Axicon beam scanning device

A technology of rotating axicon and beam scanning, which is applied in the field of optical scanning systems, can solve the problems of cogging customization cost, affecting driving accuracy, and difficult space layout, etc., and achieve simple and reliable connection relationships, improve transmission accuracy, and reduce error transmission links. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

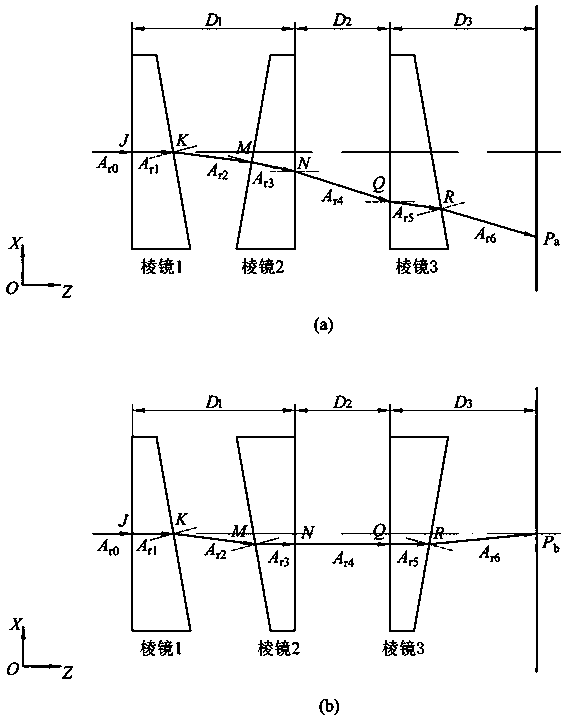

[0054] Set the prism to have exactly the same parameters: α =10°, n =1.517, d 0 =5 mm, D p =80 mm; and D 1 =100mm, D 2 =100 mm, D 3 =100 mm. Under this condition, the scanning domain radius of the rotating double prism system composed of only the first wedge prism and the second wedge prism is R d =45.4892 mm, the radius of the blind zone is R dbz=7.1207 mm; while the scanning field radius of the axicon system composed of the first wedge prism, the second wedge prism and the third wedge prism at the same position is R t =53.0426 mm, the radius of its blind zone becomes R tbz =0 mm. Therefore, the expansion rate of the scanning domain caused by the third wedge prism is δ=[ R t 2 -( R d 2 - R dbz 2 )] / ( R d 2 - R dbz 2 )=39.38%, and the expansion effect of the newly added prism on the scanning domain will follow D 3 growth has become more pronounced. In addition, it can be further determined that the critical distance to eliminate the blind zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com