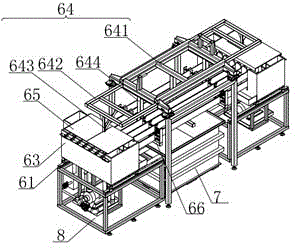

Two-end tin-plating automatic production line

An automatic production line and tin plating technology, applied in electrolytic coatings, jewelry, etc., can solve the problems of ineffective control of product process standardization, increased probability of safety problems, and increased waste water treatment costs, so as to save electroplating liquid and cleaning liquid , reduce processing costs, and improve order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

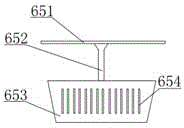

[0024] The working principle of the present invention is: place the workpiece to be plated on the flybar seat, adjust and clamp the plated piece (in order to ensure the stability of the electrical conductivity and the stability of the plated piece), and then insert the flybar into the corresponding slot (purpose In order to isolate and seal the plating solution), the driving is controlled by PLC to carry out electroplating at both ends according to the set process steps and time.

[0025] Work process of the present invention:

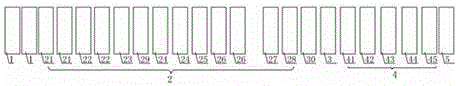

[0026] Feeding, hanging—manual clamping—embedded flybar—starting equipment—electrodegreasing—electrodegreasing—washing 1—washing 2—pickling—washing 1—washing 2—washing 3—passivation—washing 1—washing 2—exchange position—activation—washing—spare—tin plating—washing—ultrasonic cleaning—neutralization—washing—hot water drying—...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com