Automatic basketing method and equipment for sleeving-shrinkage casings

A technology for casings and baskets, which is applied in the directions of automatic packaging control, packaging, and lifting devices, which can solve the problems of reducing the effective storage space of the material frame and complex structure, so as to increase the effective storage space, simplify the equipment structure, and reduce the coordination degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

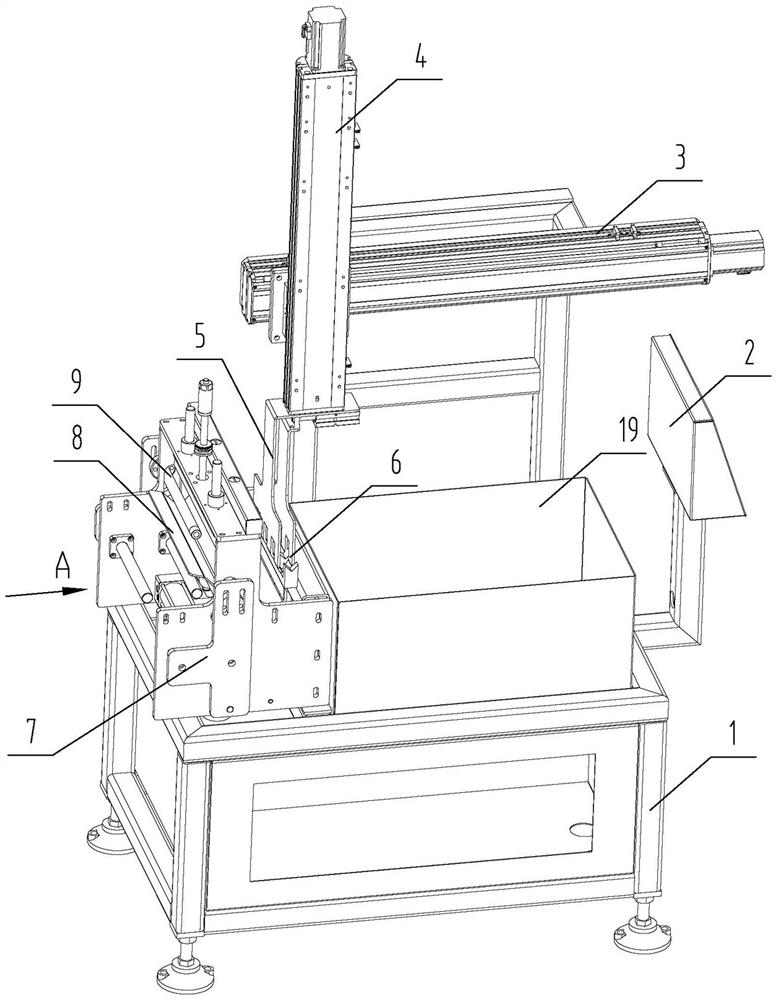

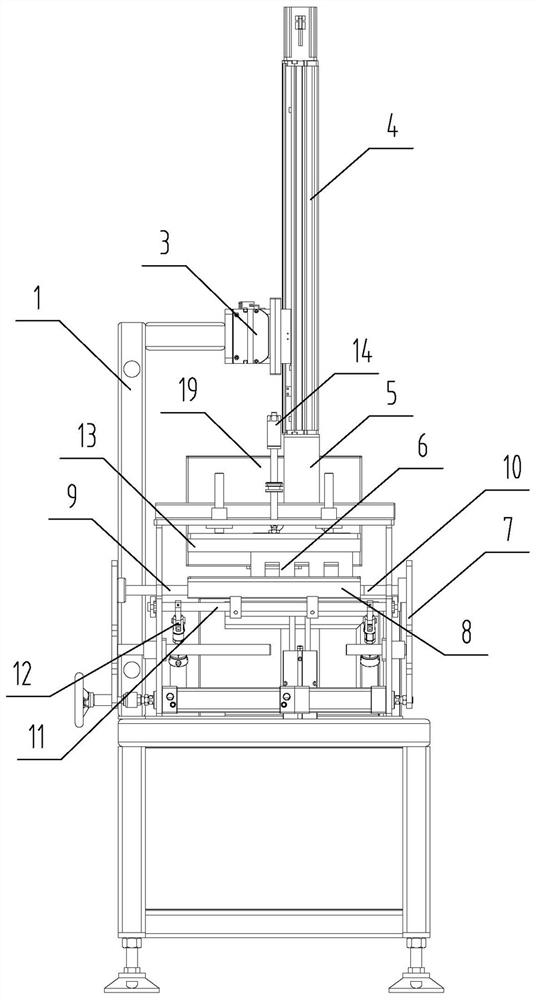

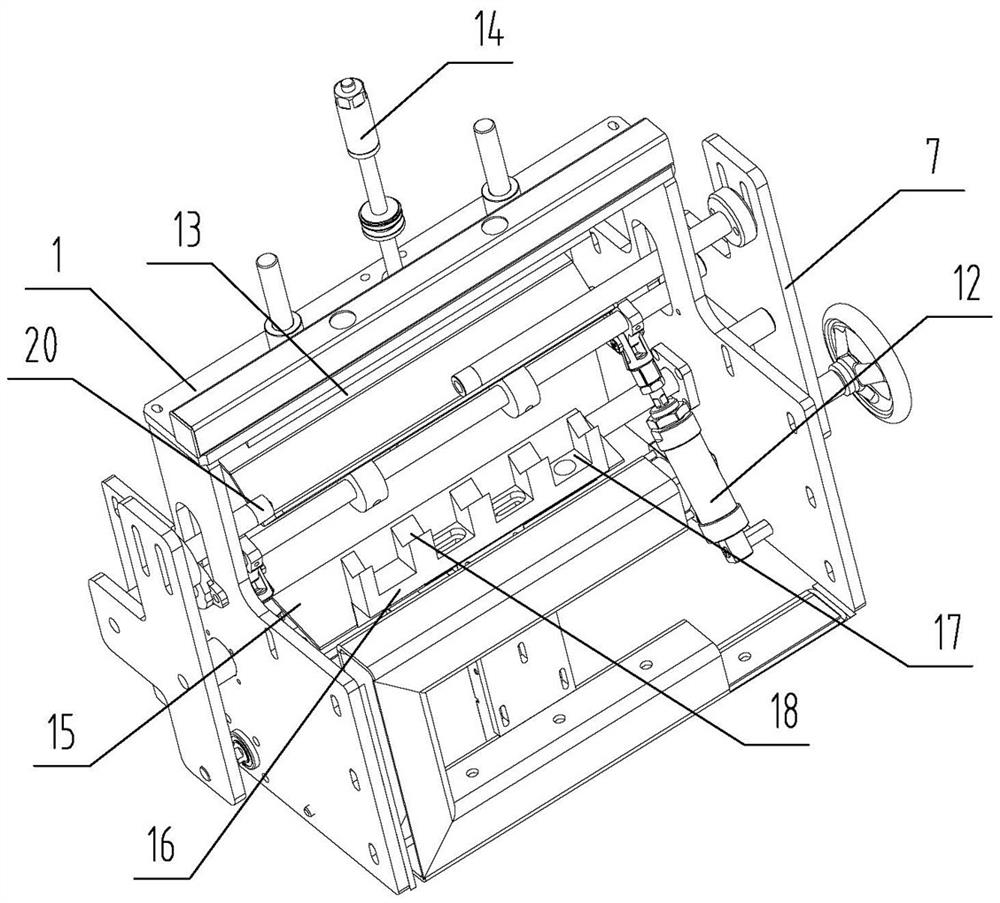

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] In the present invention, refer to the moving direction of the casing from front to back as the longitudinal direction, that is, the entry end of the casing is defined as the front end, and the end where the basket 19 is located is defined as the rear end accordingly, and the direction perpendicular to the longitudinal direction in the horizontal plane is defined as Horizontal: define the end close to the ground as the lower end or the bottom end, and correspondingly define the other end away from the ground as the upper end or the top end.

[0038] The gist of the present invention is: a slot is provided on the top wall of the lifting platform, and the automatic basket loading of casing shrink tubes is realized through the following steps:

[0039] (1) Setting: The casing shrink tube is positioned horizontally and then transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com