Welding deformation control method based on high-energy ultrasonic treatment

A technology of welding deformation and control method, which is applied in the direction of welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing material properties, surface micro-cracks, and damage to thin-walled components, so as to improve the processing effect and efficiency, and promote microscopic Effect of plastic deformation and elimination of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

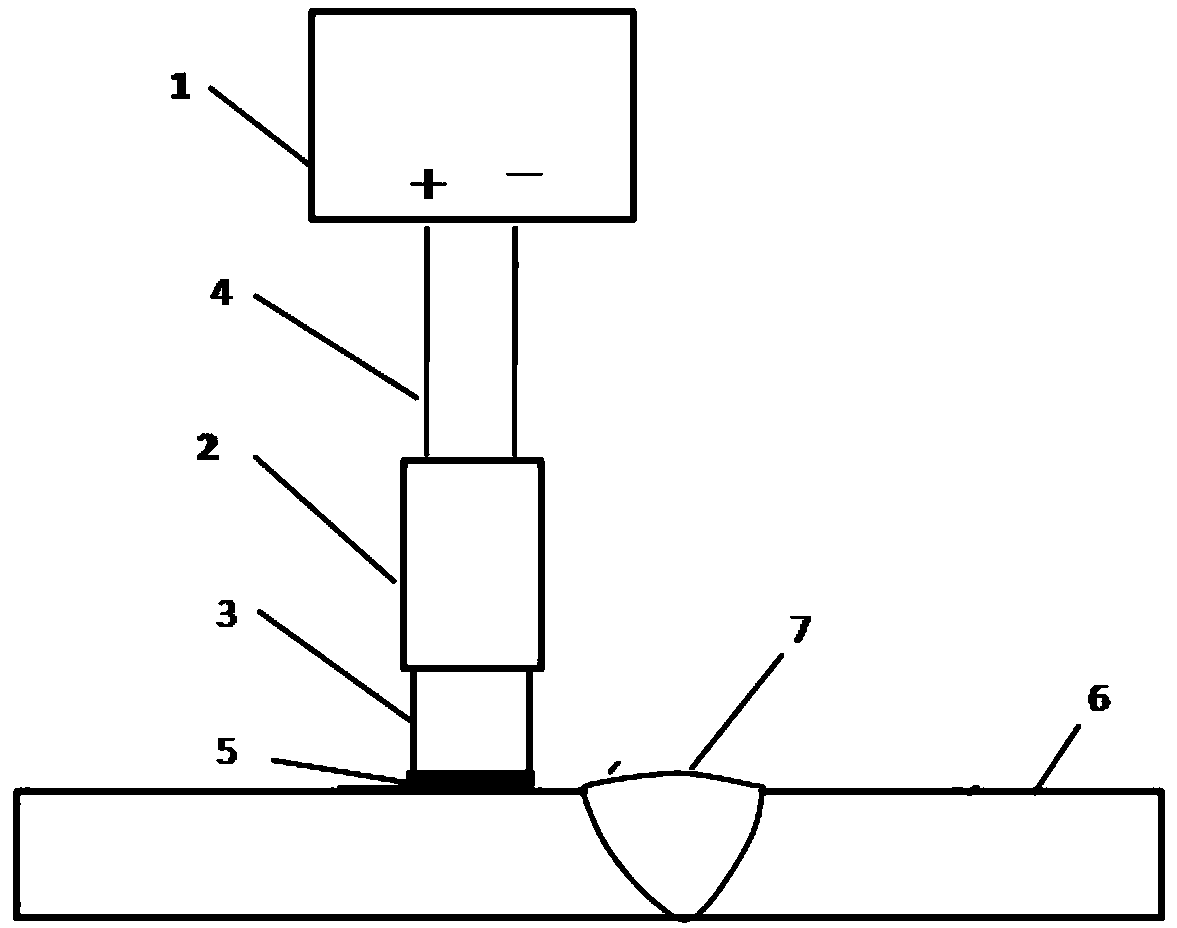

[0028] A welding deformation control method based on high-energy ultrasonic treatment, using the method to perform high-energy ultrasonic control treatment of welding deformation during lap welding of 2219 aluminum alloy test plates of 300mm×150mm×2mm, the steps of the method are as follows:

[0029] (1) arrange the transducer

[0030] Such as figure 1 As shown, four cylindrical ultrasonic transducers 2 with a diameter of 70 mm are used, and butter is evenly spread on the end of the excitation head 3 as the coupling agent 5, and then the ultrasonic transducers are evenly distributed along the length direction of the weld of the test plate 6 on the At a position 20mm from one side of the center of the weld, use a compression tool to press the transducer on the welding test plate, or embed the transducer in the welding tool.

[0031] (2) Connect the transducer

[0032] The four transducers are connected by a multi-channel ultrasonic power supply 1 through an ultrasonic transmi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com