Monolithic catalyst having macroporous cerium manganese oxide skeleton and preparation method thereof

A technology of oxides and catalysts, which is applied in the field of directly growing three-dimensional ordered macroporous cerium manganese oxide frameworks on the surface of cordierite DPF, which can solve the problems of increasing back pressure and reducing the ignition temperature of soot particles, which is not easy to achieve Shedding, the method is practical and effective, and the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

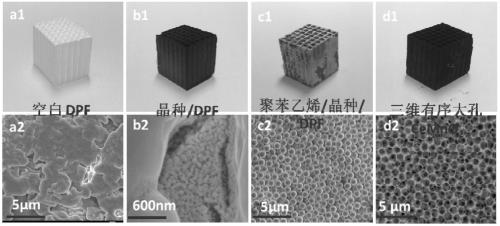

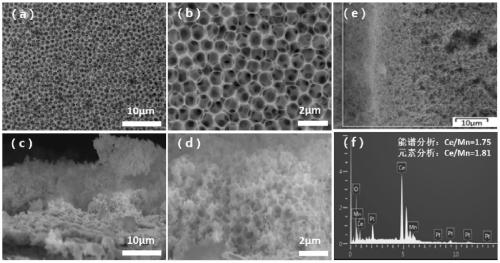

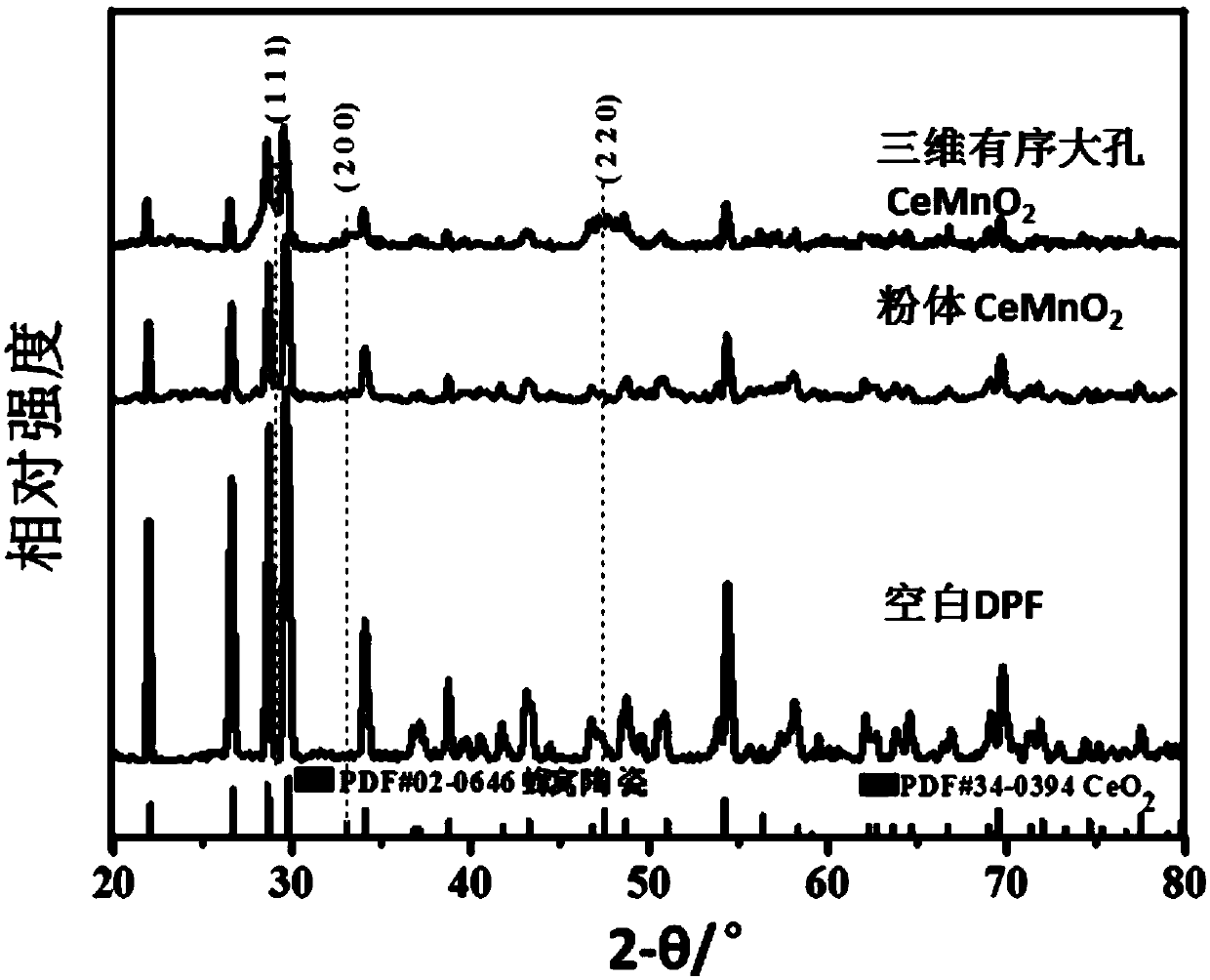

[0051] This embodiment provides a three-dimensional ordered macroporous cerium manganese oxide Ce 0.6 mn 0.4 o 2 (3DOM CeMnO 2 ) skeleton growth to the method for cordierite DPF surface, concrete steps are as follows:

[0052] 1. Washing of cordierite DPF carrier

[0053] Cut a commercial cordierite DPF (square channel 3mm×3mm) into a cube-shaped sample with a size of 6channel*7channel*1cm, and then ultrasonically clean it with distilled water, n-hexane, acetone, and ethanol in sequence, and the cleaning time of each solvent is 10min ; Then put the cleaned cordierite DPF carrier into an oven at 80°C for 12 hours to dry to obtain a dry and clean cordierite DPF substrate for use;

[0054] 2. Preparation of colloidal solution of cerium manganese oxide precursor

[0055] Dissolve 15mM cerium nitrate, 10mM manganese nitrate, and 25mM citric acid monohydrate in 50mL ethanol solvent, ultrasonically dissolve and disperse it completely, and then stir continuously at room temperatu...

Embodiment 2

[0072] In order to further evaluate the catalytic activity of the catalyst of the present invention, the present invention uses soot particulate matter low-temperature catalytic oxidation activity evaluation experiment for evaluation.

[0073] The catalytic oxidation activity evaluation experiment of soot particles (Soot) was carried out in a fixed-bed reactor simulated by a quartz tube with a diameter of 23mm. 800mg of monolithic catalyst (about 80mg of cerium manganese oxide active component and the quality of soot is 8mg) is loaded in a quartz tube, the quartz tube is placed in a tube furnace, and the temperature is programmed to rise. The temperature rise program is: from room temperature to Heat to 200°C and keep it warm for 30min at a heating rate of 10°C / min, then raise the temperature from 200°C to 700°C at a heating rate of 2°C / min, then keep at 700°C for 30min. The total gas flow rate is 50mL / min, O 2 10% of the total traffic, the rest is N 2 . Finally, the tail g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com