Automatic testing and sorting machine for integrated circuit IC chip

An automatic testing and sorting machine technology, applied in sorting and other directions, can solve problems such as low efficiency, unsatisfactory, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

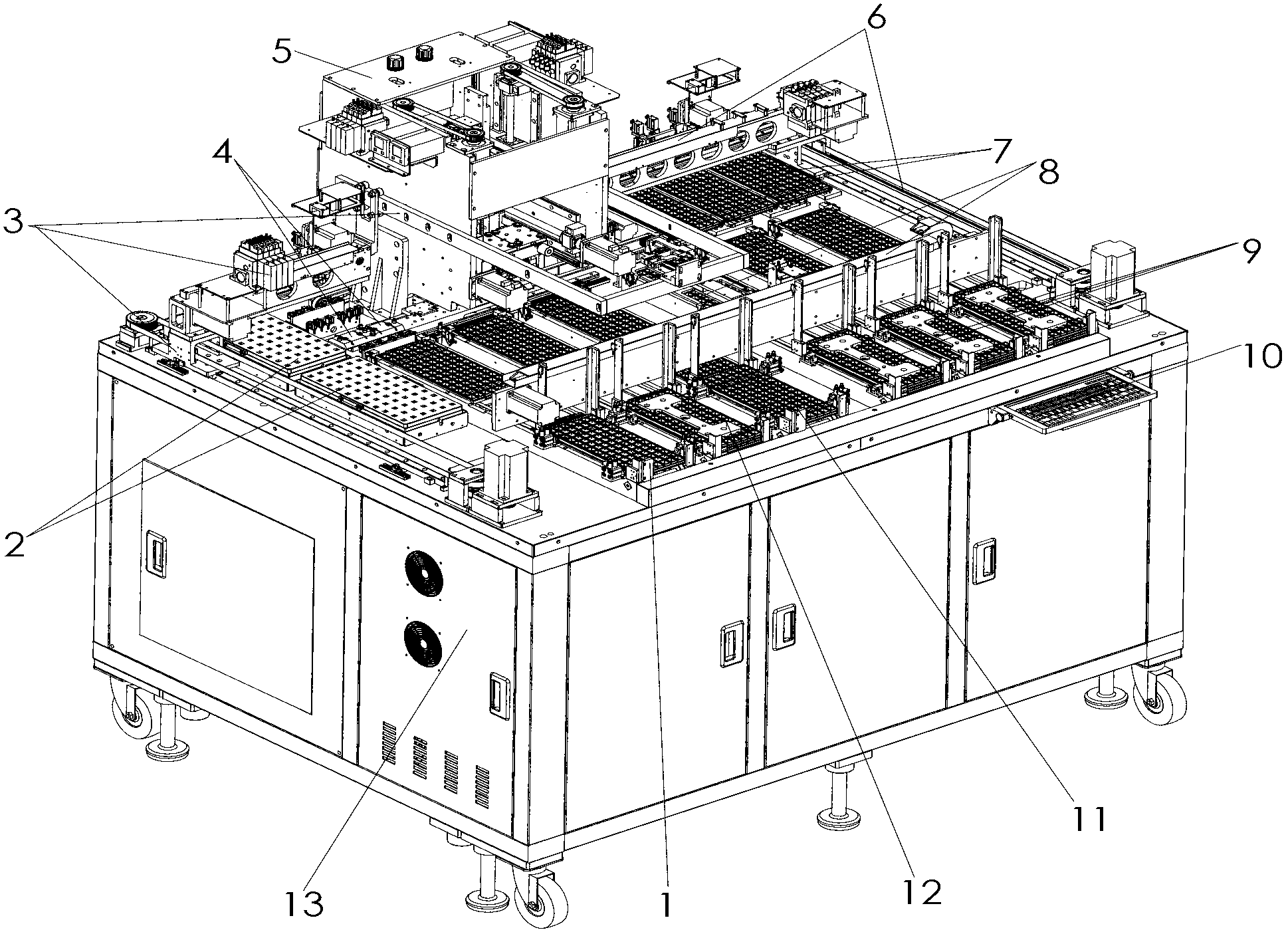

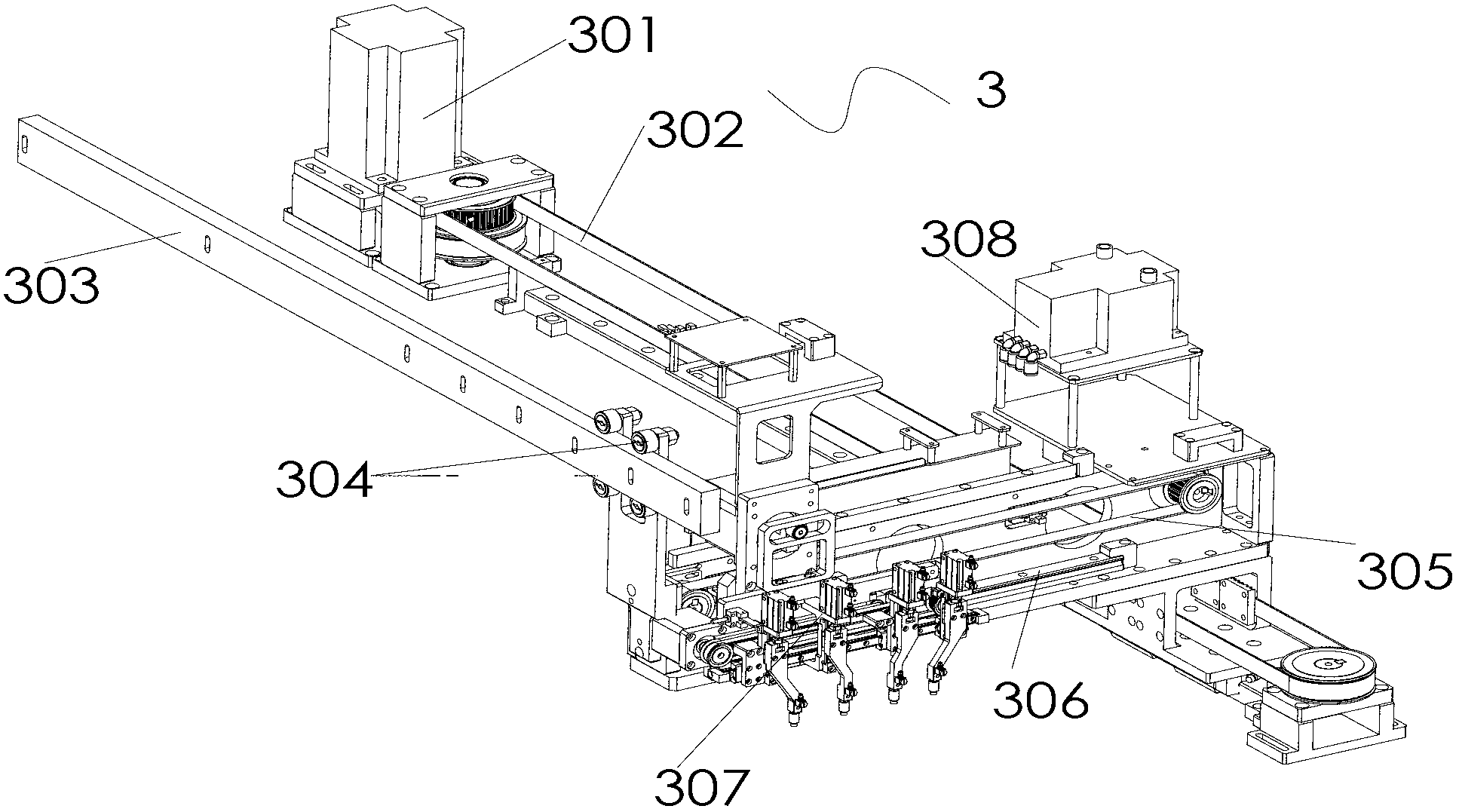

[0032] The structural composition of IC chip automatic testing machine of the present invention is as figure 1 As shown, it is mainly composed of a material-loading pallet separation input device 1, a heating platform device 2, a material-feeding gripper platform device 3, a material ship module device 4, a test gripper combination module device 5, and a material-feeding sorting gripper platform Device 6, defective product classification and collection module 7, empty pallet sorting device 8, qualified product classification and collection module 9, operation keyboard 10, unloading empty pallet separation input device 11, loading empty pallet output stacking device 12 , electronic control system 13, testing machine (view not shown) and other components.

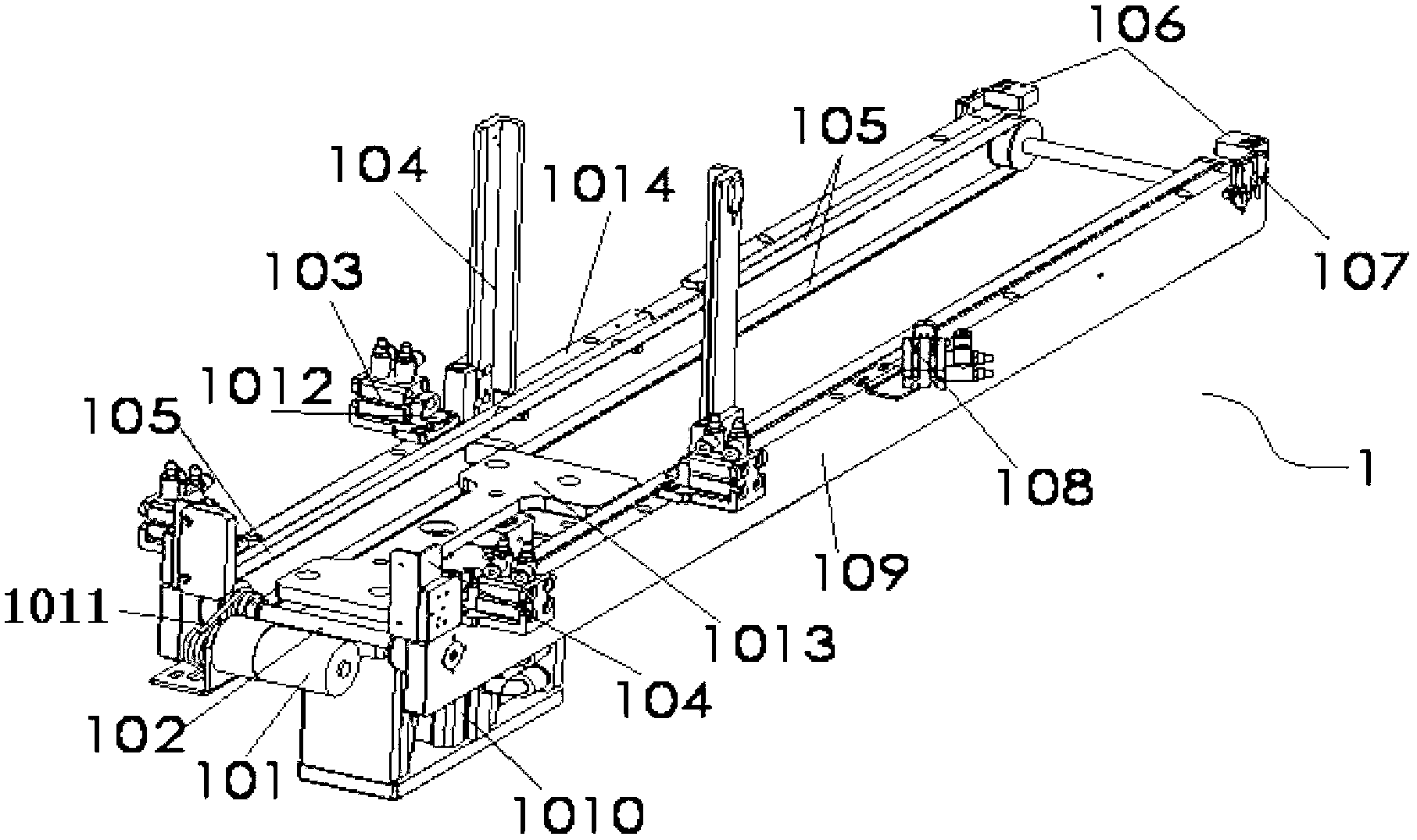

[0033] Tray separation input device 1 of the present invention is as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com