Patents

Literature

72results about How to "Guarantee the quality of plating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

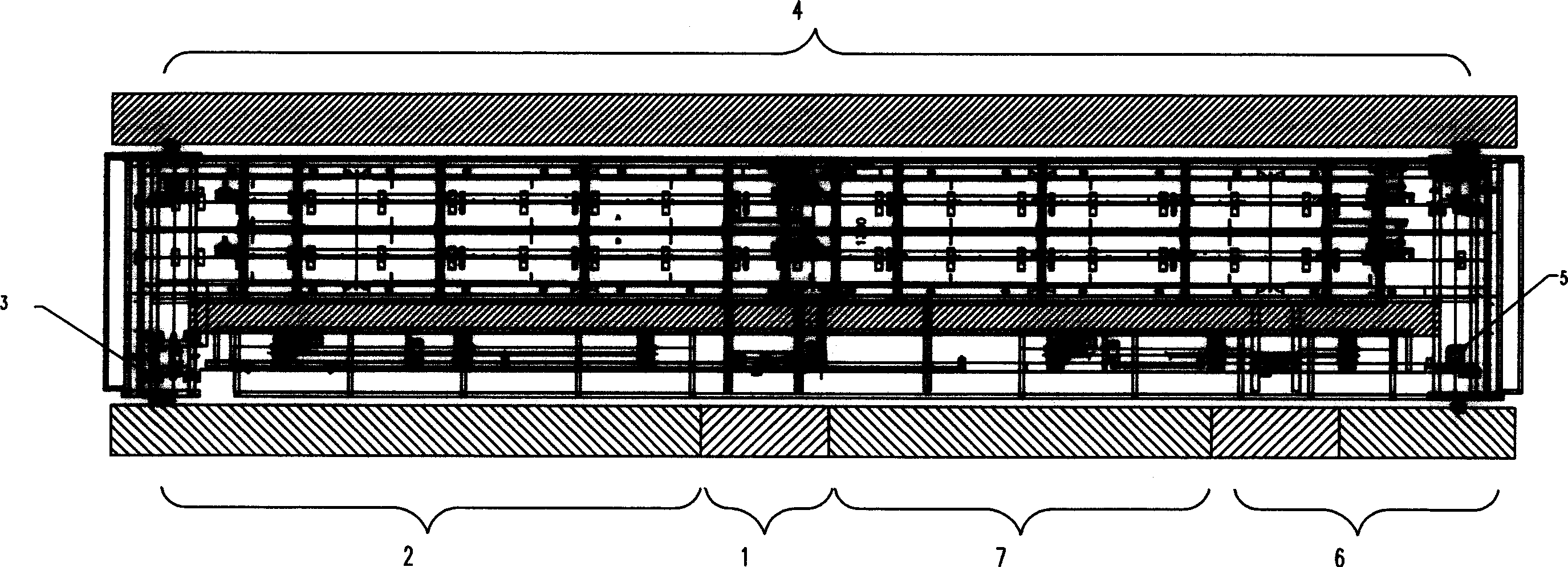

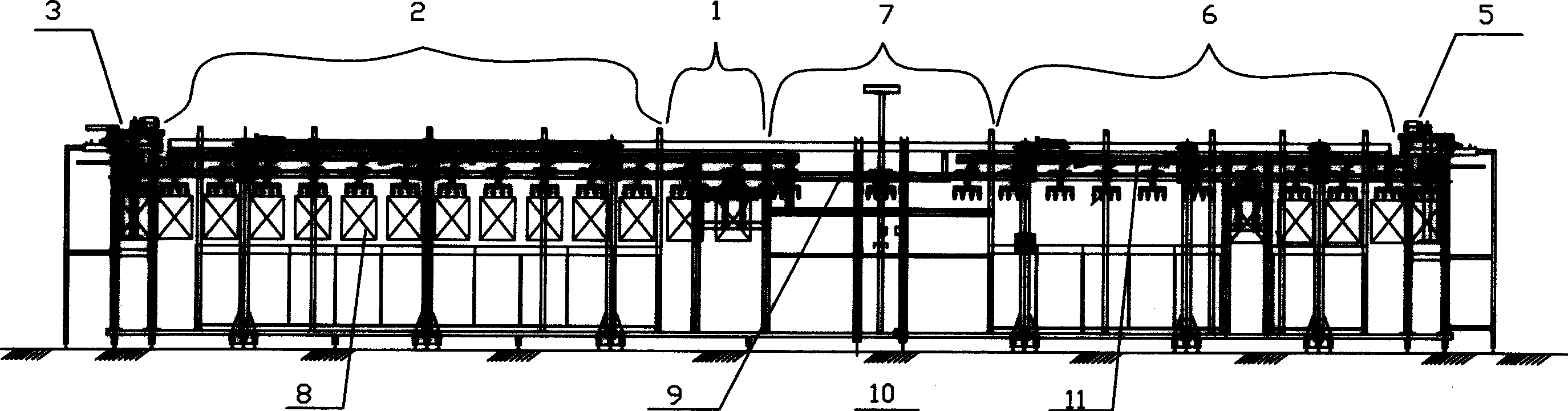

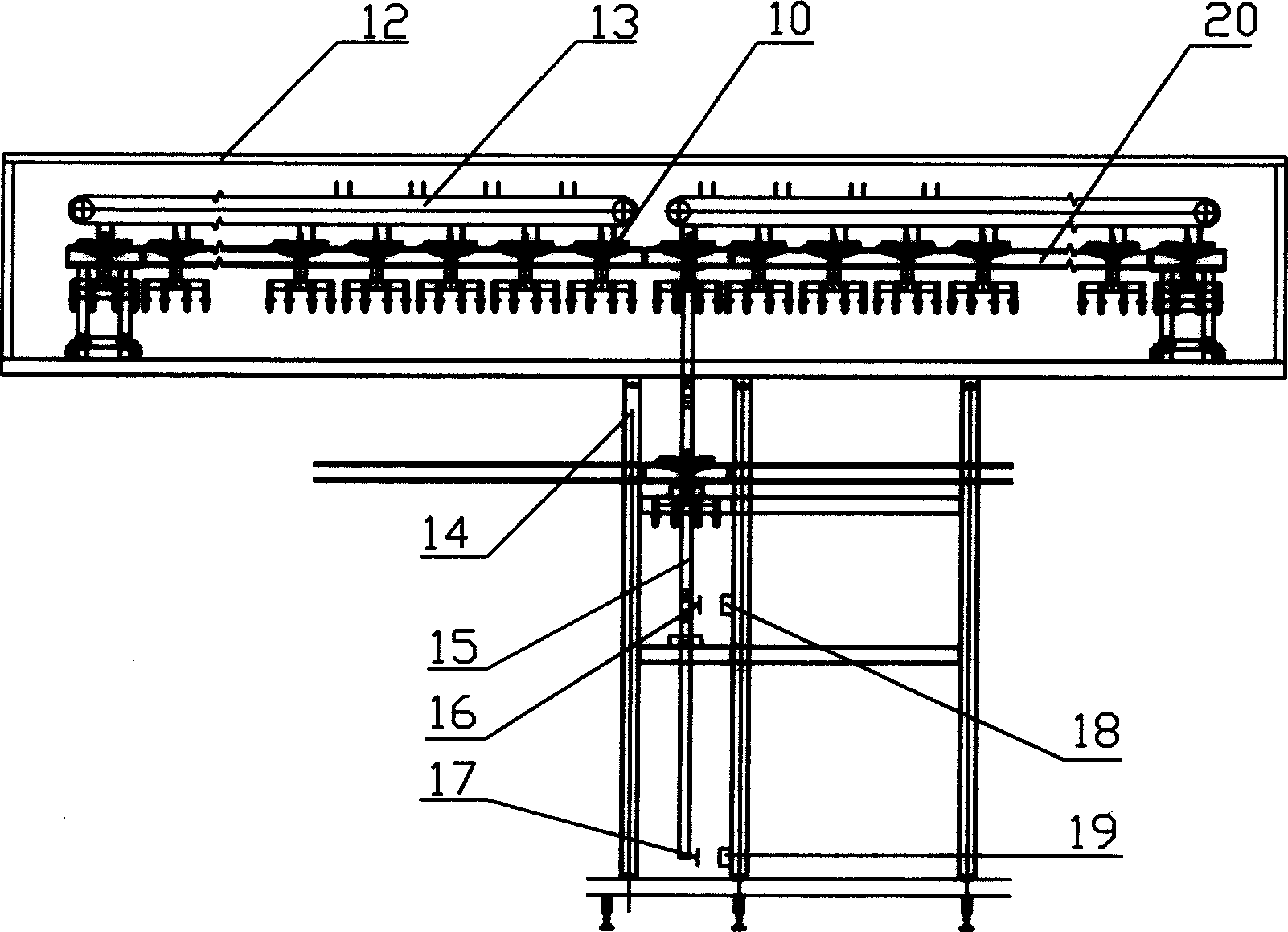

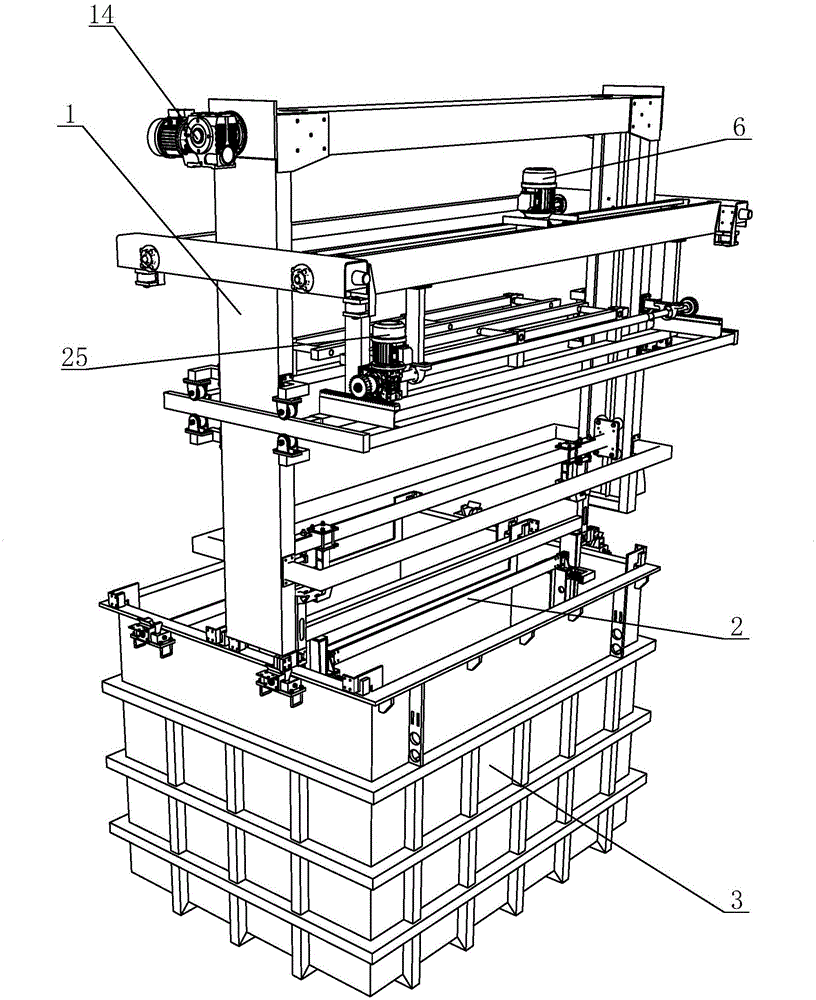

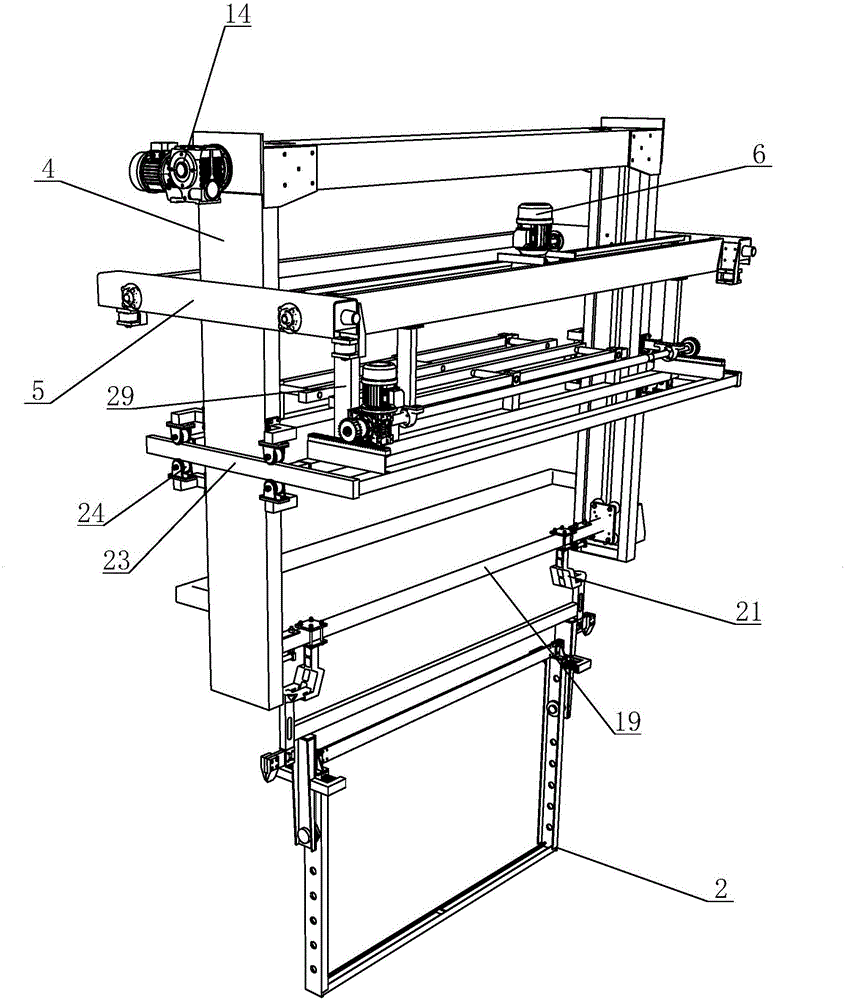

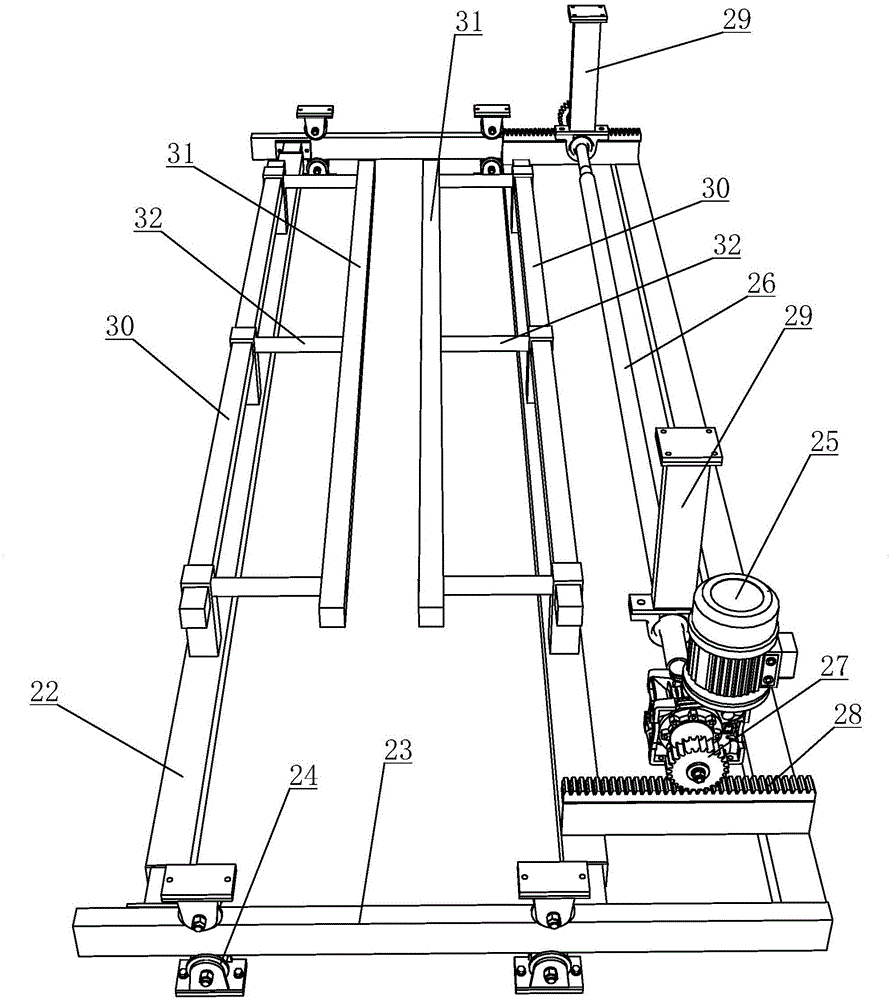

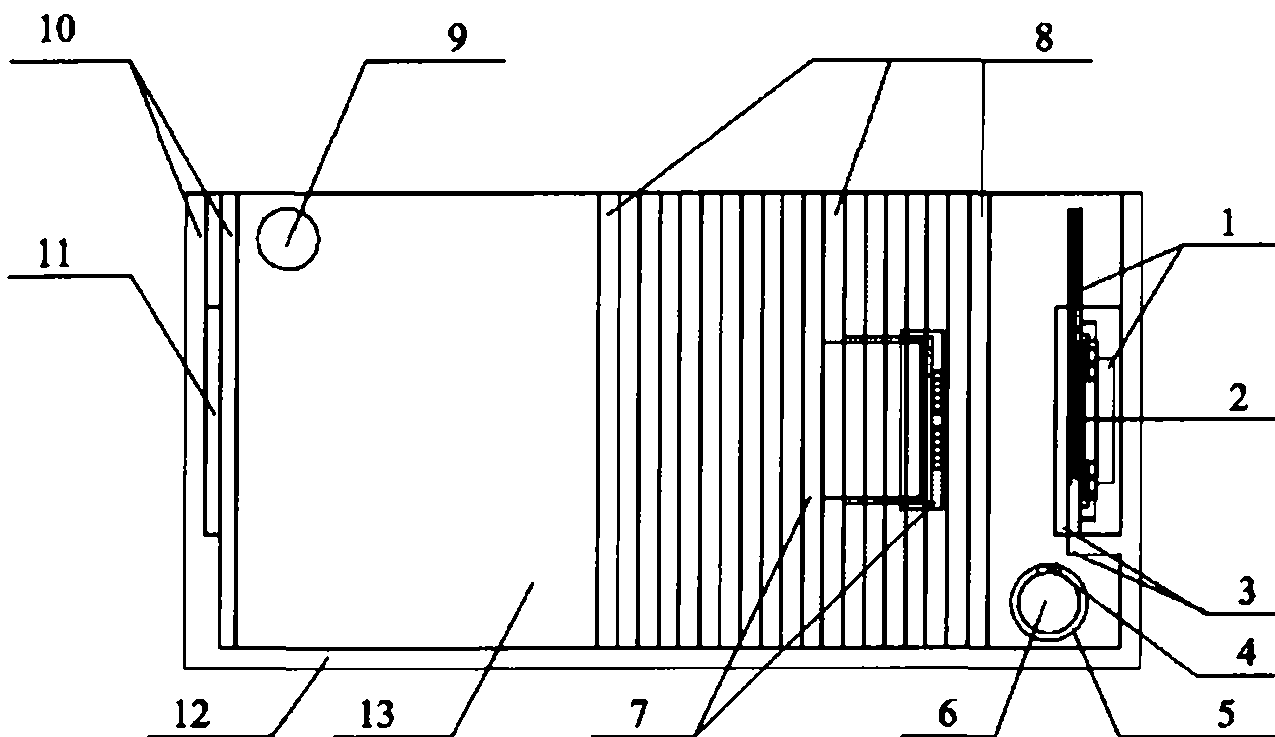

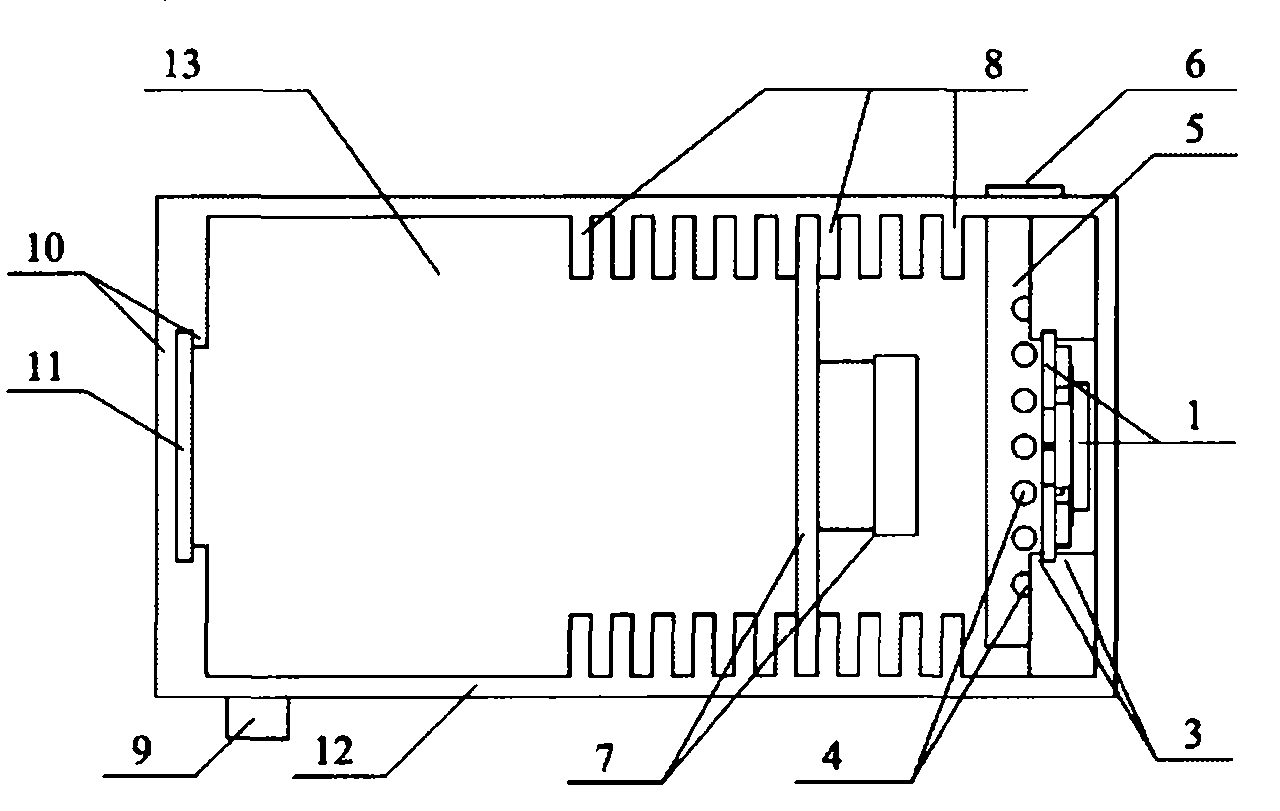

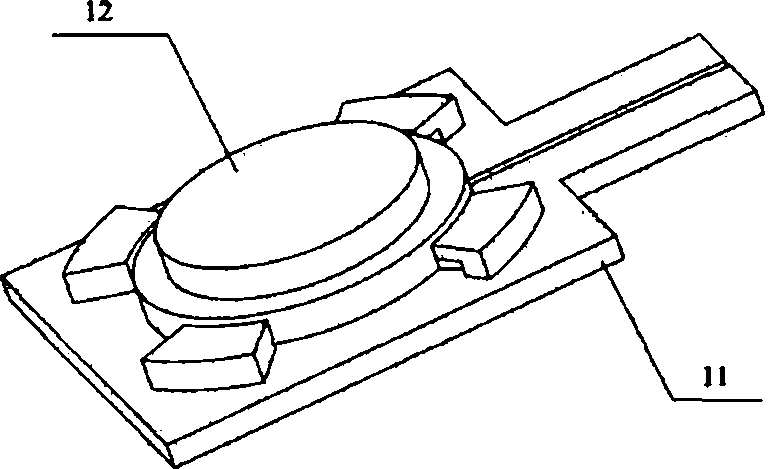

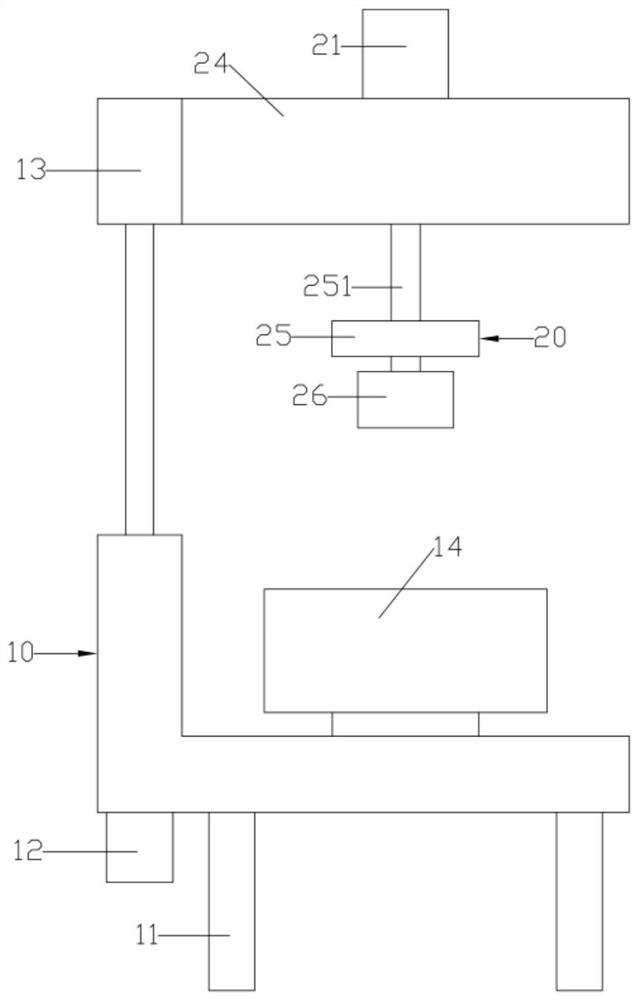

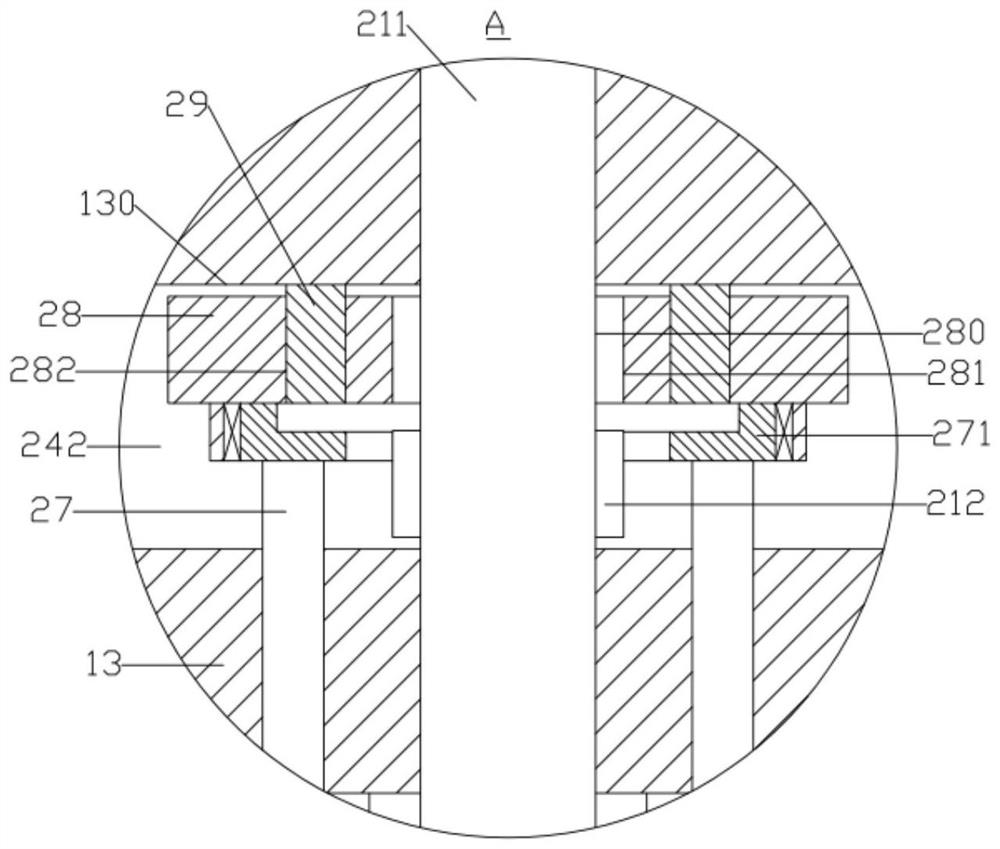

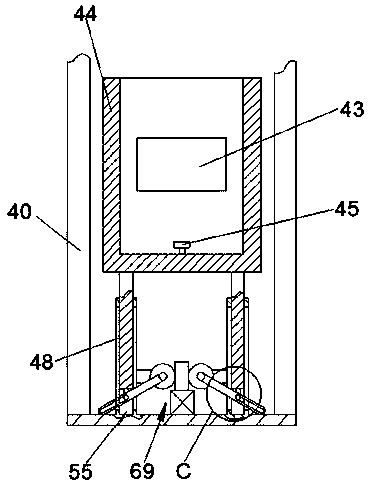

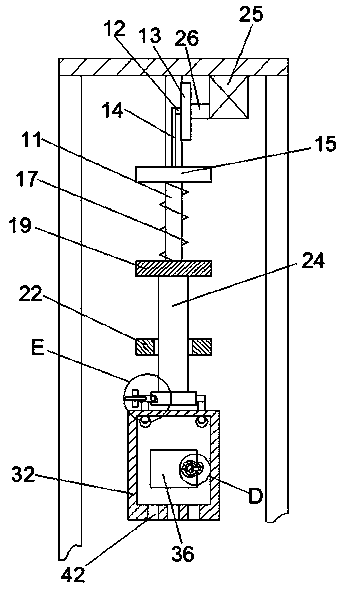

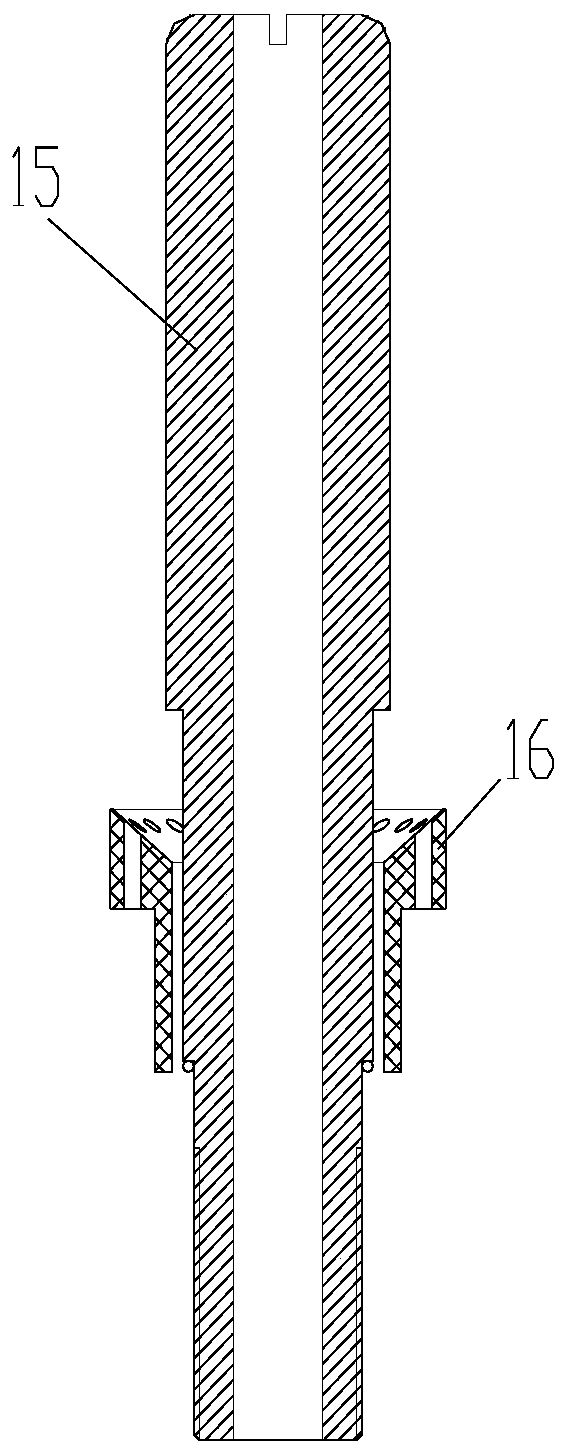

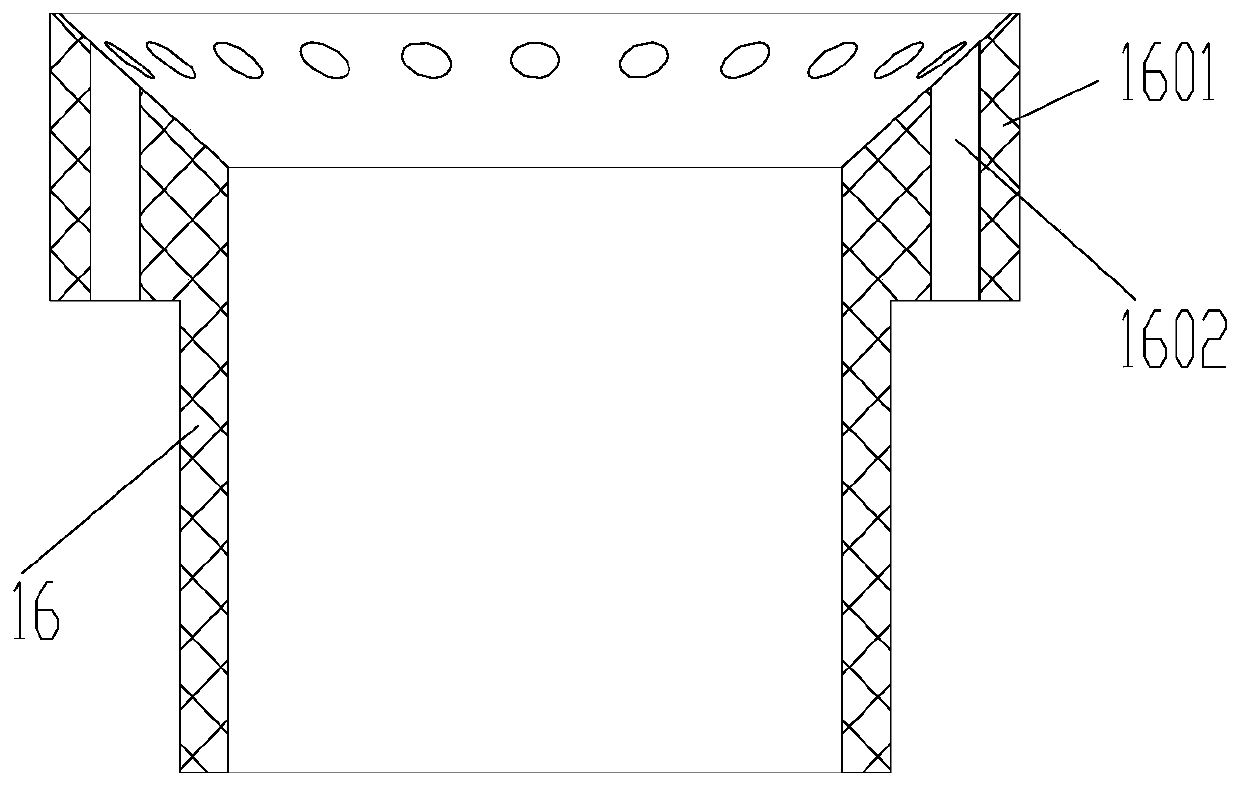

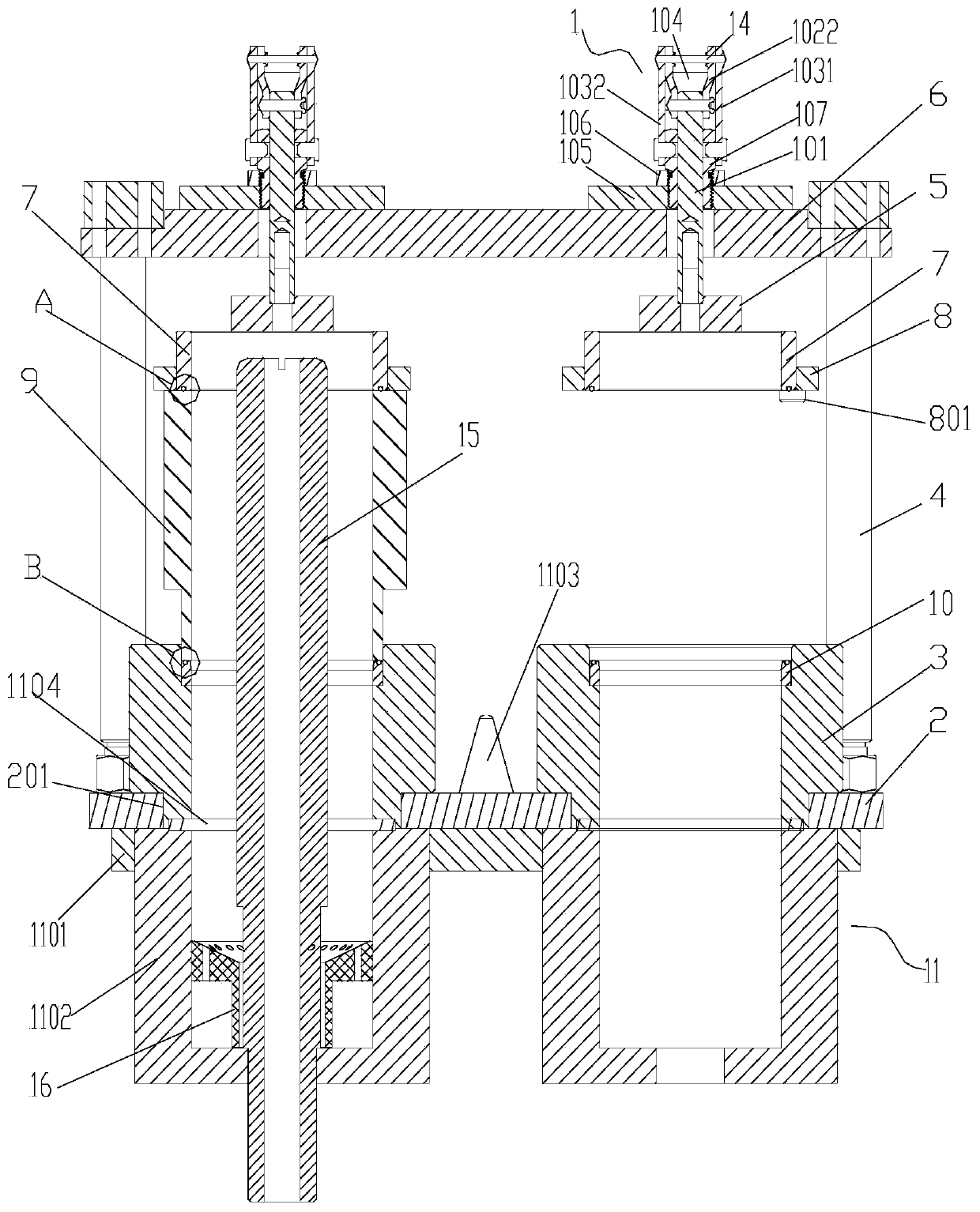

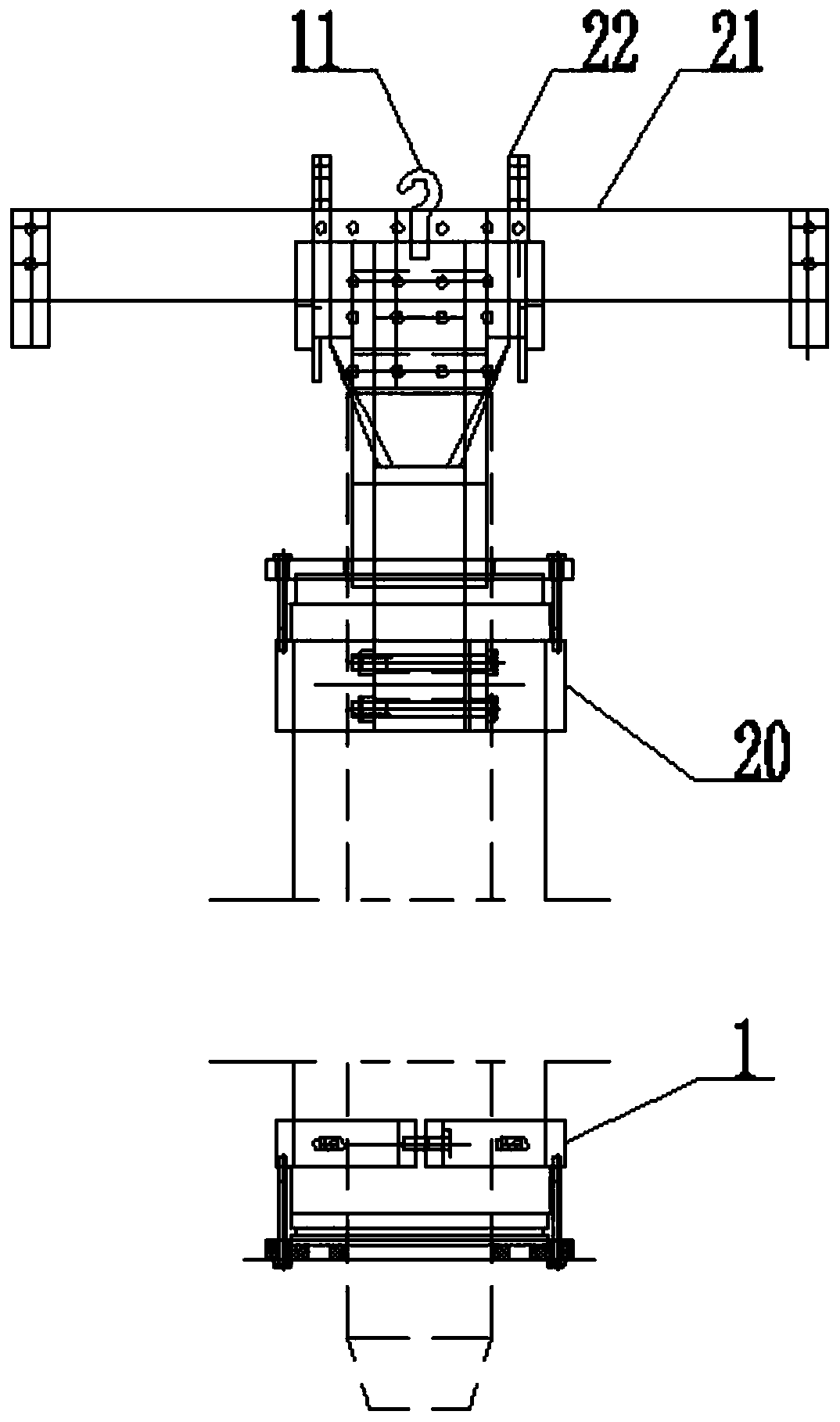

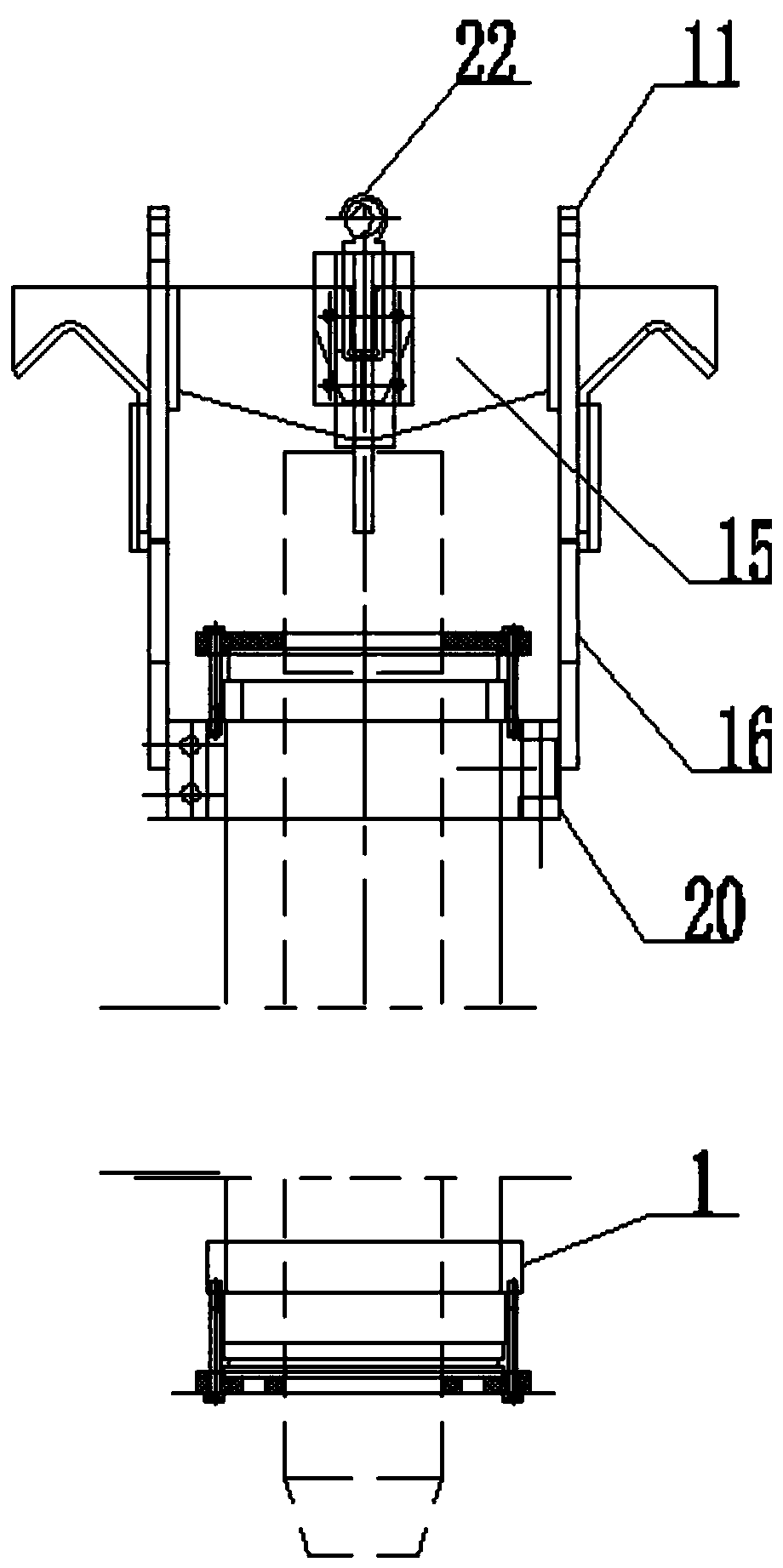

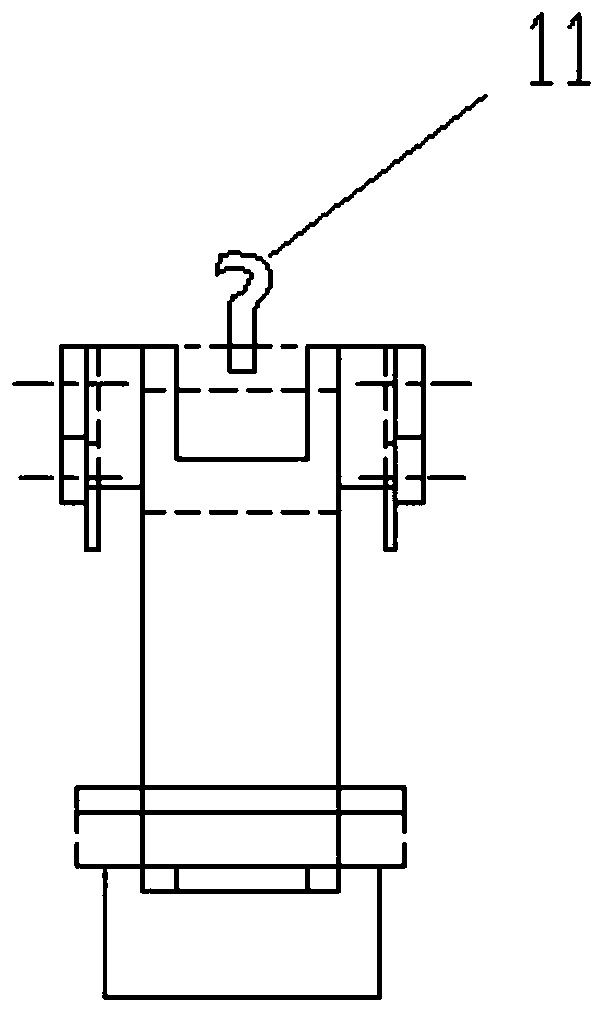

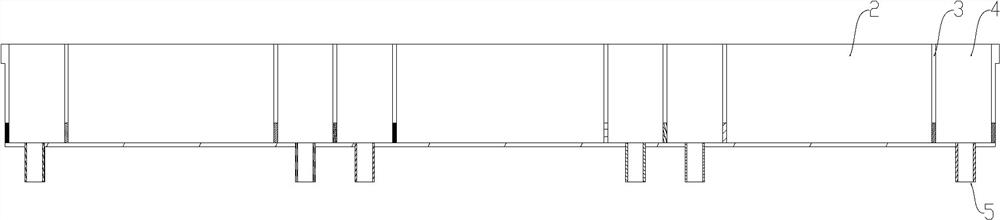

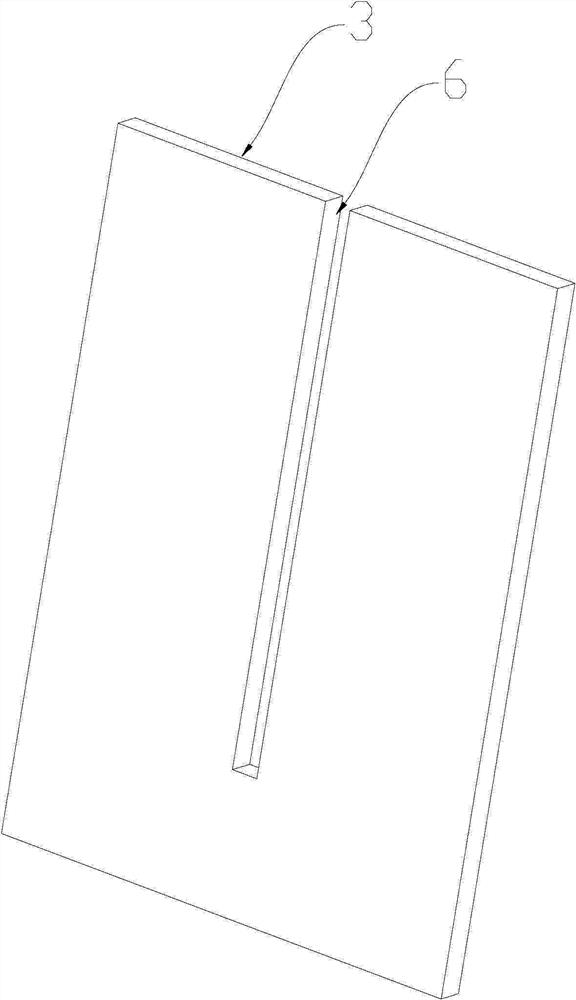

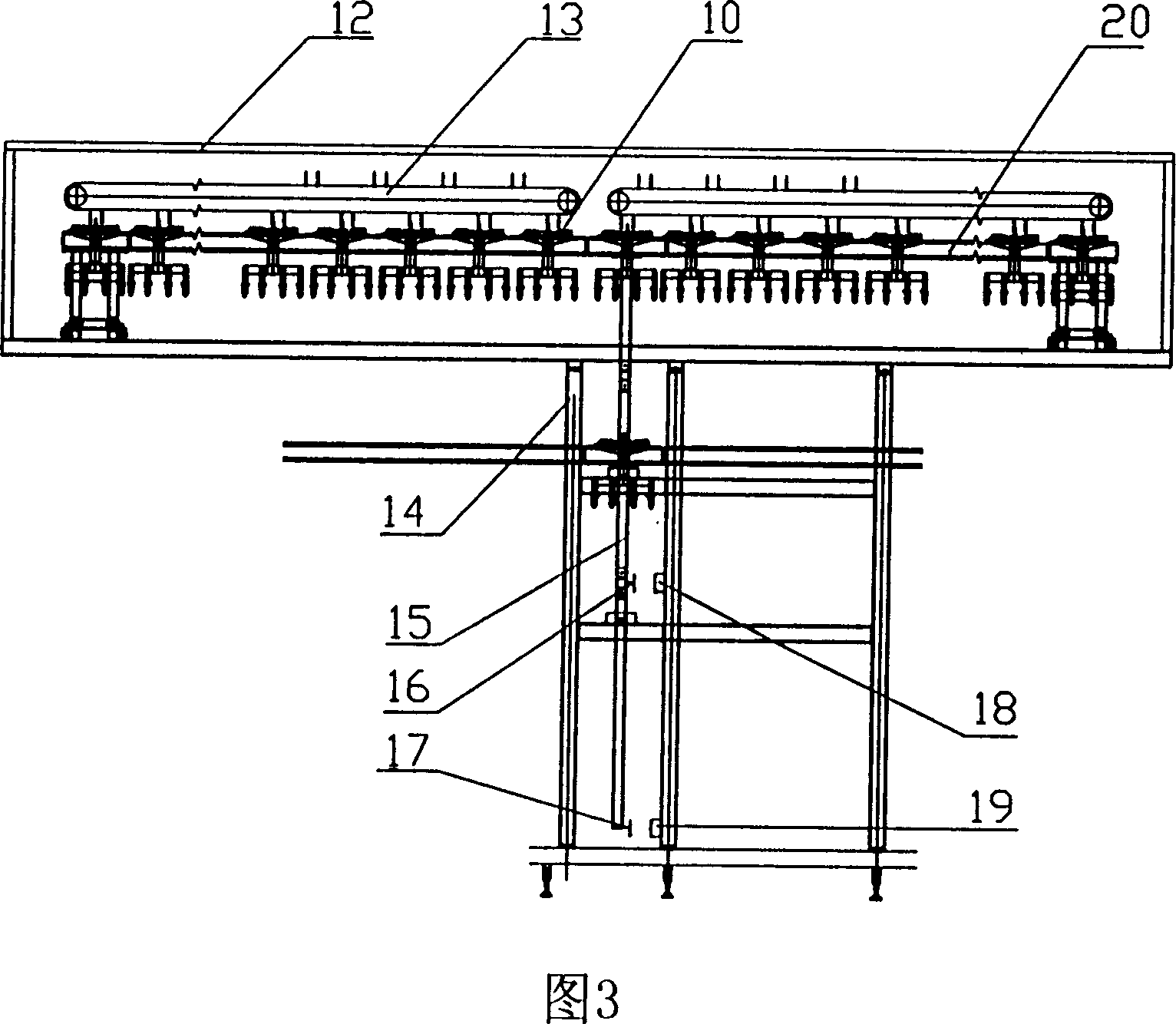

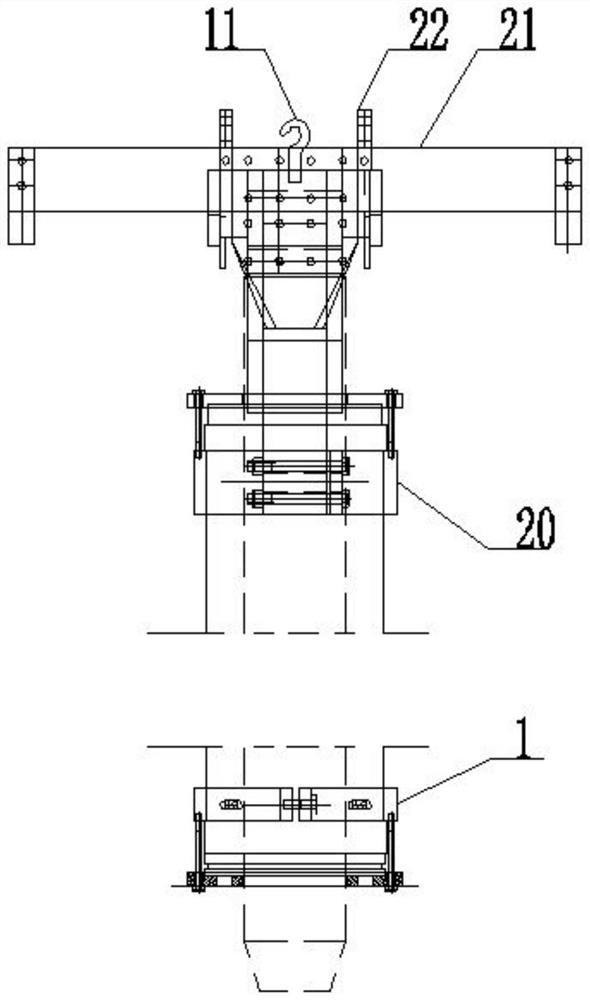

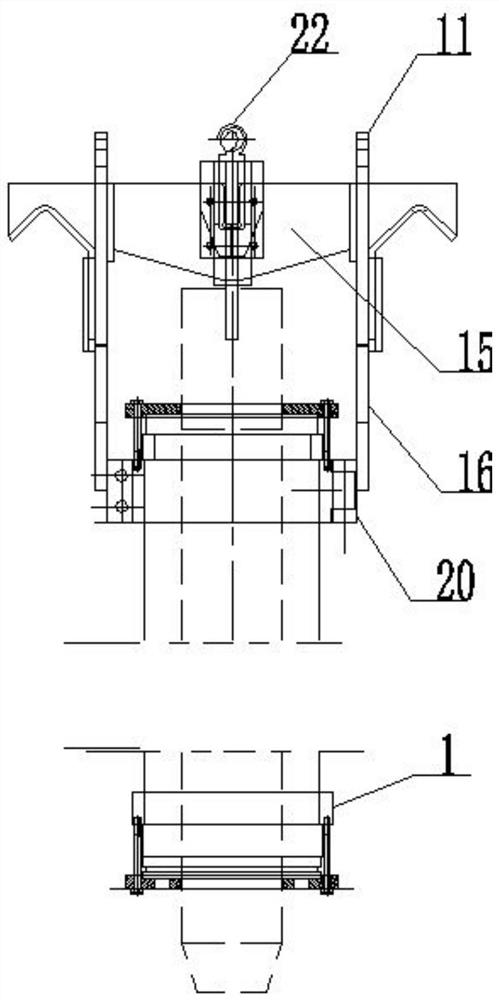

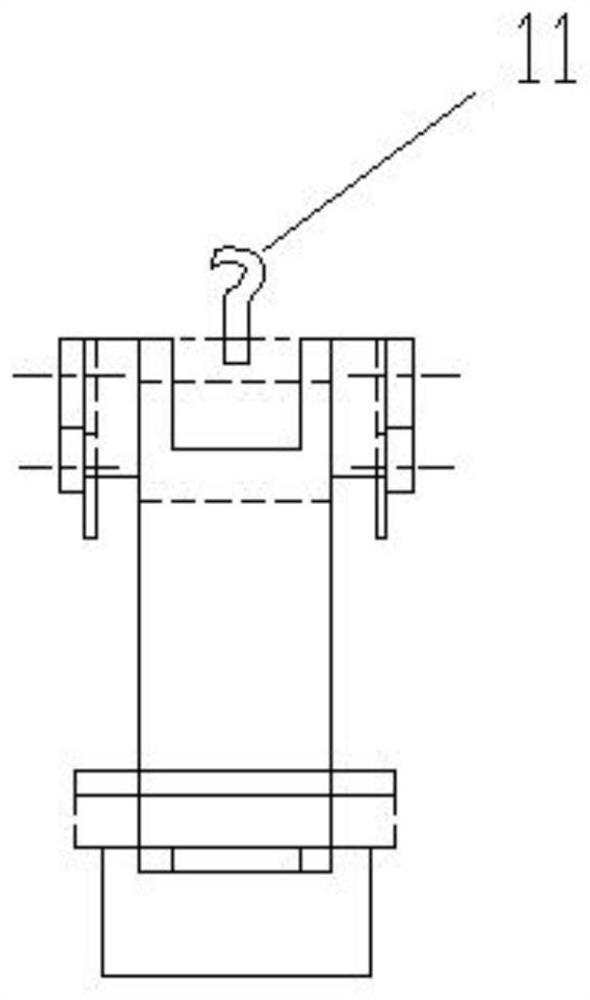

Electroplating machine capable of automatically accessing hanger

ActiveCN1587445AGuarantee the quality of platingSave human effortElectrolysis componentsElectroplatingMechanical engineering

The electroplating machine capable of automatically accessing jig includes electroplating bath, jig, jig conveying system and control circuit. The jig conveying system set over the electroplating bath may be divided into upper plate section, front processing section, electroplating bath section, post processing section and temporarily set section. The temporarily set section has automatically jig accessing unit consists of jig storing mechanism and automatic elevating mechanism. The control circuit is connected to the jig accessing mechanism and the automatic elevating mechanism. The automatic elevating mechanism is connected to the jig accessing mechanism and the temporarily set section to realize the automatic accessing of jig. Compared with available technology, the present invention has raised electroplating effect, less man-made error and low cost.

Owner:宝盈科技(深圳)有限公司

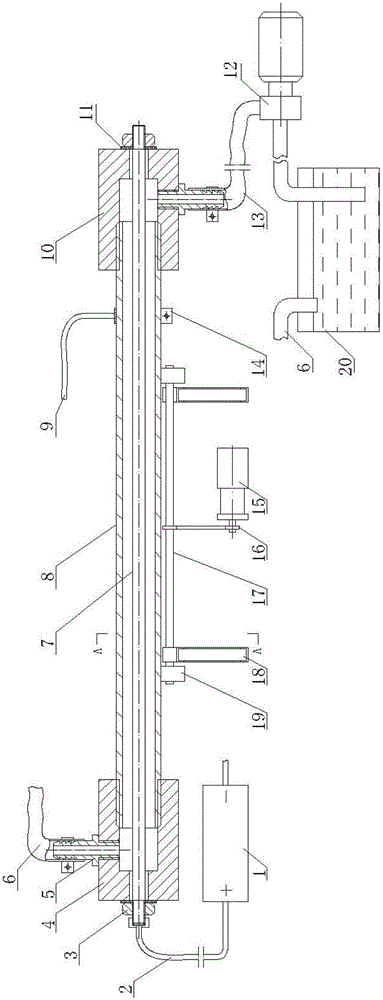

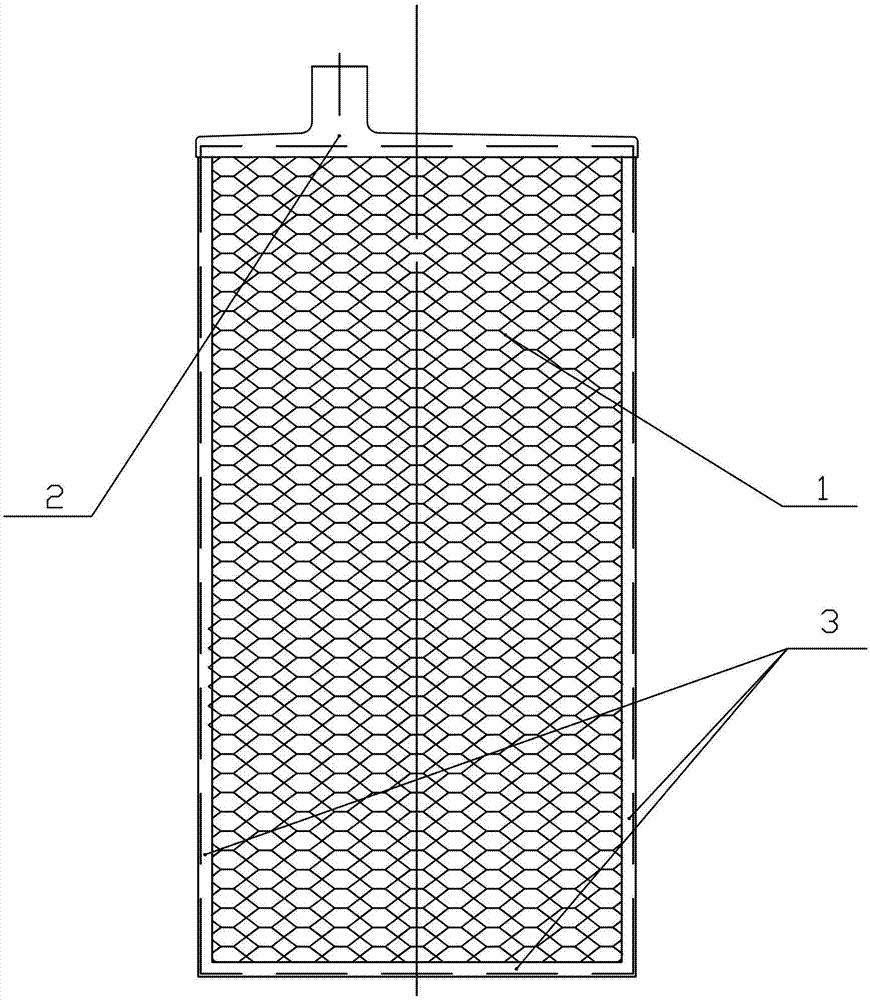

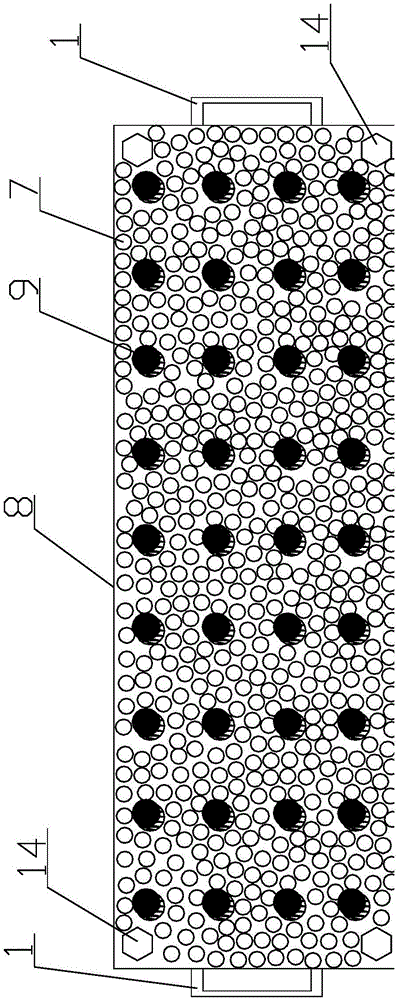

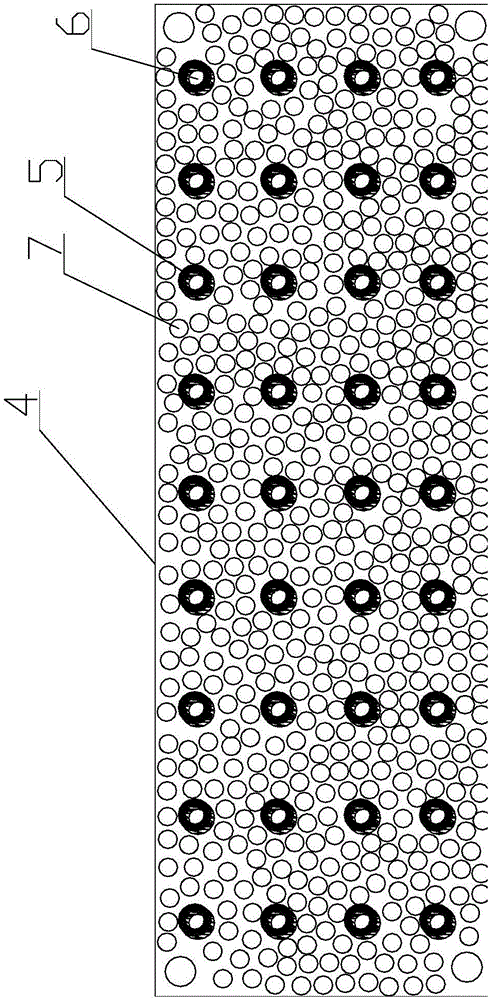

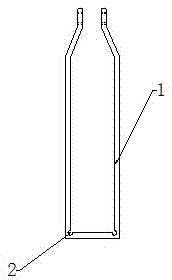

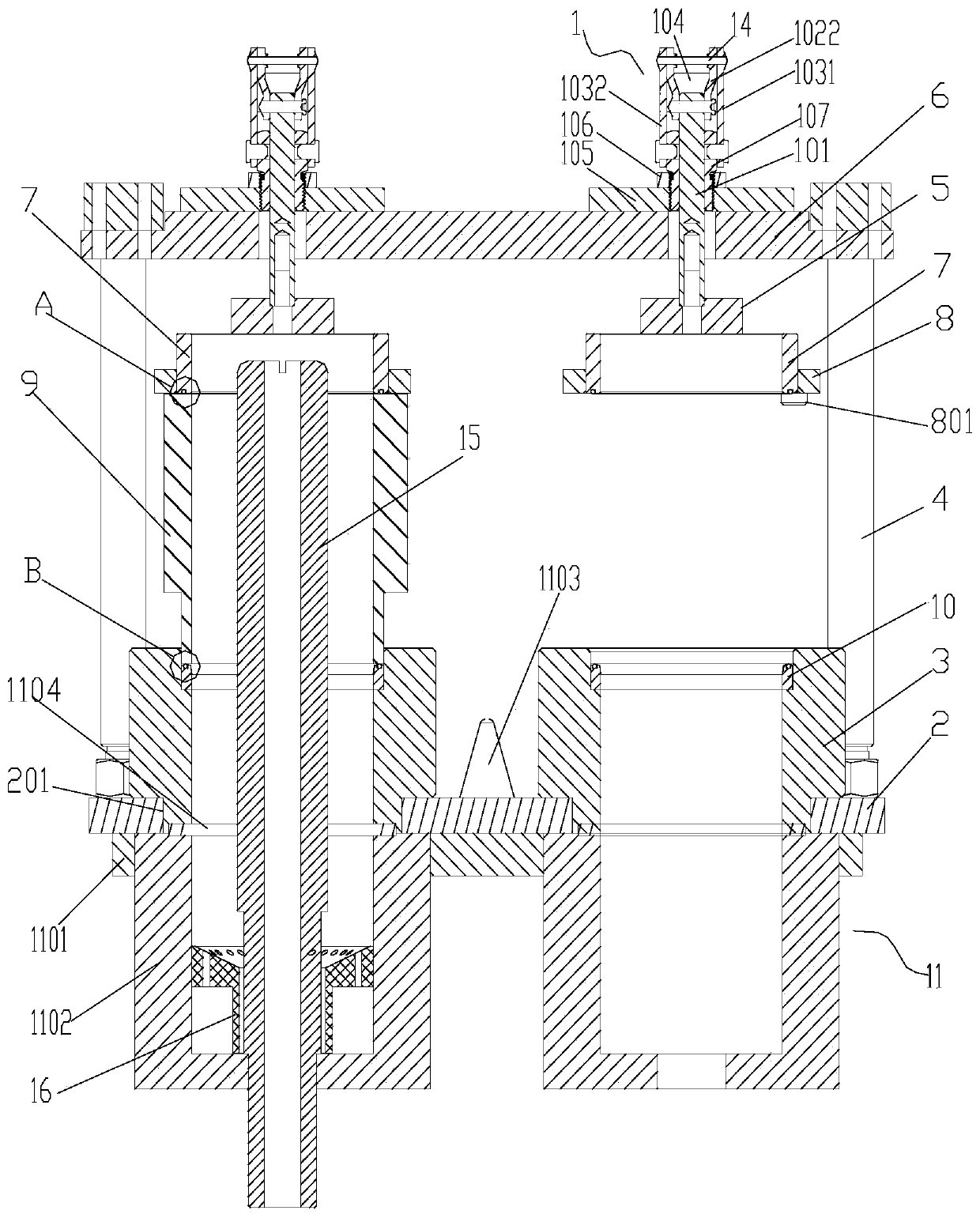

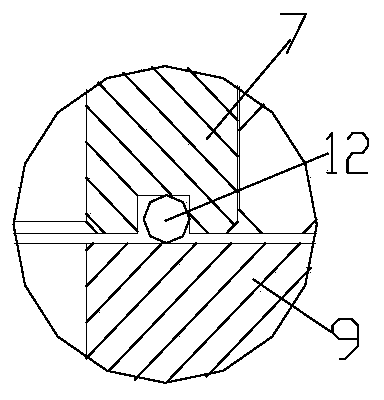

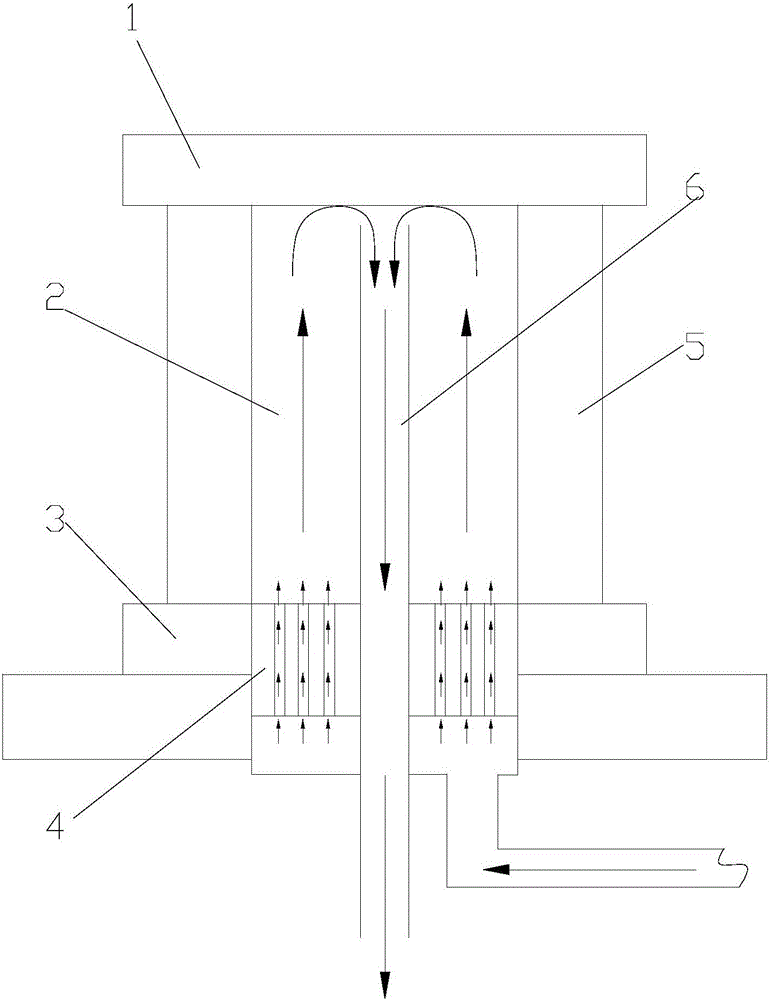

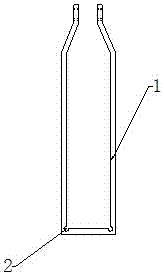

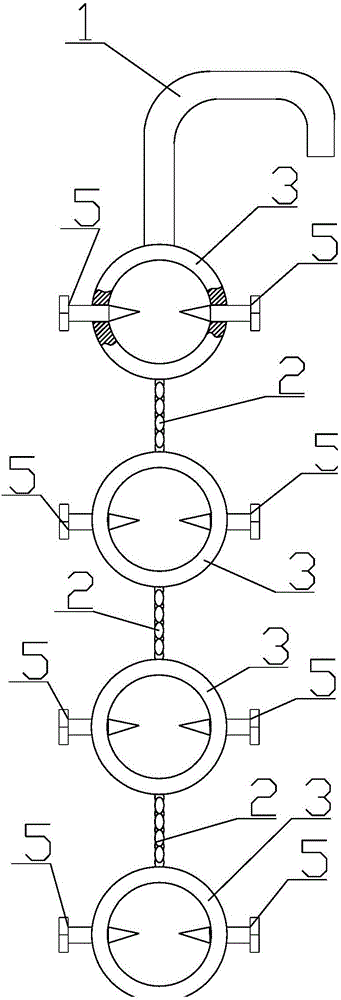

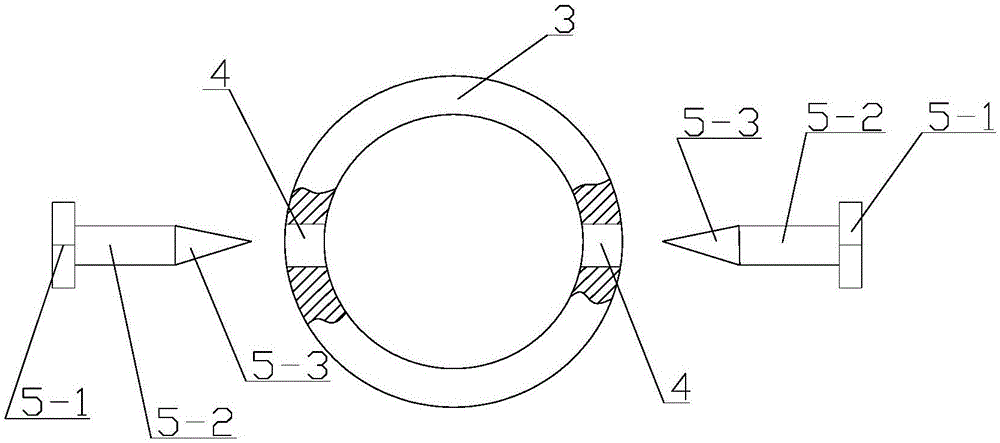

Swinging-type long-pipe inner wall electroplating method and electroplating equipment applying same

InactiveCN105002539AImprove plating qualityImprove plating efficiencyCellsLiquid storage tankEngineering

The invention discloses a swinging-type long-pipe inner wall electroplating method and electroplating equipment applying the same. The electroplating process comprises the following steps that an inner anode penetrates through a cathode long pipe to be electroplated; the two ends of the cathode long pipe are separately connected to a liquid inlet connector and a liquid outlet connector; the liquid inlet connector and the liquid outlet connector are communicated with a liquid storage tank; the two ends of the inner anode are separately fixed on the liquid inlet connector and the liquid outlet connector; then one end of the inner anode and the outer wall of the cathode long pipe are separately connected to the positive electrode and negative electrode of a power source through flexible conductors; an electroplating solution is circularly injected into the cathode long pipe through a liquid inlet in the liquid inlet connector and a liquid outlet in the liquid outlet connector, and the inner cavity of the cathode long pipe is fully filled with the electroplating solution; the power source is started, and the cathode long pipe and the inner anode are driven to swing in a reciprocating manner by a swinging mechanism, so that an electroplating layer is formed on the inner wall of the cathode long pipe. The swinging-type long-pipe inner wall electroplating method has the beneficial effects that a recovery groove does not need to be arranged; the electroplating layer is uniform in thickness; the electroplating quality is ensured; and moreover, a liquid conveying mechanism and a power delivery mechanism of the equipment are greatly simplified.

Owner:黄激扬 +1

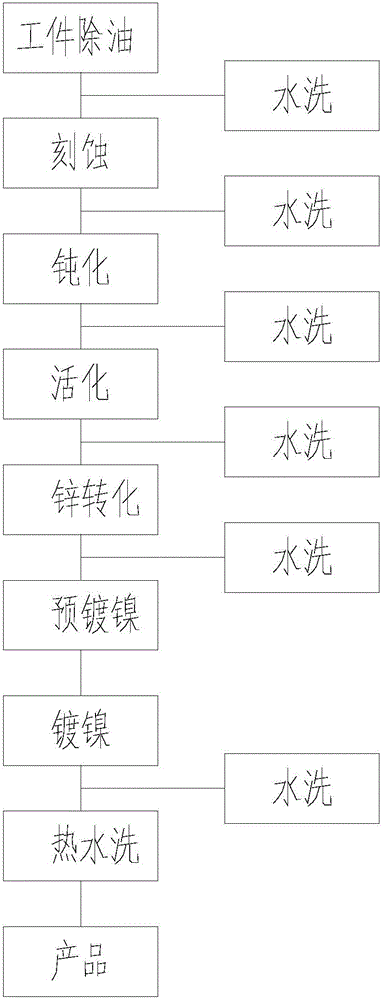

Method for restoring dimension discrepancy of bearing utilizing chemical plating nickel

InactiveCN1485460ALow costFix out-of-tolerance dimensionsLiquid/solution decomposition chemical coatingChemical platingWarm water

An application of chemically plating nickel, especially a method of repairing different sizes of bearing by chemically plating nickel. The method comprises : washing bearings with gasoline; washing bearings with methanol; washing bearings with warm water, the temperature of the warm water is 60 -70degree Cú¼washing for 2 min; washing bearings with chemicals, the temperature thereof is 60-70degreeCú”washing with cool water; immersing in an acid and activating for 1-2min, the concentration of the acid is 10í†5ú”washing with cool water; preheating bearings with hot water for 5-10min, the temperature thereof is 80-90 degree C;preparing the chemical plating nickel solution.

Owner:宁夏西北轴承石油机械轴承有限公司

Manufacturing method of lead-acid storage battery negative grid

ActiveCN103117395AGuaranteed StrengthEliminate the risk of short circuitsElectrode carriers/collectorsAlloyCopper

The invention relates to a manufacturing method of a lead-acid storage battery negative grid, and the manufacturing method comprises the following steps of a, stretching a copper plate to be reticulate so as to form copper stretch metal, and tailoring the copper stretch metal into a rectangular structure; b, pouring lead alloy on one end of the copper stretch metal to form a lug; c, electroplating lead on the surface of the copper stretch metal with the lug, and forming a lead-plated layer on the surface of the copper stretch metal; and d, carrying out the injection molding on the other end of the width direction and two ends of the length direction of the copper stretch metal to form a plastic frame. By adopting the manufacturing method, after the copper stretch metal is stretched, the operation for curling the frame is not needed; after a copper frame is removed and the molded frame is adopted for the copper stretch metal, no conditioning fluid remains in the lead electroplating process, so that the electroplating quality is guaranteed, and the rejection rate is reduced; and due to the adoption of the plastic frame, the strength of the grid can be guaranteed, the short-circuit potential danger of the negative electrode and the positive electrode can be eliminated, and components such as a frame protection sleeve are not needed.

Owner:ZIBO TORCH ENERGY

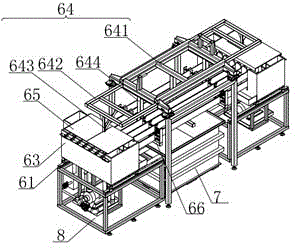

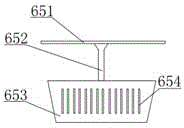

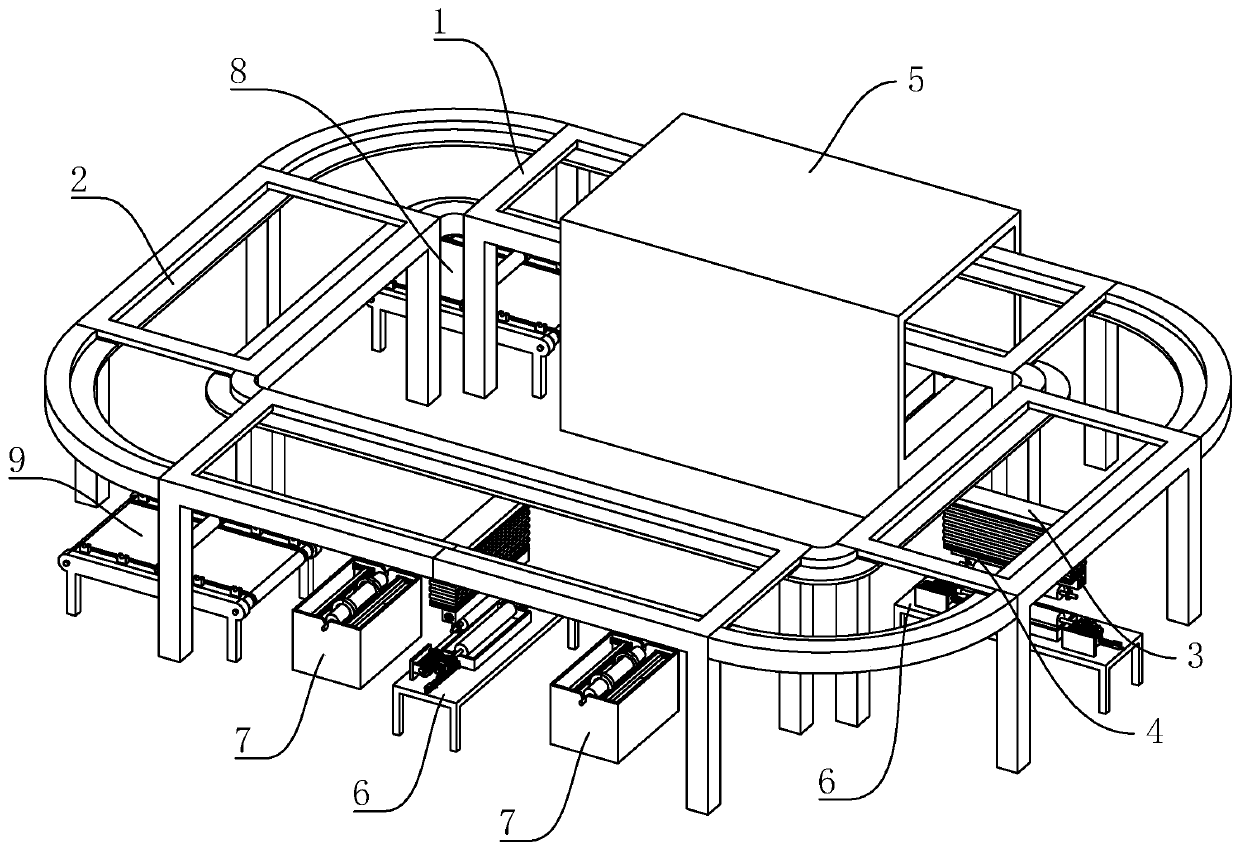

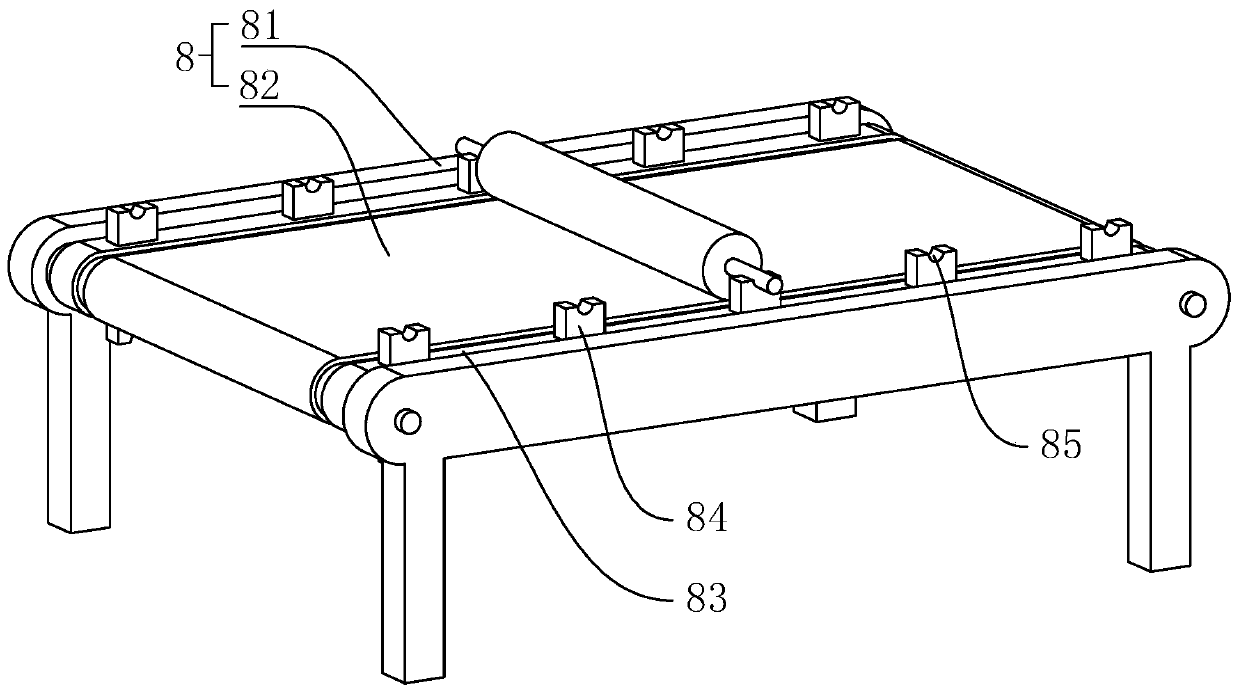

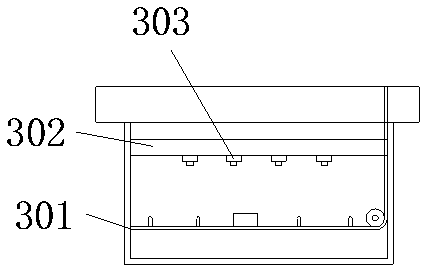

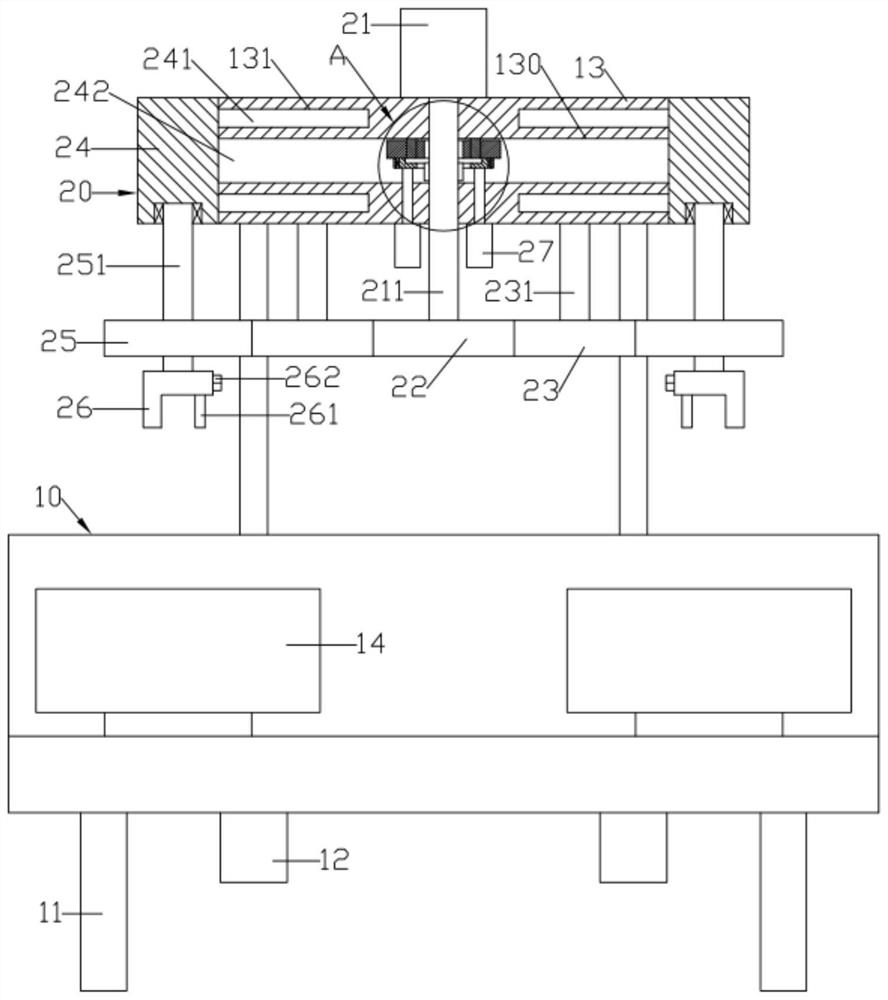

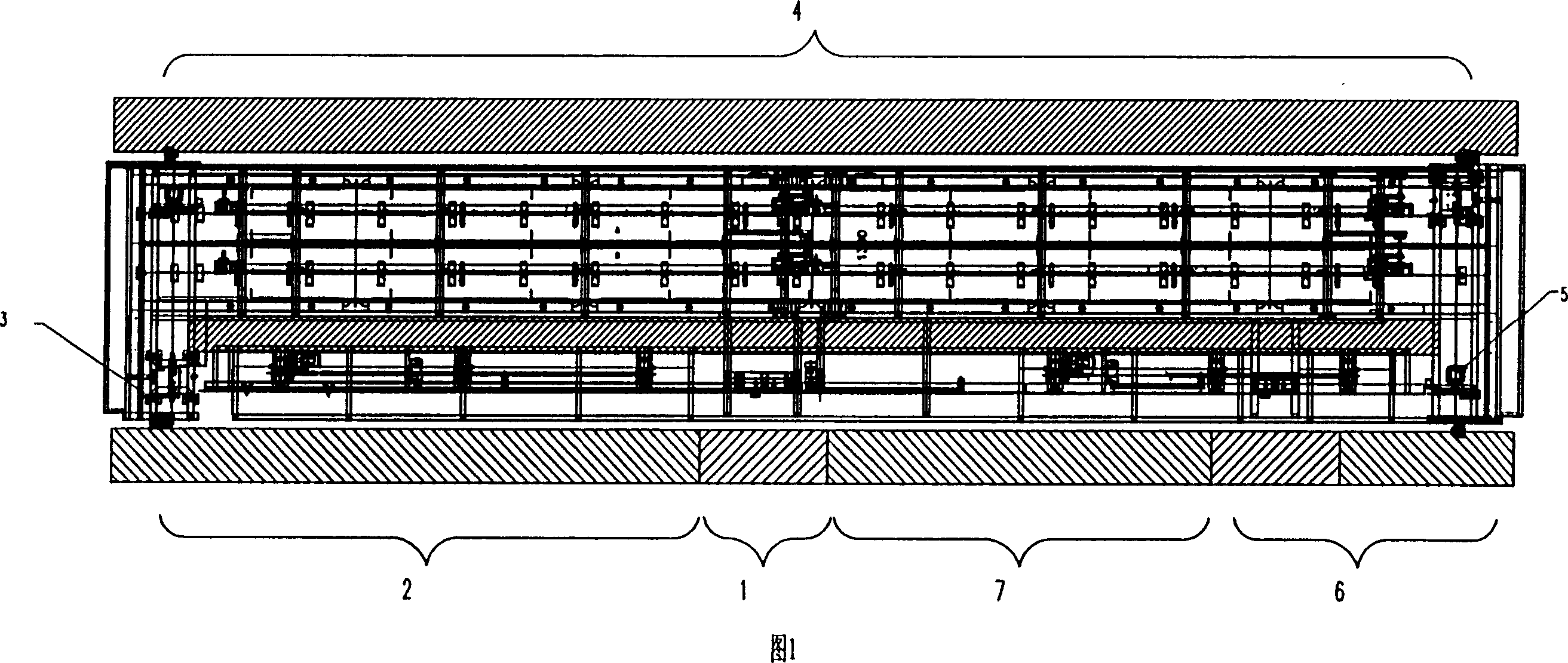

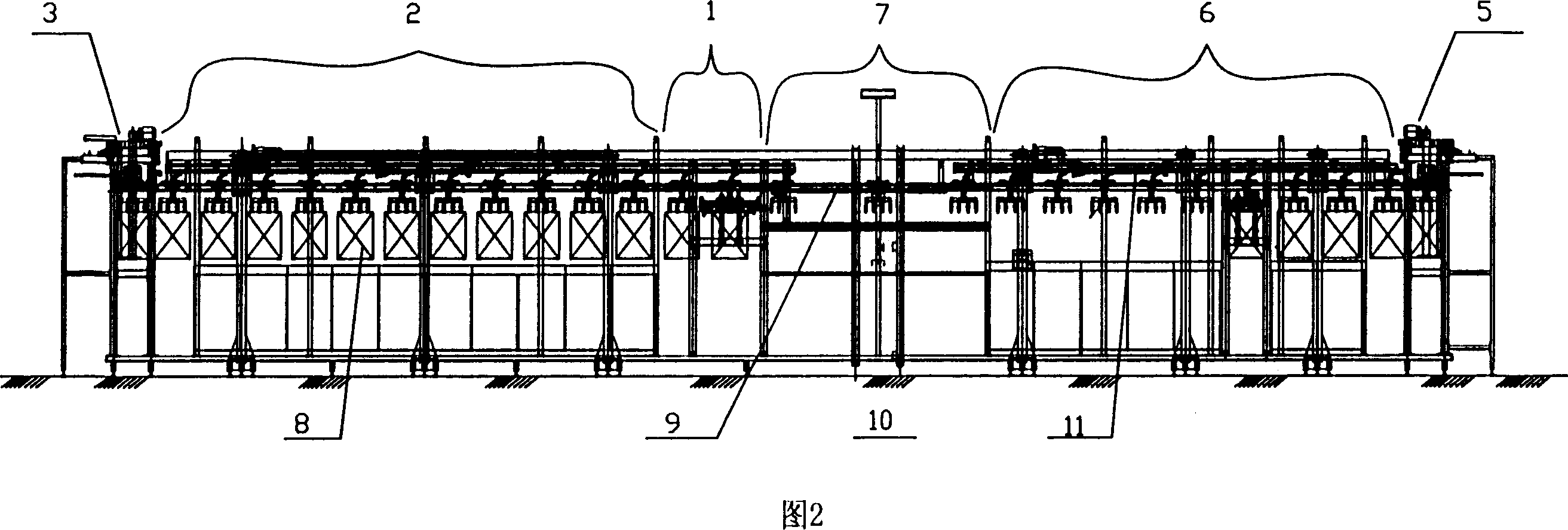

Two-end tin-plating automatic production line

ActiveCN106702469AGuarantee the quality of platingQuality assuranceElectrolytic coatingsJewelleryElectrolysisTin plating

The invention relates to a two-end tin-plating automatic production line. The two-end tin-plating automatic production line includes a loading device, a first cleaning device, a tin-plating tank, a second cleaning device and an unloading device which are successively connected; the tin-plating tank, the first cleaning device and the second cleaning device are all connected with a PLC and an exhausting system; the first cleaning device comprises an electrolysis oil-removing tank, a water washing tank, a pickling tank, a passivation tank and an activation tank; the second cleaning device comprises an ultrasonic cleaning and tank, a neutralization tank, a water washing tank and a dry-scalding tank; the electrolysis oil-removing tank, the pickling tank, the passivation tank, the activation tank, the tin-plating tank and the neutralization tank are each provided with a Feiba; the Feiba comprises a Feiba base, a tin-plating liquid box group, a Feiba frame, and a cover sheet covering the tin-plating liquid box group. Compared with the prior art, the two-end tin-plating automatic production line has controllable programming operation; wastewater is greatly reduced, and thus the wastewater treatment cost is reduced; the work environment is improved, and odor generated by chemical agents required for electroplating is directly discharged through an air treatment device via the exhausting system.

Owner:镇江大全金属表面处理有限公司

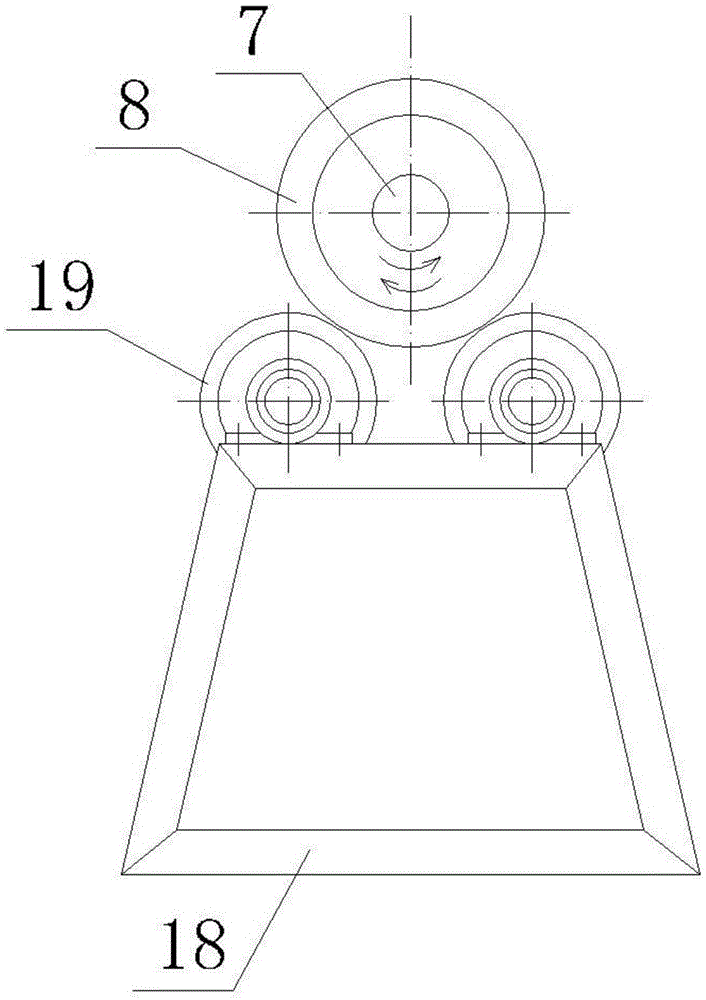

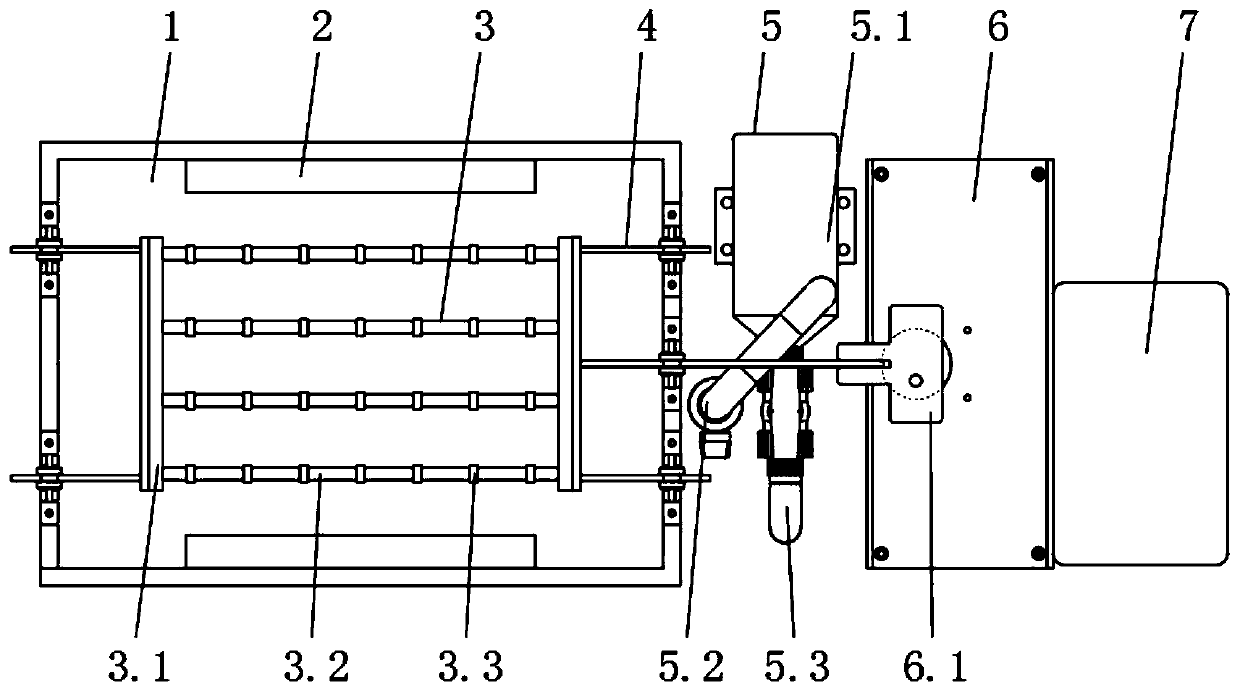

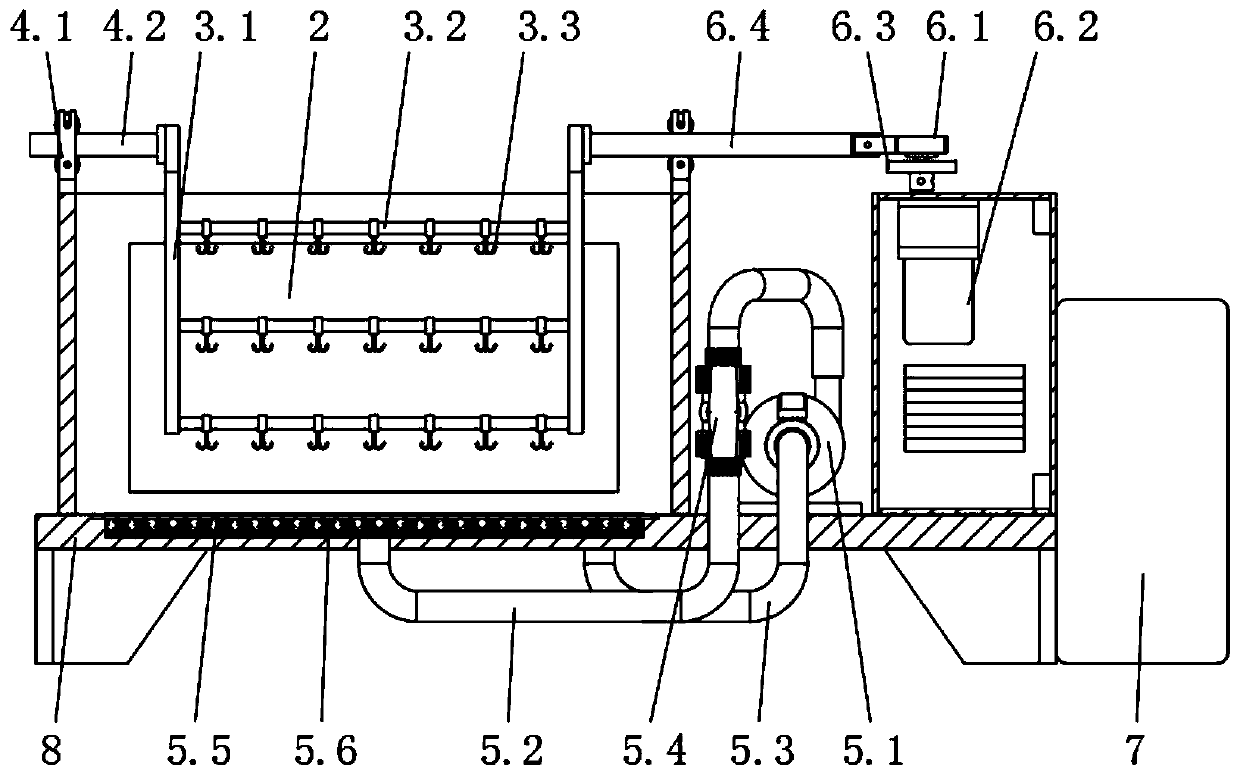

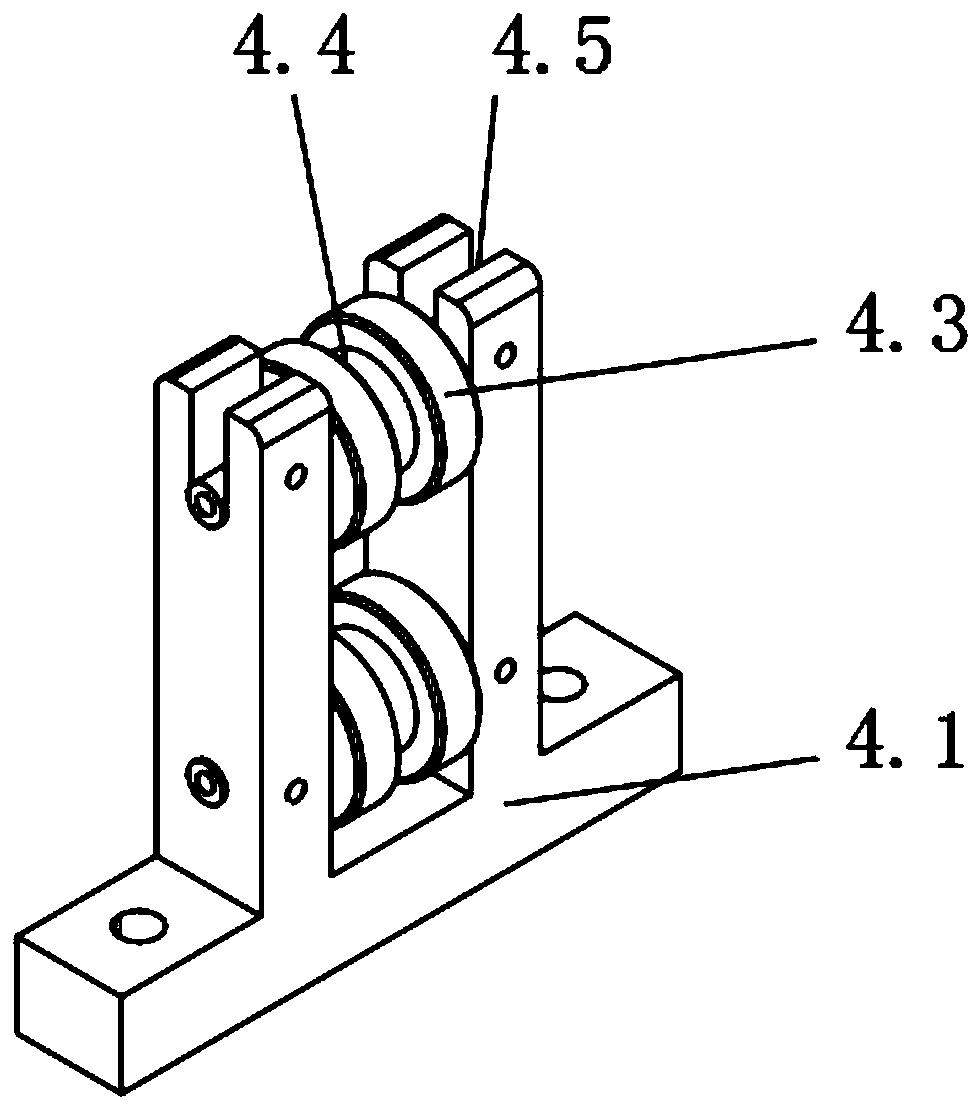

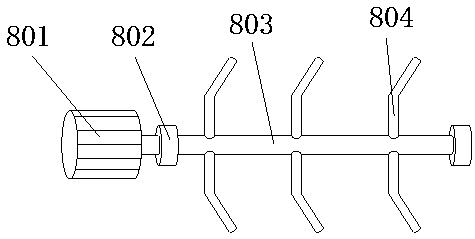

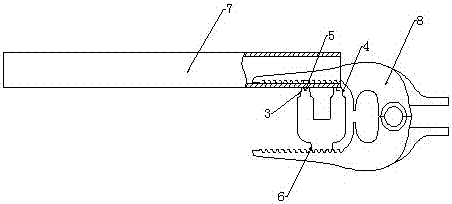

Electroplating conductive stick swinging and water-pouring device

ActiveCN105112987AReduce riskGuarantee the quality of platingElectrolysis componentsEngineeringElectroplating

The invention discloses an electroplating conductive stick swinging and water-pouring device. The electroplating conductive stick swinging and water-pouring device comprises an electroplating special traveling crane, an electroplating conductive stick and an electroplating groove; the electroplating special traveling crane comprises a traveling crane rack, a traveling device, a hoisting device and a swinging device; the swinging device comprises a swinging frame; the swinging frame is provided with a driving device; two striking rods are arranged on the swinging frame at intervals; the electroplating conductive stick comprises two booms, two hoisting plates and a swinging rack; the two hoisting plates are fixedly connected with the two booms; the swinging rack is arranged between the two hoisting plates through a swinging bearing; a conductive rod is fixed on the top of the swinging rack; and after the electroplating conductive stick is hoisted by the hoisting device, the conductive rod is positioned between the two striking rods. By the electroplating conductive stick swinging and water-pouring device, workpieces can swing in the left-right direction; after the electroplating conductive stick swinging and water-pouring device is inclined at a certain angle, liquid taken out by the workpieces can pour to the groove within a short time, the electroplating efficiency is improved, electroplating quality is guaranteed, and waste of medicament solution is reduced.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

Copper plating production line for producing printing rollers

The invention relates to a copper plating production line for producing printing rollers. The copper plating production line for producing the printing rollers includes a support frame; a circular double speed chain is arranged on the support frame; a horizontal moving frame is connected to the circular double speed chain; a vertical moving frame is slidingly connected to the horizontal moving frame; the vertical moving frame includes a connecting plate, a pneumatic finger connected to the lower end of the connecting plate, and a roller body limit ring fixedly connected to the output end of the pneumatic finger; a pretreatment working section, an electroplating section and a cleaning section are arranged under the support frame in order along the moving direction of the roller body; and aloading device and an unloading device are arranged between the pretreatment working section and the cleaning section. According to the invention, when performing an electroplating operation on the roller body, the circular double speed chain can drive the horizontal moving frame and the vertical moving frame to move, and the roller body can be driven to move automatically during the movement process of the horizontal moving frame and the vertical moving frame, which cannot cause collision between the roller body and the machine body; and therefore, the relatively stable movement of the rollerbody can be ensured, and the quality of the roller body electroplating can be ensured.

Owner:太仓市施美电镀有限公司

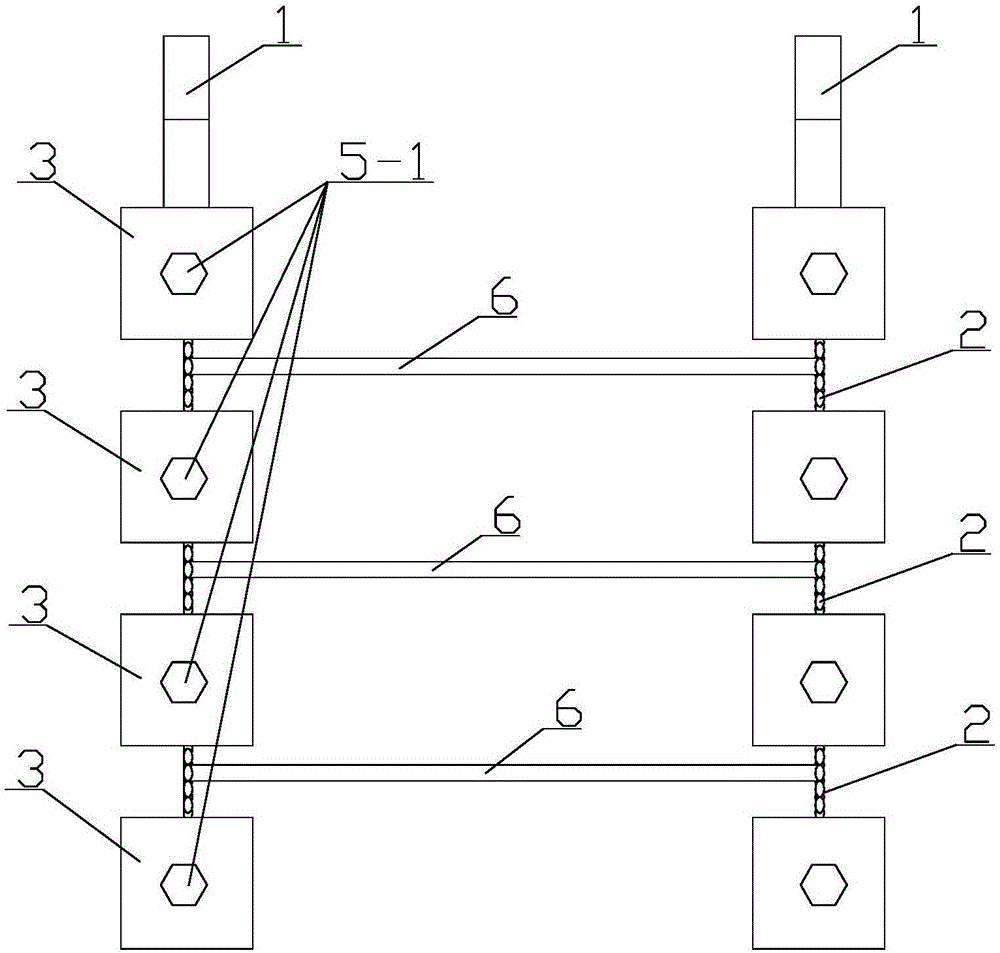

Clamp system special for electroplating of fixing bolts

ActiveCN106367788AAvoid Dark SpotsGuarantee the quality of platingElectrolysis componentsBlack spotEconomic benefits

The invention relates to a clamp system special for electroplating of fixing bolts. The clamp system comprises pressing plate assemblies, a base plate assembly, handles, a steel wire rope and a pull ring. The pressing plate assemblies are arranged at the upper end of the base plate assembly in parallel. The handles are arranged at the two ends of the pressing plate assemblies. The handles are connected through the steel wire rope. The pull ring is arranged in the middle of the steel wire rope. The base plate assembly comprises a base plate, circular truncated cone protrusions, containing holes and through holes. Each pressing plate assembly comprises a pressing plate, through holes, fixing blocks, first compression springs and pressing blocks. By adoption of the clamp system special for electroplating of the fixing bolts, multiple fixing bolts can be placed in clamps to be electroplated at a time, black spots of the fixing bolts are avoided, and the overall production efficiency is improved and the economic benefits are increased while the electroplating quality for the fixing bolts is guaranteed.

Owner:JIANGSU MENGDE NEW MATERIALS TECH CO LTD

Electroplating current optimization method applicable to continuous electrotinning unit

InactiveCN103695991AAvoid frequent changesGuarantee the quality of platingCellsHigh current densitySlice thickness

The invention provides an electroplating current optimization method applicable to a continuous electrotinning unit. The method comprises the following steps: (1) making a steel coil production plan according to plating thickness and carrying out continuous production of steel coils; (2) starting all the electroplating passes of the unit when producing a tin plate with plating thickness of no less than 5.6 g / m<2>, and starting half of the electroplating passes of the unit when producing a tin plate with plating thickness of no more than 2.8 g / m<2>; (3) when changes of plating specifications cause reduction of total current, maintaining the number of started electroplating passes to be unchanged while changing current distribution of each pass to reduce total current for front and rear steel coils with plating thickness in a same divided interval, and halving the number of plating baths while changing current distribution of each pass to reduce total current for front and rear steel coils with plating thickness in different divided intervals; and (4) when speed reduction of the unit causes reduction of total current, maintaining the number of started electroplating passes to be unchanged while changing current distribution of each pass to reduce total current. The method provided by the invention takes high current density distribution principles into consideration, employs a small number of plating baths for thin strip steel and enables distribution current density to be high, thereby guaranteeing electroplating quality.

Owner:WISDRI ENG & RES INC LTD

Metal ornament surface electroplating treatment device

InactiveCN110644041AReduce concentration polarizationEnhanced convectionCellsEngineeringElectroplating

The invention discloses a metal ornament surface electroplating treatment device. The device comprises an electroplating tank, an anode, a cathode, a rectifier and a base, wherein the anode and the cathode are arranged in the electroplating tank, the cathode is erected at the middle position in the electroplating tank through a guiding mechanism, the base is arranged below the electroplating tank,one side, located on the base, of the electroplating tank is sequentially provided with a filtering unit and a swinging mechanism, and the rectifier is arranged on one side of the base. According tothe device, the arranged cathode is erected in the electroplating tank through the guiding mechanism to cooperate with the swinging mechanism, and the cathode and an ornament hung on the cathode swingin a regular low-frequency manner in the electroplating tank, so that convection of solution is accelerated, metal ions consumed in the vicinity of the cathode are timely supplemented, concentrationpolarization effect of the cathode is reduced, the electroplating efficiency of the metal ornament is improved, through the low-frequency cathode movement mode, the defect that mud and slag are proneto deposit on a plated piece is overcome, and the electrode reaction speed is improved while the electroplating quality is ensured.

Owner:义乌市傅宝仙饰品有限公司

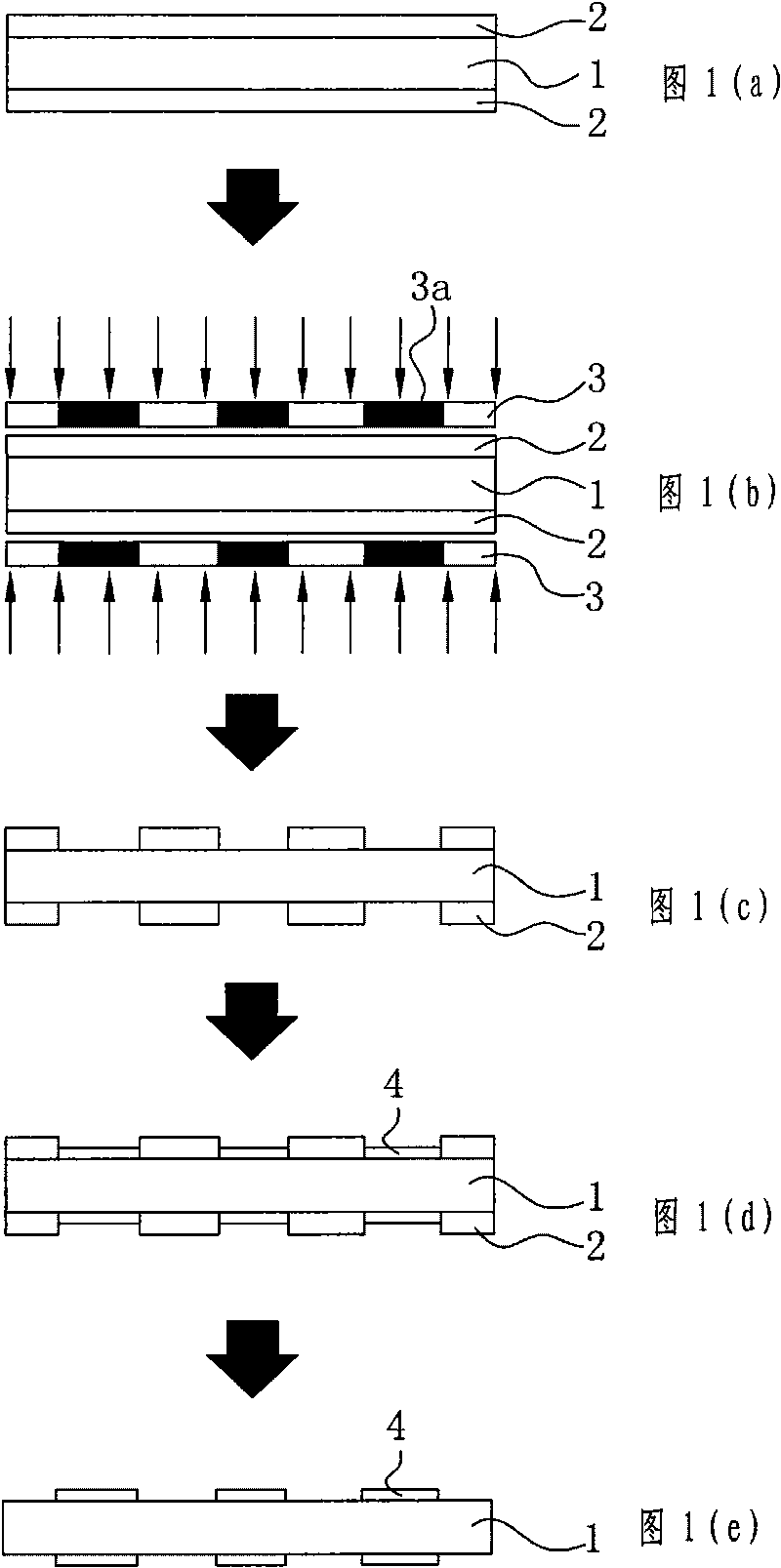

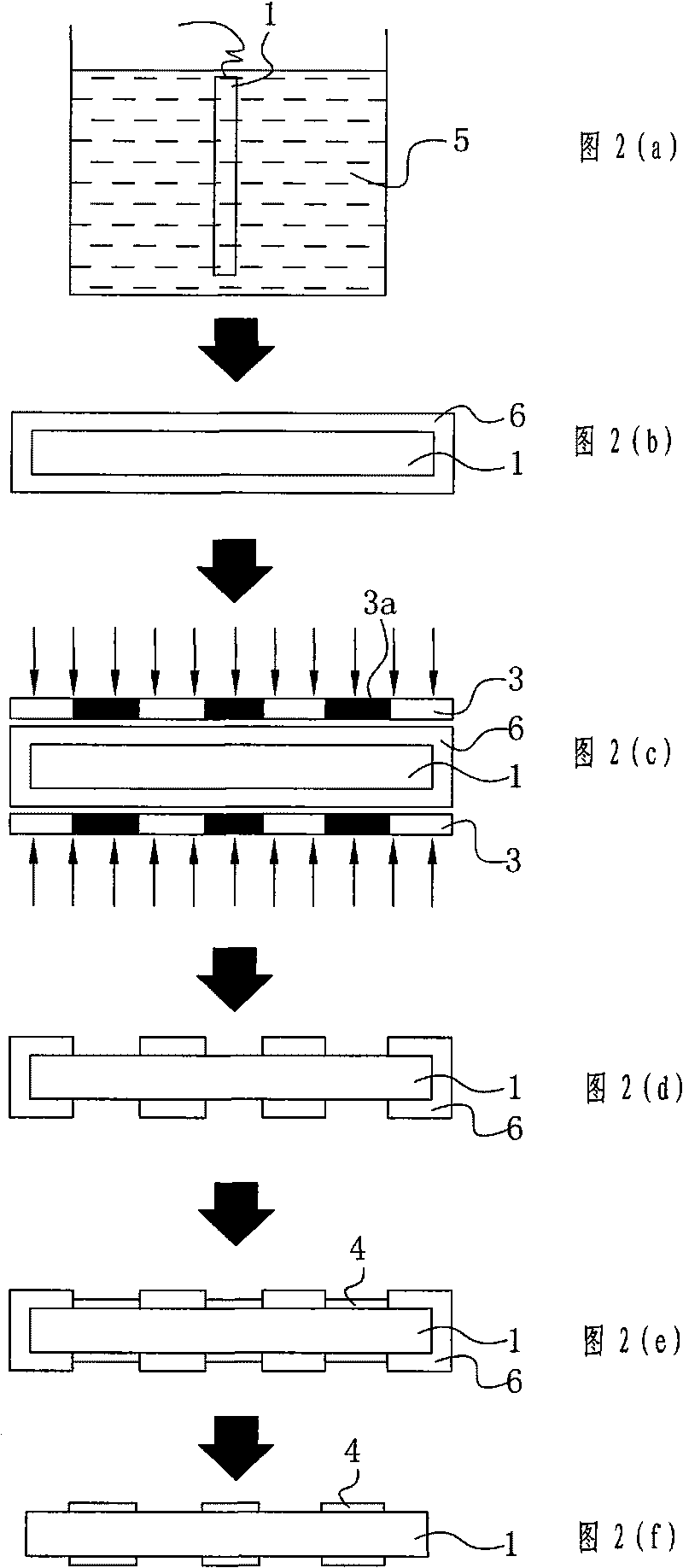

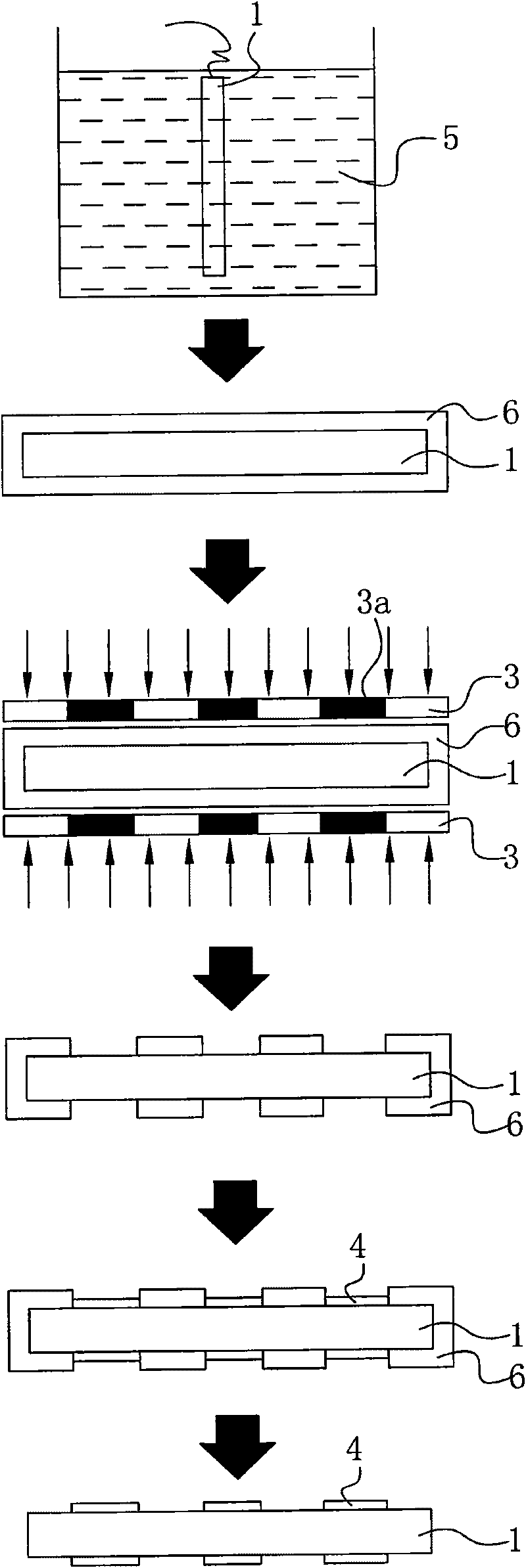

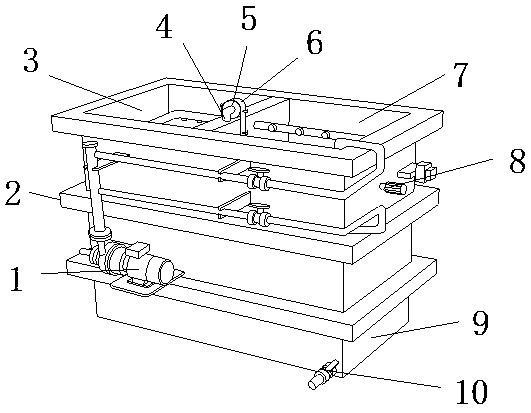

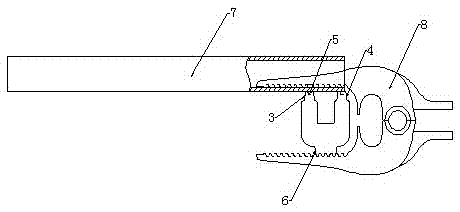

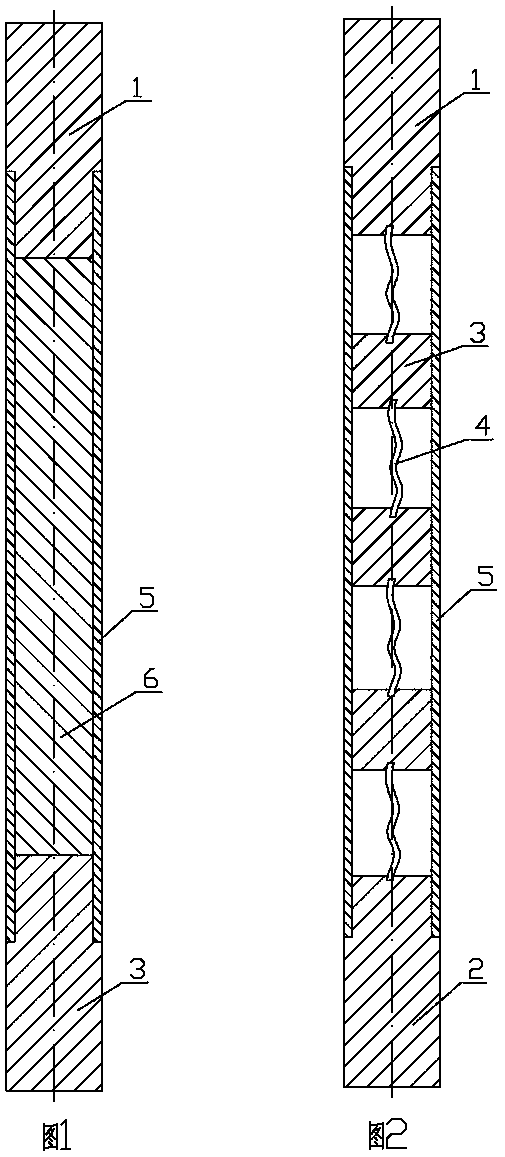

Method for electroplating lead frame

ActiveCN101707185AGuarantee the quality of platingLow priceSemiconductor/solid-state device manufacturingElectrolytic organic material coatingBiochemical engineeringLead frame

The invention discloses a method for electroplating a lead frame, which comprises the following steps: (1) preparing a wet-film solution (5); (2) electroplating a film layer on the lead frame; (3), cleaning and drying the lead frame; (4) exposing the lead frame; (5) developing the lead frame; (6) electroplating a metal layer on the lead frame; (7) performing film removal treatment; and (8) cleaning and air-drying the lead frame. Compared with the prior art, the method has the advantages that: because a mask treatment is performed on the lead frame by using an electroplated film before the metal layer is plated on the lead frame, the side edge of the lead frame is also electroplated with a mask, a metal plating layer cannot be plated on the side edge of the lead frame when the metal layer is electroplated on the lead frame, and the electroplating quality of the lead frame is ensured; and simultaneously the price of the film is lower than that of a dry film. Thus, the method has a low electroplating cost, is favorable for batch production and has a high yield of finished products.

Owner:NINGBO KANGQIANG ELECTRONICS CO LTD

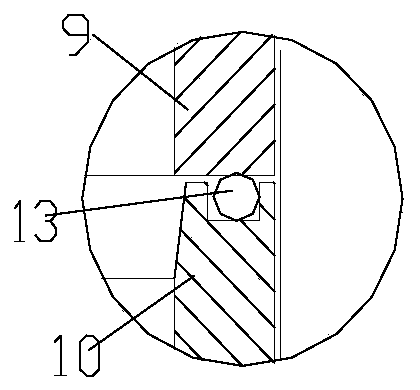

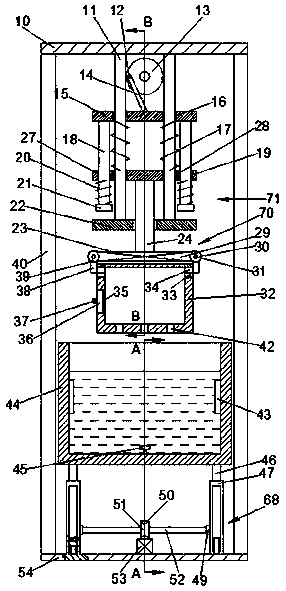

Micro-electroforming apparatus

InactiveCN101376996BUniform thicknessUniform compositionElectroforming processesEngineeringElectric field

The invention relates to a micro-electroforming device which comprises a cathode clamp, a cathode, an electroforming solution stirring pipe, a solution inlet, electric field distribution baffles, electric field distribution baffle positioning baffles, a solution outlet, an anode and a micro-electroforming bath. The anode and the cathode clamp are vertically arranged on the side surfaces of the micro-electroforming bath and face to each other; the cathode is arranged in the cathode clamp; the side plate of the micro-electroforming bath is provided with positioning baffles used for fixing the anode and the cathode clamp as well as a plurality of electric field distribution baffle positioning baffles; the electric field distribution baffles are arranged between the anode and the cathode; thesolution inlet is arranged below the side plate adjacent to the cathode; the electroforming solution stirring pipe is arranged right below the cathode and connected with the solution inlet. The solution outlet is arranged above the side plate adjacent to the anode. A plurality of sets of electric field distribution baffles in concentric circles as well as the circular auxiliary cathode before or on the front side of the cathode clamp make sure the electric fields are evenly distributed on a wafer, which realizes even thickness of MEMS device microstructure layers, convenient operation and high practicality.

Owner:SHANGHAI JIAO TONG UNIV

Multifunctional ship accessory surface electroplating processing device

InactiveCN108660493AGuaranteed cleanlinessGuarantee the quality of platingCleaning using liquidsPipingElectroplating

The invention discloses a multifunctional ship accessory surface electroplating processing device. The device structurally comprises a pump, a rack, a cleaning tank, a shaft frame, a rolling wheel, aconveying belt, an electroplating tank, a stirring device, a waste water treatment device and a water outlet valve; the pump are connected to the cleaning tank, the cleaning tank is movably connectedto the conveying belt, the conveying belt is movably connected to the rolling wheel, the rolling wheel is movably connected to the shaft frame, the shaft frame is connected to the rack, and the rack is provided with the cleaning tank; and the electroplating tank is provided with the stirring device, the bottom of the cleaning tank is connected to the waste water treatment device, the waste water treatment device is provided with the water outlet valve, the cleaning tank is composed of a tank body, a water pipe and a nozzle, the tank body is connected to the water pipe, and the water pipe is connected to the nozzle. According to the multifunctional ship accessory surface electroplating processing device, the cleaning tank is arranged, a workpiece before electroplating can be cleaned, the surface of the workpiece is ensured to be clean, and the electroplating quality is guaranteed.

Owner:镇江鸿瑞机械制造有限公司

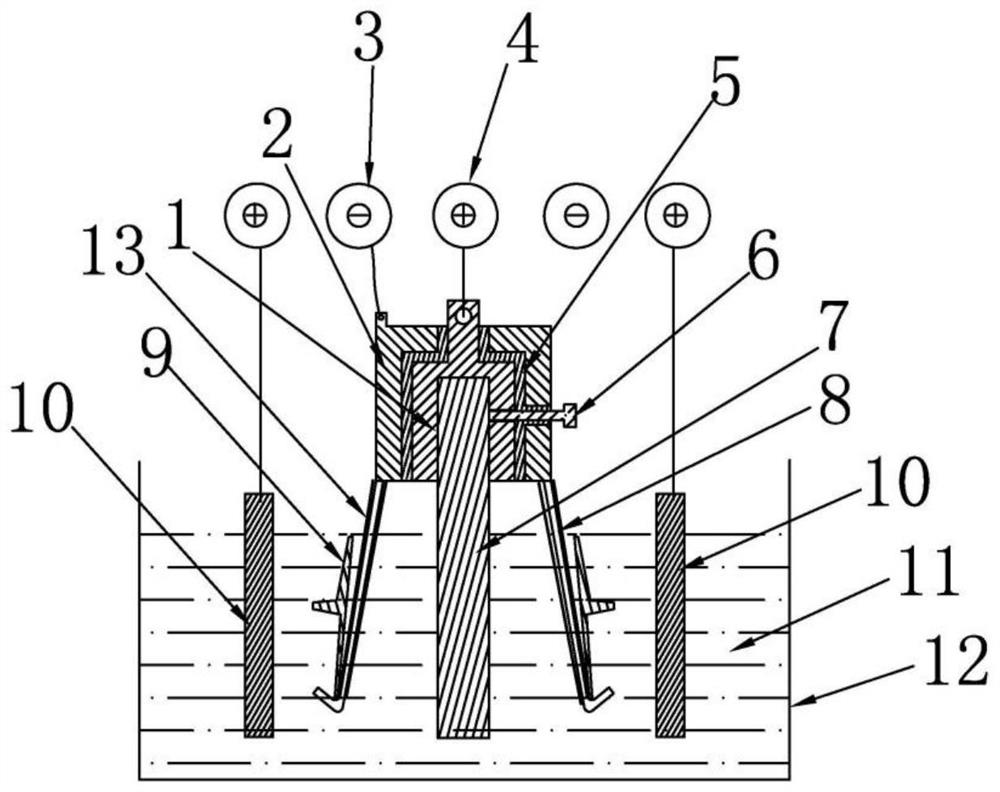

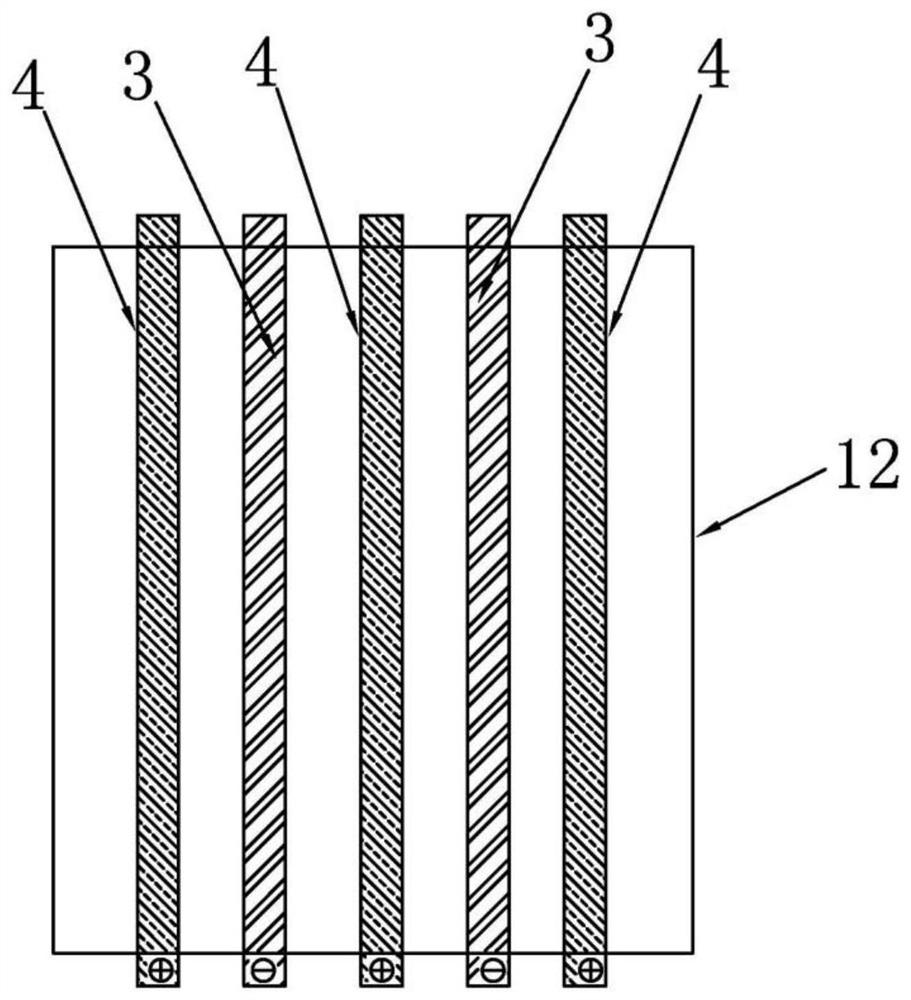

Hollow part electroplating device

PendingCN112391668AImprove the plating effectImprove plating efficiencyElectrodesComposite materialCathode

The invention discloses a hollow part electroplating device which belongs to the technical field of electroplating. The device comprises an electroplating slot, an anode assembly and a cathode assembly, wherein a plurality of anode rods which are arranged side by side are arranged above the electroplating slot; a cathode anode is arranged between adjacent two anode rods above the electroplating slot; the cathode assembly is used for placing a hollow part; the anode assembly is detachably connected to the cathode assembly and is positioned at the inner side of the cathode assembly; the anode assembly and the cathode assembly are kept insulated; the cathode assembly is electrically connected to the cathode rods; and the anode assembly is electrically connected to the anode rods. In an electroplating process, the anode rods are mounted inside the hollow part, and anode plates are mounted outside the hollow part, so that inner and outer surfaces of the hollow part are good in electroplating effect and are high in electroplating efficiency. The hollow part is supported by a hanger, so that the hollow part can be effectively limited, placed and taken, and thus, electroplating efficiencyis favorably improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

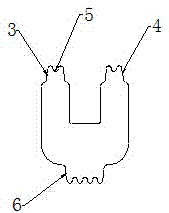

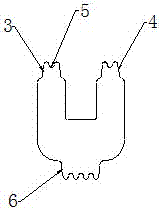

Two-purpose aluminum pipe hanging tool

ActiveCN105442029APass smoothlyPrevent looseningHot-dipping/immersion processesAnodisationEngineeringElectroplating

The invention relates to a two-purpose aluminum pipe hanging tool which comprises a transverse rod and hanging frames arranged at the two ends of the transverse rod. Each hanging frame is made from an aluminum profile bent in a U shape. The cross section of each aluminum profile is in a U shape. An isosceles trapezoidal first protrusion and an isosceles trapezoidal second protrusion are arranged at the two top ends of each U shape respectively. The junction between each first protrusion and the corresponding U shape and the junction between each second protrusion and the corresponding U shape are in smooth transition. Flow guide grooves formed in the aluminum profile extending direction are formed in the upper surfaces of the first protrusions and the second protrusions. A rectangular third protrusion is arranged in the center of the lower end of each U shape. The junction between each third protrusion and the bottom of the corresponding U shape is in smooth transition. Corrugated serrated structures are arranged on the lower surfaces of the third protrusions. The two-purpose aluminum pipe hanging tool has the beneficial effects that by the adoption of the hanging tool, galvanization and electroplating can be achieved smoothly, a corresponding manner can be selected according to actual production, and the use number of hanging tools is reduced.

Owner:RUGAO HUAYANG ALUMINUM PROD

Electroplating equipment for two-side feeding and discharging of electroplated parts

InactiveCN112680767AEasy loading and unloadingLoading and unloading safetyCellsGear wheelRack and pinion

The invention discloses electroplating equipment for two-side feeding and discharging of electroplated parts. A pair of left-right moving seats are arranged on the left side and the right side of a central lifting plate in a left-right moving mode correspondingly. A central rotating column is rotationally arranged on the central lifting plate. The central rotating column vertically penetrates through a left-right moving groove and is provided with a central gear. The central gear is located between a pair of left and right driving racks and engaged with the pair of left and right driving racks. A clutch device is arranged in the left-right moving groove. The clutch device is used for separating and combining the central rotating column and the central gear. A central driving gear is arranged at the bottom of the central rotating column. The lower end surface of the central lifting plate is pivoted with a pair of transmission central shafts which are symmetrically arranged left and right. A central transmission gear is fixed at the bottom of the transmission central shaft. A side central column is pivoted to the bottom surface of the left-right moving seat. A rotary gear is fixed to the lower portion of the side central column.

Owner:苏州耀水源环境科技有限公司

Electroplating device for electroplating outside cylinder body tank

ActiveCN110886004AGuaranteed real-time replacementGuaranteed firmnessSealing devicesElectrodesCylinder blockMaterials science

The invention discloses an electroplating device for electroplating outside a cylinder body tank. The electroplating device comprises an anode, a flow guide piece and an electroplating environment forming assembly, the anode is installed on the electroplating environment forming assembly, an electroplating environment is formed around the anode, and the flow guide piece is used for guiding electroplating liquid into the electroplating environment and enabling the electroplating liquid to flow into the anode center from the top end of the anode and flow back. The flow guide piece is provided with a plurality of flow distribution holes for electroplating liquid to pass through, and the flow distribution holes are distributed in a circulation interface of the electroplating liquid. The structure that the flow distribution holes are formed in the circulation interface of the electroplating liquid is adopted; large impact is prevented from being formed under the driving of the pump; a stable electroplating environment can be provided in the dynamic electroplating process; the advantages of dynamic electroplating are still achieved, it is guaranteed that positive ions on a plating layerare replaced in real time, indifferent concentrations and stable and uniform flowability are formed, and therefore compactness of the plating layer is well guaranteed, and the electroplating quality is guaranteed.

Owner:LONCIN MOTOR

Efficient gravure chromeplating additive

The invention relates to an efficient gravure chromeplating additive, which effectively solves the problems that the current efficiency is low, the electric energy consumption is high and a plated piece is corroded. The efficient gravure chromeplating additive is prepared from 12-18kg of 1,5-naphthalene sulfonic acid sodium salt, 8-12kg of potassium iodide, 9-15kg of methylene sodium binaphthalene sulfonate, 0.4-0.6kg of sulfuric acid, 0.25-0.35kg of alcohol, 0.4-0.6kg of chromic anhydride and 25-39kg of purified water. The efficient gravure chromeplating additive is prepared by the steps of: adding 1,5-naphthalene sulfonic acid sodium salt into the purified water; agitating till 1,5-naphthalene sulfonic acid sodium salt is dissolved; adding potassium iodide; agitating till potassium iodide is dissolved; adding and agitating sodium methylene binaphthalene sulfonate; adding and agitating alcohol till the alcohol is dissolved; and adding and agitating chromic anhydride till the chromic anhydride is dissolved. The efficient gravure chromeplating additive provided by the invention has a very good effect, and the chromeplating solution with the additive is high in current efficiency, great in deposition velocity, free from fluorides and does not corrode the plated piece and the lead plate of the anode, so that the electroplating quality is ensured.

Owner:ZHENGZHOU DAYOU PLATEMAKING CO LTD

Groove external electroplating technology of cylinder body

InactiveCN105887147AGuaranteed closure propertiesImprove protectionElectrolytic coatingsHydrogenEngineering

The invention discloses a groove external electroplating technology of a cylinder body. Groove external electroplating is adopted, the inner surface of the cylinder body is used as a cathode and sleeves an anode, electroplating liquid flows through an annulus clearance between the inner surface of the cylinder body and the outer surface of the anode to form an electroplating environment, electrification is implemented, and then electroplating is finished. According to the scheme, the electroplating environment is formed by the flowing electroplating liquid, by the flowing electroplating liquid, real-time substitution of positive ions on a plating layer is guaranteed, concentration difference between the positive ions on the surface of the plating layer of the cathode is not changed basically, large concentration difference is avoided, the thickness of the plating layer is variable and controllable, meanwhile, by the undifferentiated concentration, compactness of the plating layer is guaranteed, the flowing electroplating liquid can balance change of the PH environment of the plating liquid caused by the hydrogen evolution effect, poor binding force is avoided, and electroplating quality is guaranteed.

Owner:LONCIN MOTOR

Semiconductor lead electroplating equipment

The invention discloses semiconductor lead electroplating equipment. An upper bottom plate is arranged on the lower side of a lower bottom plate, the lower bottom plate and the upper bottom plate arefixedly connected through four first supporting rods 1, an electroplating tank for containing an electroplating liquid is arranged on the upper side of the upper bottom plate, vibrators enabling the electroplating liquid to vibrate are symmetrically and fixedly arranged on the left inner wall and the right inner wall of the electroplating tank, discharging nails for discharging the electroplatingliquid are fixedly arranged on the inner wall of the lower side of the electroplating tank, and a lifting device for lifting the electroplating tank upwards is arranged between the electroplating tankand the lower bottom plate. The semiconductor lead electroplating equipment is easy and convenient to operate and low in manufacturing cost, the box for containing the workpieces can move up and downin a mixing mode, the electroplating liquid makes full contact with the workpieces during electroplating, and the electroplating quality is guaranteed.

Owner:泰州市昶宇电气科技有限公司

Anode assembly used for electroplating outside cylinder body tank

The invention discloses an anode assembly for electroplating outside a cylinder body tank. The anode assembly comprises an anode and a flow guide piece, the flow guide part is used for introducing electroplating liquid into the electroplating environment, flowing into the anode center from the top end of the anode and refluxing; the flow guide part is provided with a plurality of flow distributionholes for the electroplating liquid to pass through, and the flow distribution holes are distributed in a circulation interface of the electroplating liquid; the structure that the flow distributionholes are formed in the circulation interface of the electroplating liquid is adopted; large impact is prevented from being formed under the driving of the pump; a stable electroplating environment can be provided in the dynamic electroplating process, the advantages of dynamic electroplating are still achieved, it is guaranteed that positive ions on a plating layer are replaced in real time, indifferent concentrations and stable and uniform flowability are formed, and therefore compactness of the plating layer is well guaranteed, and the electroplating quality is guaranteed.

Owner:LONCIN MOTOR

Electroplating method for improving deep plating capacity of circuit board with high aspect ratio

InactiveCN105256351AImprove plating qualityGuarantee the quality of platingJewelleryCopper sulfatePrinted circuit board

The invention relates to an electroplating method for improving deep plating capacity of a circuit board with a high aspect ratio. The electroplating method comprises the following steps: S1, preparing a plating solution: flushing the inner wall of a cylinder body to clear impurities, controlling each liter of the plating solution in a plating bath to comprise the following components: 200-240g of sulfuric acid, 60-68g of copper sulfate and the balance of deionized water, and controlling the temperature in the plating bath to be 20-25 DEG C; S2, loading: clamping a to-be-plated circuit board on a material plate clamp, and putting the to-be-plated circuit board into the plating bath; S3, plating: controlling current density to be 10-15 ASF, controlling a single-side swing amplitude of the material plate clamp to be 3.5-5.5cm, controlling swing frequency to be 9-12 times / min, and controlling electroplating time to be 32-36 minutes; and S4, picking: getting down the plated circuit board from the material plate clamp and drying. The electroplating method has the advantages that: the board with the high aspect ratio is good in deep electroplating capacity, and market competitiveness is improved; and utilization of copper balls and thin balls is reduced, and electroplating cost is reduced.

Owner:四川普瑞森电子有限公司

Method for preventing electrochromism product from skip plating and hard spots

InactiveCN103834944AGuarantee the quality of platingGuaranteed no missing platingLiquid/solution decomposition chemical coatingSuperimposed coating processElectroless nickelCopper plating

The invention discloses a method for preventing an electrochromism product from skip plating and hard spots. The method comprises the steps of oil removing, coarsening, recovering, reducing at two times, activating with palladium, peptizing, plating of chemical nickel, copper pre-plating, copper plating, activating with acid, semi-bright nickel plating, bright nickel plating, nickel sealing, chromium plating, reducing, ultraviolet sterilizing, wind shearing, and drying, wherein washing is performed between every adjacent two processes; when activating with palladium, palladium activating liquid with high tin concentration or palladium activating liquid with low tin concentration is added to a palladium activating bath to control the concentration of tin ions to be 1.2 to 1.8g / L. The invention also provides a method for controlling the concentration of tin ions in the electroplating process. The method is characterized in that two kinds of palladium activating liquid are utilized for effectively adjusting to control the tin ion concentration to be within the optimal range of 1.2 to 1.8g / L, additionally, the content of palladium can also be supplemented, and thus the activating with palladium is effectively promoted, and as a result, the electroplating quality of the product is ensured, and the product is also prevented from skip plating and hard spots.

Owner:延康汽车零部件如皋有限公司

An aluminum tube dual-purpose hanger

ActiveCN105442029BPass smoothlyPrevent looseningAnodisationHot-dipping/immersion processesIsosceles trapezoidEngineering

The invention relates to a two-purpose aluminum pipe hanging tool which comprises a transverse rod and hanging frames arranged at the two ends of the transverse rod. Each hanging frame is made from an aluminum profile bent in a U shape. The cross section of each aluminum profile is in a U shape. An isosceles trapezoidal first protrusion and an isosceles trapezoidal second protrusion are arranged at the two top ends of each U shape respectively. The junction between each first protrusion and the corresponding U shape and the junction between each second protrusion and the corresponding U shape are in smooth transition. Flow guide grooves formed in the aluminum profile extending direction are formed in the upper surfaces of the first protrusions and the second protrusions. A rectangular third protrusion is arranged in the center of the lower end of each U shape. The junction between each third protrusion and the bottom of the corresponding U shape is in smooth transition. Corrugated serrated structures are arranged on the lower surfaces of the third protrusions. The two-purpose aluminum pipe hanging tool has the beneficial effects that by the adoption of the hanging tool, galvanization and electroplating can be achieved smoothly, a corresponding manner can be selected according to actual production, and the use number of hanging tools is reduced.

Owner:RUGAO HUAYANG ALUMINUM PROD

Novel hanging tool for electroplating of inner wall of oil cylinder

The invention discloses a novel hanging tool for electroplating of the inner wall of an oil cylinder and belongs to the technical field of electroplating. The novel hanging tool comprises a cathode lifting component and an anode positioning component, wherein the cathode lifting component is used for clamping the upper end of a to-be-plated cylinder barrel; the anode positioning component is usedfor clamping the lower end of the to-be-plated cylinder barrel; an anode lifting component is connected to the cathode lifting component in a hanging manner; the cathode lifting component comprises apair of oppositely-arranged vertical plates; each vertical plate is connected with a cathode lifting hook; the outer side of each vertical plate is fixedly provided with a V-shaped hook; the two vertical plates are fixedly connected with each other by a pair of middle plates; the two middle plates are provided with clamping openings which face to each other; and the lower ends of the two verticalplates are each fixedly connected with a cathode clamping ring which is used for clamping the upper end of the to-be-plated cylinder barrel. According to the novel hanging tool disclosed by the invention, the anode lifting component, the anode positioning component and the cathode lifting component are combined mutually so that the components are simplified, the original complicated structure is broken, an integrated tool is realized, quick installation and integrated lifting are realized, the electroplating efficiency is improved, and the electroplating quality is guaranteed.

Owner:XCMG HYDRAULICS CO LTD

Slender bar plating hanger

The invention relates to the technical field of plating hangers, in particular to a slender bar plating hanger which comprises a hanger body. The hanger body comprises a hook, a plurality of pipe type clamp assemblies and chains. The pipe type clamp assemblies are fixedly connected to the lower end of the hook and fixedly connected through the chains and comprise outer pipes, fixing holes and fixing screws. The fixing holes are symmetrically formed in the outer pipes in the radial directions and movably provided with the fixing screws. The slender bar plating hanger is simple in structure, a slender bar is quite well fixed through the pipe type clamp assemblies, manpower and material resources are saved, damage to the slender bar is avoided, the plating quality of the slender bar is ensured, and the machining efficiency of the slender bar is improved.

Owner:JIANGSU MENGDE NEW MATERIALS TECH CO LTD

Anode device for electroplating on the inner wall of oil pipe

The invention relates to the technical field of an anode device for electroplating, in particular to an anode device for electroplating of an oil pipe inner wall. The anode device comprises an upper copper rod, a lower copper rod, copper connecting blocks, a copper cable and a titanium tube; a mounting ring groove is formed in the outer wall of the lower end of the upper copper rod, a mounting ring groove is formed in the outer wall of the upper end of the lower copper rod, and the mounting ring groove in the outer wall of the lower end of the upper copper rod and the inner wall of the upper end of the titanium tube are fixedly mounted together; the mounting ring groove in the outer wall of the upper end of the lower copper rod and the inner wall of the lower end of the titanium tube are fixedly mounted together; at least two copper connecting blocks are arranged in a cavity formed among the upper copper rod, the lower copper rod and the titanium tube at intervals, and the diameter of the copper connecting blocks is matched with the inner diameter of the titanium tube. The anode device is reasonable and compact in structure, the weight of the whole anode device can be effectively reduced, the device is not likely to be bent, meanwhile, the manufacturing difficulty and the manufacturing cost of the anode device can be effectively reduced, meanwhile, it is ensured that electric conduction is more uniform, and therefore electroplating quality is ensured, the yield is improved, and the production cost is reduced.

Owner:KARAMAY SHUANGXIN ANTICORROSION TECH

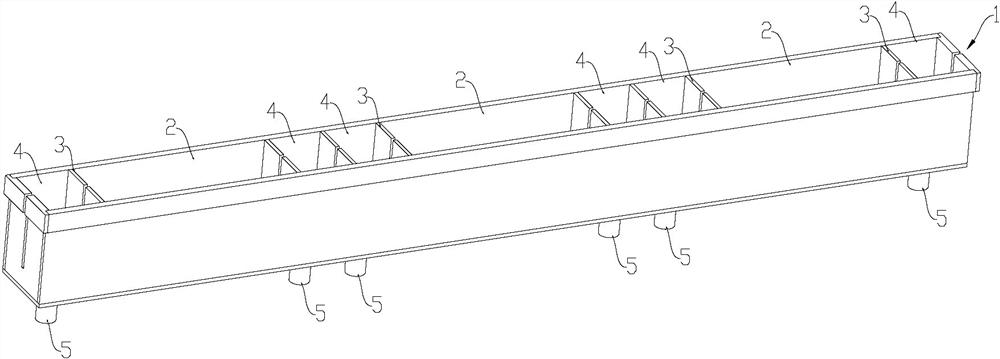

Station tank for copper strip continuous electroplating production line and copper strip continuous electroplating production line

The invention discloses a station tank for a copper strip continuous electroplating production line and the copper strip continuous electroplating production line. The station tank is small in size and simple in structure, and liquid among units cannot be mixed. According to the technical scheme, a rectangular tank body is included, at least two station tanks are arranged on the tank body, every two adjacent station tanks are isolated through at least three partition plates arranged at intervals, the outer ends of the station tanks are isolated through at least two partition plates arranged atintervals, and an overflow recovery tank is formed by the adjacent partition plates. The lower end of the overflow recovery tank is connected with a recovery pipeline, and at least one longitudinal open groove allowing a copper strip to pass through is formed in the partition plates. The station tank for the copper strip continuous electroplating production line and the copper strip continuous electroplating production line have the following advantages that the U-shaped production line is formed by connecting the multiple independent station tanks, the size is small and assembling and transporting are convenient. In addition, the special station tank design is adopted, the different kinds of the liquid in all the stations cannot be mixed with one another, and therefore the electroplatingquality is guaranteed.

Owner:YUEQING JINGU FITTINGS

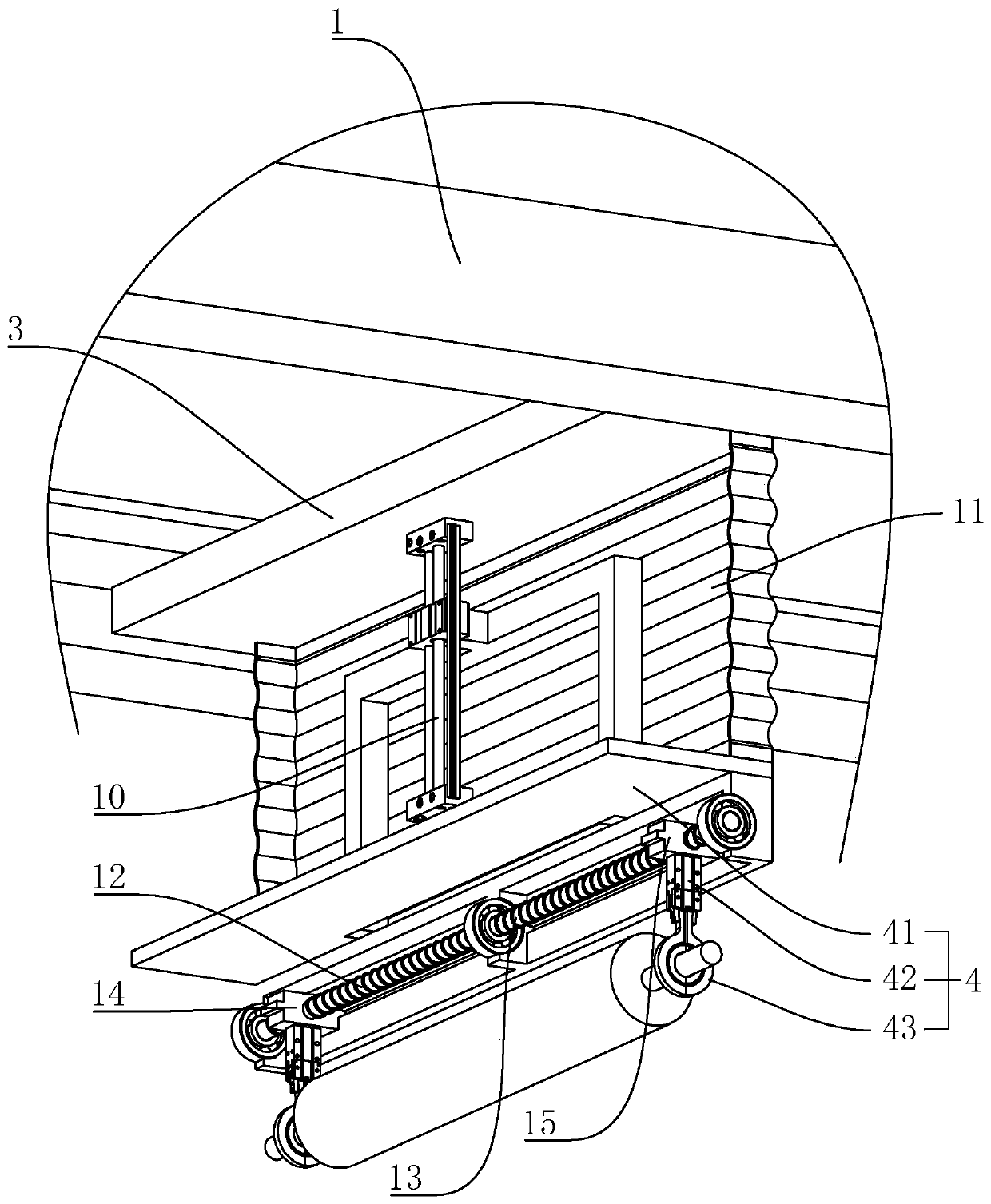

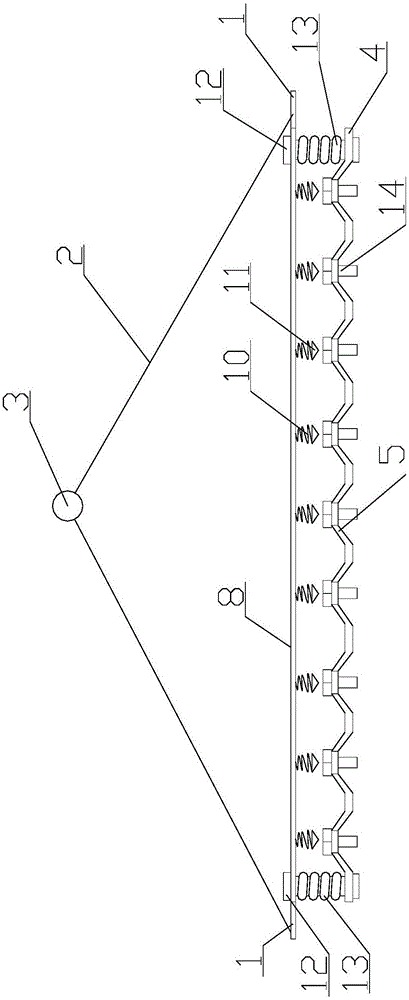

Electroplating machine capable of automatically accessing hanger

ActiveCN1322171CAuto SpacingGuarantee the quality of platingElectrolysis componentsEngineeringWork flow

The electroplating machine capable of automatically accessing jig includes electroplating bath, jig, jig conveying system and control circuit. The jig conveying system set over the electroplating bath may be divided into upper plate section, front processing section, electroplating bath section, post processing section and temporarily set section. The temporarily set section has automatically jig accessing unit consists of jig storing mechanism and automatic elevating mechanism. The control circuit is connected to the jig accessing mechanism and the automatic elevating mechanism. The automatic elevating mechanism is connected to the jig accessing mechanism and the temporarily set section to realize the automatic accessing of jig. Compared with available technology, the present invention has raised electroplating effect, less man-made error and low cost.

Owner:宝盈科技(深圳)有限公司

A new type of electroplating hanger for the inner wall of the oil cylinder

ActiveCN110592645BQuick installationImprove plating efficiencyElectrodesEngineeringMechanical engineering

The invention discloses a novel electroplating hanger for the inner wall of an oil cylinder, which belongs to the technical field of electroplating. It includes a cathode hoisting assembly for clamping the upper end of the cylinder to be plated, and an anode positioning assembly for clamping the lower end of the cylinder to be plated, and an anode hoisting assembly is hung on the cathode hoisting assembly; the cathode hoisting assembly includes A pair of oppositely arranged vertical plates, the vertical plates are connected with cathode hooks, and V-shaped hooks are fixed on the outside of the vertical plates; the two vertical plates are fixedly connected by a pair of intermediate plates, and the two intermediate plates are provided with Opposite bayonets; the lower ends of the two vertical plates are fixedly connected with a cathode card circle for clamping the upper end of the cylinder to be plated. The anode hoisting assembly, anode positioning assembly, and cathode hoisting assembly of the present invention are combined with each other to simplify the parts, break the original complex structure, realize an integrated tooling, realize rapid installation and overall hoisting, improve the electroplating efficiency, and ensure the electroplating quality.

Owner:XCMG HYDRAULICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com