Fully automatic hydraulic pulping machine

A refiner, fully automatic technology, applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problems of reducing the service life of the grinding disc, increasing the temperature of the working environment, increasing fiber loss, etc., to achieve Eliminate process fluctuations, slow output speed, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

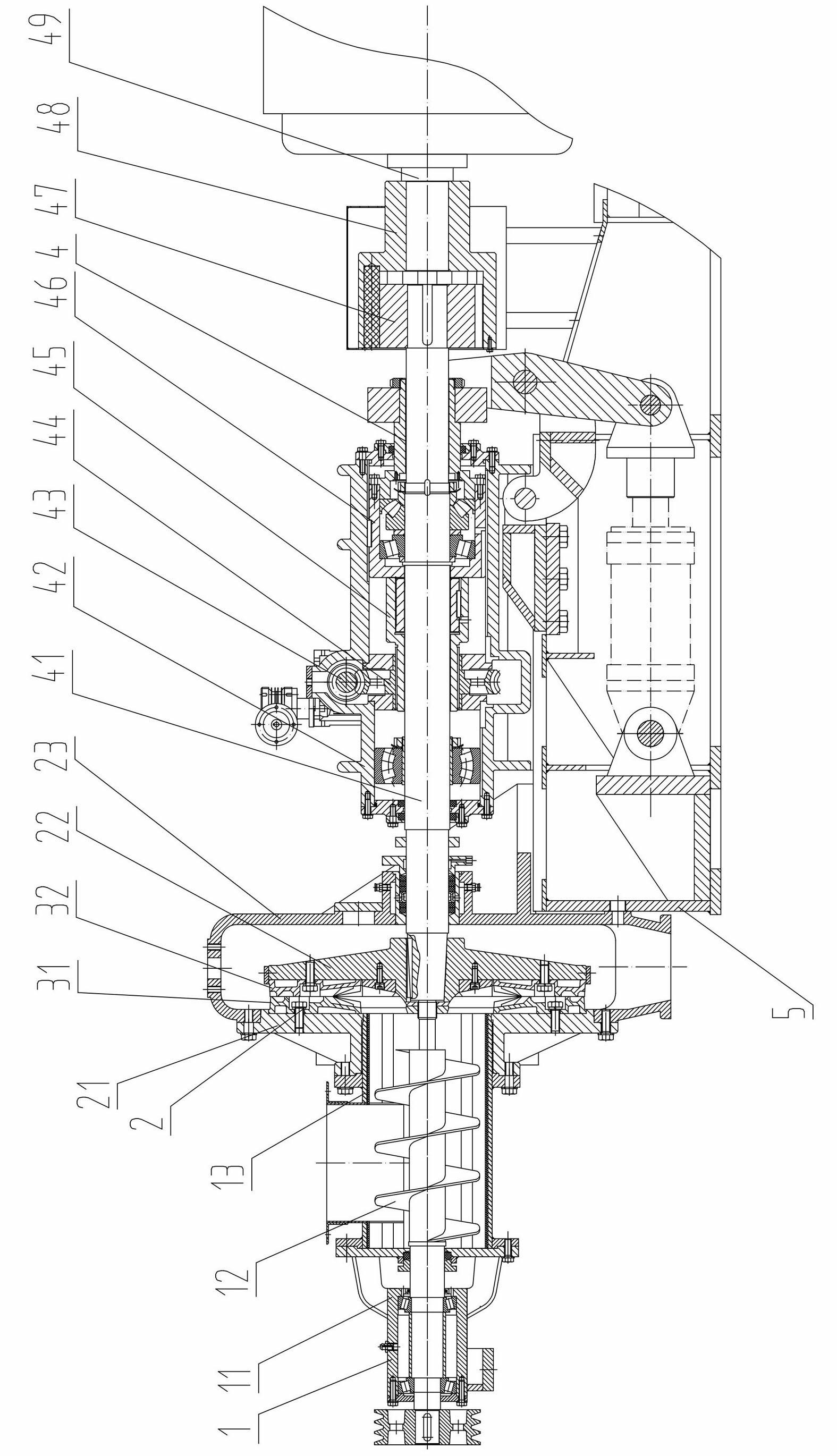

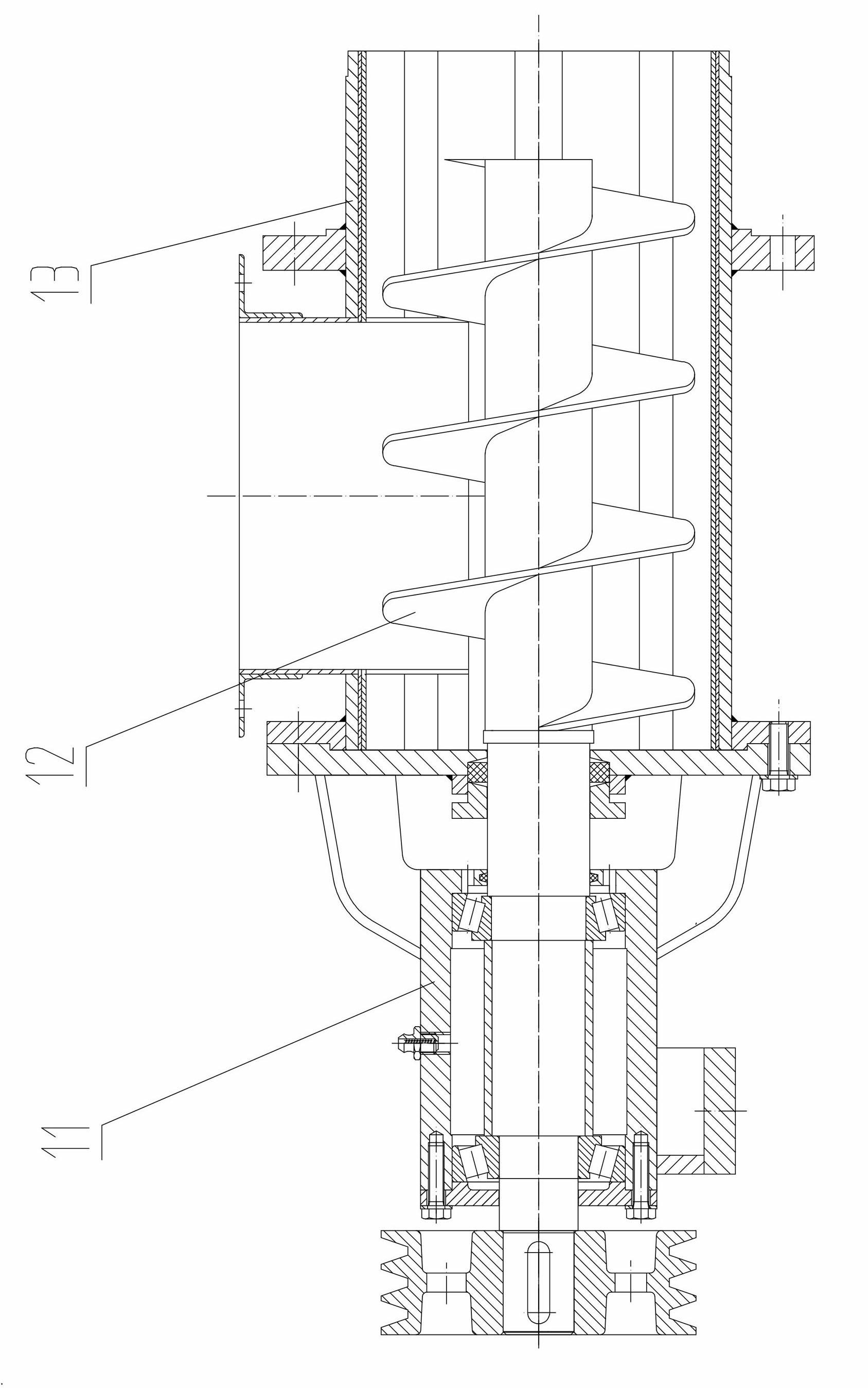

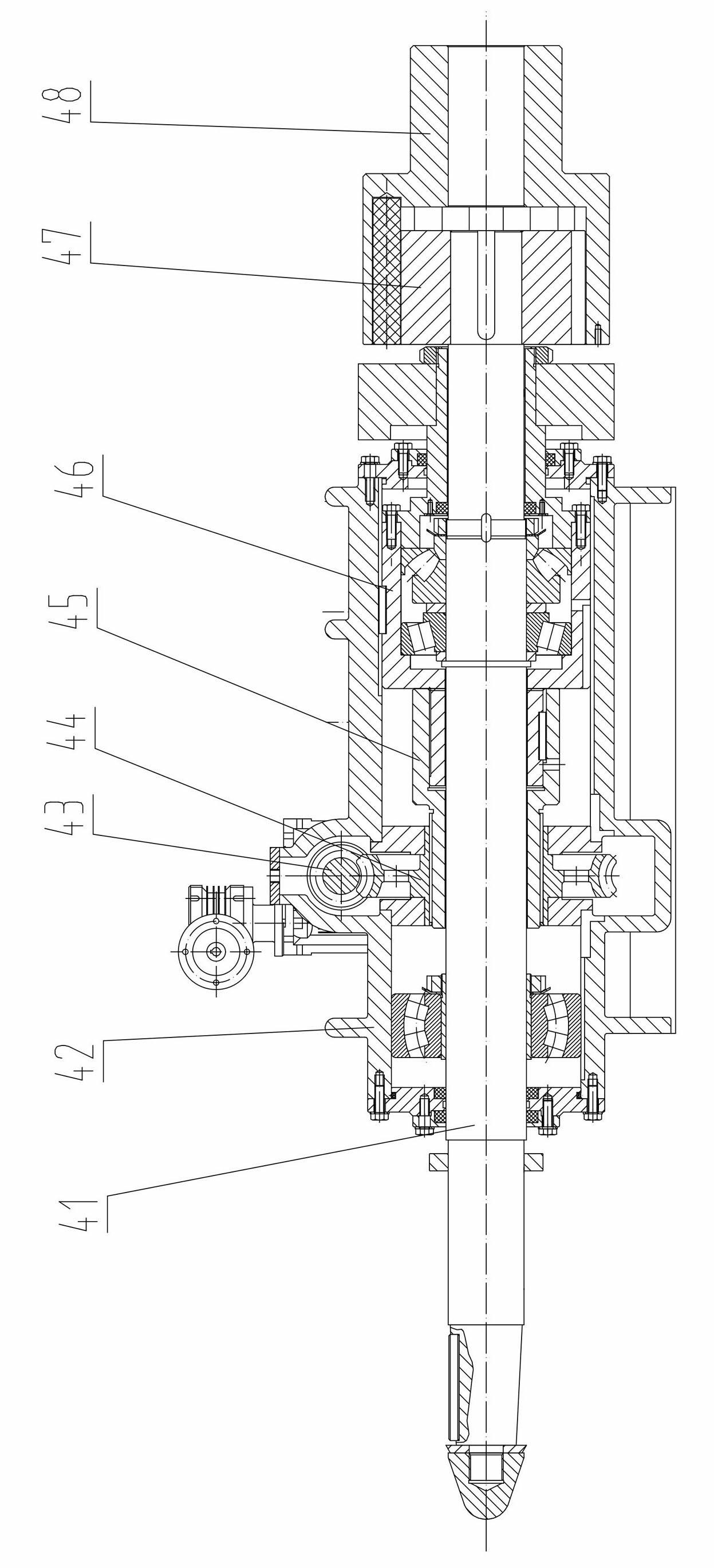

[0027] Such as figure 1 , figure 2 and image 3 As shown, the fully automatic hydraulic refiner of the present invention includes a feed assembly 1, a machine base 5, a hydraulic station, a grinding disc assembly 2 and a transmission assembly 4 fixed on the machine base 5, and the hydraulic station (not shown in the figure) is an independent Install and provide refining pressure during work to realize automatic advance and retreat of the knife. The transmission assembly 4 includes a main shaft 41 connected to the driving mechanism (not shown in the figure), the main shaft 41 is installed on the bearing housing 42, and one end of the main shaft 41 is connected with the driving mechanism through a driven coupling 47 and a driving coupling 48, for example The driving mechanism is the main motor, the driven coupling 47 can be sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com