Automatic steel bar binding system

A steel bar, automatic technology, applied in the field of steel bar automatic binding system, can solve the problems of reduced work efficiency and lack of adjustability, and achieve the effects of improving work efficiency, reducing labor intensity, and being convenient and quick to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

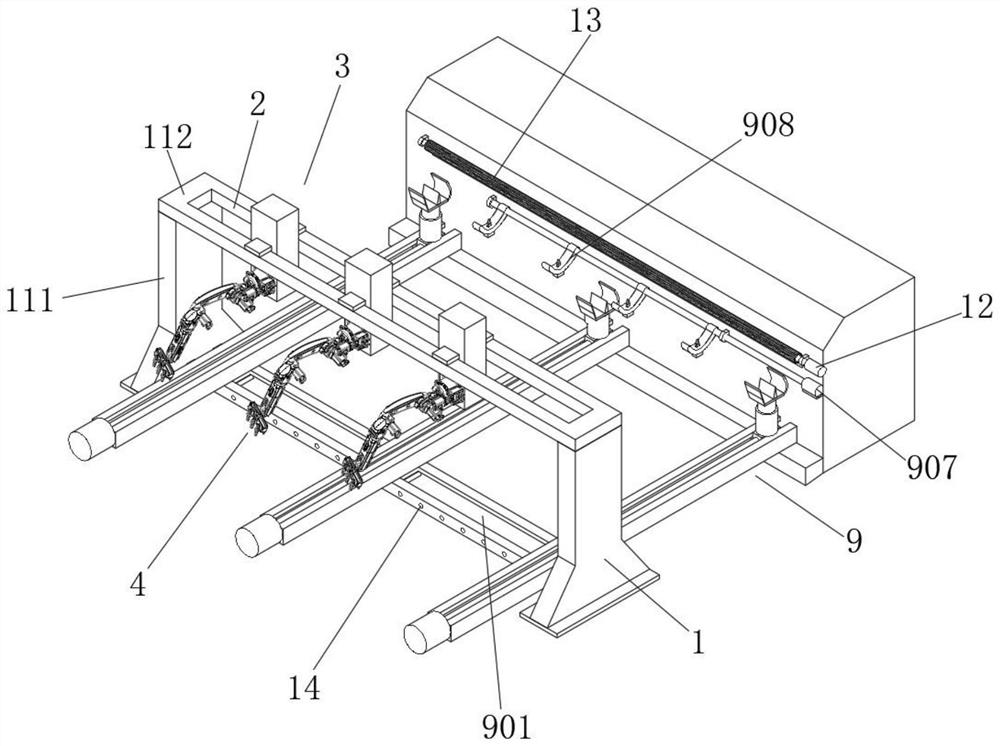

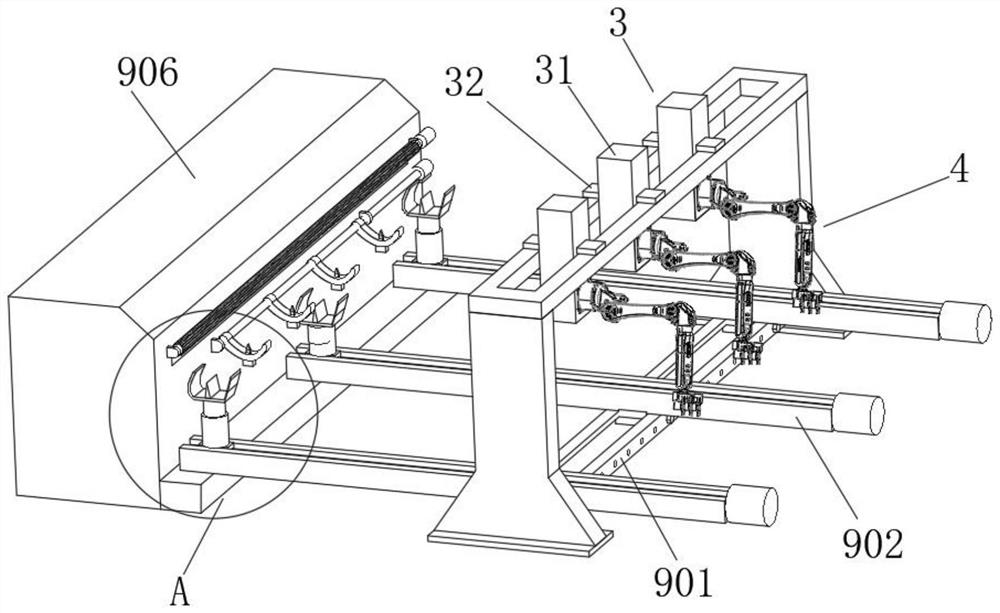

[0027] see figure 1 and Figure 6 , an automatic binding system for steel bars. The truss 1 is composed of two support bases 111 and a beam 112. The beam 112 is welded on the top of the two support bases 111. The first sliding platform 2 is set inside the beam 112. The second sliding platform 3 It is composed of a vertical plate 31 and a horizontal plate 32. The vertical plate 31 vertically passes through the gap between the two beams 112 and forms a sliding connection. The horizontal plate 32 is arranged on the top surface of the first slide table 2 and forms a sliding connection. connection, the two third sliding tables 6 are horizontally opposite to each other, and the third sliding table 6 is a ball screw sliding table. When in use, by sliding the second sliding table 3, the position of the mechanical arm 4 can be greatly adjusted. By setting The mechanical arm 4 can adjust the binding gun 8 at any position. The third sliding table 6 is a ball screw sliding table, and the...

Embodiment 2

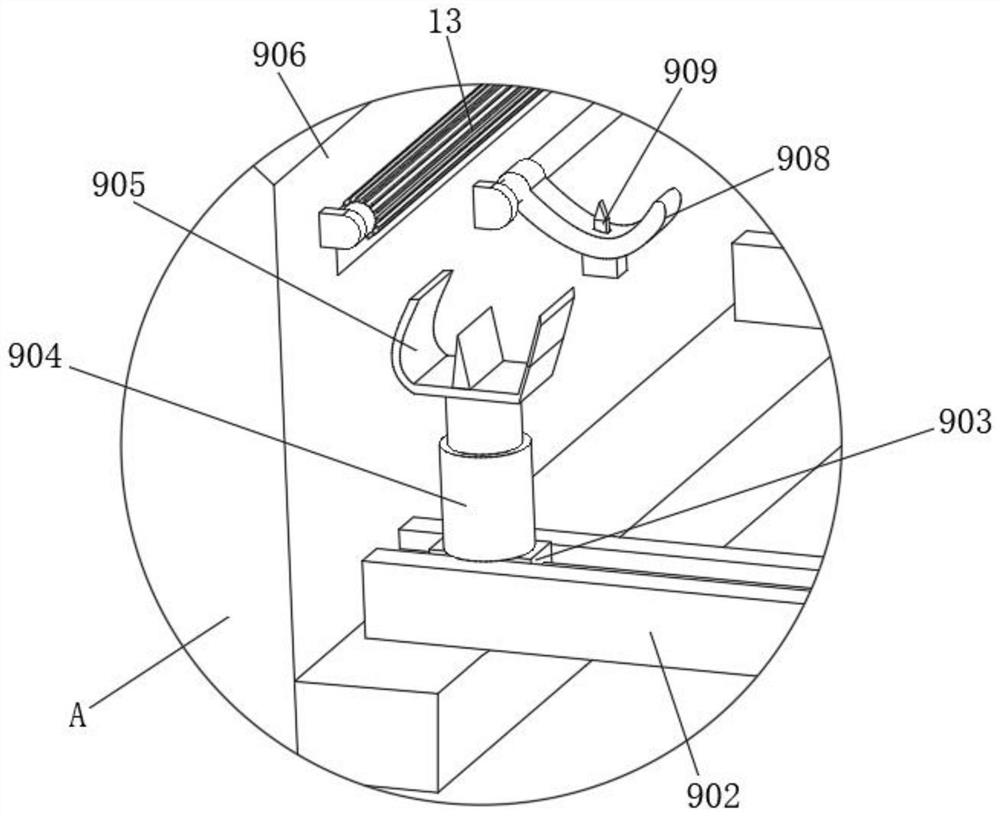

[0029] see Figure 1-6 , on the basis of Embodiment 1, the conveying mechanism 9 includes a first carriage 901 welded on the inside of the truss 1, the first carriage 901 is slidably connected with a conveying frame 902, and the inside of the conveying frame 902 is slidably connected with a moving frame through a ball screw. Block 903, the top of the moving block 903 is fixedly equipped with a hydraulic rod 904, the top of the hydraulic rod 904 is fixedly installed with a transport support frame 905, and one side of the transport frame 902 is movably connected with a steel bar conveyor 906, and one side of the steel bar conveyor 906 is fixed A first motor 907 is installed, and the output end of the first motor 907 is connected to a steel bar collection rack 908 through a transmission shaft. The inside of the steel bar collection rack 908 is provided with a separation electric push rod 909 for realizing the bundling of steel bars. The inside of the steel bar conveyor 906 A deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com