Novel hanging tool for electroplating of inner wall of oil cylinder

A technology of electroplating racks and oil tanks, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc. It can solve the problems of difficult and precise installation, increase the difficulty of operation, and difficult installation, so as to improve the efficiency of electroplating, ensure the quality of electroplating, and achieve versatility high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

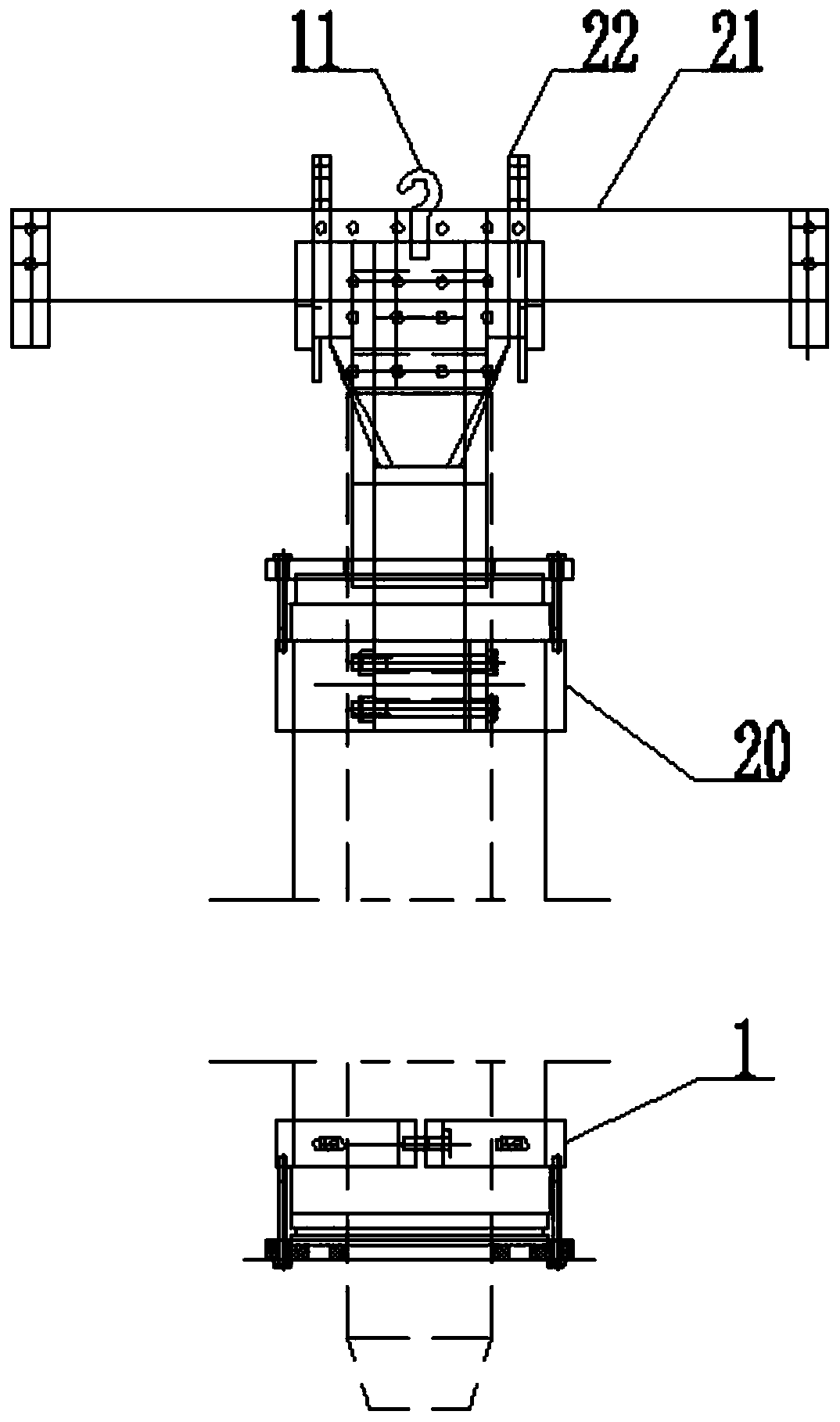

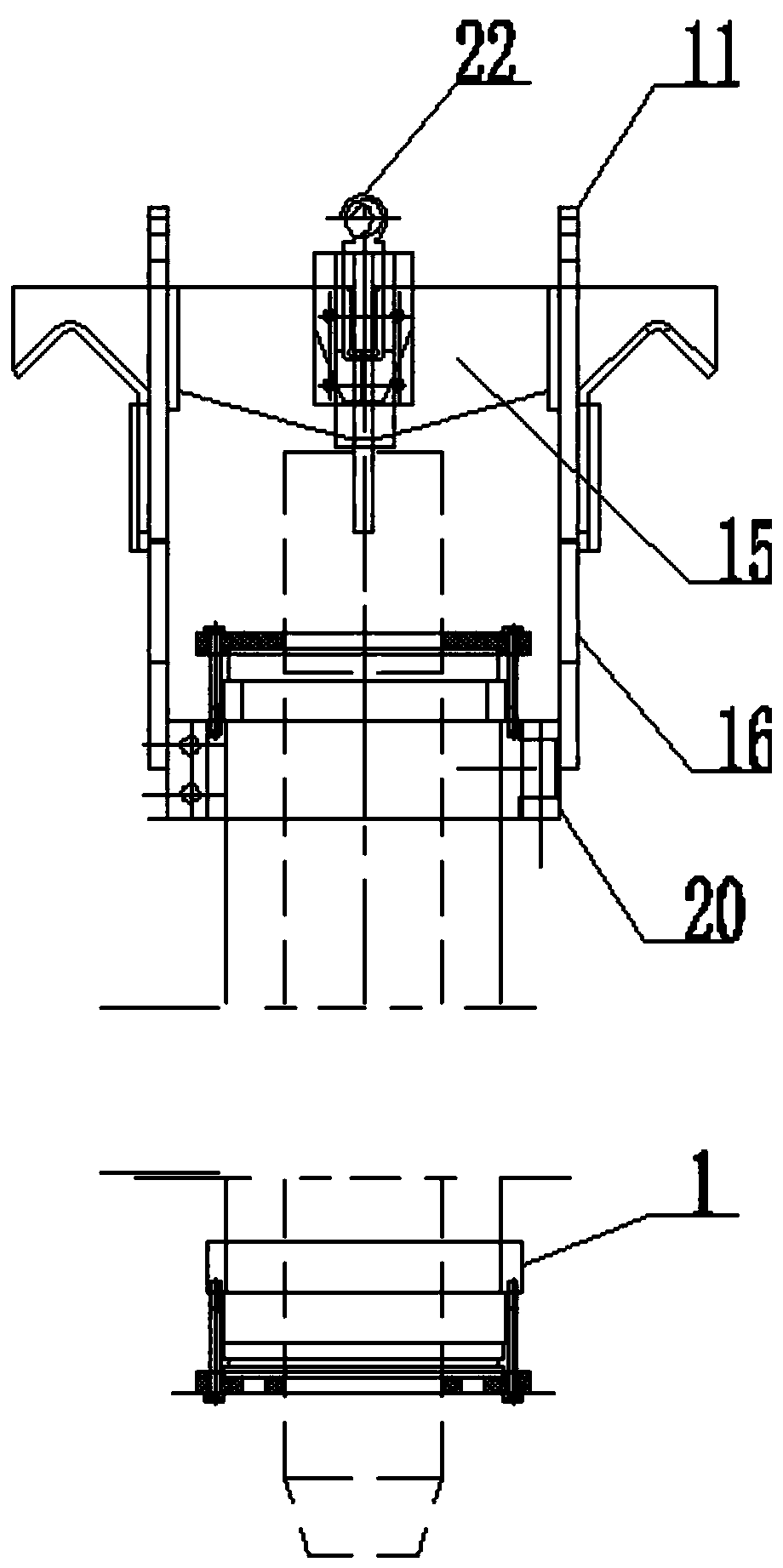

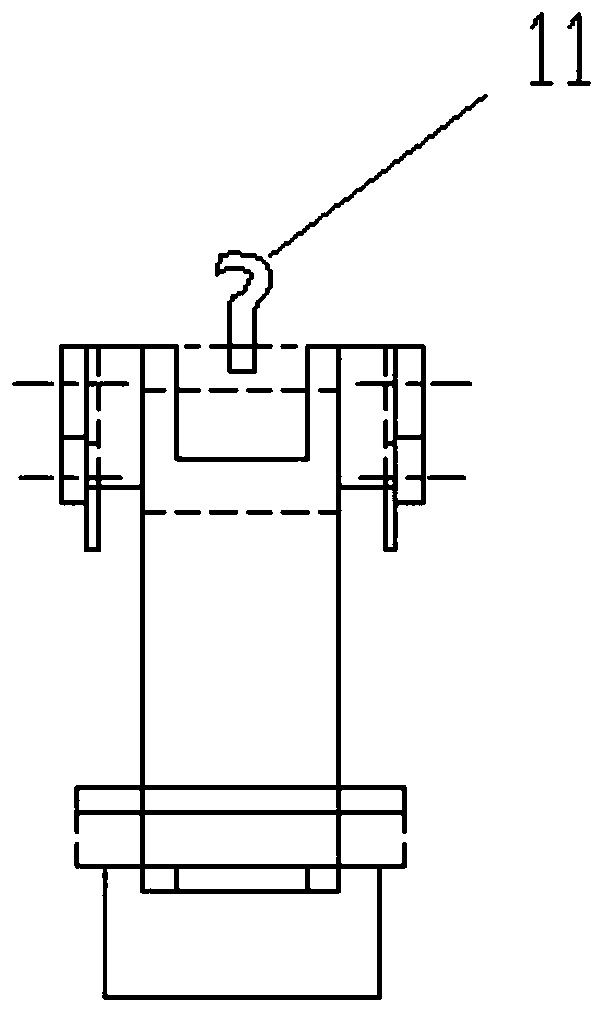

[0032] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

[0033] combine Figure 1 to Figure 4 , Image 6 and Figure 11 As shown, a new type of electroplating hanger for the inner wall of the oil cylinder, the cathode lifting assembly clamps the upper end of the cylinder 9 to be plated, and the cathode lifting assembly is used to connect the upper end of the cylinder 9 to be plated and the cathode conductive device. The anode positioning assembly clamps the lower end of the cylinder 9 to be plated, and the anode positioning assembly is used to connect the lower end of the cylinder 9 to be plated with the anode conductive device. The anode suspension assembly is hung in the bayonet 18 of the cathode suspension assembly, and the anode 23 in the anode suspension assembly passes downward through the cylinder 9 to be coated.

[0034] Anode positioning components: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com