PCB lifting and overturning mechanism

A technology of PCB board and turning mechanism, which is applied in the direction of conveyor objects, electrical components, printed circuits, etc., can solve the problems of affecting production progress, high overall cost, and large workshop space, so as to save occupied area, simplify equipment process, turn over fast face effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

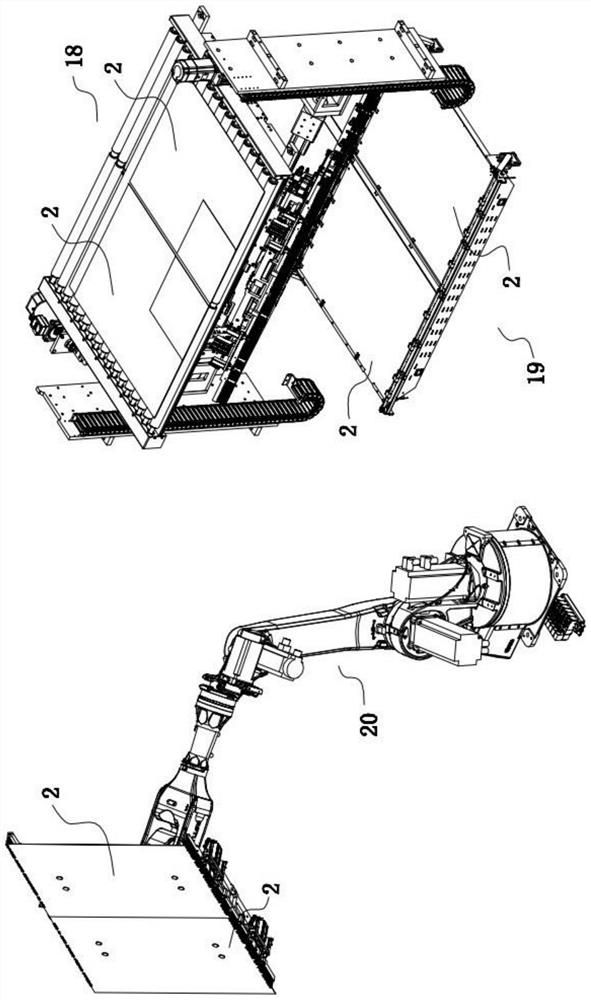

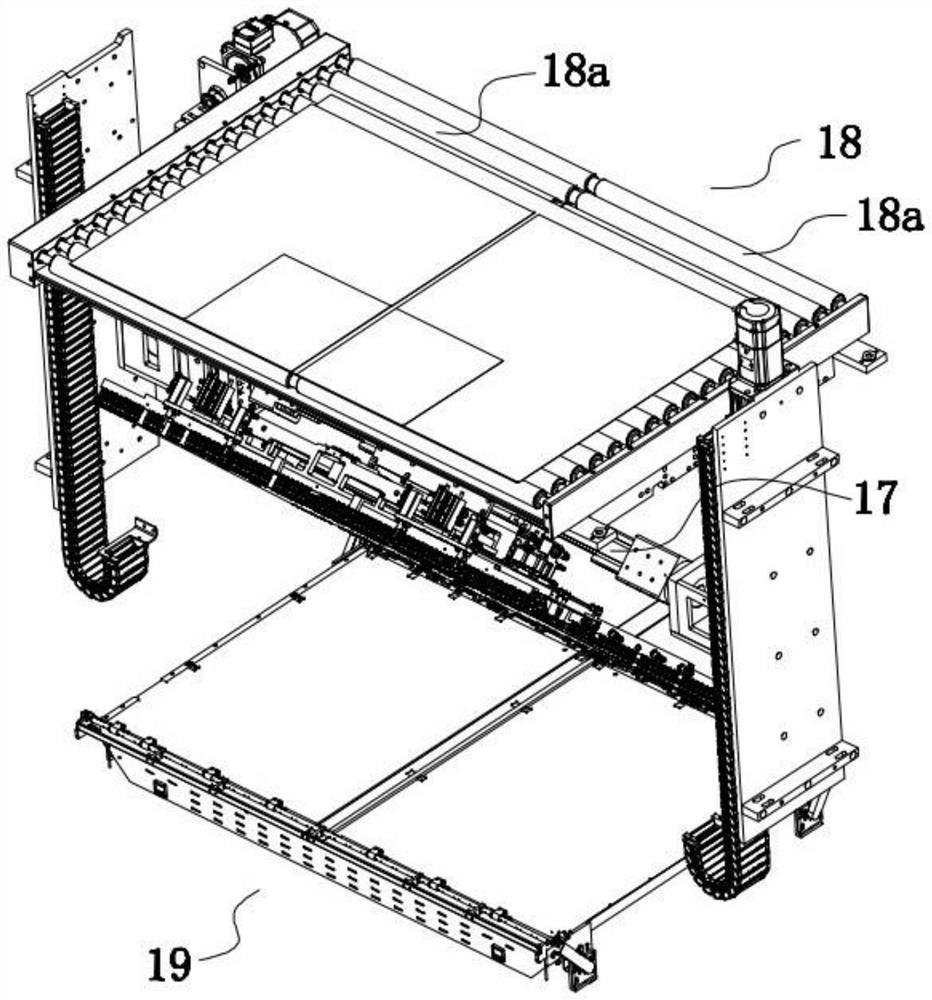

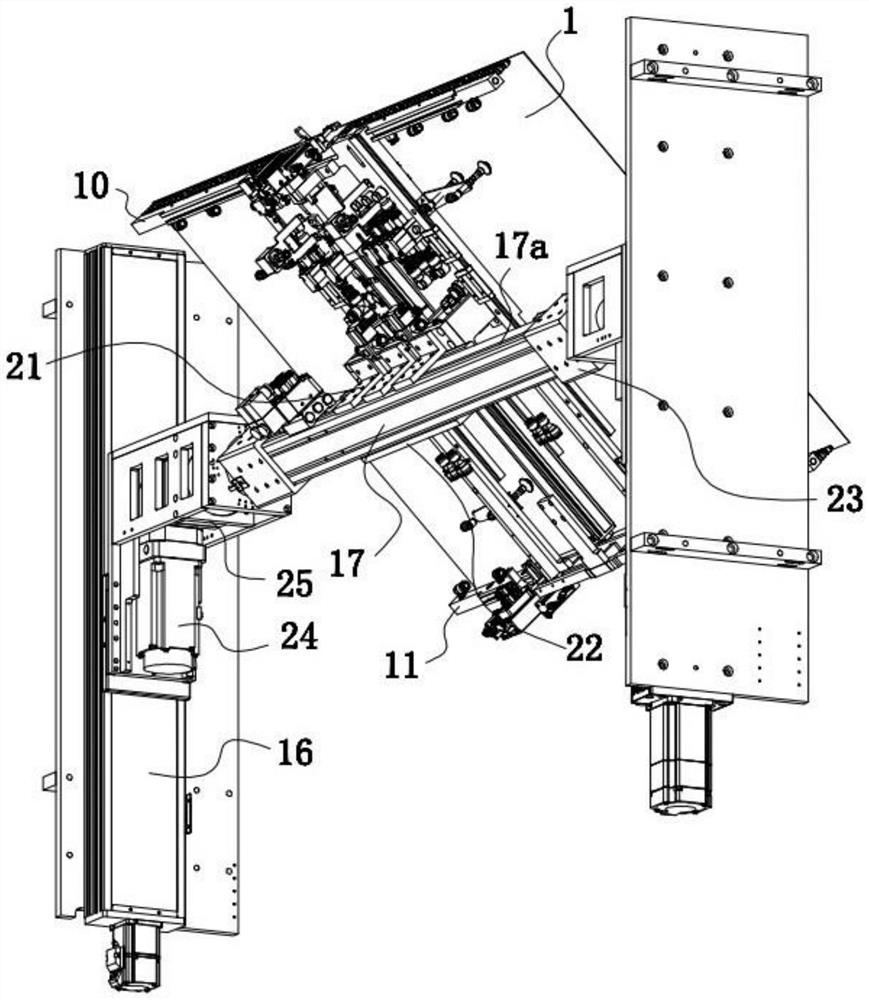

[0039] In order to achieve the purpose of the present invention, a PCB board lifting and turning mechanism includes: a suction device, which is adsorbed on one side of the PCB board; a lifting and turning mechanism, equipped with a horizontal turning bar 17, and the two ends of the turning bar 17 are connected with vertical straight lines Module 16, one end of the turning lever 17 is connected with a servo motor 24, and the turning lever 17 is equipped with a suction device, and the turning lever 17 has a degree of freedom of vertical lifting and a degree of freedom of rotation around its own axis; Streamline platform 18, exposure platform 19 above and below 17, the flow directions of streamline platform 18, exposure platform 19 are parallel and opposite; The manipulator 20 of the device.

[0040] The beneficial effects of adopting the above technical solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com