Station tank for copper strip continuous electroplating production line and copper strip continuous electroplating production line

An electroplating production line and station cell technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of easy mixing of liquids, complex structure, troublesome assembly and transportation, etc., and achieve the effect of ensuring electroplating quality, small size, and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

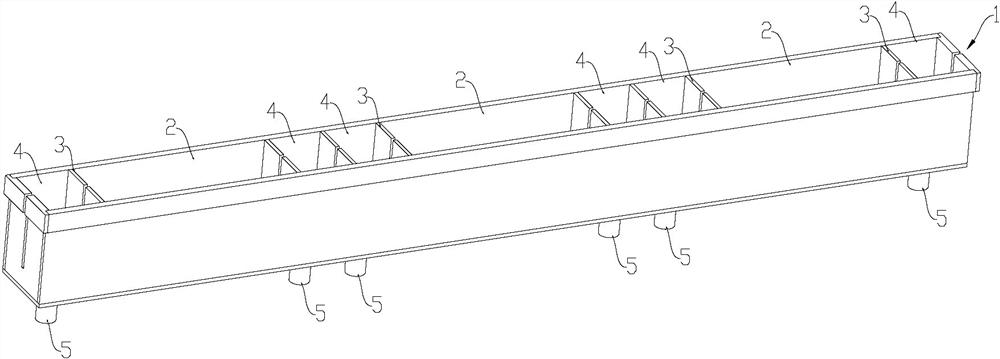

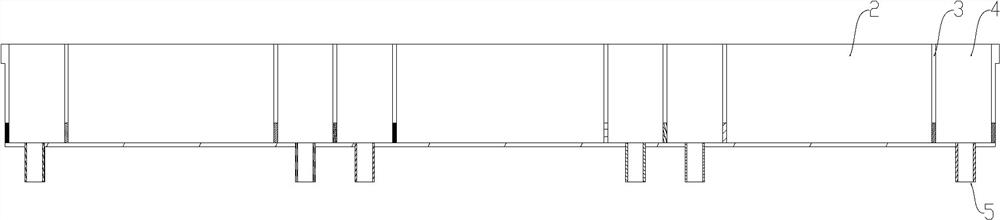

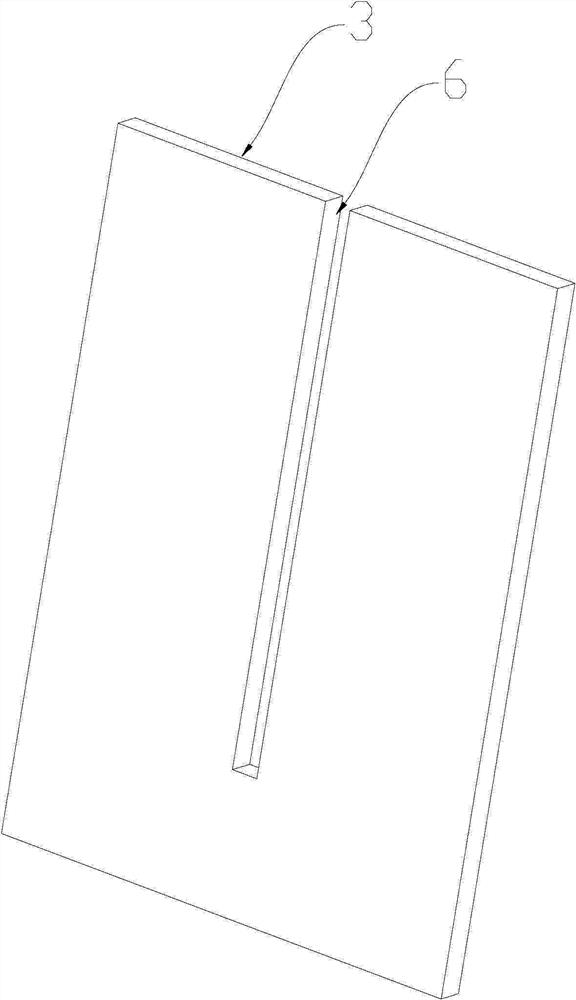

[0020] Such as Figure 1 to Figure 4 As shown, the station tank for the copper strip continuous electroplating production line of the present invention includes a rectangular tank body 1 . The tank body 1 is provided with at least two work stations 2 , and the adjacent work stations 2 are separated by three spaced partitions 3 . The outer end of the station 2 is isolated by two partitions 3 arranged at intervals. Adjacent partitions 3 form overflow recovery tanks 4 . A recovery pipe 5 is connected to the lower end of the overflow recovery tank 4 , and a longitudinal slot 6 for the passage of the copper strip 24 is provided on the partition plate 3 . When in use, each of the stations 2 is equipped with different cleaning liquids. When the copper strip passes through the slot 6, the liquid will overflow to the overflow recovery tank 4 for recovery, thereby preventing the cleaning between different stations. Mixing of liquids.

[0021] Preferably, the distance between adjacen...

Embodiment 2

[0024] Such as Figure 4 As shown, the copper strip continuous electroplating production line of the present invention mainly consists of coil material discharging mechanism 7, degreasing and degreasing tank 8, electrolytic degreasing tank 9, first cleaning tank 10, pickling Tank 11, second cleaning tank 12, pre-plating tank 13, electroplating tank 14, third cleaning tank 15, bright treatment tank 16, fourth cleaning tank 17, fifth cleaning tank 18, drying box 19, coil material collection The body consists of 20. Wherein, the degreasing and degreasing tank 8 , the electrolytic degreasing tank 9 , and the first cleaning tank 10 are composed of a station tank as described in Embodiment 1. The pickling tank 11, the second cleaning tank 12, and the pre-plating tank 13 are also composed of a workstation tank described in Embodiment 1. These two station tanks are arranged in the feeding end of electroplating tank 14 successively. The third cleaning tank 15, the bright treatment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com