Novel composite silencer

A composite muffler, a new type of technology, applied in the direction of sounding equipment, instruments, fluid heaters, etc., can solve problems such as inability to eliminate and effectively absorb high-energy sound waves, and achieve the effect of reducing wind resistance and stabilizing air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

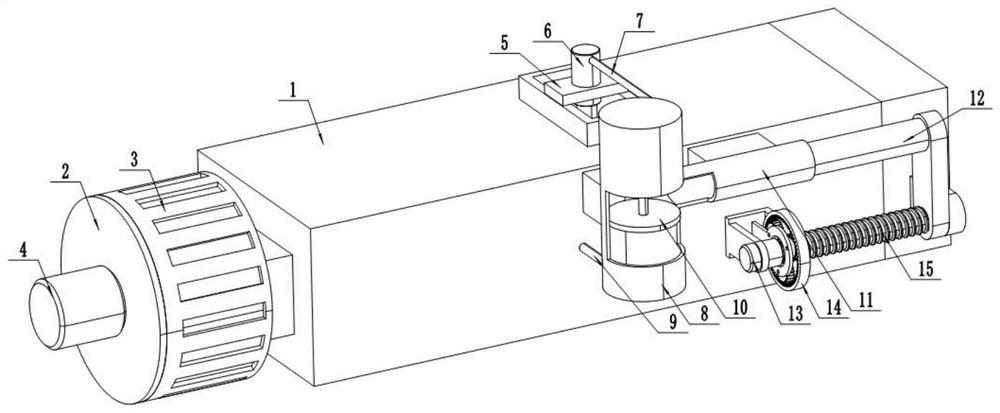

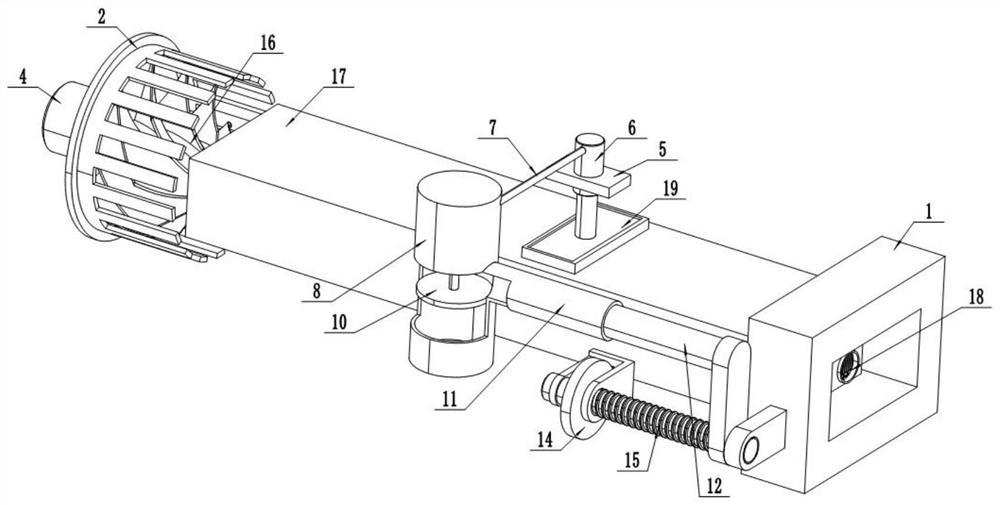

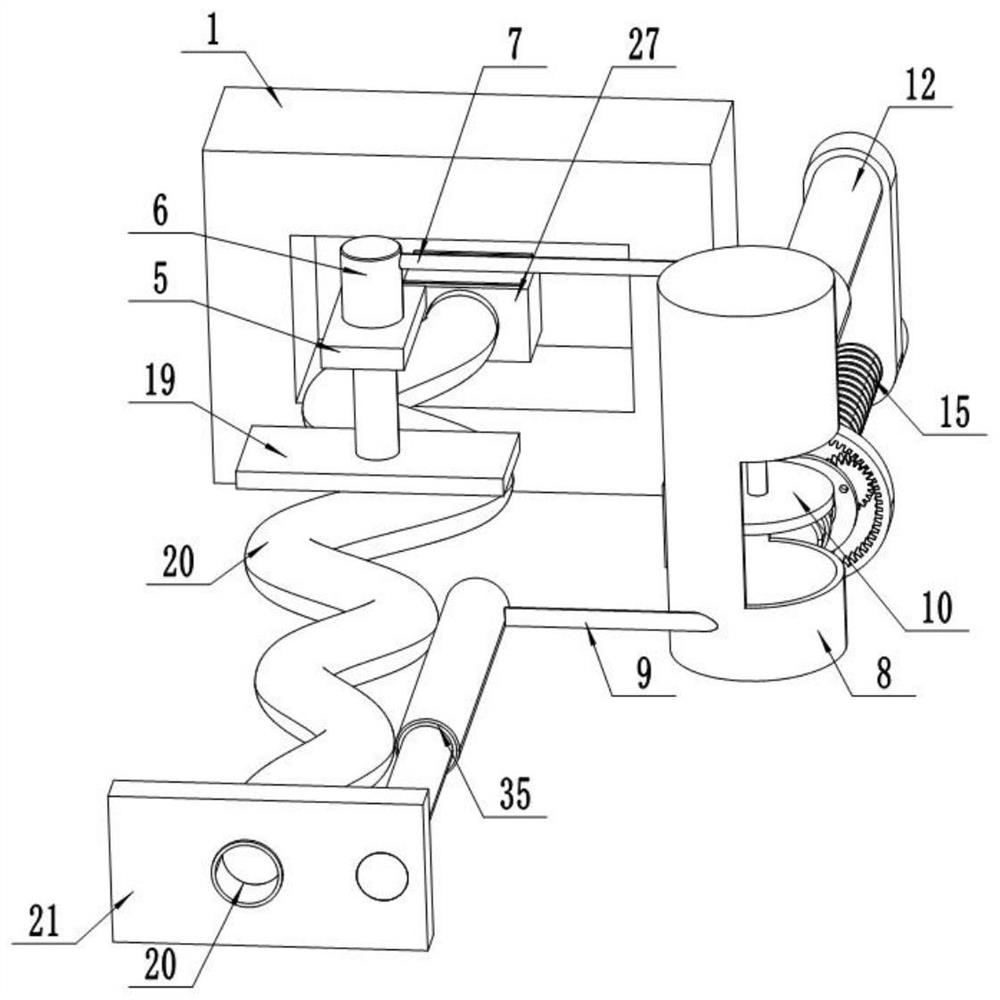

[0026] Example: Reference figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10A new composite muffler shown includes a casing 1 with openings at both ends, an air outlet assembly with a filtering function installed at the end of the casing 1 with an opening, and an automatic pressure regulating assembly is provided on the side of the casing 1, The inside of the outer shell 1 is provided with an inner shell 17, the length and width of the inner shell 17 are smaller than that of the outer shell 1, the space between the outer shell 1 and the inner shell 17 is close to vacuum, the air content is minimized, and it is filled with sound insulation cotton, the inside of the inner shell 17 is close to vacuum The end of the inner shell 17 away from the air outlet assembly is provided with a high-temperature air intake detection assembly, and the end of the inner shell 17 close to the air outlet assembly is slidably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com