Sand producing equipment and process suitable for materials of various specifications

A material and equipment technology, applied in the field of sand making system equipment, can solve problems such as unstable work efficiency, lower production compliance rate, roughness, etc., and achieve the effects of reasonable production process settings, improved production capacity and product quality, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

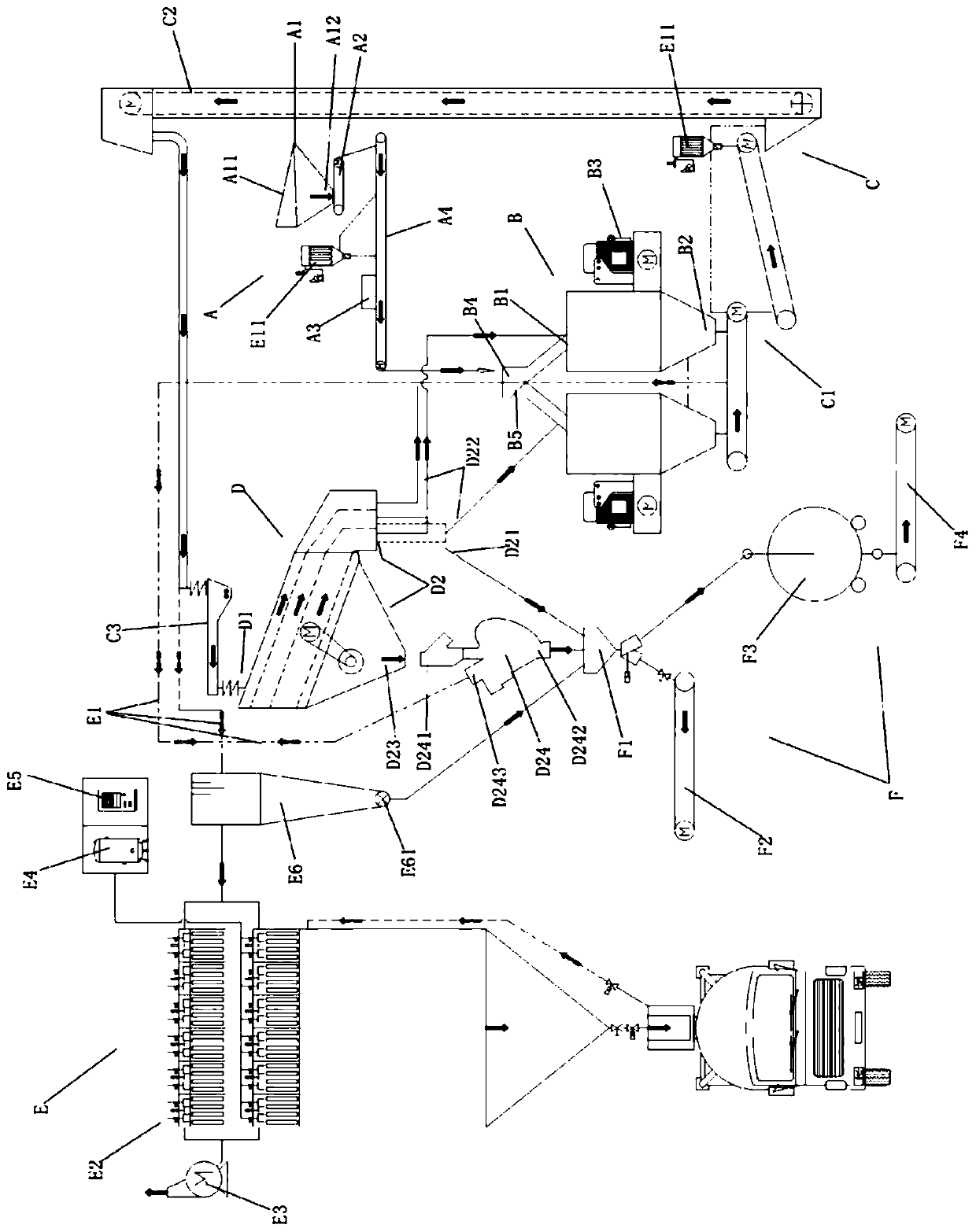

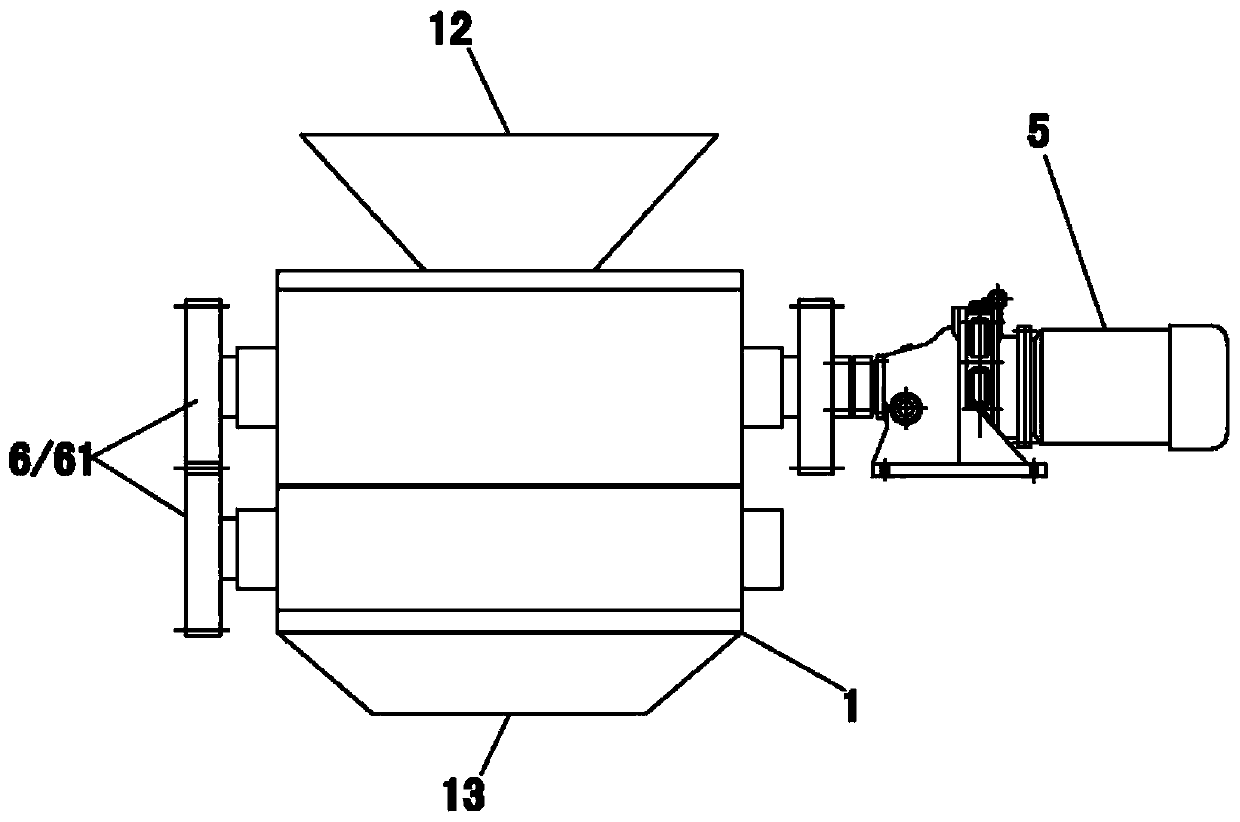

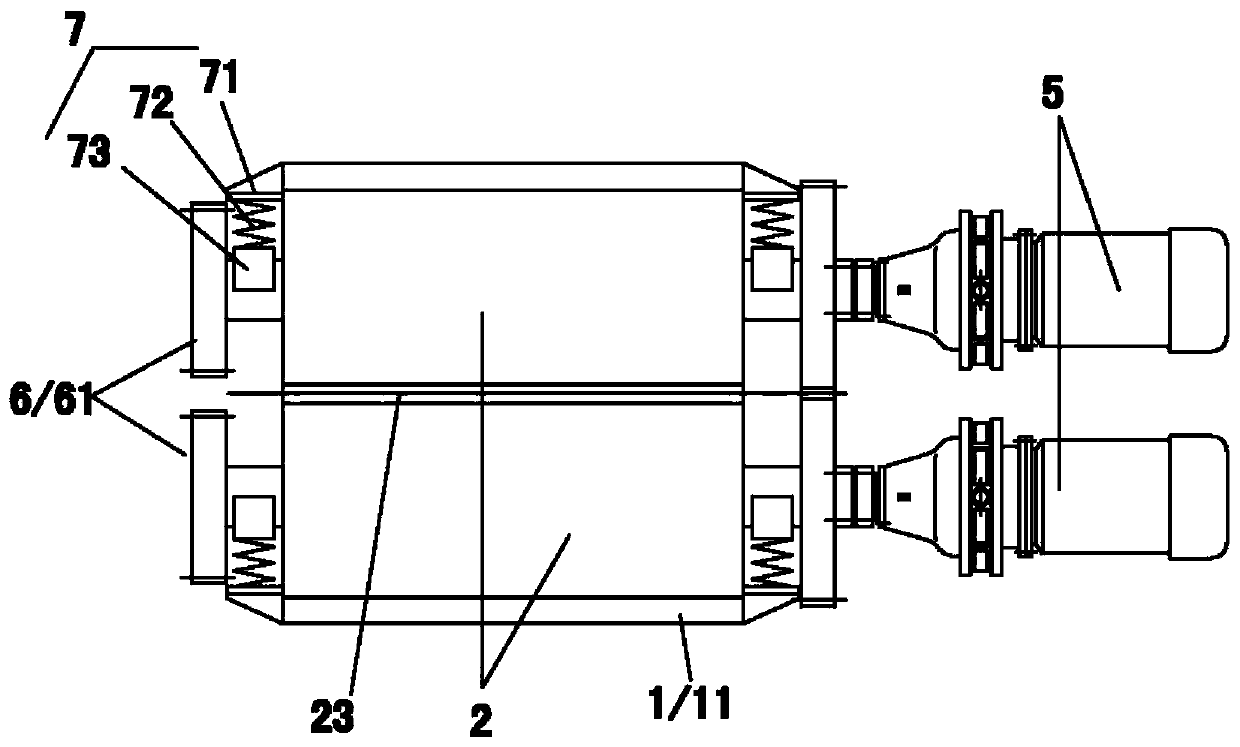

[0074] The invention discloses a kind of sand making equipment that can adapt to materials of various specifications, such as figure 1 As shown, it includes raw material conveying line A, raw material crusher B, semi-finished product conveying line C, semi-finished product screening machine D, powder removal system E and finished product output line F. The position, structure and connection relationship of each part will be described in detail with reference to the accompanying drawings.

[0075] The powder removal system E includes a plurality of dust removal lines E1, respectively corresponding to the raw material conveying line A, the raw material crusher B, the semi-finished product conveying line C and the semi-finished product screening machine D; the powder removing system E also includes a powder bin dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com