Following mechanism used during spiral welding pipe cutting and operation method of mechanism

A technology of spiral welded pipe and pipe cutting, which is applied in the direction of pipe shearing device, shearing device, and the attachment of shearing machine, etc., which can solve the problems of increasing waste pipe rate, delay or resistance, etc., and achieve the improvement of pipe cutting yield and weight Lightweight, simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

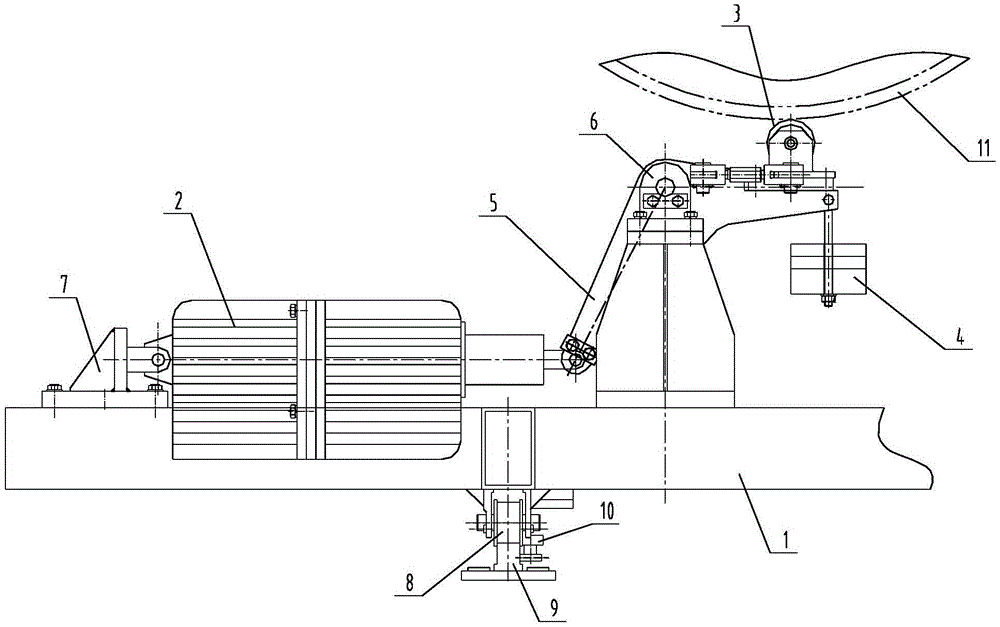

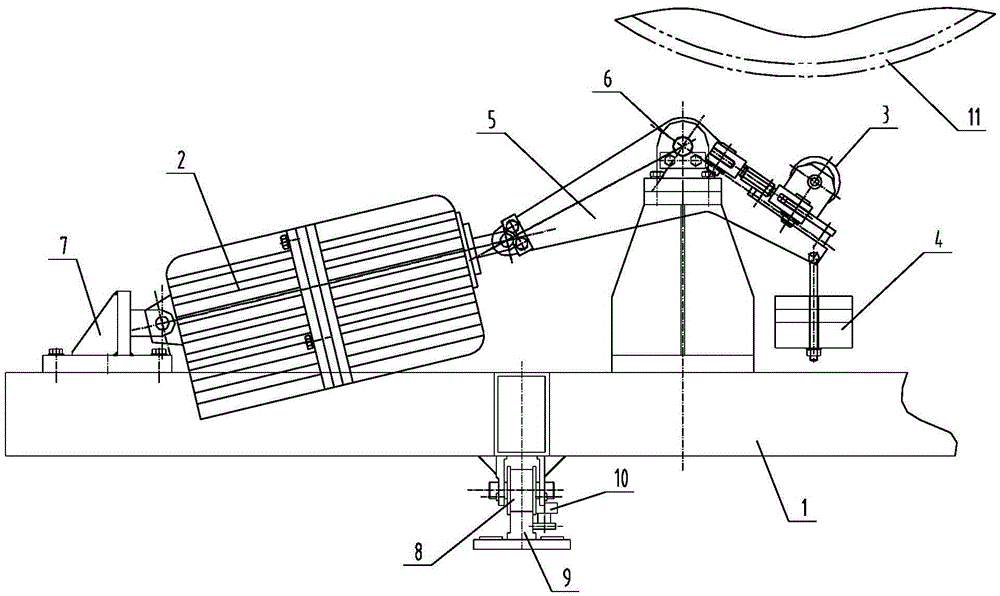

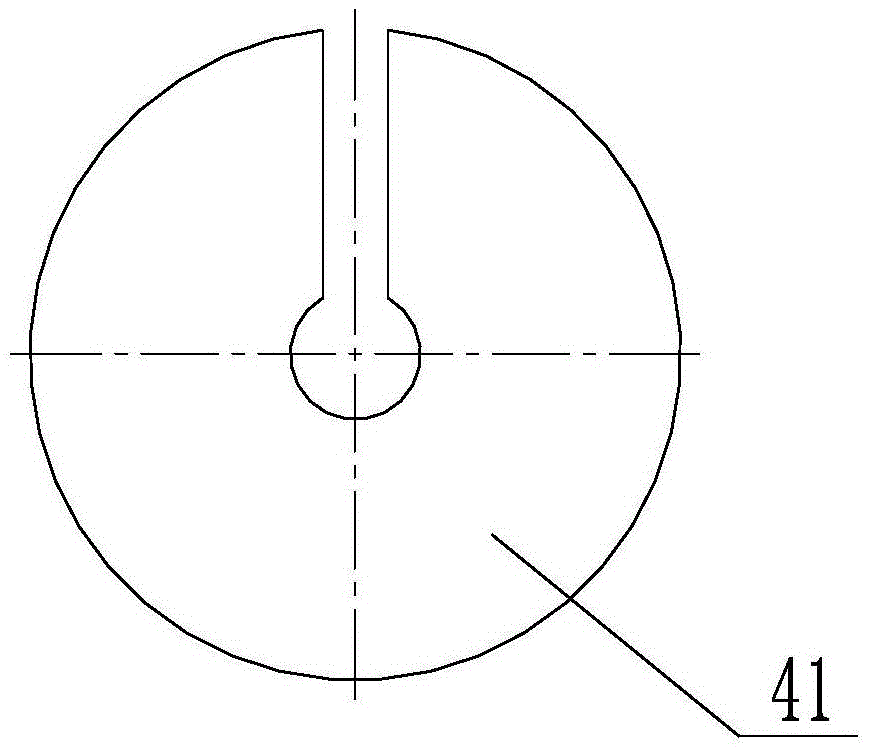

[0022] Such as Figure 1-Figure 2 Shown is a structural schematic diagram of the accompanying mechanism when a spiral welded pipe is cut according to the present invention. An accompanying mechanism for spiral welded pipe cutting according to the present invention includes an accompanying platform 1, an electro-hydraulic push rod 2, an L-shaped swing arm 5, a cutter wheel 3 and a weight 4, and a traveling wheel 8 is arranged at the bottom of the accompanying platform 1 , can drive the accompanying platform 1 to walk along the track parallel to the conveying direction of the spiral welded pipe 10; Its hinge point is higher than the electro-hydraulic push rod 2; the two ends of the L-shaped swing arm 5 are suspended in the air, and one end is hinged with the extended end of the electro-hydraulic push rod 2, and the upper part of the other end is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com