Air bearing and bearing matrix thereof and manufacturing method

A technology for air bearings and manufacturing methods, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as the influence of bearing work stability, changes in porosity and air permeability, and clogging of processed surfaces, and achieve increased welding area, preventing secondary deformation, and strengthening the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

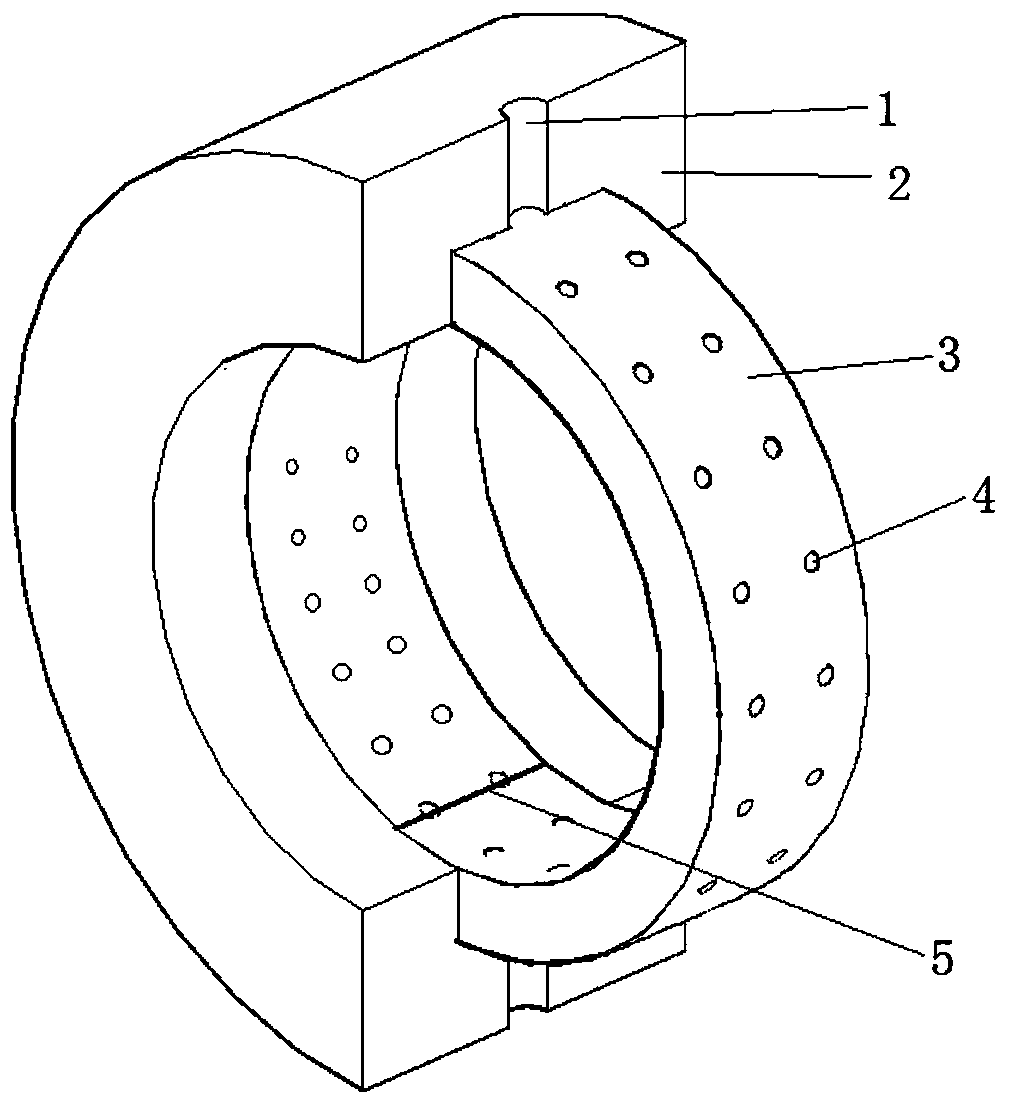

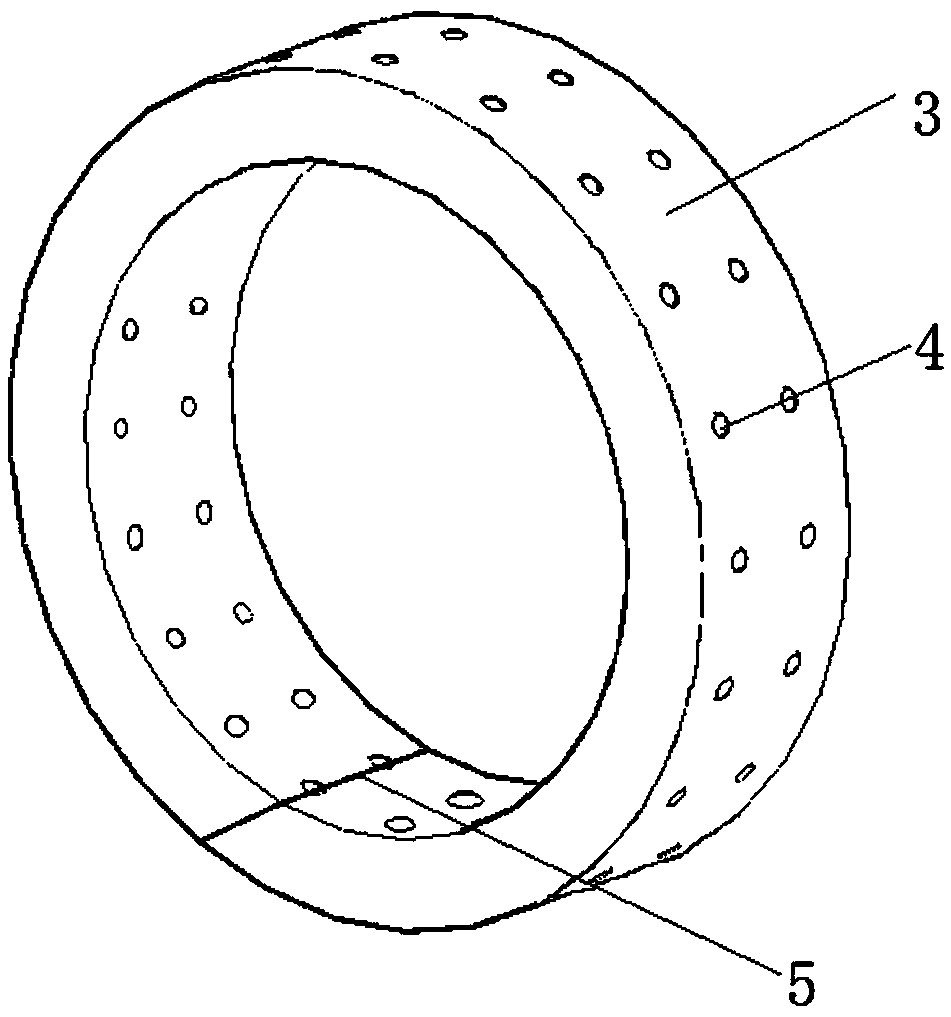

[0034] Embodiment 1 of the air bearing of the present invention, such as figure 2 and image 3 As shown, it includes a housing 2 and a bearing base 3 arranged in the housing 2 .

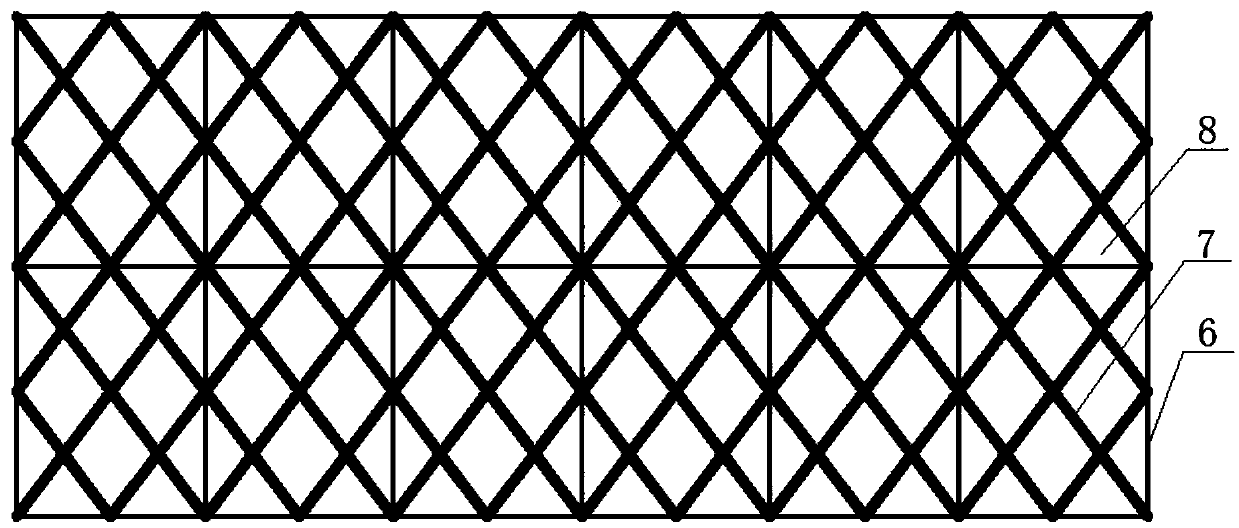

[0035] The bearing matrix 3 is first made of metal wire as a raw material through a three-dimensional weaving process to make a plate material, and then the plate material is bent and deformed and then butted end-to-end. There are a large number of pores between the metal wires in the three-dimensional braided structure, and these pores are regularly arranged on the plate material, which can ensure the porosity and air permeability requirements of the air bearing. Tell me more.

[0036] The two ends of the produced plate material are butt ends, and the end faces of the butt ends are butt surface 5, and the butt surface 5 is an inclined surface that can be joine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com