Harvester for rhizomatic crops

A technology for crops and rhizomes, applied in the field of rhizome crop harvesters, can solve the problems of reducing the harvest rate of rhizome crops, reducing the working efficiency of the harvester, complicated structure of the lifting device, etc., so as to facilitate collection and stacking, prevent damage, increase The effect of digging the channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

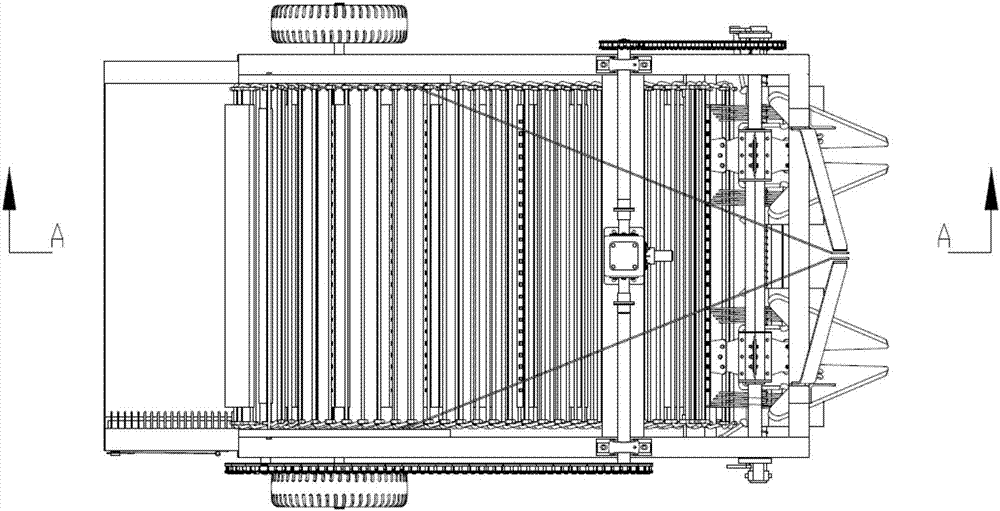

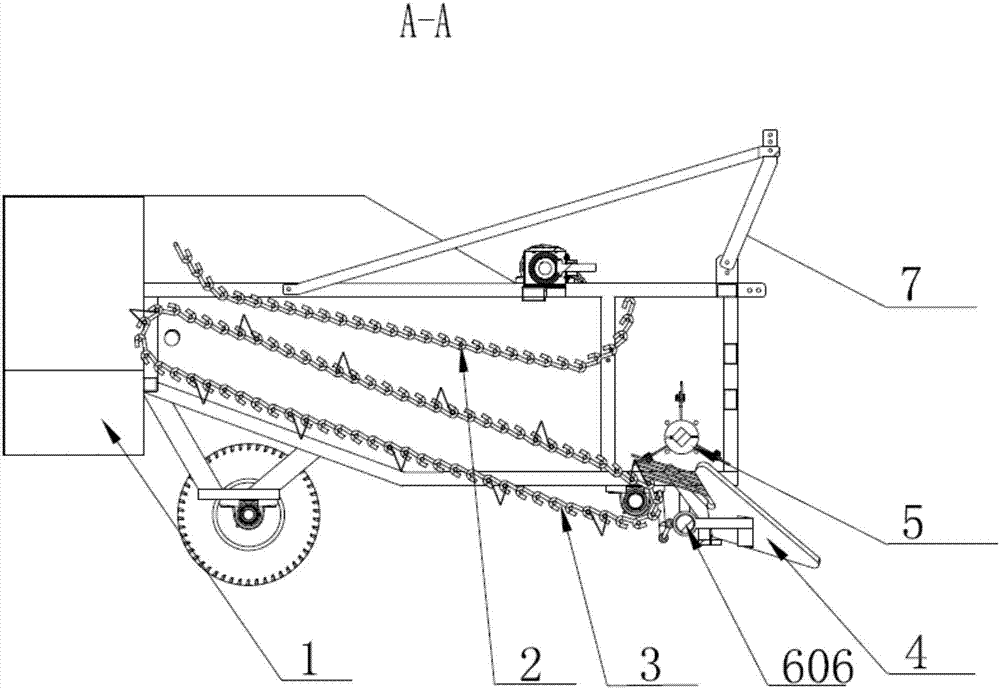

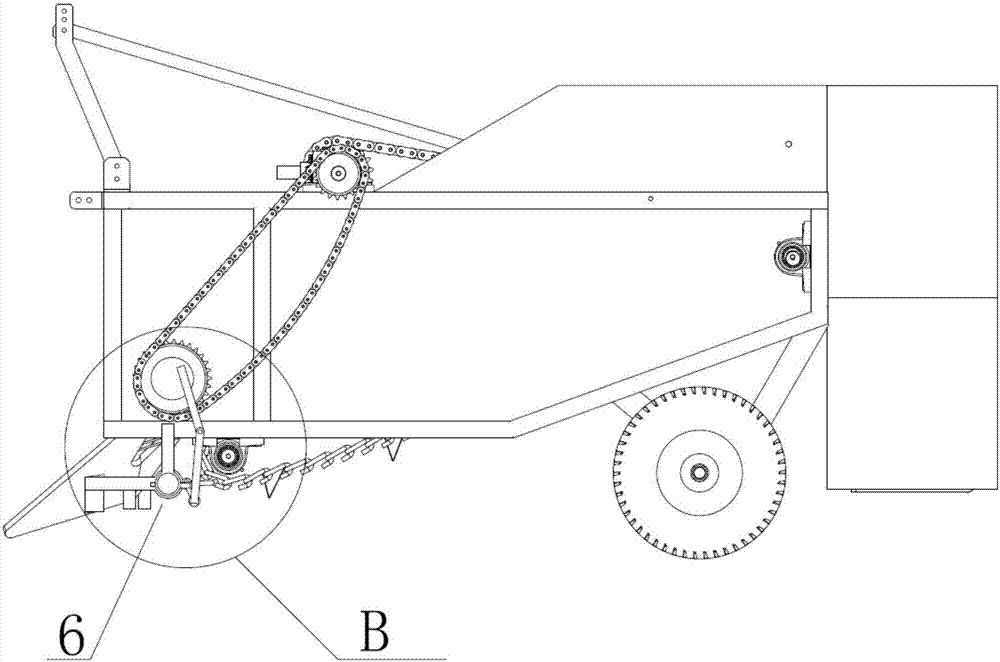

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] like figure 1 and figure 2 As shown, the rhizome crop harvester of the present invention includes a frame 7, a squeeze-type excavating device, a press-support type conveying and cleaning device and a directional laying device 1, and the squeeze-type excavating device includes a dial wheel 5, an excavating shovel 4 and the angle adjustment mechanism of the digging shovel, wherein the digging shovel 4 and the dialing wheel 5 are arranged on the front part of the frame 7, the digging shovel 4 is used to dig out the rhizome crops from the soil, and the dialing wheel 5 is used to dig out the root crops The rhizome crops are thrown to the pressure-assisted conveying and cleaning device. Digging wheel 5 is arranged on the top of digging shovel 4, and digging shovel 4 is arranged in pairs, and every pair of digging shovel comprises two digging shovels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com