechanism is connected with the first splint or the second splint so that the second splint can slide horizontally relative to the first splint. The invention is suitable for correction and leveling of silicon steel columns.

Owner:四川省隆昌诚信印务有限公司

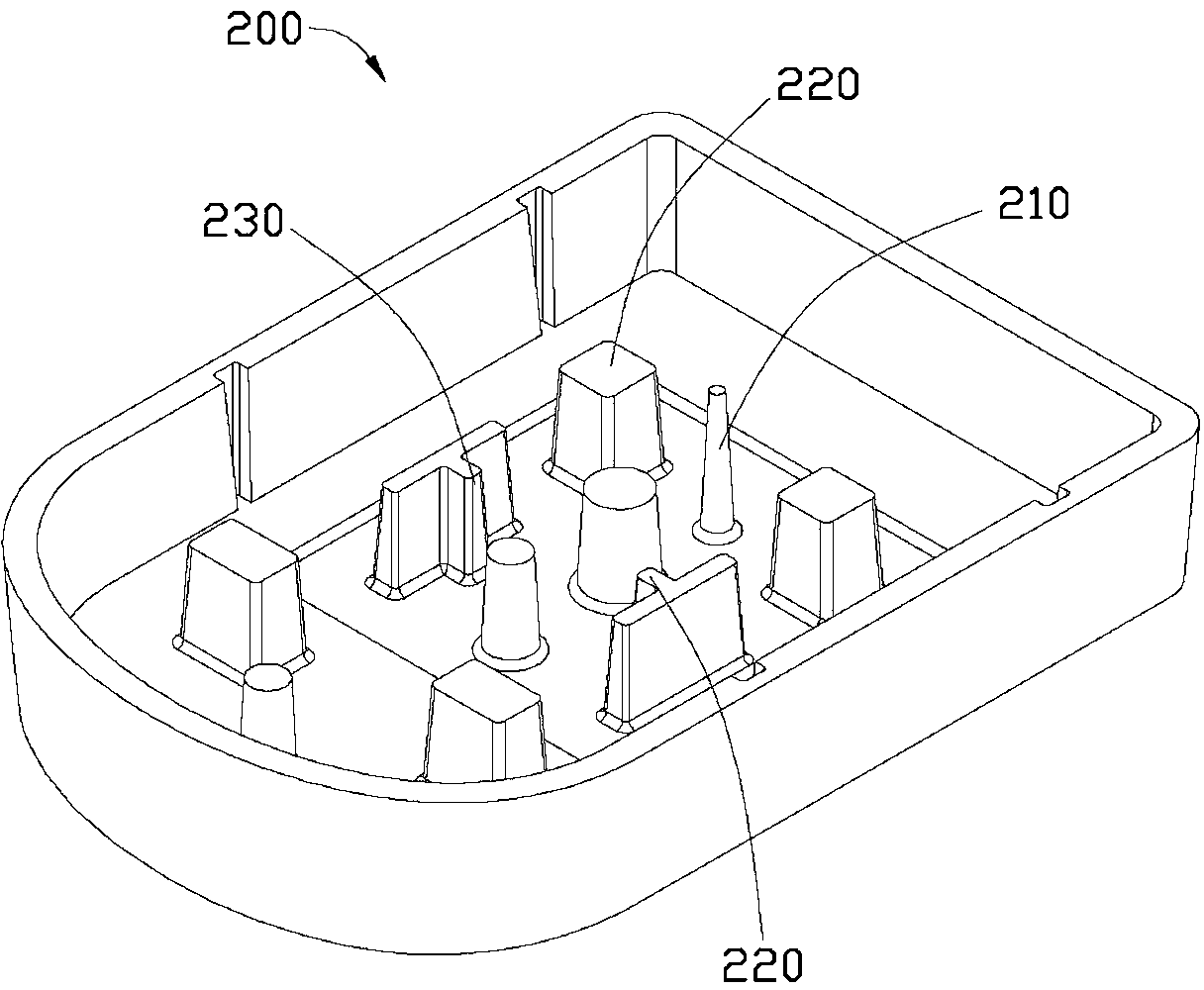

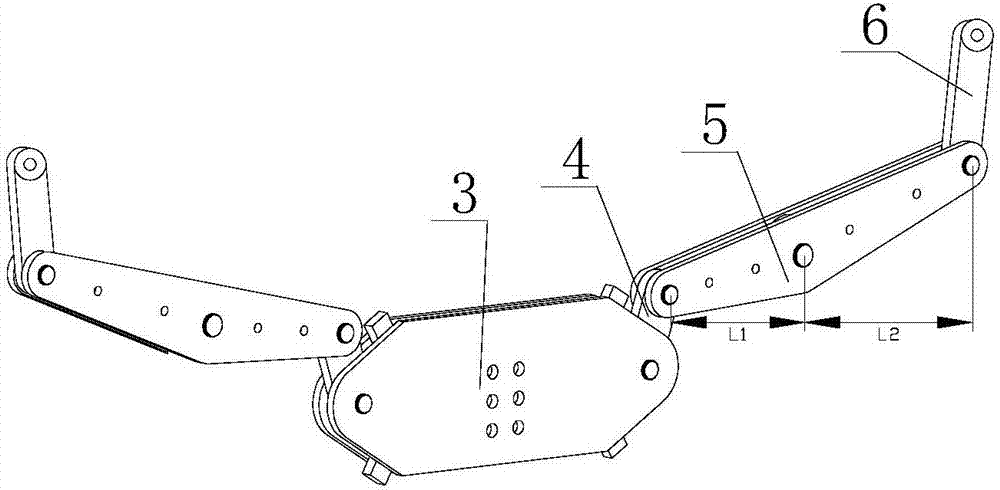

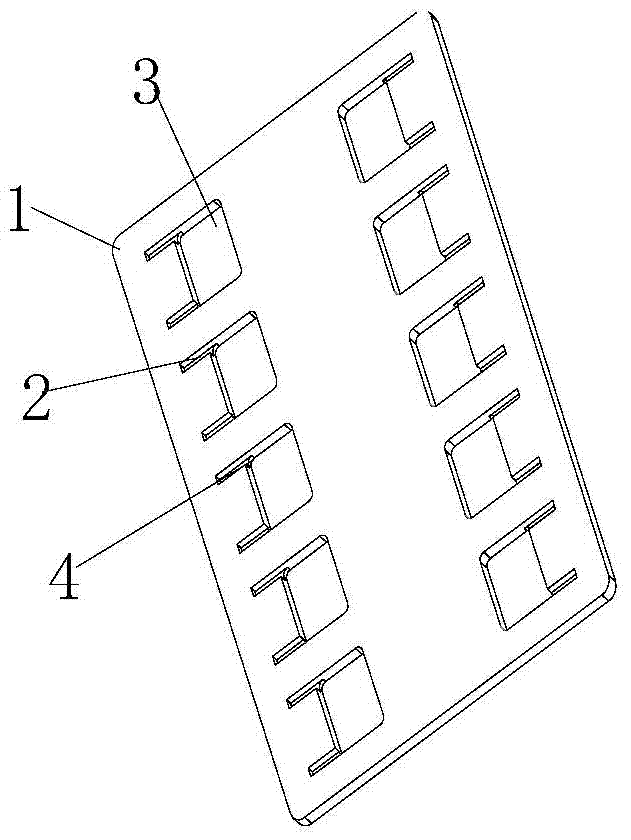

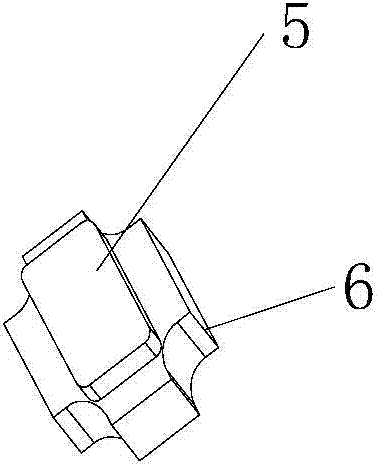

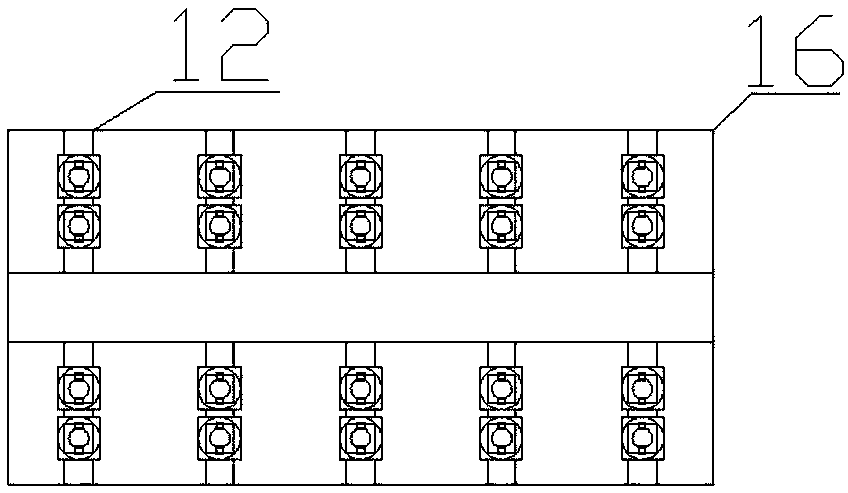

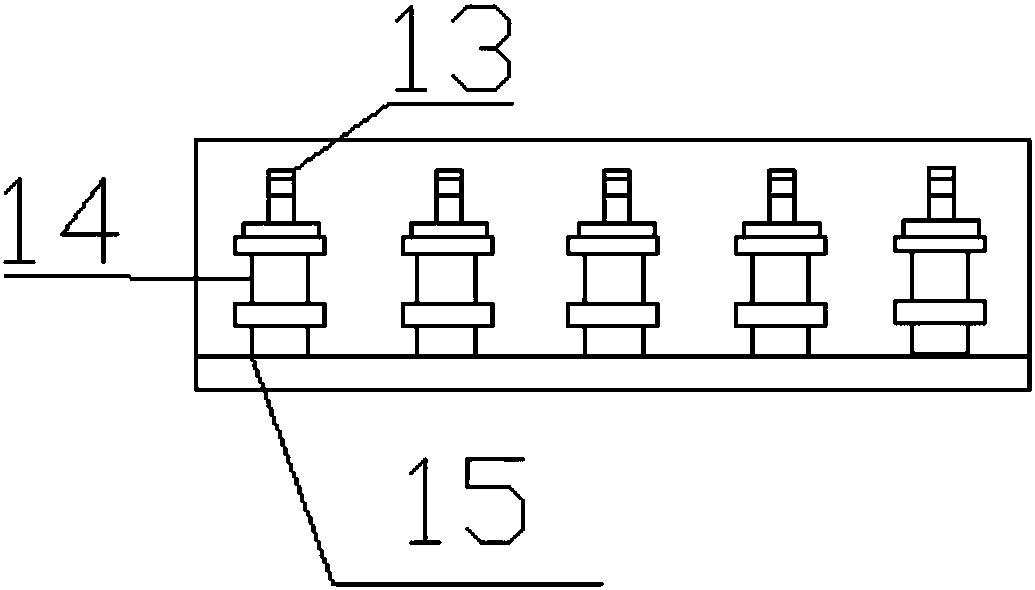

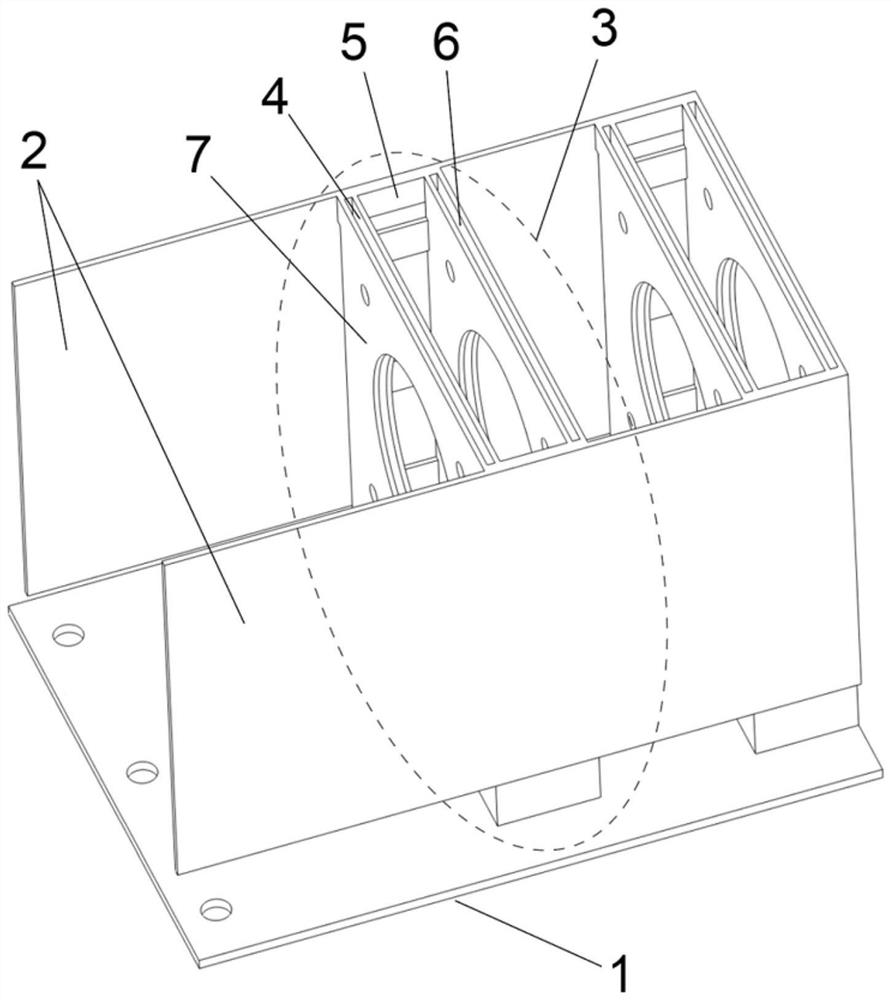

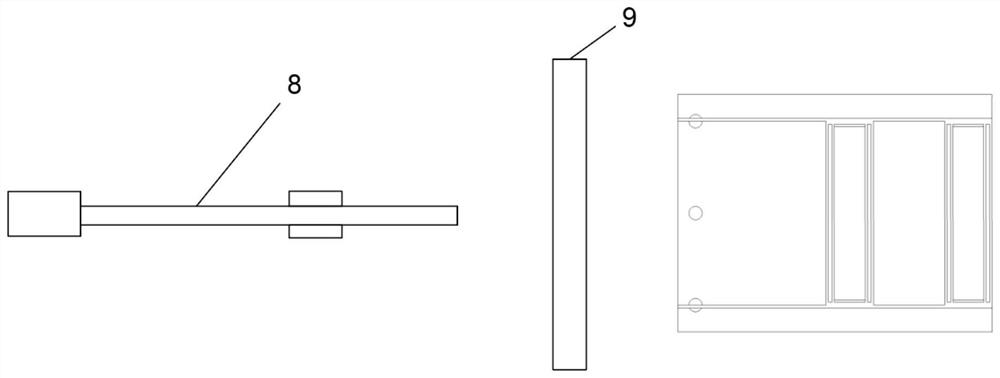

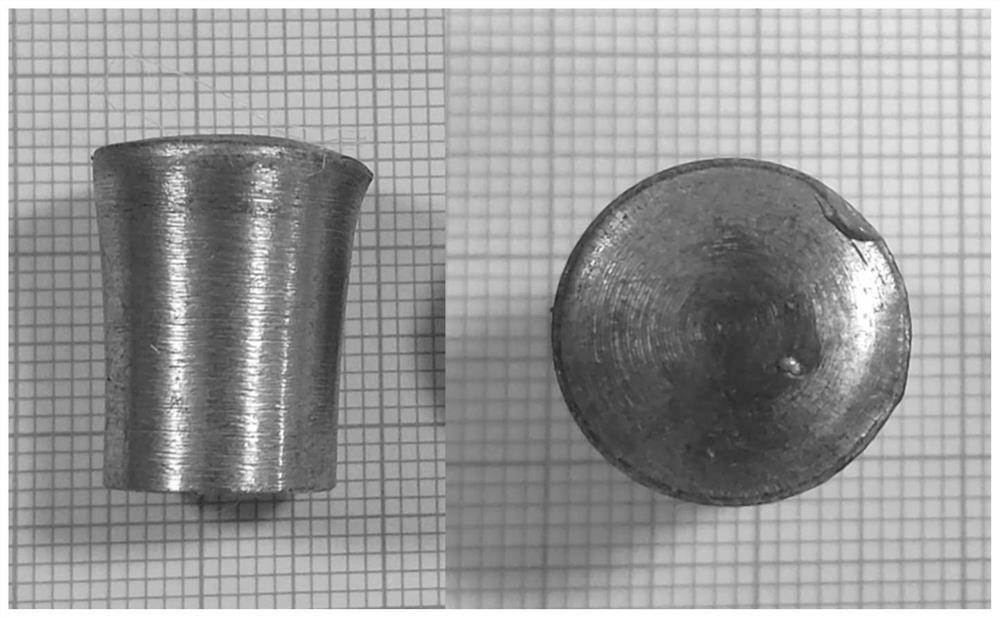

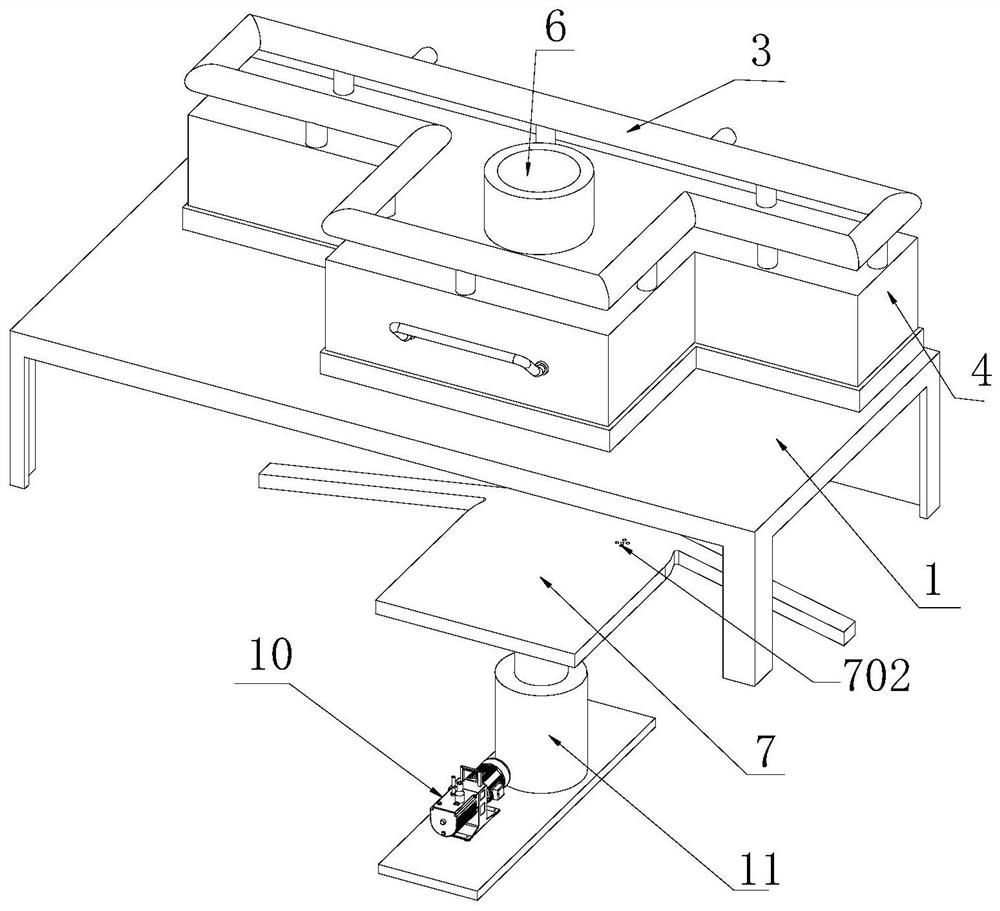

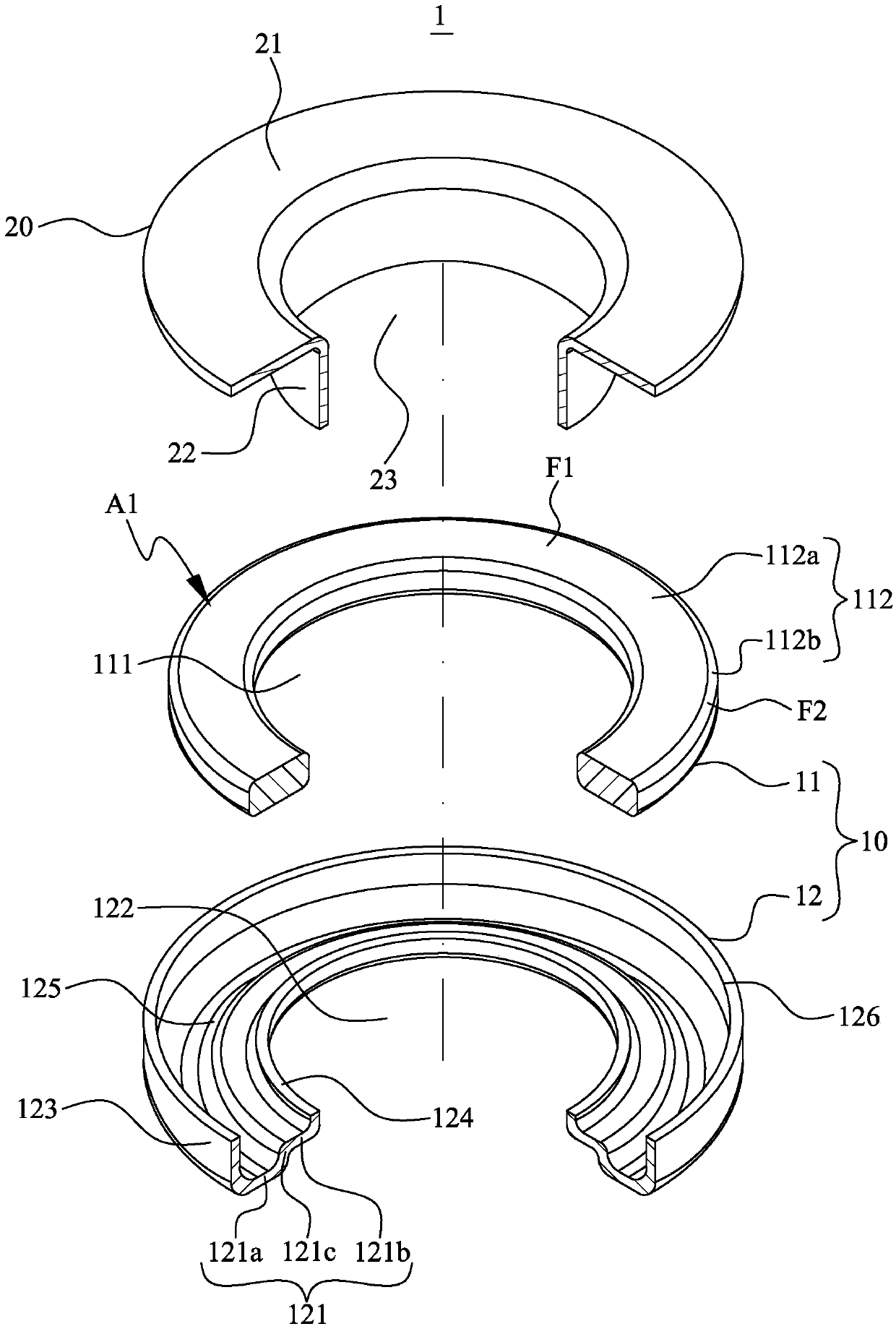

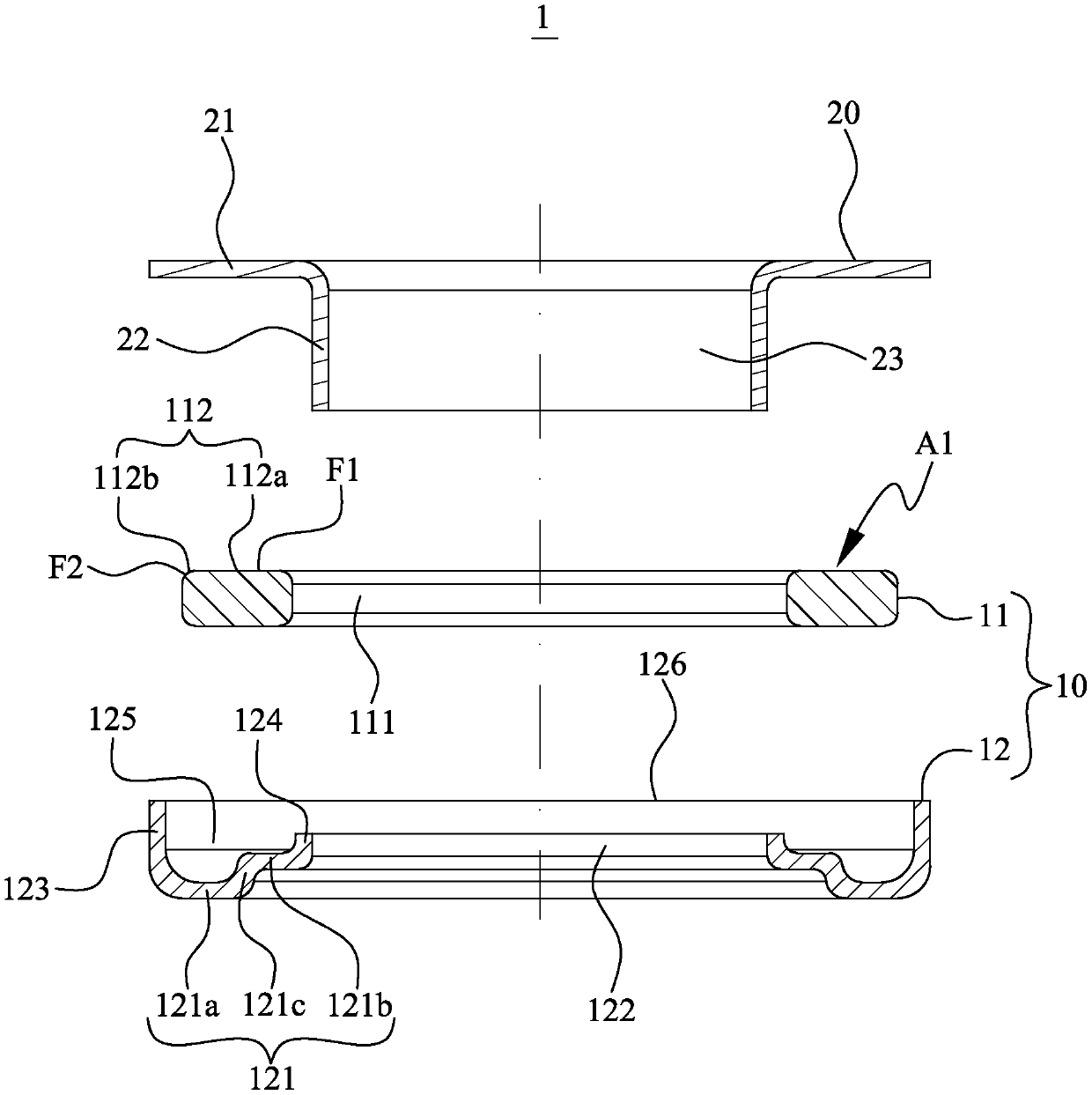

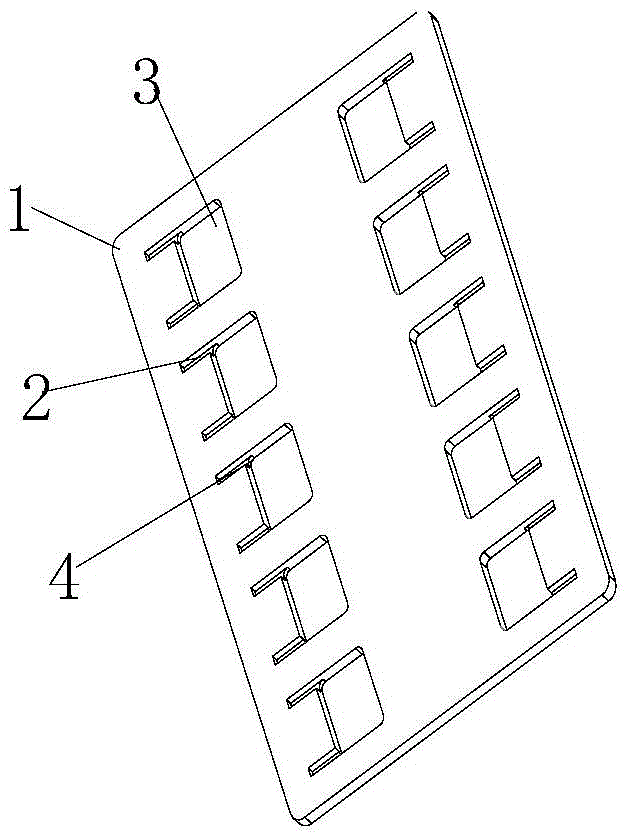

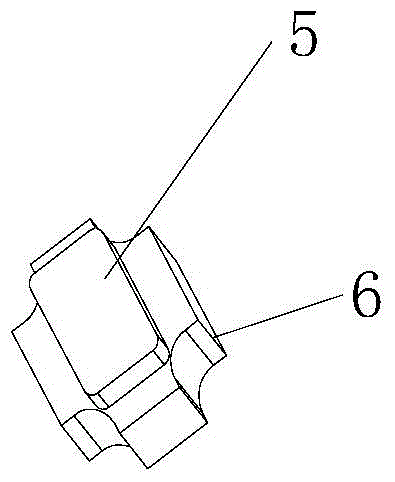

Tool and technology for shaping loudspeaker voice coil

ActiveCN103596115AAvoid secondary deformationQuality assuranceElectrical transducersEngineeringBlock match

The invention belongs to the field of loudspeakers, and particularly relates to a tool and technology for shaping a loudspeaker voice coil. The tool for shaping the loudspeaker voice coil comprises a tool substrate and is characterized in that containing holes holding the loudspeaker voice coil are evenly formed in the tool substrate; the portion, at one side of each containing hole, of the tool substrate is provided with a lead groove used for holding one lead of the voice coil; the tool for shaping the loudspeaker voice coil further comprises ejection blocks matched with the containing holes; each ejection block comprises an ejection body and a holding portion; each ejection body and the corresponding holding portion are integrally arranged; the outer diameter of each ejection body is larger than the outer diameter of the voice coil and smaller than the inner diameter of each containing hole; the shaping technology of heating is conducted on the loudspeaker voice coil. According to the tool and technology for shaping the loudspeaker voice coil, the uniformity of the size of the voice coil can be effectively guaranteed and the stability of the quality of a loudspeaker is guaranteed.

Owner:BESTAR HLDG

Automobile body concave-convex recovery device for automobile metal plate

InactiveCN113798350APromote repairAchieve heatingShaping toolsCleaning using gasesHydraulic cylinderElectric machinery

The invention relates to an automobile body concave-convex recovery device for an automobile metal plate. The device comprises a connecting pipe and a sucking disc, the sucking disc is mounted at one end of the connecting pipe, an executing mechanism is arranged in the connecting pipe, at least two auxiliary mechanisms are arranged on the connecting pipe, the auxiliary mechanisms are uniformly distributed at the outer portion of the connecting pipe in the circumferential direction with the axis of the connecting pipe as the center, the executing mechanism comprises a moving disc, a hydraulic cylinder and a sealing assembly, the sealing assembly comprises a driving motor, a driving disc, two air holes and two sealing units, and each sealing unit comprises a sealing disc and a connecting unit. According to the automobile body concave-convex recovery device for the automobile metal plate, the recovering function of the automobile metal plate is achieved through the executing mechanism, the function of removing impurities on the automobile metal plate is achieved through the auxiliary mechanisms, and secondary deformation caused by the impurities during automobile concave-convex recovery due to the impurities is prevented.

Owner:纪兴元

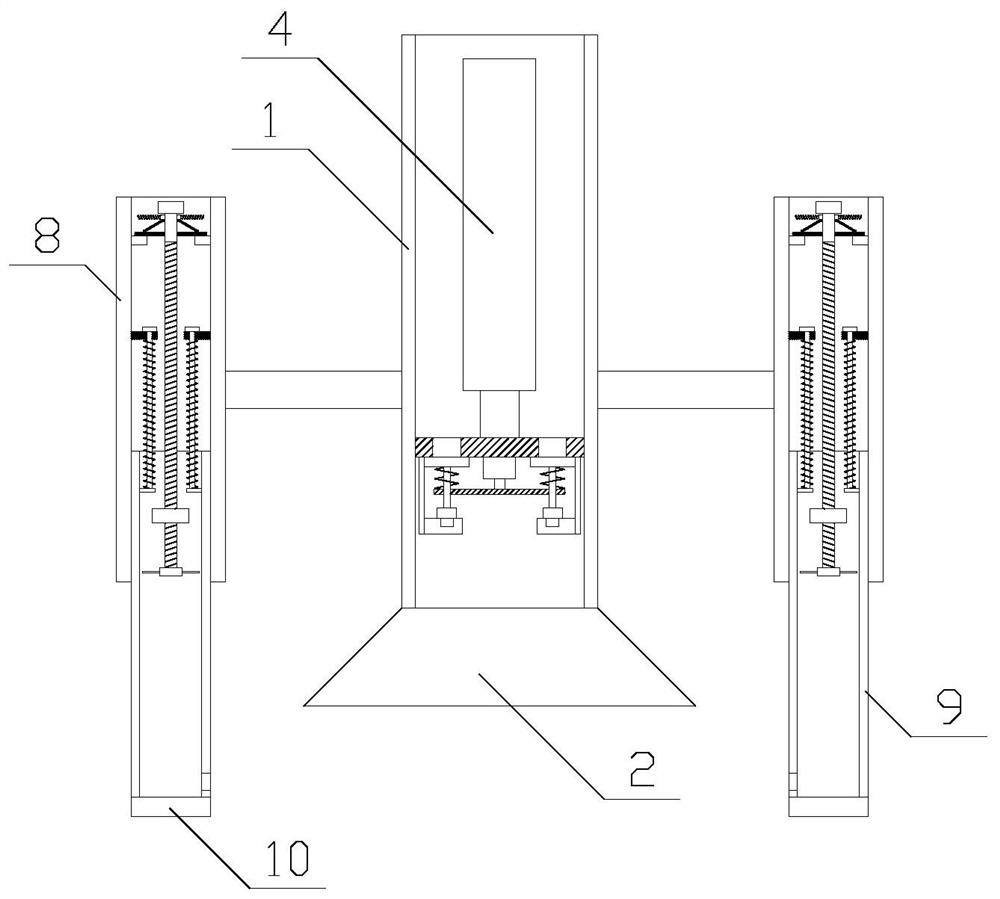

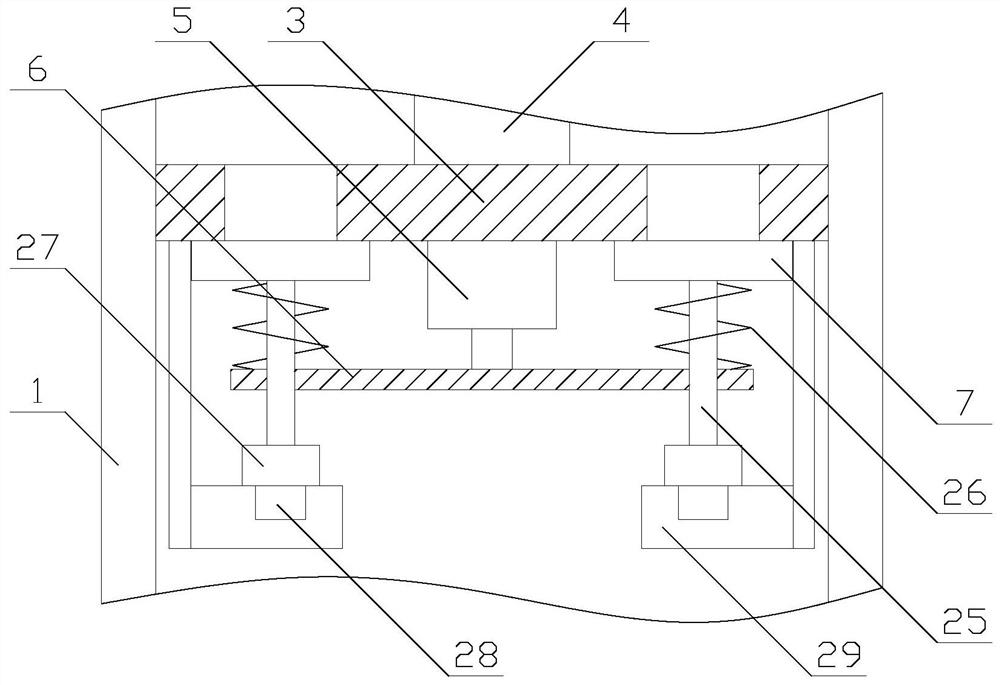

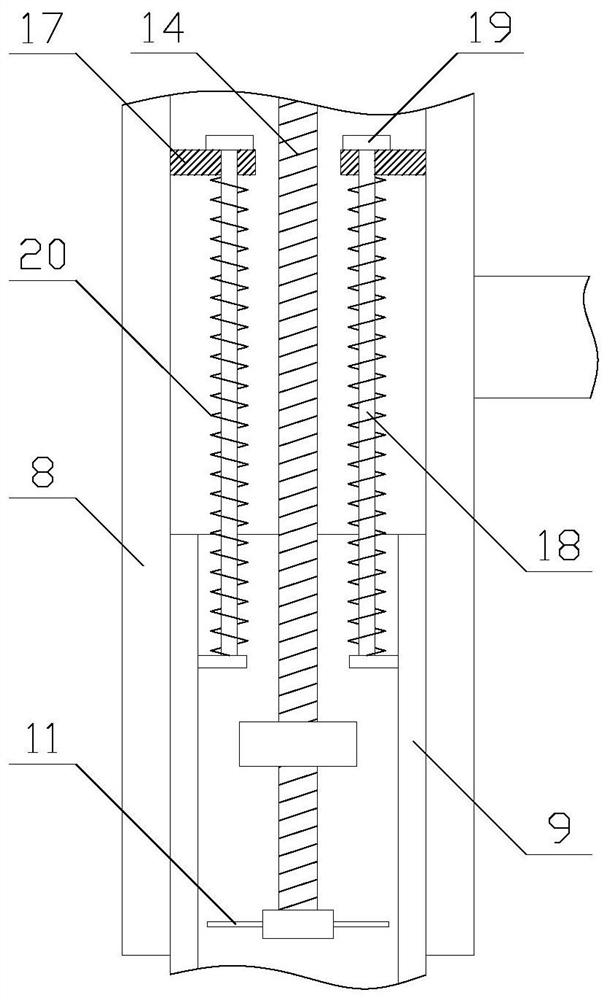

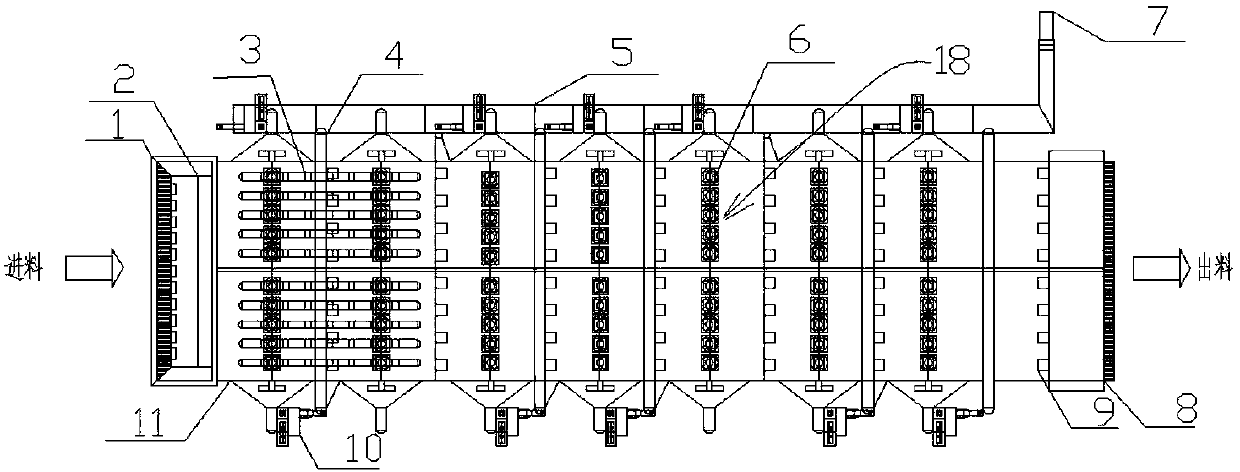

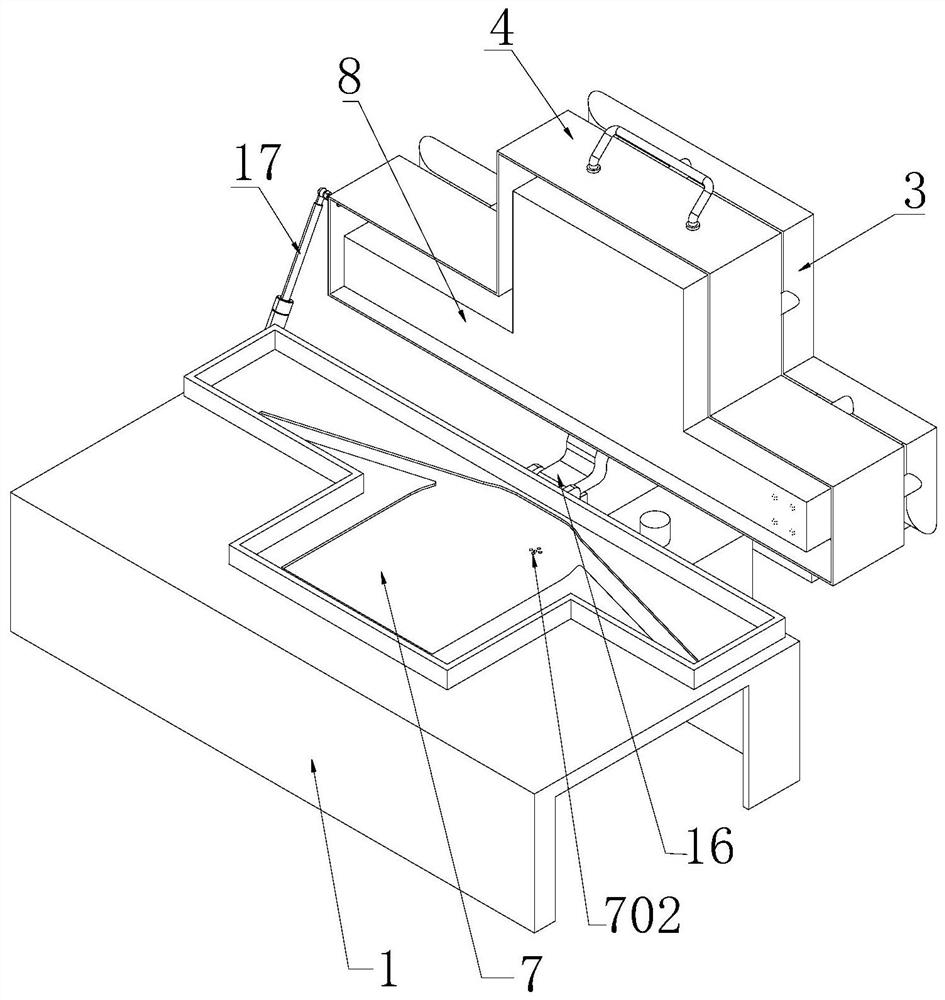

Round bamboo drying and forming device

InactiveCN107796189AAvoid secondary deformationDrying solid materials without heatDrying gas arrangementsMechanical engineering

The invention discloses a round bamboo drying and forming device which is used for drying round bamboos. The round bamboo drying and forming device comprises a drying tank, a carrying rack and a bending die. The drying tank is used for drying round bamboos arranged in the drying tank. The carrying rack is arranged in a drying cavity and is used for carrying the round bamboos. The bending die is arranged on the carrying rack and is used for making the round bamboos keep a preset bent shape. By means of the drying device, the bending die is used for shaping the round bamboos before drying, thenthe shaped round bamboos are dried, after drying is completed, the round bamboos can keep the fixed bent shape, and therefore secondary deformation of the round bamboos is effectively prevented.

Owner:INT CENT FOR BAMBOO & RATTAN

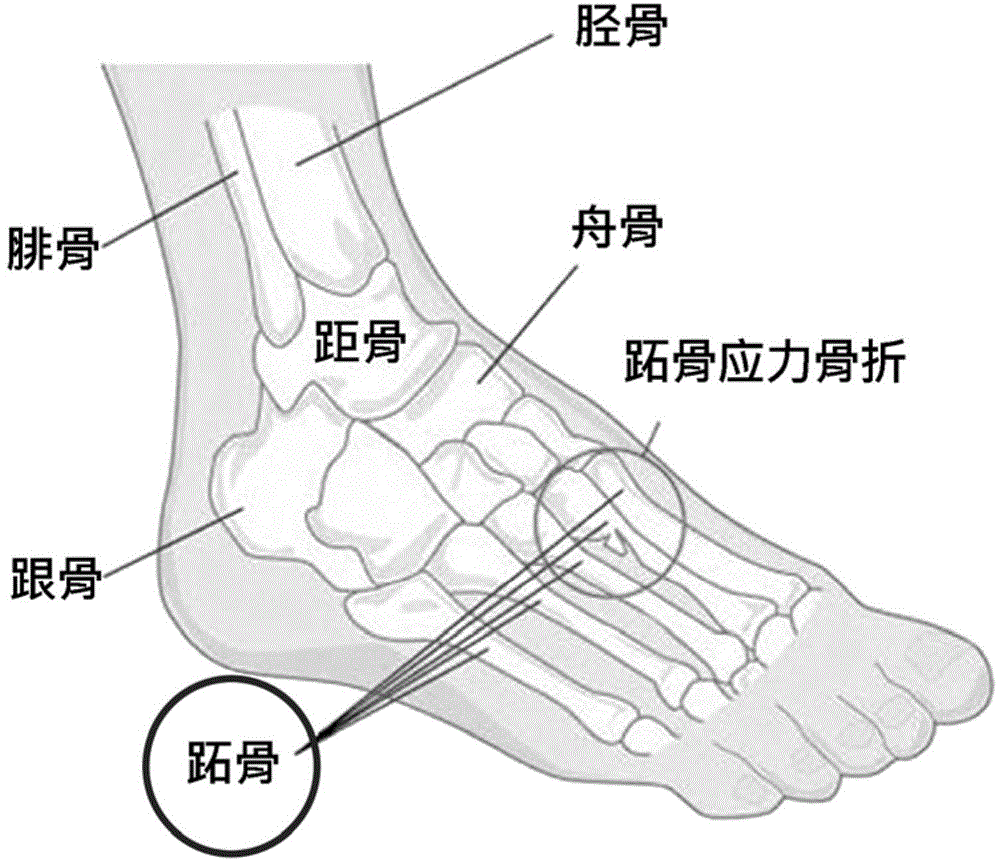

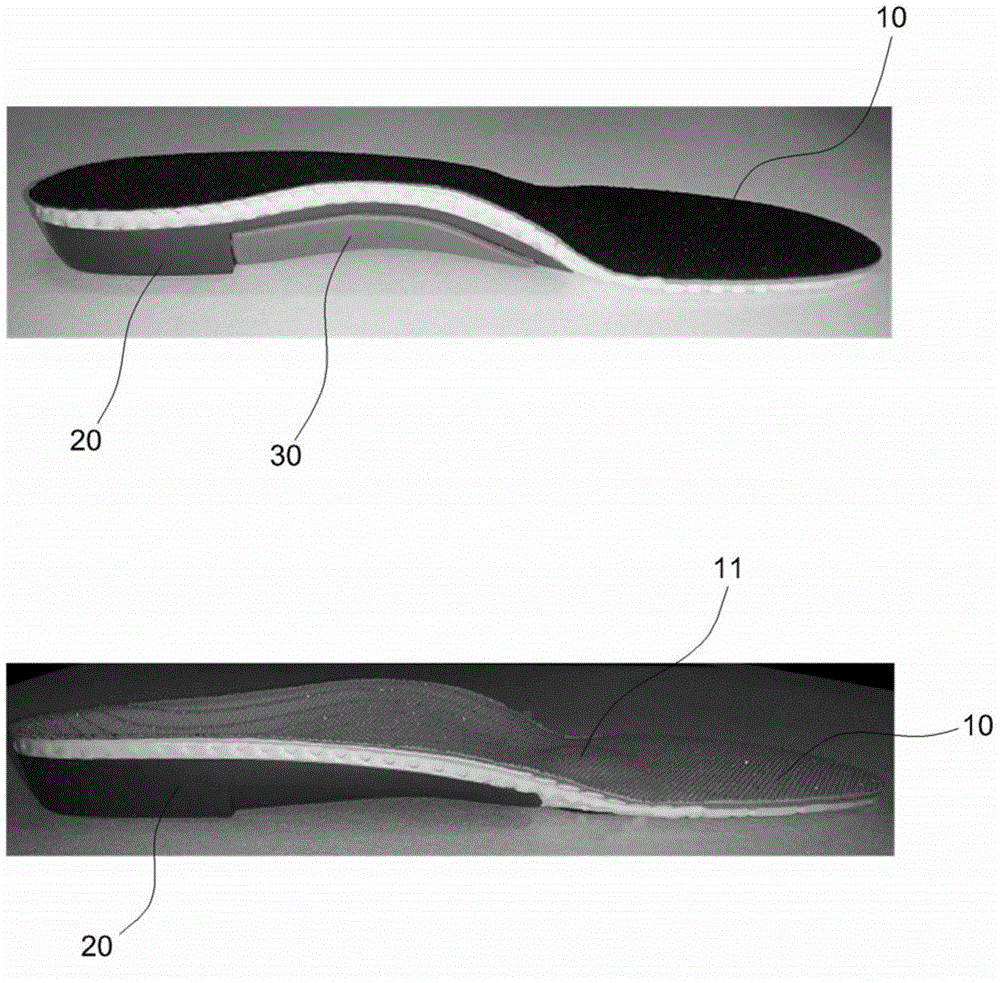

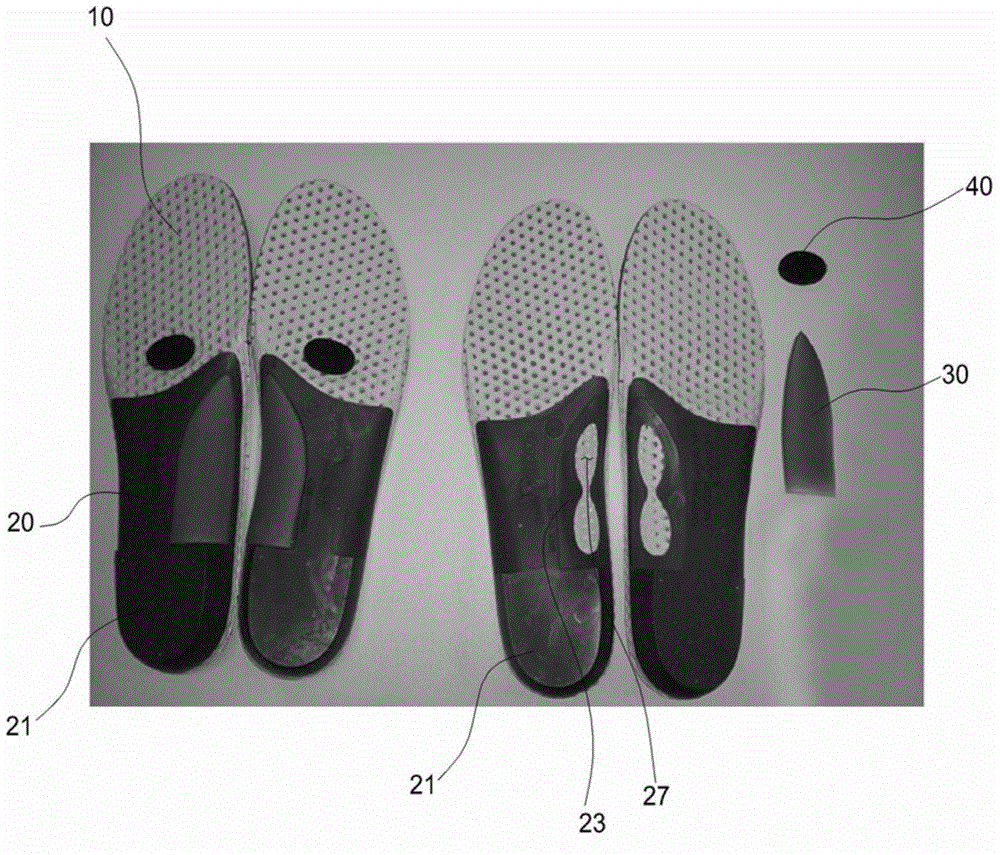

Fit insole for correcting posture

The present invention relates to a fit insole for correcting posture which is inserted in a shoe to protect a foot and a sole and to allow a correct posture to be guided. The fit insole for correcting posture according to the present invention comprises: a body having a shape of a sole; a hard member which includes a heel cup part with a flat bottom surface, an arch part connected to a front side of the heel cup part and having a concave structure, a curved part formed to be curved at an edge of an upper surface thereof, wherein the hard member is attached to a rear side of a lower surface of the body so that an upper surface of the body surrounds a sole and closely contacts and supports an arch portion of the sole; and an arch cookie attached to the arch part of the hard member to support the arch part not to collapse through a load, wherein an elastic groove having a shape of letter ''8'' is formed at the arch part of the hard member to provide elasticity, and the arch cookie is configured as a set to have a different hardness according to a shape of user's foot.

Owner:FOOTHEALTH

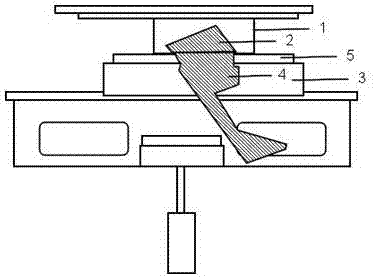

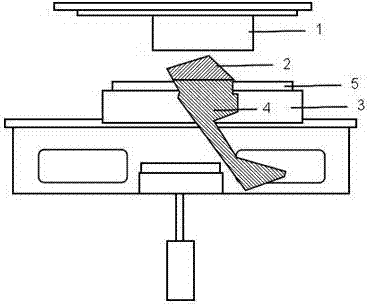

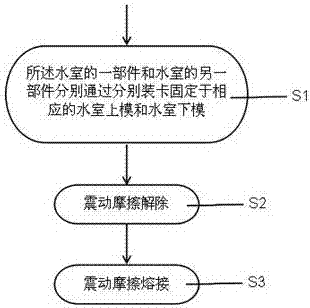

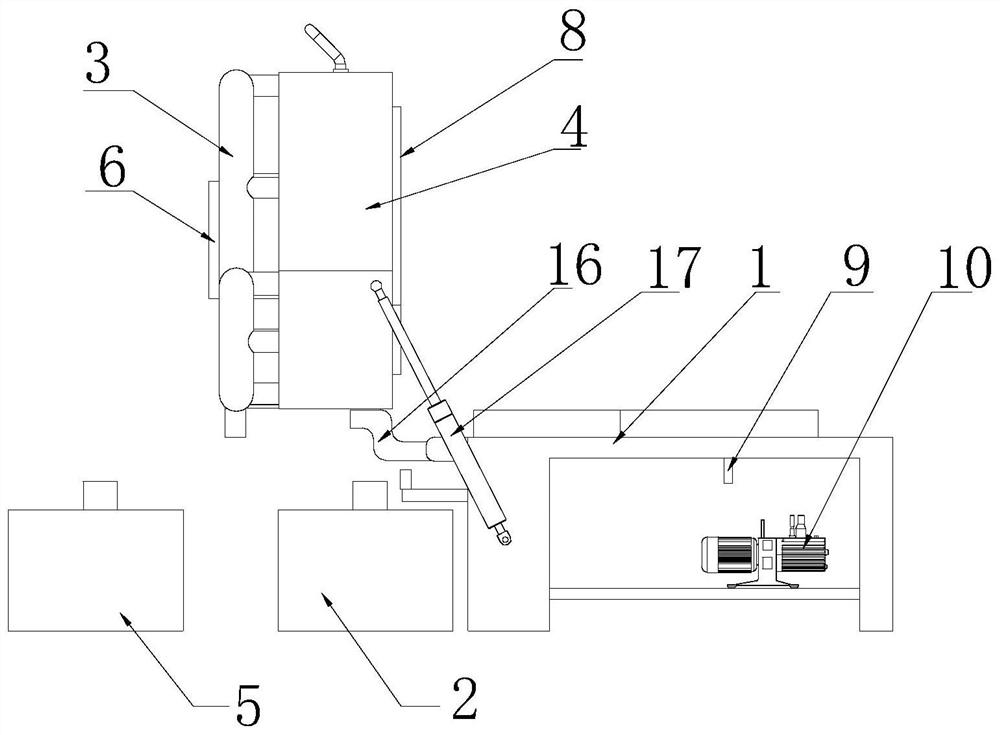

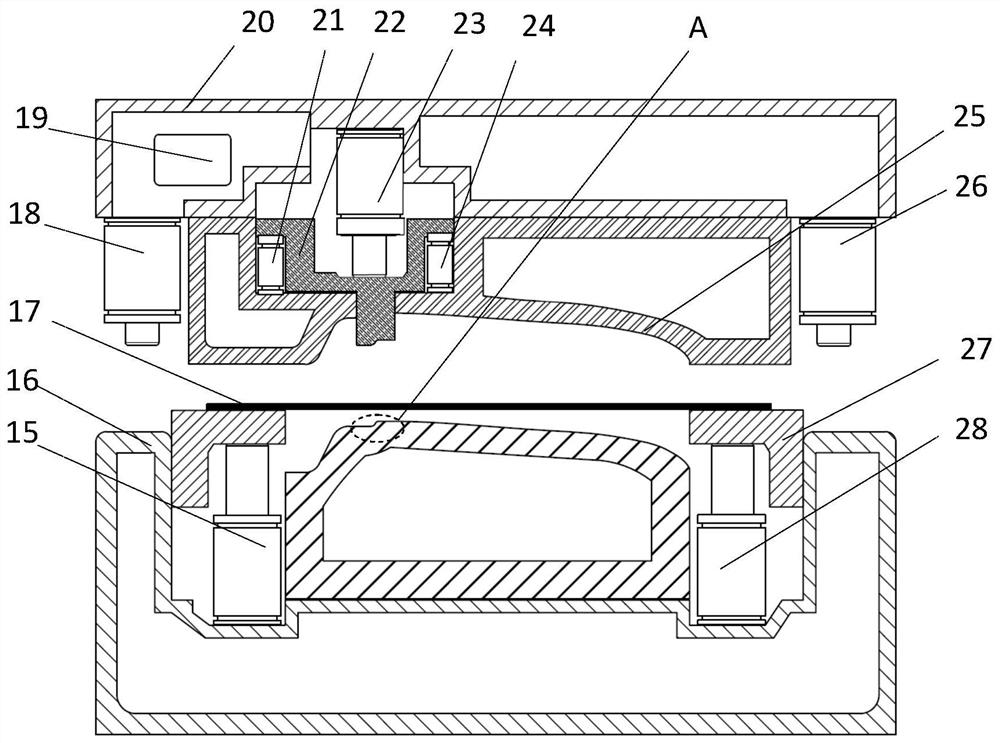

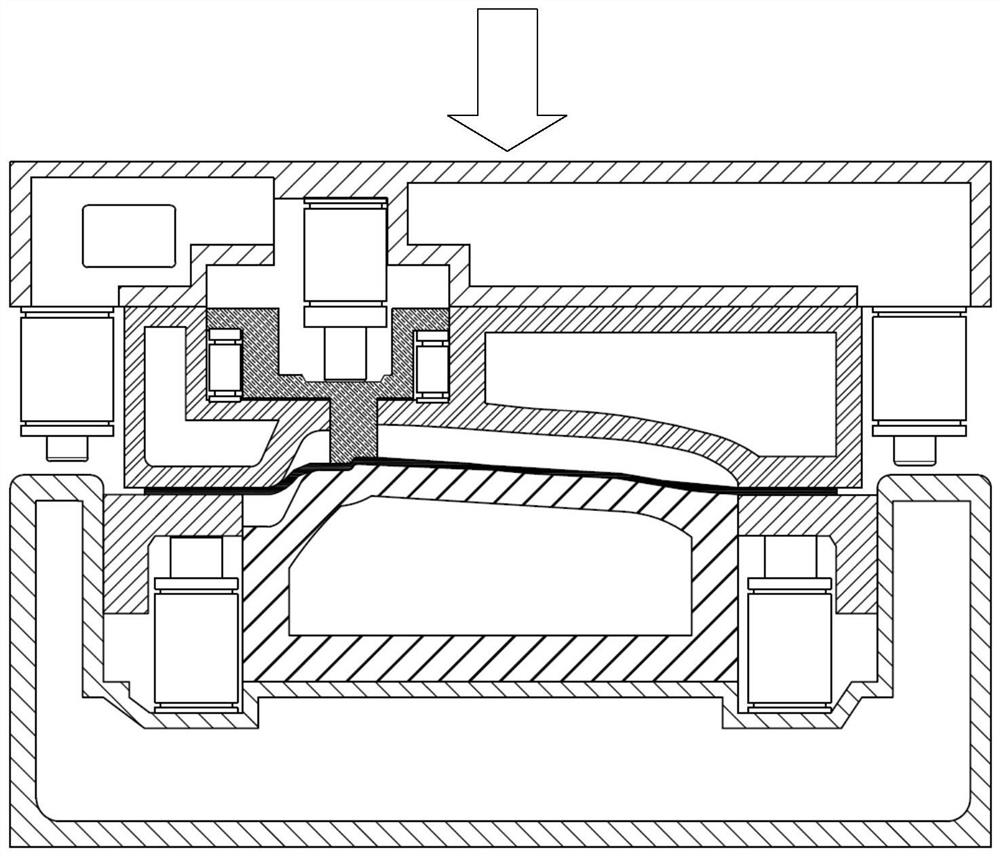

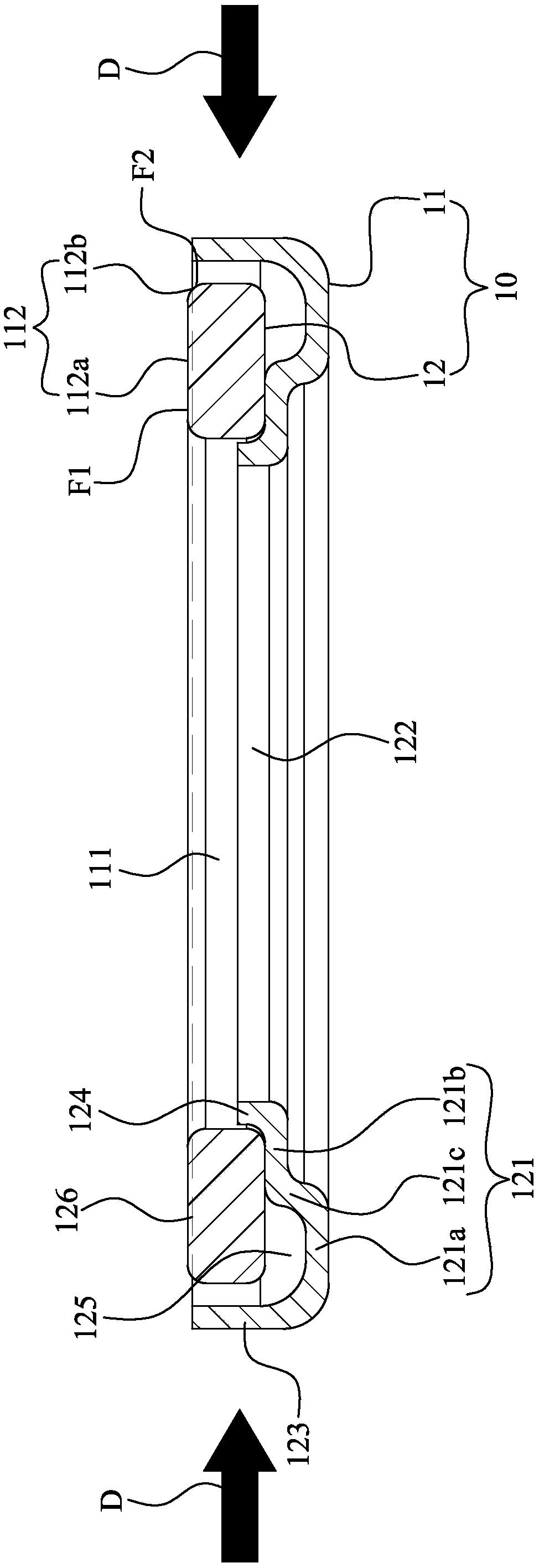

Friction welding device for kettle type water chamber

PendingCN107262913AHomogeneous hot melt bondingAvoid secondary deformationNon-electric welding apparatusEnvironmental geologyMechanical engineering

The invention belongs to the technical field of welding devices and particularly relates to a friction welding device for a kettle type water chamber. The friction welding device comprises a component, clamped to a water chamber upper die, of the water chamber and the other component, corresponding to the component and clamped to a water chamber lower die, of the water chamber. The water chamber upper die is connected to the water chamber lower die through an ultrasonic swing device in a die combination manner. The component of the water chamber is welded to the other component of the water chamber through vibration friction of the ultrasonic swing device. By the adoption of the friction welding device, the problems that by means of the process in the prior art, the secondary deformation of parts is caused due to hot melting, the hot melting bonding is not uniform, the leakage of unfixed positions is likely to happen in the pressure use process, and the unnecessary cost waste is caused are solved, and the friction welding device has the beneficial technical effects that the secondary deformation is prevented, the hot melting bonding is uniform, the cost is lowered, and the production process is facilitated.

Owner:法拉达汽车散热器(天津)有限公司

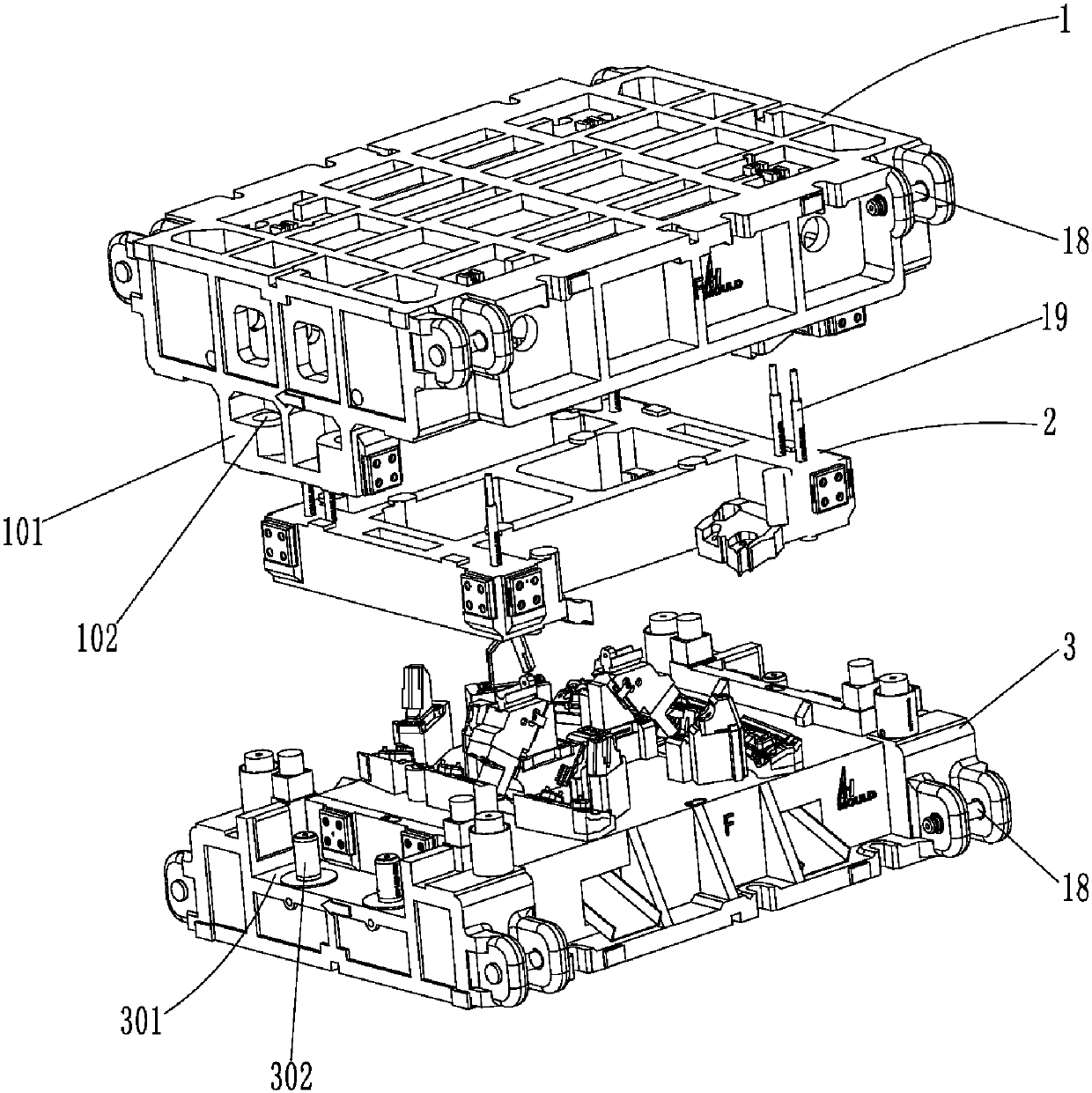

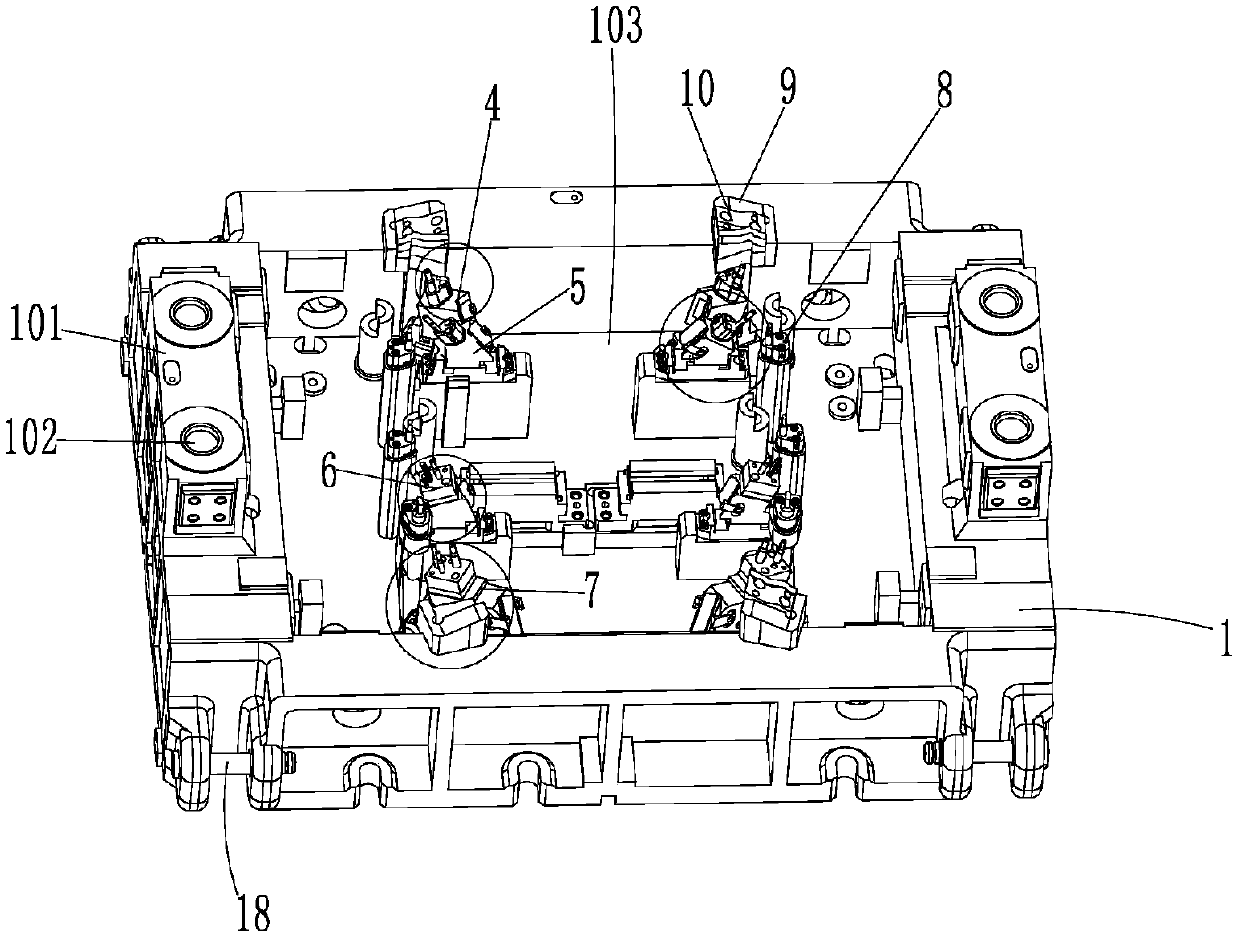

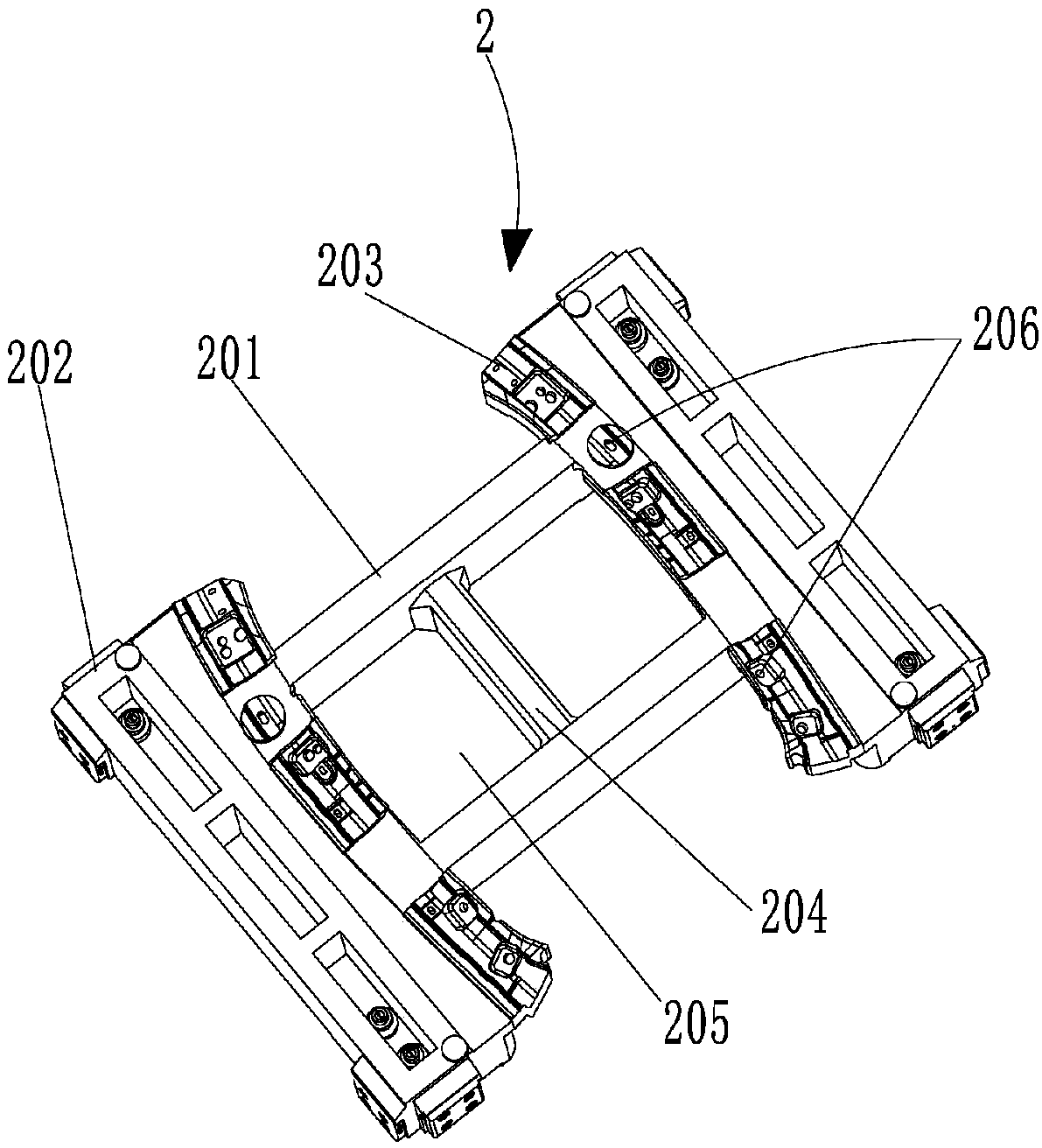

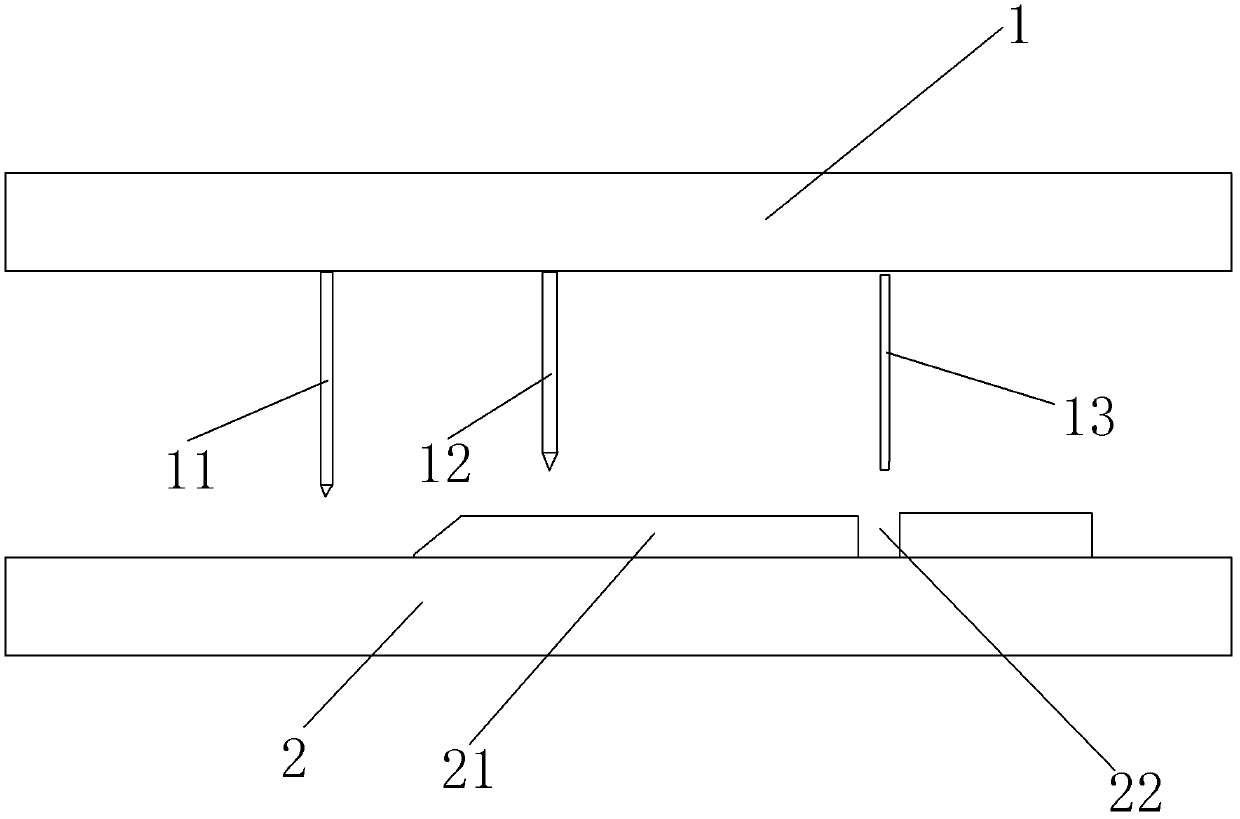

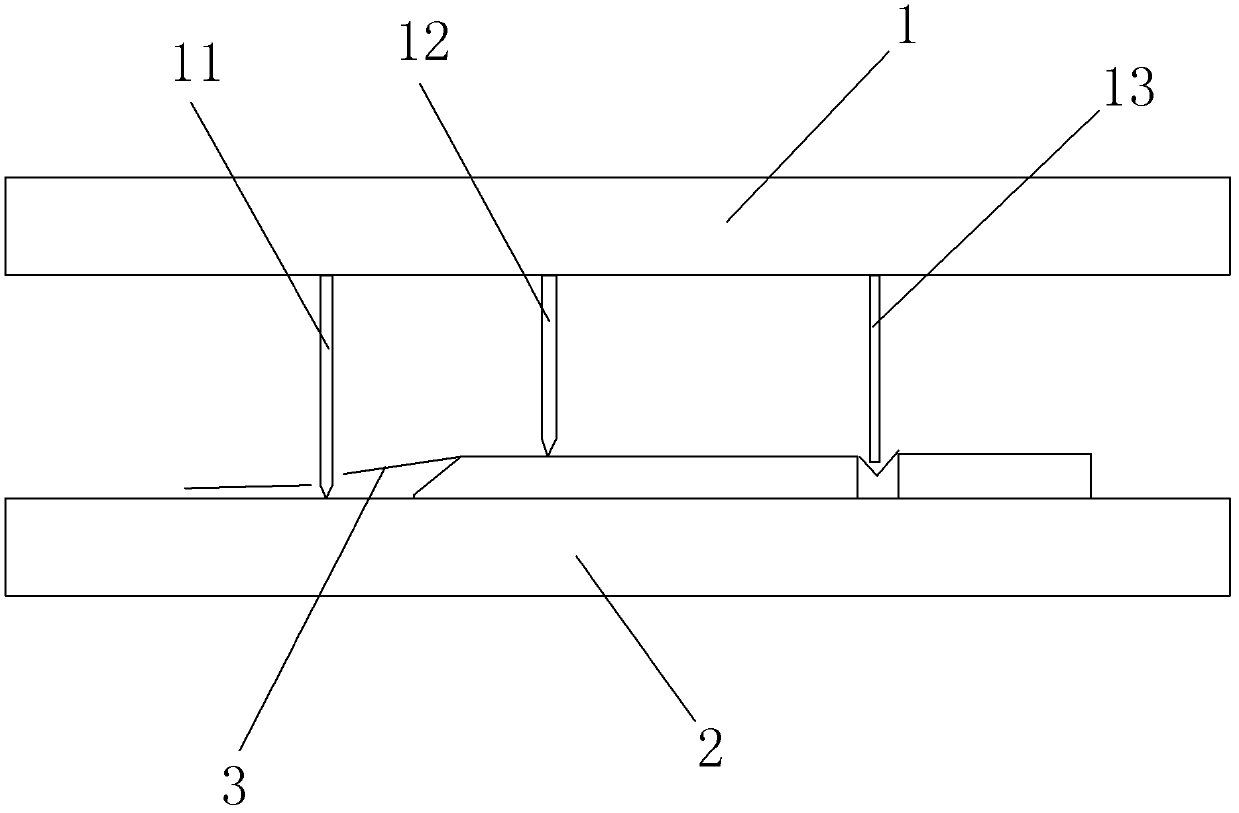

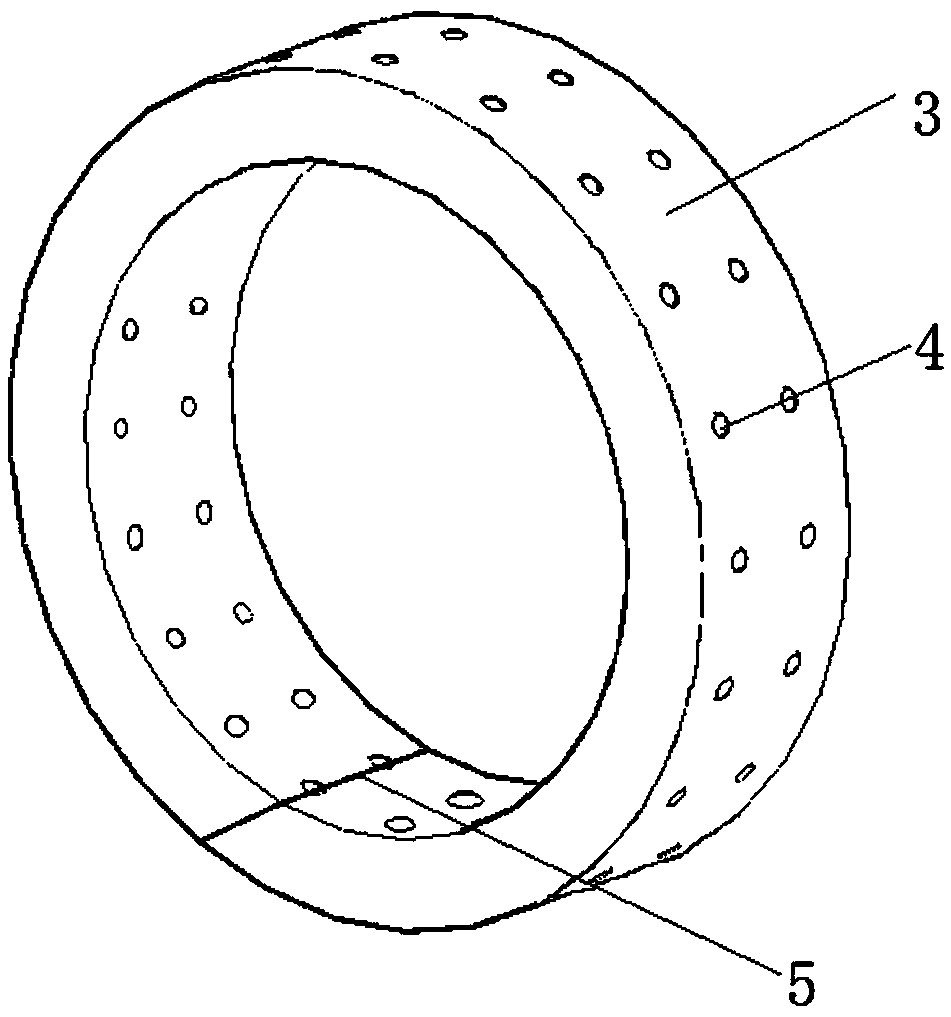

Arc plate porous machining mold

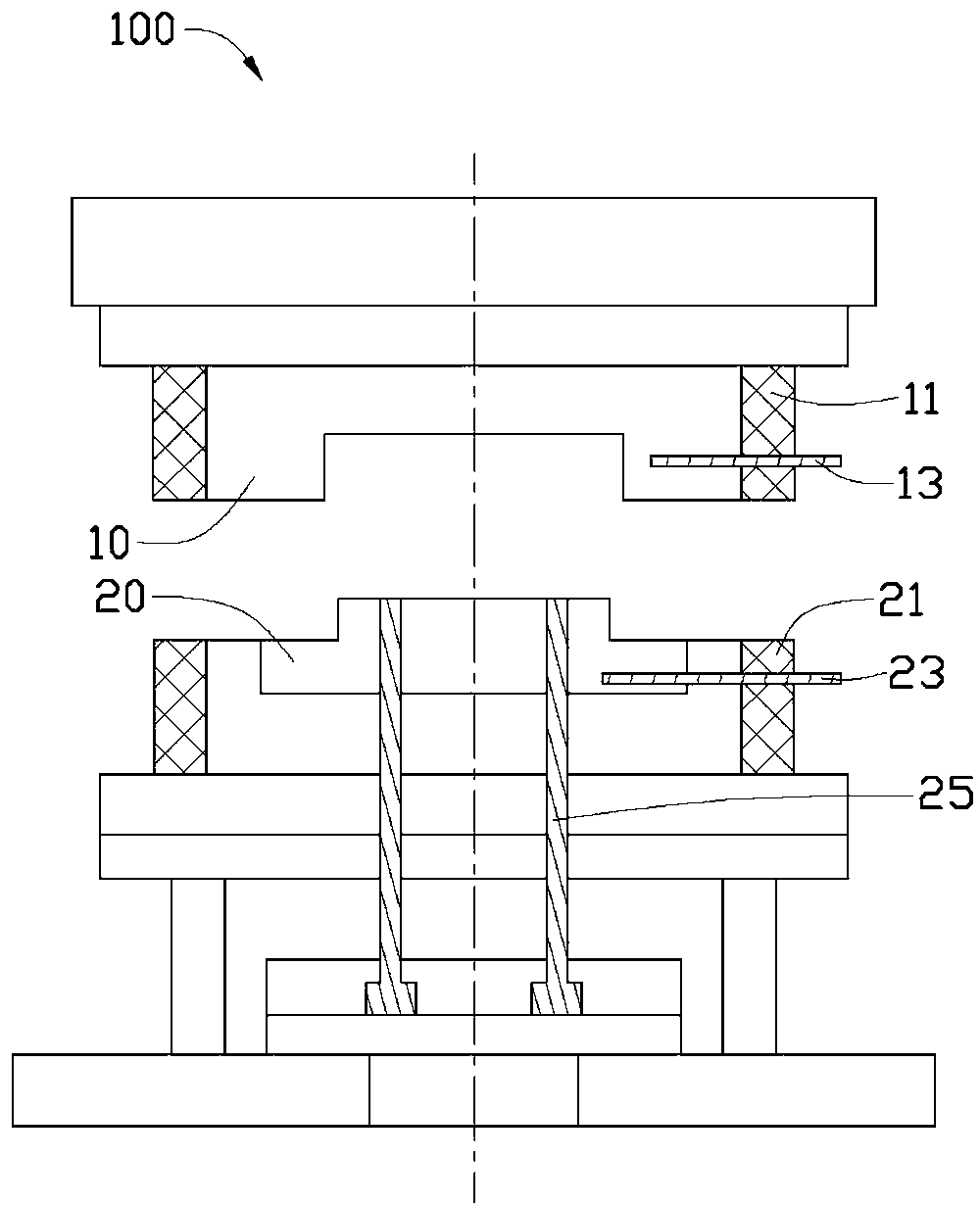

PendingCN107803425AAvoid secondary deformationAvoid multiple processingShaping toolsPerforating toolsFixed rampEngineering

The invention provides an arc plate porous machining mold. The arc plate porous machining mold comprises an upper mold, a lower mold and a material press; a mounting groove is formed in the middle part of the upper mold; two sets of inclined surface punching mechanisms are fixed in the mounting groove; three sets of plane punching modules are arranged on the outer sides of the two sets of inclinedsurface punching mechanisms; the material press comprises a rectangular frame, and mounting parts positioned at two ends of the rectangular frame; pressing blocks with arc structures are arranged attwo ends of the rectangular frame; multiple via holes matched with the inclined surface punching mechanisms and the plane punching modules are formed in the top surfaces of the pressing blocks; the mounting parts are connected to a top plate of the upper mold through multiple travel limiting rods; two sets of slide guide rails matched with the inclined surface punching mechanisms are arranged at the middle part of the upper surface of the lower mold; positioning blocks are arranged on the outer sides of the slide guide rails; and the positioning blocks are provided with punching concave moldscapable of moving through matching with punches. In the punching process, arc plates cannot move, and concave surfaces of the pressing blocks and concave surfaces of the positioning blocks can be matched with the structures of the arc plates, so that secondary deformation of the arc plates caused by the extrusion process is prevented.

Owner:重庆安亚模具制造有限公司

Staged metal fragment recovery device for ballistic test

ActiveCN114459300AEfficient recyclingGood cushioning and energy absorptionAmmunition testingProcess efficiency improvementLiquid layerStructural engineering

The invention relates to a graded metal fragment recovery device for a ballistic test, and belongs to the technical field of ballistic tests. The recycling device comprises a bottom plate, a movable side plate and recycling structure units, the n recycling structure units are arranged in the length direction of the bottom plate with the length direction of the bottom plate as the front-back direction and the width direction of the bottom plate as the left-right direction, and the lower ends of fixed steel plates of the recycling structure units are fixedly connected with the bottom plate. The two movable side plates are symmetrically installed on the left side and the right side of the bottom plate, and the upper ends of the movable side plates are connected with the fixed steel plate through hinges. The layered recovery structure unit composed of the aramid fiber layer, the liquid layer and the PE layer is adopted to effectively intercept the metal fragments, secondary deformation of the metal fragments in the recovery process is avoided, the number of the recovery structure units is adjusted and controlled, recovery of the metal fragments under different speed conditions can be achieved, and the recovery efficiency is improved. And the recovery device is easy to search and recover the metal fragments.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

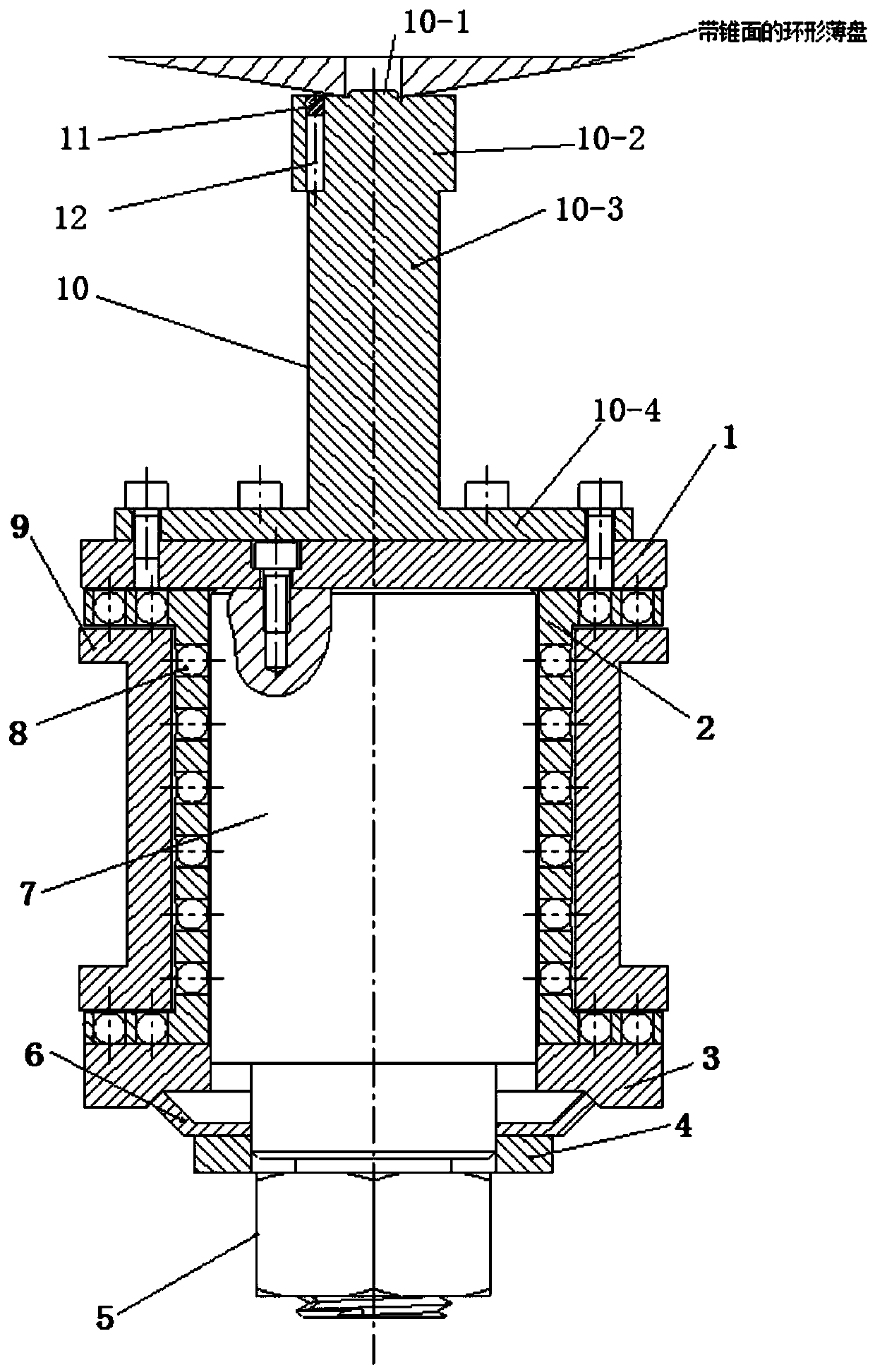

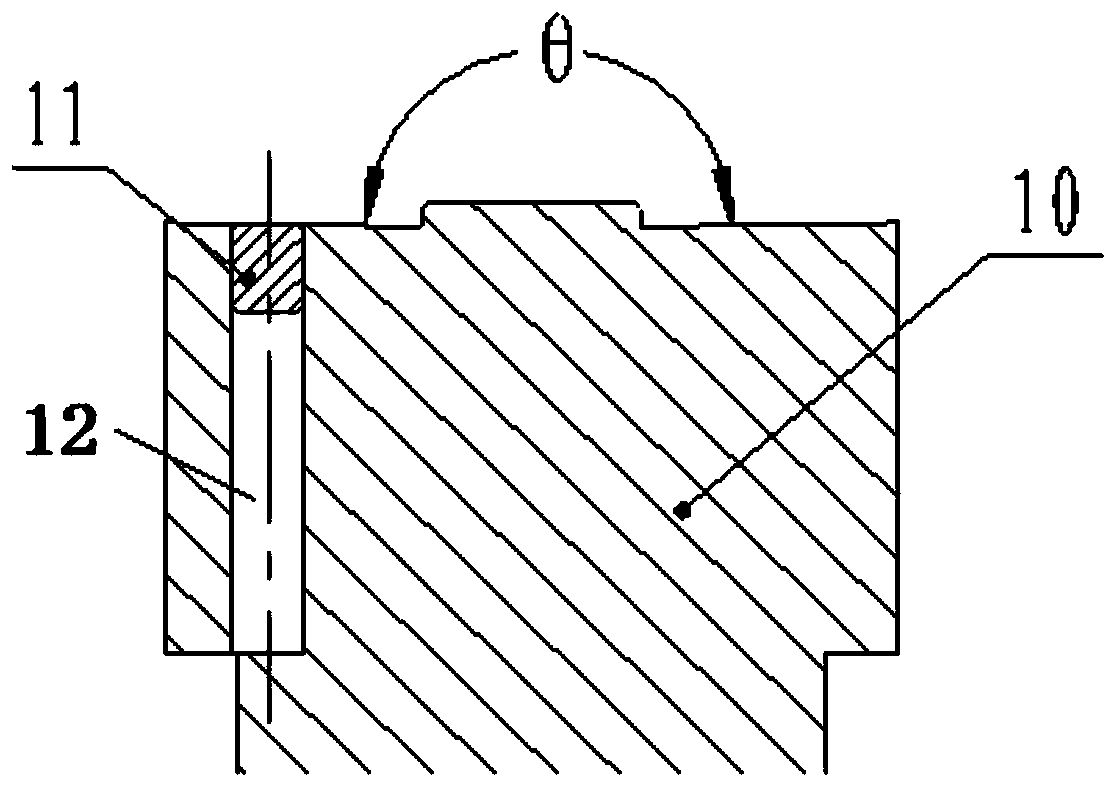

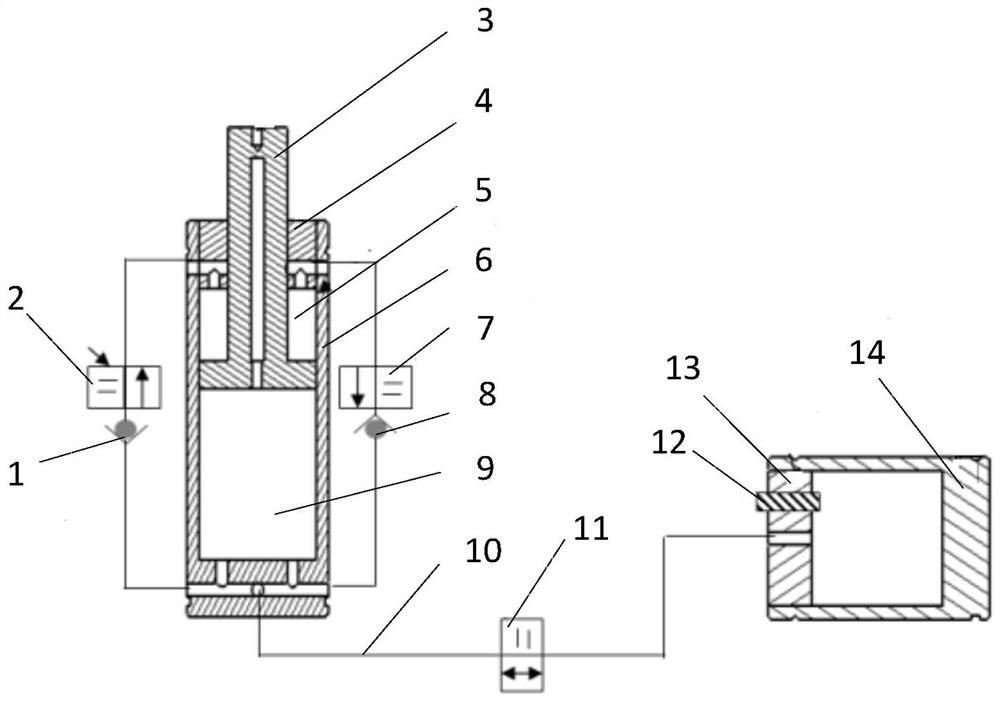

Magnetic adsorption type positioning and rotating mechanism and using method thereof

PendingCN111006623AQuick card positioningAvoid secondary deformationMechanical measuring arrangementsMagnetic tension forceFriction torque

The invention discloses a magnetic adsorption type positioning and rotating mechanism and a using method thereof. The magnetic adsorption type positioning and rotating mechanism comprises a positioning mechanism and a rotating mechanism which are fixedly connected to form a synchronous rotating whole body. Rapid clamping and positioning of an annular thin disc with a conical surface can be achieved, a magnetic adsorption mode is adopted for axial positioning, and the adsorption force is adjusted by changing the axial position of a strong magnetic column in a guide hole, so that secondary deformation in the detection positioning process is avoided, and meanwhile, accurate detection of form and location tolerance parameters can be guaranteed; the rotating precision of the rotating mechanismreaches 0.003 mm, the precision error is within + / -0.001 mm at different rotating speeds, and the system error of a transmission system is reduced to the maximum extent; the integrated design of a rotary shaft system and a workpiece positioning table is realized, and the matching error between the transmission mechanism and the positioning mechanism is avoided; and the magnetic adsorption type positioning and rotating mechanism also has the remarkable advantages of small friction torque, large load, high reliability and the like, can effectively avoid system errors caused by low rotation precision of the rotary shaft system, and meets the point sampling requirement of rapid detection of the annular thin disc with the conical surface.

Owner:中核新科(天津)科技有限公司

Die cutting method of sticking port of packaging paper box with hidden and easily-torn port

ActiveCN102259440BGuaranteed die-cutting effectAvoid secondary deformationContainer making machineryEngineeringDislocation

Owner:SHANGHAI TOBACCO GRP CO LTD +1

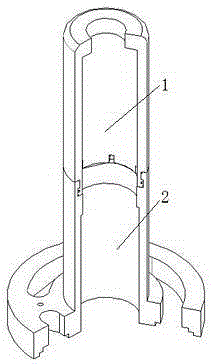

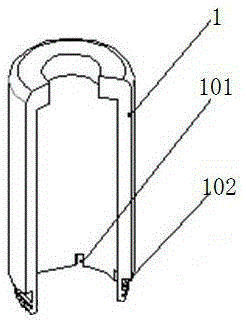

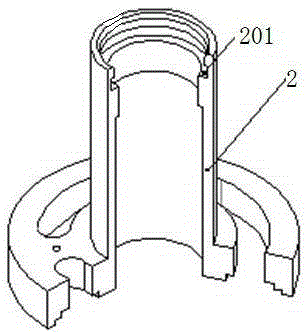

High-voltage circuit breaker and nozzle thereof

ActiveCN105355507AKeep shapePrevent axial movementHigh-tension/heavy-dress switchesAir-break switchesEngineeringHigh pressure

The invention relates to the field of high-voltage power supply and distribution, particularly to a high-voltage circuit breaker and a nozzle thereof, so as to solve the problems of inconvenient processing and installation of the nozzle since the existing nozzle is connected with a flange through threads. In order to solve the technical problem, one end of the nozzle used for the high-voltage circuit breaker is processed with notches extending along the axial direction, wherein the notches allow the tail end of the nozzle to form elastic contact fingers which can deform in a stretchable manner along the radial direction, the elastic contact fingers are processed with convex edges, and grooves which can be clamped with the convex edges in a matched manner are processed in a flange. The axial fixation of a workblank is achieved by utilizing the notches in the nozzle when using a tooling for fixing the workblank in a radial manner, the axial movement of the workblank during the processing process is prevented, and the processing precision is guaranteed; and the convex edges on the nozzle can be clamped and matched with the grooves in the flange by inserting the nozzle into the flange through pressing the elastic contact fingers in assembly without using a tool for auxiliary fastening, thereby avoiding the resulting secondary deformation and processing design of the tool and operation tooling.

Owner:PINGGAO GRP +1

Production method of heat insulating and preserving ceramic composite plate with decorative properties

ActiveCN102877614BReduce construction costWith thermal insulationCovering/liningsClaywaresCeramic compositeFoaming agent

The invention discloses a method for producing a heat insulating and preserving ceramic composite plate with decorative properties, comprising the following steps: preparing the powder of a decorative layer; preparing the powder of a heat insulating and preserving layer; loading the powder in a ceramic sagger in the secondary distribution way; sintering in a roller kiln in one time without drying and moulding by a ceramic pressing machine; demoulding, polishing and finishing the decorative surface, and determining the thickness and shape of the heat insulating and preserving surface by mechanical dry cutting. By the joint reaction of the ultrafine foaming agent, the dolomite, the diatomaceous earth and the polishing slag at high temperature, the heat insulating and preserving plate filled with tiny closed pores can be formed. The product has high strength, strong penetration resistance and lower thermal conductivity than the existing ceramic heat preserving material and has the characteristics of low production energy consumption, good decorative effect and prominent heat preservation, heat insulation and sound insulation effects.

Owner:FOSHAN RONGZHOU NO 2 BUILDING CERAMICS FACTORY

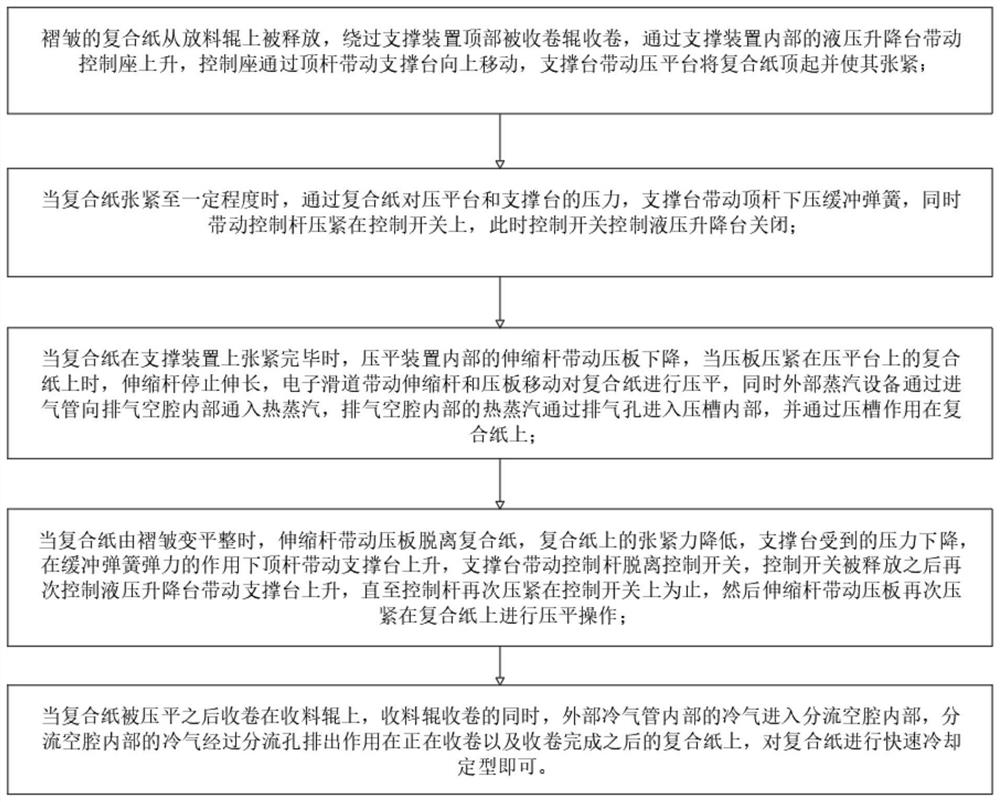

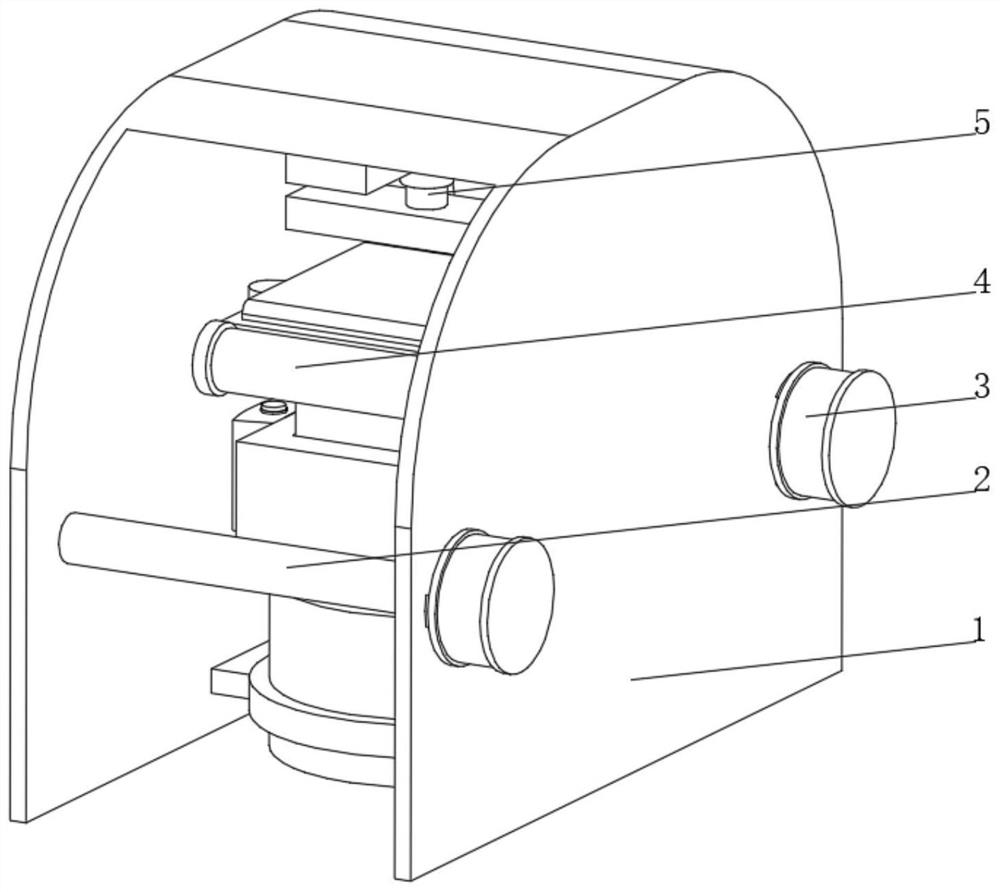

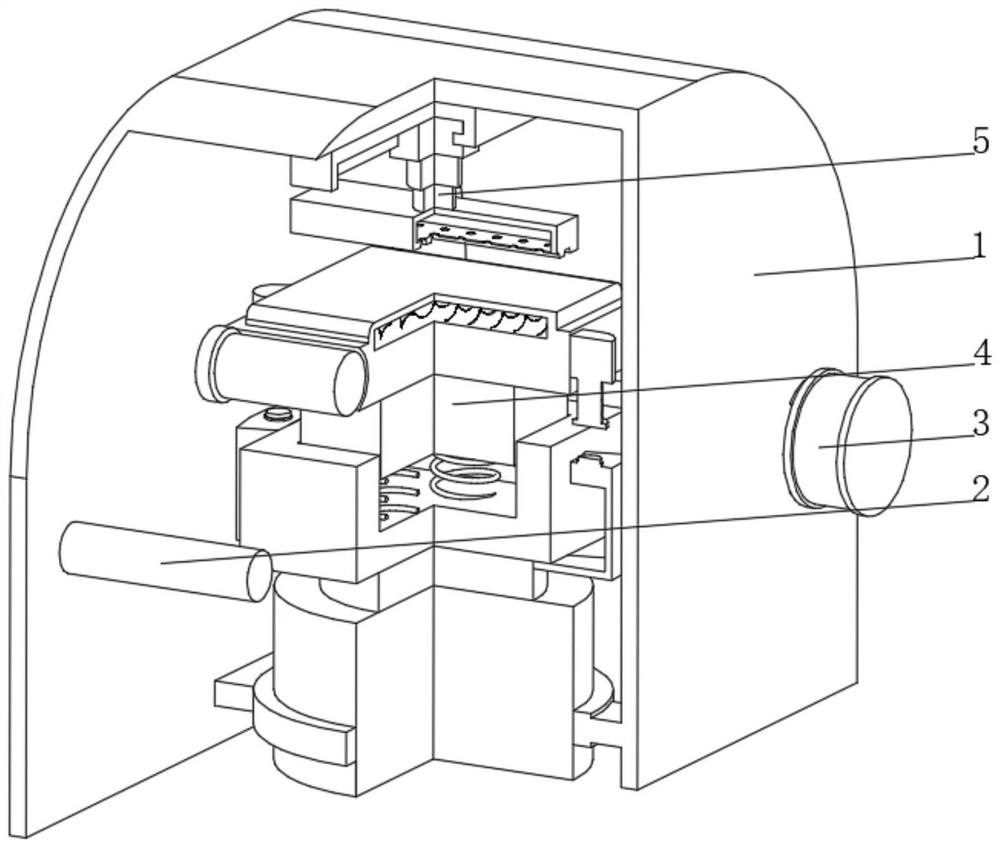

Aluminum-plated film composite paper flattening treatment equipment and treatment method

ActiveCN114193835AAvoid damageEasy to useMechanical working/deformationWebs handlingMechanical engineeringComposite material

The aluminum-plated film composite paper flattening treatment equipment specifically comprises an outer frame, one end of the inner wall of the outer frame is rotationally connected with a discharging roller, and the end, away from the discharging roller, of the inner wall of the outer frame is rotationally connected with a receiving roller and a supporting device; the supporting device is arranged in the outer frame and located between the discharging roller and the collecting roller. The flattening device is arranged at the top of the inner wall of the outer frame, and the bottom of the flattening device right faces the supporting device; the supporting device comprises a supporting table, and rotating rollers are fixedly connected to the two ends of the supporting table. According to the flattening treatment equipment and method for the aluminum-plated film composite paper, tension changes on the composite paper can be conveniently adapted, so that the flattening operation is more thorough, the flattening effect is better, water is conveniently supplemented while the composite paper is flattened, and the situation that the composite paper is prone to wrinkling due to the fact that water in the composite paper is evaporated to dryness during flattening is avoided.

Owner:淮安市富源包装材料有限公司

Aluminum forged water meter

ActiveCN105624482ANo pollution in the processIncrease brightnessMetal-working apparatusWater leakageCopper

The invention discloses an aluminum forged water meter. A shell of the water meter is manufactured through the steps that aluminum alloy is heated to 480+ / -5 DEG C and then placed in a die-forging die to be forged into the shell. The price of the whole aluminum forged water meter can be lowered by about 20%, the brightness of the water meter is improved by three times compared with that of water meters made of copper or iron or stainless steel, the density is increased, pores and water leakage are avoided, and the environment is not polluted in the forging process.

Owner:JIANGSU FUERDA MACHINERY

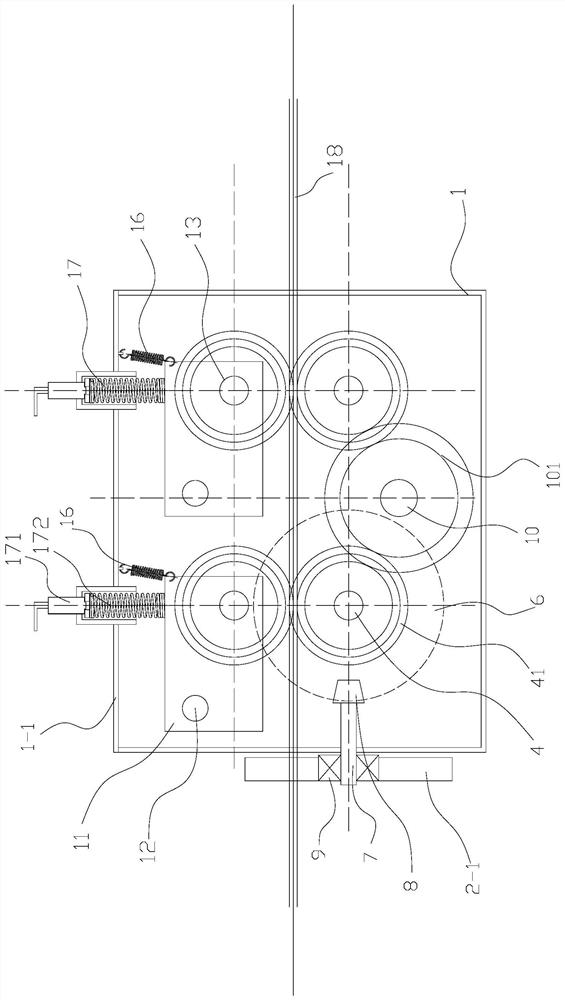

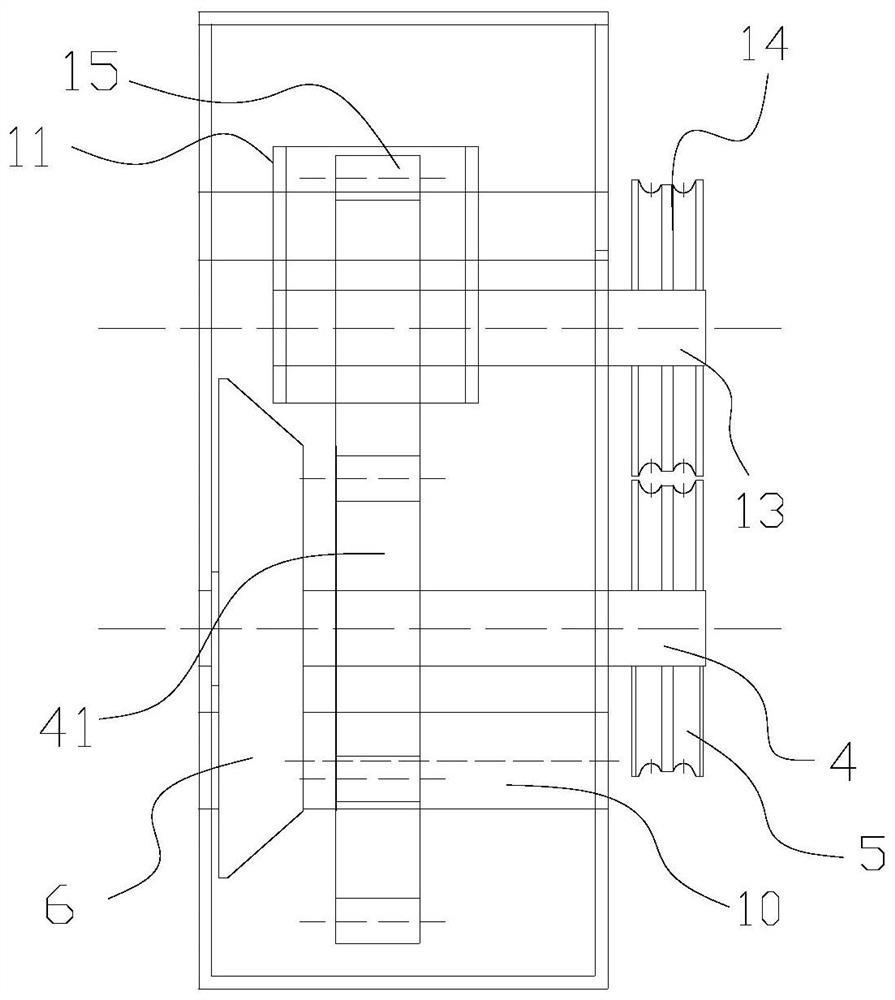

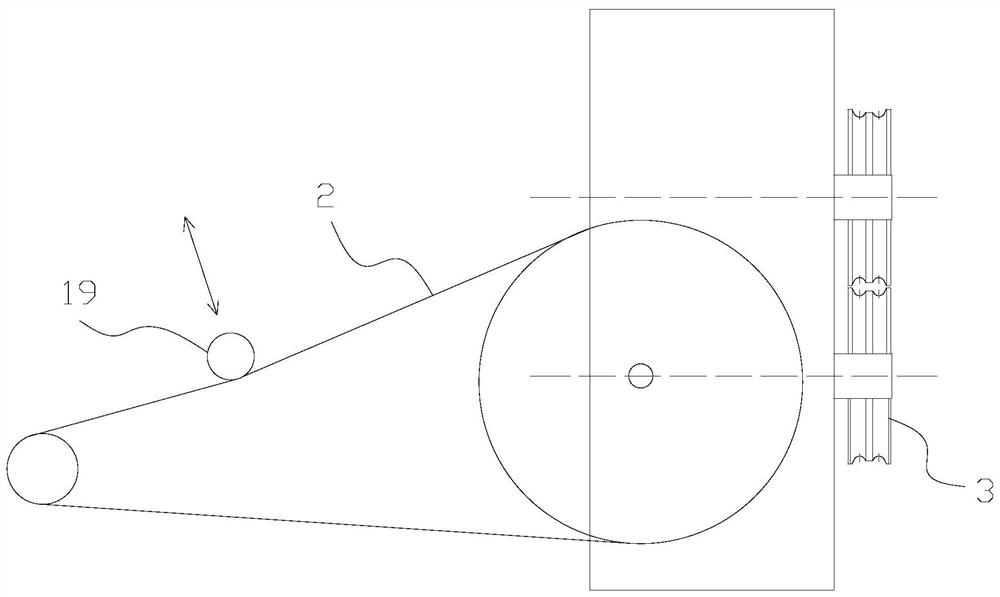

Straightening and wire feeding device of prefabricated reinforced concrete pipe reinforcement cage seam welder

The invention discloses a straightening and wire feeding device of a prefabricated reinforced concrete pipe reinforcement cage seam welder. The straightening and wire feeding device of the prefabricated reinforced concrete pipe reinforcement cage seam welder is provided, is compact in structure, organically combines wire feeding and straightening without mutual interference, and avoids secondary deformation in the effective straightening and wire feeding process. The straightening and wire feeding device comprises a case, a driving motor, a belt transmission group and a guide roller group; a tension spring is arranged on a floating box, one end of the tension spring is connected with a top cover of the case, and the other end of the tension spring is connected to the corner, away from a hinge shaft, of the top of the floating box; and a pressing mechanism is further arranged at the top of the floating box and drives the floating box to move downwards, so that a floating gear in the floating box is meshed with a main transmission gear. According to the straightening and wire feeding device, the end feeding work can be realized; and action interference does not occur between the twoworking conditions, and secondary deformation is effectively avoided.

Owner:JIANGSU JIANGYANG BUILDING MATERIAL MACHINERY

Intelligent automobile maintenance pretreatment system

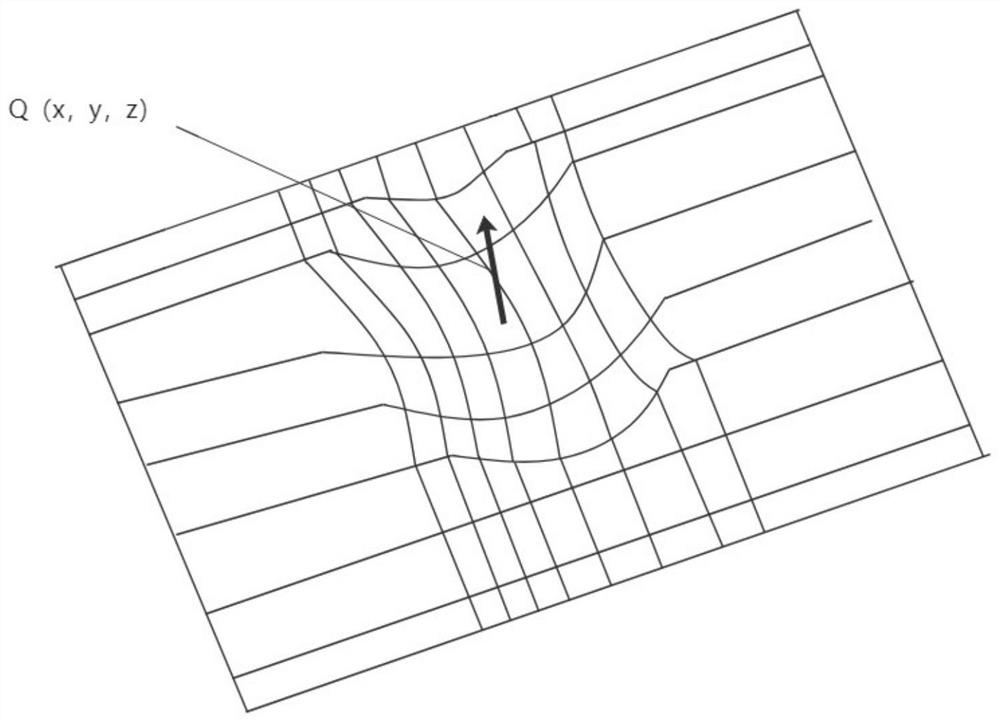

ActiveCN113000628AAvoid secondary deformationEliminate the effects ofShaping toolsTemperature controlEngineering

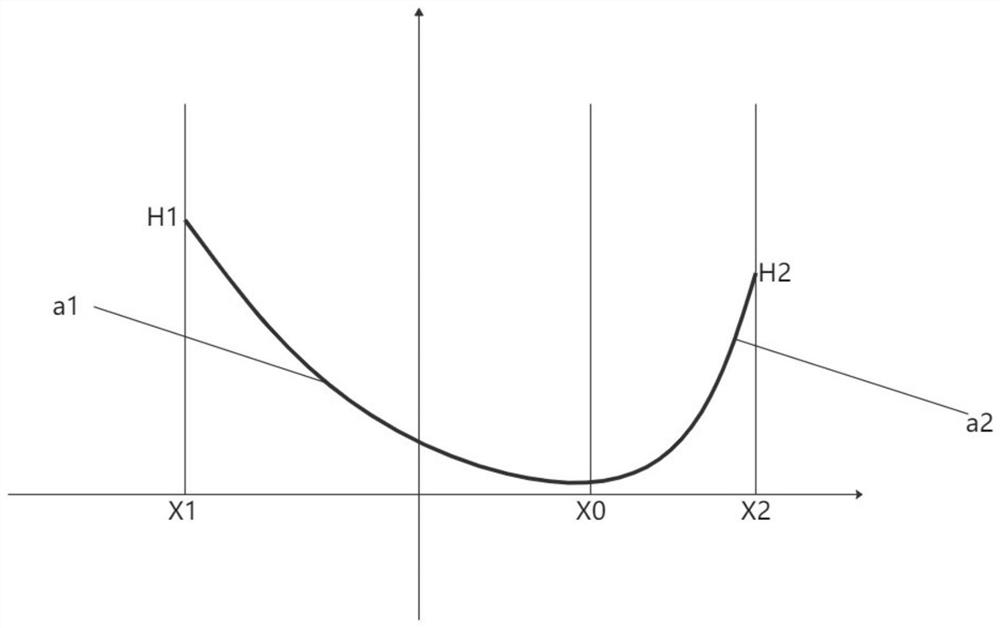

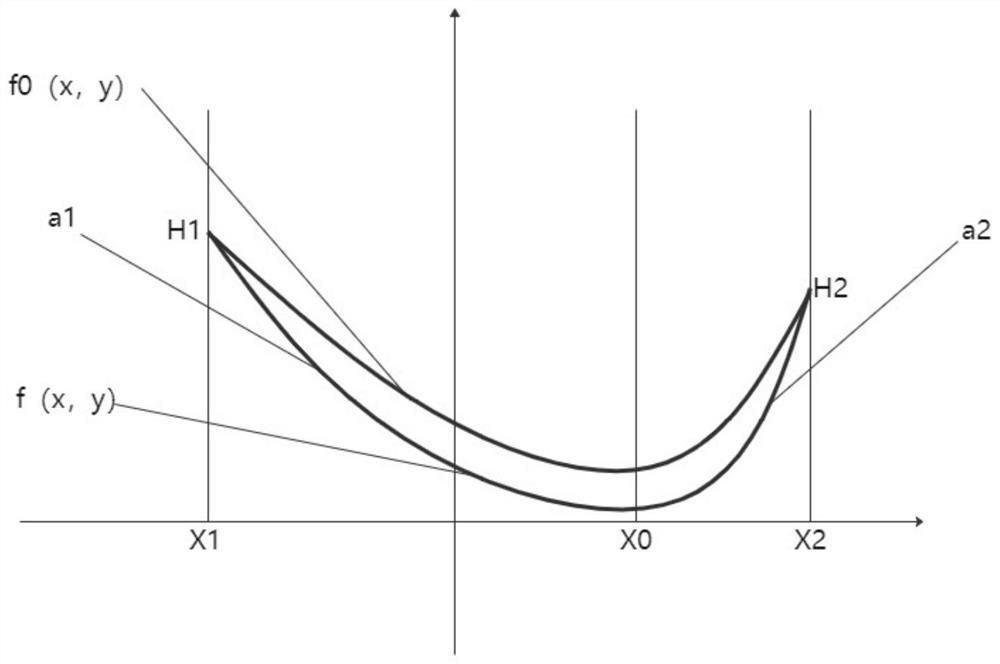

The invention relates to an intelligent automobile maintenance pretreatment system. The system is characterized in that before a sunken area is repaired, an optimal stretching angle is determined through a sunken surface contour coordinate set f(x, y, z) of a sunken position of a central control processor; when the sunken area is repaired, the central control processor determines the tensile strength and the heating temperature of an absorber according to the yield strength of the position where the sunken position is located, controls the absorber on the mechanical arm to conduct stretching, divides stretching stages, corrects the stretching direction every time the stretching stage is passed and determines an optimal stretching angle to avoid secondary deformation of the sunken position due to the improper stretching angle, meanwhile, the stretching direction is corrected according to each stretching stage, the influence caused by accidental deformation in the stretching process is eliminated, the stretching direction is adjusted in real time, and the final deformation recovery effect is ensured.

Owner:北京鹏龙星徽汽车销售服务有限公司工会

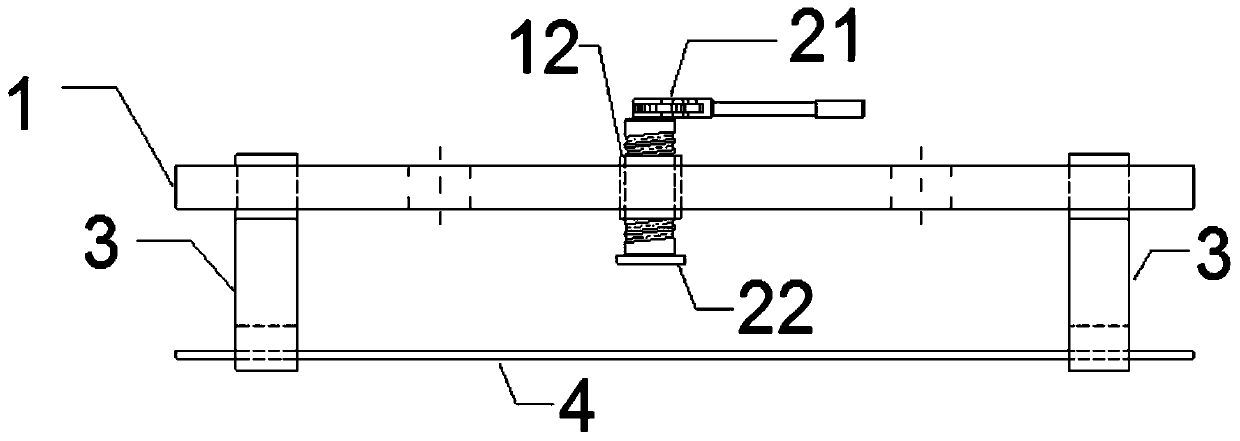

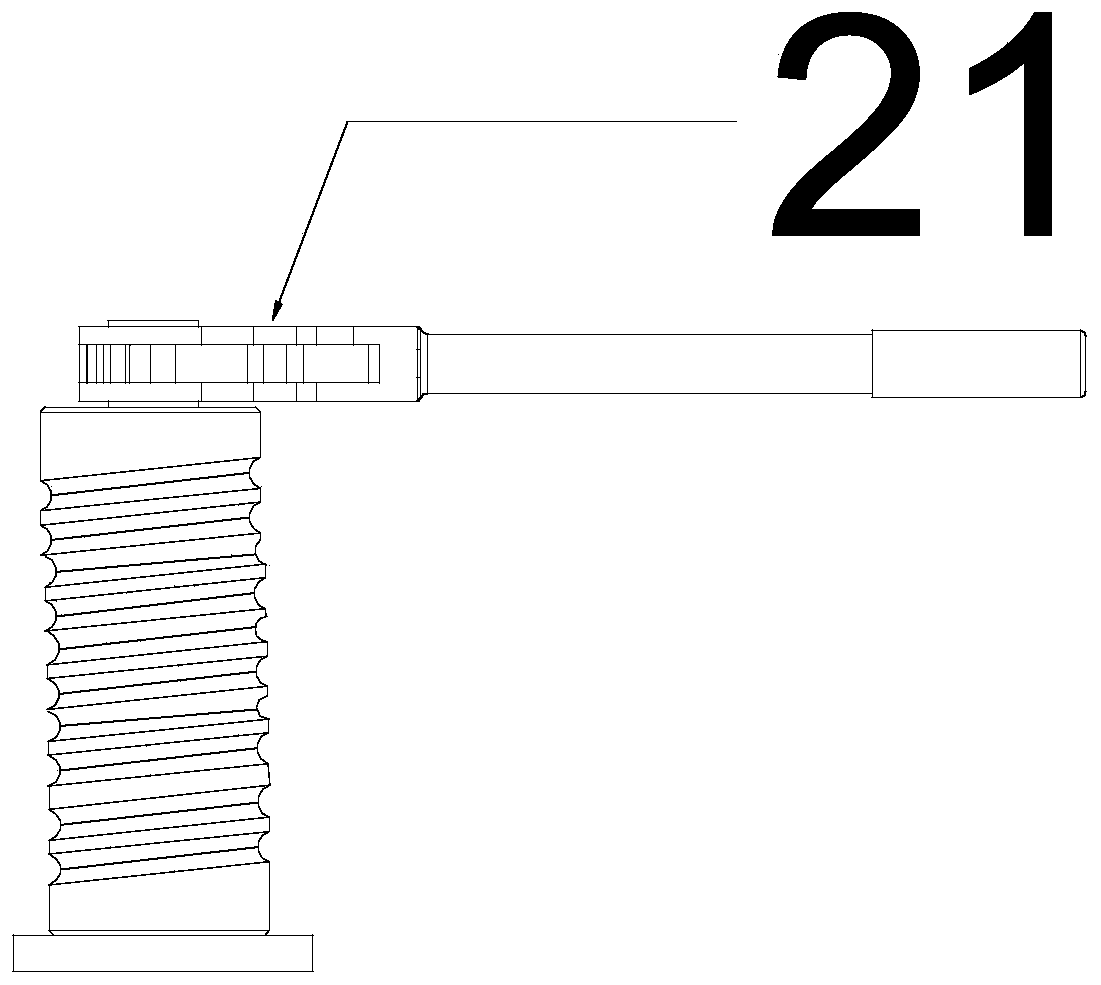

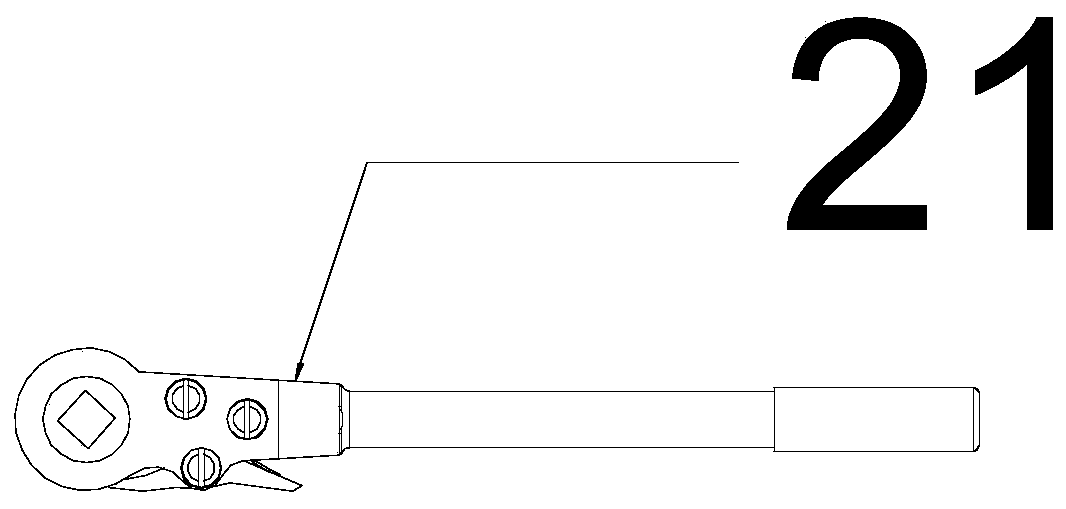

Adjustable bending straightening tool for power transmission line splicing sleeve

The invention relates to an adjustable bending straightening tool for a power transmission line splicing sleeve and belongs to the technical field of power transmission line splicing sleeve straightening. The tool comprises a straightening cross beam, a straightening force-bearing screw rod, straightening force-bearing hooks and a limiting rod; a plurality of straightening force-bearing hook fixing screw holes are uniformly distributed in the straightening cross beam; a force-bearing screw rod nut is mounted on the straightening cross beam; the straightening force-bearing screw rod comprises aratchet wrench, a force-bearing screw rod and a base; each straightening force-bearing hook comprises a fixing screw rod matched with a straightening force-bearing hook fixing screw hole; each straightening force-bearing hook further comprises a fixing hook; a limiting rod hole matched with the limiting rod in size is formed in each fixing hook; and each fixing hook is provided with a limiting rod locking bolt. The tool is adjustable; the installation position of the straightening force bearing hook can be adjusted, so that the tool can adapt to the straightening of deformed splicing sleeveswith different lengths and different bent parts. The straightening tool is light, universal and easy to operate; and the straightening tool can be used for ground splicing sleeve bending straighteningand can also be used for high-altitude straightening; and the straightening tool is easy to apply and popularize.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

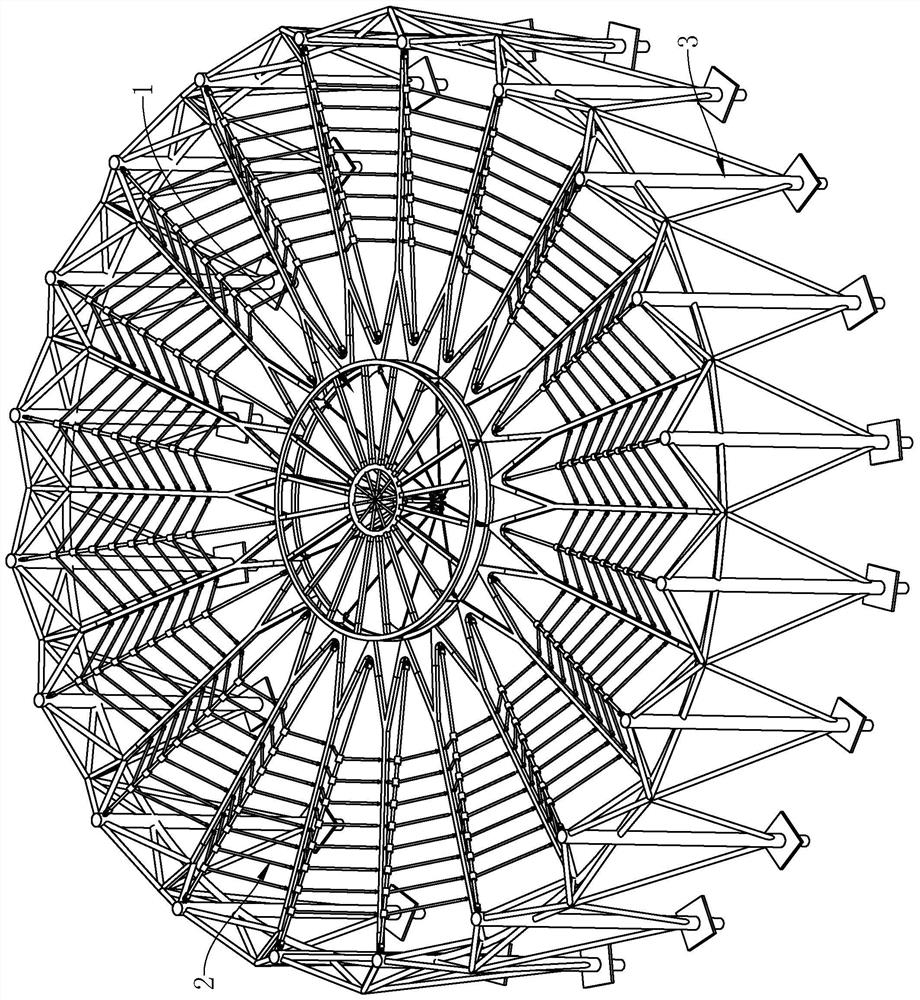

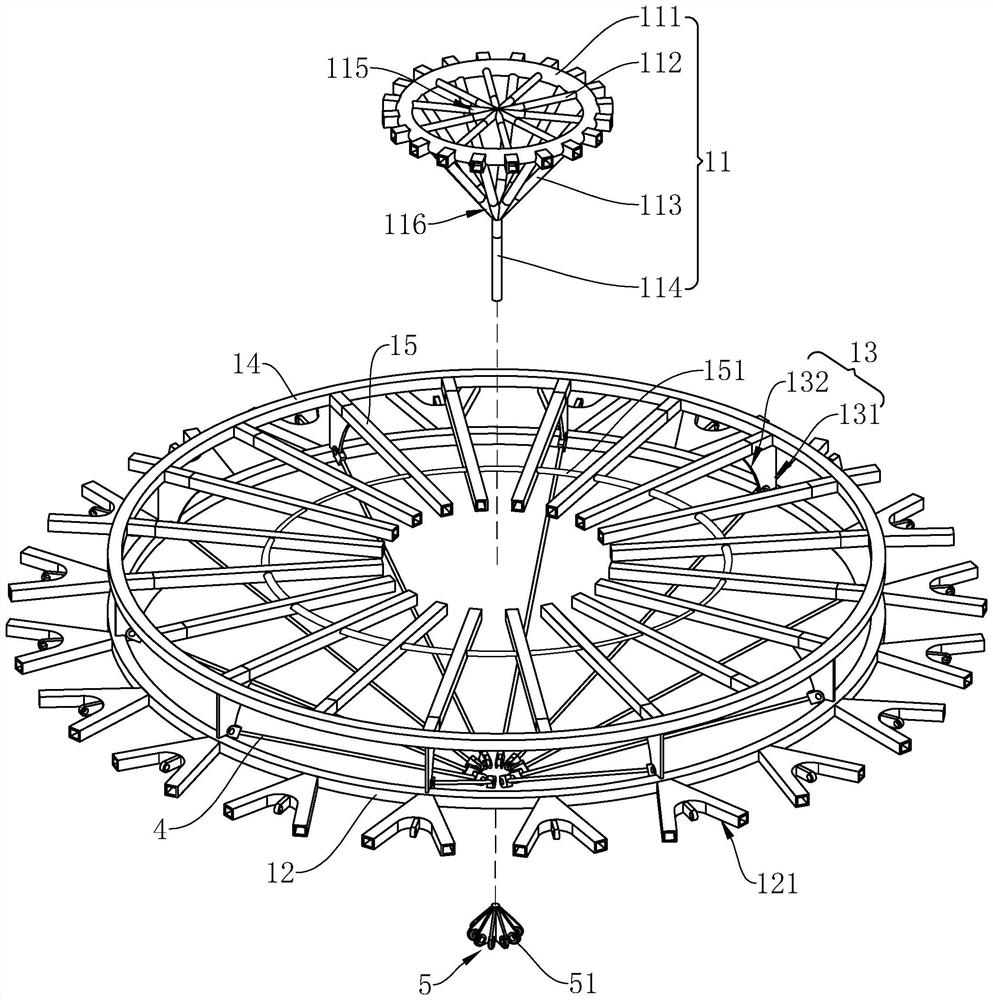

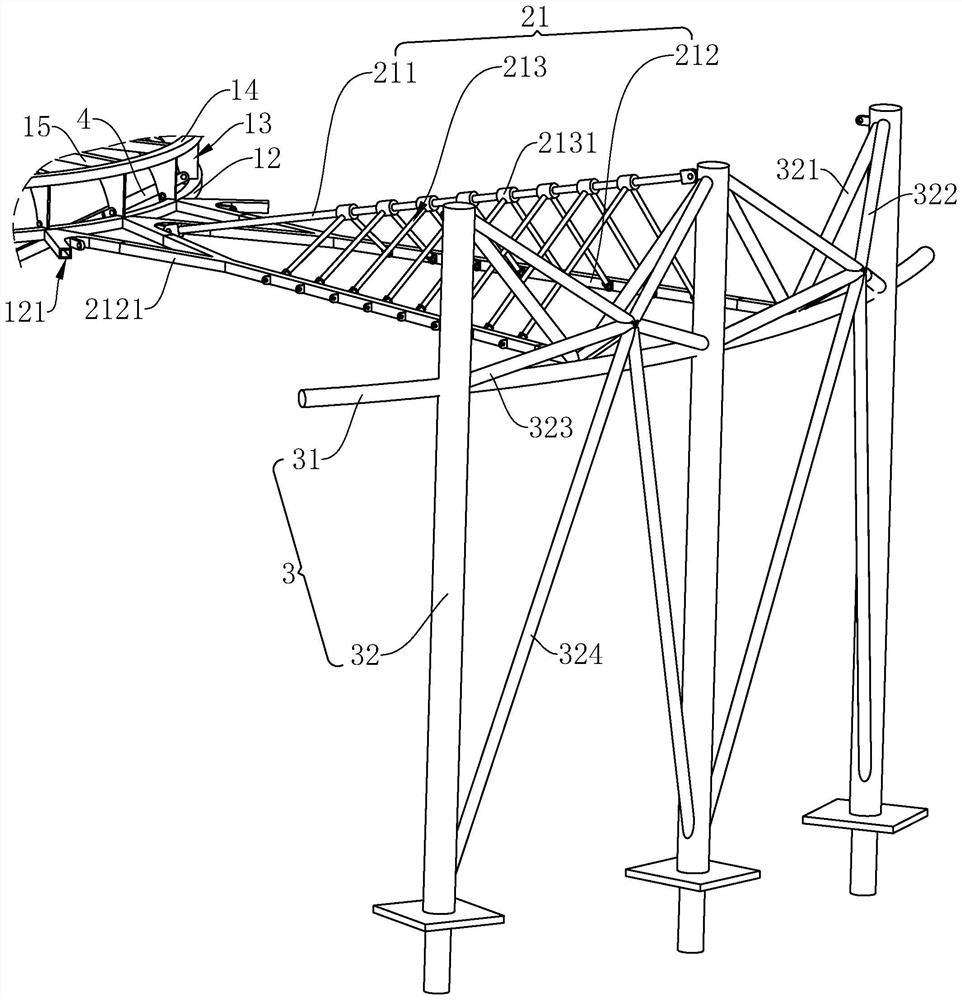

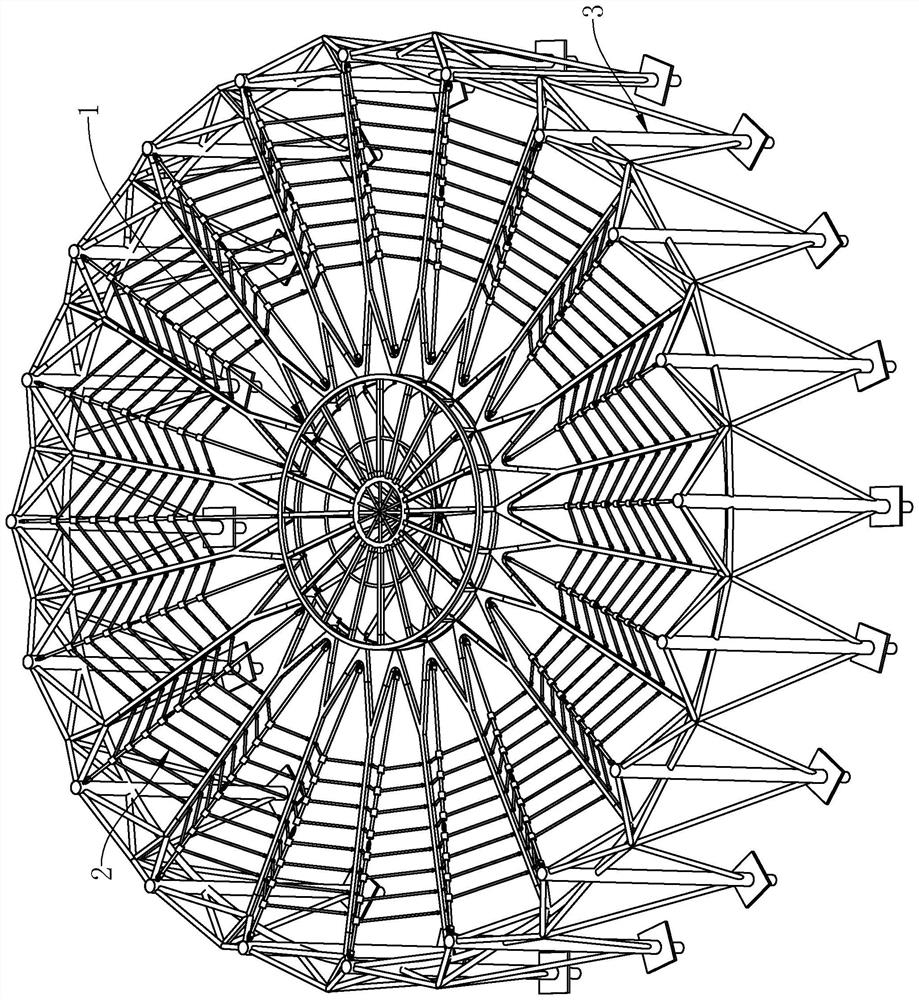

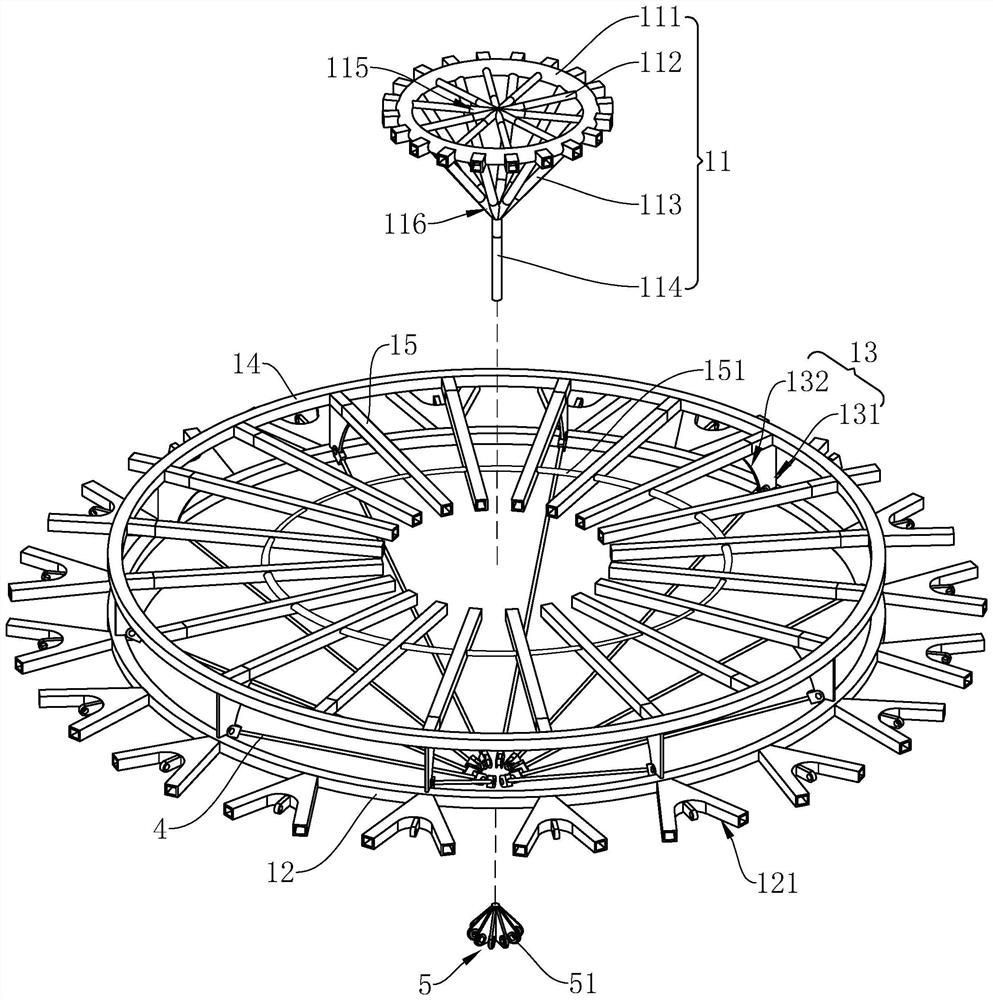

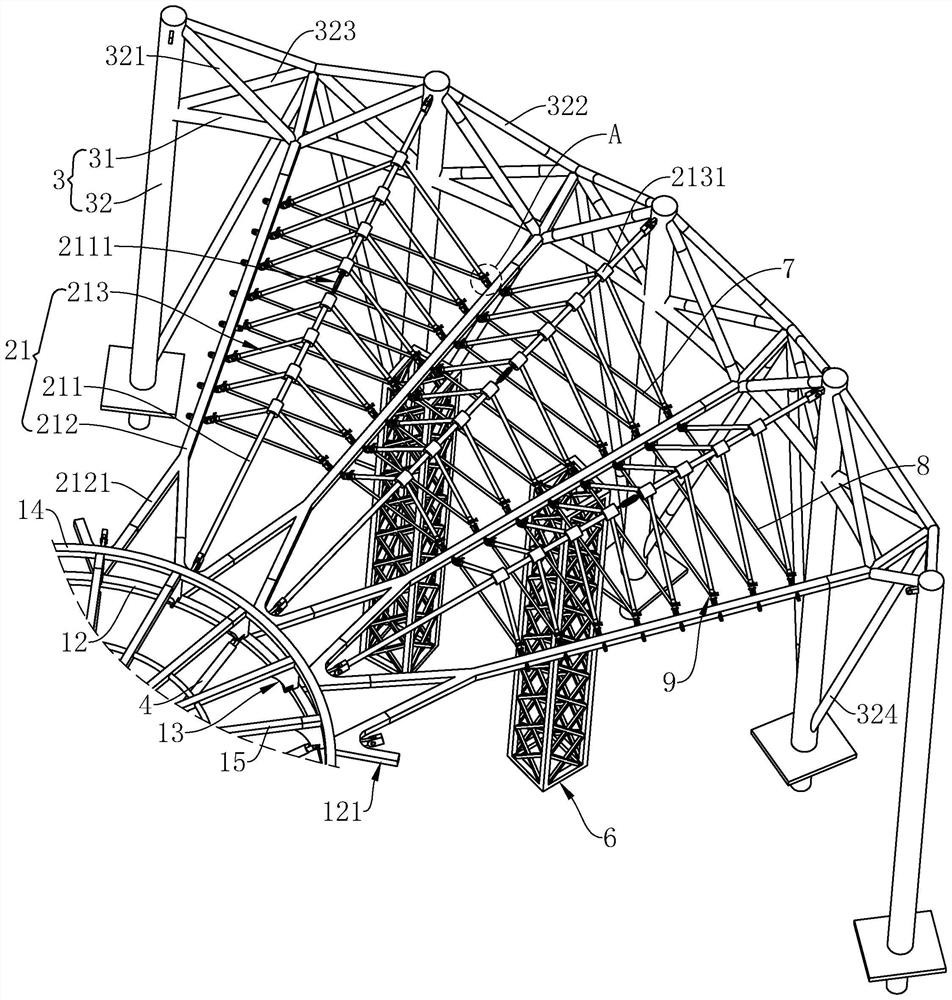

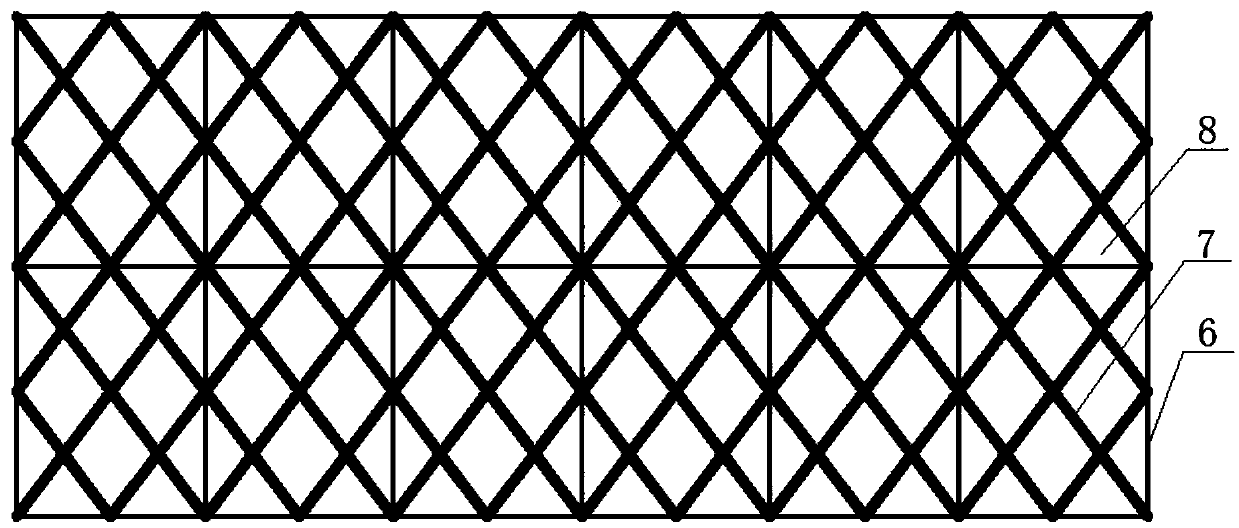

Double-ring inhaul cable large-span steel structure

PendingCN114703970AImprove stiffness performanceStrong rigidityBuilding constructionsStructural deformationClassical mechanics

The invention relates to the technical field of large-span space buildings, in particular to a double-ring inhaul cable large-span steel structure which comprises an inner ring steel structure system, an inhaul cable connecting structure system between an inner ring and an outer ring and an outer ring steel structure system. The inhaul cable connecting structure system between the inner ring and the outer ring is connected with the inner ring steel structure system and the outer ring steel structure system. The outer ring steel structure system can abut against the ground to support the inner ring steel structure system and the inner and outer ring inhaul cable connecting structure system. The inhaul cable connecting structure system between the inner ring and the outer ring comprises a plurality of three-dimensional fan-shaped units which are connected with one another, each fan-shaped unit comprises at least one bearing cable, and the two ends of each bearing cable are connected with the inner ring steel structure system and the outer ring steel structure system correspondingly. Structural deformation of the large-span steel structure is effectively controlled, and after the temporary supporting columns are dismantled, the probability of secondary deformation of the large-span steel structure is reduced, and the possibility that an existing structure part generates harmful internal force is reduced.

Owner:SHANGHAI CONSTR NO 1 GRP

Blow-drying and setting equipment for clothing processing and use method thereof

ActiveCN113564858AAvoid secondary deformationShorten the timeHeating/cooling textile fabricsEngineeringProcess engineering

The invention relates to the field of garment production, and particularly discloses blow-drying and setting equipment for garment processing and a use method thereof. The blow-drying and setting equipment comprises an operation table, an air heater, a hot air conveying pipeline and a hot air cover; the air heater communicates with the hot air cover through the hot air conveying pipeline, and the hot air cover is arranged on the operation table; the blow-drying and setting equipment further comprises a steam generator, a steam conveying pipeline, a clothes ironing table and a steam spray head; the steam generator is communicated with the steam spray head through the steam conveying pipeline; the steam spray head is fixedly connected into the hot air cover; the clothes ironing table is movably arranged below the steam spray head; and the table top of the clothes ironing table corresponds to a panel of the steam spray head. According to the structure, when clothes are processed, ironing and drying can be integrated, the clothes can be quickly blow-dried and set, the process is simplified, the working efficiency is improved, and the processing cost is reduced.

Owner:合肥兴际服饰有限公司

Controllable nitrogen cylinder capable of achieving delayed return stroke

The invention belongs to the technical field of metal stamping die production, and particularly relates to a controllable nitrogen cylinder capable of achieving delayed return stroke. Storage of high-pressure nitrogen and opening and closing and direction of high-pressure nitrogen flow are controlled through electric signals of electromagnetic valves, and the controllable nitrogen cylinder capable of achieving delayed return stroke is composed of two one-way valves, the three electromagnetic valves, a nitrogen cylinder body, an air storage cylinder and other devices. In the stamping forming process, during the return stroke of an upper die body of a die, after the upper die body and a workpiece reach a safe distance, a control signal is sent to the electromagnetic valves, and thus the return stroke of a piston of the controllable nitrogen cylinder is delayed. In this way, the collision damage of secondary deformation of a stamped part caused by the fact that a traditional common nitrogen cylinder cannot delay the return stroke is avoided.

Owner:JILIN UNIV +1

Eyelet gasket and eyelet fastener thereof

The invention relates to an eyelet gasket and an eyelet fastener thereof. The eyelet gasket is provided with a gasket made of a plastic material and a sleeve piece made of a rigid material, the eyeletgasket is connected to a riveting piece; the eyelet gasket and the riveting piece are clamped and fixed on an object together; the gasket can deform in an extrusion state; the sleeve piece is provided with an annular baffle wall; an accommodating space for accommodating the gasket is defined by the baffle wall; an opening with caliber smaller than that of the gasket is formed at one end; the baffle wall deforms so that the caliber of the opening can be smaller than that of the gasket. A part of the gasket is positioned in the accommodating space, and the rest part of the gasket protrudes outof the opening to be in contact with the object, so that the gasket is in contact with the object to prevent the eyelet gasket from moving on the surface of the object, the riveting piece can be quickly mounted on the eyelet gasket to improve the production efficiency, and meanwhile, a base can be prevented from directly touching the object to cut the object.

Owner:邱庆祝

Aluminum Forged Water Meter

ActiveCN105624482BNo pollution in the processIncrease brightnessMetal-working apparatusWater leakagePhysical chemistry

The invention discloses an aluminum forged water meter. A shell of the water meter is manufactured through the steps that aluminum alloy is heated to 480+ / -5 DEG C and then placed in a die-forging die to be forged into the shell. The price of the whole aluminum forged water meter can be lowered by about 20%, the brightness of the water meter is improved by three times compared with that of water meters made of copper or iron or stainless steel, the density is increased, pores and water leakage are avoided, and the environment is not polluted in the forging process.

Owner:JIANGSU FUERDA MACHINERY

Loudspeaker voice coil shaping tooling and shaping process

ActiveCN103596115BAvoid secondary deformationQuality assuranceElectrical transducersEngineeringBlock match

Owner:BESTAR HLDG

Cable replacing method for double-ring inhaul cable large-span steel structure

PendingCN114776063AReduce the impactReduce internal force changesBuilding repairsClassical mechanicsEngineering

The invention relates to the technical field of large-span space buildings, in particular to a double-ring inhaul cable large-span steel structure cable replacement method which comprises the following steps that S1, the position for replacing a bearing cable is determined; s2, a main transverse supporting rod is arranged at the bottom of the splayed support connected with the bearing cable needing to be replaced, and the main transverse supporting rod and the splayed support form a triangular structure; s3, a temporary jig frame support is arranged at the bottom of the connecting main beam at the position where the bearing cable is replaced; s4, the old load-bearing cable is dismantled; s5, a new bearing cable is installed; s6, the new bearing cable is connected with the splayed support; s7, the new bearing cable is tensioned till the supporting internal force of the temporary jig frame is zero; s8, the temporary jig frame supports, the main transverse supporting rods and the auxiliary transverse supporting rods are dismantled; and S9, finely adjusting the internal force of the new bearing cable to enable the internal force of the new bearing cable to be equal to the internal force of the old bearing cable. In the cable replacement process, the internal force change and deformation, caused by the annular internal force of the inhaul cable connecting structure system between the inner ring and the outer ring, of the structure of the cable replacement area can be reduced.

Owner:SHANGHAI CONSTR NO 1 GRP

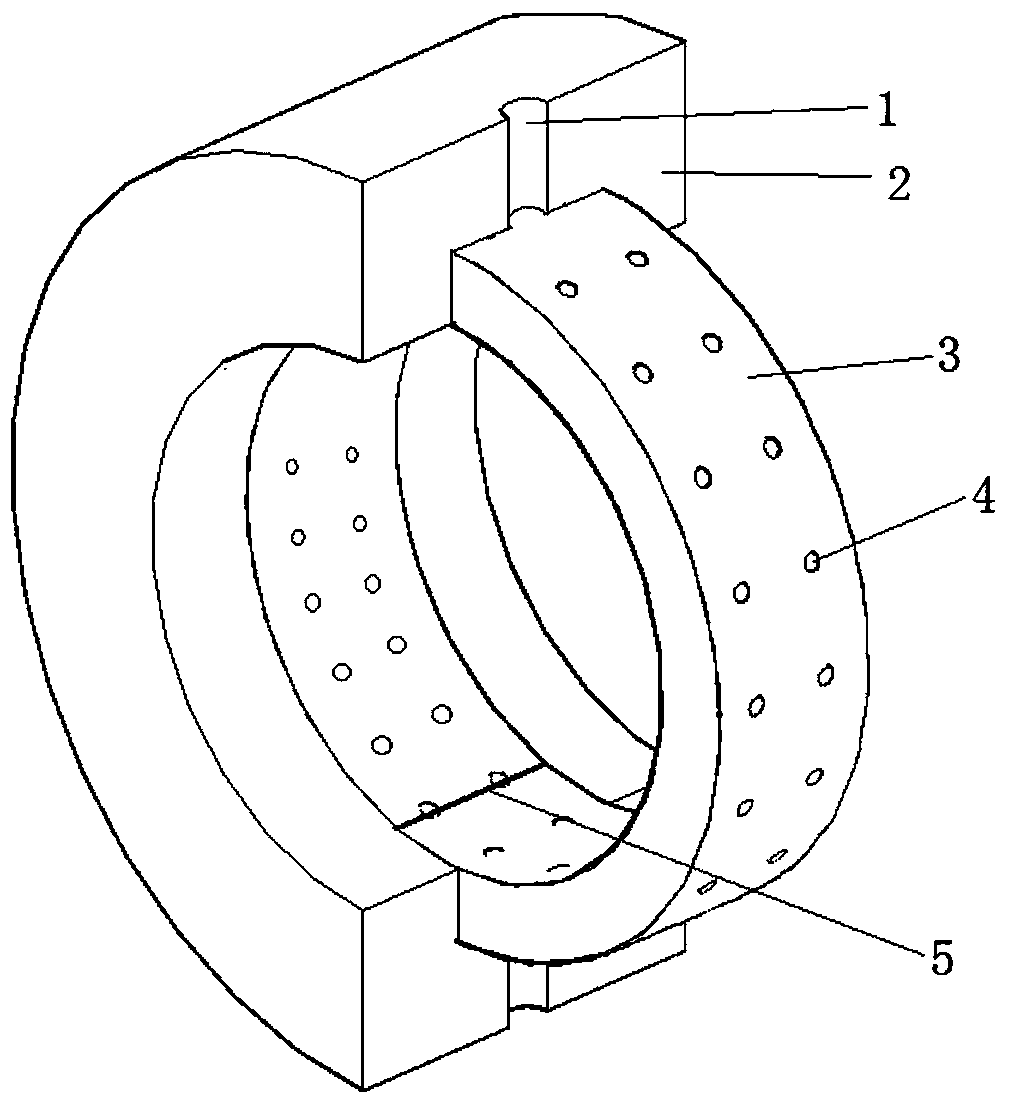

Air bearing and bearing matrix thereof and manufacturing method

The invention relates to the field of sliding bearings, in particular to an air bearing and a bearing matrix thereof and a manufacturing method. The air bearing comprises a shell and the bearing matrix arranged in the shell, the bearing matrix is manufactured in the mode that three-dimensionally braided plate block materials are bent and deformed and then connected end-to-end, the butt-joint surfaces are fixed through welding, and multiple strength strengthening points which are arranged at intervals in the circumferential direction and used for strengthening the strength of the bearing matrixare arranged on the circumference of the bearing matrix through a local heat treatment method. A large quantity of pores exist among metal wires in the three-dimensionally braided structure, influences of cutting machining on the material porosity can be avoided through overall sequential braided molding and welding after limiting and deforming, and meanwhile influences on the stability of the bearing matrix of the air bearing is avoided.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com