Copper strip splitting machine

A technology of slitting machine and copper strip, applied in shearing devices, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems that processing cannot effectively meet people's requirements, low degree of automation, low production efficiency, etc. The effect of saving labor, high degree of automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

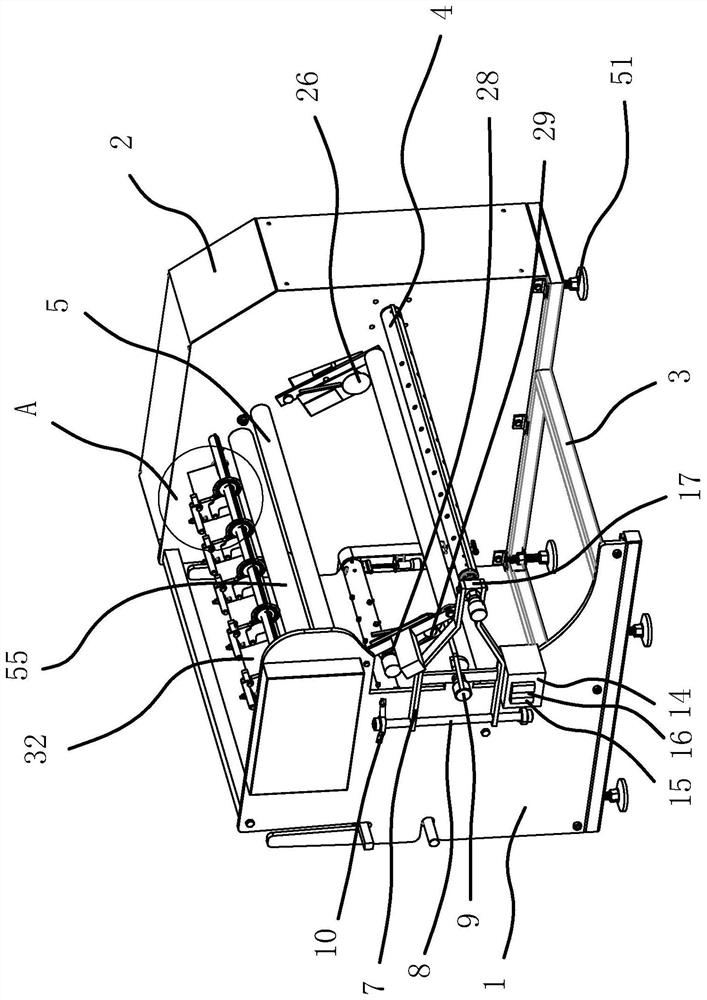

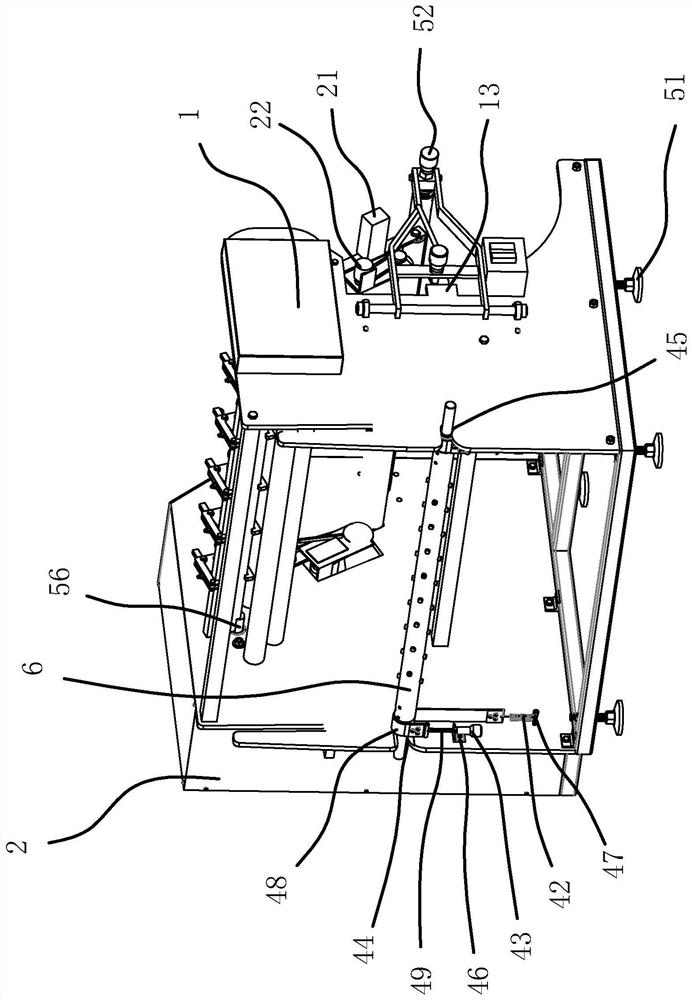

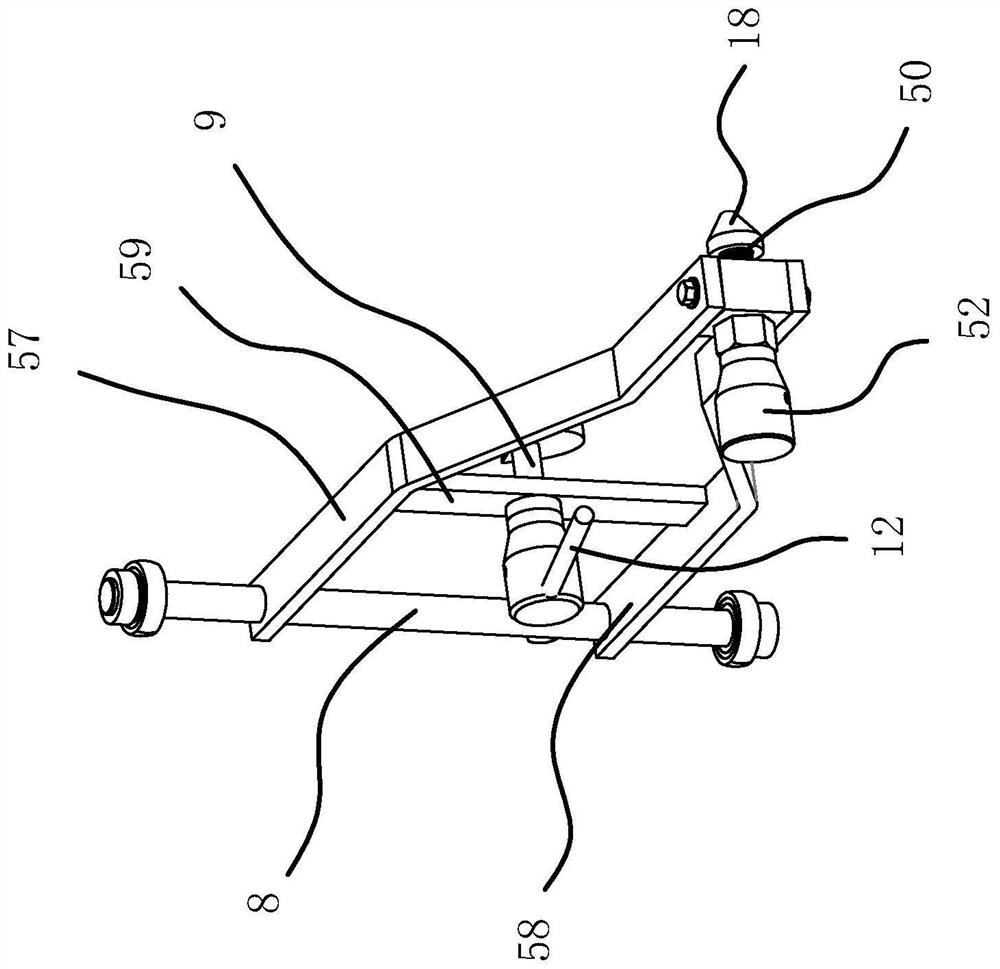

[0039] like figure 1 , 3 , The copper strip slitting machine of the present invention includes a left side plate 1 and a right side box body 2, the left side plate 1 is connected with the right side box body 2 through a connecting rod 3, and the left side plate 1 and the right side box body 2 are connected. 2 are sequentially provided with an unwinding mechanism, a waste edge cutting mechanism, a guide roller 5, a blade adjusting mechanism, and a winding mechanism. Two fixing seats 10 are fixed on the outer side of the left side plate 1, the longitudinal rotating shaft 8 is rotatably connected between the two fixing seats 10, and the rear end of the swing frame 7 is sleeved on the longitudinal rotating shaft 8 and can be opposite to the left si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com