Patents

Literature

42results about How to "Auto Spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

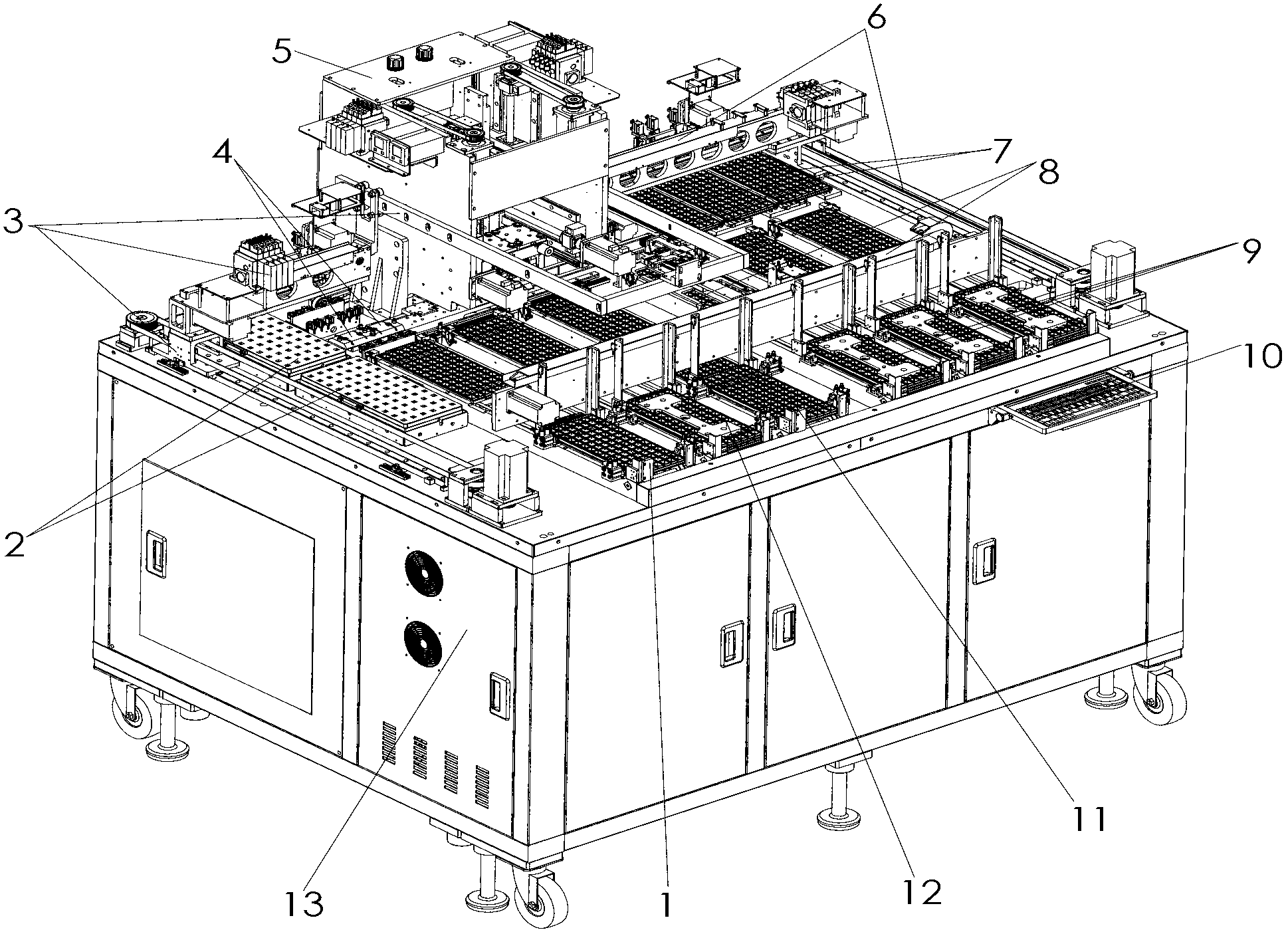

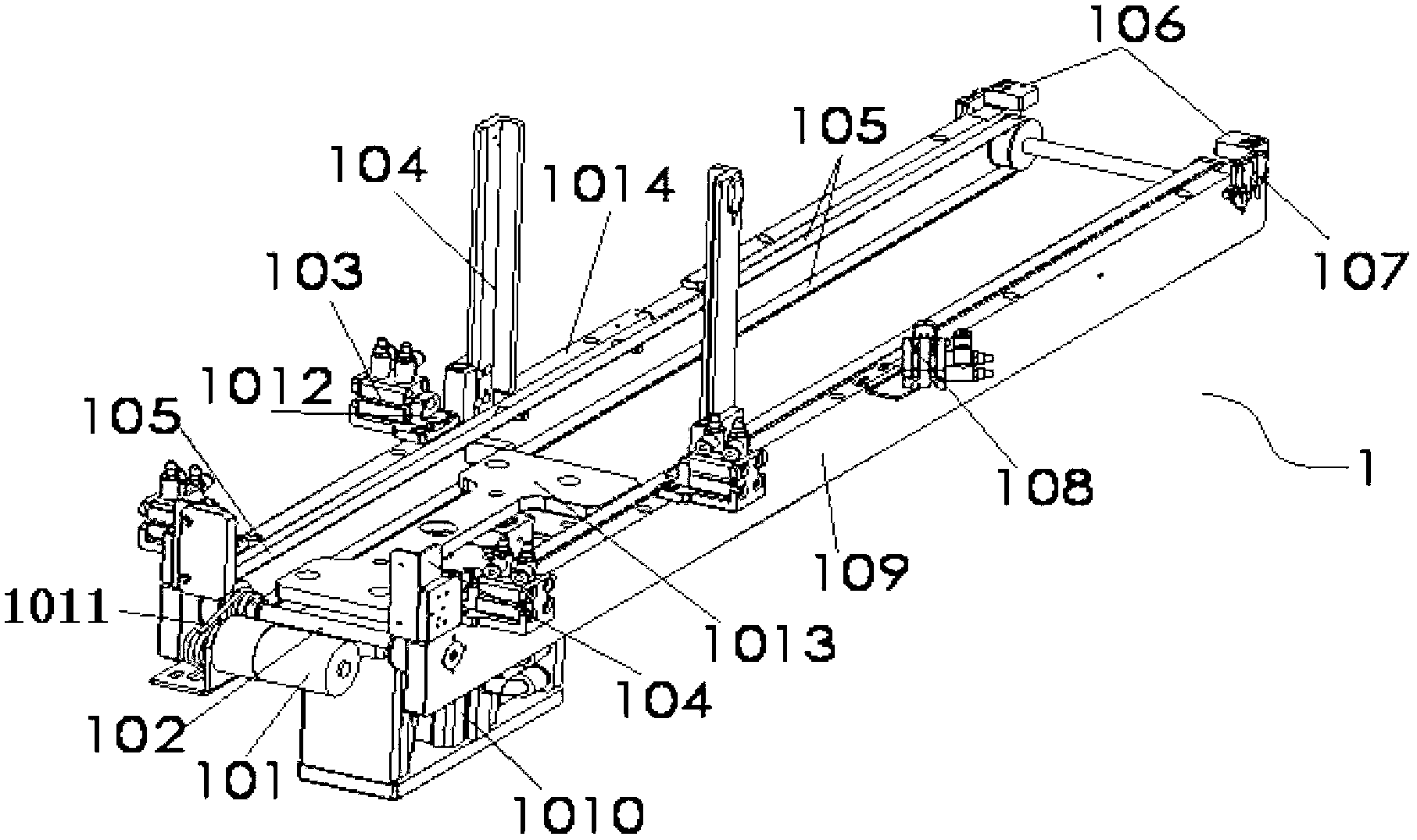

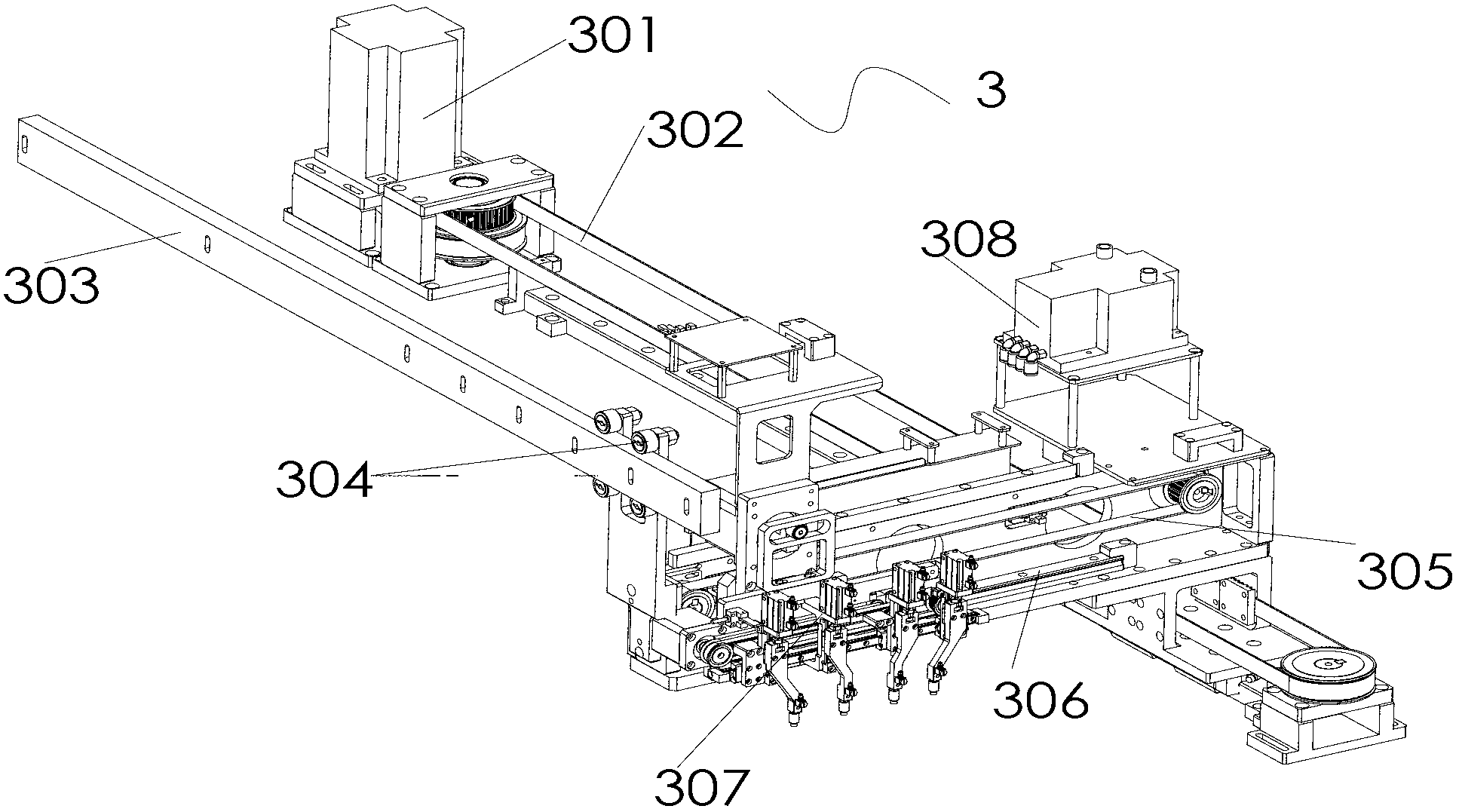

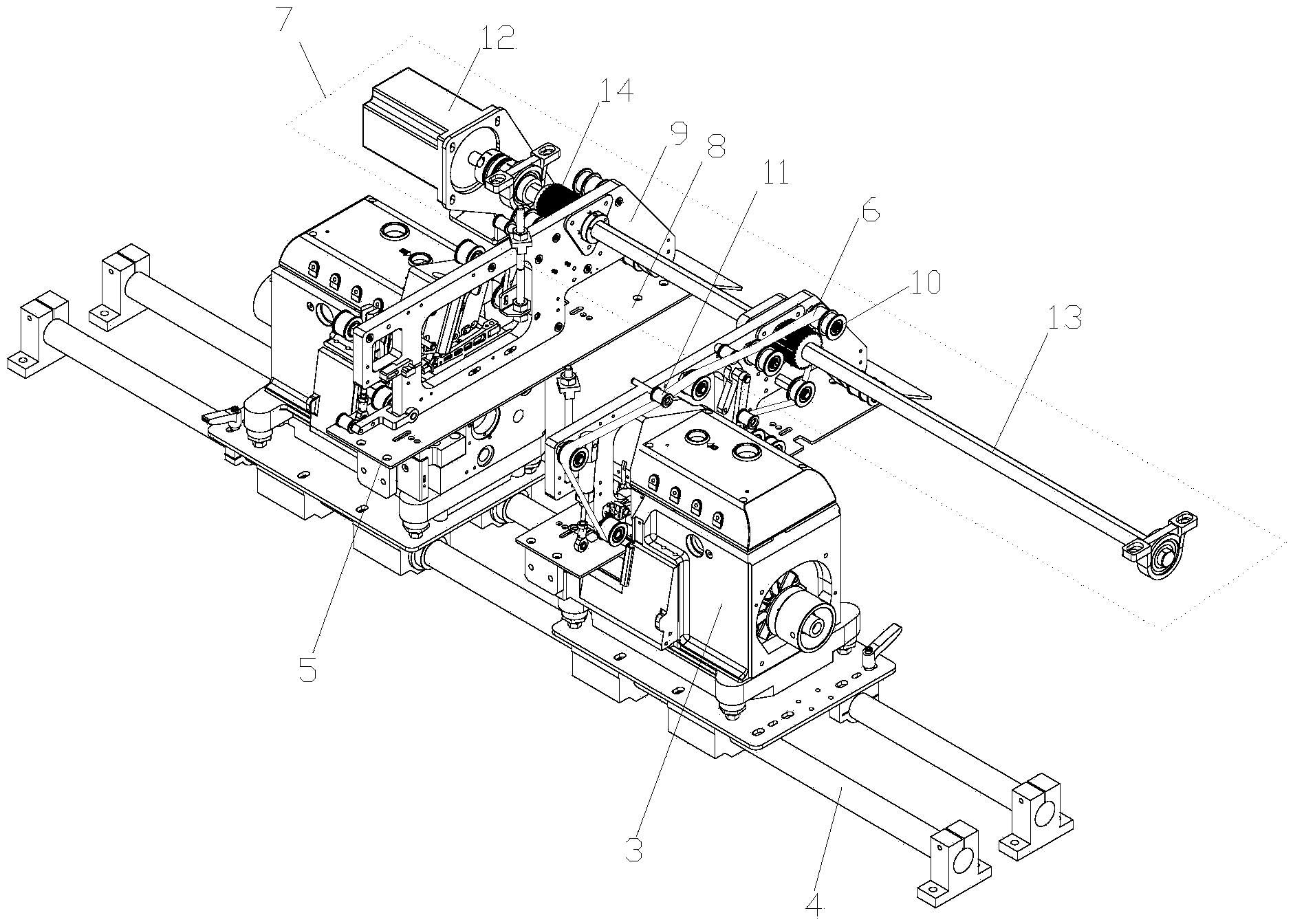

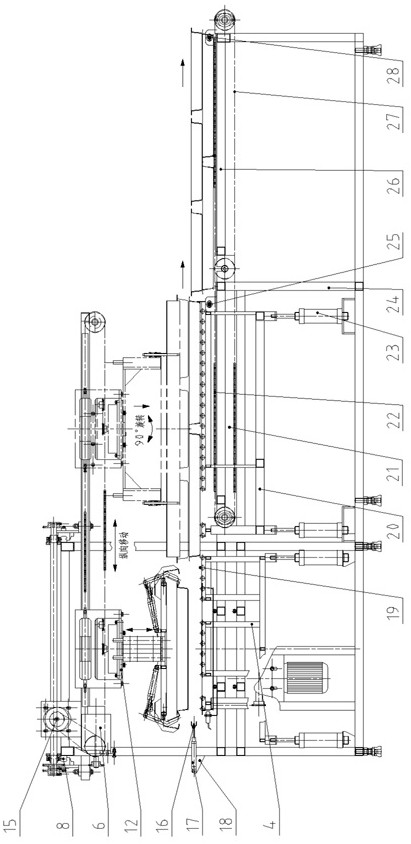

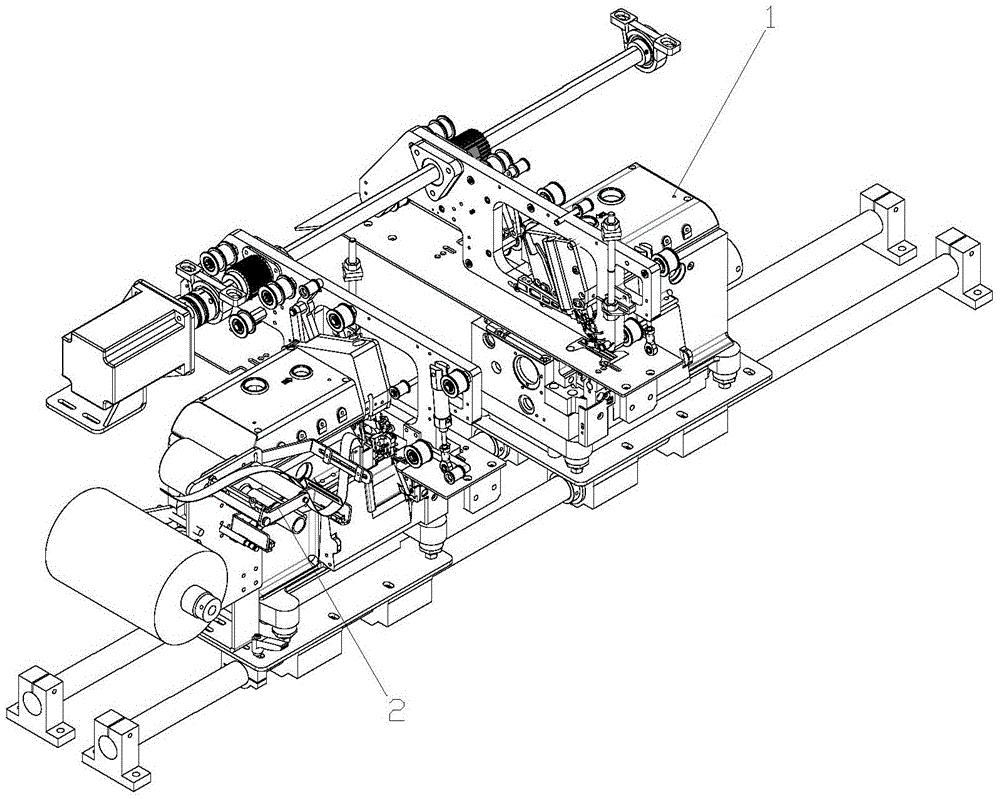

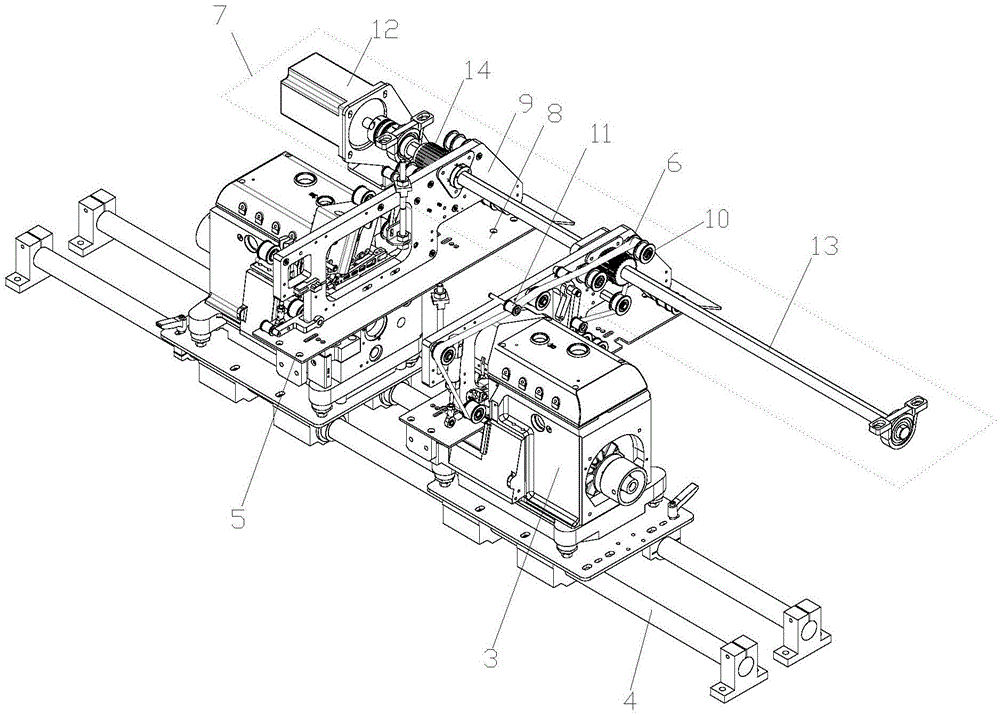

Automatic testing and sorting machine for integrated circuit IC chip

The invention discloses an automatic testing and sorting machine for an integrated circuit IC chip. The machine comprises a charging tray separating and inputting device, a material boat module device, a qualified product sorting and collecting module and an inferior-quality product sorting and collecting module, wherein the charging tray separating and inputting device can separate stacked material trays one by one; the material boat module device comprises a left material boat for holding chips to be tested and a right material boat for holding the tested chips, and the left material boat and the right material boat are controlled by a servo motor to swing left and right; the qualified product sorting and collecting module is used for holding the chips tested to be qualified in the right material boat; and the inferior-quality product sorting and collecting module is used for holding the chips tested to be unqualified. A tray full of chips to be tested and sorted is automatically input to the right position by the tray separating and inputting device, then, the chips are transferred to the boats by a charging gripper platform device one by one; and the chips to be tested in the left material boat are precisely absorbed and moved to a testing position to be tested by a testing gripper combined module device, then, are placed back to the right material boat to be further conveyed to a sorting position, and finally, are sorted and placed in a corresponding finished product tray or inferior-quality product tray by a discharging and sorting gripper platform device according to the test result, and conveyed out of the machine in order after fully filled in the tray.

Owner:深圳格芯集成电路装备有限公司

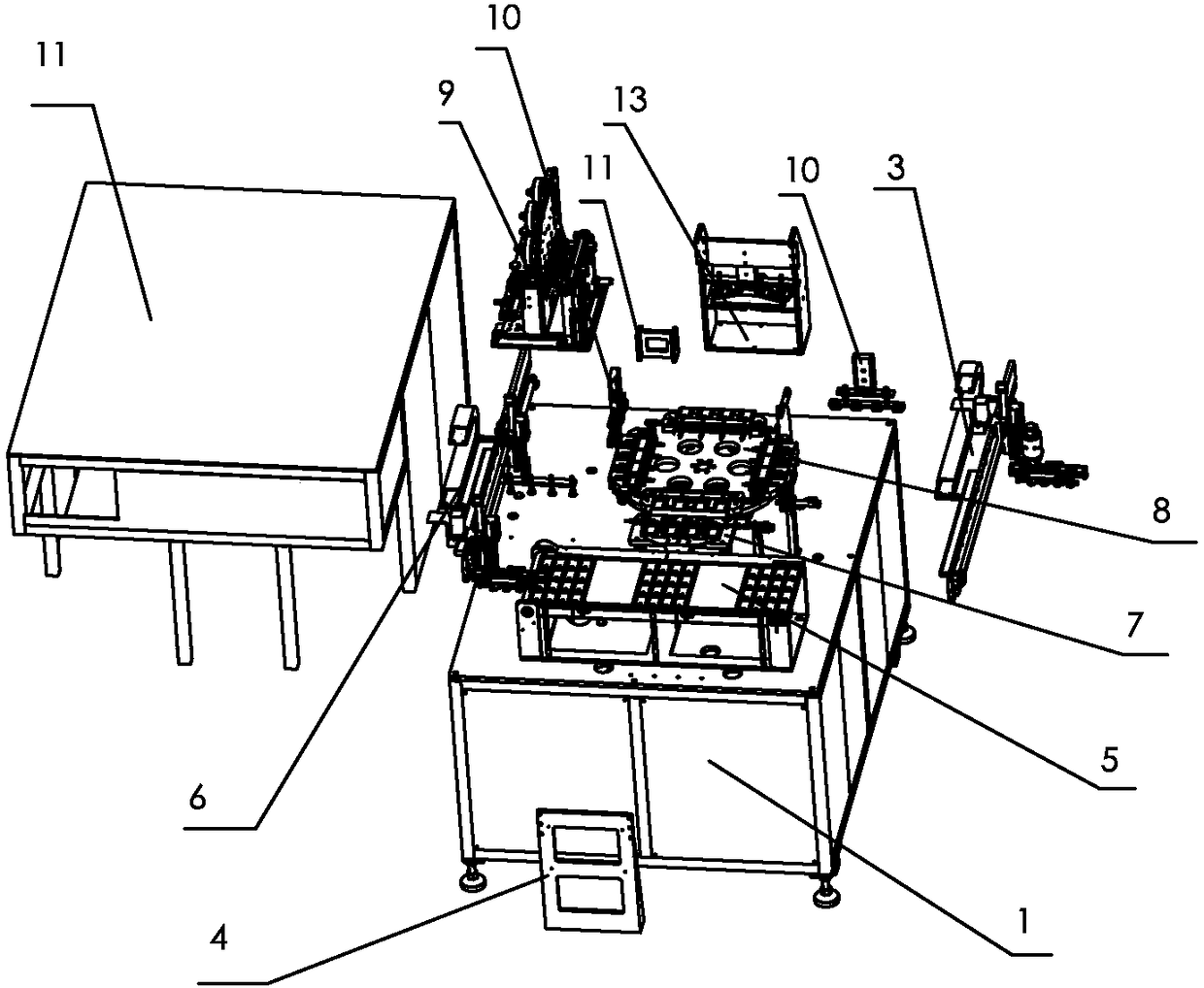

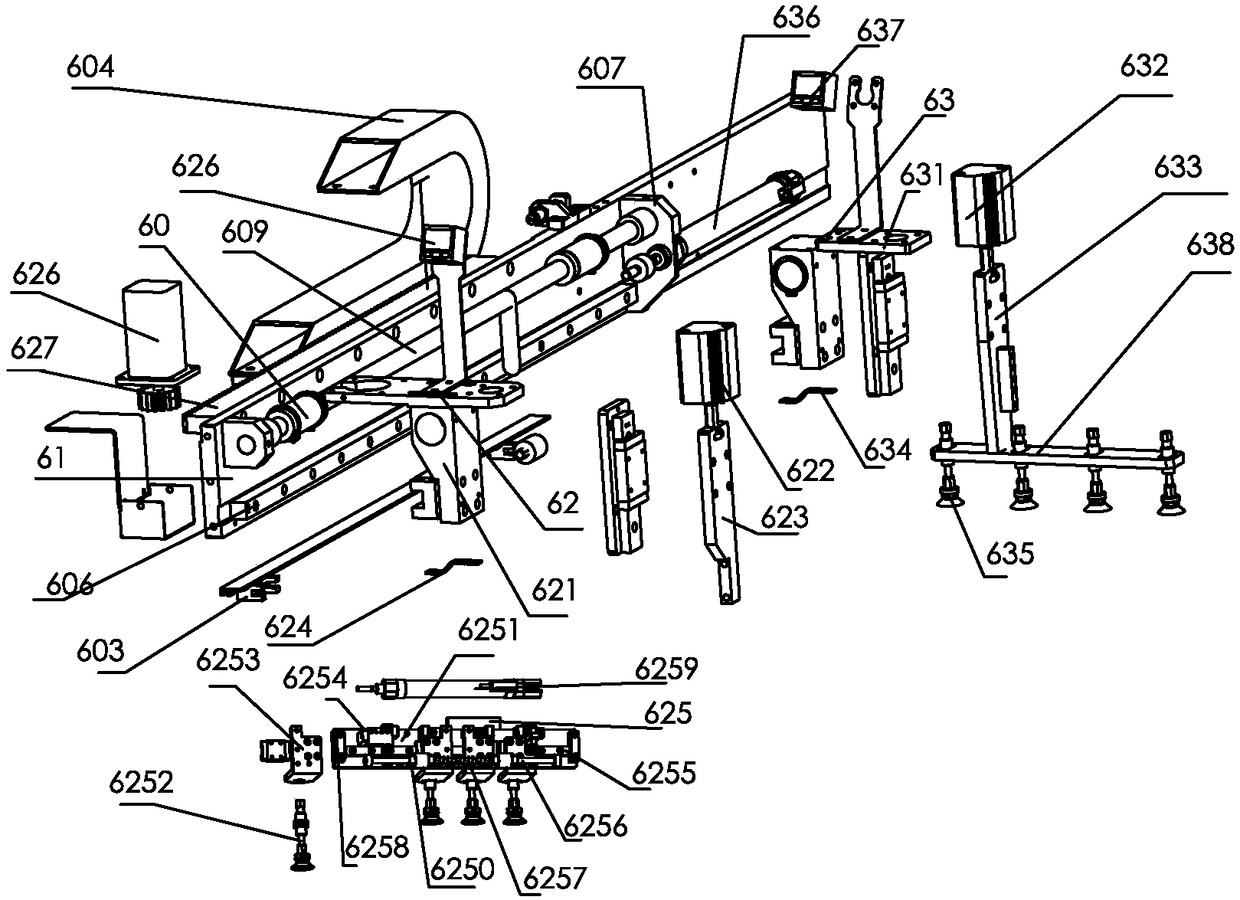

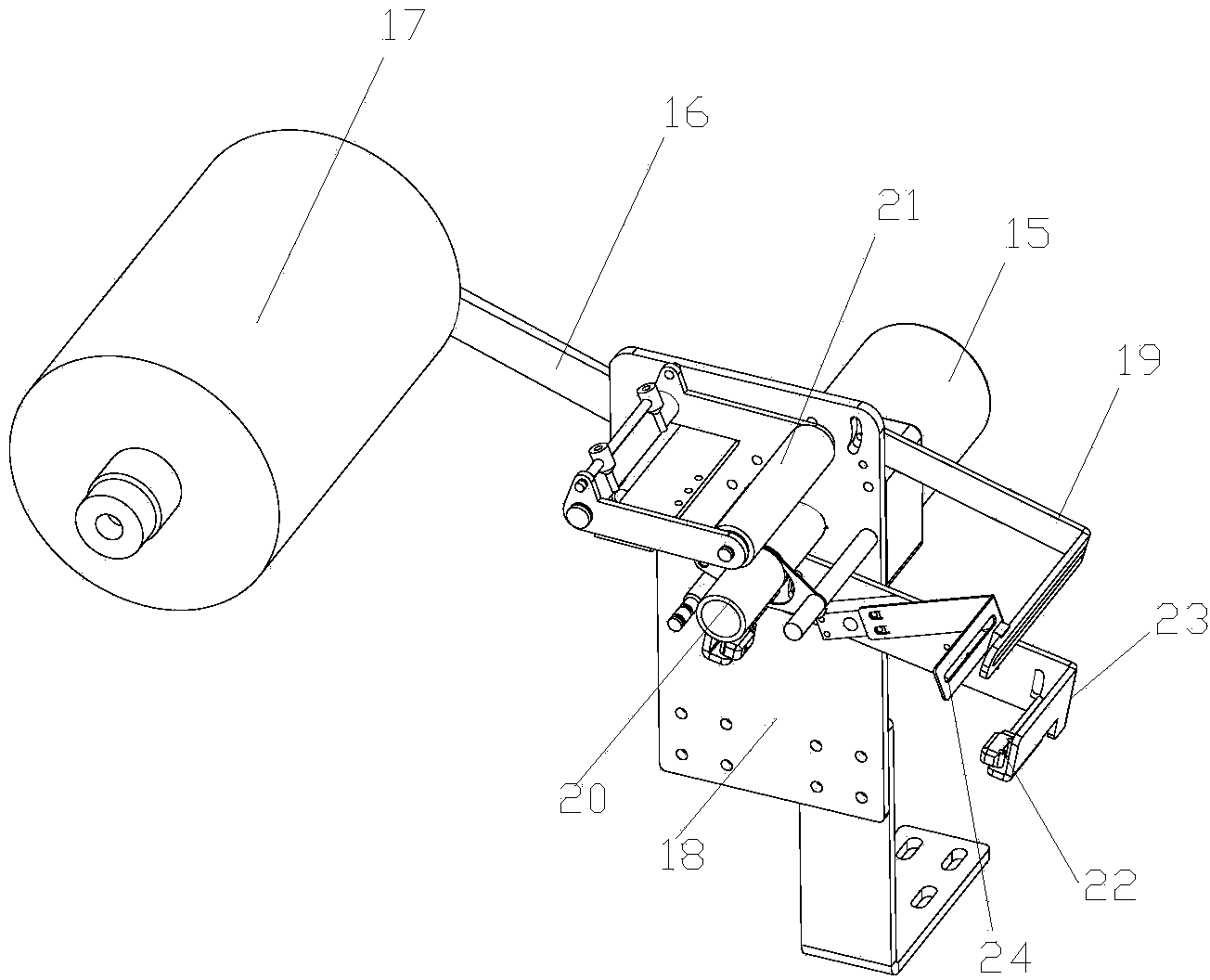

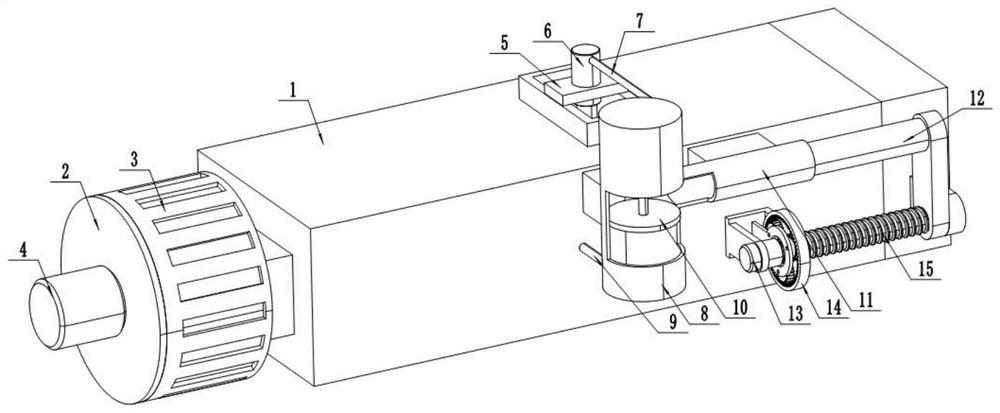

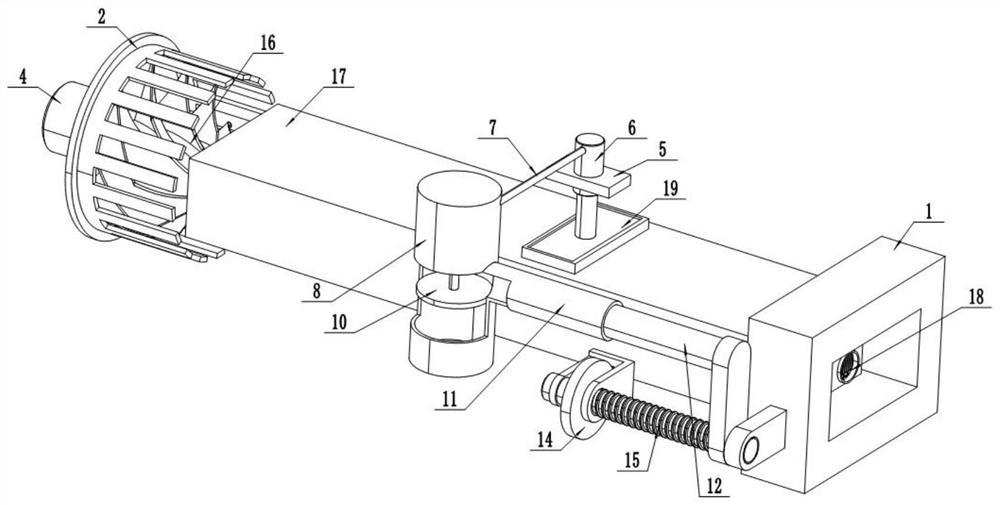

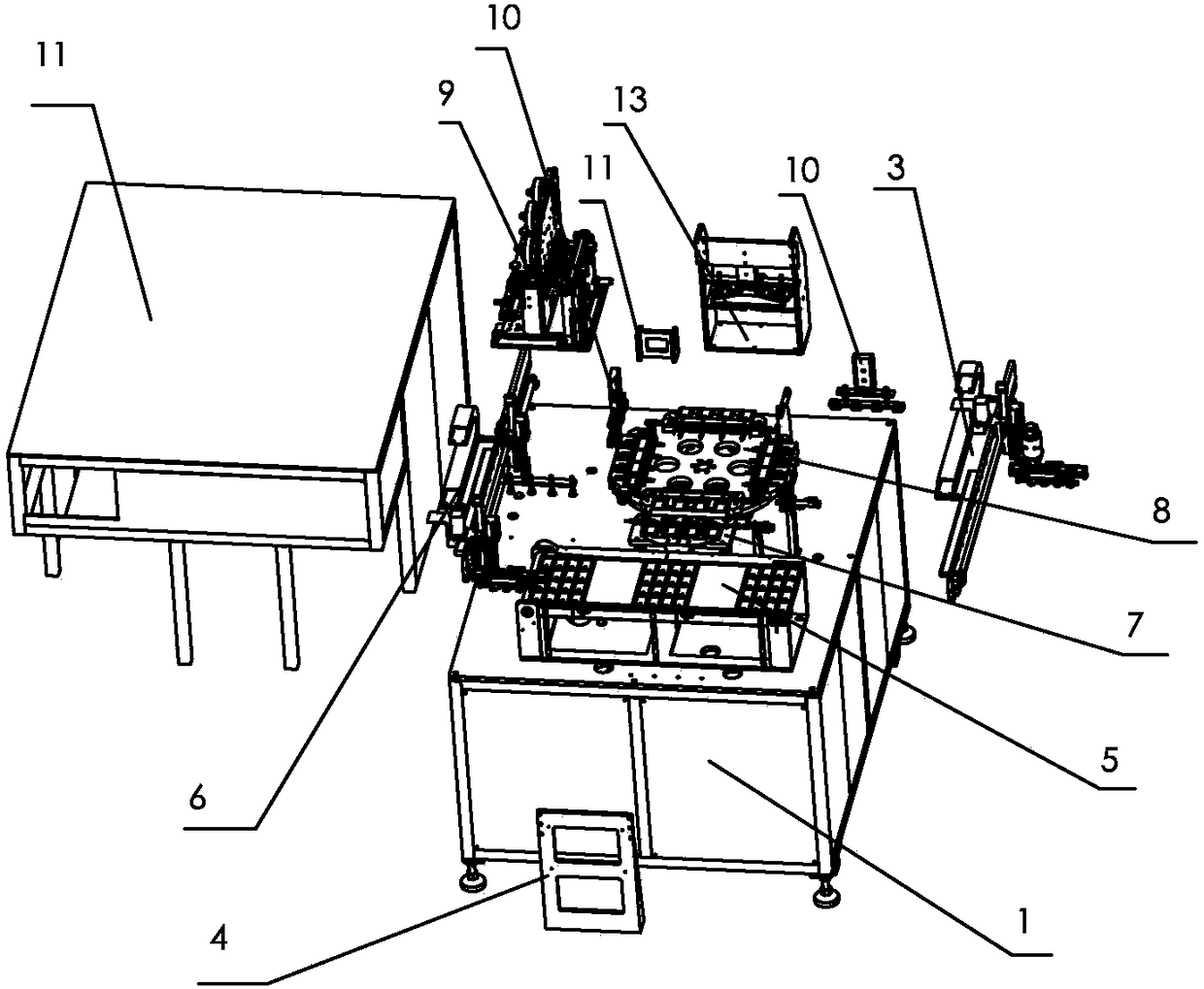

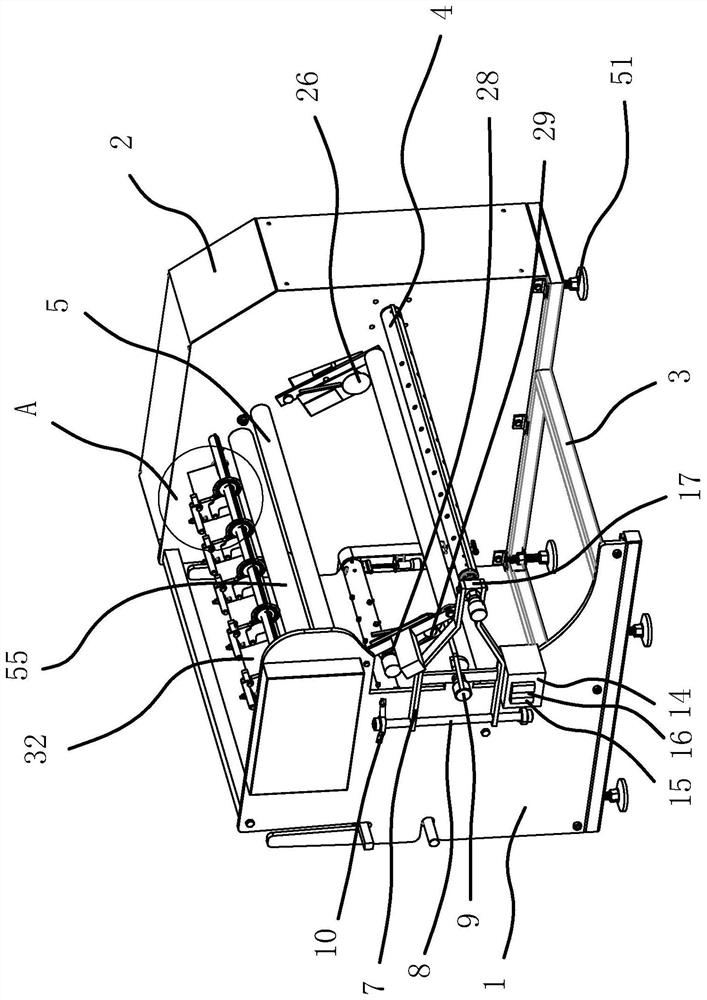

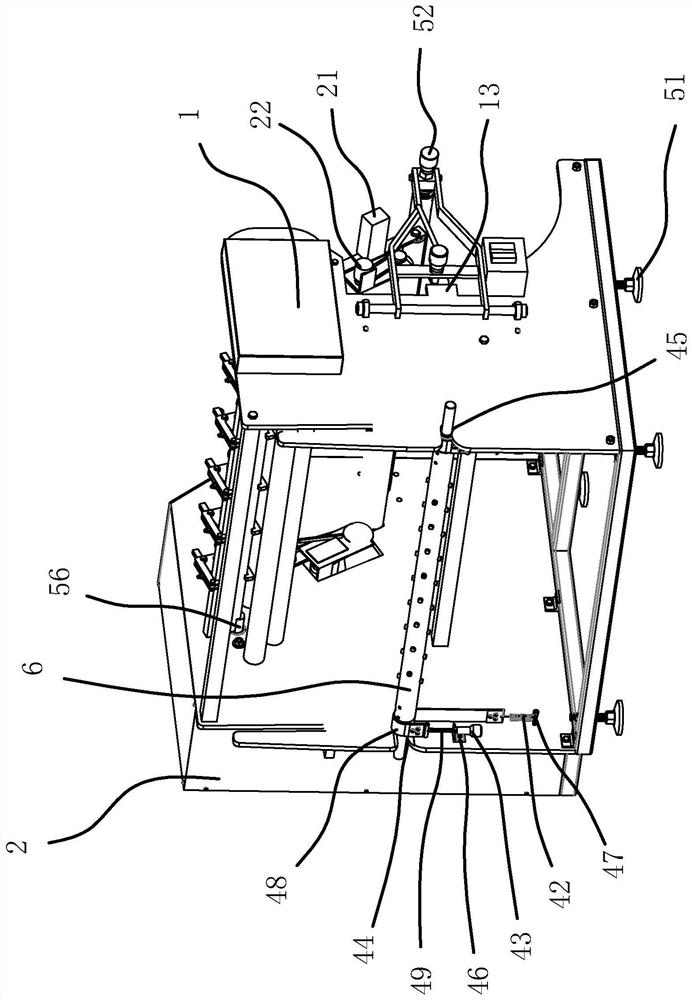

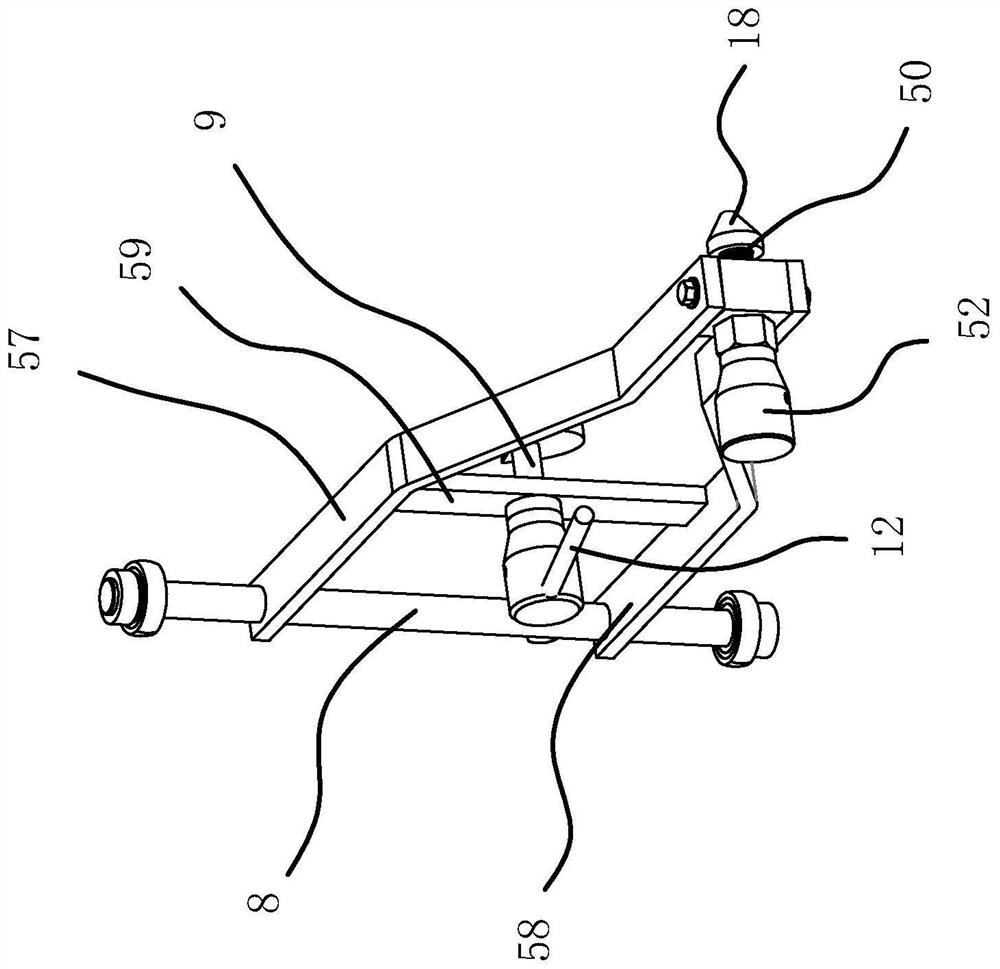

Lithium battery taping machine

InactiveCN108539287AAuto SpacingFinal product manufactureElectrolyte accumulators manufactureControl systemNew energy

The invention relates to the technical field of new energy production. A lithium battery taping machine comprises a frame component, a control system, a support frame, a cell feeding component, a feeding manipulator component, a transfer component, a turnplate component, a taping component, a tape pressing component, a tape covering component, and a discharging manipulator component. The lithium battery taping machine has the advantages that the machine may automatically adapt to taping of cells having different spaces, and top taping and lateral end tape covering are fully automated.

Owner:留丹翠

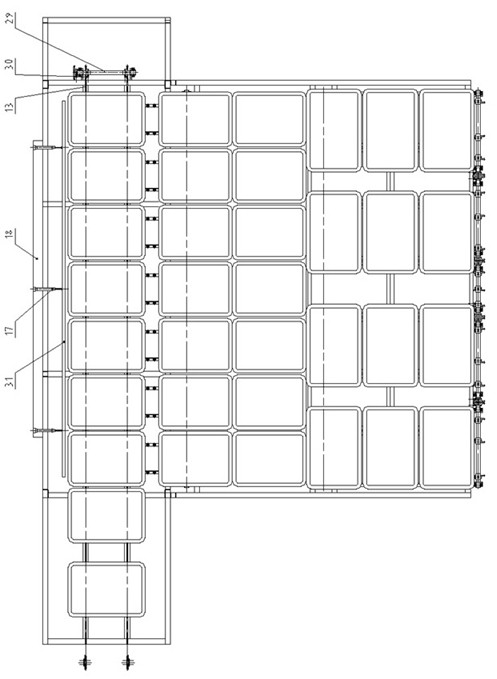

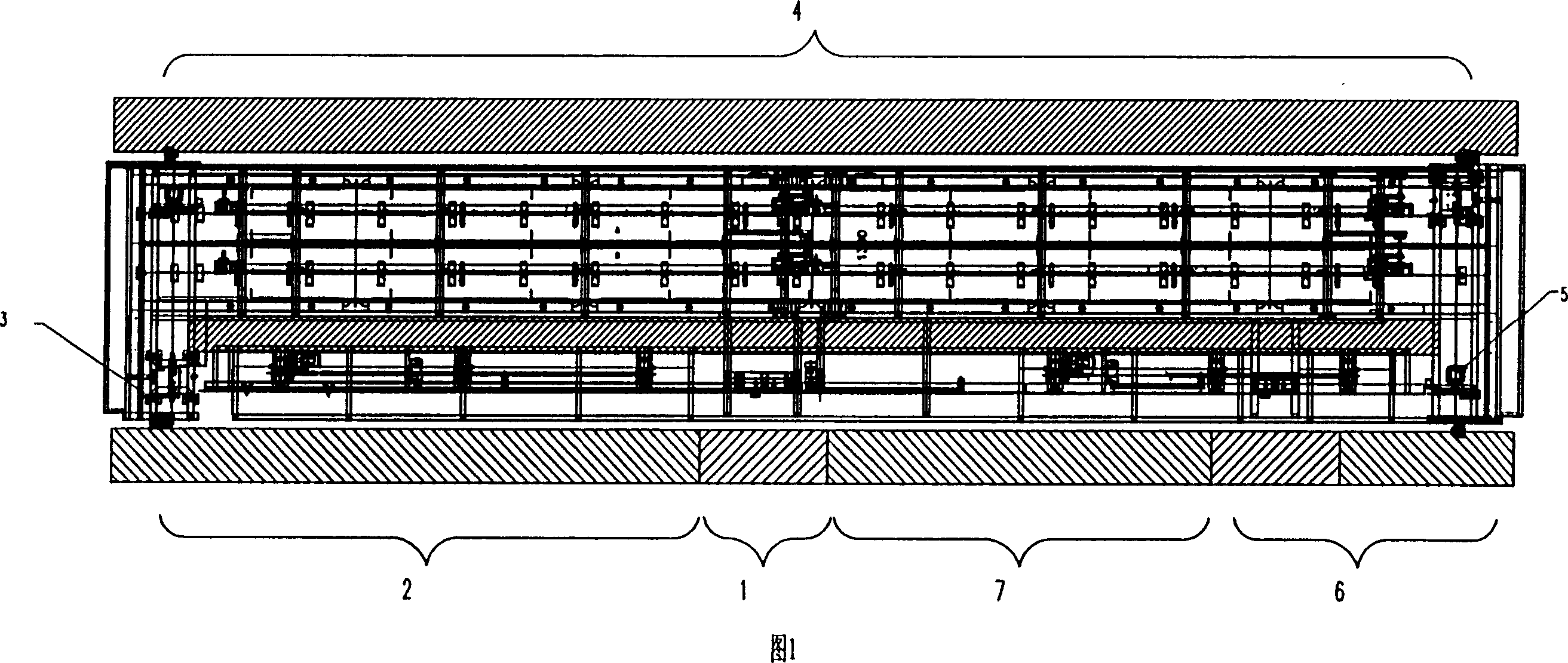

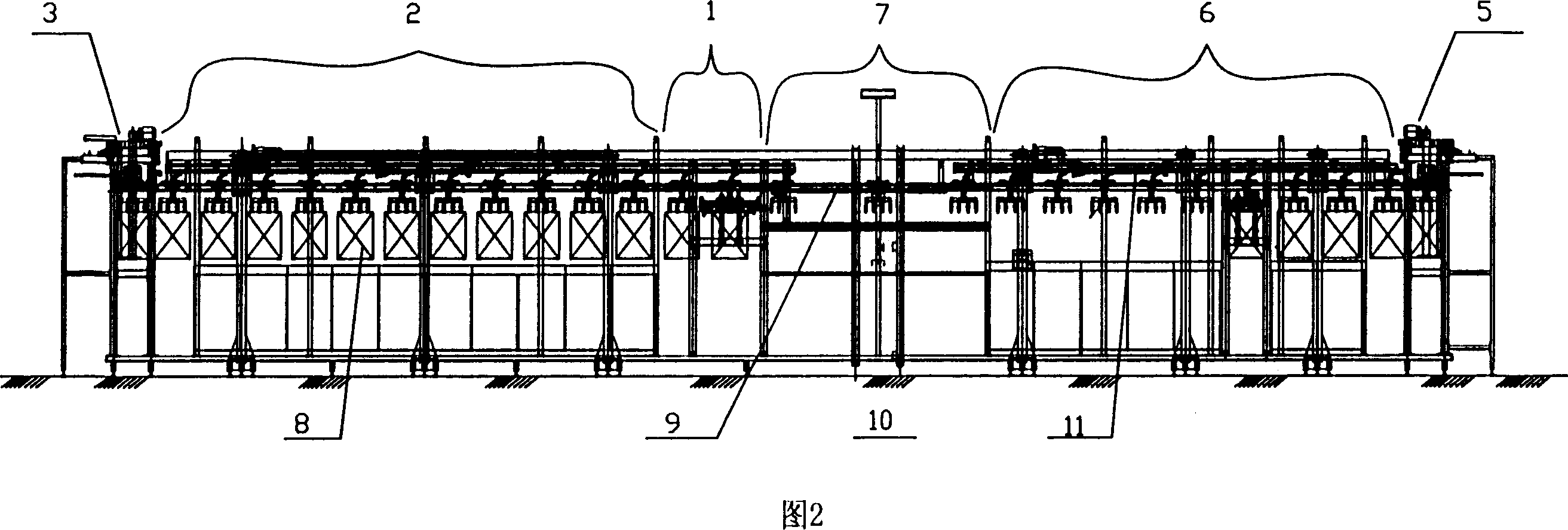

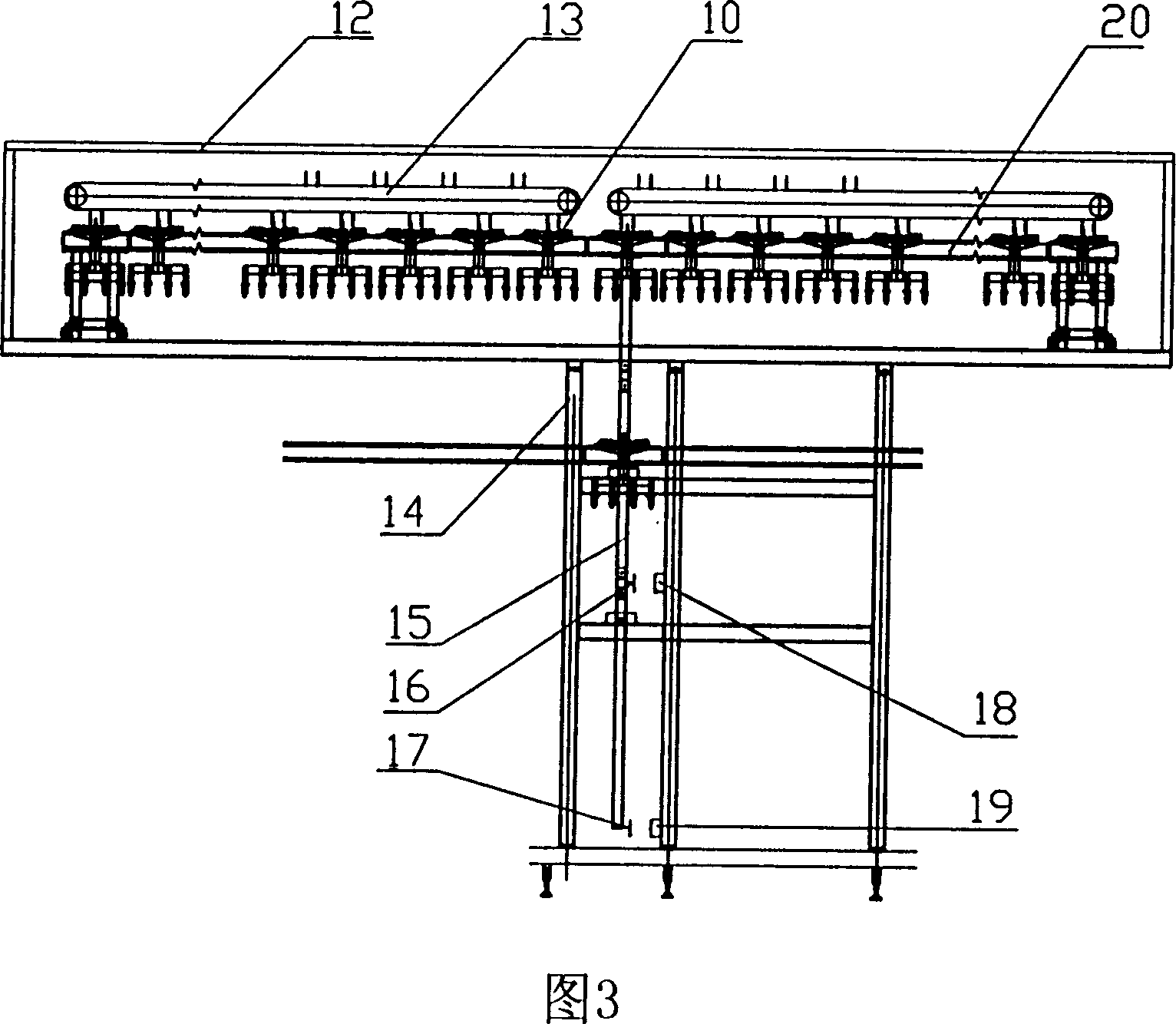

Electroplating machine capable of automatically accessing hanger

ActiveCN1587445AGuarantee the quality of platingSave human effortElectrolysis componentsElectroplatingMechanical engineering

The electroplating machine capable of automatically accessing jig includes electroplating bath, jig, jig conveying system and control circuit. The jig conveying system set over the electroplating bath may be divided into upper plate section, front processing section, electroplating bath section, post processing section and temporarily set section. The temporarily set section has automatically jig accessing unit consists of jig storing mechanism and automatic elevating mechanism. The control circuit is connected to the jig accessing mechanism and the automatic elevating mechanism. The automatic elevating mechanism is connected to the jig accessing mechanism and the temporarily set section to realize the automatic accessing of jig. Compared with available technology, the present invention has raised electroplating effect, less man-made error and low cost.

Owner:宝盈科技(深圳)有限公司

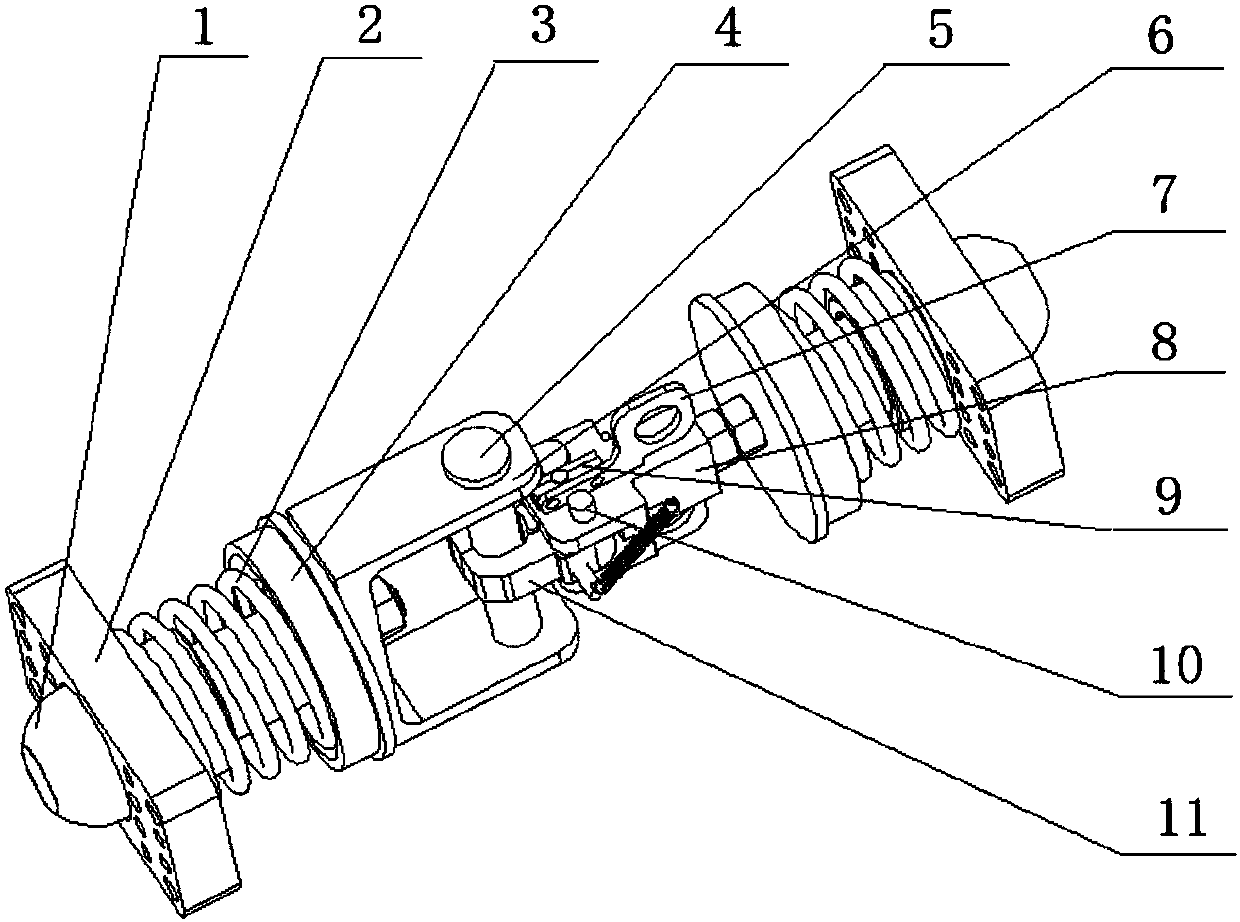

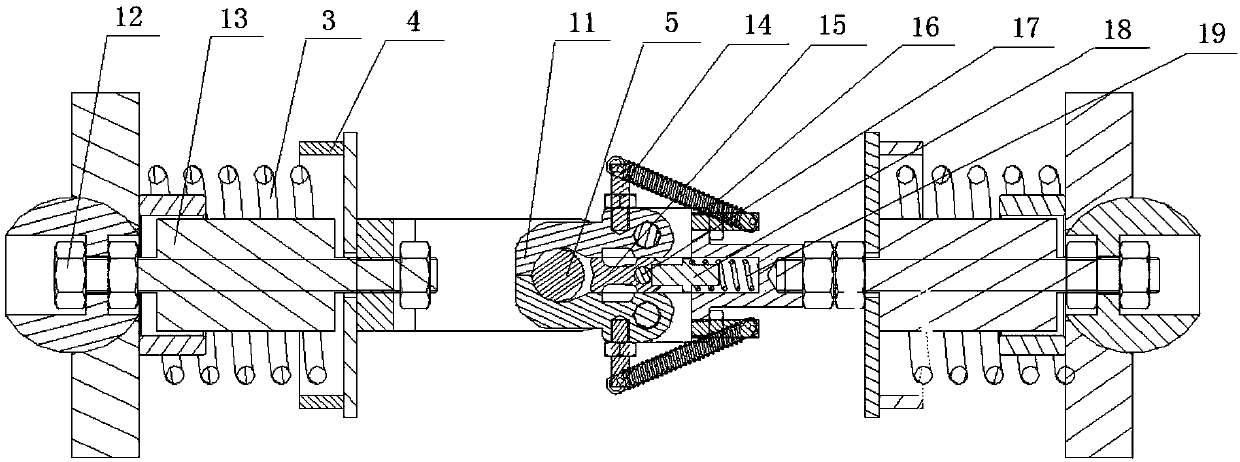

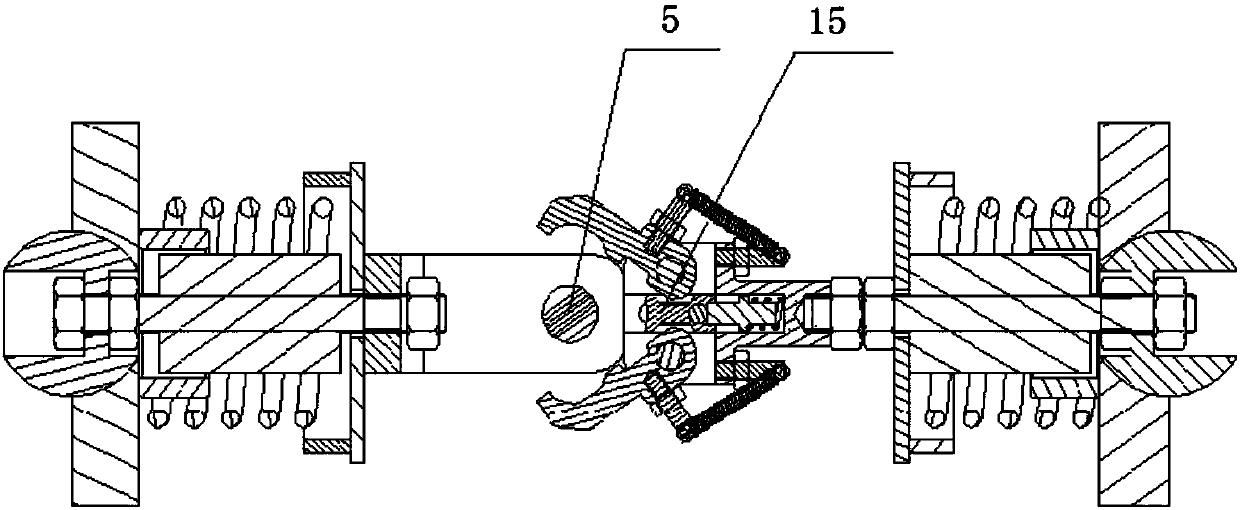

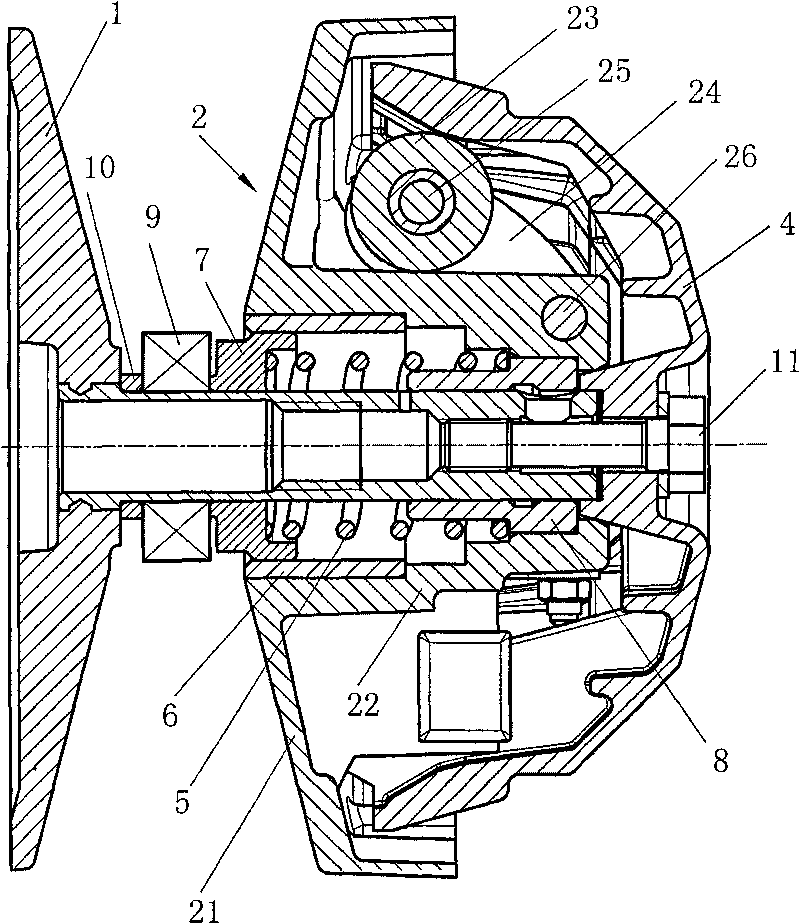

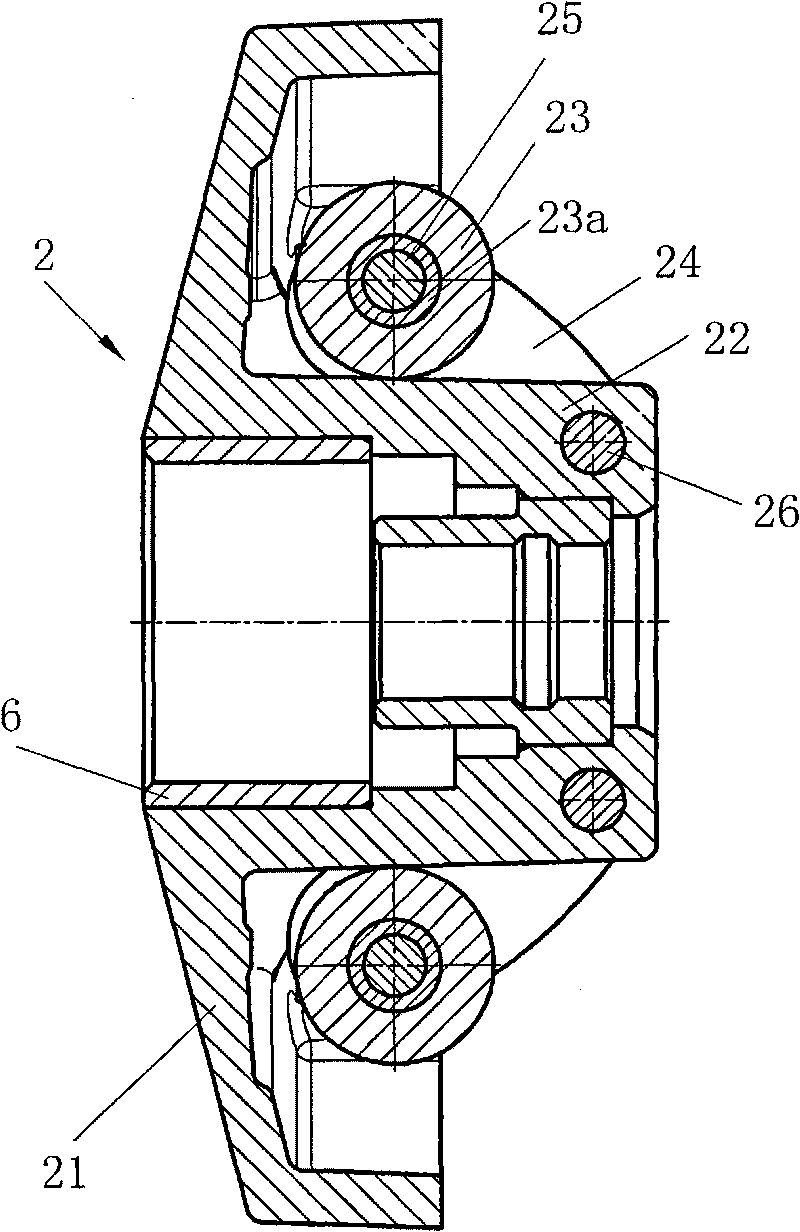

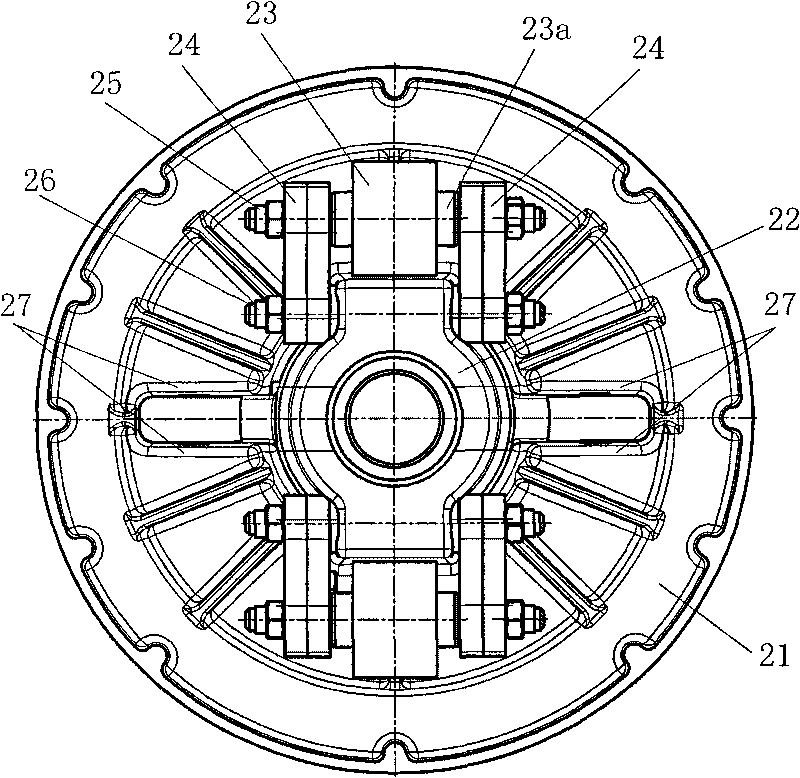

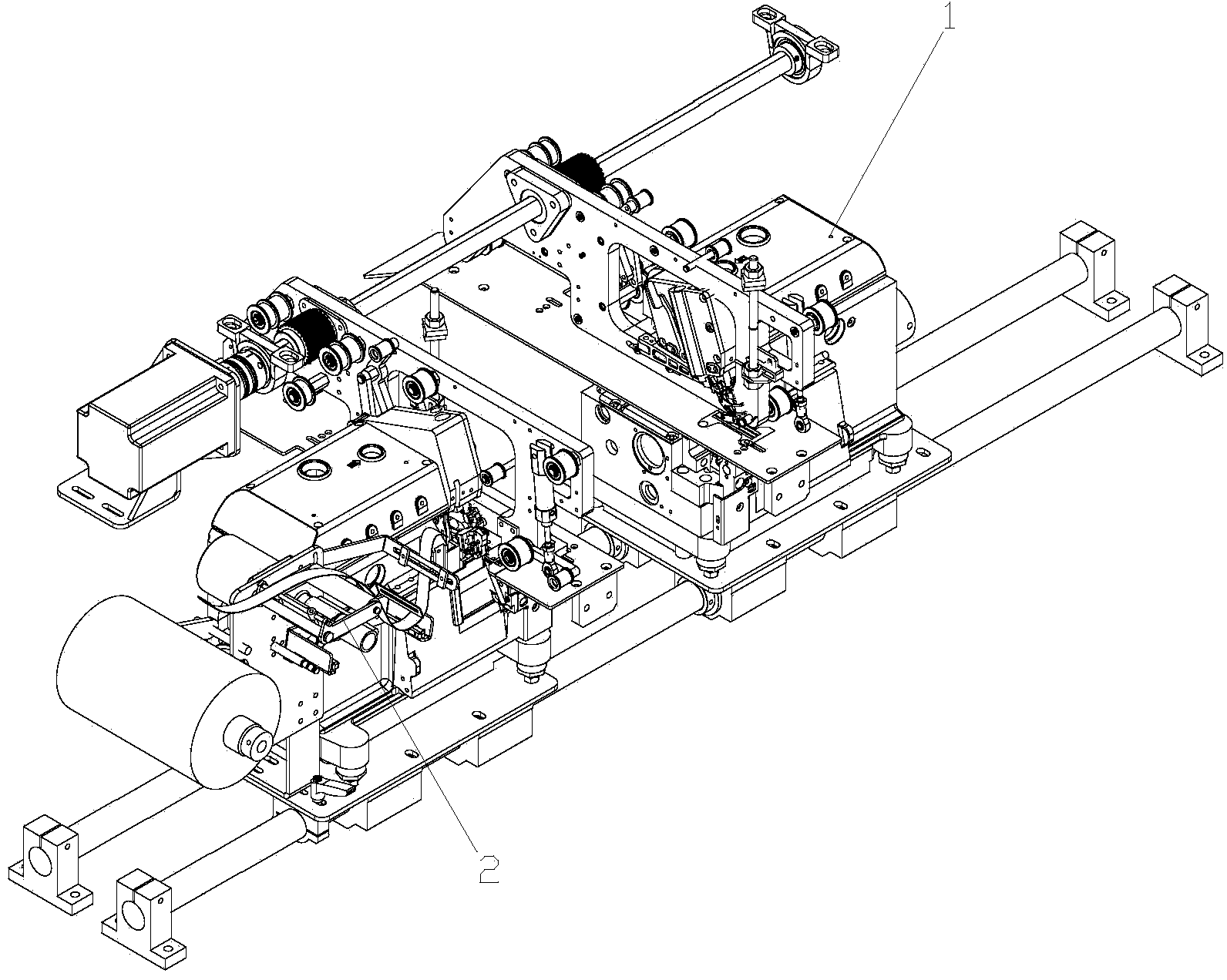

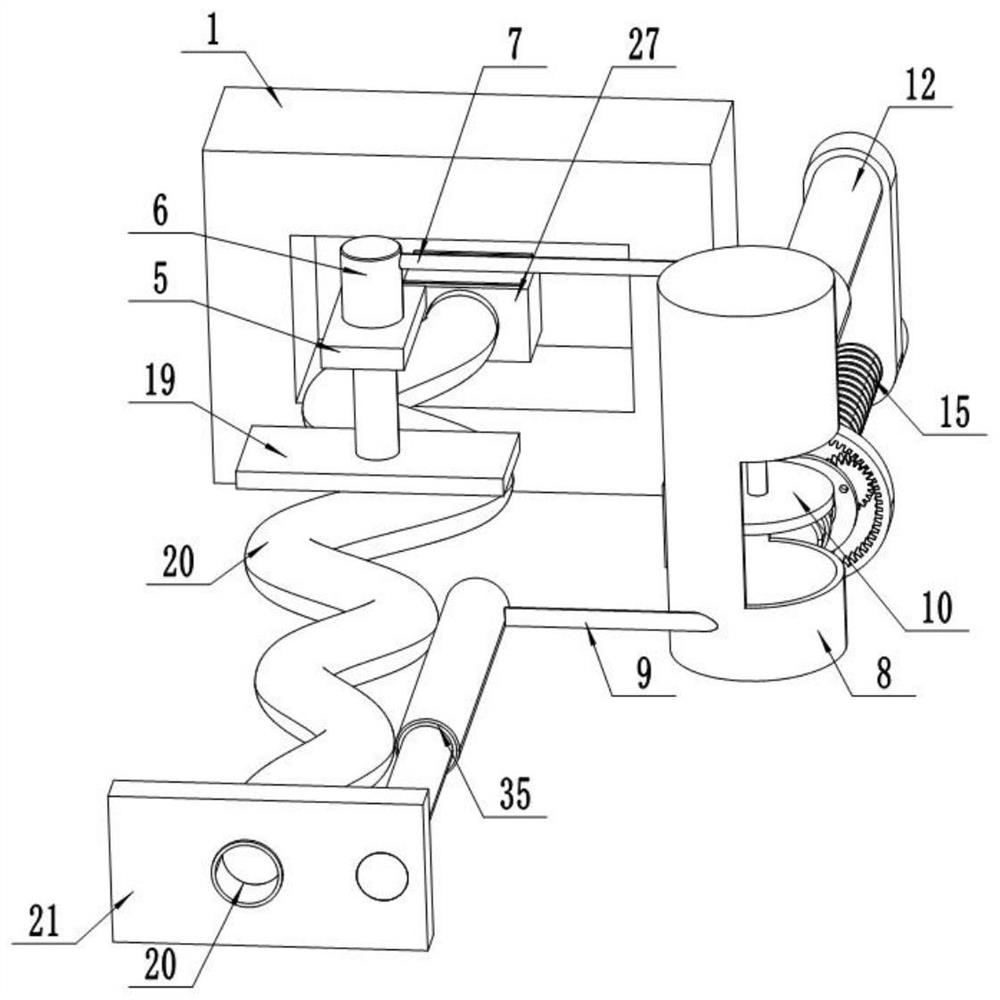

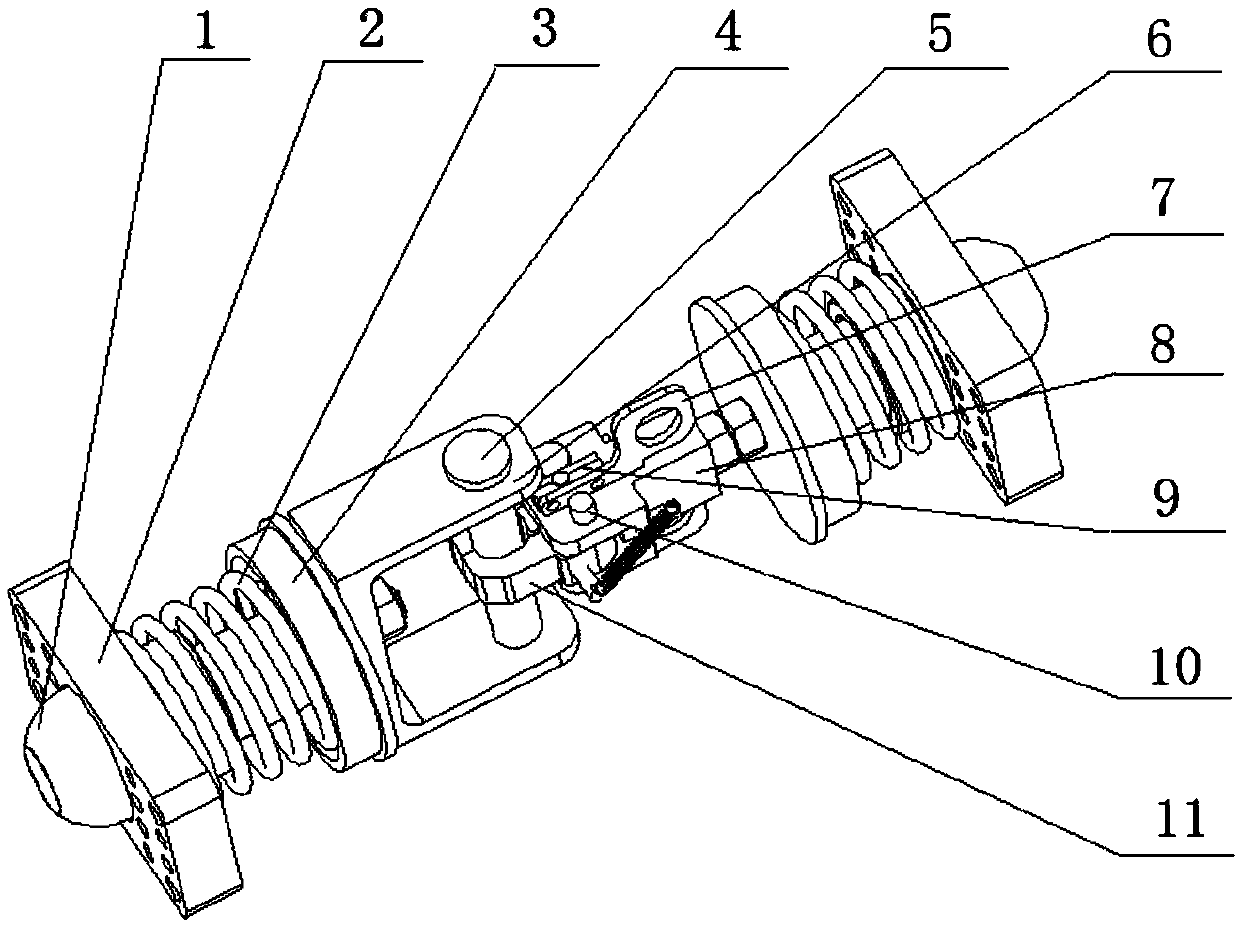

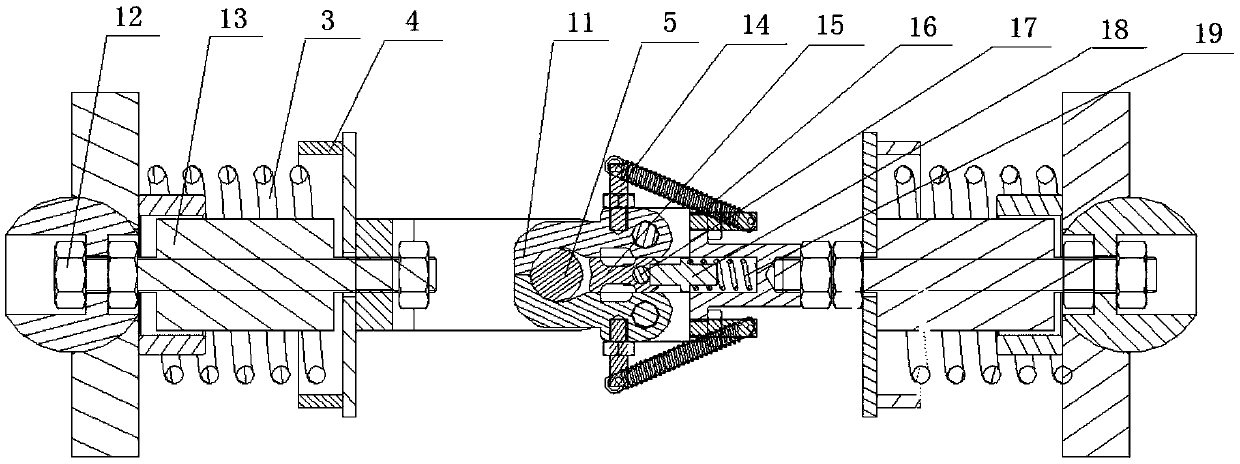

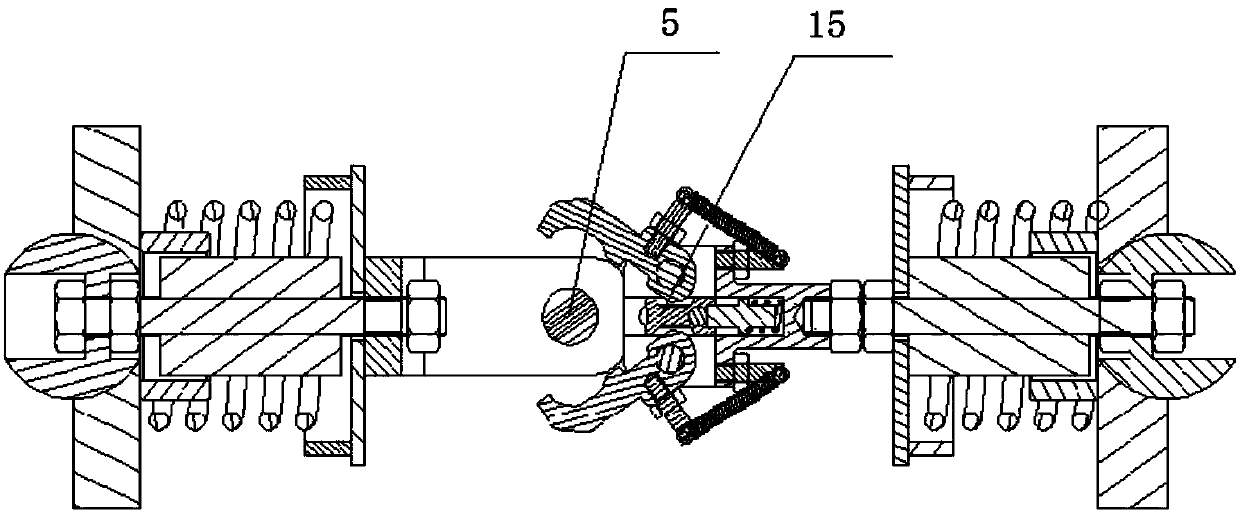

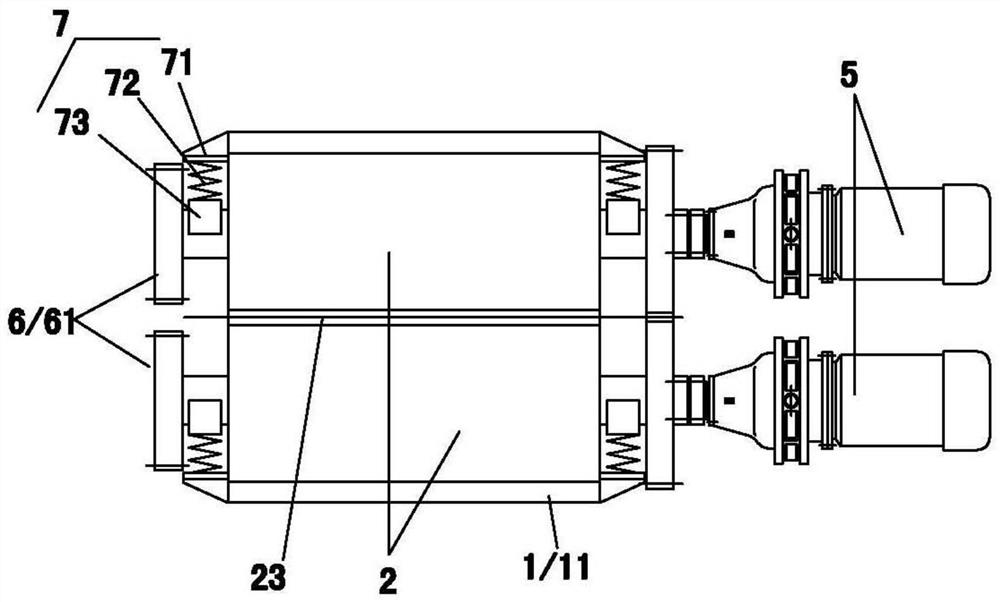

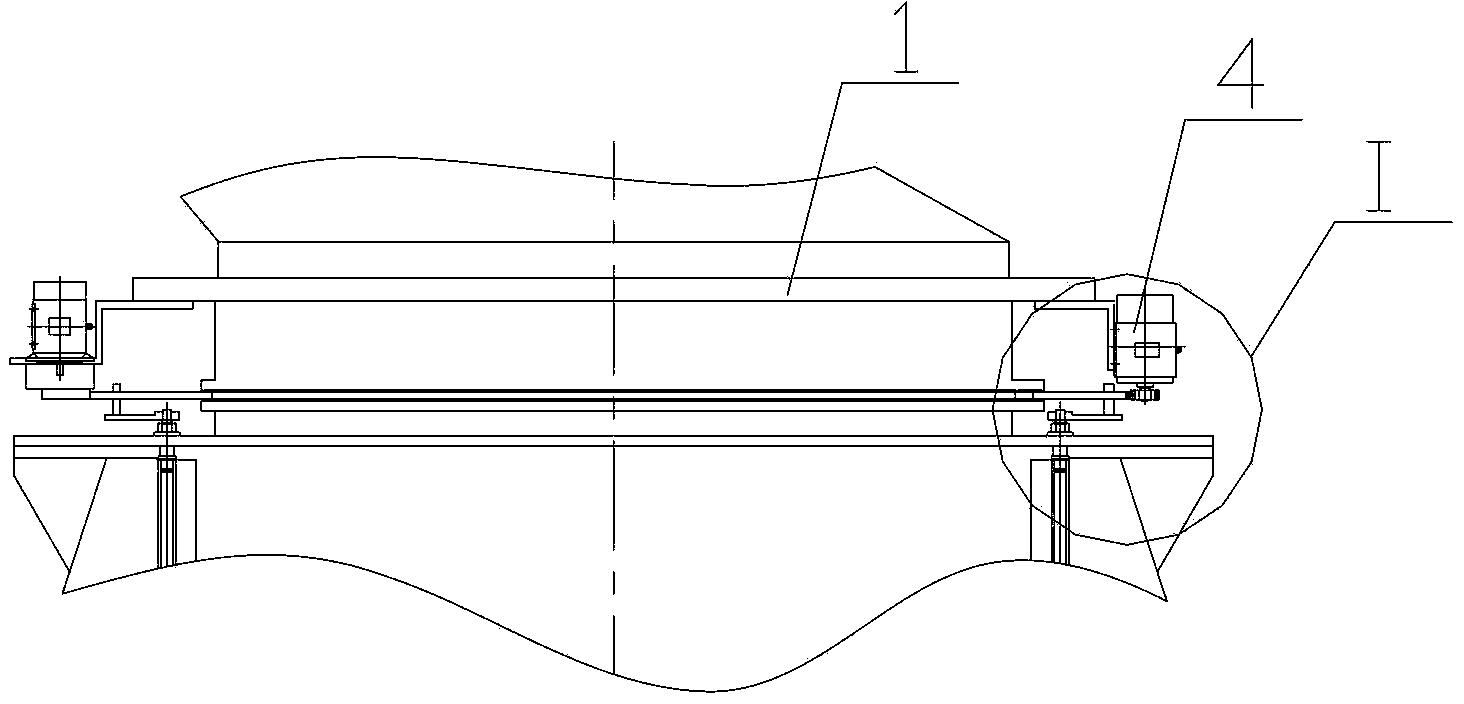

Automatic connection device for rail vehicles

ActiveCN107719407AAuto SpacingImprove connection efficiencyRailway coupling accessoriesEngineeringMechanical engineering

The invention provides an automatic connection device for rail vehicles, comprising two spherical hinge components connected with two rail vehicles in rotatable and telescopic manner; the spherical hinge components can be rotated and swayed relative to the rail vehicles by connecting the spherical components to the ends of the rail vehicles; since a connection component and a locking component arealso connected between the two spherical hinge components, when the two adjacent rail vehicles are close, the locking component may be automatically aligned with, connected with and locked to the connection component; the automatic connection device also comprises an unlocking component mounted between the connection component and the locking component; when the connection needs to be disabled, the unlocking component can be controlled to separate the locking component and the connection component. The automatic connection device for rail vehicles provided herein is simple in structure and convenient to mount and can provide automatic connection for rail vehicles.

Owner:长沙开元仪器有限公司

Continuously variable transmission of snowmobile

The invention discloses a continuously variable transmission (CVT) of a snowmobile. The CVT comprises a driving wheel, a driven wheel and a transmission belt which is used for connecting the driving wheel with the driven wheel. The driving wheel is provided with a fixed disc with a conical surface, a movable disc and a central shaft. The CVT is characterized in that the central shaft arranged between the fixed disc and the movable disc is sheathed with a rolling bearing; the periphery of the movable disc is uniformly provided with 2-4 idler wheels; two sides of each idler wheel are symmetrically provided with counterweight arms; one end of the central shaft, far away from the fixed disc, is fixed with a cover; the idler wheels on the movable disc always prop against the internal surface of the cover under the action of a compressive spring; and positions on the internal surface of the cover, corresponding to the idler wheels, are provided with idler wheel slideways. The CVT has simple structure and low manufacture cost, can play a function of turning off the power and replacing a clutch when the transmission belt falls on the ball bearing, has greater centrifugal force at a certain rotation speed, and leads the driving wheel to quickly and forcibly push the fixed disc, thus reliably and effectively changing the groove size of the driving wheel and the driven wheel automatically, and realizing speed change.

Owner:重庆永发科技有限公司

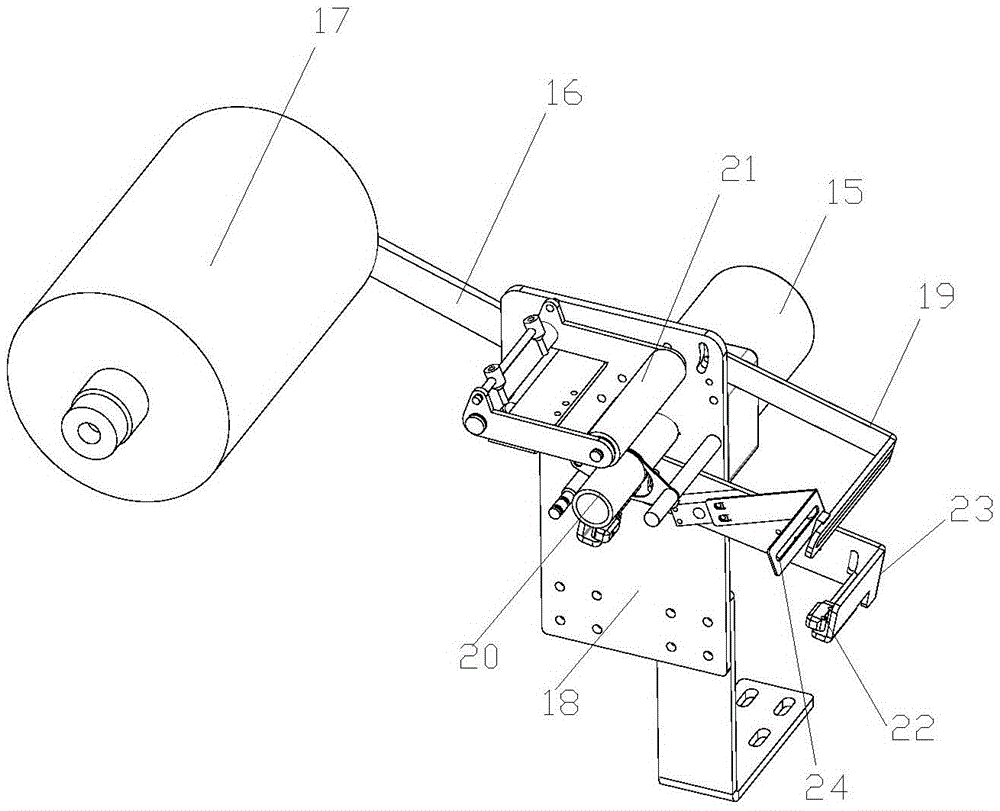

Edge covering device

ActiveCN104250890AImprove work efficiencyImprove processing qualityWork-feeding meansElectric machineryStructural engineering

The invention relates to an edge covering device. The edge covering device comprises a twin-needle machine bind-off mechanism and a band conveying device. The band conveying device conveys textile bands to the twin-needle machine bind-off mechanism for fabric edge covering; the twin-needle machine bind-off mechanism comprises a twin-needle machine, slide rails, a carrier, a belt and a synchronous transmission component fixedly arranged on the carrier. The twin-needle machine sleeves the slide rails to perform double-side binding off on fabrics between the twin-needle machine and the slide rails; the band conveying device is fixedly arranged on one side of the twin-needle machine and comprises a first motor, a side plate, a material band cylinder, a guide hook plate, a bottom plate, a power roller, a guide roll and an optical sensor, and the power roller is vertically fixed onto the bottom plate. Material bands sequentially pass through the guide roller and the power roller to be tensioned into vertical S shapes; the light sensor is fixedly arranged below the power roller and sends electric signals to the first motor after sensing states of the material bands; the first motor drives the power roller to rotate the plate. The edge covering device has the advantage that nonwoven fabrics can be covered onto the edges of towels during binding off of the towels.

Owner:SUZHOU TRANSPARENT TECH CO LTD

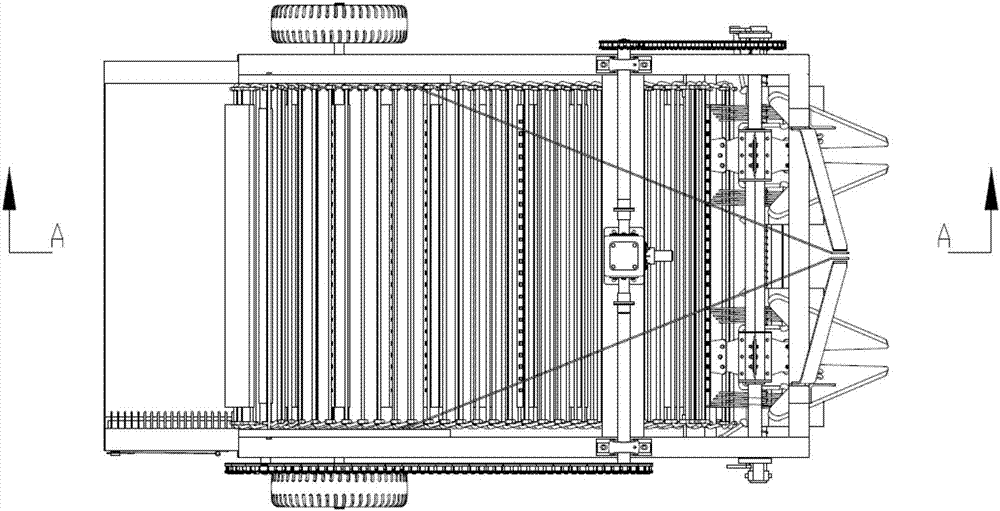

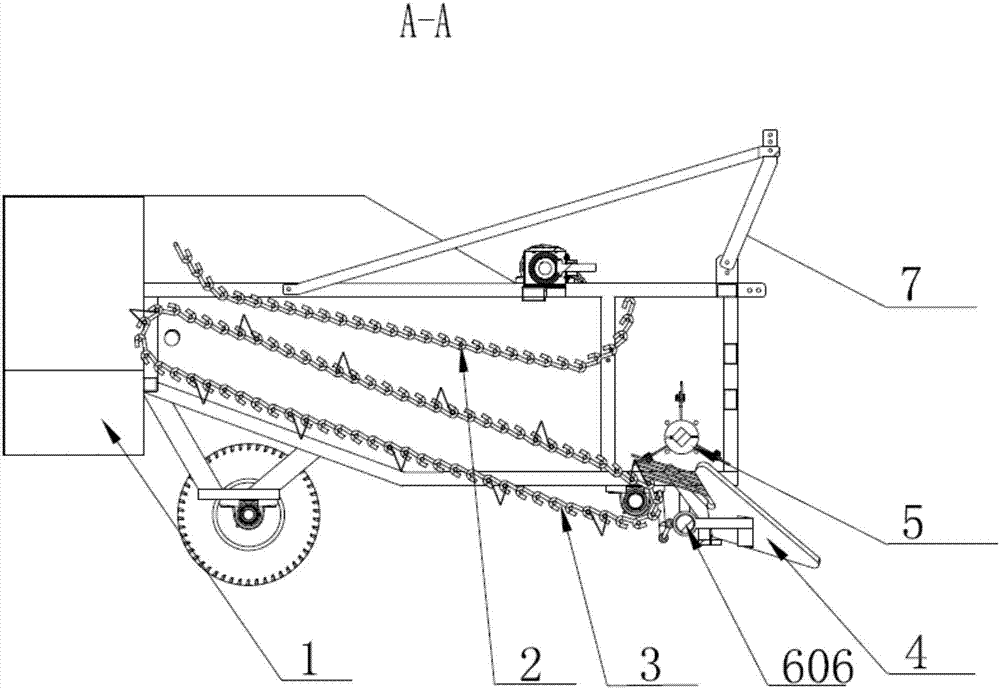

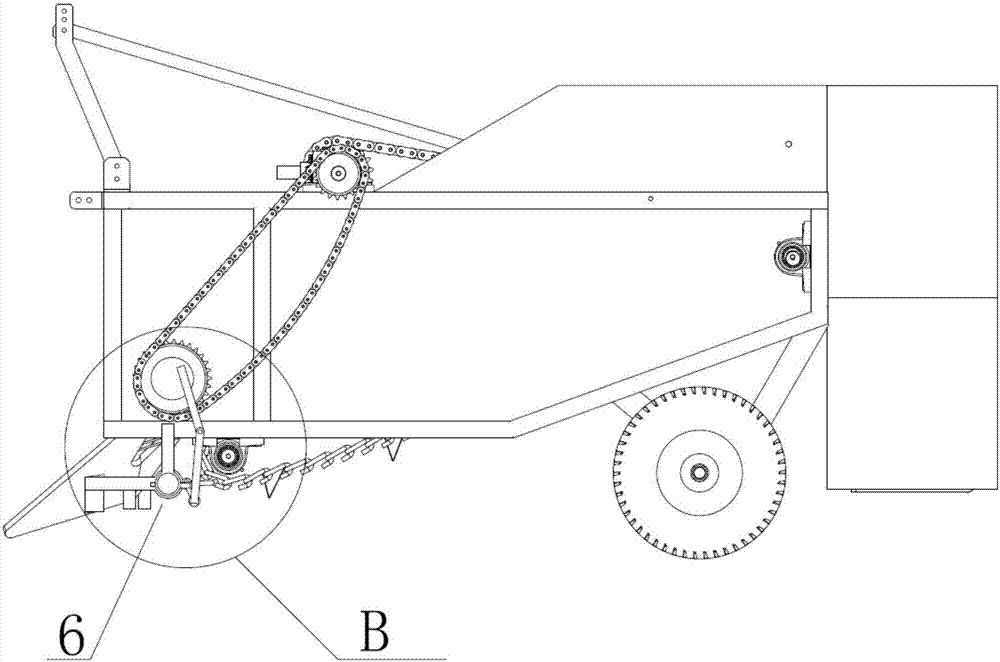

Harvester for rhizomatic crops

ActiveCN107046912ADigging space adjustableReduce resistanceSaving energy measuresDiggersEngineeringShovel

The invention relates to a crop harvesting machine, in particular to a harvester for rhizomatic crops. The harvester comprises a rack, a compacted vibration type digging device and a pressure supporting type conveying and cleaning device, wherein the compacted vibration type excavating device comprises vegetable picking wheels, digging shovels and a digging shovel angle adjusting mechanism, wherein the digging shovels and the vegetable picking wheels are arranged at the front part of the rack; the digging shovels are arranged in pairs; each pair of digging shovels comprises two digging shovels; the two digging shovels are symmetrically arranged to form a wedge shape; one vegetable picking wheel is arranged above each pair of digging shovels; the pressure supporting type conveying and cleaning device comprises a sling chain and a conveying chain; the sling chain and the conveying chain are arranged at the middle part of the rack; the sling chain is located above the conveying chain and is fixed on the rack; a clearance is formed between the sling chain and the conveying chain. According to the harvester, angle adjustability of the digging shovels is realized, and the harvesting rate of the rhizomatic crops is improved.

Owner:QINGDAO AGRI UNIV

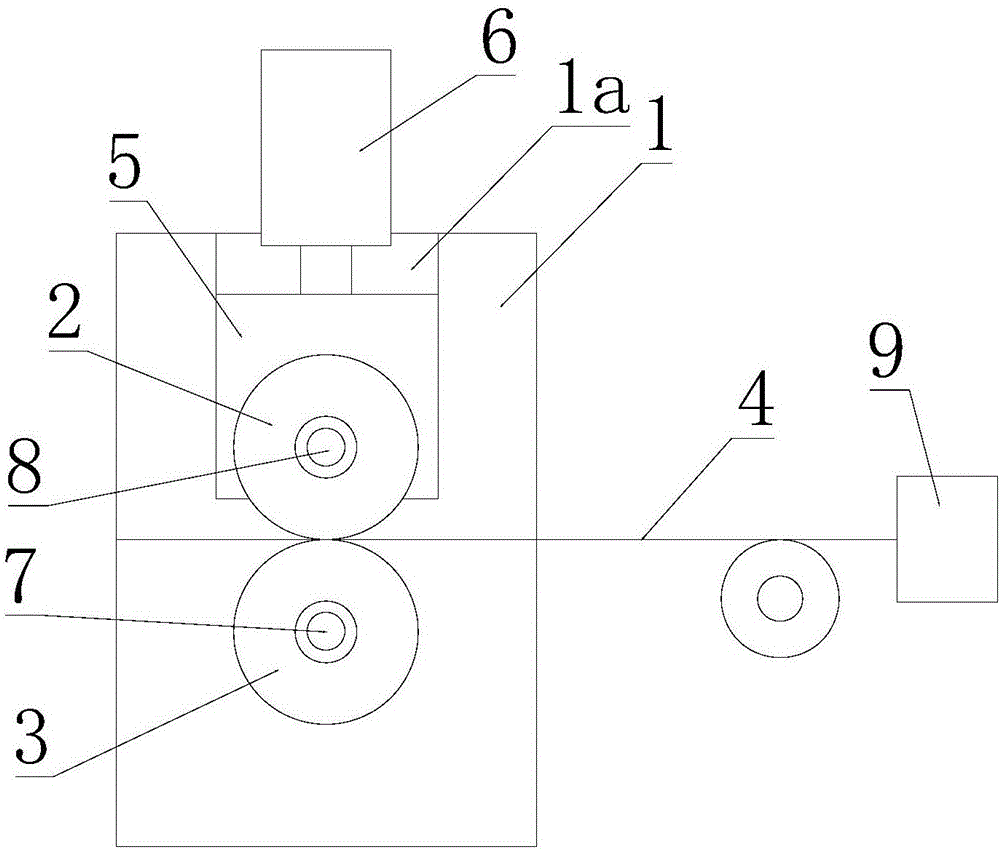

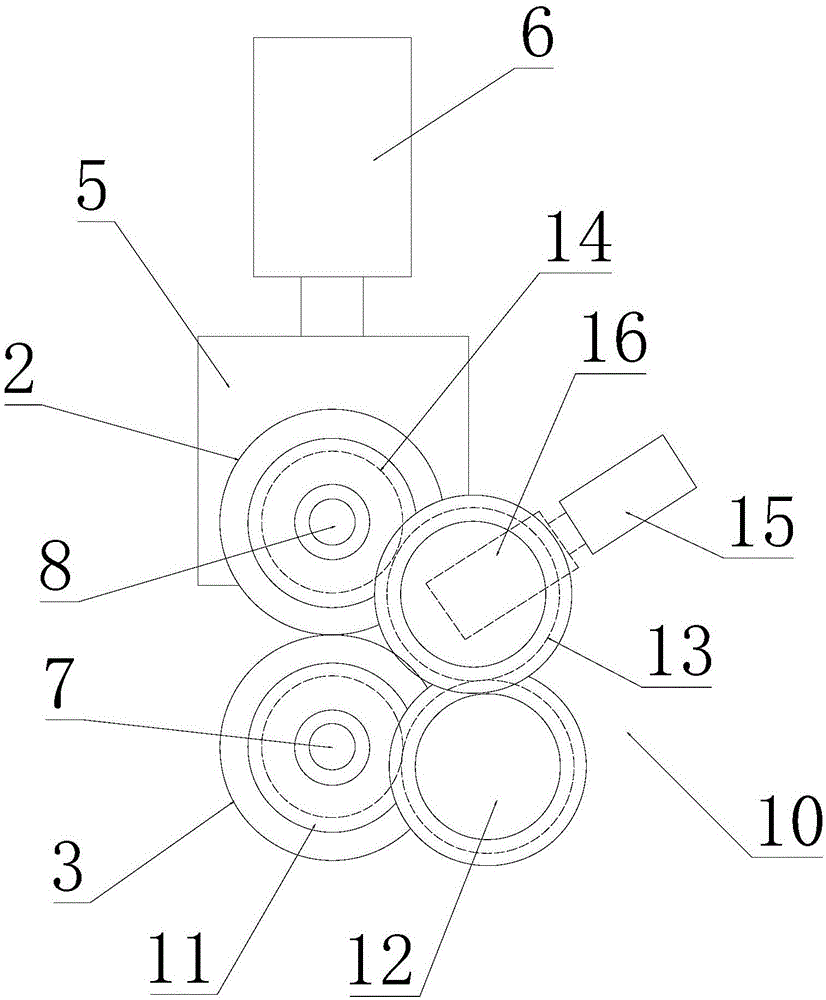

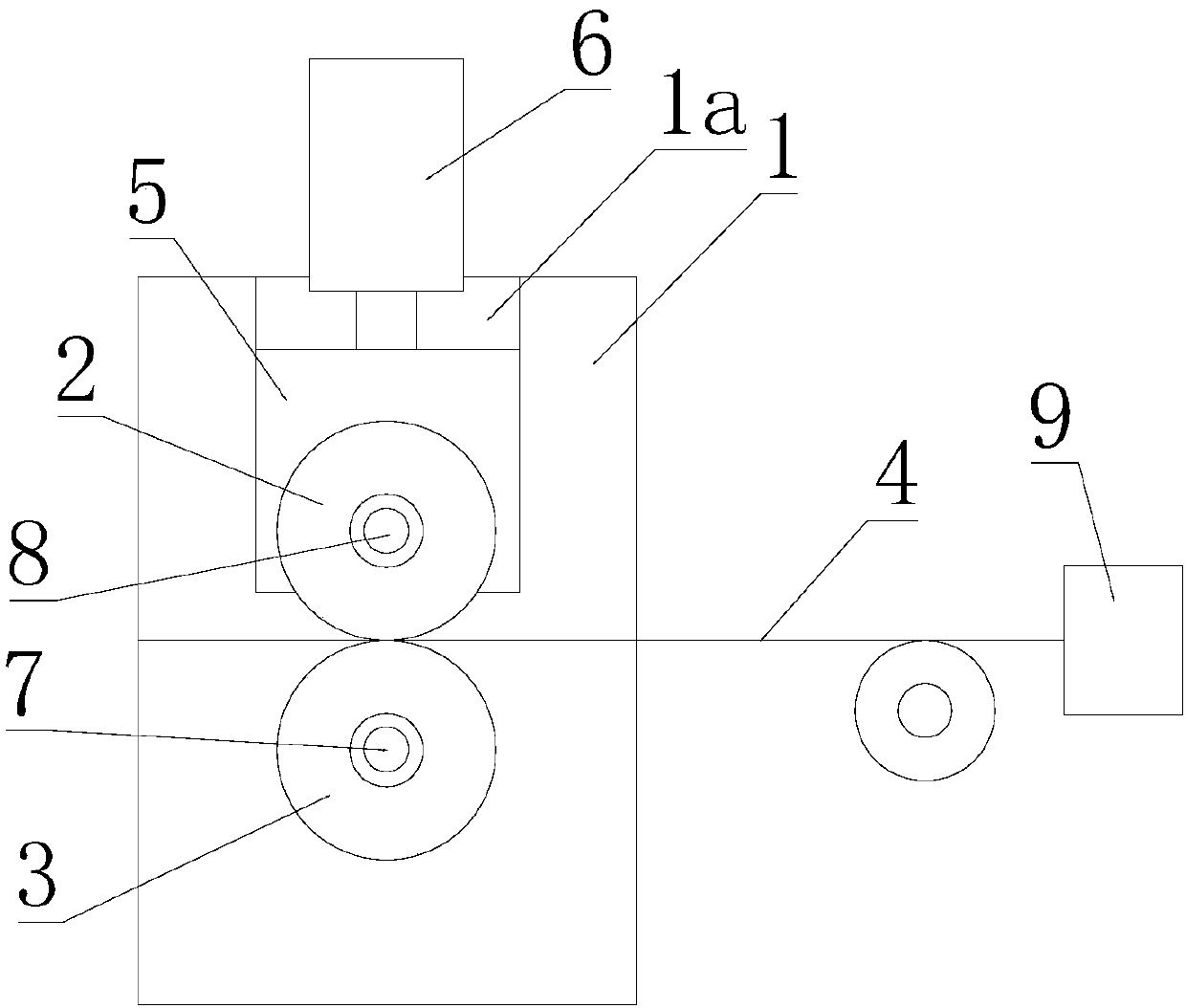

Cable pressing apparatus

InactiveCN106205873AConsistent thicknessGood suppression effectManufacturing extensible conductors/cablesMechanical engineeringMonitoring data

The invention provides a cable pressing apparatus. The cable pressing apparatus comprises a machine body, and an upper pressing wheel and a lower pressing wheel are rotatably arranged on the machine body; the upper pressing wheel and the lower pressing wheel are oppositely arranged in an up-down manner, and a pressing channel used for pressing a cable is formed between the upper pressing wheel and the lower pressing wheel; the upper pressing wheel and / or the lower pressing wheel is rotatably arranged on a mounting seat; the mounting seat is arranged on the machine body in a manner of moving up and down; and a telescopic mechanism used for adjusting the distance between the upper pressing wheel and the lower pressing wheel is arranged between the machine body and the mounting seat. The cable pressing apparatus provided by the invention is simple in structure and more convenient to use, is capable of automatically adjusting the distance between the upper and lower pressing wheels according to monitoring data at any time, and meets the requirements of keeping consistent cable thickness and always keeping a set cable pressure, thereby always keeping an ideal pressing effect of the cable.

Owner:国昌线缆有限责任公司

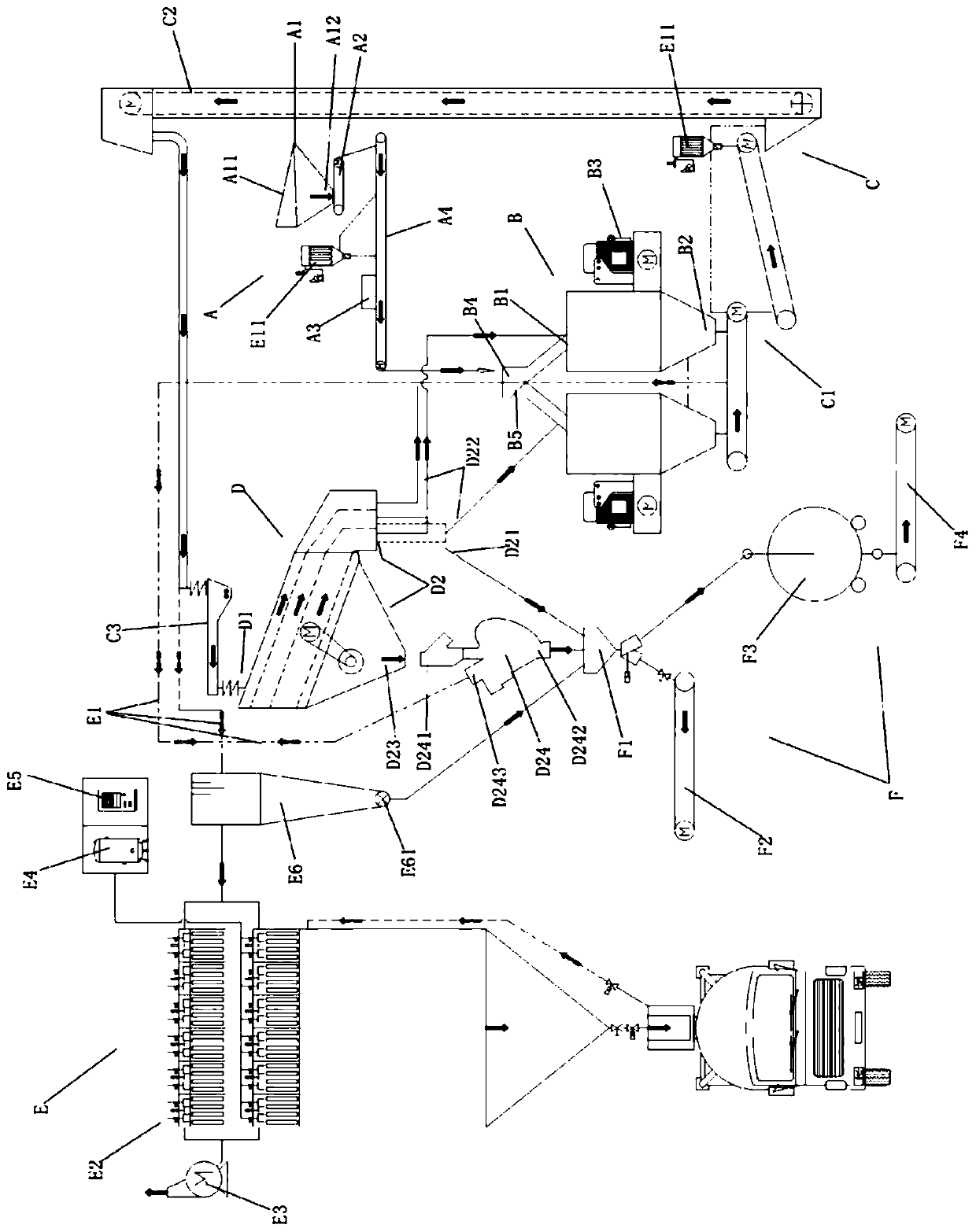

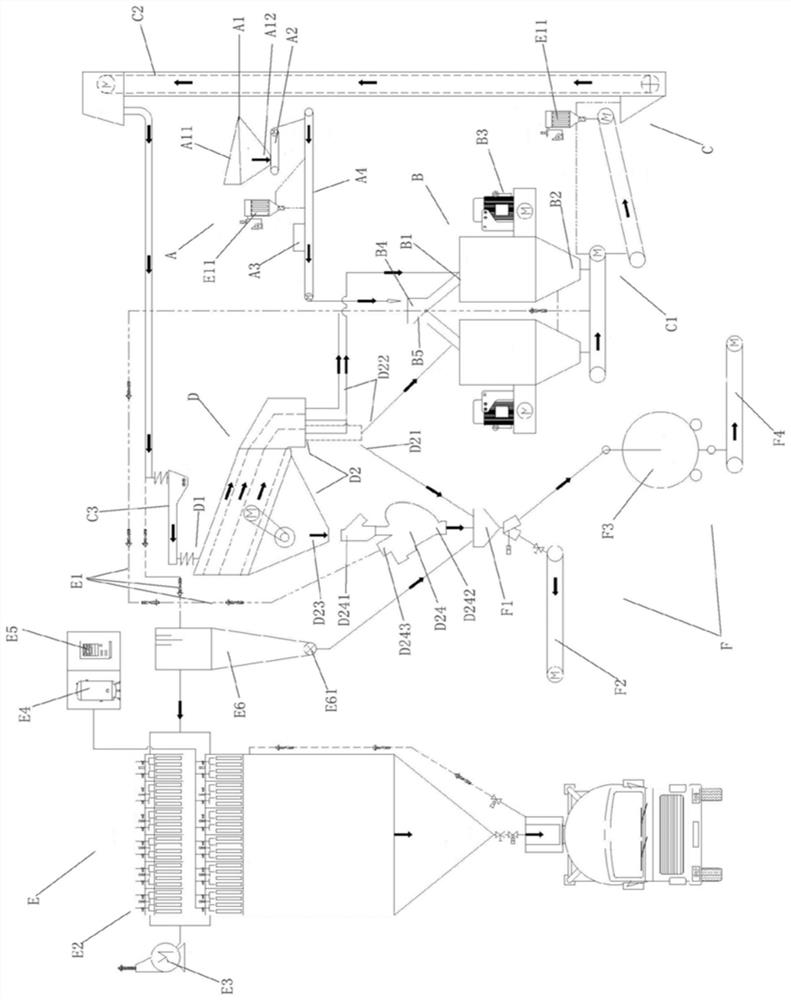

Sand producing equipment and process suitable for materials of various specifications

ActiveCN111013710AReasonable structureReasonable workmanshipGrain treatmentsDust controlProcess engineering

The invention discloses sand producing equipment and process for materials of various specifications. The sand producing equipment comprises a raw material conveyor line, a raw material crusher, a semi-finished product conveyor line, a semi-finished product screening machine, a powder removal system and a finished product output line, wherein a conveying start end of the raw material conveyor lineis provided with a raw material bin; the raw material crusher comprises a raw material inlet which is jointed with a conveying tail end of the raw material conveyor line, and a semi-finished productoutlet for discharging a crushed semi-finished product; a conveying start end of the semi-finished product conveyor line is jointed with the semi-finished product outlet; the semi-finished product screening machine comprises a screening inlet jointed with the conveying tail end of the semi-finished product conveyor line, and a screening outlet for discharging screened semi-finished products according to the specifications; the powder removal system comprises a plurality of dust removal lines which separately correspond to the raw material conveyor line, the raw material crusher, the semi-finished product conveyor line and the semi-finished product screening machine; the screening outlet comprises a finished product outlet and a returned crushed material outlet; a conveying start end of thefinished product output line is jointed with a finished product outlet; and the returned crushed material outlet is jointed with a raw material inlet of the raw material crusher. The sand producing equipment of the structure can be suitable for producing materials of various specifications, and can achieve relatively high production standards.

Owner:FUJIAN NONNON TECH

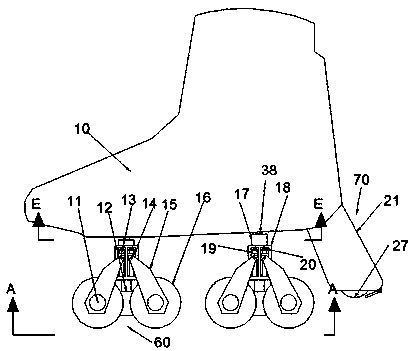

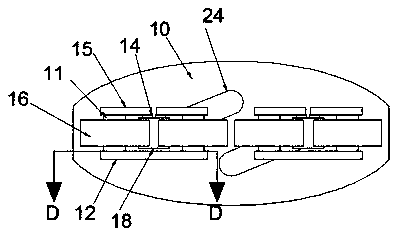

Pair of single-row and double-row roller skates capable of being automatically switched

ActiveCN110694254AEasy to useGood practicalitySkate-boardsRoller skatesDouble rowStructural engineering

The invention discloses a pair of single-row and double-row roller skates capable of being automatically switched. Each skate includes a roller skate, wherein two roller sets are mounted on the sole surface of the skate; two parallel electric guide rails are fixedly arranged on the sole surface of each roller skate body. Each roller set comprises a supporting plate. A supporting block is fixedly arranged on the upper end surface of the supporting plate; the supporting block is installed on the lower end face of the sliding block on the lower side of the electric guide rail. Therefore, the tworoller sets can slide on the sole surface in parallel; single-row and double-row automatic switching is realized; when the skate is used, the skate can be used, a user can switch the rollers into a single row or double rows according to use conditions; the switching process is automatic switching, manual switching is not needed, rollers used for switching do not need to be carried, use is more convenient, after single row or double rows of rollers are switched, the distance between the rollers is automatically adjusted, energy can be recycled in the braking process in the sliding process, andgood practicability is achieved.

Owner:管文荣

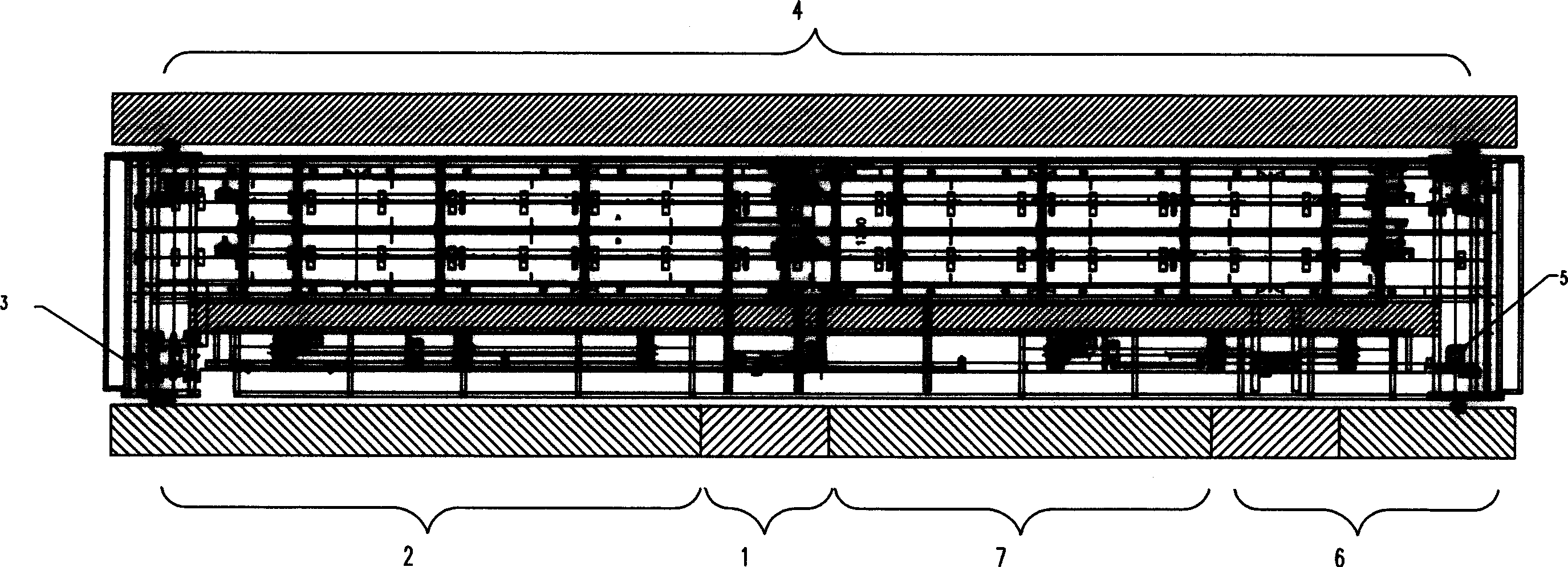

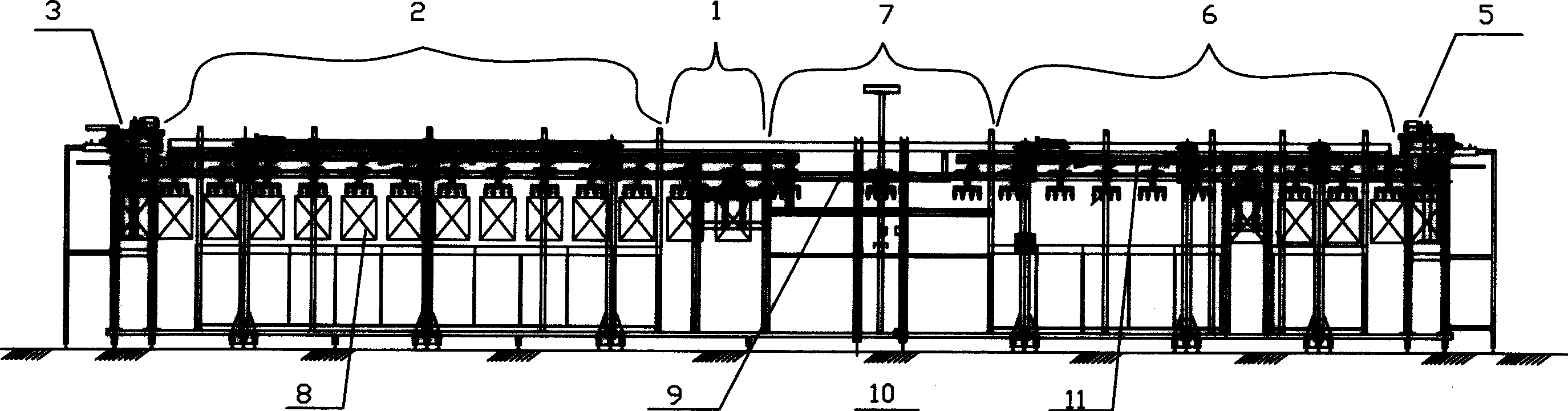

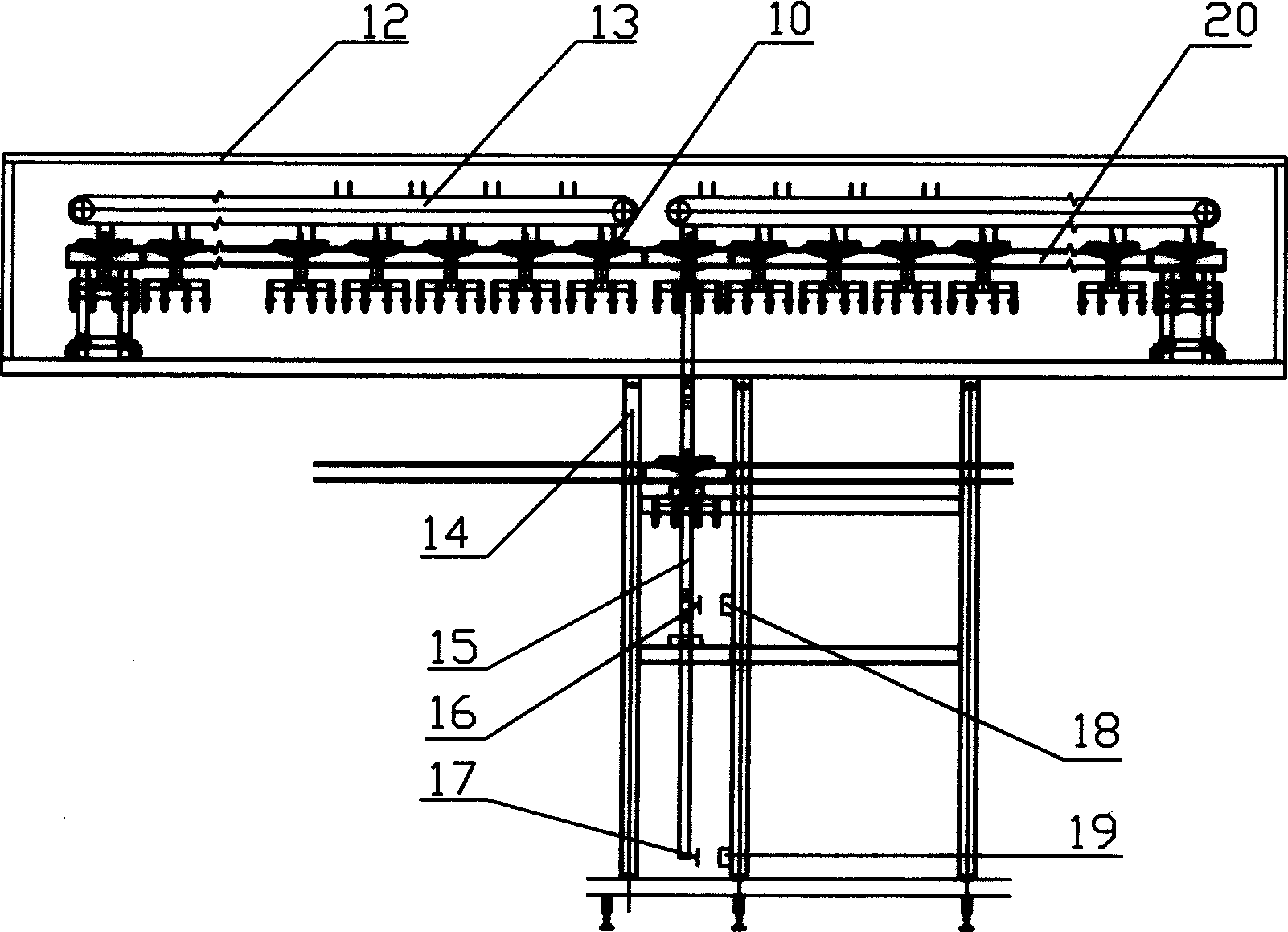

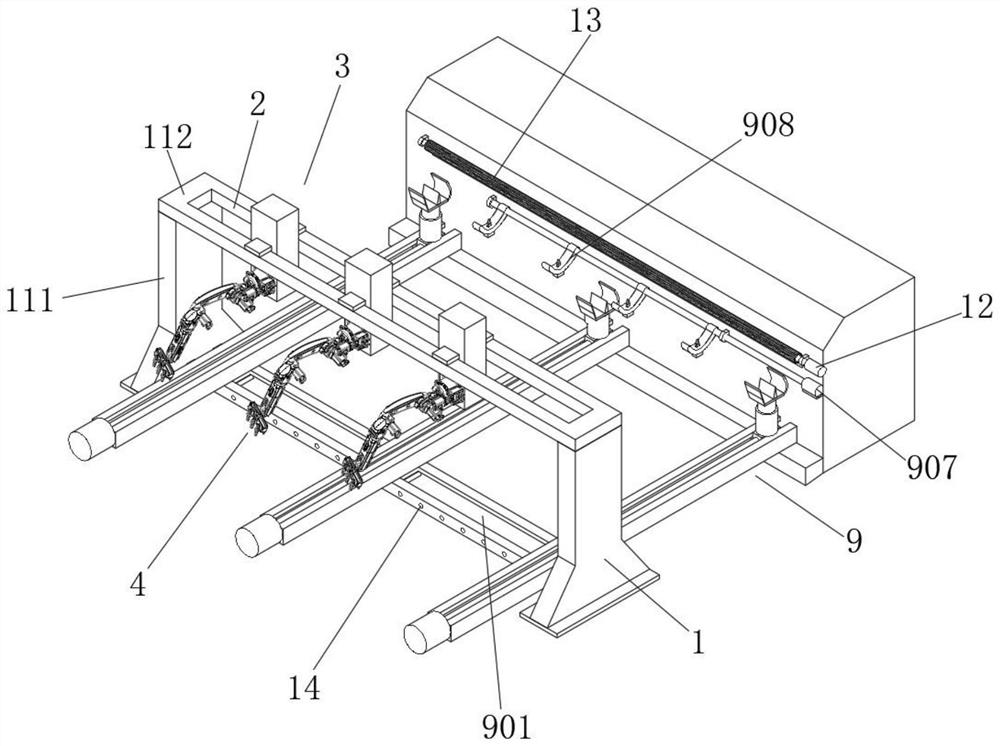

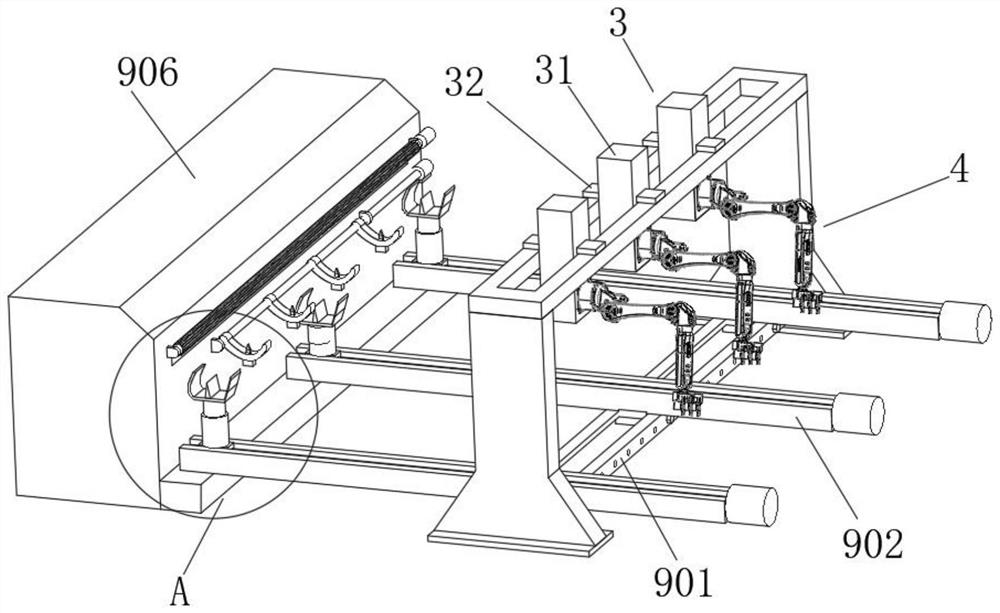

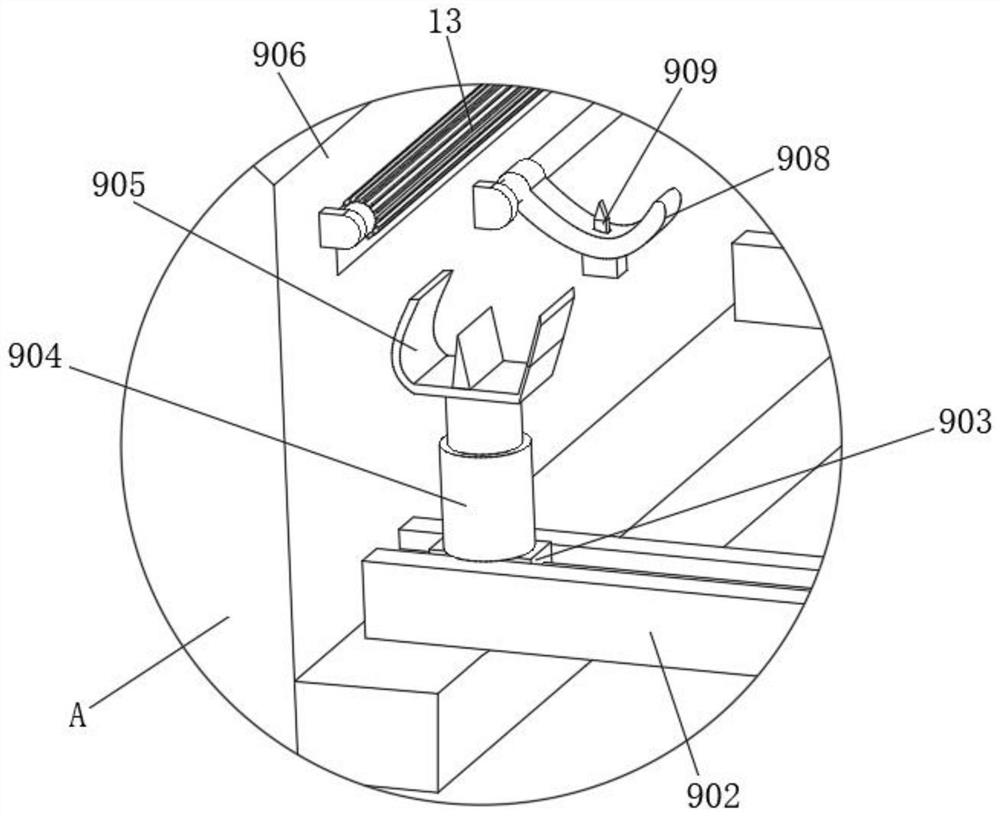

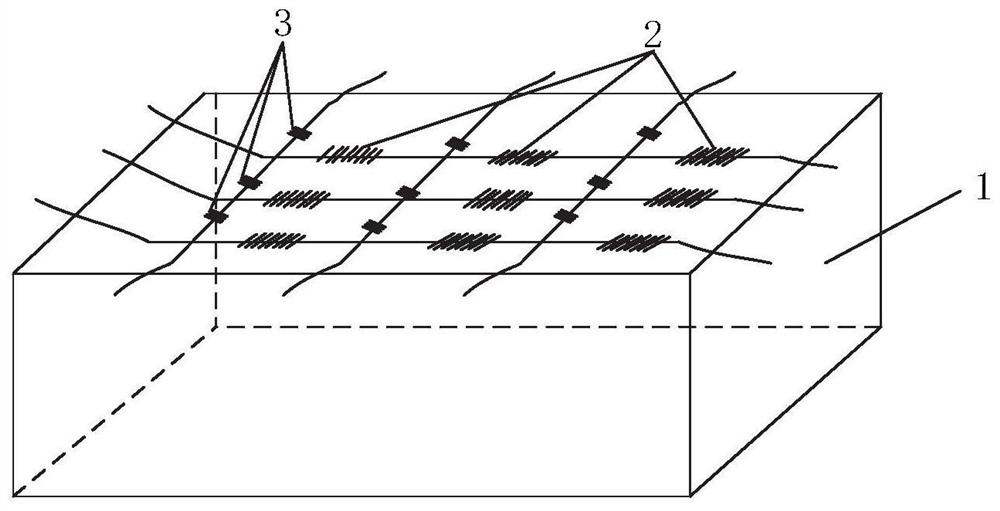

Automatic steel bar binding system

ActiveCN113733341ADoes not affect normal deliveryTo achieve different binding needsCeramic shaping apparatusRebarMechanical engineering

The invention relates to the field of automatic steel bar binding, in particular to an automatic steel bar binding system. The automatic steel bar binding system comprises a truss, a first sliding table mounted at the top of the truss, three second sliding tables vertically mounted at the top of the first sliding table, mechanical arms mounted on mounting seats at the bottoms of the second sliding tables, and a conveying mechanism for conveying multiple bundles of steel bars, wherein the conveying mechanism comprises a first sliding frame welded to the inner side of the truss, and the first sliding frame is connected with a conveying frame in a sliding mode. According to the system, by arranging the conveying mechanism, multi-bundle conveying can be achieved, the conveying efficiency is improved, normal conveying of a reinforcing steel bar conveyor is not affected even when reinforcing steel bars with the small bundle number are conveyed and bundled, meanwhile, through cooperation of third sliding tables and binding guns, the distance between the binding guns can be automatically adjusted according to needs, different binding requirements are met, continuous operation can be achieved, use is convenient and fast, operation efficiency is greatly improved, and labor intensity is reduced.

Owner:北京好运达智创科技有限公司

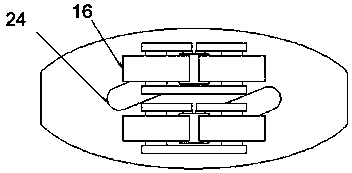

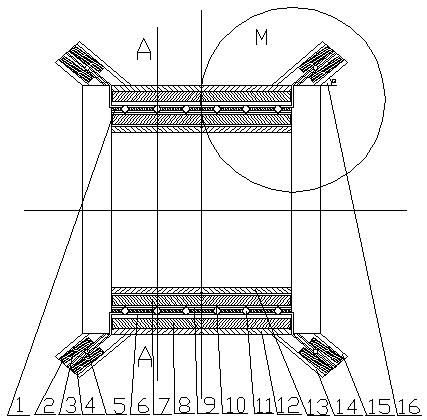

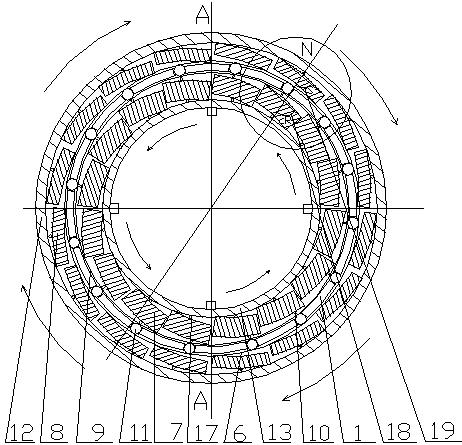

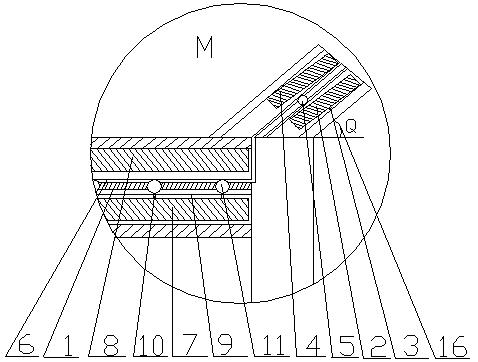

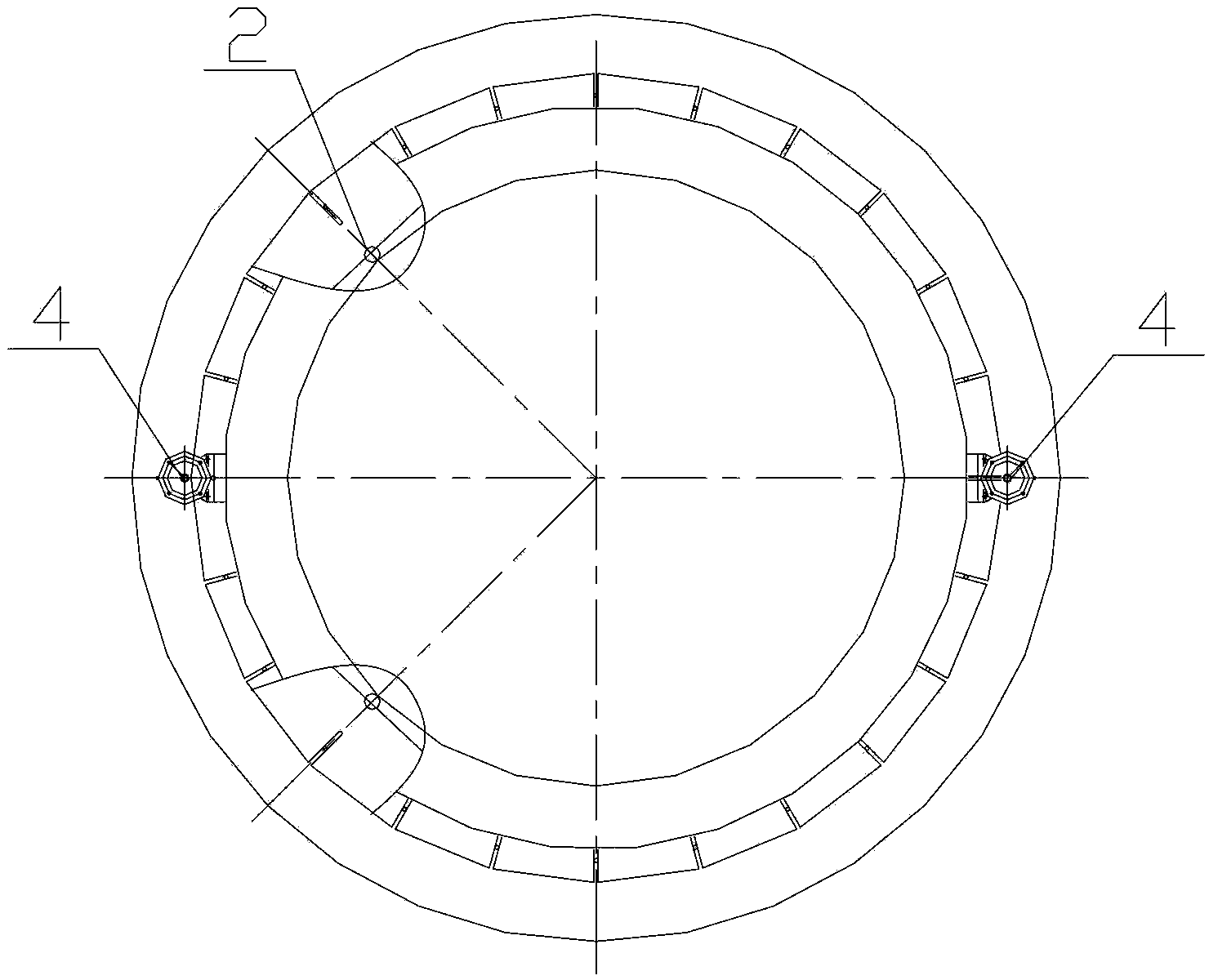

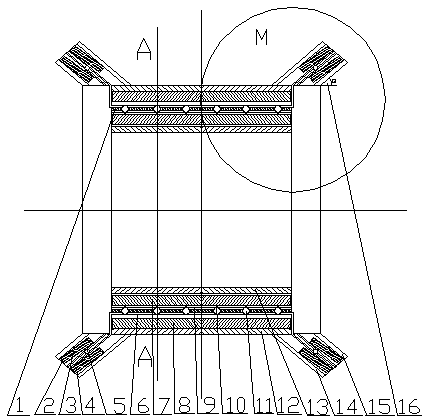

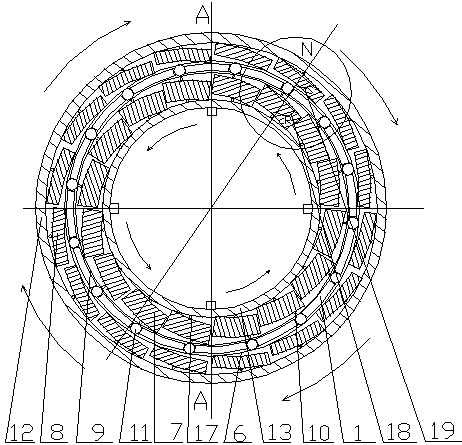

Self-aligning permanent magnet magnetic bearing

InactiveCN102518666AAuto SpacingIncrease the magnetic line densityBearingsChange densityMagnetic bearing

A self-aligning permanent magnet magnetic bearing comprises an inner ring, an outer ring, a plurality of elongated tile-shaped or rectangular permanent magnets, bearing balls, drive bars and drive rollers, wherein magnetic lines of force of the permanent magnets in sequential arrangement and a radial line of the bearing form small angles, the permanent magnets are mounted in interlayers of the inner ring and the outer ring, the bearing balls capable of rotating and moving radially are arranged between the inner ring and the outer ring, and the drive bars and the drive rollers push the inner ring or outer ring permanent magnets to rotate by certain small angles when the bearing balls move. The self-aligning permanent magnet magnetic bearing is characterized in that like poles of the bearing inner ring permanent magnets are opposite to those of the bearing outer ring permanent magnets, the included angles between the bearing inner ring or outer ring permanent magnets and the radial lineare different, a rotary bearing shaft is arranged at the center of inside of the inner ring permanent magnets, another rotary bearing shaft is arranged at the center of outside of the outer ring permanent magnets, and the permanent magnets can rotate around the rotary bearing shafts to adjust the included angles between the magnetic lines of force of the permanent magnets and the radial line so as to change density of the magnetic lines force in the radial direction, so that magnetic repulsive force of the magnets is changed.

Owner:魏伯卿

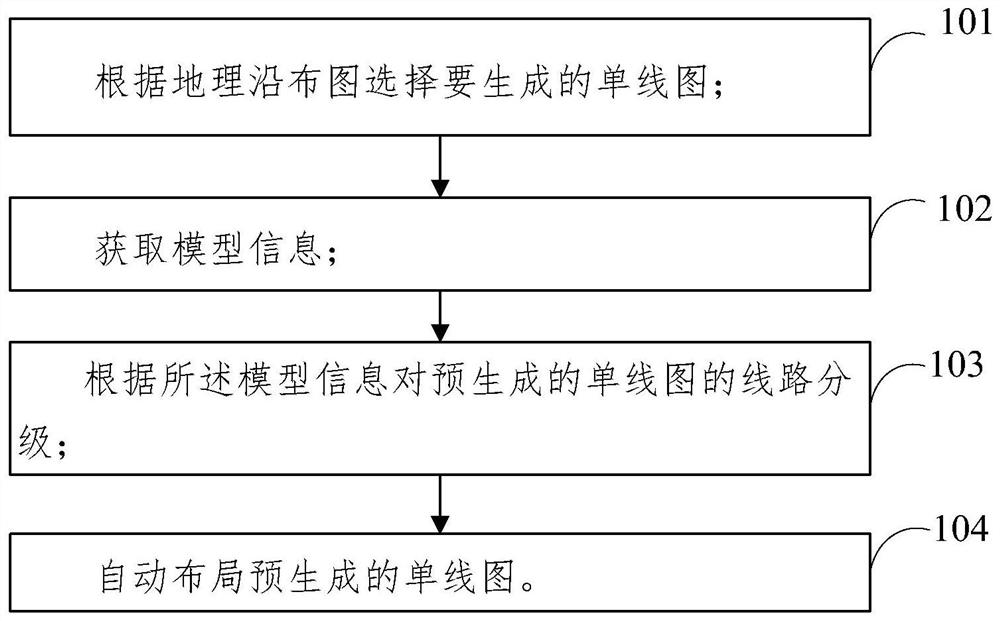

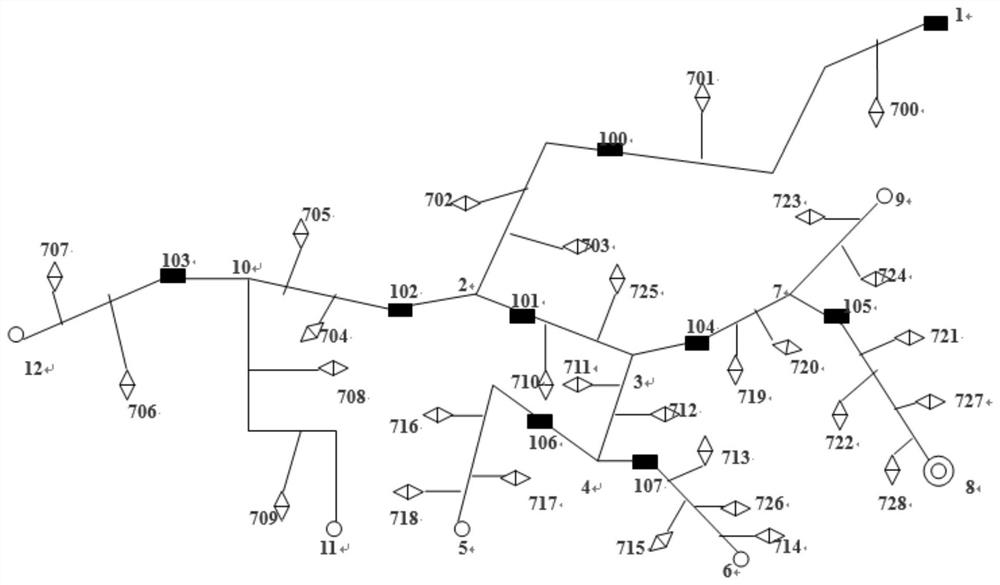

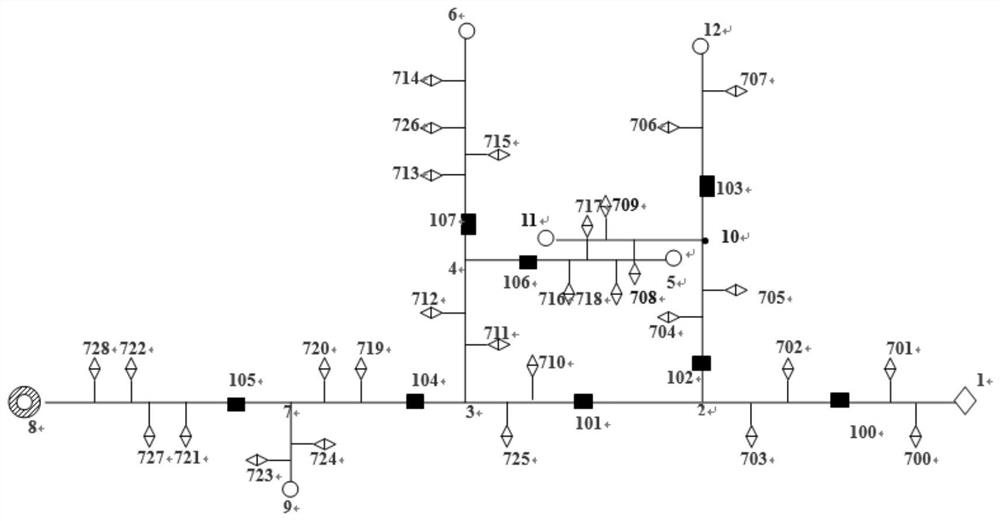

Method for automatically generating single line diagram based on geographic edge layout

PendingCN111639412AClear graphicsTo clearGeometric CADDrawing from basic elementsOne-line diagramAlgorithm

The invention discloses a method for automatically generating a single line diagram based on geographic edge layout and the method comprises the steps: determining the position of a power point and the trend of a main line based on the geographic edge layout, and guaranteeing that the power point is always located at the edge part of a single-line diagram; and based on the trend of the geography along the layout, determining the trend of the single-line diagram branches so as to ensure that the generated single-line diagram is consistent with the trend of the geography along the layout. A horizontal and vertical single-line diagram is generated through mapping of geography along the layout, so that the diagram is clear and clear in trend. The line spacing is automatically adjusted by combining the sizes of the icons when the single line diagram is generated, so that the diagram is amplified as much as possible on the premise of not crossing, not overlapping and displaying the whole diagram in a full-screen manner. The finally generated single line diagram is reasonable and attractive in layout, free of equipment overlapping, line crossing and topology errors. The phenomena of poorlayout flexibility, congestion, open space and even overlapping of the existing single-line diagram automatic mapping are optimized.

Owner:XUJI GRP +3

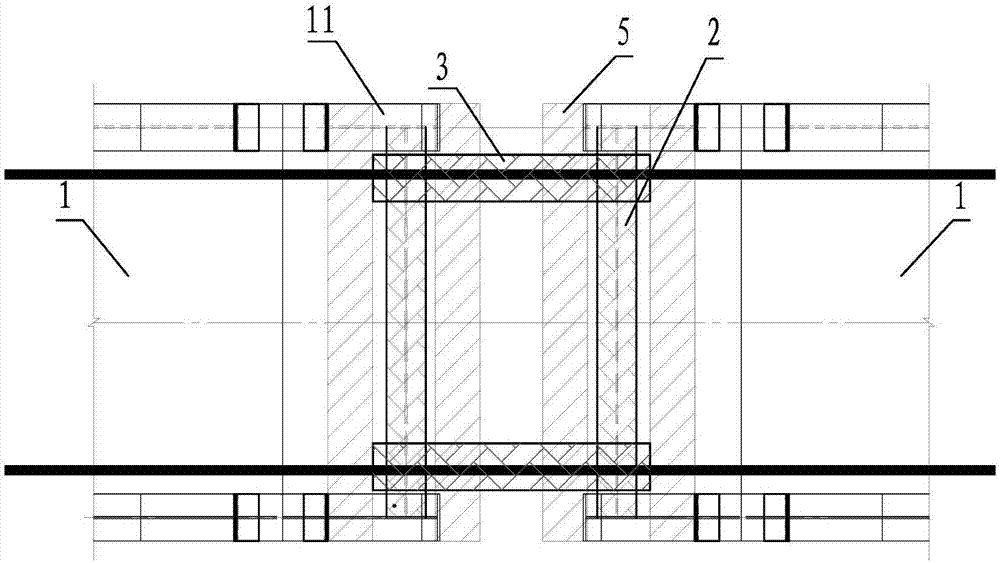

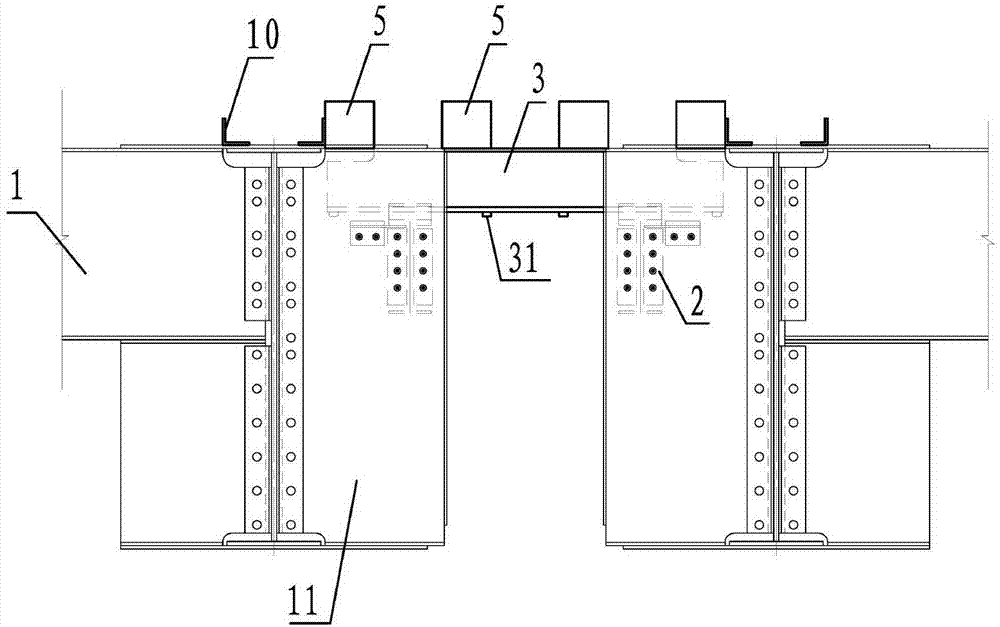

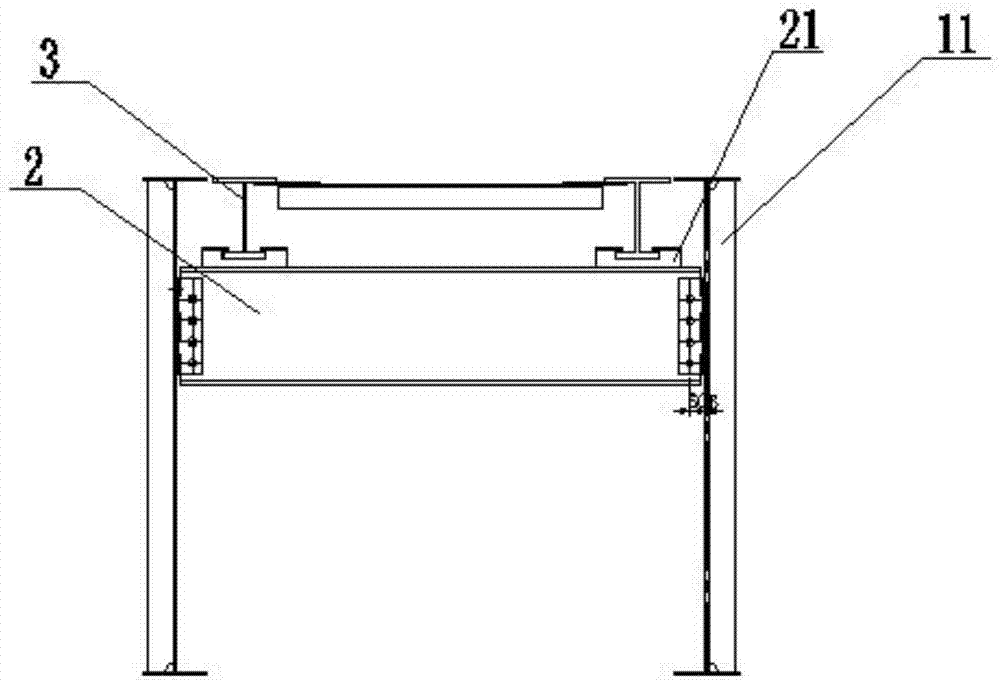

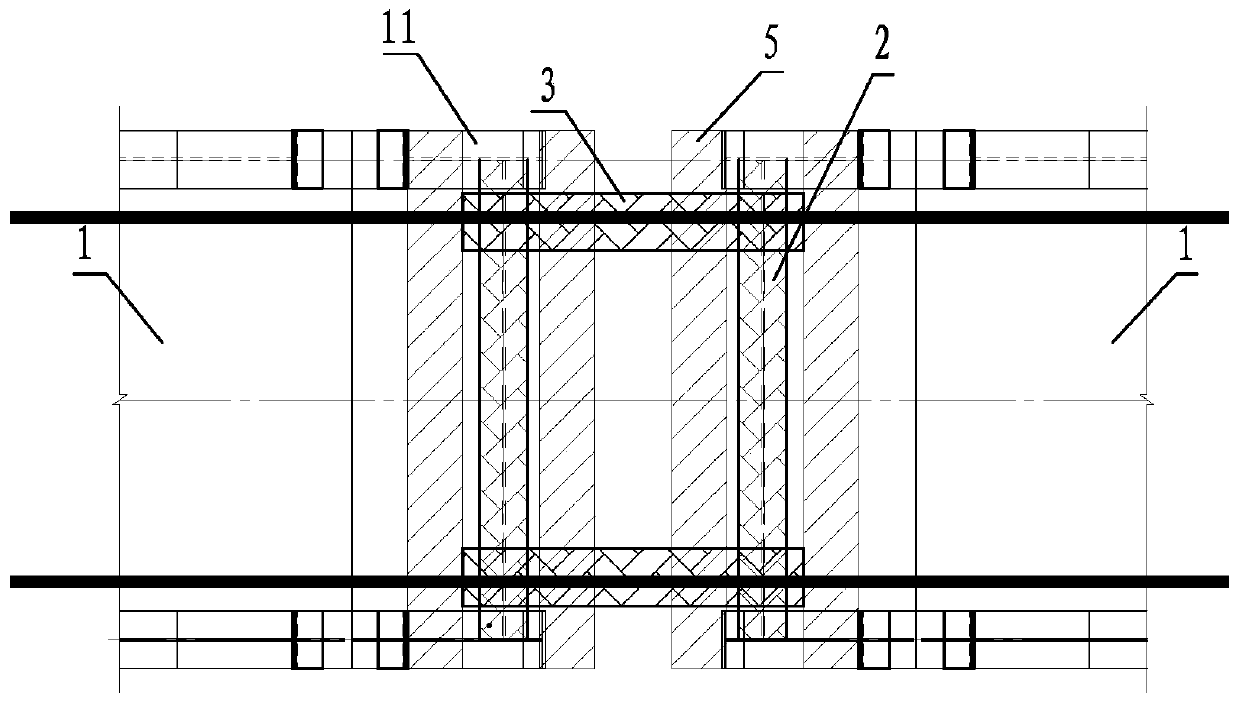

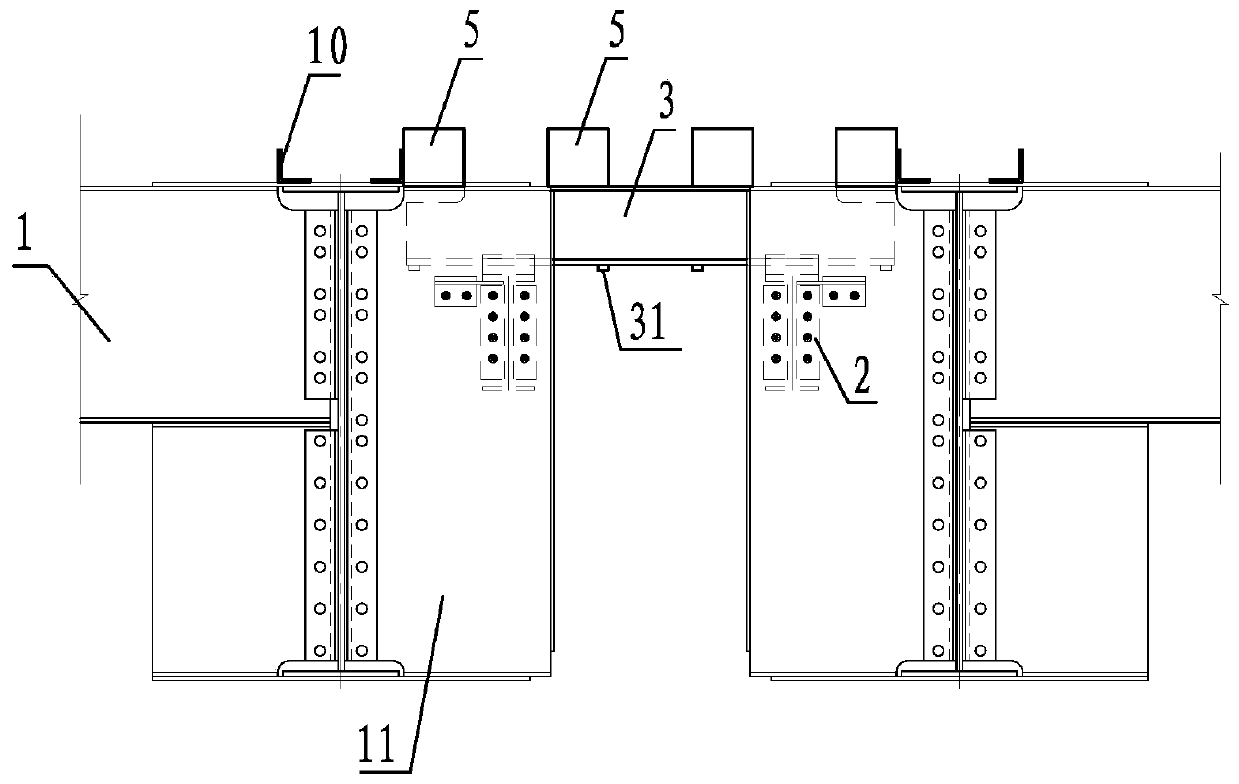

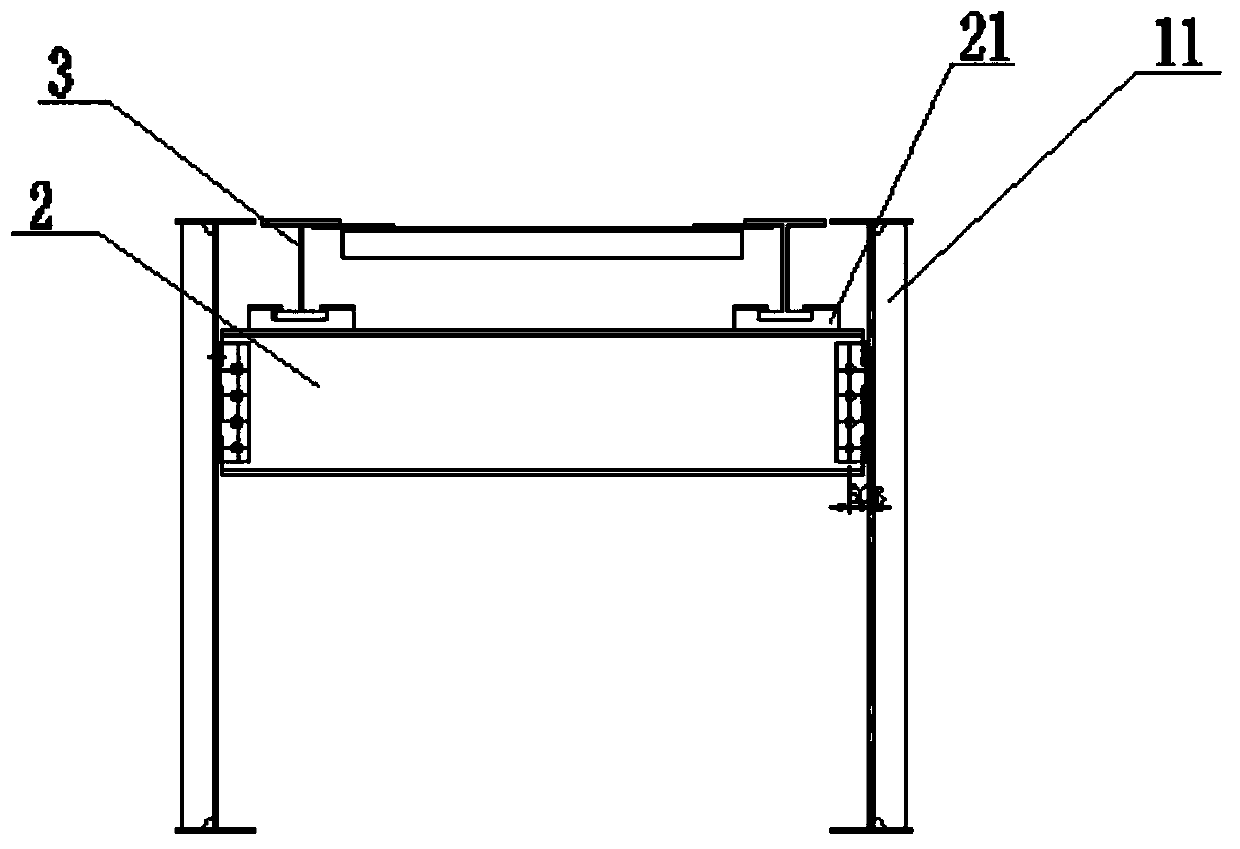

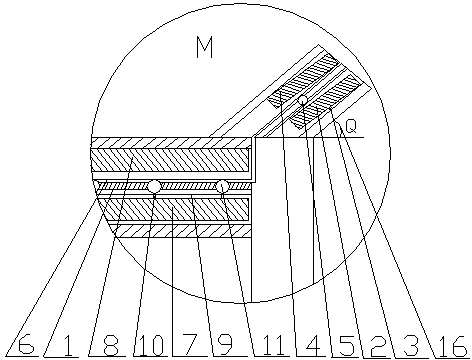

System for supporting and adjusting sleepers at rail traffic bridge steel beam crevices and erection method thereof

ActiveCN107881911AHas the ability to coordinate deformationAuto SpacingBridge structural detailsBridge erection/assemblyEngineeringDislocation

The invention provides a system for supporting and adjusting sleepers at rail traffic bridge steel beam crevices and an erection method thereof and relates to the technical field of bridge design construction. Small connected cross beams and small movable longitudinal beams are erected at steel beam ends respectively, the small movable longitudinal beams can produce limited displacements on the small connected cross beams, sleepers are erected on the steel beams and the small movable longitudinal beams, gauge adjusting devices are arranged among the sleepers in a beam crevice range, the smallmovable longitudinal beams and the gauge adjusting devices jointly and automatically adjust separation distances of the sleepers during dislocation or longitudinal deformation of the beams, and a sleeper erection system having coordinative deformation capability is achieved.

Novel composite silencer

PendingCN114187887ANo breakageStable air pressureFluid heatersSound producing devicesNoiseEngineering

The invention discloses a novel composite silencer, and relates to the technical field of boiler silencers, the novel composite silencer comprises a double-layer sound receiving pipe with a pit on the inner side, the sound receiving pipe can be stretched and compressed, and by changing the bending radius of the sound receiving pipe and changing the angle between the sound wave direction and the inner wall of the sound receiving pipe, noise of different degrees can be absorbed. The device further comprises an air storage barrel, a sliding piston is arranged in the air storage barrel in a sliding mode, it is guaranteed that the air pressure of the outer shell and the air pressure of the inner shell are stable through movement of the sliding piston, and the interior of the outer shell and the interior of the inner shell are both in a nearly-vacuum state. And targeted elimination is carried out according to high and low frequencies of sound.

Owner:连云港市运国环保设备有限公司

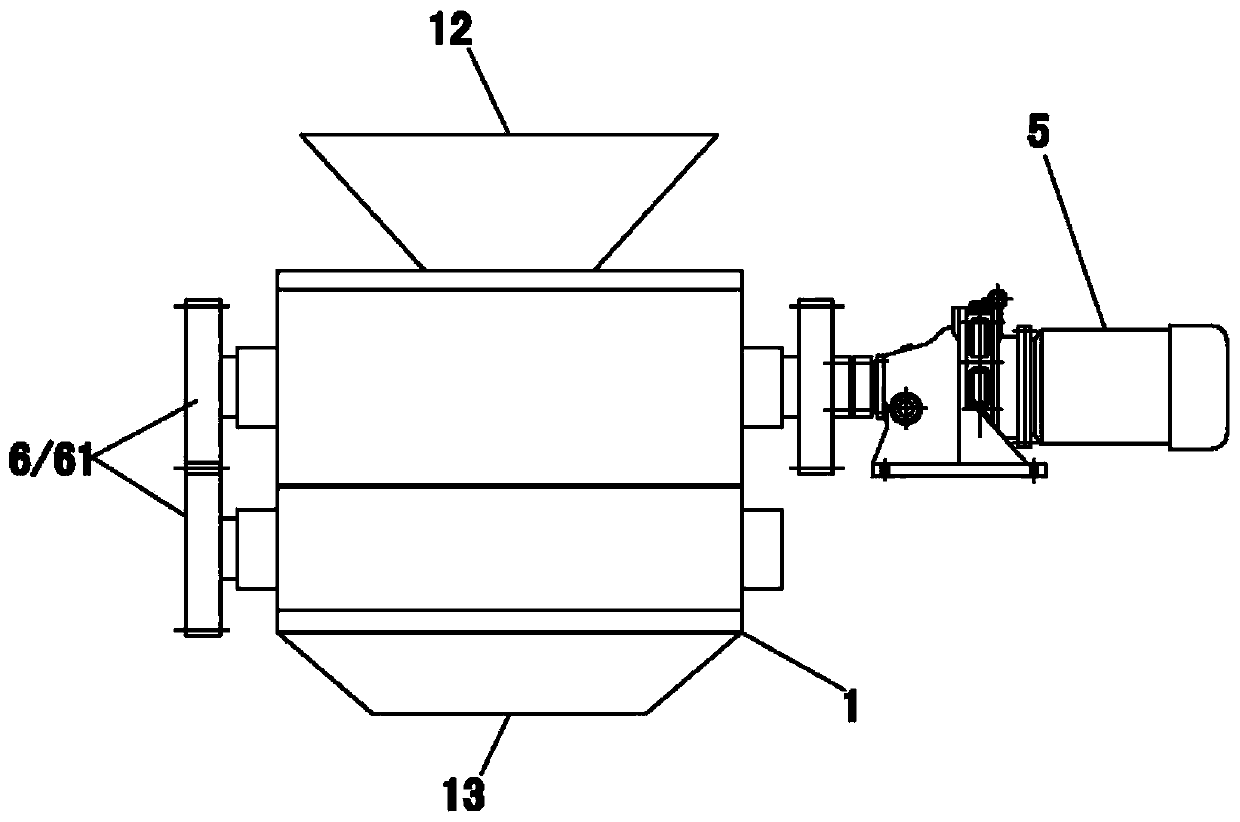

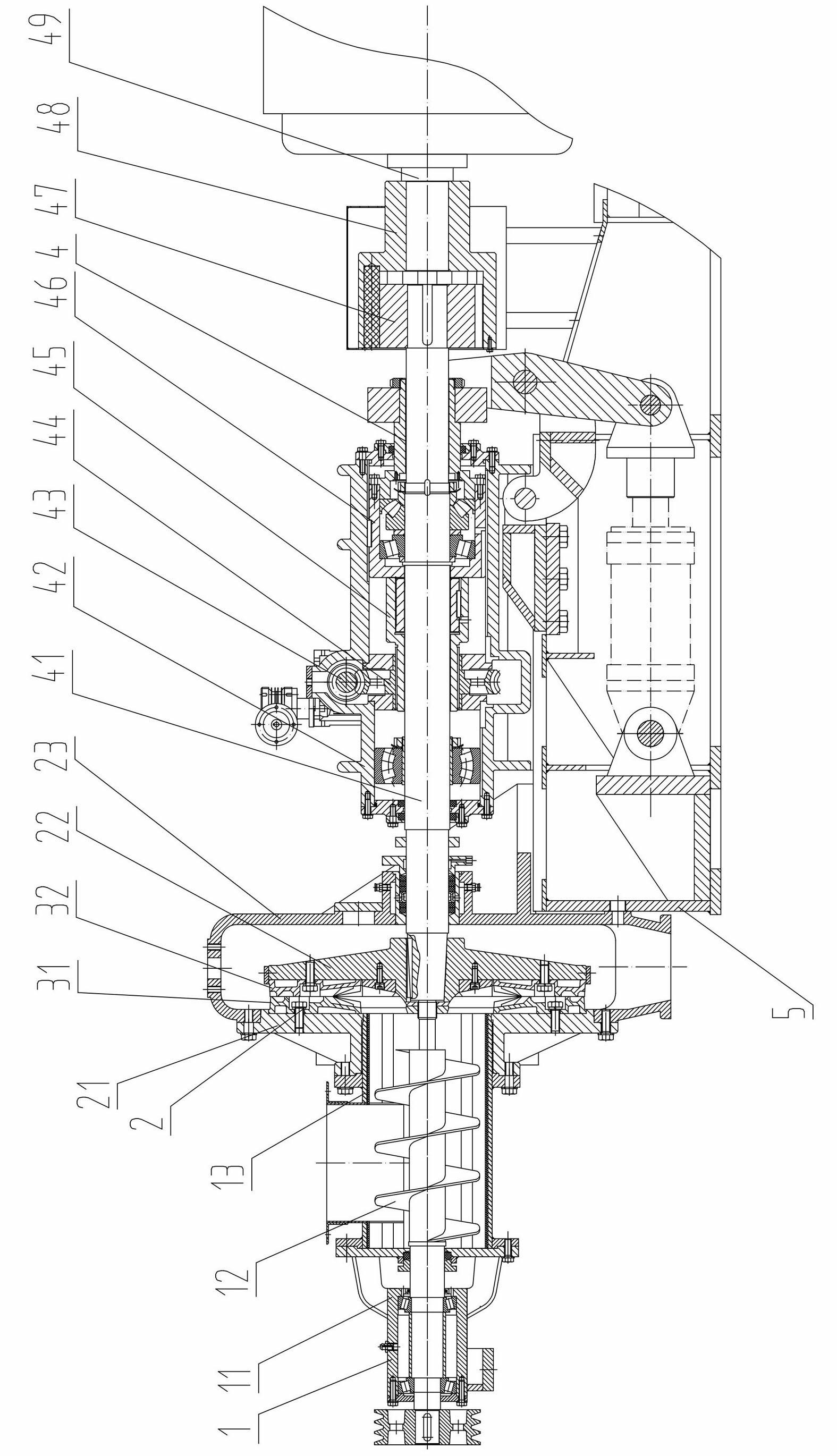

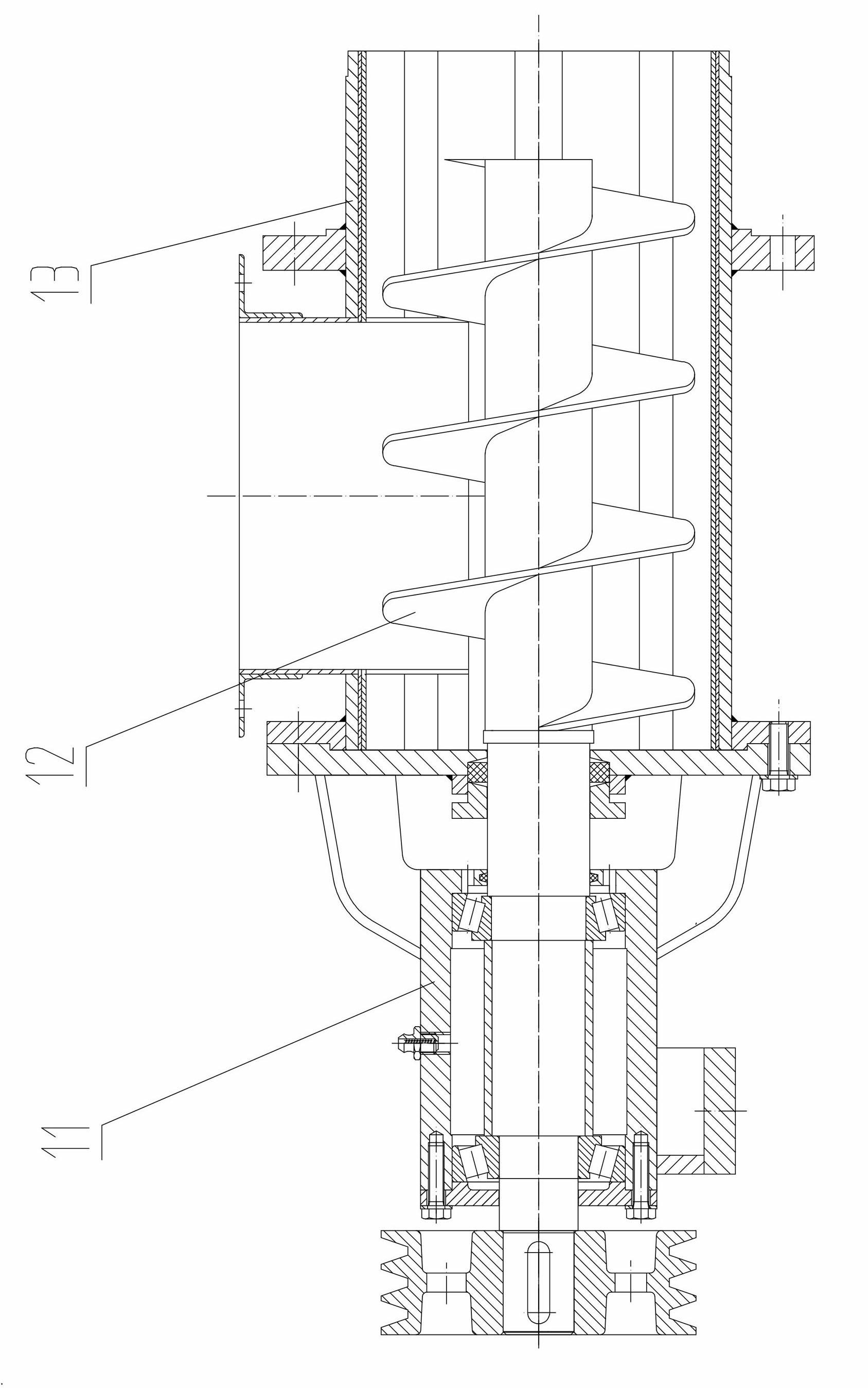

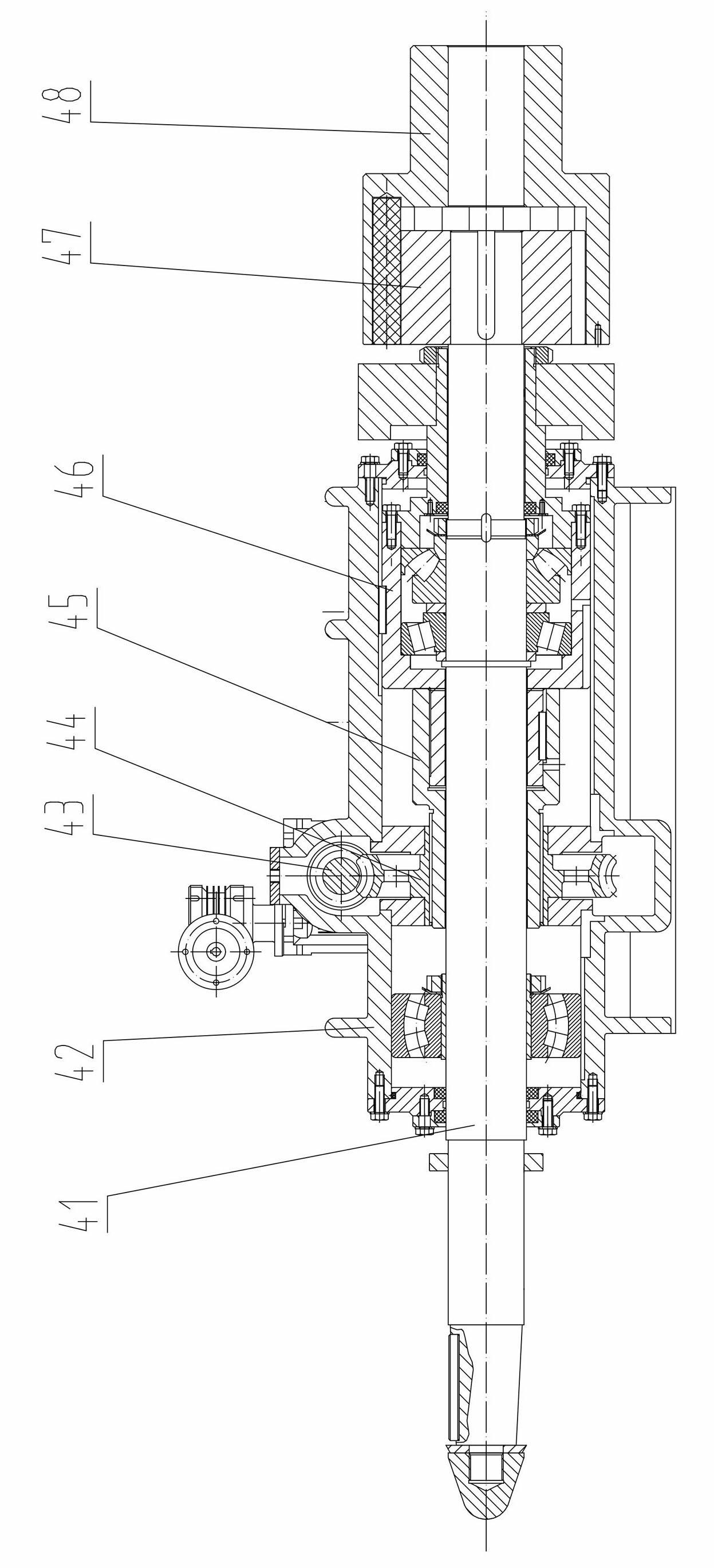

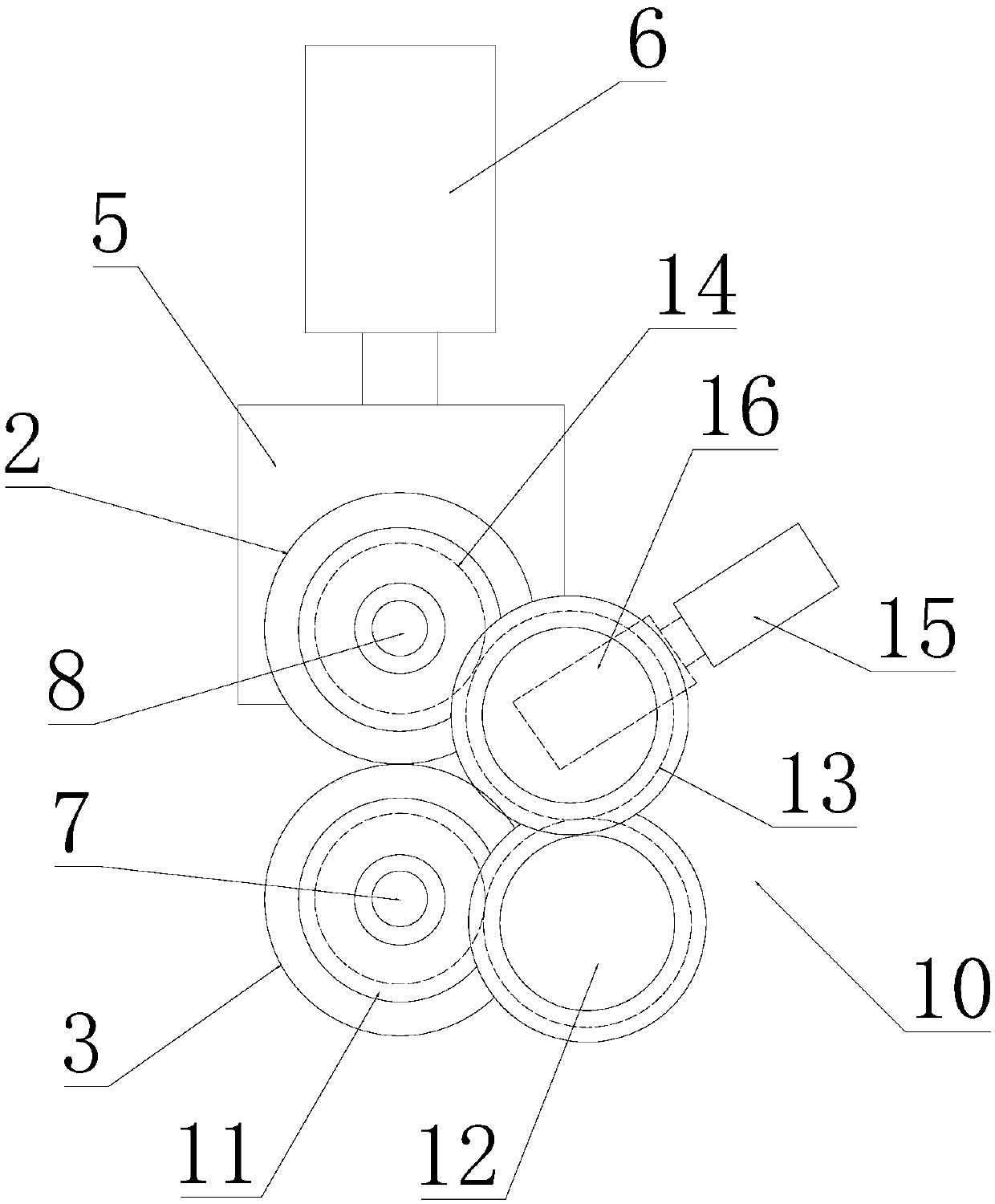

Fully automatic hydraulic pulping machine

ActiveCN102146636AAffect working distanceEliminate process fluctuationsPulp beating/refining methodsPulp and paper industryFully automatic

The invention discloses a fully automatic hydraulic pulping machine. The fully automatic hydraulic pulping machine comprises a feeding component, a machine base, a grinding disc component and a drive component, wherein the grinding disc component and the drive component are fixed to the machine base; the drive component comprises a main shaft connected with a drive mechanism; a space adjusting device is arranged on the main shaft; the space adjusting device comprises a worm wheel, a worm, a space adjusting sleeve and a mobile sleeve, wherein the worm is connected with the drive component; the mobile sleeve is connected with a hydraulic drive cylinder; the space adjusting sleeve and the mobile sleeve are connected with the outer side wall of the main shaft; the worm wheel matched with the worm for driving is sleeved outside of the space adjusting sleeve; and the worm wheel and the space adjusting sleeve are in threaded fit. The fully automatic hydraulic pulping machine has the advantages of simple and compact structure, low cost, convenience for operation, stable and reliable work, and capacity of reducing energy consumption, reducing noise pollution, stabilizing finished pulp quality and the like.

Owner:CHANGSHA CC PAPER MACHINERY

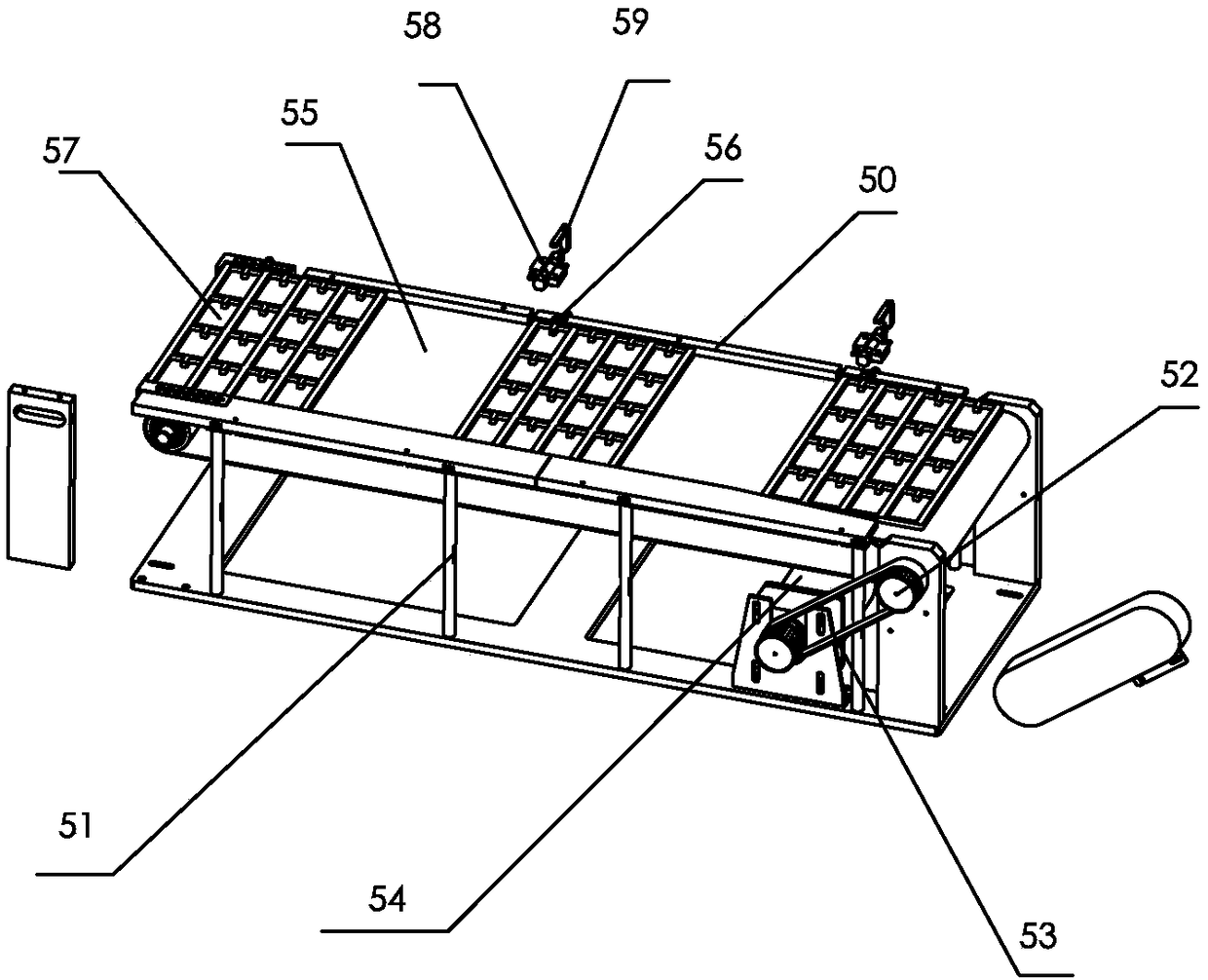

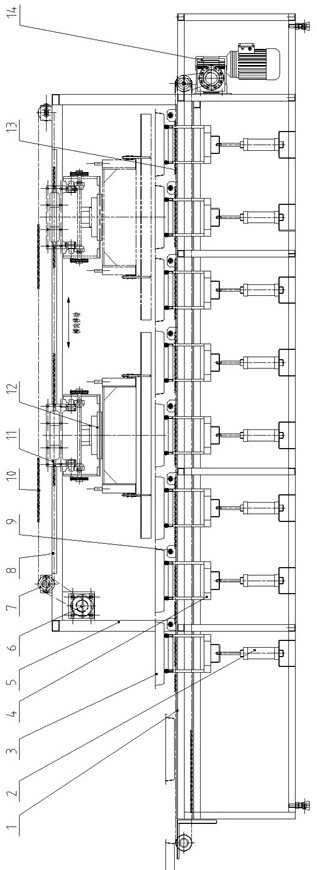

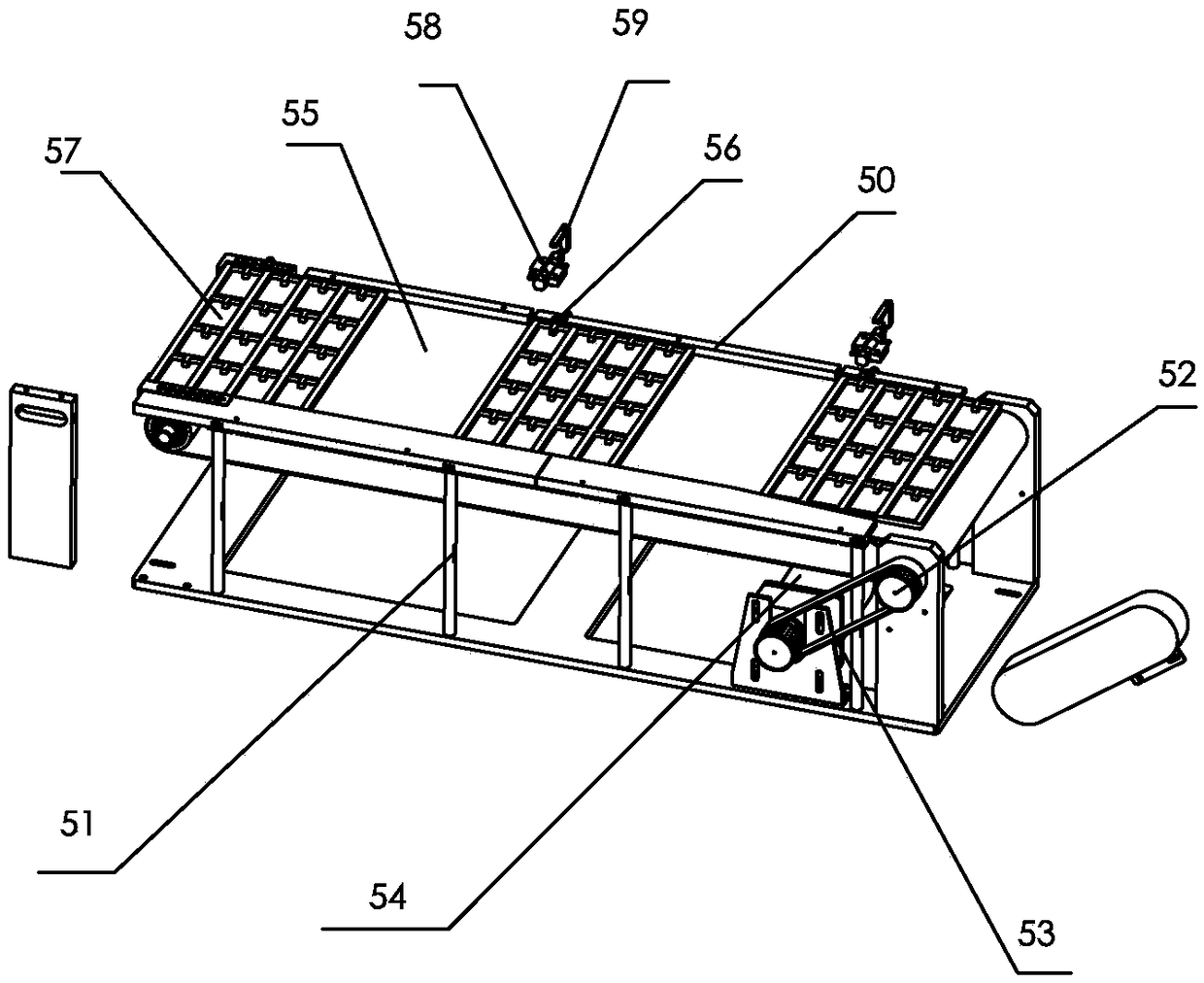

Automatic disc stacking machine

PendingCN112644750ARealize automatic inputAuto SpacingPackaging automatic controlIndividual articlesComputer hardwareAutomatic control

The invention discloses an automatic disc stacking machine which comprises a disc stacking machine frame, an input device, a disc pushing device, a moving device, a grabbing device, a servo disc feeding device, a double-speed disc feeding device, a large bracket and an automatic control system. The input device is arranged on the disc stacking machine frame, the large bracket is arranged on one side of the input device in parallel, and the disc pushing device is arranged on the disc stacking machine frame and located on the outer side of the input device. A transverse guide rail is arranged above the disc stacking machine frame, and the moving device is arranged on the transverse guide rail. The grabbing device is fixed to the moving device and can move along the transverse guide rail along with the moving device. The servo disc feeding device and the double-speed disc feeding device are sequentially arranged in the steamed bun disc conveying direction, and the servo disc feeding device is arranged below the large bracket. The automatic disc stacking machine is high in automation degree, capable of saving labor and high in disc stacking efficiency, and is indispensable ideal equipment for automatic food production.

Owner:SHANDONG YINYING COOKING MACHINERY

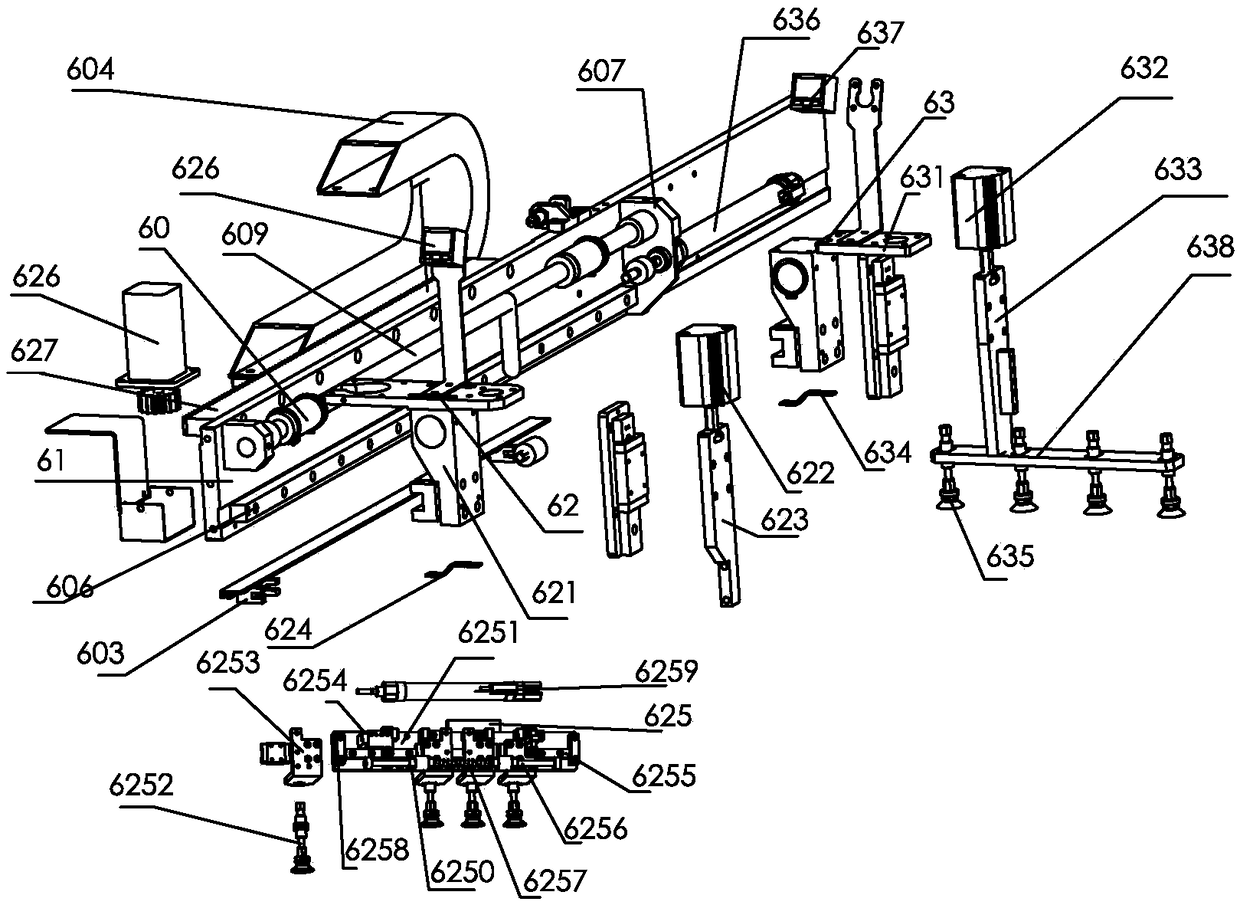

Lithium battery rubberizing machine

InactiveCN108417900AAuto SpacingFinal product manufactureElectrolyte accumulators manufactureNew energyManipulator

The invention relates to the technical field of new energy production and specifically relates to a lithium battery rubberizing machine which comprises a machine frame assembly, a supporting frame, abattery cell feeding assembly, a feeding manipulator assembly, a transferring assembly, a rotary disk assembly, a rubberizing assembly, a rubber pressing assembly, a rubber coating assembly and a discharging manipulator assembly. The lithium battery rubberizing machine has the advantages of being automatically suitable for performing rubberizing operation on battery cells of different intervals and sizes; furthermore, top surface rubberizing and lateral end face rubber coating can be operated in a fully-automatic mode.

Owner:留丹翠

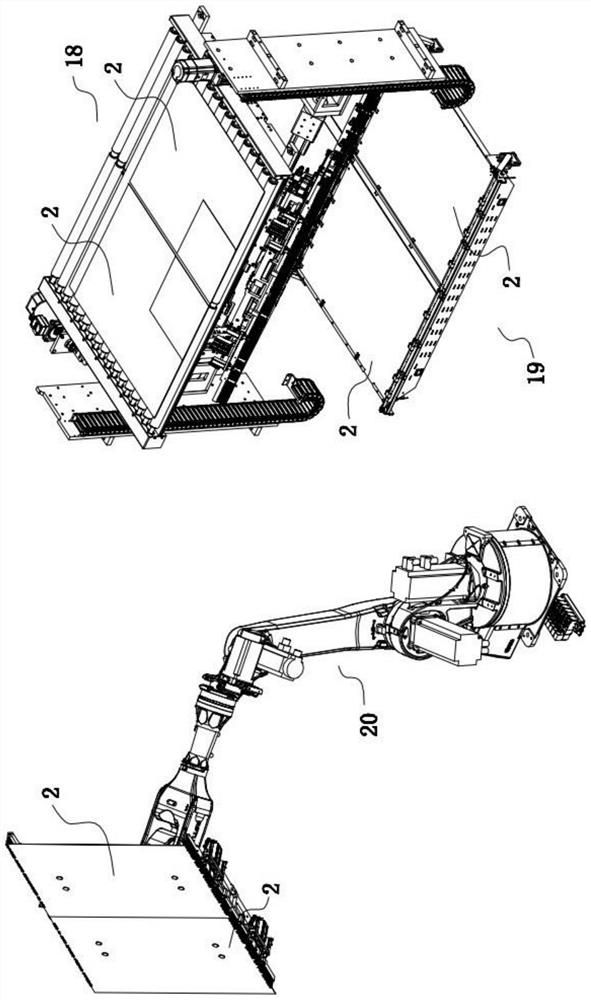

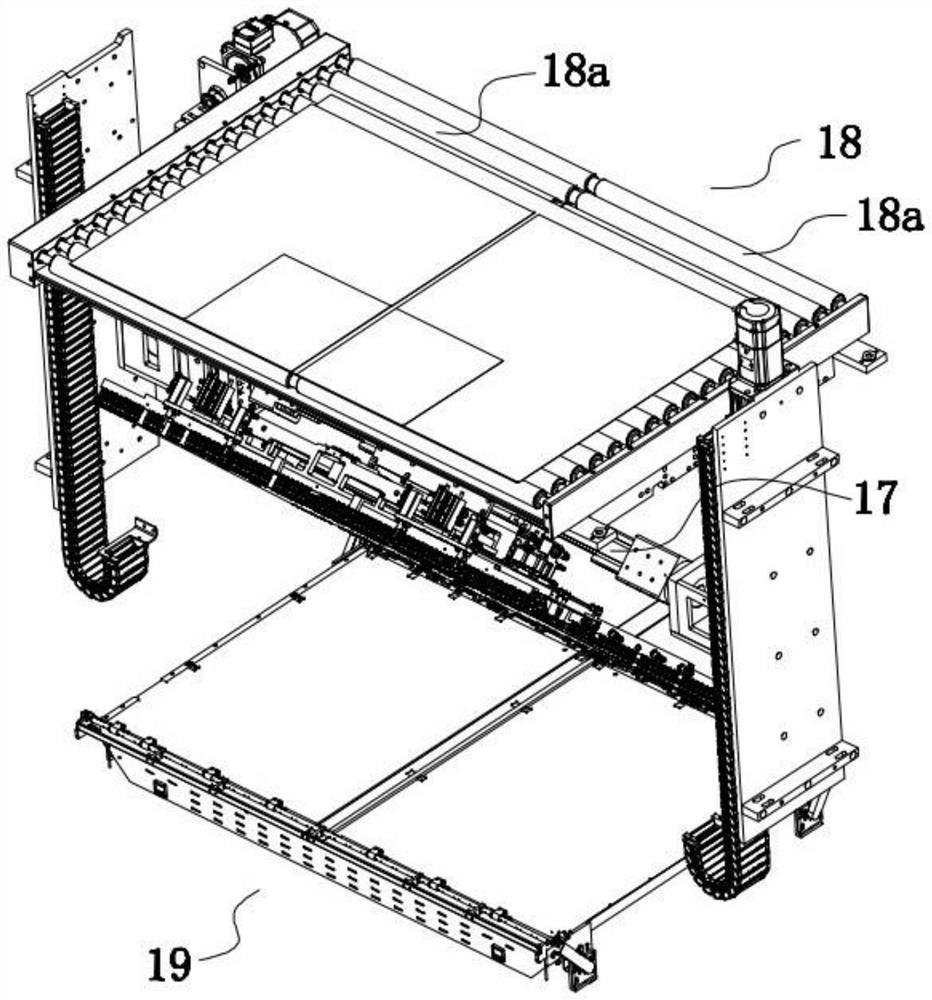

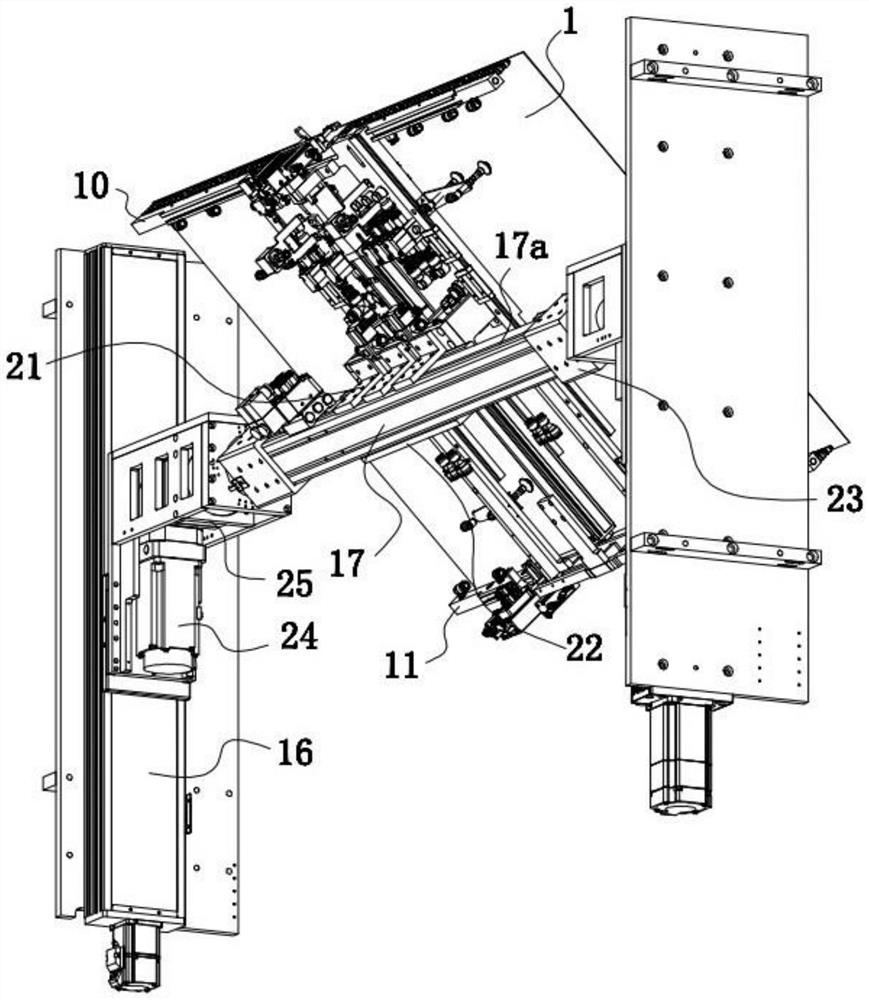

PCB lifting and overturning mechanism

PendingCN114180335ASmall footprintCompact structurePrinted circuit manufactureConveyor partsRobot handClassical mechanics

The invention discloses a PCB (Printed Circuit Board) lifting and overturning mechanism which comprises a suction device which is adsorbed with one surface of a PCB; the lifting and overturning mechanism is provided with a horizontal overturning rod, the two ends of the overturning rod are connected with vertical linear modules, one end of the overturning rod is connected with a servo motor, a suction device is assembled on the overturning rod, and the overturning rod has the vertical lifting freedom degree and the rotation freedom degree around the axis of the overturning rod; the assembly line comprises a streamline platform and an exposure platform which are arranged above and below the overturning rod respectively, and the flowing directions of the streamline platform and the exposure platform are parallel and opposite; and a manipulator with a suction device is arranged in the same end direction of the manipulator, the streamline platform and the exposure platform. According to the invention, the material taking function and the turn-over function are integrated together, the device is arranged right above the exposure machine platform, the vertical space is fully utilized, and the overall structure is compact. And the device is close to the exposure machine, small in overturning action and high in efficiency.

Owner:苏州八零七智能科技有限公司

Electroplating machine capable of automatically accessing hanger

ActiveCN1322171CAuto SpacingGuarantee the quality of platingElectrolysis componentsEngineeringWork flow

The electroplating machine capable of automatically accessing jig includes electroplating bath, jig, jig conveying system and control circuit. The jig conveying system set over the electroplating bath may be divided into upper plate section, front processing section, electroplating bath section, post processing section and temporarily set section. The temporarily set section has automatically jig accessing unit consists of jig storing mechanism and automatic elevating mechanism. The control circuit is connected to the jig accessing mechanism and the automatic elevating mechanism. The automatic elevating mechanism is connected to the jig accessing mechanism and the temporarily set section to realize the automatic accessing of jig. Compared with available technology, the present invention has raised electroplating effect, less man-made error and low cost.

Owner:宝盈科技(深圳)有限公司

A rail vehicle automatic coupling device

ActiveCN107719407BAuto SpacingImprove connection efficiencyRailway coupling accessoriesEngineeringMechanical engineering

The invention provides an automatic connection device for rail vehicles, comprising two spherical hinge components connected with two rail vehicles in rotatable and telescopic manner; the spherical hinge components can be rotated and swayed relative to the rail vehicles by connecting the spherical components to the ends of the rail vehicles; since a connection component and a locking component arealso connected between the two spherical hinge components, when the two adjacent rail vehicles are close, the locking component may be automatically aligned with, connected with and locked to the connection component; the automatic connection device also comprises an unlocking component mounted between the connection component and the locking component; when the connection needs to be disabled, the unlocking component can be controlled to separate the locking component and the connection component. The automatic connection device for rail vehicles provided herein is simple in structure and convenient to mount and can provide automatic connection for rail vehicles.

Owner:长沙开元仪器有限公司

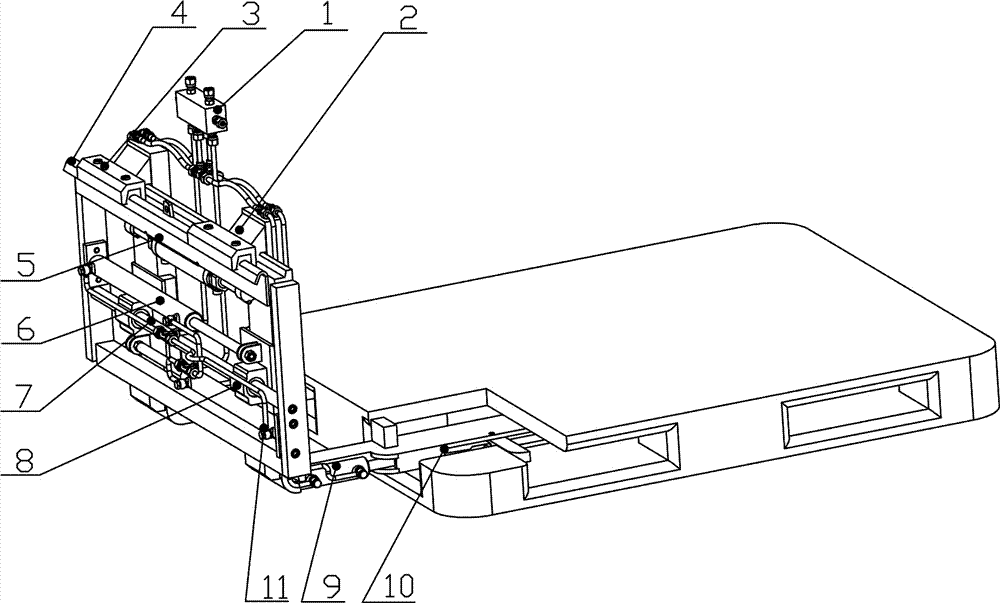

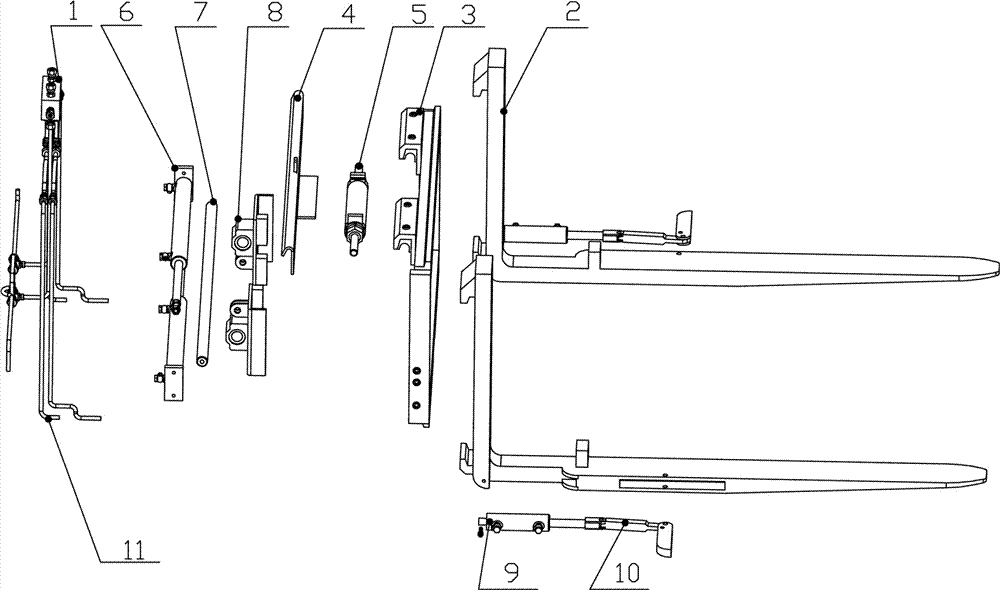

Forklift automatic operation system

InactiveCN104555828BImprove work efficiencyPrevent slippingLifting devicesControl systemWorking environment

The invention relates to an automatic operating system of a forklift; the automatic operating system is composed of a control system, consisting of a control valve, a side-shift cylinder, a pallet fork pitch-adjusting cylinder, a locking cylinder and an oil pipe, as well as a load-bearing, moving and positioning part, consisting of a pallet fork, a pallet fork bracket, a pallet-fork upper sliding rail, a pallet-fork lower sliding rail, a lower sliding rail pedestal and a lock. With adoption of the above design, the distance between the forklift and the pallet fork can be adjusted automatically under a complex working environment; the slipping of a pallet during transshipment of cargos can be prevented by opening the lock installed on the pallet fork; the separation between the materials and the pallet is realized by the matching of a forklift thruster; various operations can be finished only by one person, so that the working efficiency of the forklift is improved greatly, the labor intensity is reduced and the operation safety is ensured.

Owner:李经纬

A cable pressing device

InactiveCN106205873BLow conductivityConsistent thicknessManufacturing extensible conductors/cablesEngineeringMechanical engineering

The invention provides a cable pressing apparatus. The cable pressing apparatus comprises a machine body, and an upper pressing wheel and a lower pressing wheel are rotatably arranged on the machine body; the upper pressing wheel and the lower pressing wheel are oppositely arranged in an up-down manner, and a pressing channel used for pressing a cable is formed between the upper pressing wheel and the lower pressing wheel; the upper pressing wheel and / or the lower pressing wheel is rotatably arranged on a mounting seat; the mounting seat is arranged on the machine body in a manner of moving up and down; and a telescopic mechanism used for adjusting the distance between the upper pressing wheel and the lower pressing wheel is arranged between the machine body and the mounting seat. The cable pressing apparatus provided by the invention is simple in structure and more convenient to use, is capable of automatically adjusting the distance between the upper and lower pressing wheels according to monitoring data at any time, and meets the requirements of keeping consistent cable thickness and always keeping a set cable pressure, thereby always keeping an ideal pressing effect of the cable.

Owner:国昌线缆有限责任公司

A kind of sand making equipment and process that can adapt to various specifications of materials

ActiveCN111013710BGood size uniformityReasonable structureGrain treatmentsDust controlProcess engineering

The invention discloses a sand-making equipment and process that can be adapted to materials of various specifications. The sand-making equipment includes a raw material conveying line, a raw material crusher, a semi-finished product conveying line, a semi-finished product screening machine, a powder removal system, a finished product output line, and a raw material conveying line. The starting end of the conveying is the raw material warehouse, the raw material crusher includes the raw material inlet connected with the conveying end of the raw material conveying line and the semi-finished product outlet for discharging the crushed semi-finished products, the conveying start end of the semi-finished product conveying line is connected with the semi-finished product export, and the semi-finished product screening machine includes the connection with the semi-finished product conveying line The screening inlet connected to the conveying end and the screening outlet of the semi-finished products discharged and screened according to specifications. The powder removal system includes multiple dust removal lines, which correspond to the raw material conveying line, raw material crusher, semi-finished product conveying line and semi-finished product screening machine. The screening outlet includes the finished product outlet and the crushing outlet. The conveying end of the finished product output line is connected to the finished product outlet, and the crushing outlet is connected to the raw material inlet of the raw material crusher. The sand making equipment with this structure can be adapted to produce materials of various specifications, and can reach higher production standards.

Owner:FUJIAN NONNON TECH

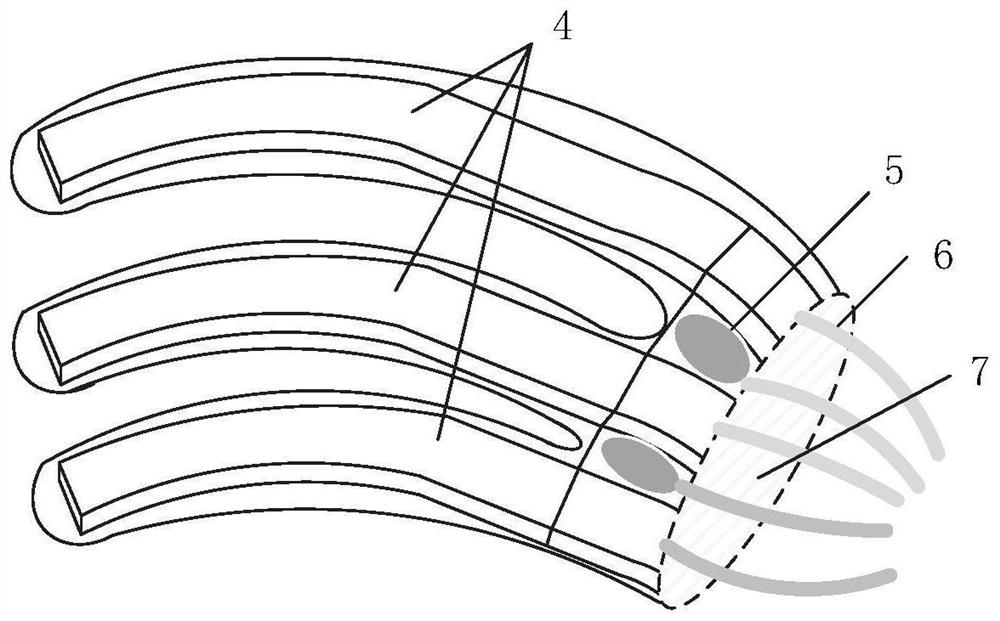

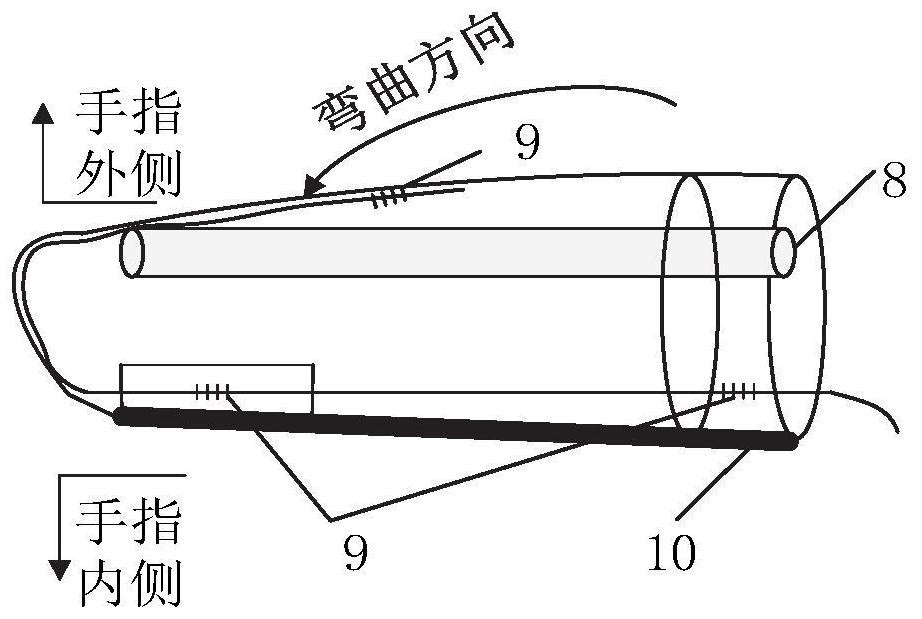

A flexible pulse diagnosis hand and traditional Chinese medicine pulse diagnosis instrument

ActiveCN112043248BAuto SpacingOvercoming individual body structure differencesCatheterDiagnostic recording/measuringPhysical medicine and rehabilitationPhysical therapy

The invention discloses a flexible pulse diagnosis hand and a traditional Chinese medicine pulse diagnosis instrument. The technical proposal is as follows: it includes a plurality of flexible fingers, one end of which is connected to form a joint of the wrist; The flexible fingers are controlled to bend; airbags are fixed between adjacent flexible fingers, and the distance between the flexible fingers is adjusted by inflating and deflating the airbags; multiple fiber Bragg gratings connected in series are arranged inside the flexible fingers. The invention can meet the non-contact autonomous detection, accurately identify the position of the wrist through the pulse pillow, automatically control the detection hand to reach above the detection point, and confirm the position of the radius according to the force cloud map at the pulse pillow, thereby determining the position of the Cunguanchi pulse test point; And it can record and store the operator's pulse diagnosis technique for further study and analysis.

Owner:SHANDONG UNIV

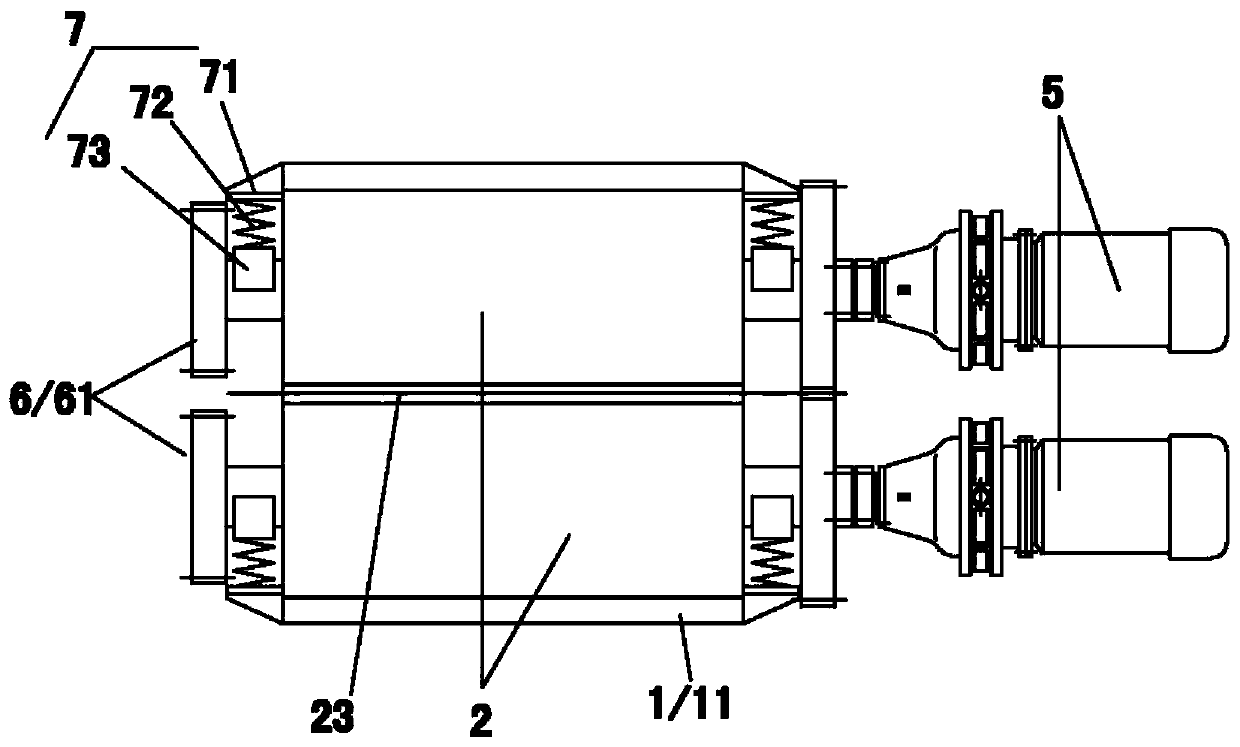

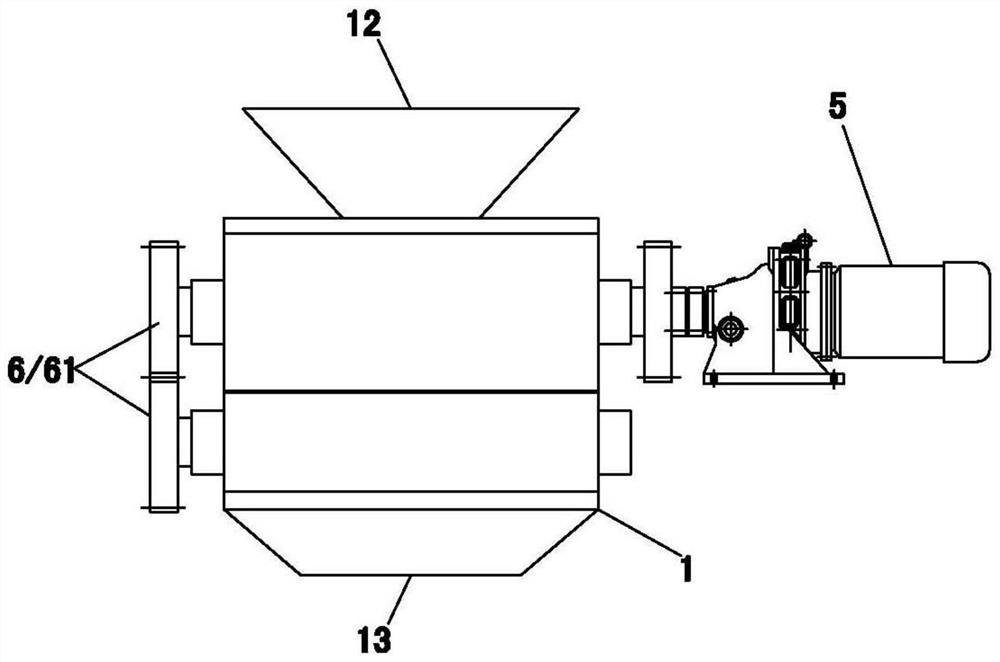

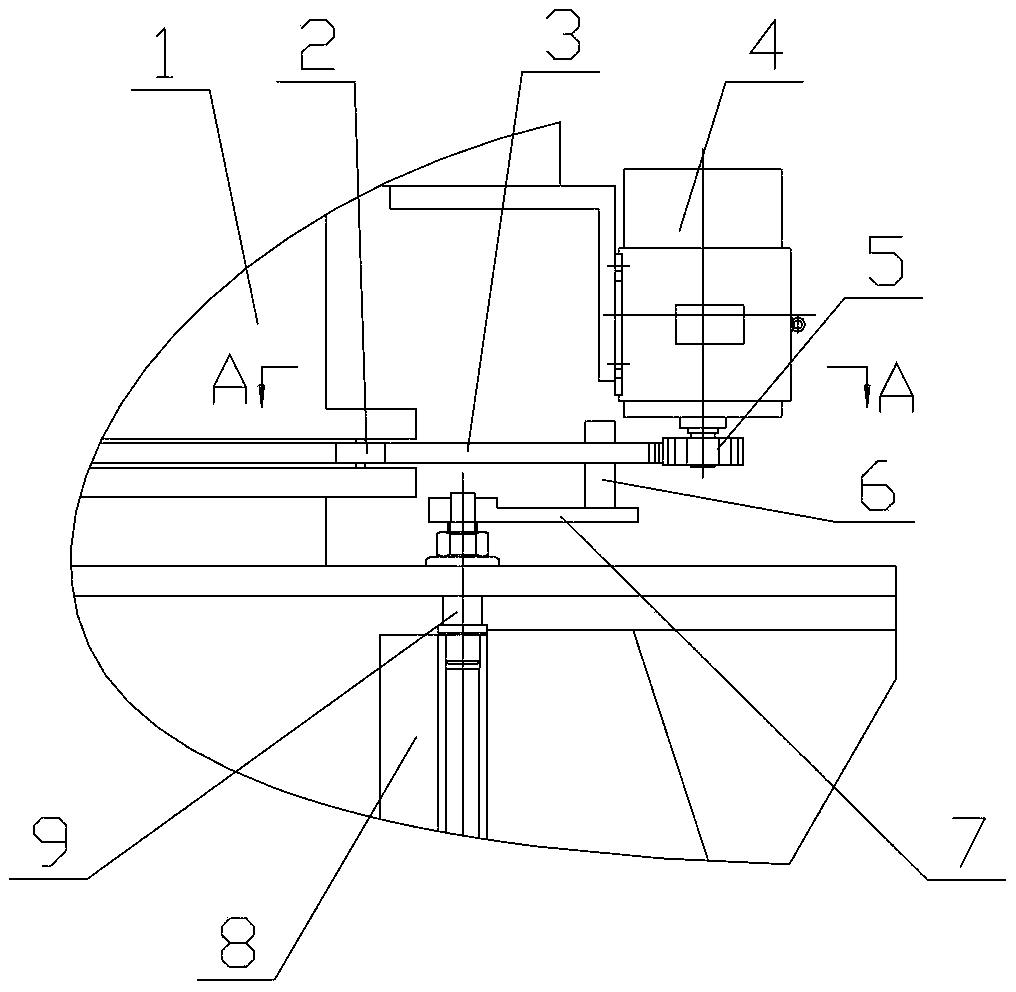

Automatic stator blade distance adjusting device for vertical roller mill powder concentrator

ActiveCN103008088BImprove adaptabilityAuto SpacingGas current separationGrain treatmentsRocker armConcentrator

Owner:中材(天津)粉体技术装备有限公司 +1

Rail Transit Bridge Steel Girder Girder Girder Seam Support Adjustment System and Erection Method for Sleepers

ActiveCN107881911BHas the ability to coordinate deformationAuto SpacingBridge structural detailsBridge erection/assemblyEngineeringDislocation

The invention provides a system for supporting and adjusting sleepers at rail traffic bridge steel beam crevices and an erection method thereof and relates to the technical field of bridge design construction. Small connected cross beams and small movable longitudinal beams are erected at steel beam ends respectively, the small movable longitudinal beams can produce limited displacements on the small connected cross beams, sleepers are erected on the steel beams and the small movable longitudinal beams, gauge adjusting devices are arranged among the sleepers in a beam crevice range, the smallmovable longitudinal beams and the gauge adjusting devices jointly and automatically adjust separation distances of the sleepers during dislocation or longitudinal deformation of the beams, and a sleeper erection system having coordinative deformation capability is achieved.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Self-aligning permanent magnet magnetic bearing

InactiveCN102518666BAuto SpacingIncrease the magnetic line densityBearingsMagnetic bearingEngineering

A self-aligning permanent magnet magnetic bearing comprises an inner ring, an outer ring, a plurality of elongated tile-shaped or rectangular permanent magnets, bearing balls, drive bars and drive rollers, wherein magnetic lines of force of the permanent magnets in sequential arrangement and a radial line of the bearing form small angles, the permanent magnets are mounted in interlayers of the inner ring and the outer ring, the bearing balls capable of rotating and moving radially are arranged between the inner ring and the outer ring, and the drive bars and the drive rollers push the inner ring or outer ring permanent magnets to rotate by certain small angles when the bearing balls move. The self-aligning permanent magnet magnetic bearing is characterized in that like poles of the bearing inner ring permanent magnets are opposite to those of the bearing outer ring permanent magnets, the included angles between the bearing inner ring or outer ring permanent magnets and the radial lineare different, a rotary bearing shaft is arranged at the center of inside of the inner ring permanent magnets, another rotary bearing shaft is arranged at the center of outside of the outer ring permanent magnets, and the permanent magnets can rotate around the rotary bearing shafts to adjust the included angles between the magnetic lines of force of the permanent magnets and the radial line so as to change density of the magnetic lines force in the radial direction, so that magnetic repulsive force of the magnets is changed.

Owner:魏伯卿

Copper strip splitting machine

ActiveCN114714095AAchieve positioningEasy to replaceShearing machinesOther manufacturing equipments/toolsStructural engineeringKnife blades

The invention provides a copper strip splitting machine, and belongs to the technical field of copper strip splitting equipment. The device comprises a left side plate and a right side box body, the left side plate is connected with the right side box body through a connecting rod, and an unwinding mechanism, a slitter edge cutting mechanism, a guide roller, a blade adjusting mechanism and a winding mechanism are sequentially arranged between the left side plate and the right side box body. A copper strip is released by the unwinding mechanism and enters the slitter edge cutting mechanism for edge cutting, the cut copper strip is conveyed to the blade adjusting mechanism through the guide roller to be cut into strips according to actual machining requirements, and finally the strips are collected by the winding mechanism. And different sizes can be adjusted and cut according to actual machining requirements, and copper strip rollers of different models can be replaced, so that the applicability is good.

Owner:浙江致信新材料科技有限公司

A wrapping device

ActiveCN104250890BImprove work efficiencyImprove processing qualityWork-feeding meansMotor driveNonwoven fabric

Owner:SUZHOU TRANSPARENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com