Shell-crosslinked polymeric micelles by using metal nanoparticles as crosslinking agent

A technology of metal nanoparticles and polymer glue, which is applied in the direction of drug combination, drug delivery, medical preparations of non-active ingredients, etc., can solve the problem of non-degradability of cross-linked polymer micelles, and meet the stability requirements , the effect of good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Amphiphilic block polymer R-(CH 2 CH 2 O) m CH 2 CH 2 OCOCH 2 CH 2 SH terminal thiol modification:

[0030] R in the block polymer is polypropylene oxide, and the amphiphilic block polymer is used as a raw material. The specific synthesis steps are as follows:

[0031] a) Add 1 part by weight of 3,3'-dithiodipropionic acid and 10 parts by weight of thionyl chloride to 1000 parts by weight of tetrahydrofuran solvent, heat to 60 ° C, react for 4 hours, and remove unreacted chloride under reduced pressure Sulfoxide and solvent, obtain intermediate product 3,3'-dithiodipropionyl chloride;

[0032] b) 1 part by weight of the intermediate product 3,3'-dithiodipropionyl chloride was dissolved in 50 parts by weight of tetrahydrofuran solvent to obtain solution A;

[0033] c) 1 weight part of precursor polymer (CH 2 CH(CH 3 )O) n -(CH 2 CH 2 O) m CH 2 CH 2 OH was dissolved in 50 parts by weight of tetrahydrofuran solvent to obtain solution B, wherein m is an ...

Embodiment 2

[0041] (1) Amphiphilic block polymer R-(CH 2 CH 2 O) m CH 2 CH 2 OCOCH 2 CH 2 SH terminal thiol modification: same as in Example 1. NMR and IR confirmed that the obtained product had the expected structure.

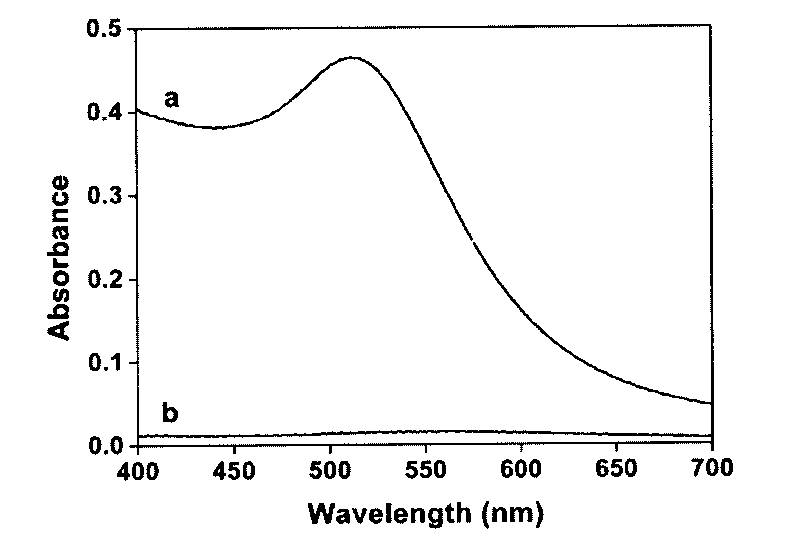

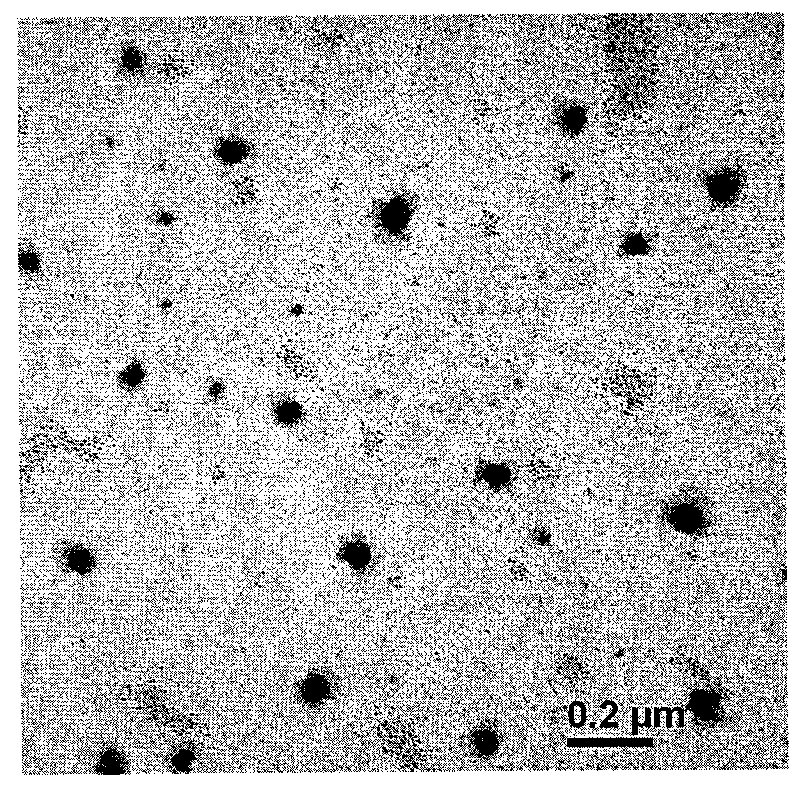

[0042] (2) Preparation of silver nanoparticles with a particle size of 3.5nm: 2.06mL of 10mg / mL silver nitrate aqueous solution was added to 200mL of sodium citrate (14.7mg) aqueous solution, and 6mL of iced sodium borohydride (22.8mg ) solution, stirred and reacted for 1h. Ultraviolet and transmission electron microscopy confirmed that the obtained silver nanoparticles had a regular structure, were uniformly dispersed and had a particle size of about 3.5nm.

[0043] (3) Cross-linking of silver nanoparticles on the surface of block polymer micelles: under the protection of nitrogen, the polymer was made into a micellar aqueous solution at 37° C., and the deoxidized silver nanoparticles were added dropwise to the above solution, and stirred overnight. Taking the c...

Embodiment 3

[0045] (1) Amphiphilic block polymer R-(CH 2 CH 2 O) m CH 2 CH 2 OCOCH 2 CH 2 SH terminal thiol modification: same as in Example 1. NMR and IR confirmed that the obtained product had the expected structure.

[0046] (2) Preparation of platinum nanoparticles with a particle size of 3.5nm: 2.06mL of 10mg / mL platinum nitrate aqueous solution was added to 200mL of sodium citrate (14.7mg) aqueous solution, and 6mL of iced sodium borohydride (22.8mg ) solution, stirred and reacted for 1h. Ultraviolet and transmission electron microscopy confirmed that the obtained platinum nanoparticles had a regular structure, were uniformly dispersed and had a particle size of about 3.5nm.

[0047] (3) Cross-linking of platinum nanoparticles on the surface of the block polymer micelles: under nitrogen protection, the polymer was made into a micellar aqueous solution at 37° C., and the deoxygenated platinum nanoparticles solution was added dropwise to the above solution, and stirred overnig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com