Patents

Literature

103results about How to "Realize automatic input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

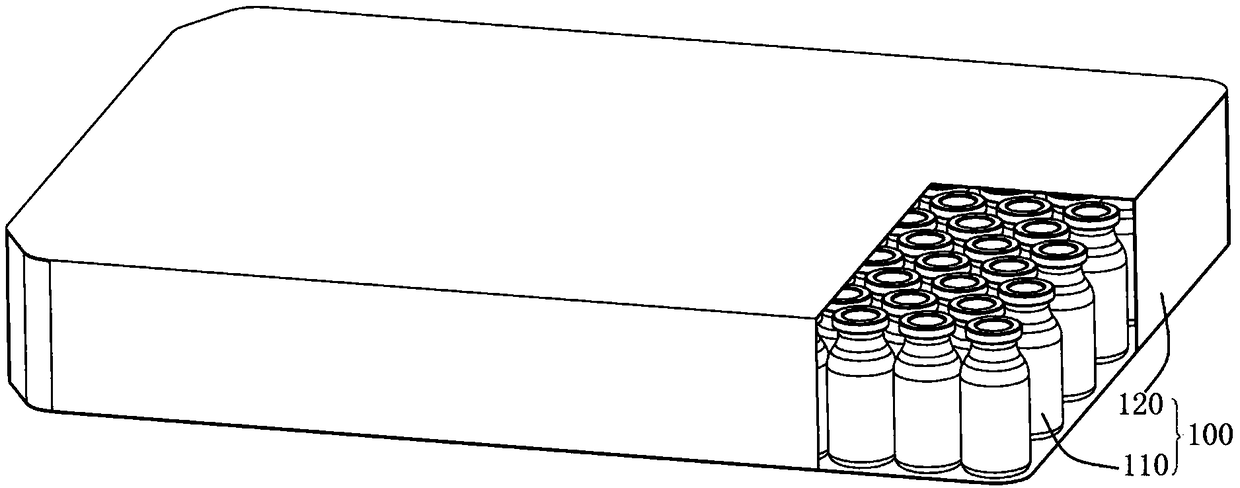

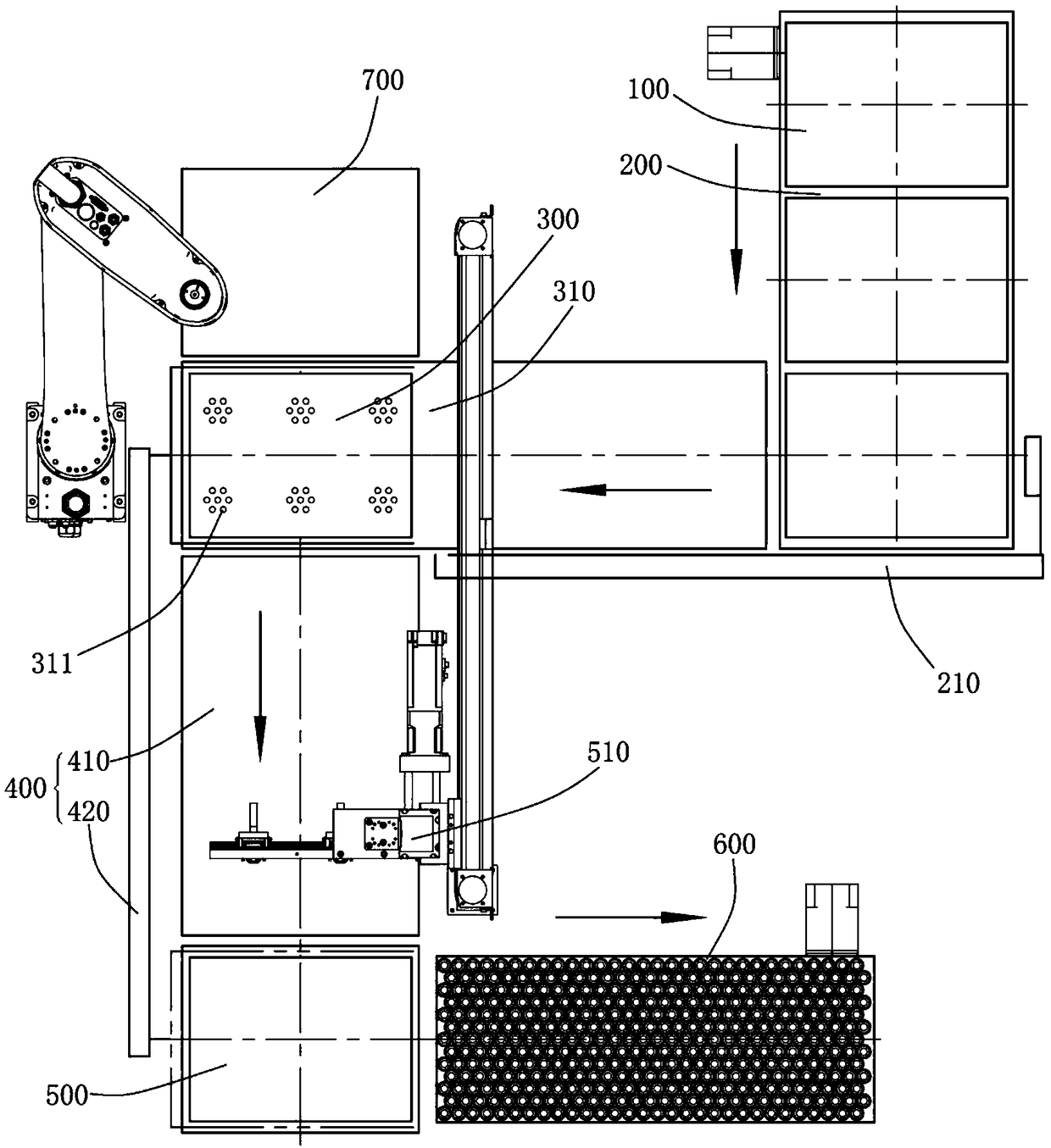

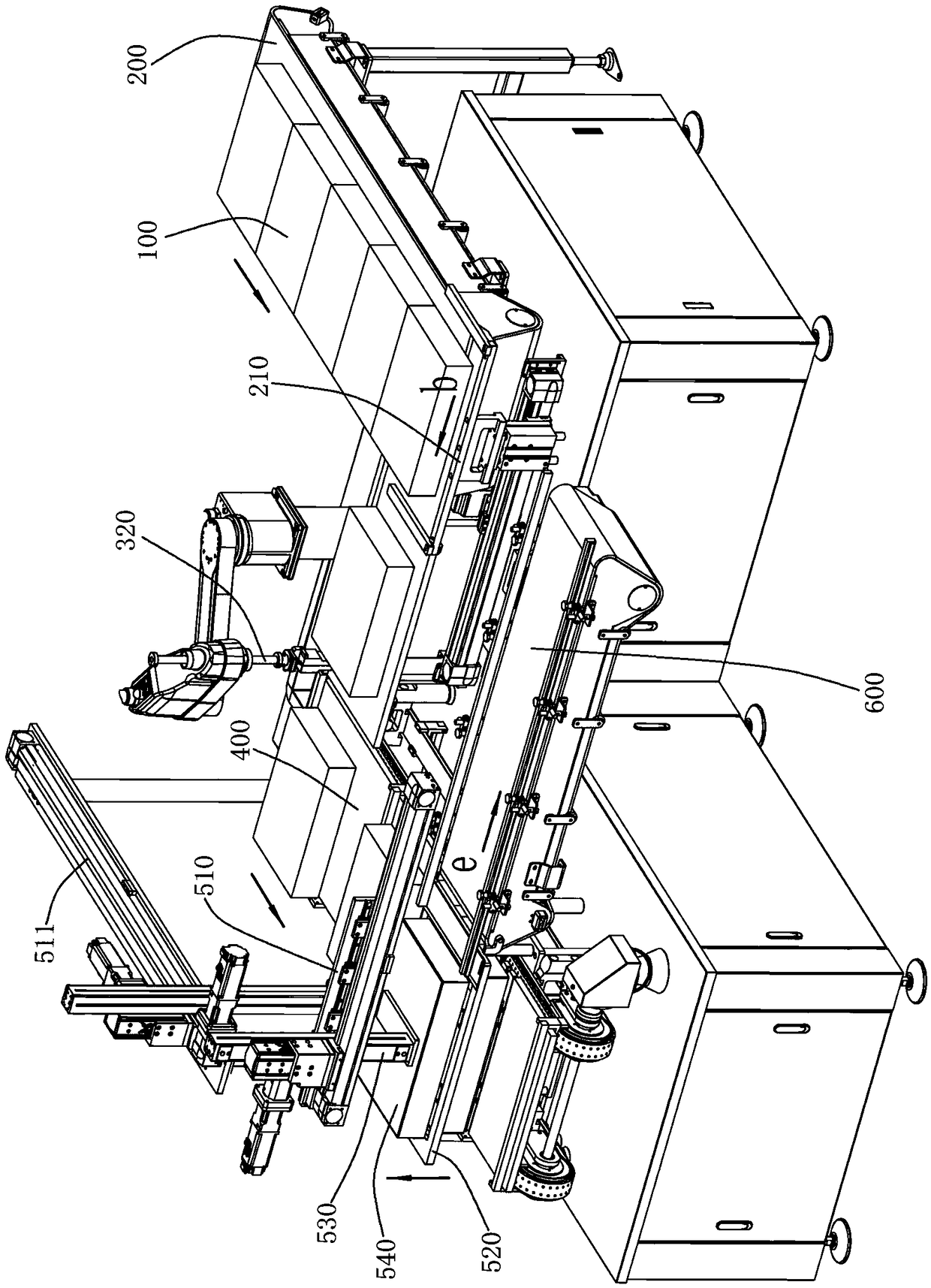

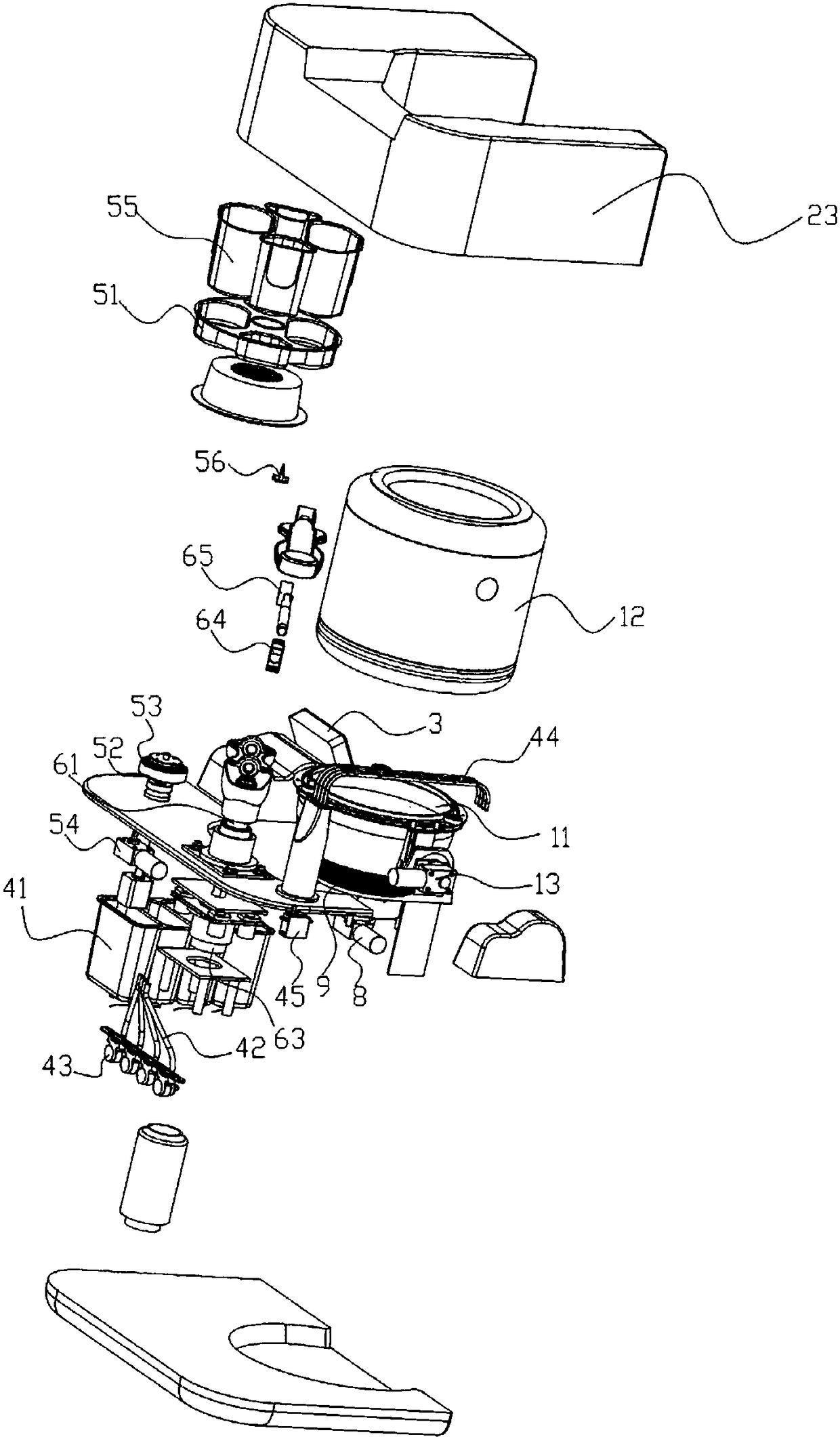

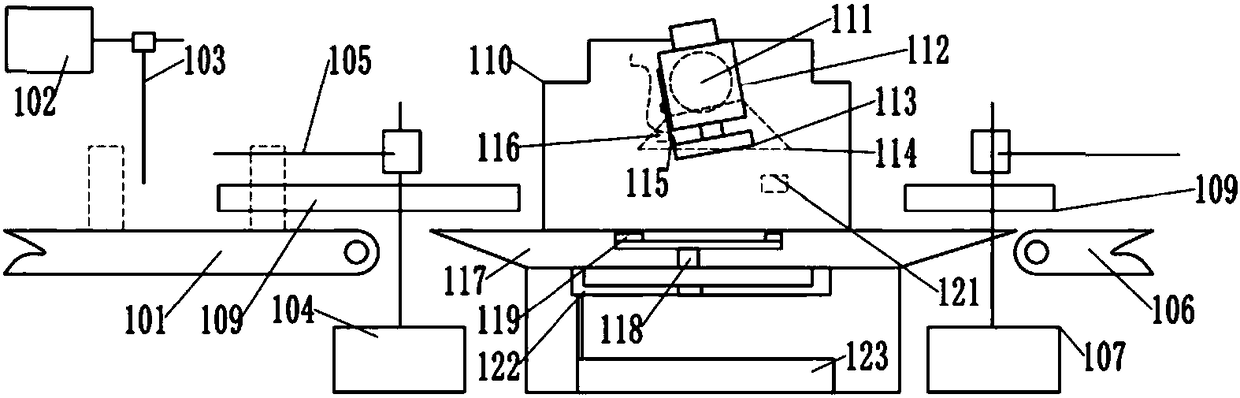

Bottle stacking machine capable of feeding and discharging bottles from low position

ActiveCN102795482ARealize automatic inputLow site requirementsStacking articlesDe-stacking articlesStack machineEngineering

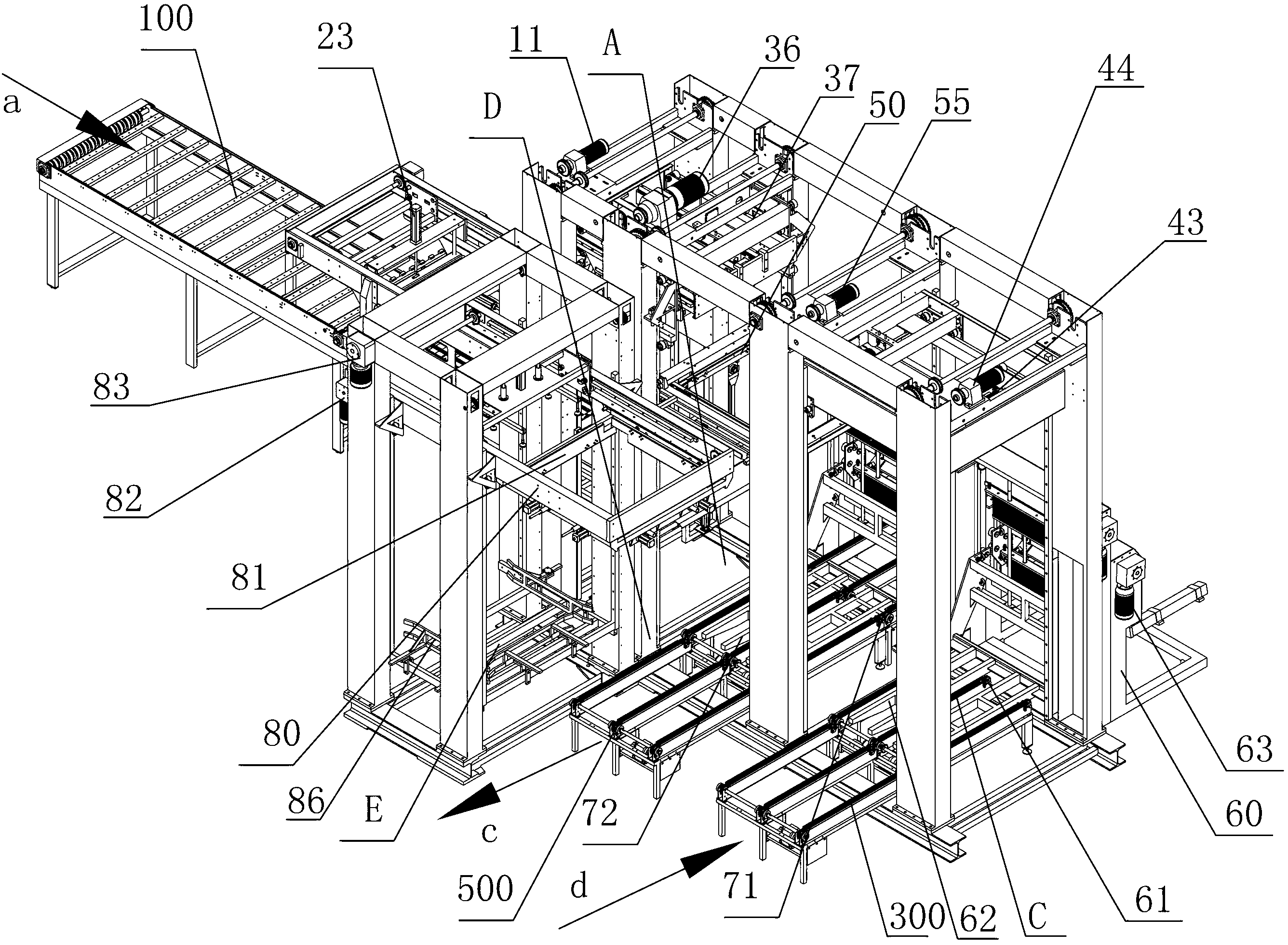

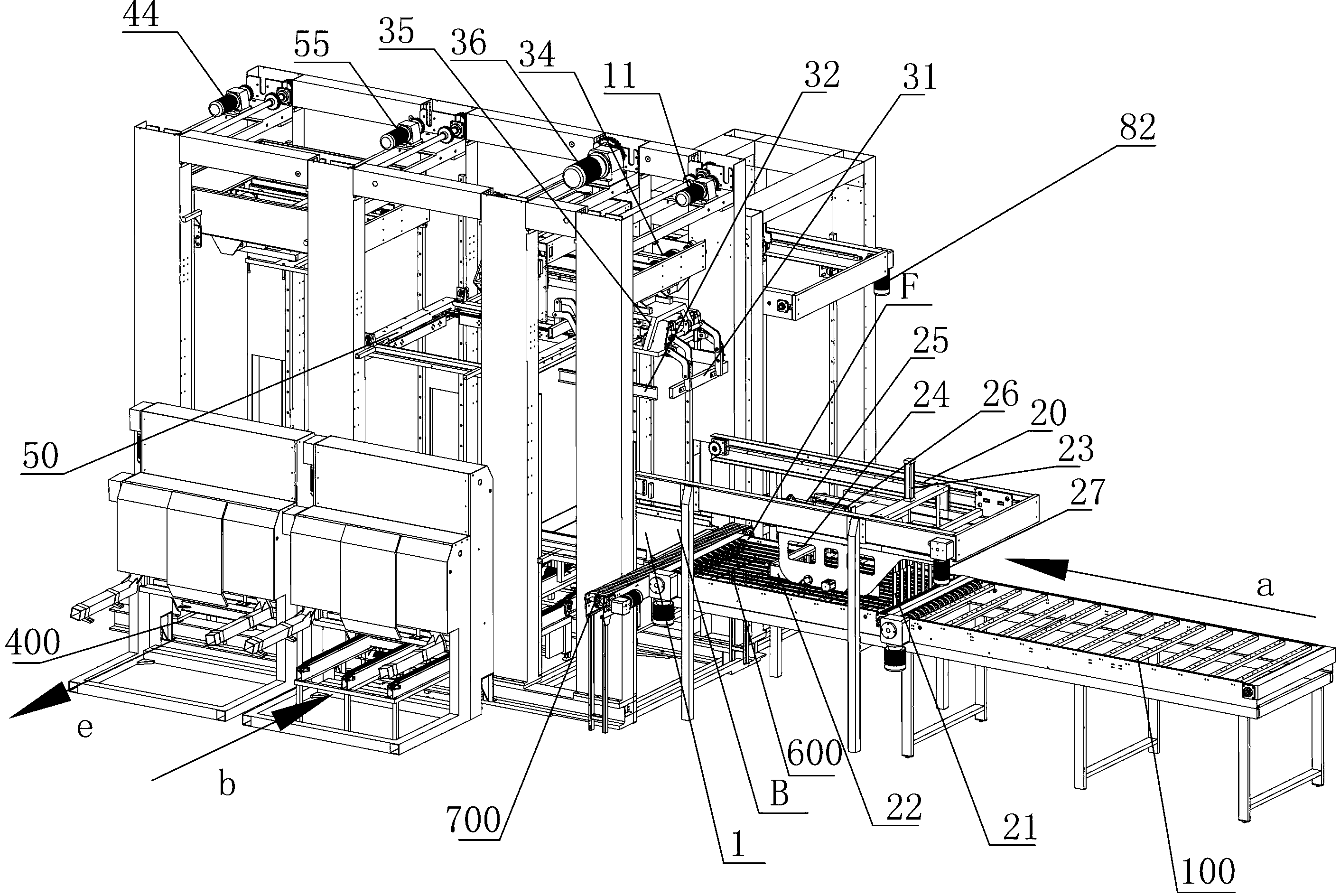

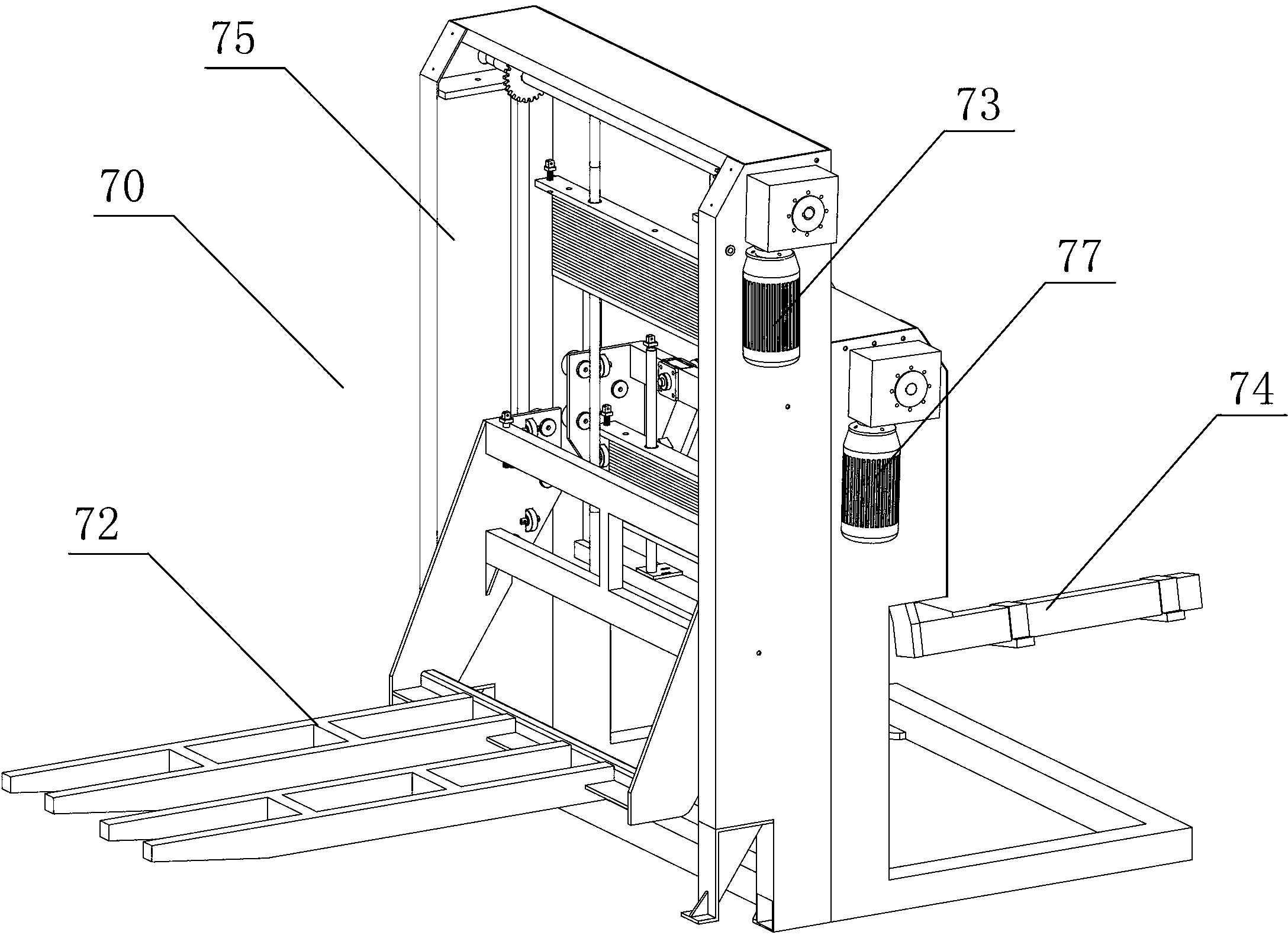

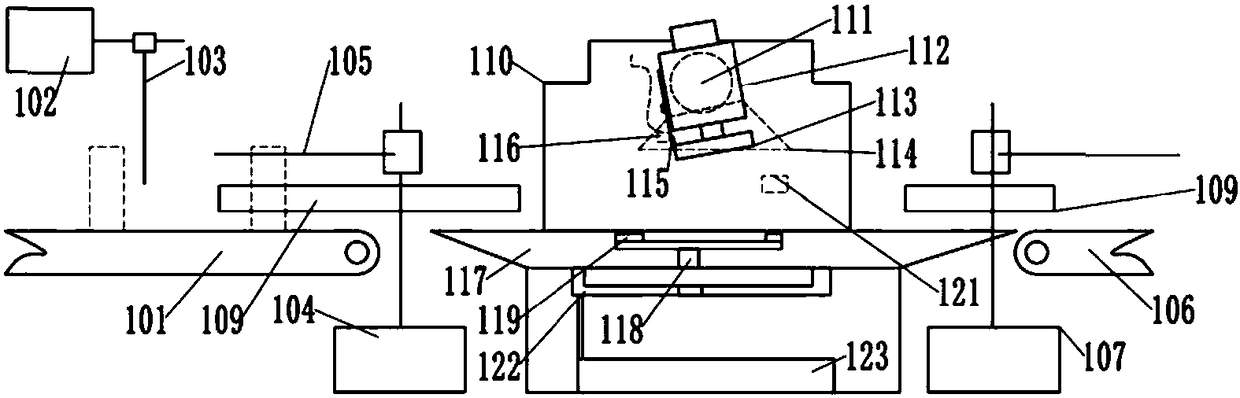

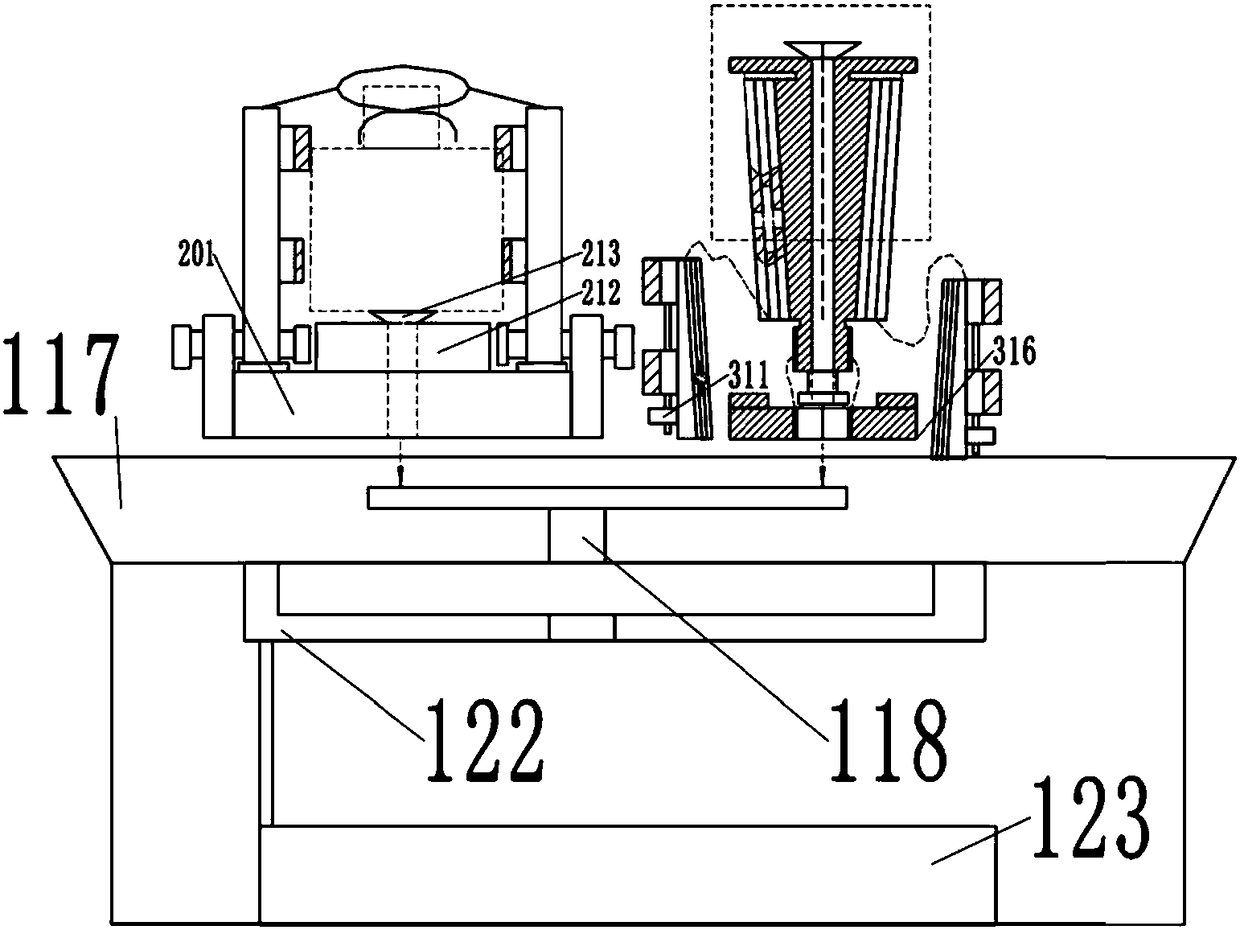

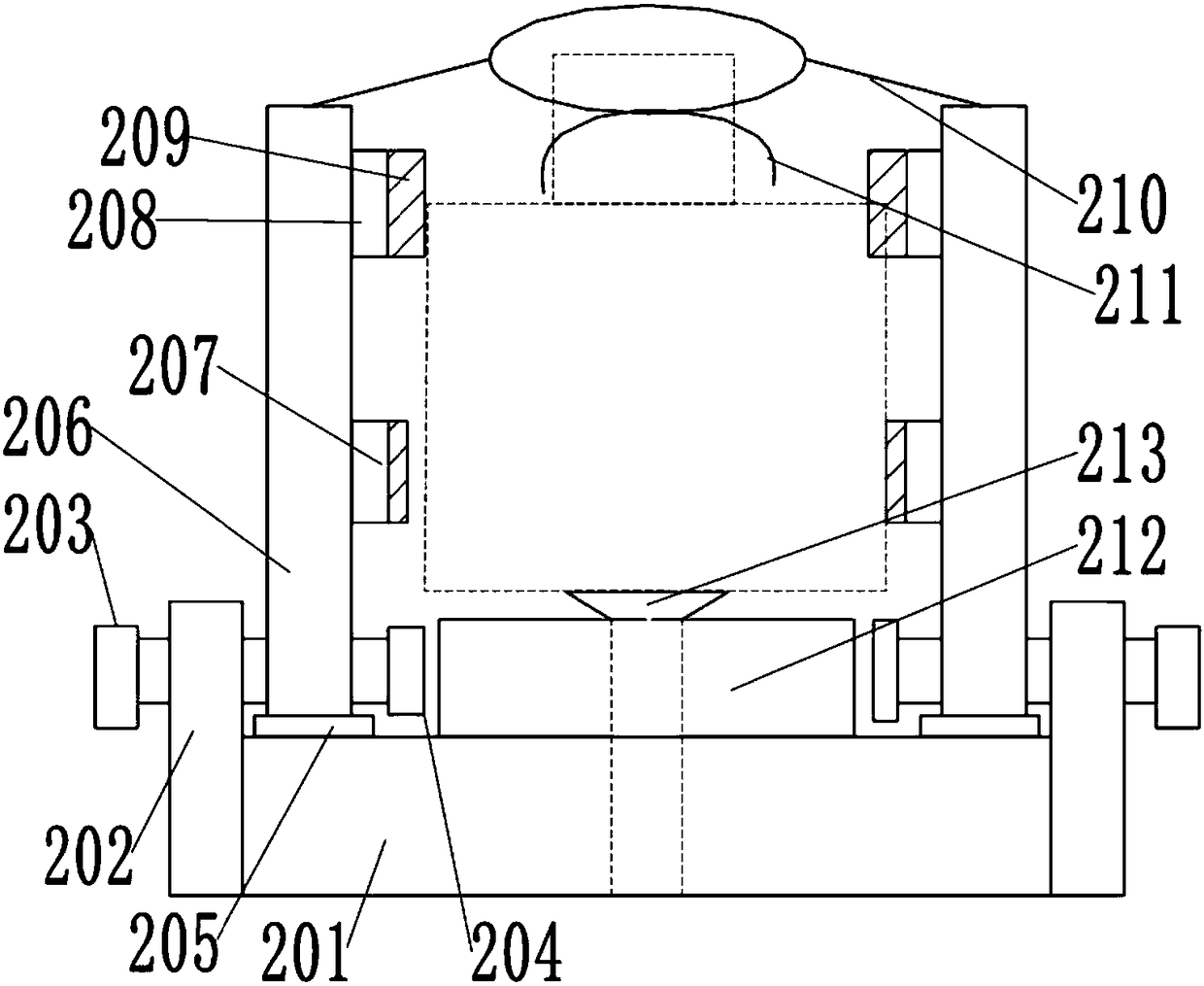

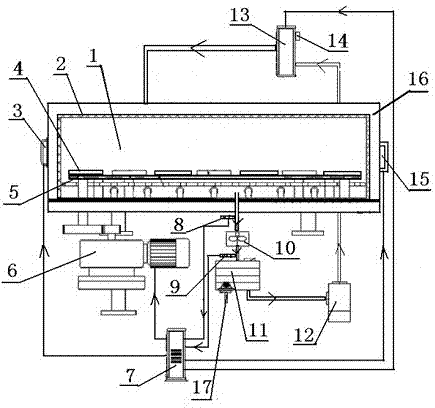

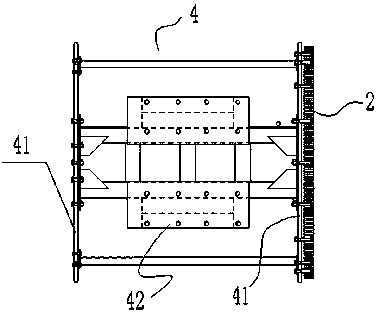

The invention provides a bottle stacking machine capable of feeding and discharging bottles from a low position, which comprises a low-position bottle conveying line, a low-position pallet conveying line, a low-position bottle stack conveying line and a low-position spacer plate conveying line. The bottle stacking machine can feed and discharge bottles from a low position so as to reduce the floor space and the requirements on workshop space, and simultaneously realizes high-speed bottle stacking on the bottle stacking machine. The automatic feeding of a pallet and spacer plates, the automatic discharging of pallet trays and automatic laying of a top plate can be realized on the basis of the bottle stacking machine, and the full mechanical automation during the bottle stacking process is realized. Furthermore, as the bottle stacking machine realizes the mechanical automation during spacer plate taking and laying and is provided with a clamping and positioning mechanism, the bottle stacking machine can adopt spacer plates with bottle positioning baffles, and the quality and the appearance of stacked bottles are greatly improved.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP

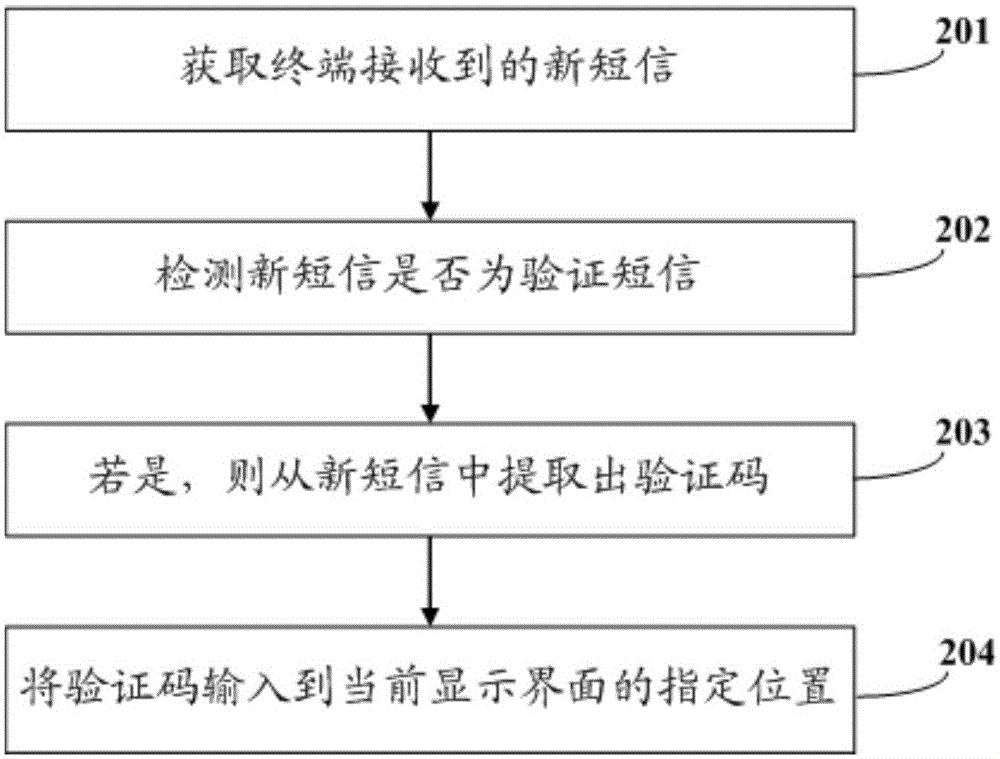

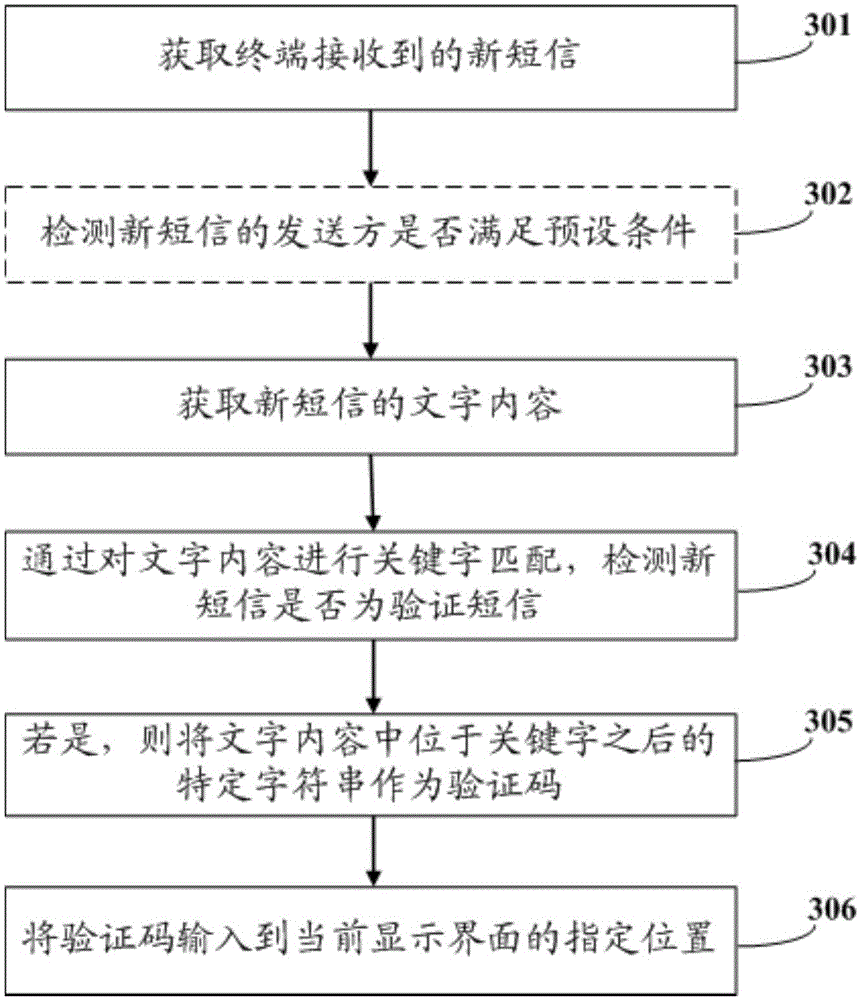

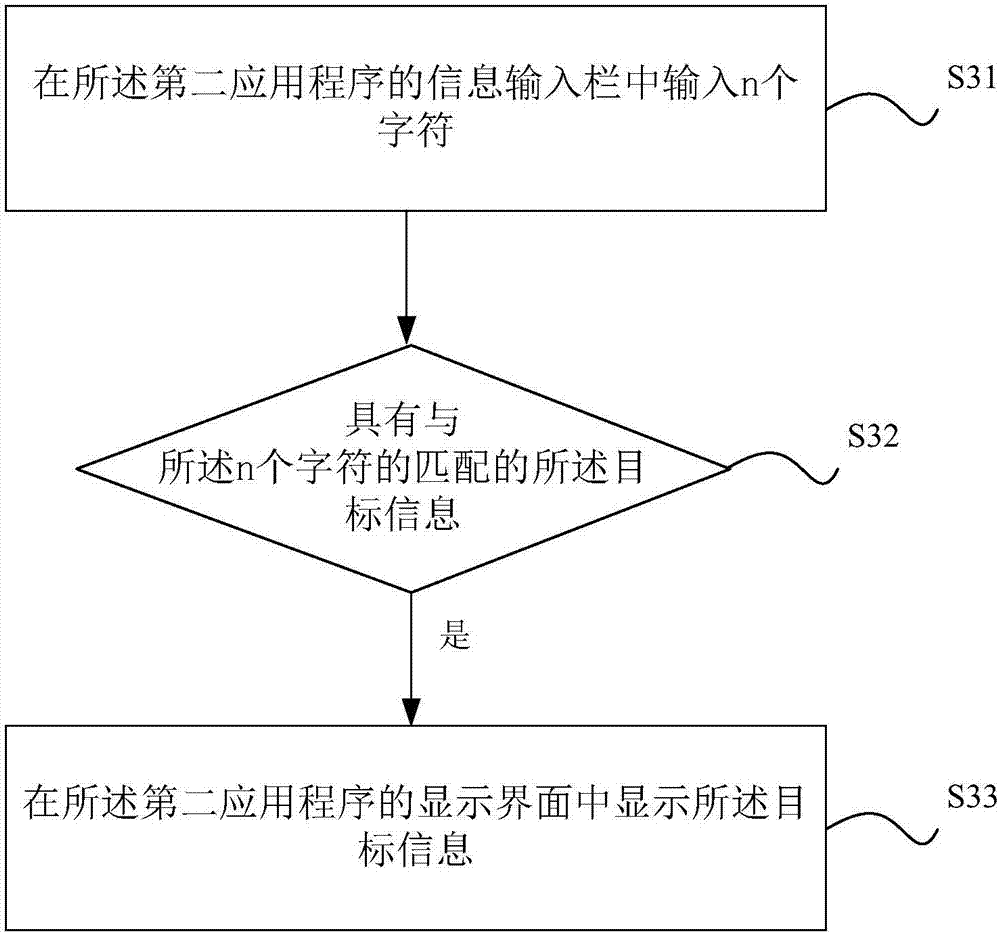

Verification code inputting method and device

InactiveCN105101122ARealize automatic inputImprove input efficiencyServices signallingMessaging/mailboxes/announcementsComputer architectureText message

The invention discloses a verification code inputting method and device. The verification code inputting method comprises: obtaining a new short message received by a terminal; detecting whether the new short message is a verification short message; if so, extracting a verification code from the new short message; and inputting the verification code into a specified position of a current display interface. The verification code inputting method is capable of automatically inputting the verification code in the verification short message; as a result, the verification code inputting efficiency is improved.

Owner:IYUNTIAN

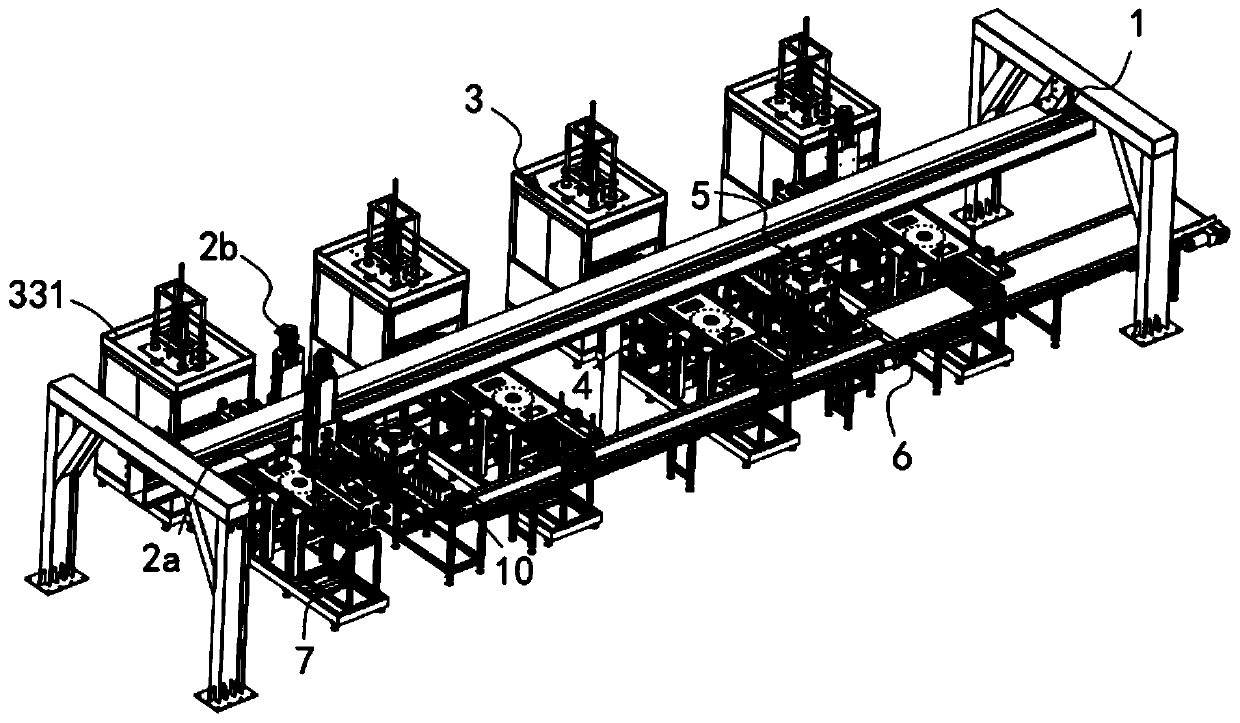

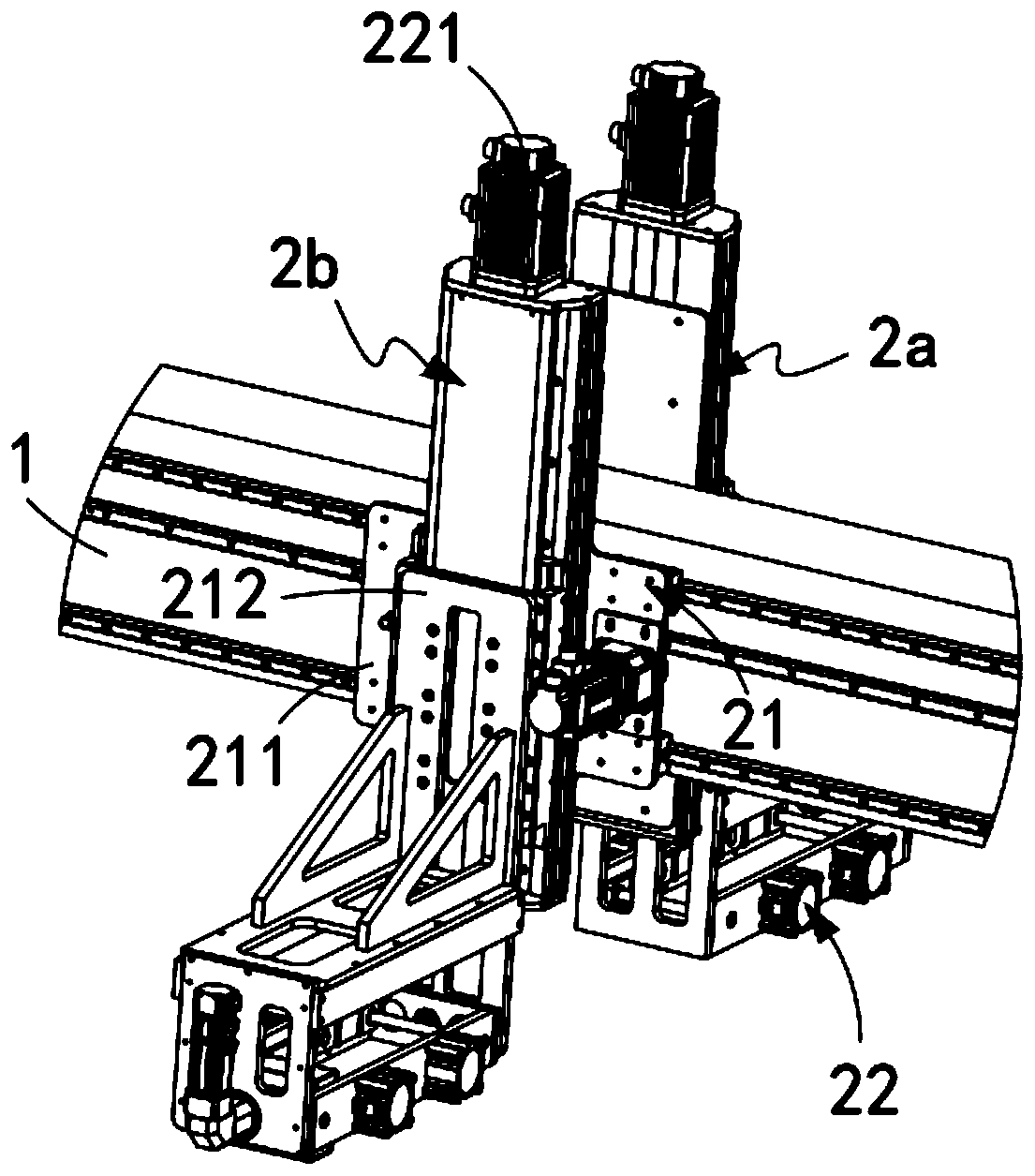

Full-automatic cast welding process and production line of lead-acid storage battery

ActiveCN111266556AConnection time is shortImprove work efficiencyCasting plantsProcess engineeringSoldering

The invention relates to a full-automatic cast welding production line of a lead-acid storage battery. The full-automatic cast welding production line comprises a gantry frame, a feeding hand and a processing production line; the processing production line comprises a discharging hand, a cast welding machine, a station switching machine and a groove entering machine, the two ends of the station switching machine are provided with a feeding station and a processing station correspondingly, and the cast welding machine comprises a lead furnace, a cast welding die and a cooling assembly. The invention also provides a full-automatic cast welding process of the lead-acid storage battery. The process comprises the step: step 1, cutting and brushing work; step 2, feeding; step 3, soldering flux adhering; step 4, lead liquid containing; step 5, cast welding processing; step 6, groove entering; and step 7, outputting. The technical problems that feeding and discharging need to be carried out manually in the cast welding process, cannot be tightly connected with the cutting and brushing work, and connection production cannot be realized are solved.

Owner:长兴玖佳机械股份有限公司

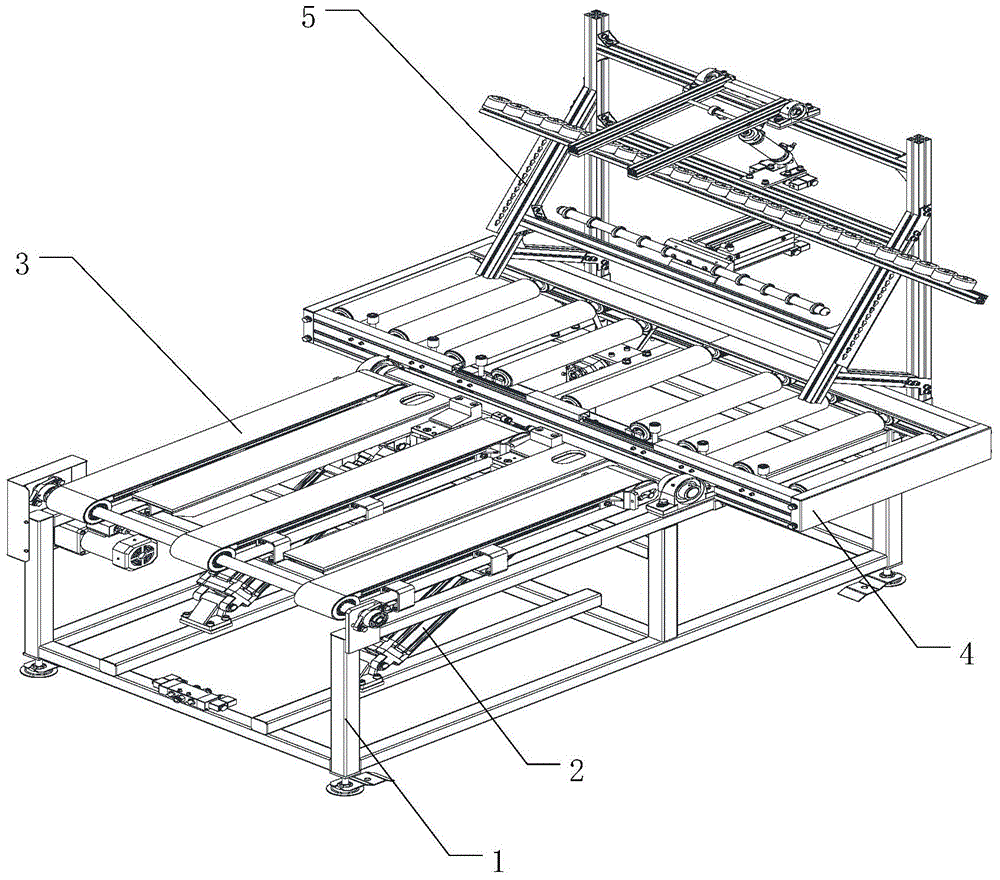

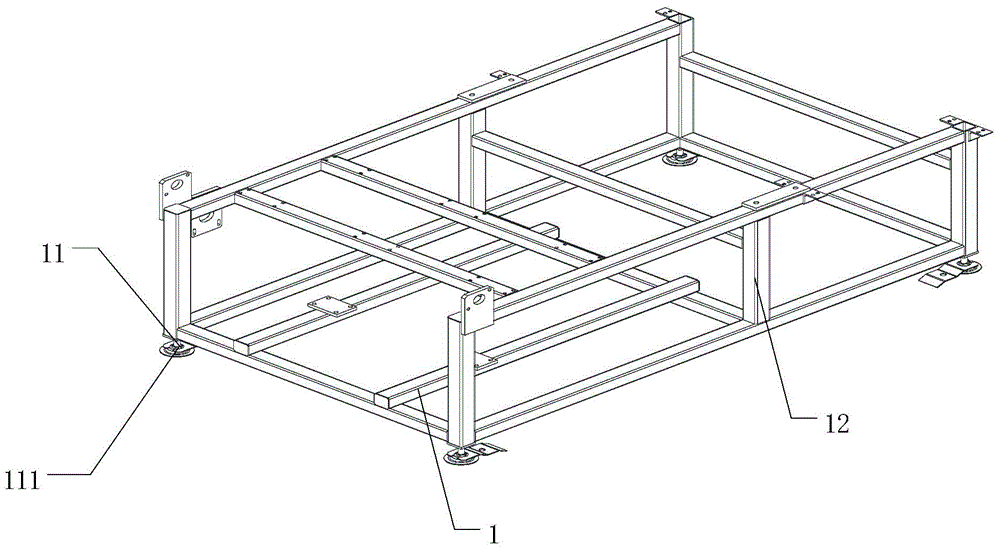

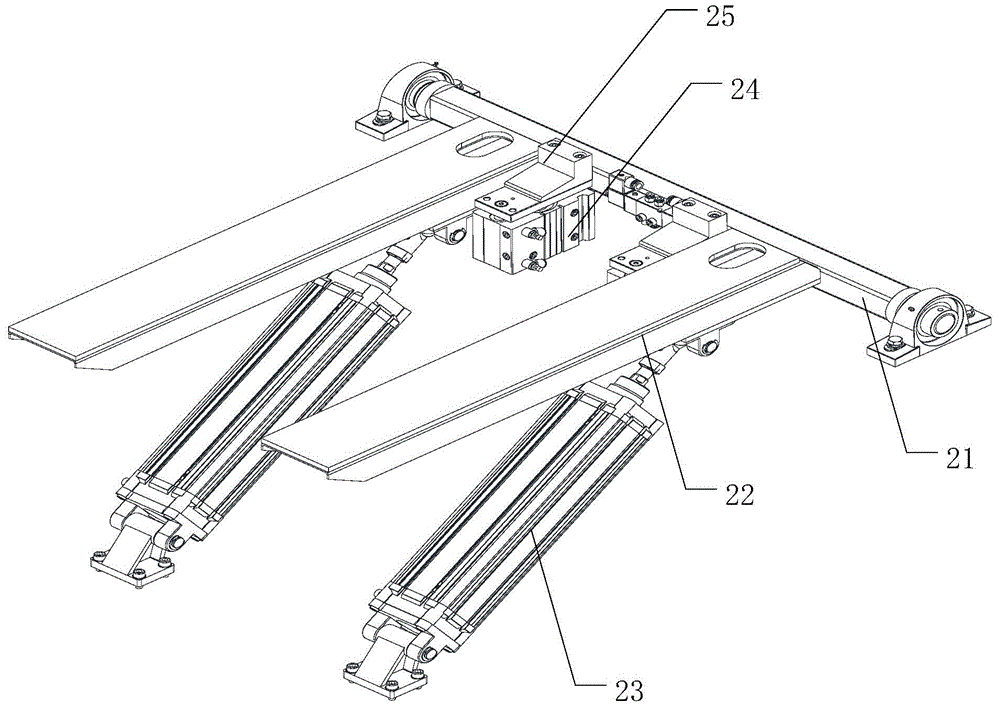

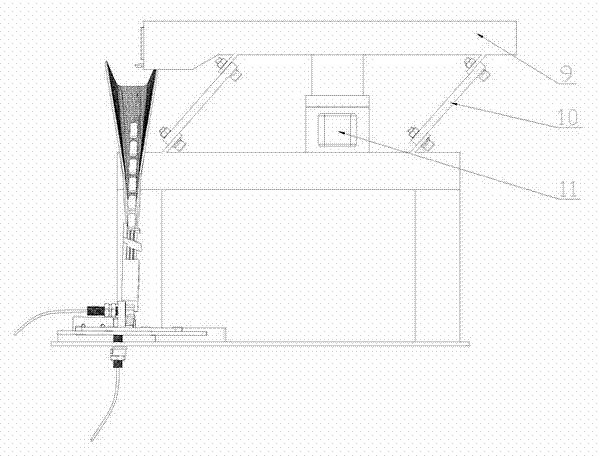

Automatic overturning and leaning device for flat-screen TV

The invention relates to an overturning and leaning device, and discloses an automatic overturning and leaning device for a flat-screen TV. The flat-screen TV can be automatically conveyed in and overturned, leans at a certain angle and is conveyed out. The automatic overturning and leaning device comprises a rack assembly, an overturning assembly, a conveying-in belt assembly, a conveying-out drum assembly and a buffer assembly, wherein the overturning assembly, the conveying-in belt assembly, the conveying-out drum assembly and the buffer assembly are arranged on the rack assembly, and the overturning assembly is arranged below the conveying-in belt assembly; the conveying-out drum assembly is positioned at the back end of the conveying-in belt assembly, and the buffer assembly is arranged at the side of the conveying-out belt assembly. The overturning and leaning device provided by the invention is suitable for producing the flat-screen TV.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

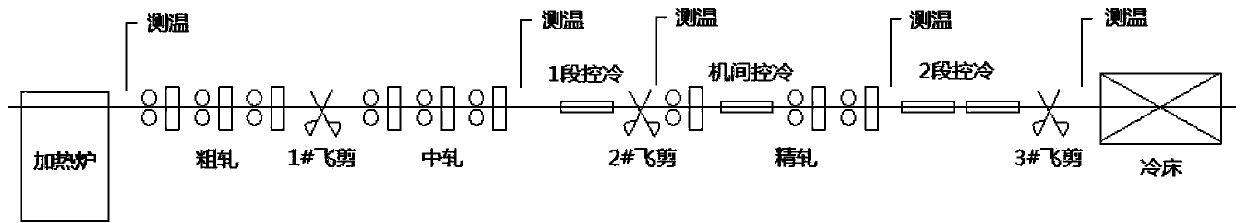

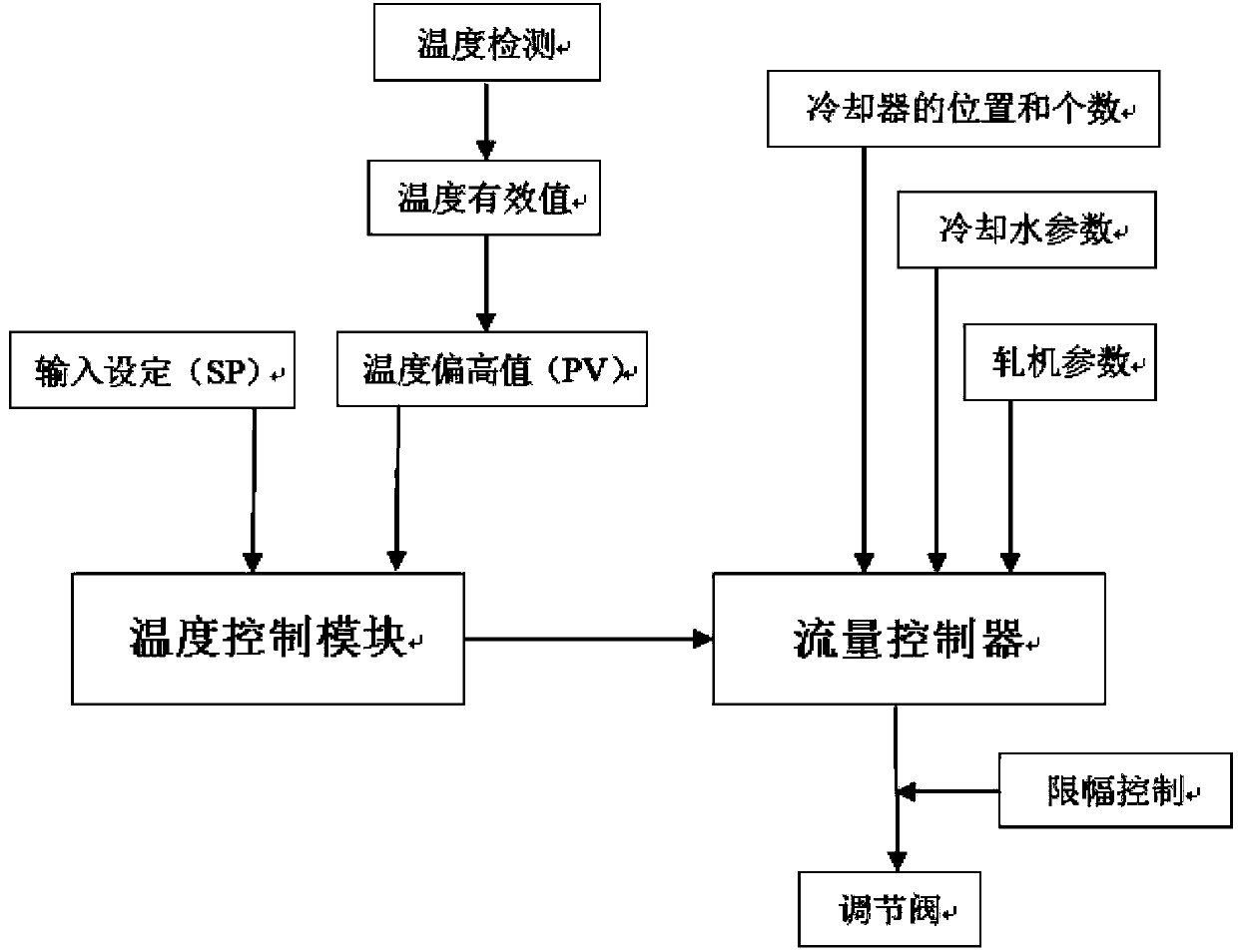

Automatic temperature control method for rod material cold control system

ActiveCN103464474ARealize fully automatic controlHigh precisionTemperature control deviceAutomatic controlEngineering

The invention provides an automatic temperature control method for a rod material cold control system, and belongs to the technical field of rod material heat treatment. The method comprises the following control steps including temperature detection treatment: the effective value of actual temperature detection equipment is judged, and the actual detection value is corrected; automatic temperature regulation: the automatic temperature regulation is realized on the temperature after the pre-cooling section before the rod material fine rolling, and the automatic temperature regulation is realized on the cold bed inlet temperature of the rod materials. The problems of temperature control precision and stability of the rod materials are effectively solved. The method has the advantages that all cold control equipment realizes the automatic operation, and the distribution of the core part temperature and the surface temperature of the rod materials after the cold control automatic control is stable, so the intensity and the toughness of steel materials are improved, the steel material tissue is improved, and in addition, electric energy sources and water energy sources are saved through automatically controlling a cooling water pump and a valve group.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

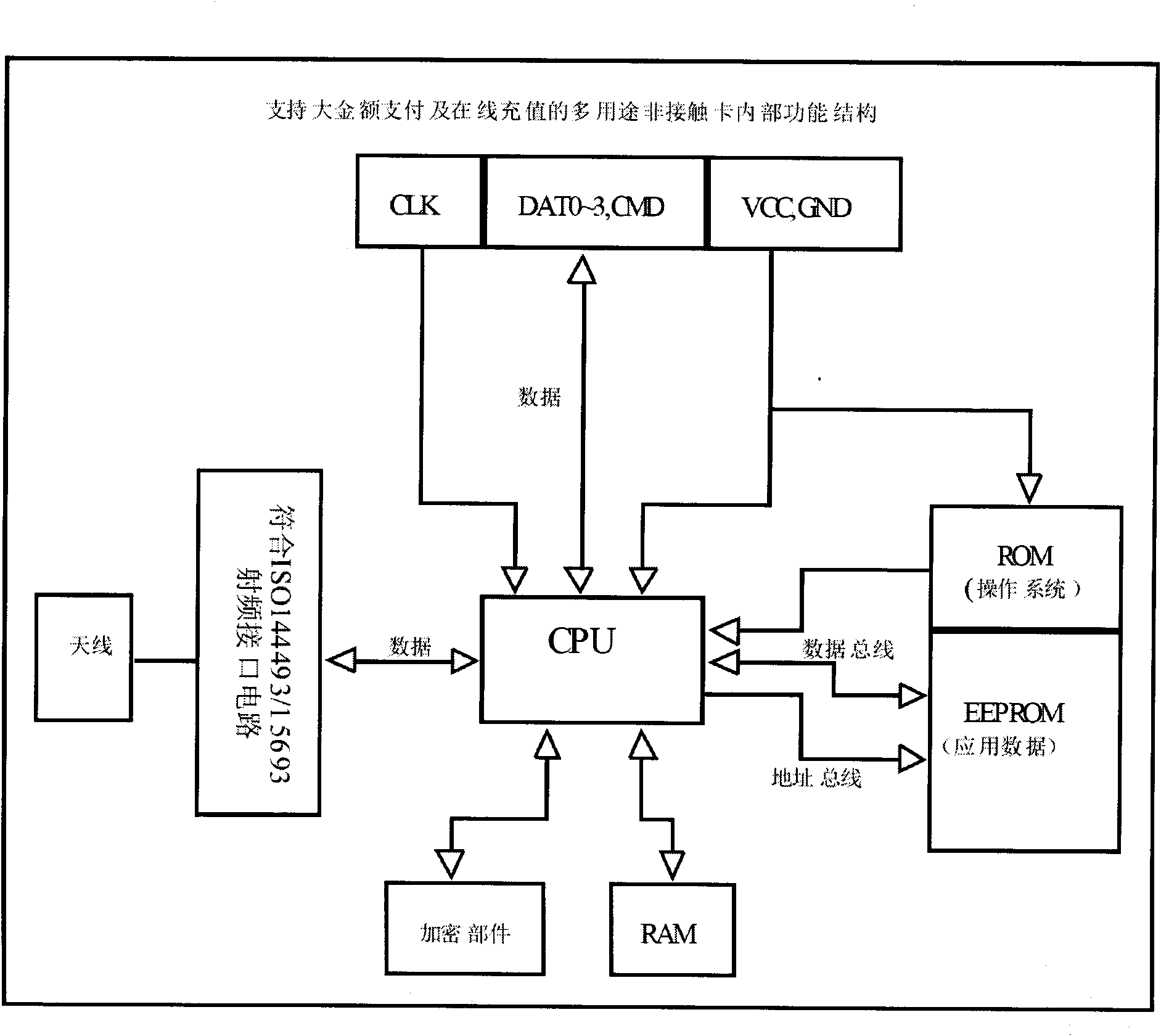

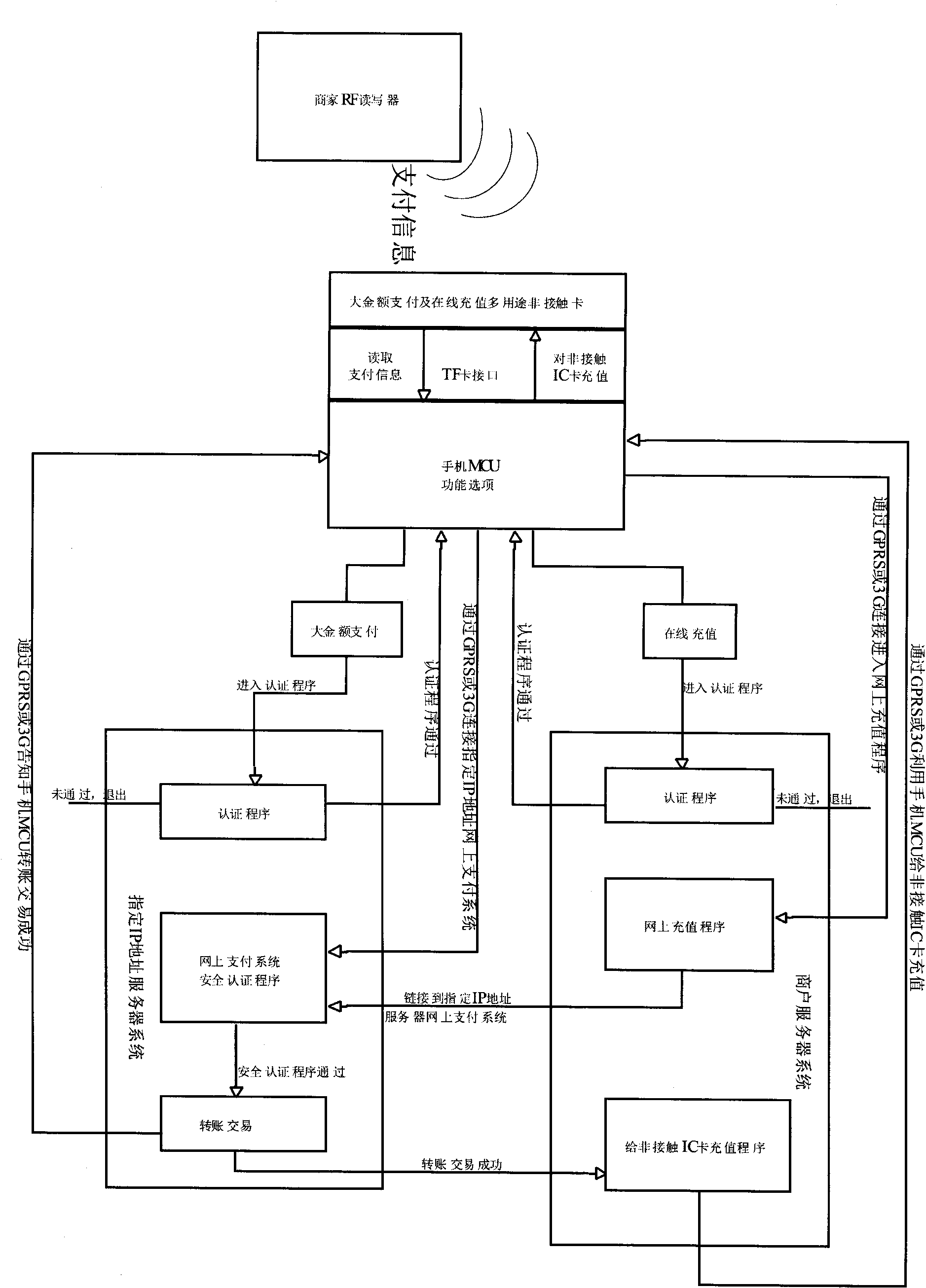

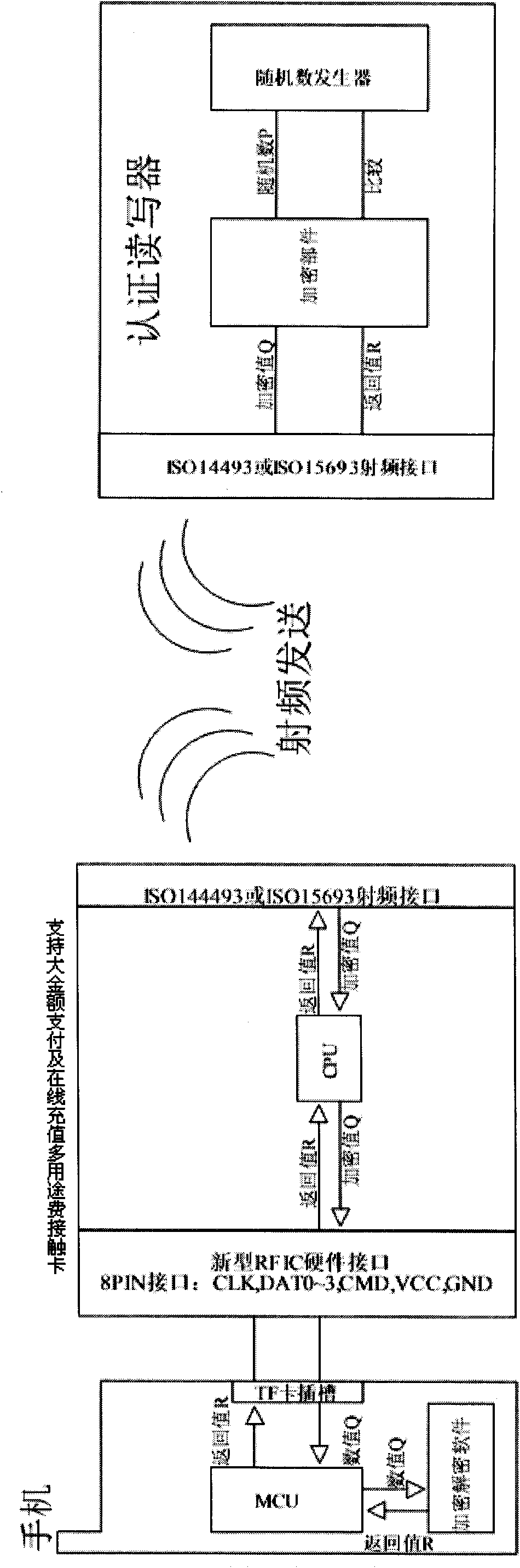

Multipurpose contactless card supporting large amount payment and online recharge and application method thereof

InactiveCN101789152ARealize automatic inputRealize large amount of payment methodPre-payment schemesRecord carriers used with machinesCommunication interfacePayment

The invention discloses a multipurpose contactless card which supports large amount payment and online recharge; the multipurpose contactless card is composed of a central processing unit, a data memory for storing an operating system, a memory for storing application data, an encryption part for encryption and decryption operation, a radio frequency interface circuit and a hardware communication interface corresponding to a mobile phone TF card slot. The hardware communication interface comprises a NO. 0 data interface, a NO.1 data interface, a NO.3 data interface, a CMD command communication interface, a CLK clock input interface, a power supply anode VCC interface and a ground GND interface. The invention also discloses an application method and an authentication method required by the application method; the application method supports large amount payment, online recharge and adapts to various authentication reader-writers, and is applicable to the multipurpose contactless card supporting large amount payment and online recharge; the security, reliability and accuracy of payment and recharge functions of the multipurpose contactless card supporting large amount payment and online recharge are guaranteed, and the practicality of the invention is also greatly improved.

Owner:黄志军

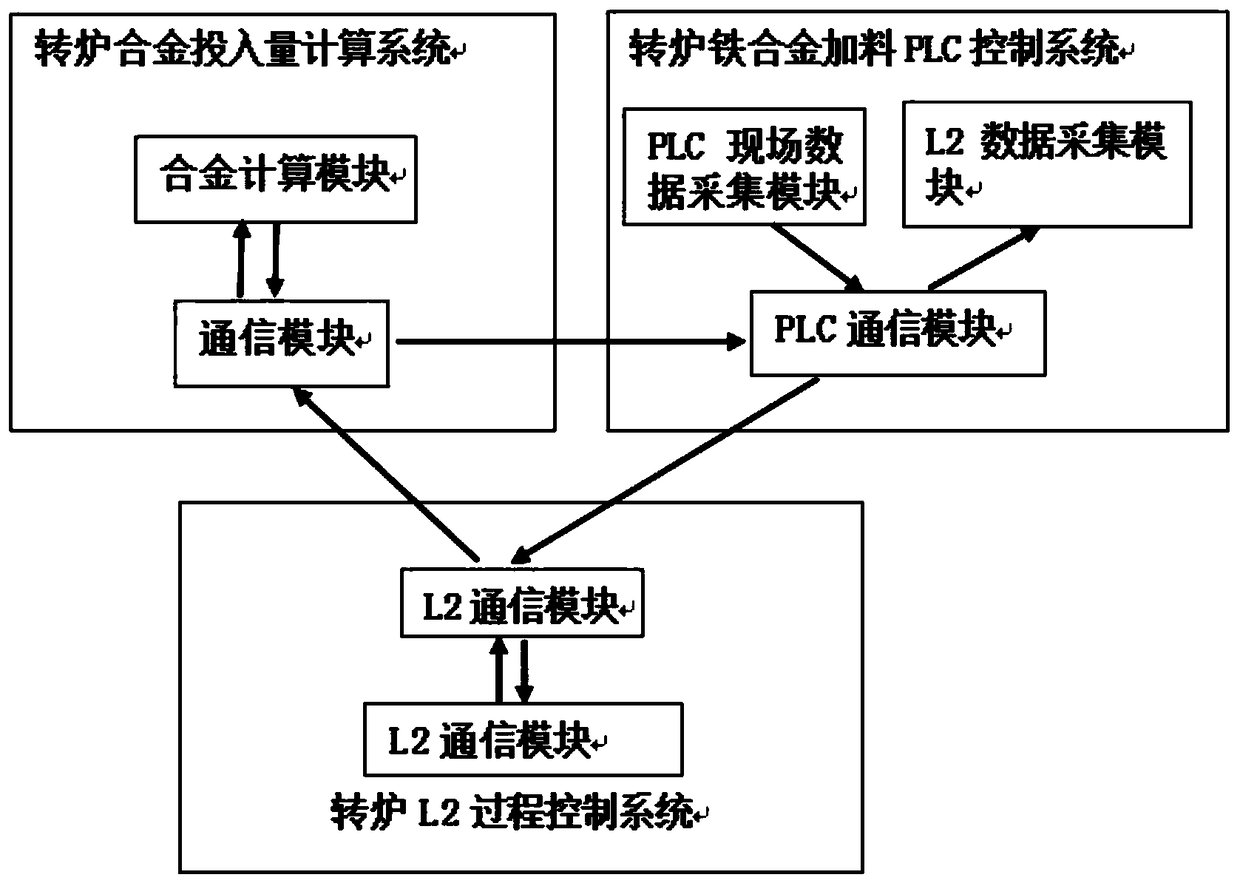

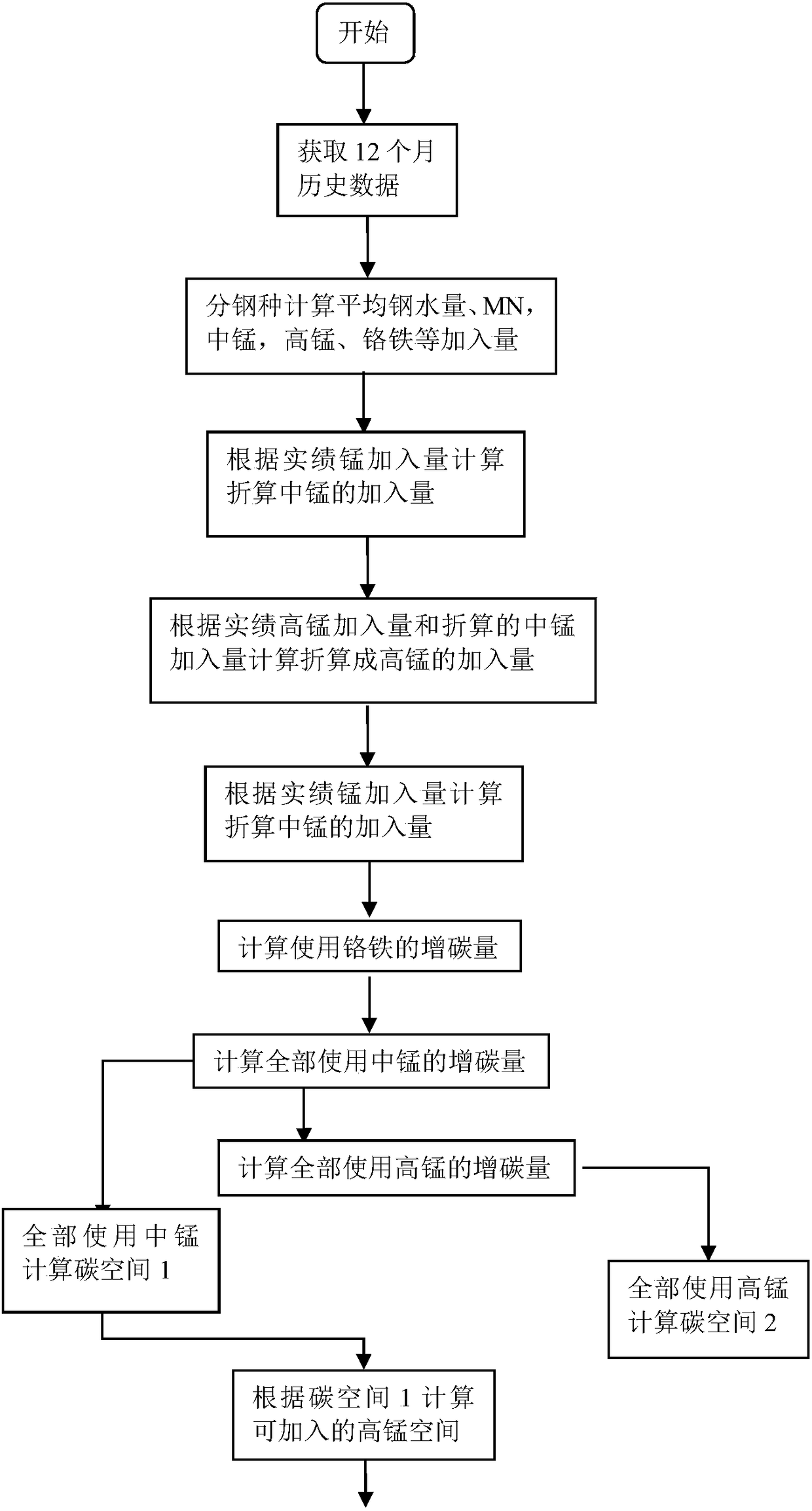

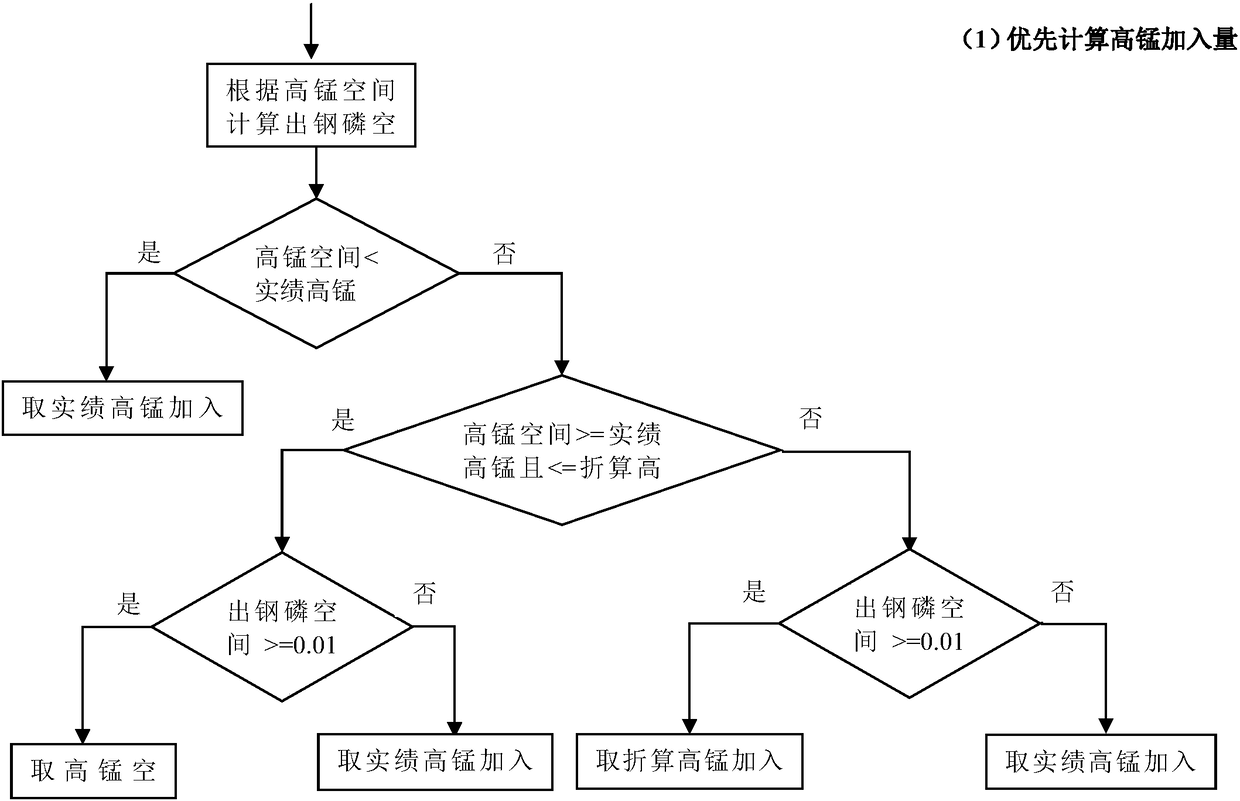

Automatic control system and automatic control method for feeding alloy into converter

InactiveCN108504815ARealize automatic calculationRealize automatic material preparationManufacturing convertersIncreasing energy efficiencyAutomatic controlAutomatic train control

The invention relates to an automatic control system and an automatic control method for feeding an alloy into a converter. The automatic control system comprises a converter alloy feeding amount calculation system, a converter alloy feeding PLC control system and a converter L2 process control system, wherein the converter alloy feeding amount calculation system comprises an alloy calculation module and a communication module, the alloy calculation module is used for alloy feeding amount calculation and calculation checking, and the communication module and the L2 control system perform datacommunication required by calculation. According to the present invention, the whole system is ingeniously designed; and with the method, the automatic calculation, the automatic material preparationand the automatic feeding of the alloy are achieved, the manual intervention is not required, the on-site alloy feeding can be automatically controlled, the influence on the molten steel quality and the yield during the converter tapping deoxidation alloying are simultaneously considered, and the alloy feeding stability can be ensured.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

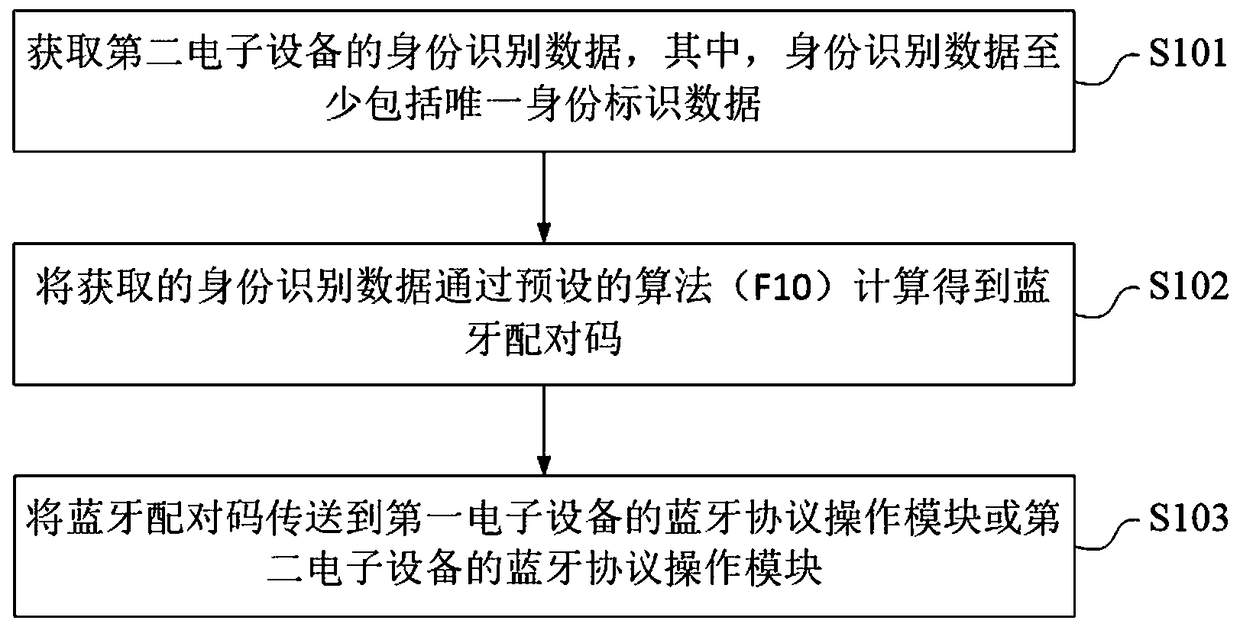

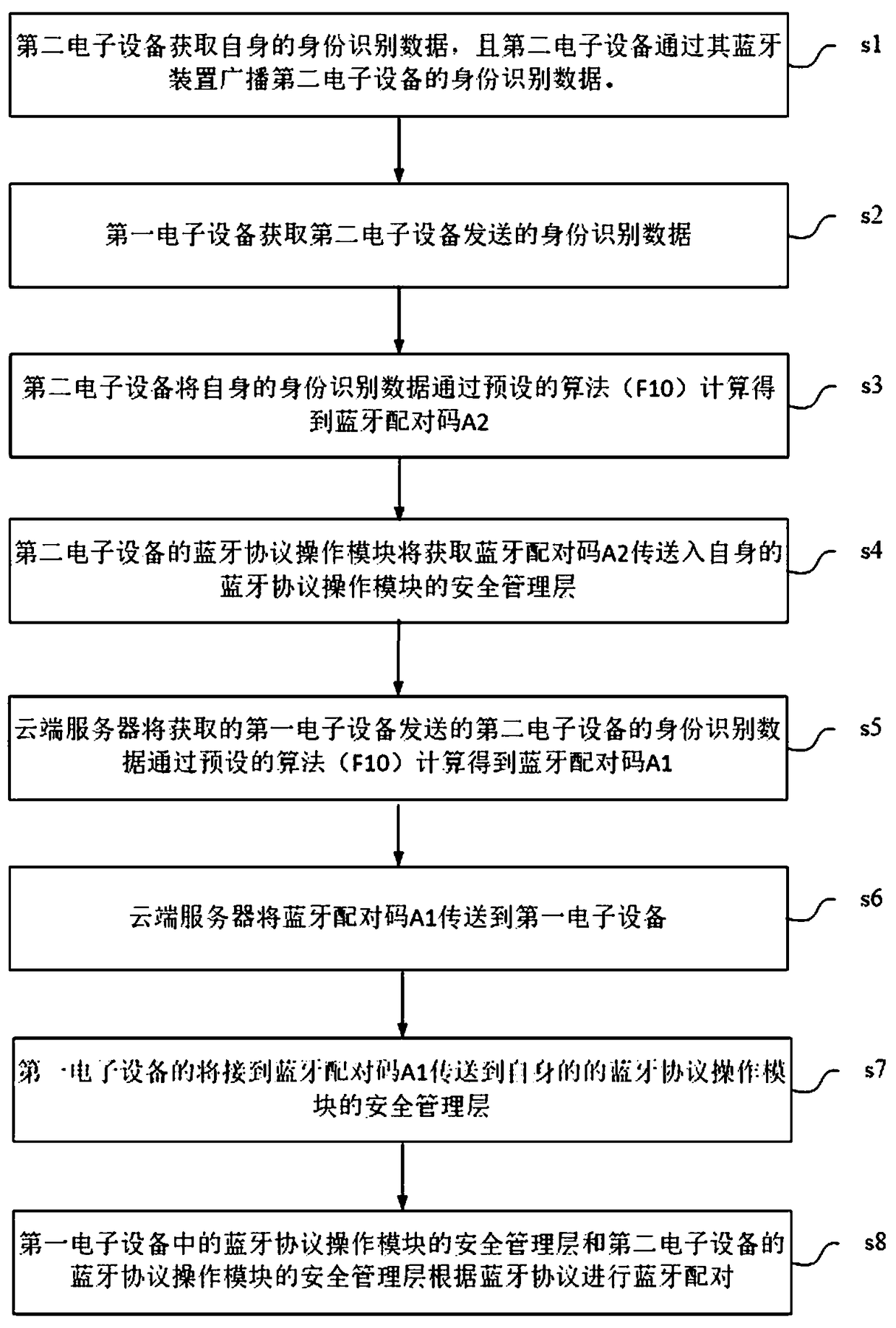

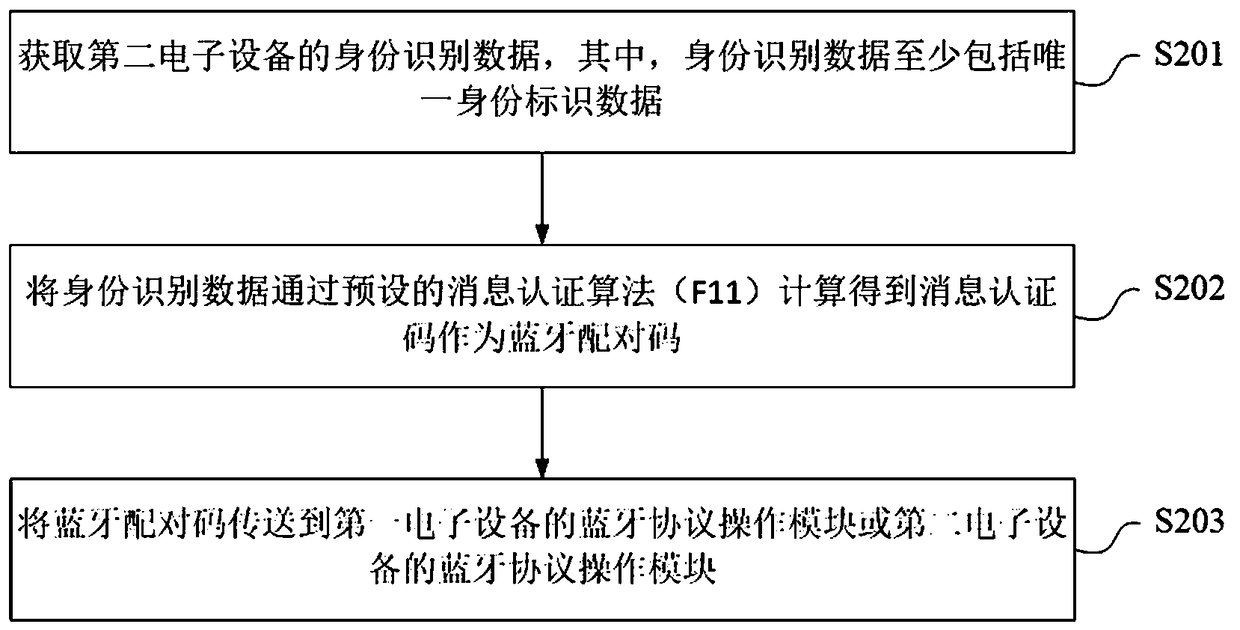

Bluetooth pairing code configuration method and system, terminal, server and vehicle-mounted device

ActiveCN108418845AImplement verifiable identityRealize automatic inputTransmissionSecurity arrangementComputer hardwareBluetooth

The invention relates to a Bluetooth pairing code configuration method and system, a terminal, a server and a vehicle-mounted device. The Bluetooth pairing code configuration method is used in a Bluetooth pairing code process between a first electronic device and a second electronic device, each of the first electronic device and the second electronic device comprises a Bluetooth protocol operation module for operating based on a Bluetooth protocol stack, and the method comprises the following steps: obtaining identity identification data of the second electronic device; calculating the obtained identity identification data through a preset algorithm to obtain a Bluetooth pairing code; and transmitting the Bluetooth pairing code to the Bluetooth protocol operation module of the first electronic device or the Bluetooth protocol operation module of the second electronic device. By adoption of the Bluetooth pairing code configuration method and system provided by the invention, the Bluetooth pairing code can verify the identity and can be automatically input, so that the Bluetooth pairing is automatically performed.

Owner:上海银基信息安全技术股份有限公司

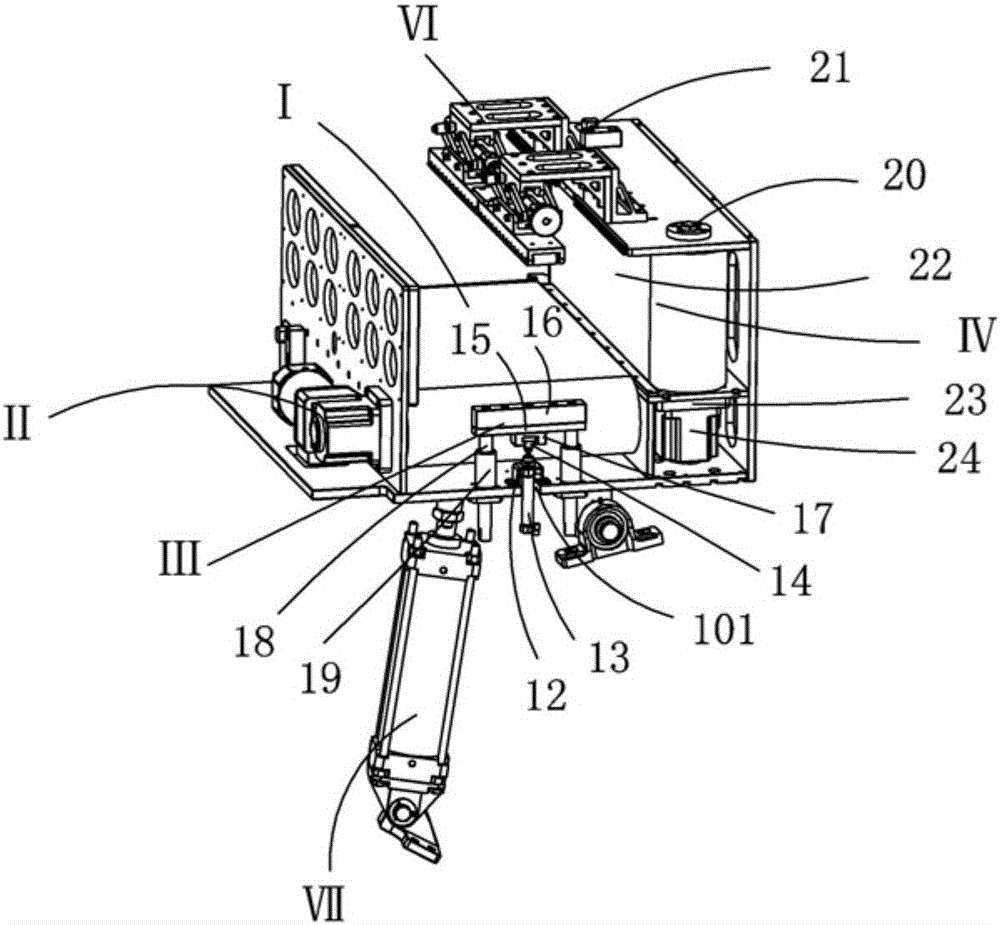

Removal device and method for container outer package

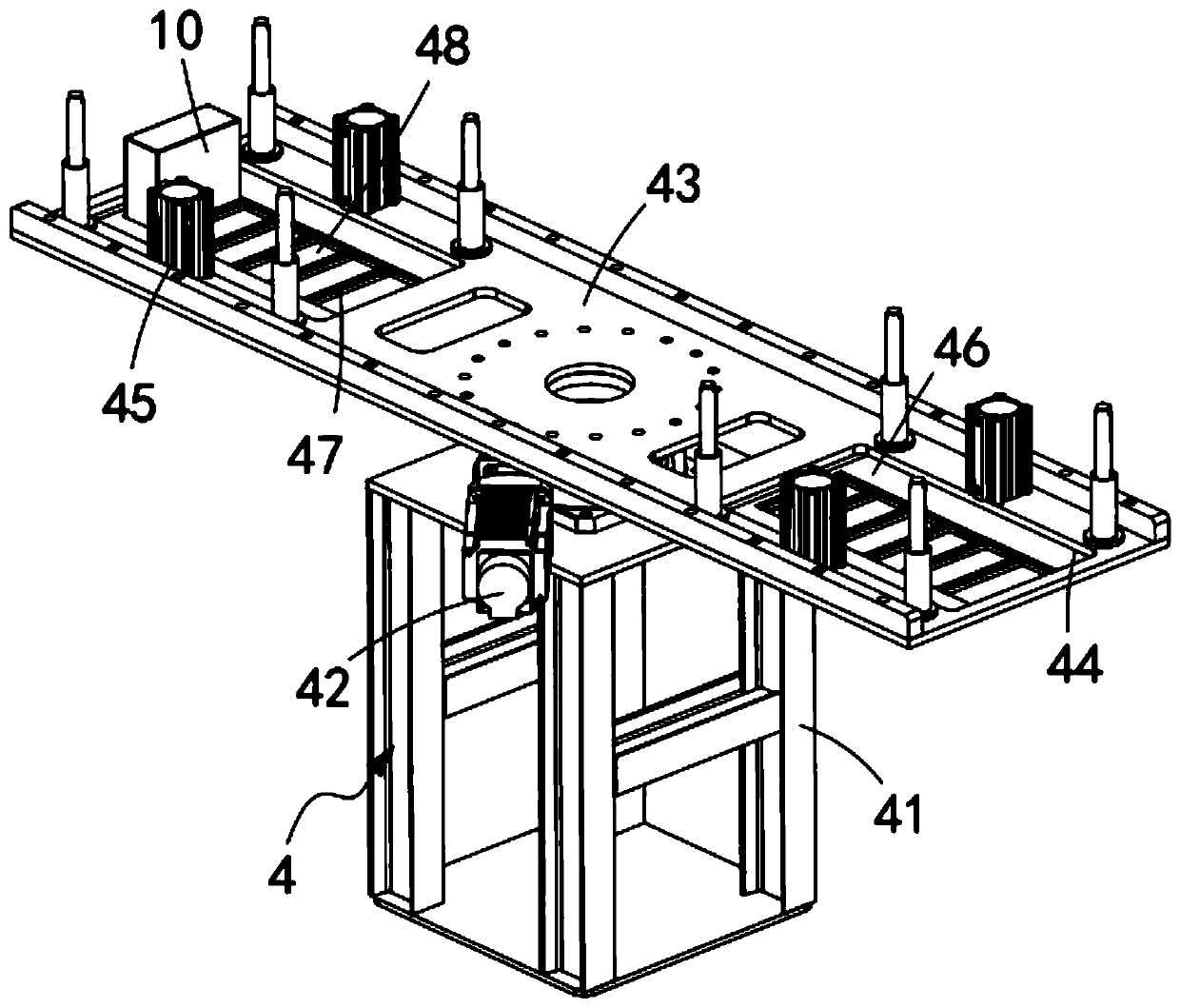

ActiveCN109229673AReduce the number of movementsImprove work efficiencyUnpacking by cuttingTransfer mechanismManipulator

The invention discloses a removal device for a container outer package. A plurality of pieces of container outer wrapping package film arranged in a matrix mode form a bottle wrapping material; the removal device is used for removing the package film and comprises a film cutting station, a conveying platform and a bottle-film separating station; the film cutting station is provided with a film cutting platform and a film cutting manipulator; the conveying platform is connected between the film cutting station and the bottle-film separating station; the bottle-film separating station is provided with a film clamping chuck, a bottle collection plate, a film separating platform, a medicine bottle transfer frame and a medicine bottle transfer mechanism; the film clamping chuck is arranged at the side, close to the conveying platform, of the bottle-film separating station, the bottom of the bottle collection plate is provided with a jacking air cylinder, the film separating platform is parallelly arranged over the bottle collection plate and provided with a platform opening for the bottle collection plate to penetrate through, the edge of the platform opening is provided with a film hanging claw, the medicine bottle transfer mechanism is connected to the top of the medicine bottle transfer frame and arranged above the film separating platform, and the inner side circumference of themedicine bottle transfer frame is matched with the side circumference surface of the bottle wrapping material. The removal device has the advantages of being simple in structure, high in efficiency and the like.

Owner:TRUKING TECH LTD

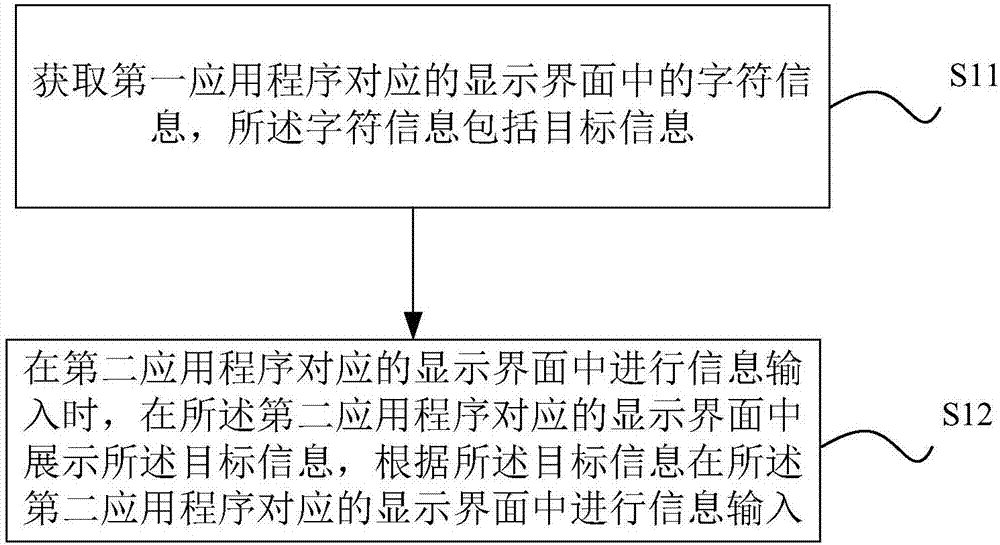

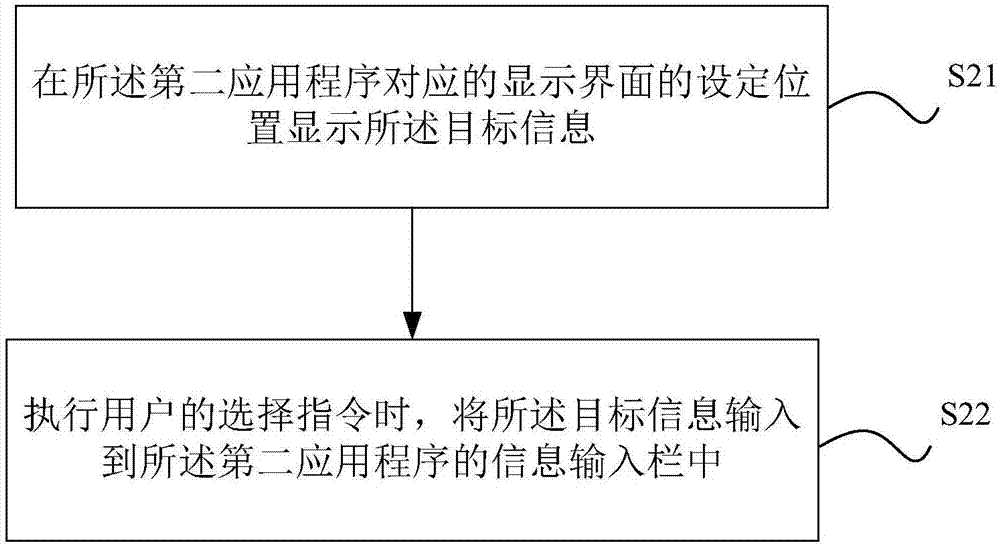

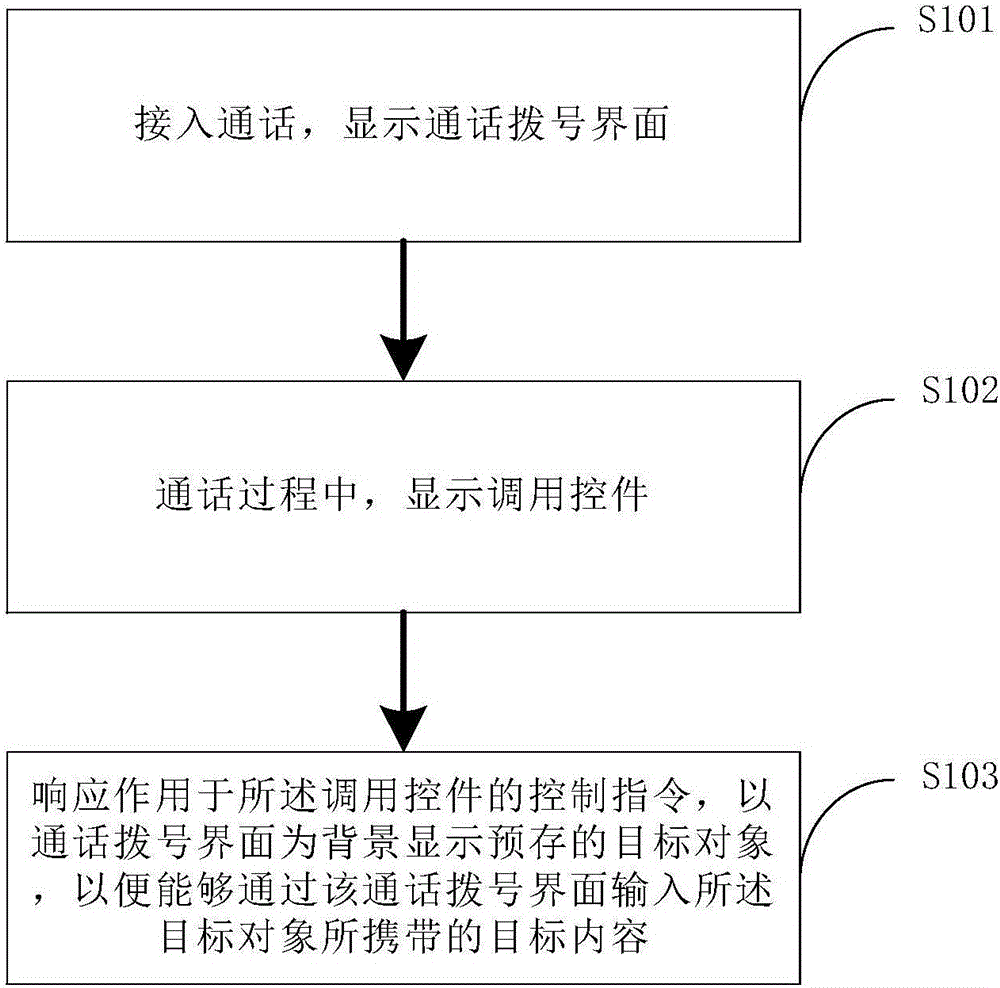

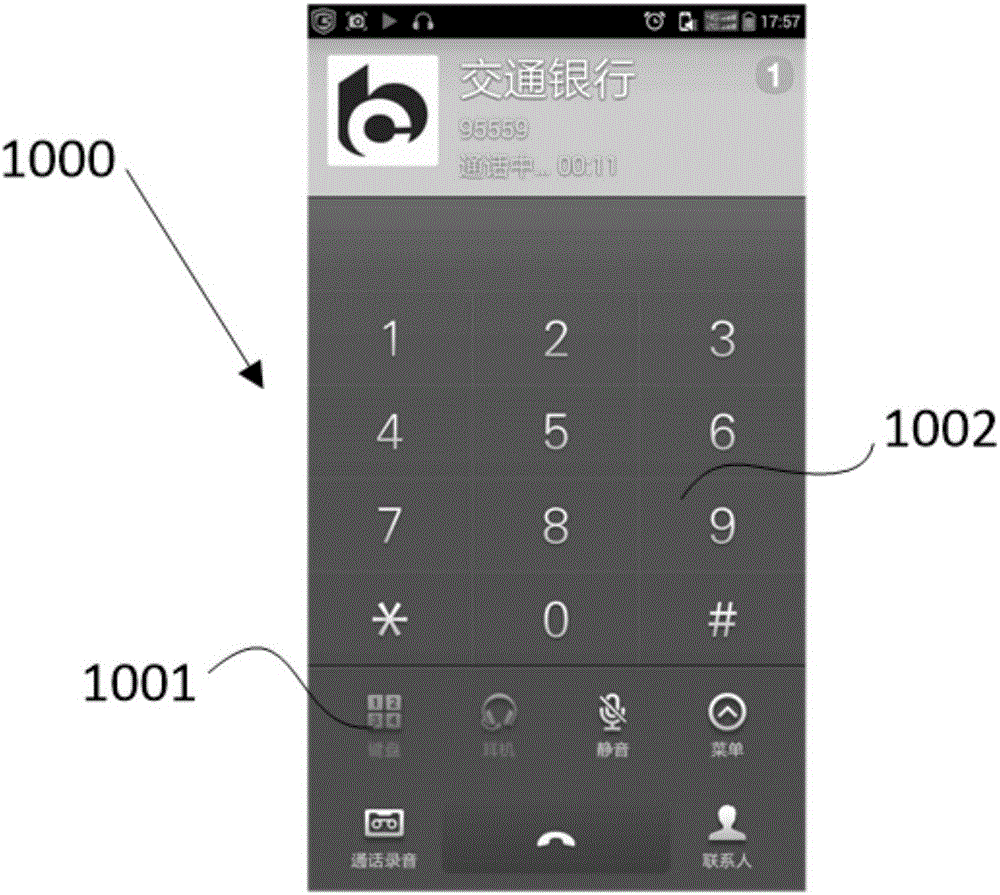

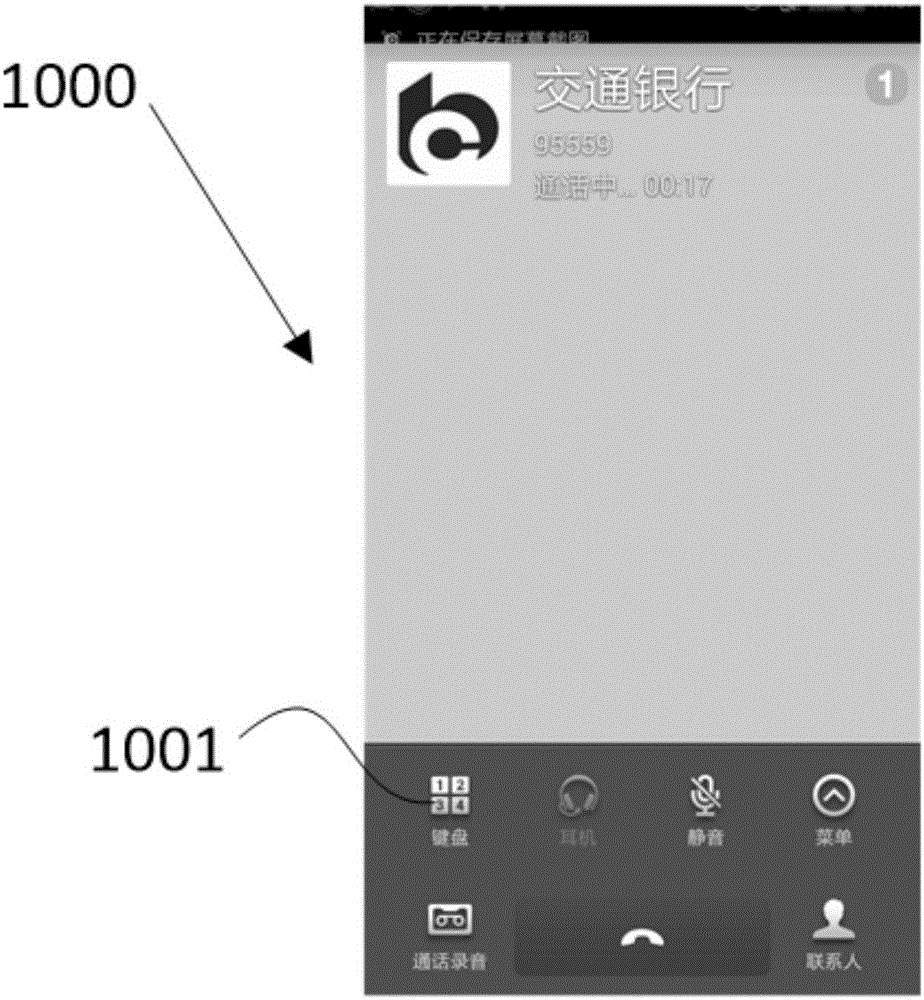

Control method and first electronic device

InactiveCN106973157ALess prone to entry errorsRealize automatic inputSubstation equipmentInput/output processes for data processingElectric equipmentComputer engineering

Owner:LENOVO (BEIJING) CO LTD

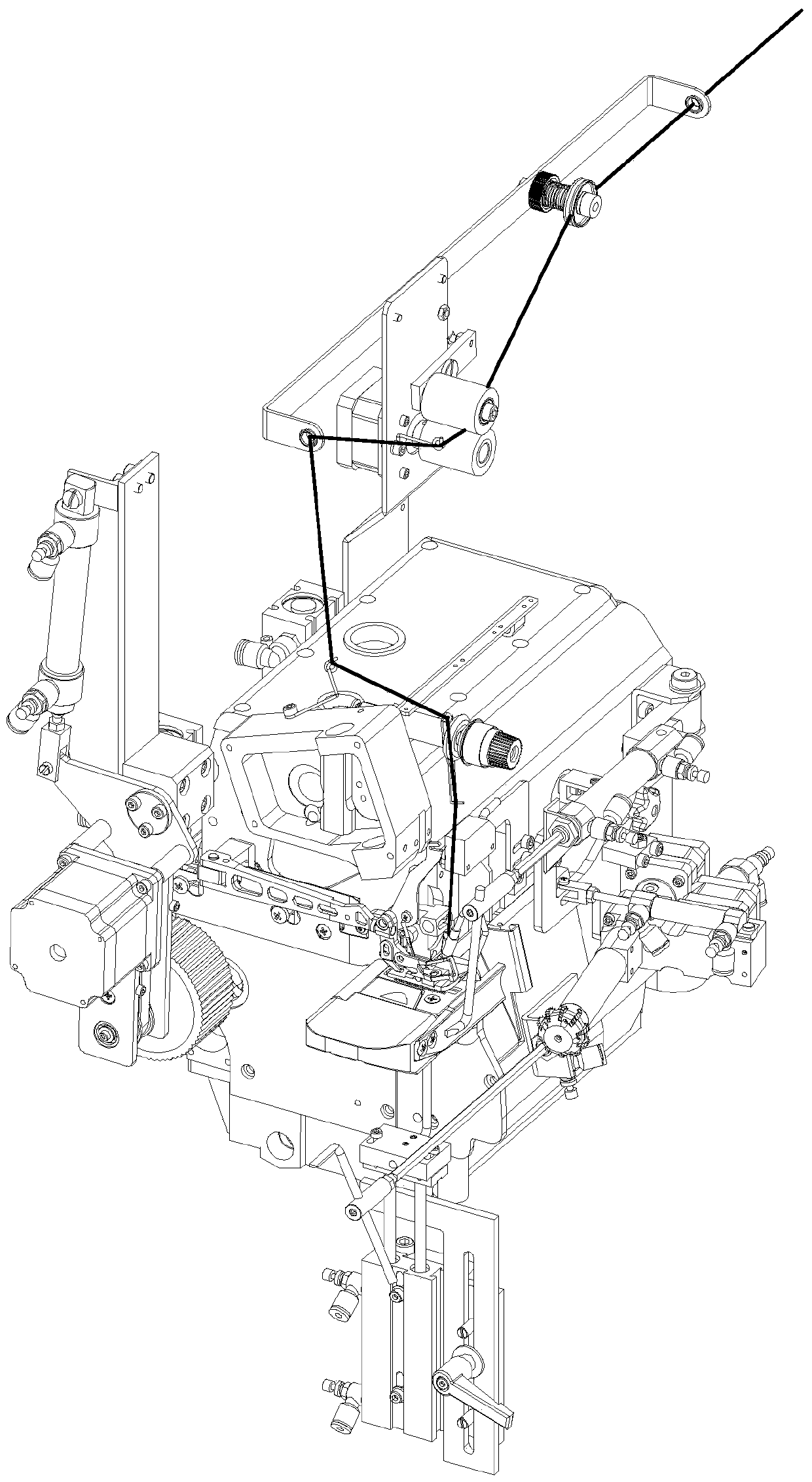

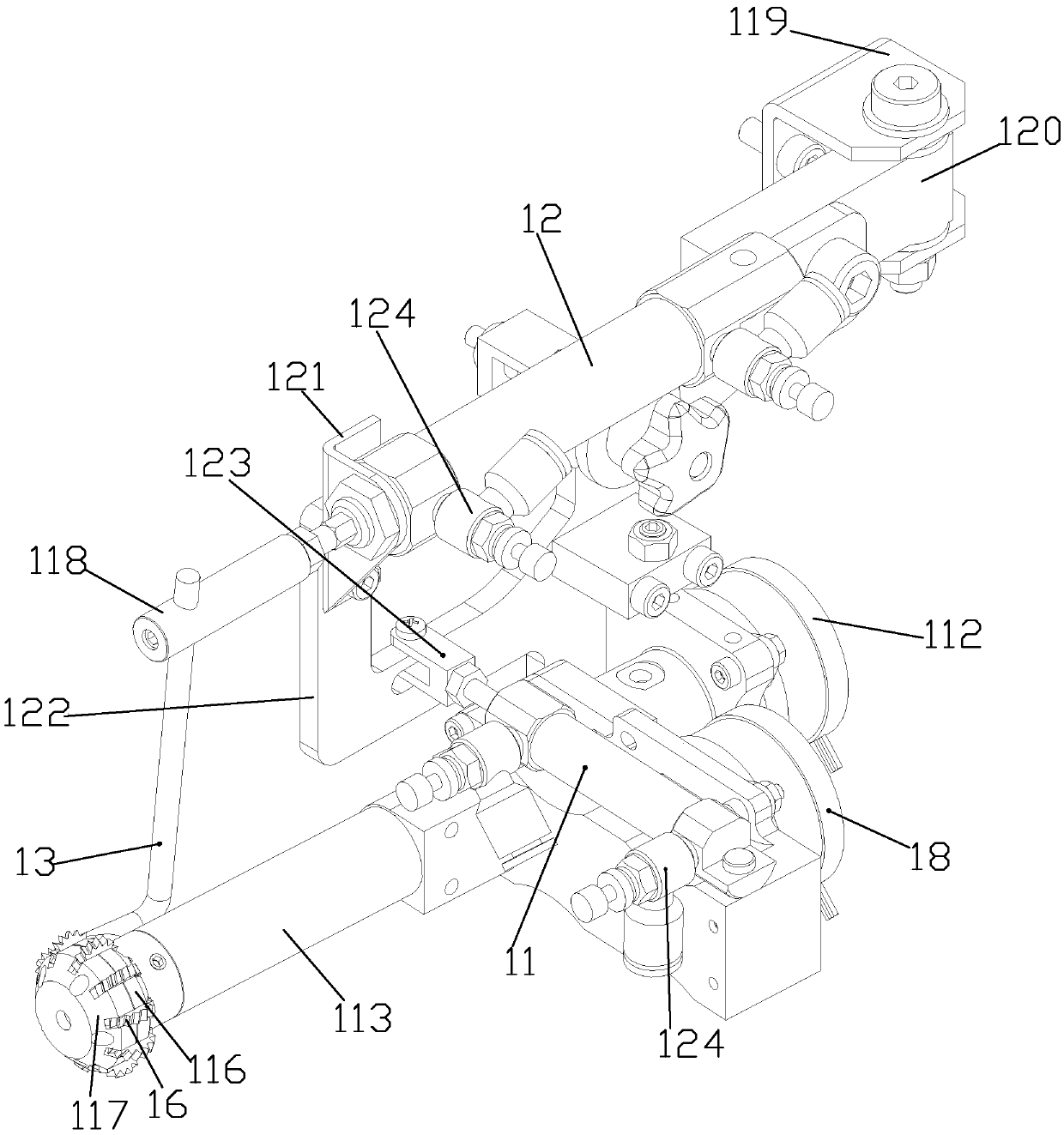

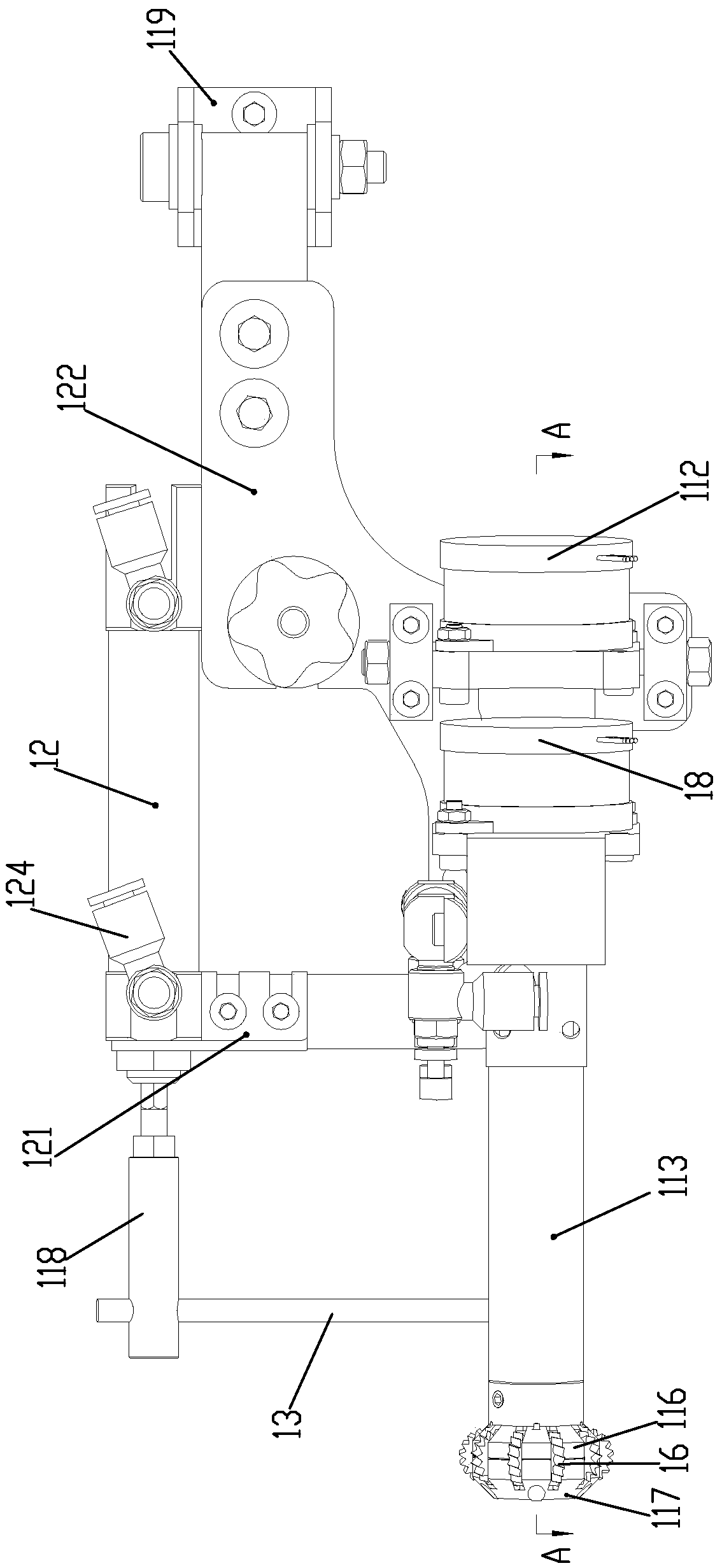

Fully-computerized glove overlock machine

ActiveCN105506868APrevent movementImprove seam qualityProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention relates to a fully-computerized glove overlock machine which comprises a glove overlock machine body and a control system. An automatic positioning device, a driving device, an expanding device and a rubber string conveying device are mounted on the glove overlock machine body and all controlled by the control system. The fully-computerized glove overlock machine has the advantages that full computer control of positioning, driving, expanding, rubber string conveying and the like is realized, high labor precision is achieved while labor efficiency is greatly improved, and glove overlock quality is guaranteed.

Owner:ZHEJIANG HAISEN KNITTING MACHINE TECHN

Grinding method for revolving container

InactiveCN108515394AImprove grinding efficiency and qualityVersatileRevolution surface grinding machinesBurnishing machinesRotary machineManipulator

The invention relates to a grinding method for a revolving container. The grinding method is implemented by virtue of a revolving container machining center, specifically, the revolving container machining center comprises a machine frame, a welding device arranged on the machine frame, an input device arranged on the left side of the machine frame, and an output device arranged on the right sideof the machine frame; an input manipulator is arranged between the input device and the machine frame, a discharge manipulator is arranged between the output device and the machine frame, and the structures of the input manipulator and the discharge manipulator are the same; and the welding device comprises a rotary machining machine head arranged on the upper portion of the machine frame, a working head arranged on the rotary machining machine head, a grinding plate arranged at the lower end of the working head and used for grinding the container, a machining table arranged below the grindingplate, and a rotary station workbench arranged in the middle of the machining table and located below the grinding plate. The design is reasonable, the structure is compact, and using is convenient.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Intelligent cooking machine based on Internet of Things technology

PendingCN108294606ASave spaceRealize the intelligent integration processVessels with intergral heatingInternet of ThingsEngineering

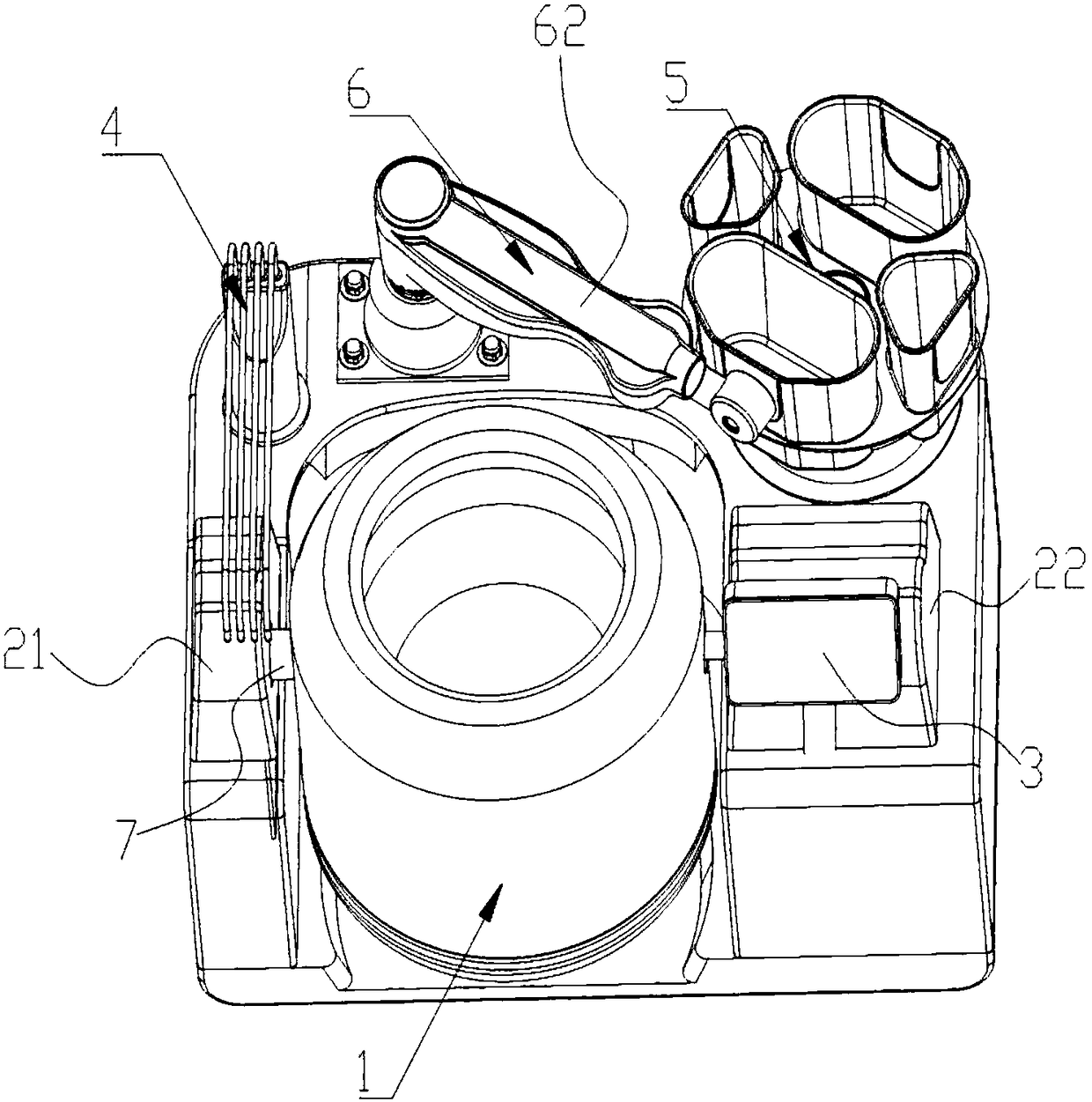

The invention provides an intelligent cooking machine based on an Internet of Things technology. The intelligent cooking machine includes an Internet of Thing control system, a pot body, bearing brackets located on both sides of the pot body, a seasoning adding mechanism, a loading mechanism and a feeding mechanical arm cooperating with the loading mechanism for use. The pot body includes an innerpot and a casing; the bottom of the casing is provided with a rotating device for the inner pot to achieve the rotation, and an electromagnetic heating device for heating is arranged around the innerpot; the bearing brackets are disposed on the two sides of the casing and provided with rotating shafts connected with the casing, respectively. An overturning device is disposed in a bearing seat and used for tilting and fixing the pot body in the vertical direction; and the Internet of Thing control system is used for controlling operations of the electromagnetic heating device, the overturningdevice, the seasoning adding mechanism, the loading mechanism and the feeding mechanical arm. According to the intelligent cooking machine, the separate addition of different food materials, the automatic filling of the seasoning, the stir-fry action by the operation of the pot body itself can be achieved, and the intelligent control of the cooking process is performed by the combination of the Internet of Thing control system.

Owner:中山市杰而普智能科技有限公司

Mobile terminal and method and device for controlling input of dialing keyboard during call

InactiveCN106027761AFewer steps placed in the backgroundImprove experienceSubstation equipmentComputer hardwareHuman–computer interaction

Owner:BEIJING QIHOO TECH CO LTD +1

Information display method and device and electronic equipment

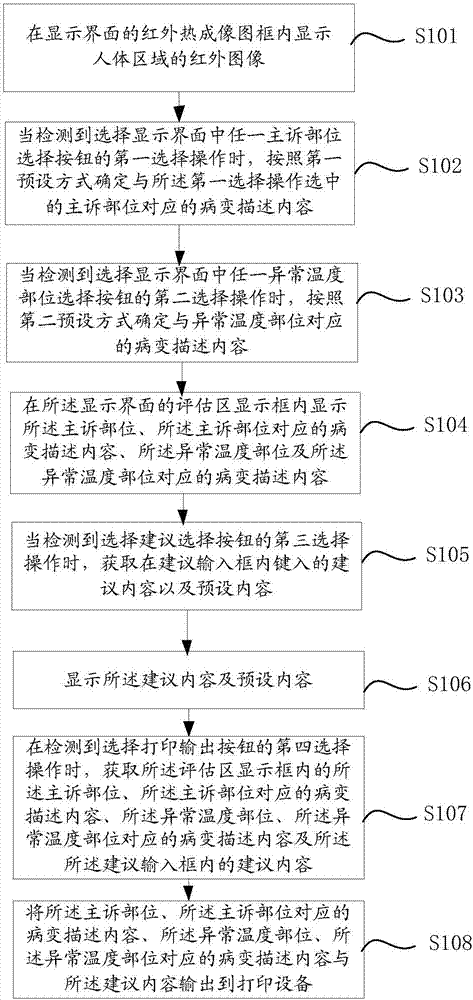

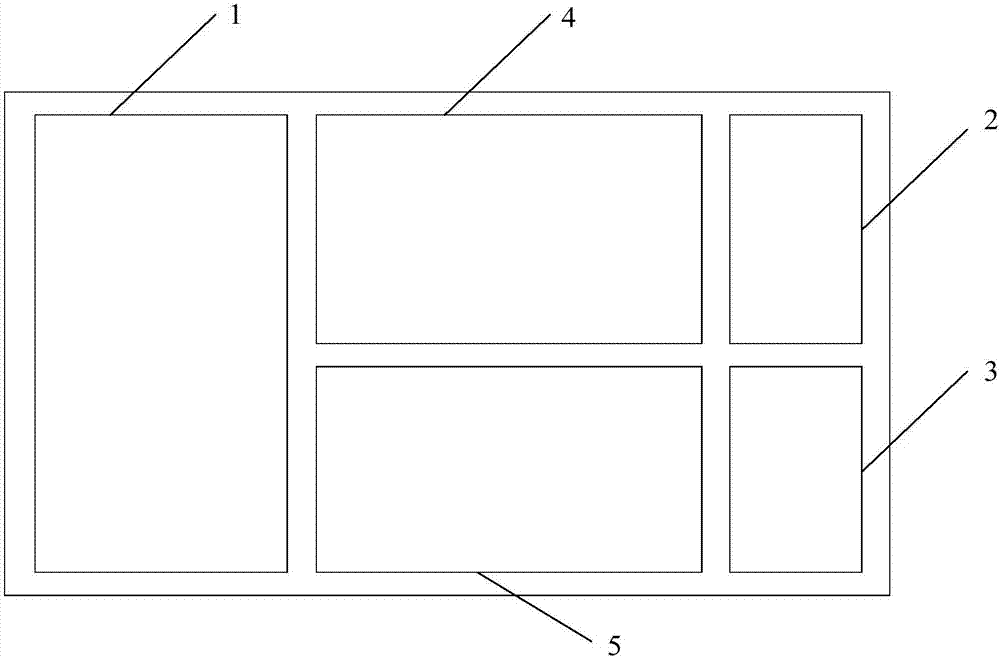

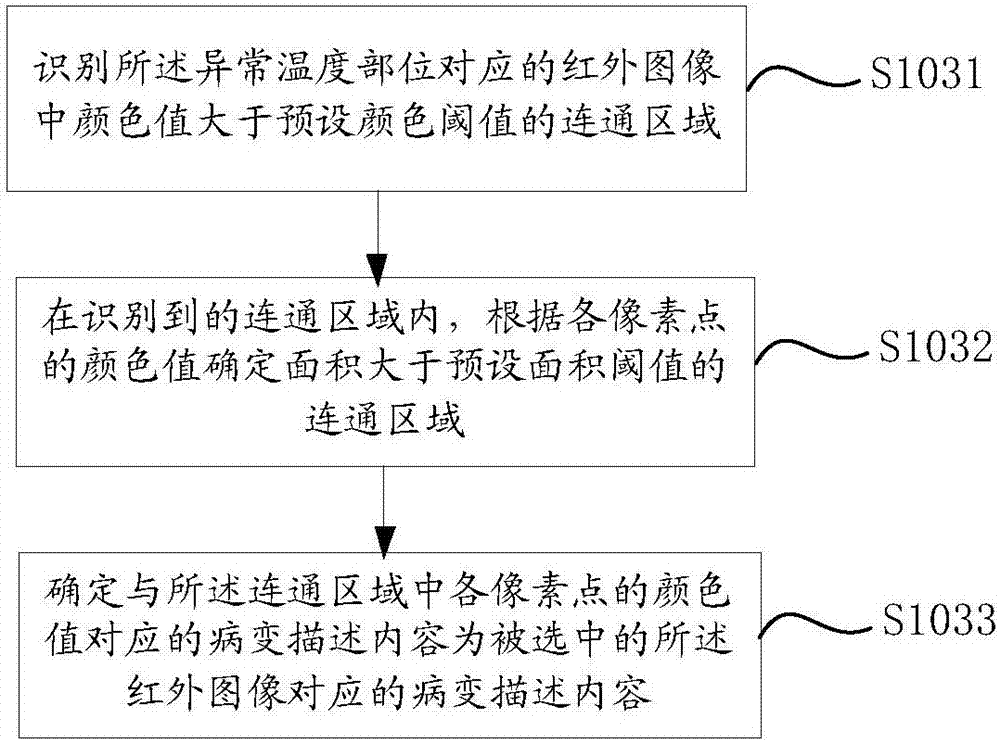

InactiveCN107341797ARealize automatic inputShorten the timeImage enhancementImage analysisComputer visionNerve entrapment

The invention provides an information display method and device and electronic equipment. The method comprises the steps that an infrared image of a human body area is displayed in an infrared thermal imaging frame of a display interface; when a first selection operation is detected, lesion description content corresponding to a chief complaint part is determined in a first preset mode; when a second selection operation is detected, lesion description content corresponding to an abnormal-temperature part is determined in a second preset mode; the chief complaint part, the abnormal-temperature part and the lesion description content are displayed in an assessment area display frame, wherein the lesion description content comprises inflammations, nerve entrapment, automatic nerve disorder and symptoms combined with the clinical; and meanwhile, report content can be given. The purposes of lesion part guide, accurate input of the lesion description content and rapid diagnosis are achieved, popularization is easy, and the technical advantages that the lesion parts and the lesion description content are automatically input, the condition that the lesion parts and the lesion description content are manually input word for word is avoided, and operation is easy are achieved.

Owner:HANGZHOU Y Z MEDICAL TECH CO LTD

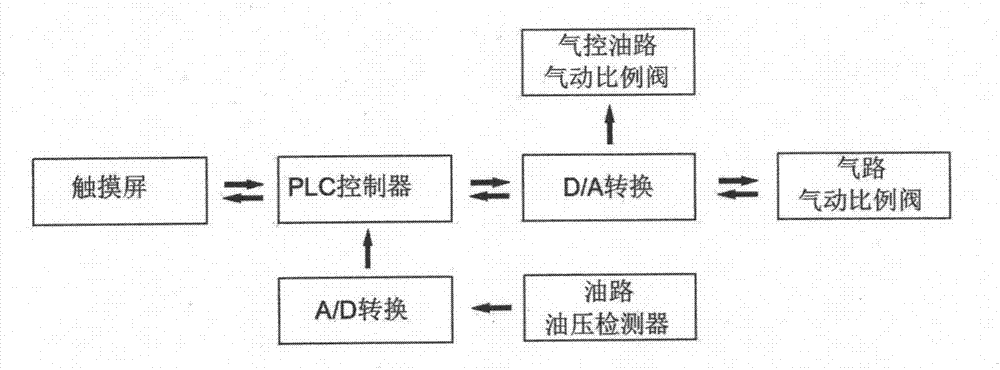

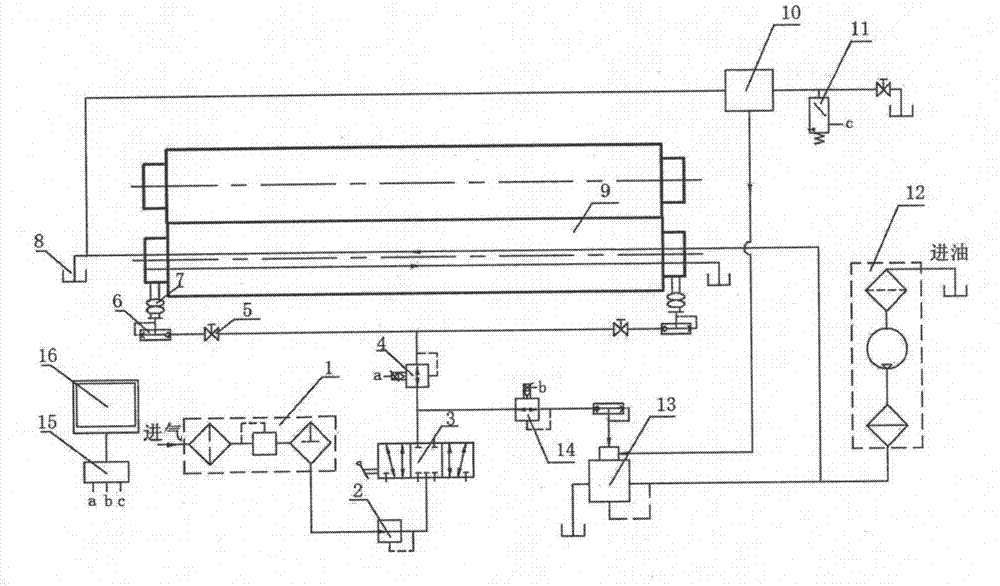

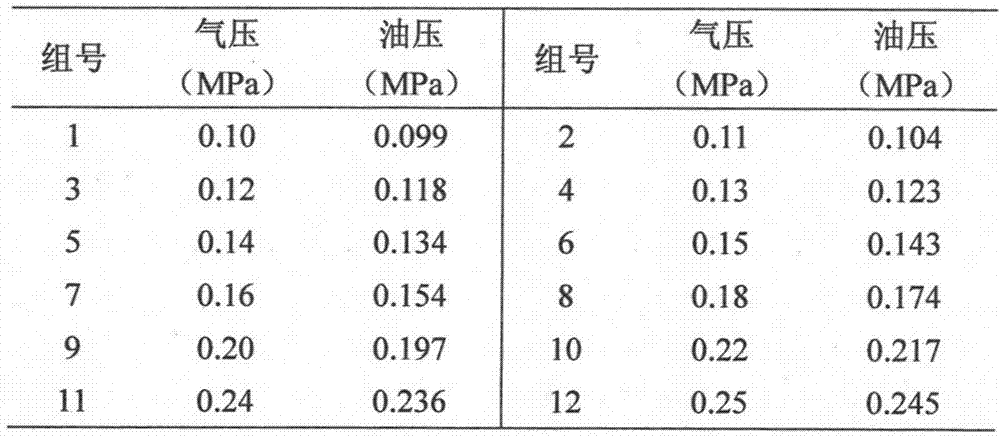

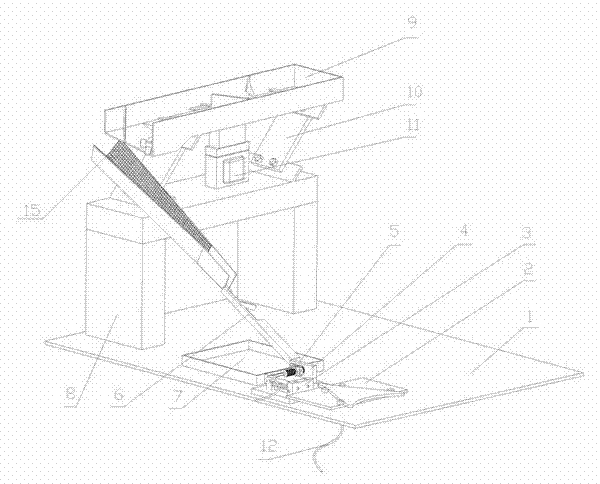

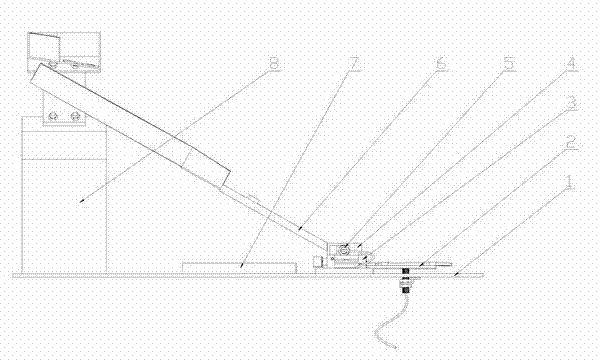

Pressure control system of evenness padder

ActiveCN107475960ASuitable for retrofitThe principle is simpleLiquid/gas/vapor removal by squeezing rollersControl systemAtmospheric pressure

The invention provides a pressure control system of an evenness padder. The system includes an air-channel pneumatic proportional valve, an ail-controlled oil-channel pneumatic proportional valve and an oil-channel oil pressure detector, wherein the air-channel pneumatic proportional valve is arranged on an air channel of the pressure control system of the evenness padder and used for controlling input of air pressure and detecting the air pressure, the ail-controlled oil-channel pneumatic proportional valve is arranged on an air-controlled oil channel of the pressure control system of the evenness padder and used for controlling input of oil pressure, and the oil-channel oil pressure detector is arranged on the oil channel of the pressure control system of the evenness padder and used for detecting the oil pressure value; the air-channel pneumatic proportional valve, the ail-controlled oil-channel pneumatic proportional valve and the oil-channel oil pressure detector are connected with a controller; according to different fabric parameters and the rotation speed of a roller, the controller calculates the air pressure value meeting the requirement of the liquid carry rate, according to a compatibility model, the corresponding oil pressure value is then calculated, and then the open degree of the air-channel pneumatic proportional valve and the open degree of the ail-controlled oil-channel pneumatic proportional valve are adjusted. According to the system, the liquid carry rate of the evenness padder and the rolling liquid uniformity can be accurately controlled, the principle of the system is simple, the structure is compact, the cost is low, the reliability is high, the stability is high, and operation and maintenance are convenient to conduct.

Owner:DONGHUA UNIV

Automatic conveying and screening device for sheet materials

ActiveCN102514943AImprove input efficiencyAvoid stickingStacking articlesJigging conveyorsProcess engineeringMaterial supply

The invention discloses an automatic conveying and screening device for sheet materials, which comprises a sheet material quantity-limiting input mechanism, a status clear-up mechanism, a stacking mechanism, a single output mechanism, wherein the mechanisms are sequentially relevant to each other. The automatic conveying and screening device for sheet materials has the advantages of being simple in structure, easy to arrange, low in cost, high in efficiency, suitable for automatic conveying and screening of various sheet materials and especially suitable for automatic screening material supply of small embedded-block sheets.

Owner:长城汽车股份有限公司平湖分公司

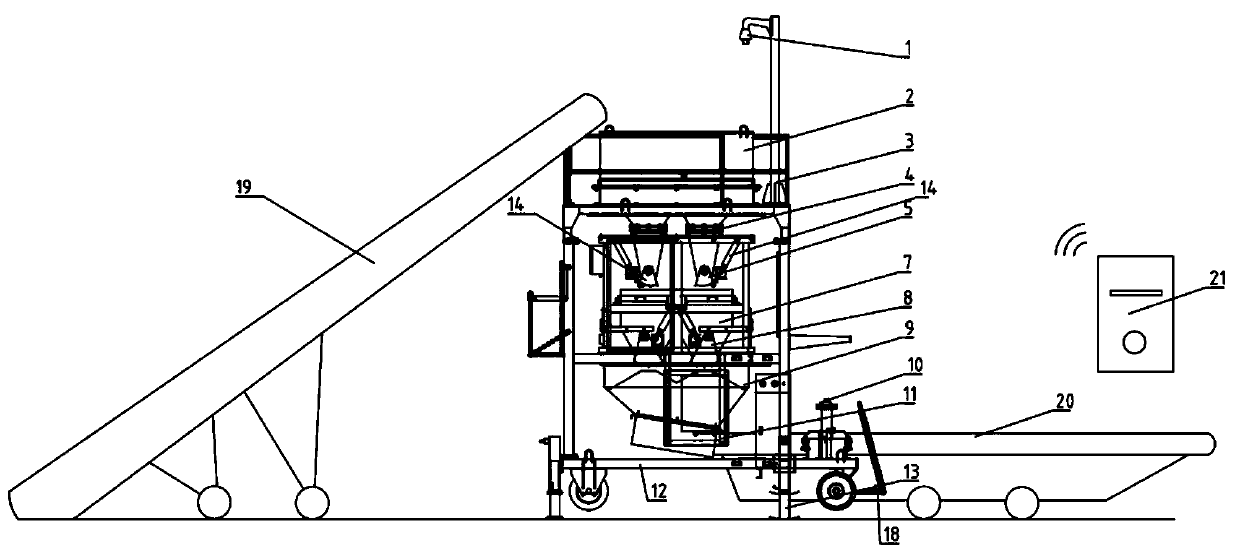

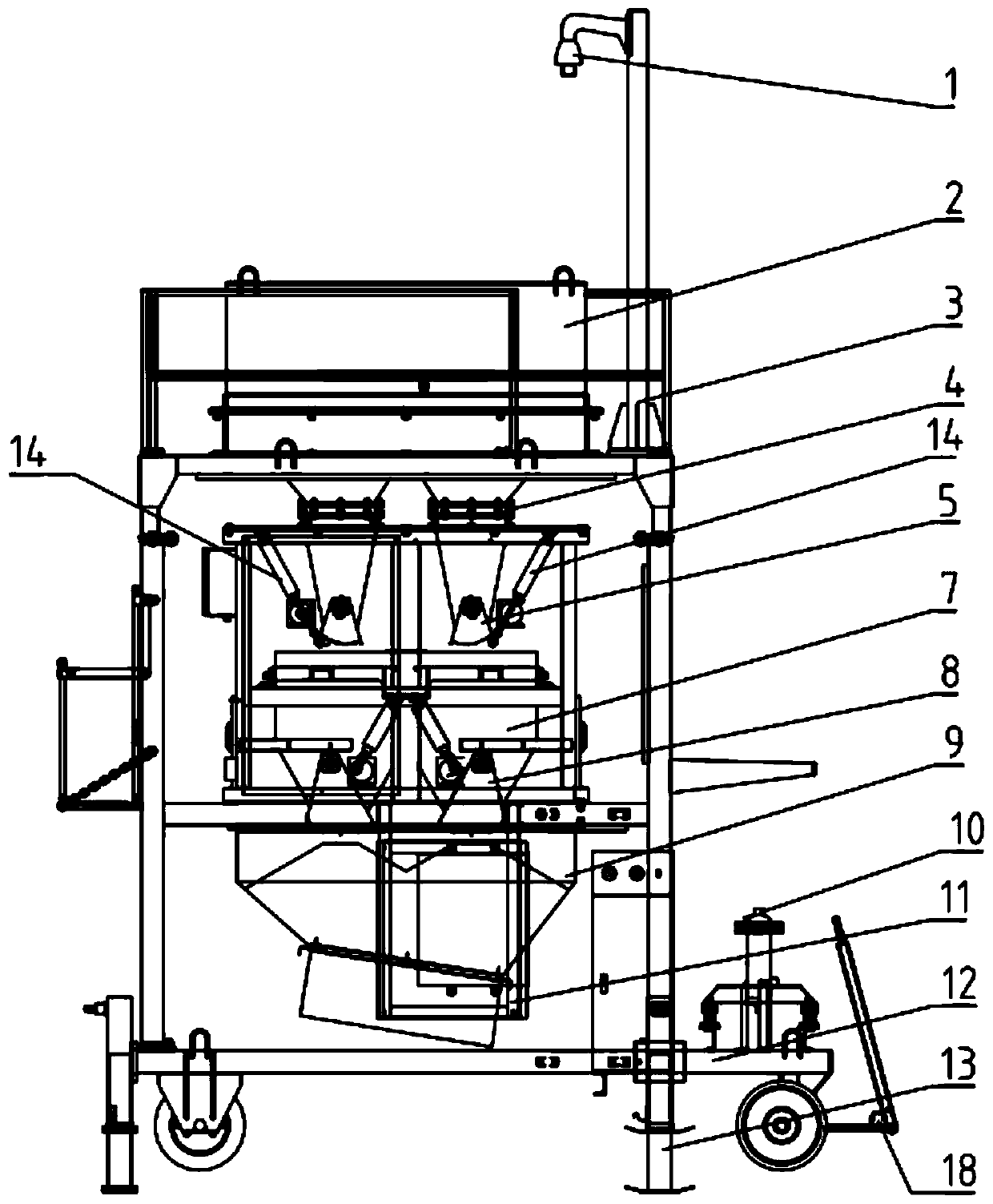

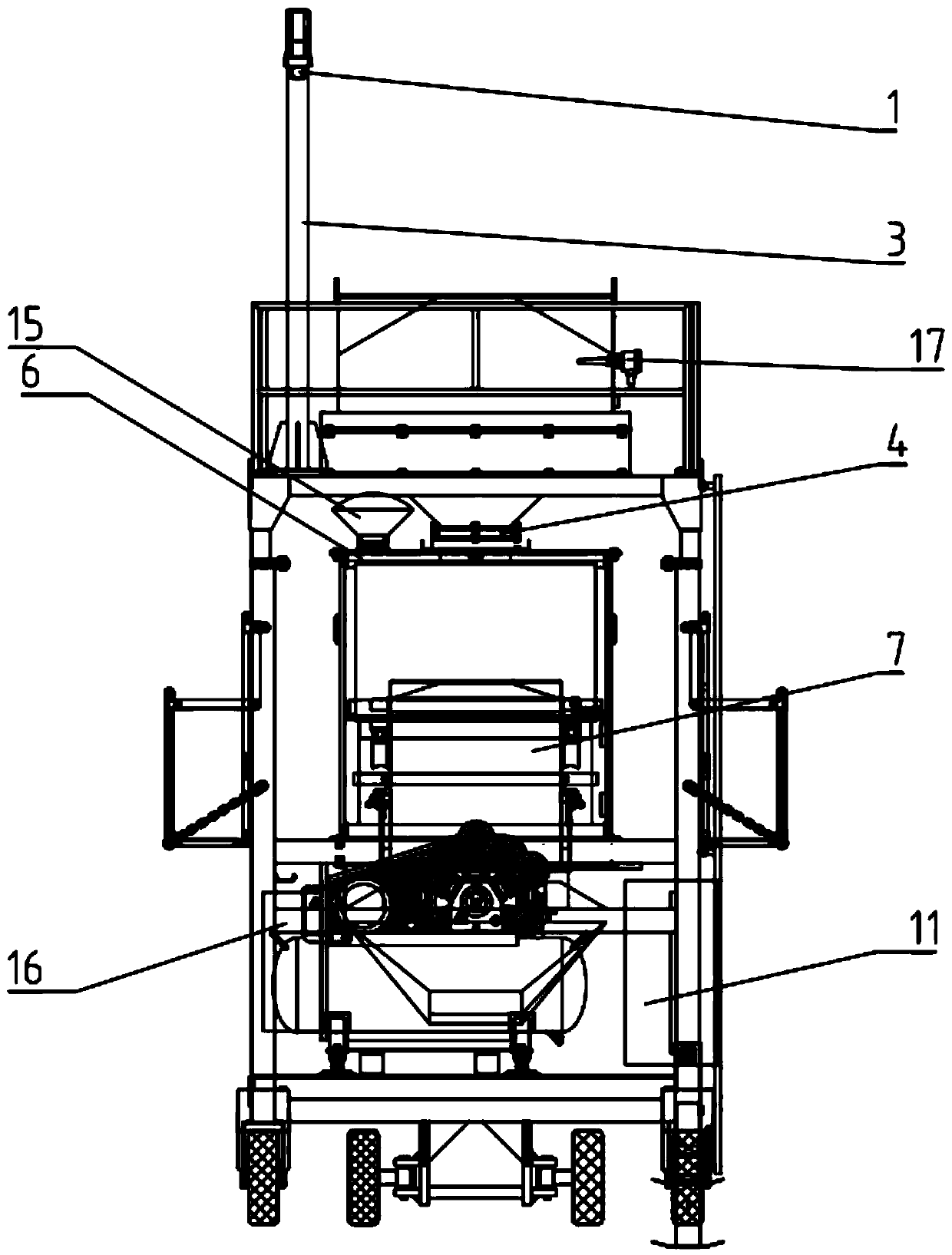

Bulk grain metering weighing system

InactiveCN110174163AImprove management efficiencyRealize automatic controlConveyorsWeighing apparatus for materials with special property/formManagement efficiencyInput/output

The invention discloses a bulk grain metering weighing system. The system comprises an input belt conveyor, a weighing system, a computer server, an output belt conveyor and a video monitoring device;the input belt conveyor conveys the grain to a weighing system, the weighing system is wirelessly connected with the computer server and transmits the weighing data to the computer server; the weighing system outputs the weighed grain through the output belt conveyor; and the video monitoring device is arranged on the weighing system. The combination of the discontinuous accumulative weighing metering and grain conveying of the grain warehouse-inputting and outputting is realized, the grain warehouse input-output transporting, warehouse changing and weighing problems are solved, the quantitative warehouse inputting-outputting, quantitative loading, automatic metering and like functions are realized, and then the data is uploaded to the computer server, the classification group querying and management can be performed on the data, and the management efficiency is improved.

Owner:JINAN JINZHONG ELECTRONICS SCALE

Transfer mechanism for adjusting product positions

ActiveCN105947611AAchieve horizontal inflowSimple structureConveyor partsProduction lineArchitectural engineering

The invention relates to a transfer mechanism for adjusting product positions. A first horizontal fixed plate is mounted between a left side baffle plate and a middle baffle plate; a second horizontal fixed plate is mounted on the right side of the upper end of the left side baffle plate; a horizontal production line is arranged between the middle baffle plate and the right side baffle plate; a horizontal driving device is mounted on the right side of the right side baffle plate; a stop mechanism capable of stopping products is arranged on a support plate at an output end of the horizontal production line; a vertical production line is mounted between the first and second horizontal fixed plates; a vertical driving device is mounted at the lower part of the first horizontal fixed plate; a pressing device capable of pressing the products on the horizontal production line is mounted on the second horizontal fixed plate; a rotating shaft is mounted at the bottom of the support plate through a rotating bracket; and a turnover driving device capable of driving the support plate to rotate around the rotating shaft is mounted at the bottom of the support plate. The horizontal and vertical production lines alternatively act to realize an overturning action of the products by 90 degrees to operate two side surfaces of the products so as to realize automatic input and output of the products.

Owner:BOZHON PRECISION IND TECH CO LTD

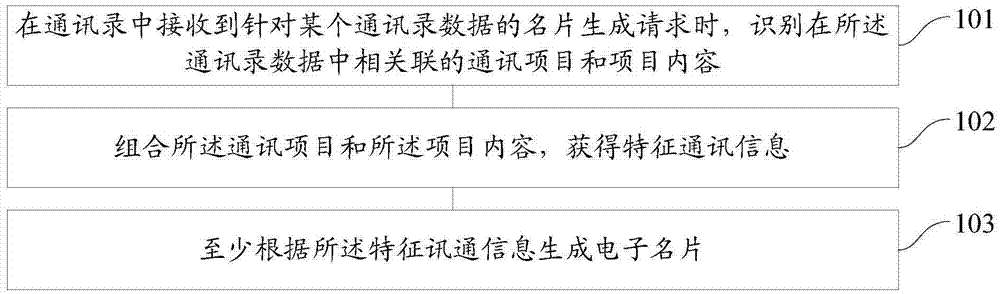

Method of generating electronic business card based on address book, electronic business card inputting method and apparatus thereof

InactiveCN106878357ARealize automatic inputImprove simplicitySubstation equipmentTransmissionFault toleranceAddress book

An embodiment of the invention provides a method of generating an electronic business card based on an address book, an electronic business card inputting method and an apparatus thereof. The method of generating the electronic business card based on the address book comprises the following steps of when a business card generation request aiming at address book data is received in the address book, identifying an associated communication project and a project content in the address book data; combining the communication project and the project content and acquiring characteristic communication information; and generating an electronic business card at least according to the characteristic communication information. In the embodiment of the invention, automatic input of the address book data is realized and manual input is avoided; operation convenience performance is increased, consumed time is reduced, and through matching of the communication project, input fault tolerance is increased; and the methods and the apparatus are suitable for different types of mobile devices and portability is high.

Owner:BEIJING QIHOO TECH CO LTD +1

High-temperature ceramic drying device

InactiveCN104748536AFast dryingDry evenlyDrying gas arrangementsDrying solid materialsAgricultural engineeringMoisture

The invention discloses a high-temperature ceramic drying device. A double-layer high-temperature channel is formed in the upper side, the left side and the right side of a drying chamber, the outer layer of the high-temperature channel is a closed layer, evenly-distributed vent holes are formed in the upper face, the left face and the right face of the inner layer of the high-temperature channel, and the bottom face of the inner layer of the high-temperature channel is a closed layer. The top of the outer layer of the high-temperature channel is connected with a high-temperature heat pump, the bottom of the inner layer of the high-temperature channel is connected with an exhaust fan, an output port of the exhaust fan is connected with a dustproof moisture exhaust box, an output port of the dustproof moisture exhaust box is connected with a high-temperature dehumidifier, and an output port of the high-temperature dehumidifier is connected with the high-temperature heat pump. The high-temperature ceramic drying device has the advantages that the ceramic body drying speed is high, drying is uniform, the drying damage rate is reduced, the quality of products is improved, remaining wind is recycled, energy is saved, environment friendliness is achieved, and the automation degree is high.

Owner:广西北流市红日紫砂陶瓷厂

Automatic overturning equipment for middle groove double-sided welding

ActiveCN108436373AImprove stabilityReduce volumeWelding/cutting auxillary devicesAuxillary welding devicesAutomatic test equipmentControl system

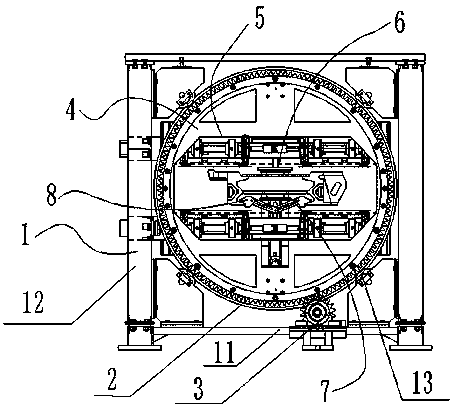

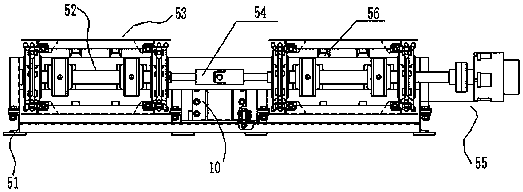

The invention provides automatic overturning equipment for middle groove double-sided welding. The automatic overturning equipment comprises a control system, an overturning mechanism, four conveyingmechanisms, a clamping mechanism and two lifting mechanisms, one pair of the conveying mechanisms are arranged inside the overturning mechanism in an upper and lower opposite manner, the other pair ofthe conveying mechanisms are connected with two opposite ends of the bottom conveying mechanisms inside the overturning mechanism correspondingly, the middle of any one of the conveying mechanisms isan unoccupied portion and two sides of any one of the conveying mechanisms are conveying portions, one of the lifting mechanisms is arranged at the unoccupied portion of one of the conveying mechanisms outside the overturning mechanism, an upper compressing component and a lower compressing component of the clamping mechanism are arranged at the unoccupied portions of the pair of the conveying mechanisms inside the overturning mechanism correspondingly, the control system is in electric connection with power sources of the overturning mechanism, the conveying mechanisms, the clamping mechanism and the lifting mechanisms, and when a large gear ring of the overturning mechanism rotates, two of the conveying mechanisms and the clamping mechanism are driven to rotate simultaneously. By meansof the automatic overturning equipment for middle groove double-sided welding, the efficiency is improved intelligently, the safety factor is improved, the application range is wide, and the stabilityperformance is improved.

Owner:SHANXI FENXI MINING GRP

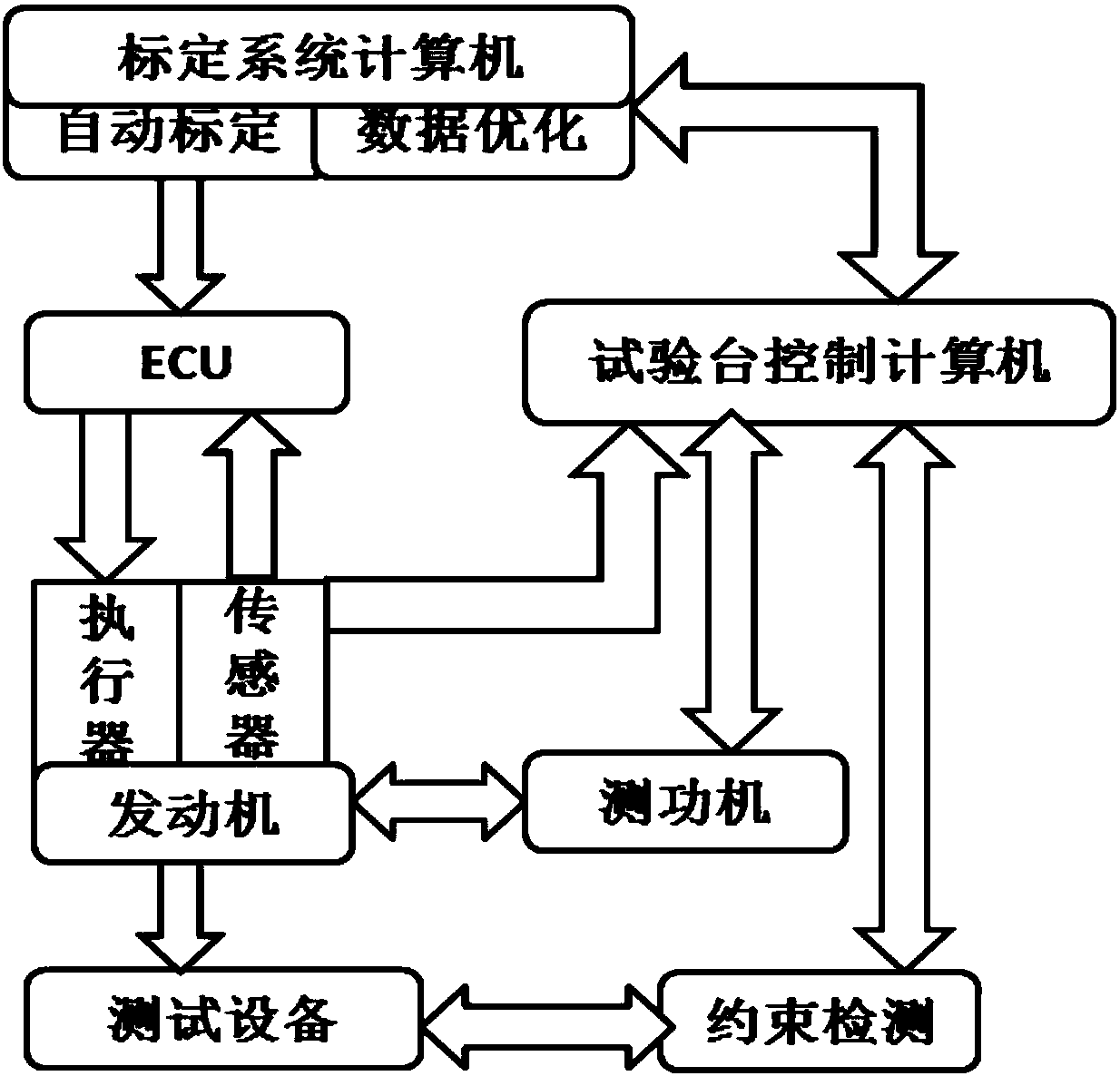

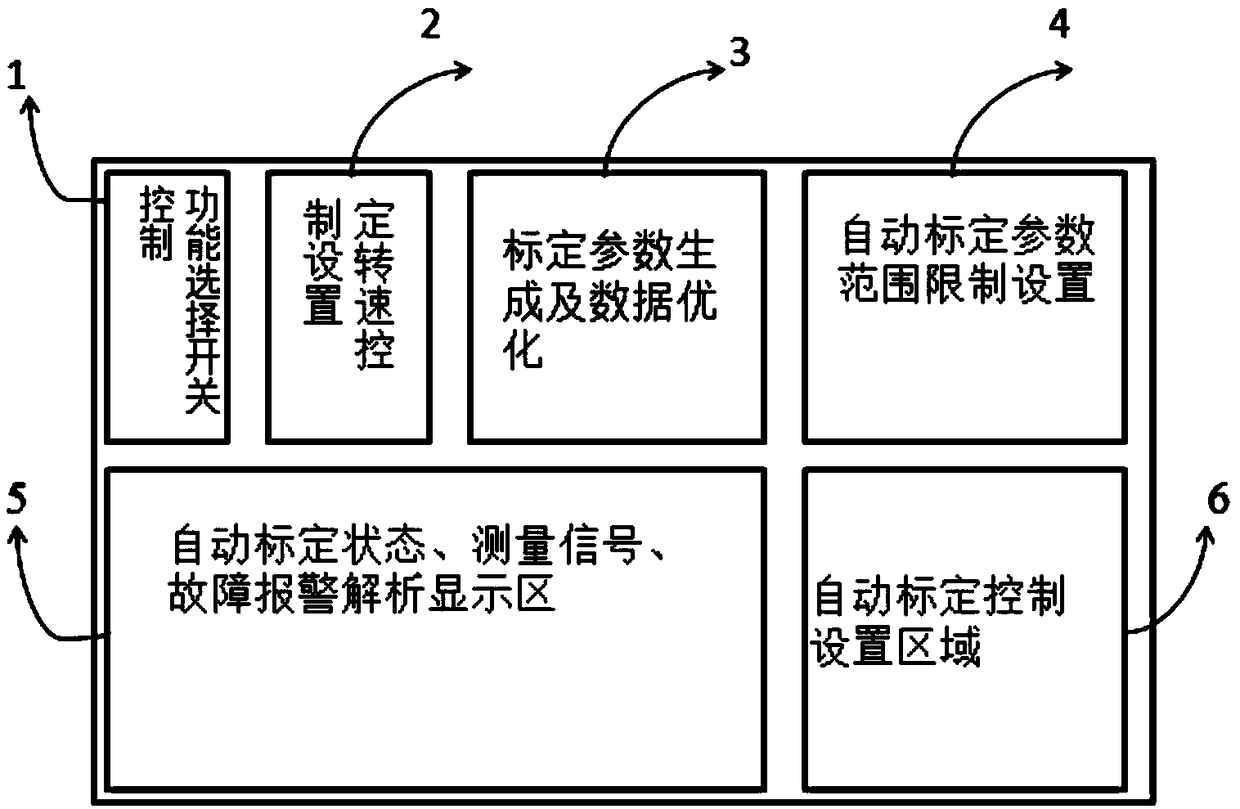

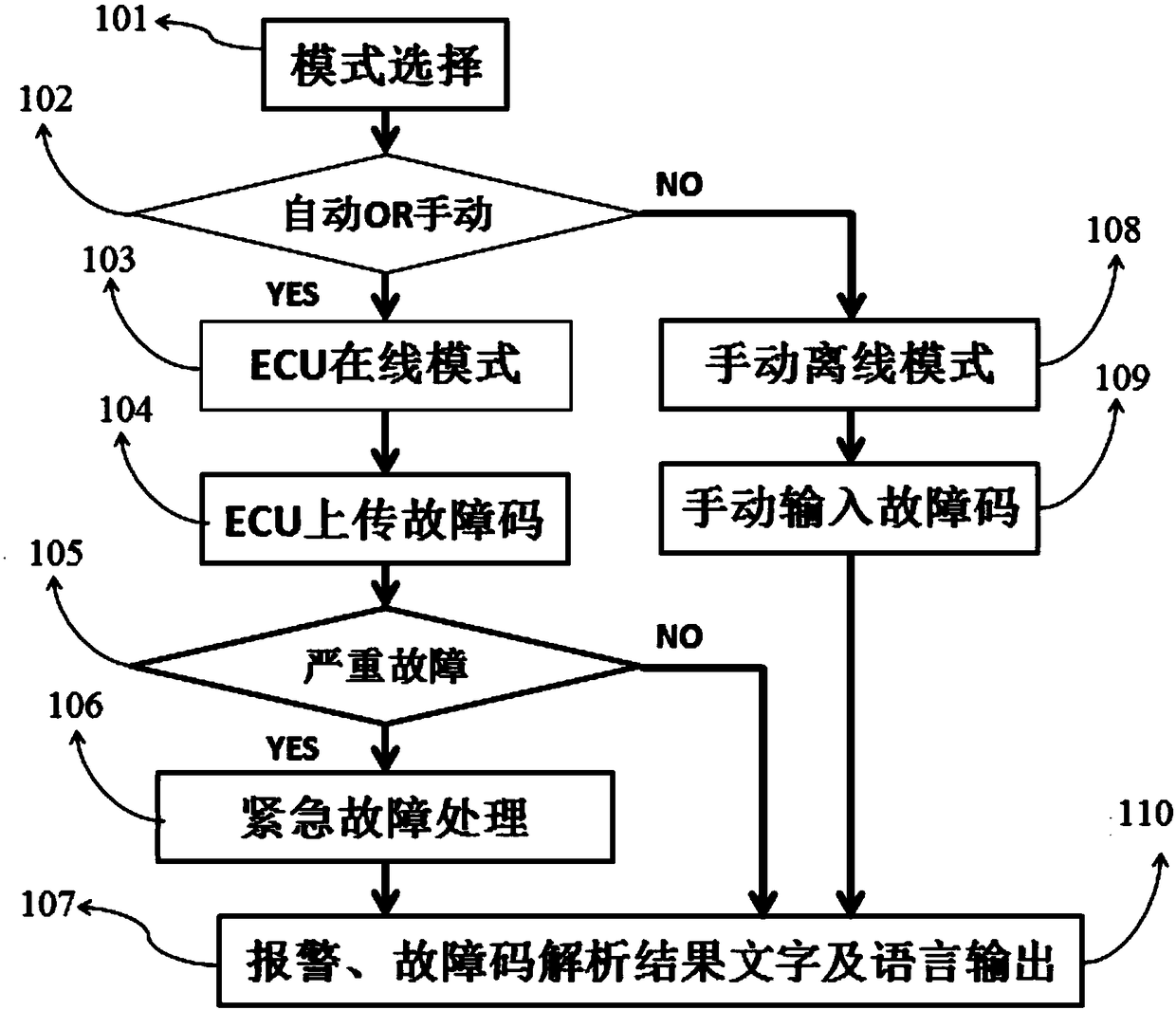

Electric control common rail automatic calibration system

InactiveCN108398937ARealize automatic inputAchieve outputElectric testing/monitoringCommon railComputer module

The invention relates to an electric control common rail automatic calibration system which is characterized by comprising a calibration system computer and a testing stand control computer, wherein an automatic calibration function module and a data optimization processing function module are integrated in the calibration system computer, the calibration system computer is connected with an ECU,automatic input of calibration parameters is realized, automatic recording of ECU calibration data and ECU test parameters can be changed, the ECU is used for controlling an engine through an actuatorand a sensor; the testing stand control computer is connected to the engine through a dynamometer and a test device so as to control operating conditions of the engine and collect engine emission data, the emission data is input into the calibration system computer, the calibration data is subjected to optimization processing operation via the data optimization processing function module, and optimization data can be obtained. Convenient and accurate data recording, flexible and convenient control, calibrating efficiency improvement, and reduction of tedious parameter control and data recording work of calibration workers are enabled via the system disclosed in the invention.

Owner:CHINA FIRST AUTOMOBILE

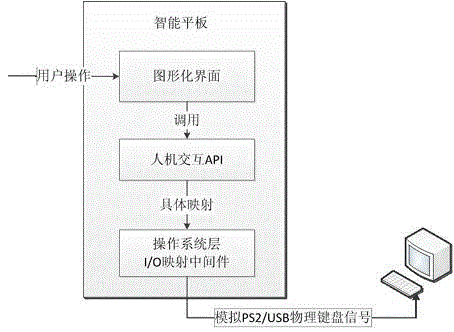

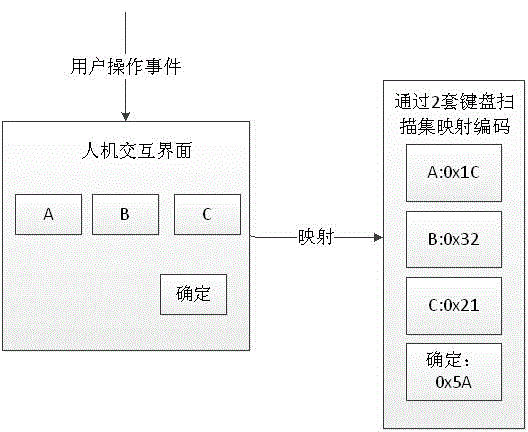

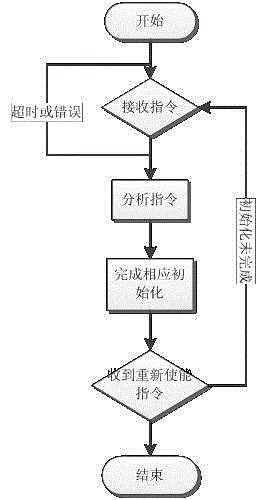

Drive-free quick response input device based on intelligent tablet computer

ActiveCN103605427AFlexible input meansInteractive mode is friendlyInput/output processes for data processingMiddlewareEmbedded system

The invention discloses a drive-free quick response input device based on an intelligent tablet computer and a method for connecting an Android tablet computer as a ps2 general keyboard into a computer system. The device and the method are used for solving the problem that the existing scheme utilizing an intelligent tablet computer system as an input device is low in response speed, the effect of plug and play cannot be achieved in a first-time use process, and large intelligent devices are often free of a wireless network accessing function. The device comprises a graphic interface, a human-computer interaction application program interface (API) and an input / output (I / O) mapping middle piece. The effect that an android embedded device is connected into the computer as a ps2 keyboard is achieved by adding a simple hardware circuit and combining corresponding software, so that relevant requirements of the large intelligent devices for flexible input means, friendly interaction modes, high response speed and good universality of the input device are met.

Owner:徐杨

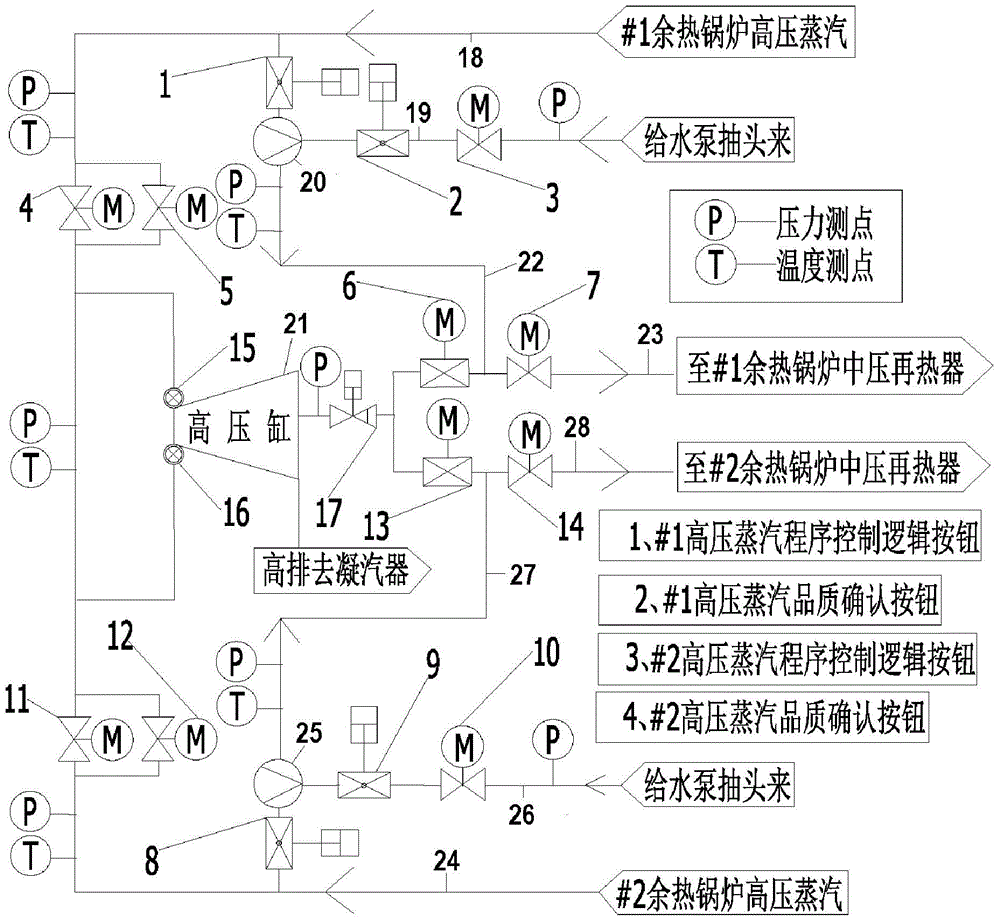

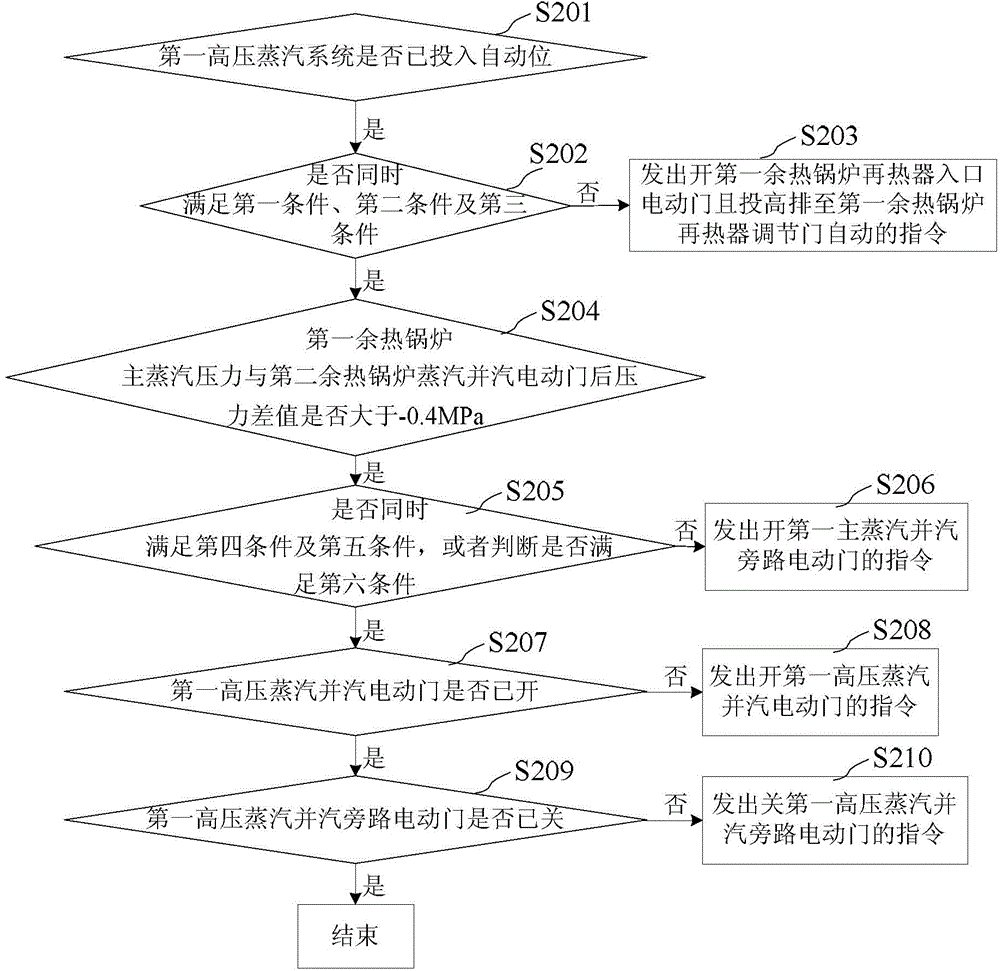

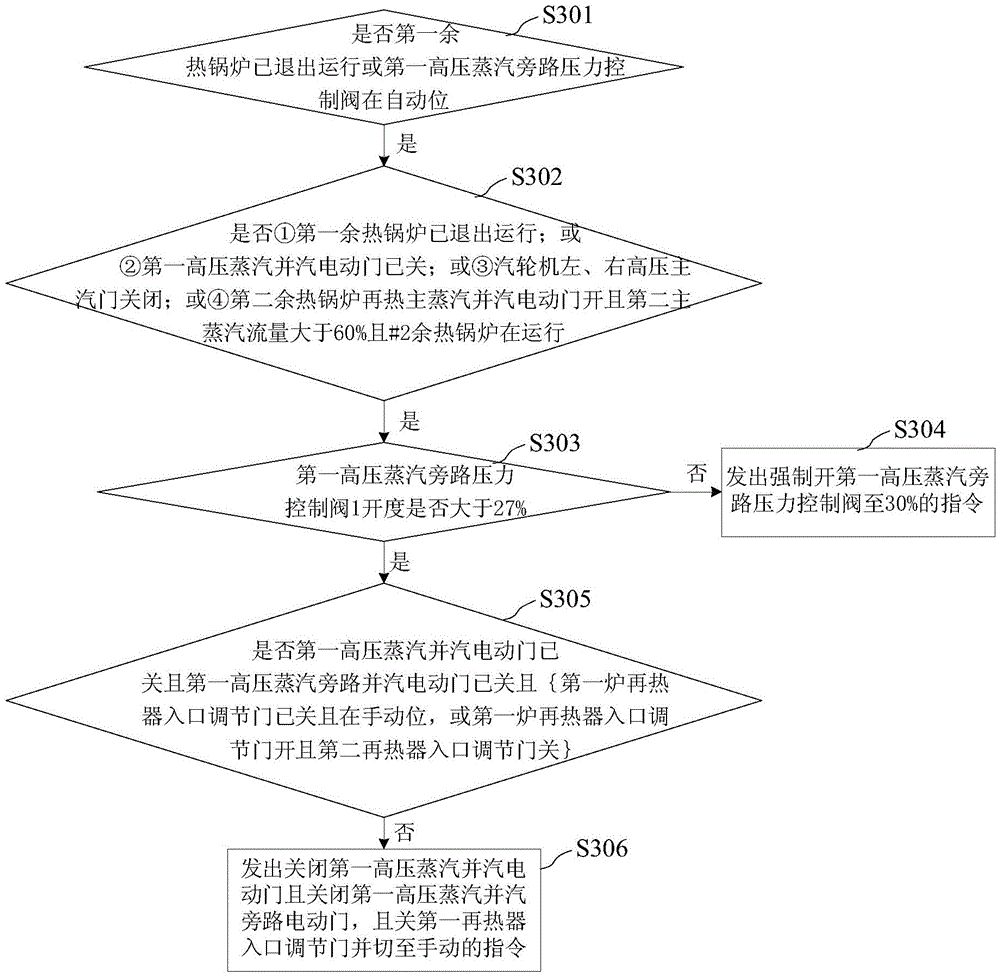

High-pressure steam system for two-pull-one unit of fuel gas thermal power plant and start-stop control method of high-pressure steam system

ActiveCN104696940ARealize automatic inputRealize automatic mergingBoiler controlSteam generation plantsStart stopEngineering

The invention relates to a high-pressure steam system for a two-pull-one unit of a fuel gas thermal power plant and a start-stop control method of the high-pressure steam system. The high-pressure steam system comprises a first high-pressure steam system, a second high-pressure steam system and a steam turbine high-pressure cylinder, wherein the first high-pressure steam system comprises a first high-pressure steam pipeline, a first high-pressure steam converging electric door, a first high-pressure steam converging bypass electric door, a first high-pressure bypass control valve, a first high side temperature-reducing water pipeline, a first high side temperature-reducing water regulating valve and a first high side temperature-reducing water electric valve; the second high-pressure steam system comprises a second high-pressure steam pipeline, a second high-pressure steam converging electric door, a second high-pressure steam converging bypass electric door, a second high-pressure bypass control valve, a second high side temperature-reducing water pipeline, a second high side temperature-reducing water regulating valve and a second high side temperature-reducing water electric valve. According to the invention, automatic investment can be realized in the steam withdrawing state of the medium-pressure steam system on the side; in the investment state, automatic steam withdrawing or automatic steam converging of the medium-pressure steam system on the side is realized.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

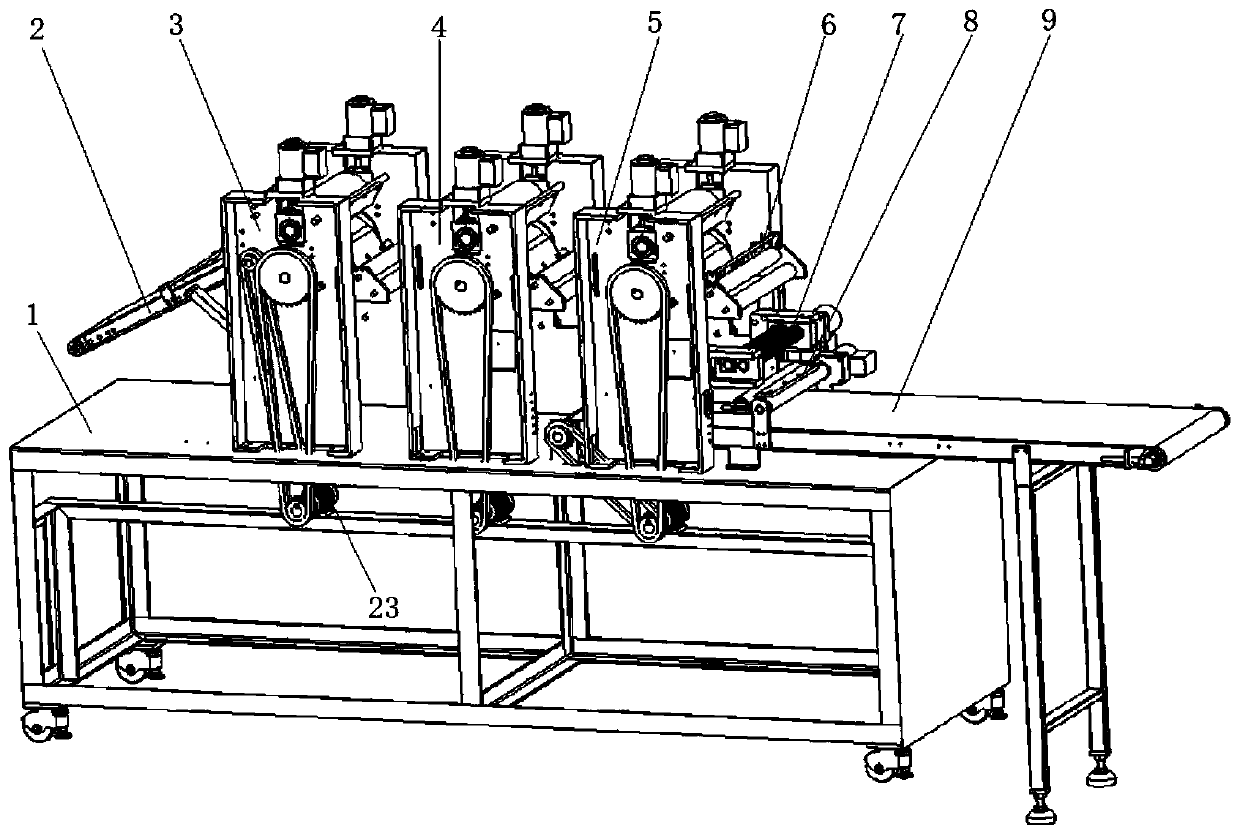

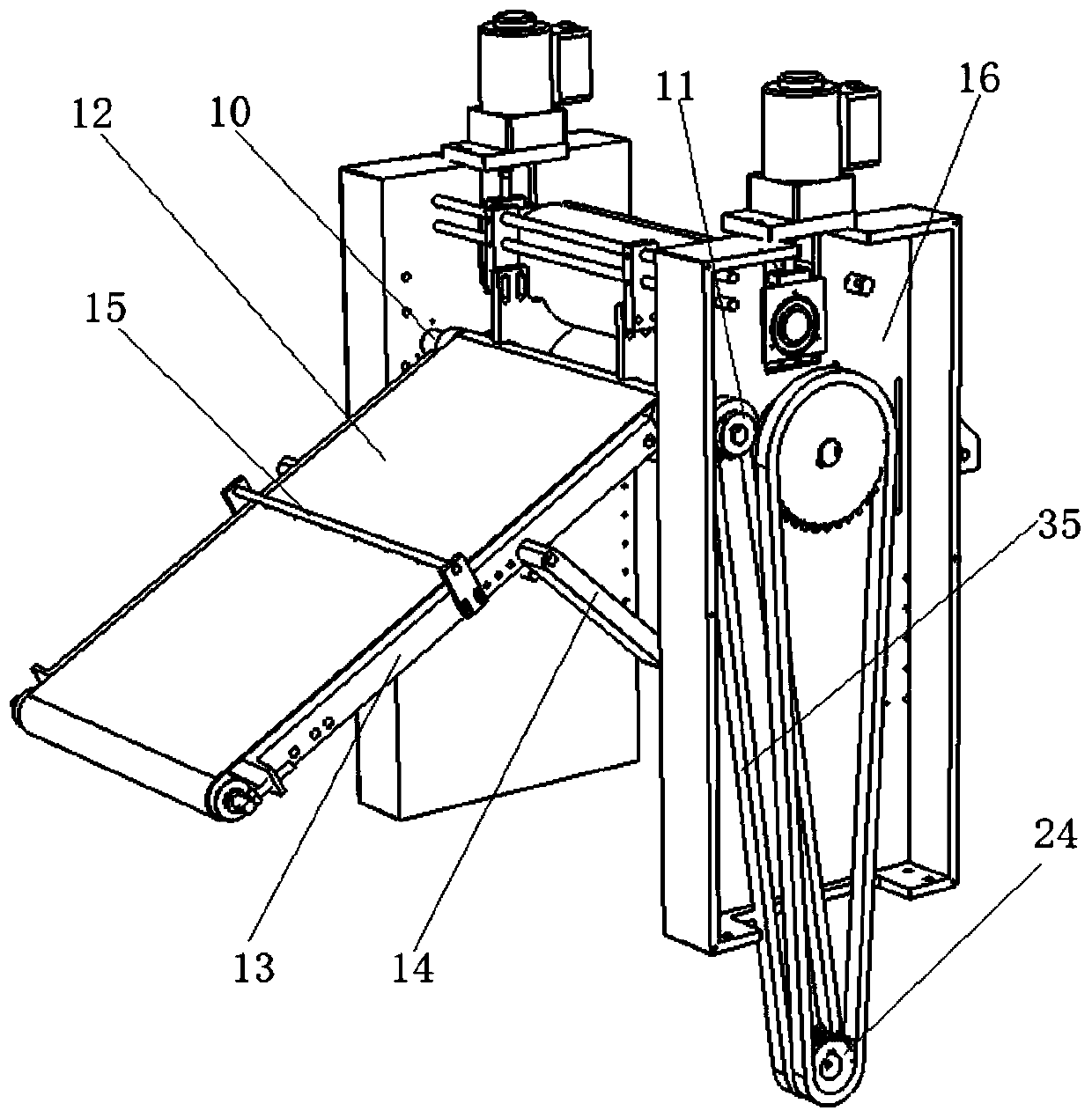

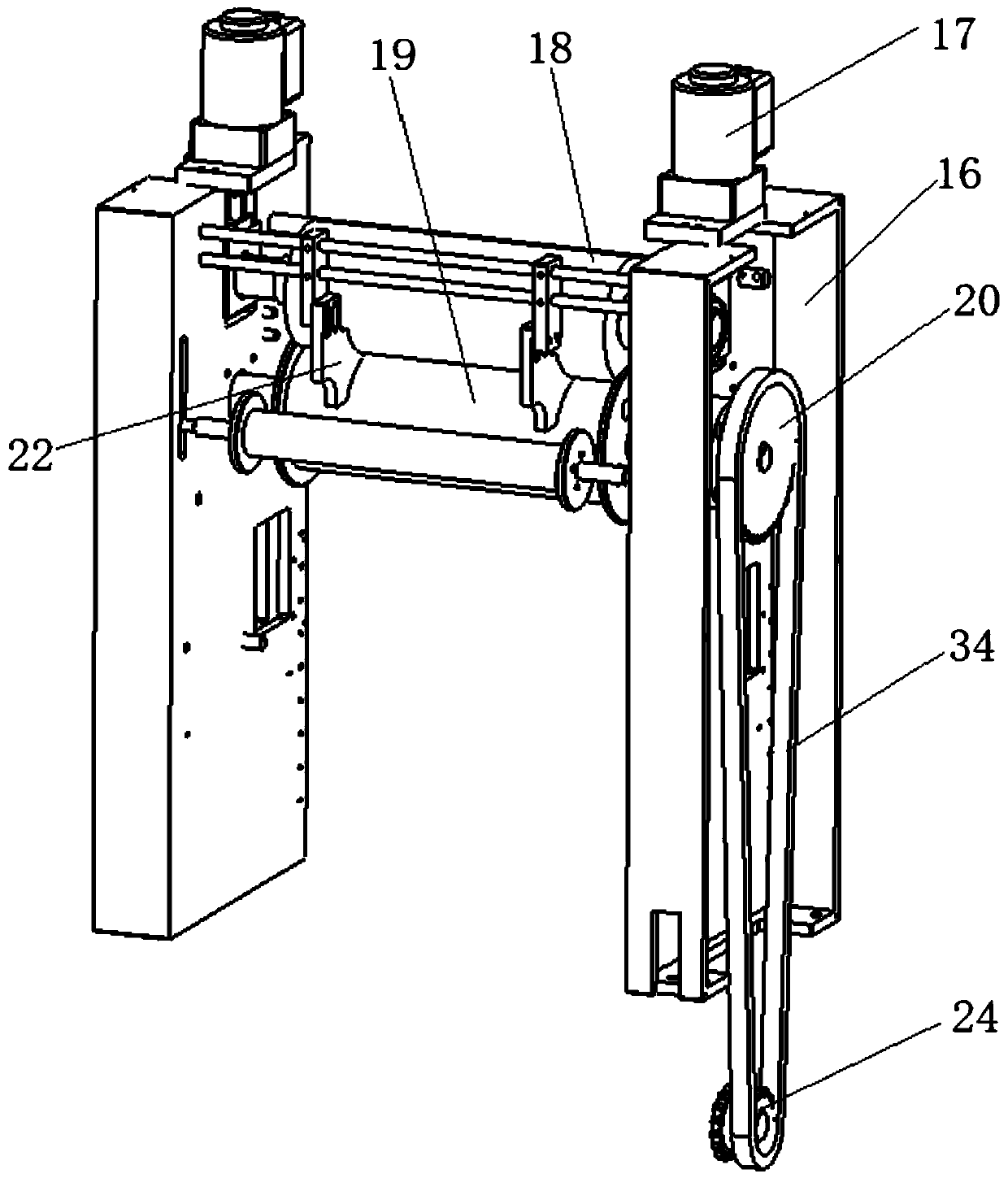

Automatic forming production device for fresh wet noodles

PendingCN110583724AImprove production efficiencyReal-time detection of thicknessDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusModular designEngineering

The invention discloses an automatic forming production device for fresh wet noodles and relates to the technical field of noodle production equipment. The device comprises a rack, a dough strip conveying assembly is arranged at the front end of the upper side of the rack, one end of the dough strip conveying assembly is connected with a first-stage calender, a second-stage calender is arranged onone side of the first-stage calender, a third-stage calender is arranged on one side of the second-stage calender, a thickness measuring assembly is connected to one side of the third-stage calender,a dough cutter assembly is arranged below the thickness measuring assembly, a cut-off assembly is arranged below the dough cutter assembly, and a conveying belt assembly is arranged on one side belowthe cut-off assembly. The device can automatically produce fresh wet noodles, has high production efficiency and is convenient to maintain due to modular design.

Owner:WUHAN POLYTECHNIC UNIVERSITY

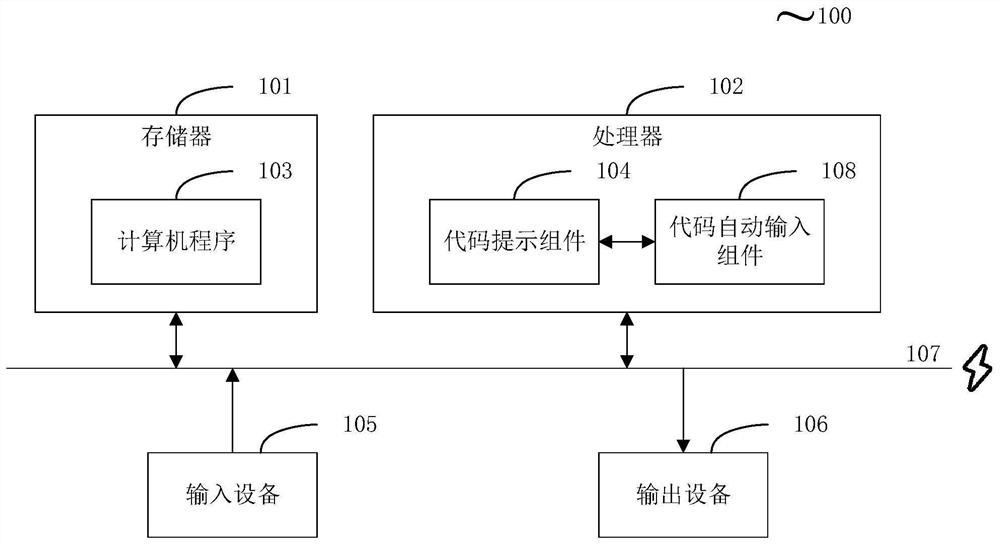

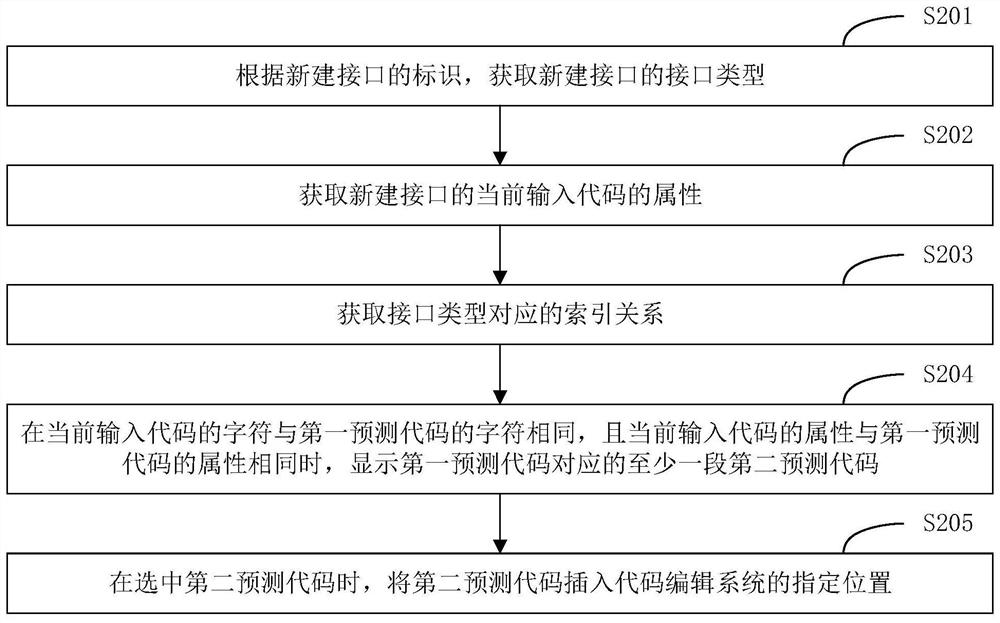

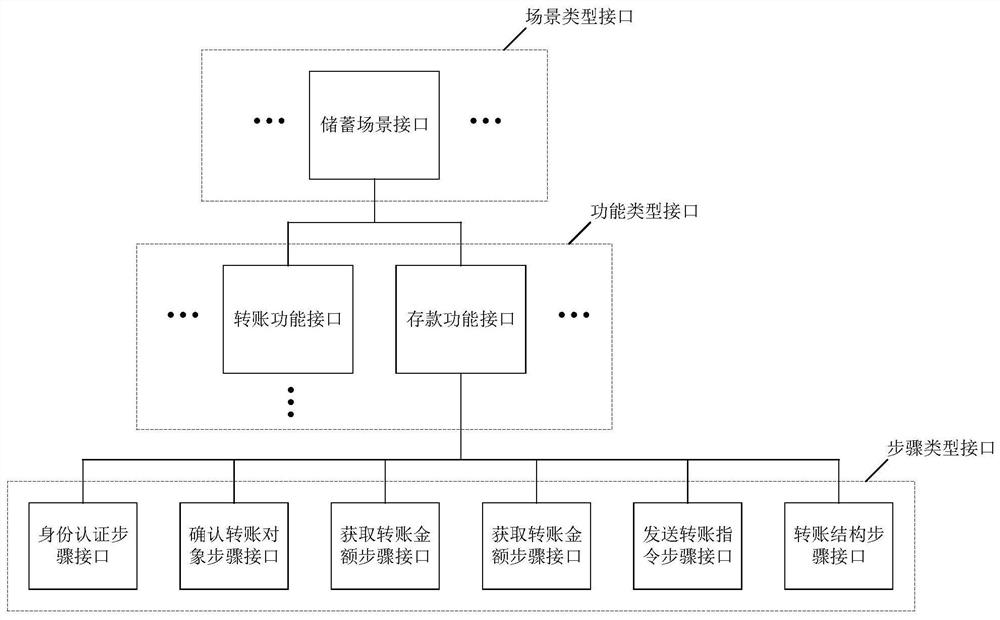

Code generation method based on machine learning, code editing system and storage medium

ActiveCN113805861AImprove intelligenceImprove coding efficiencySoftware testing/debuggingMachine learningCode generationTest efficiency

The invention is suitable for the technical field of artificial intelligence, and provides a code generation method based on machine learning, a code editing system and a storage medium. According to the code generation method, the interface type of the new interface is obtained through the code editing system, the index relation corresponding to the interface type is obtained, the prediction code which is usually matched with the current input code for use is predicted through the index relation, and the prediction code can be inserted in a specified position, high-correlation code prediction and automatic input are realized, so that the workload of a developer for writing the same code in different test cases is reduced, the writing efficiency of the test cases is improved, and the code test efficiency is further improved.

Owner:PING AN BANK CO LTD

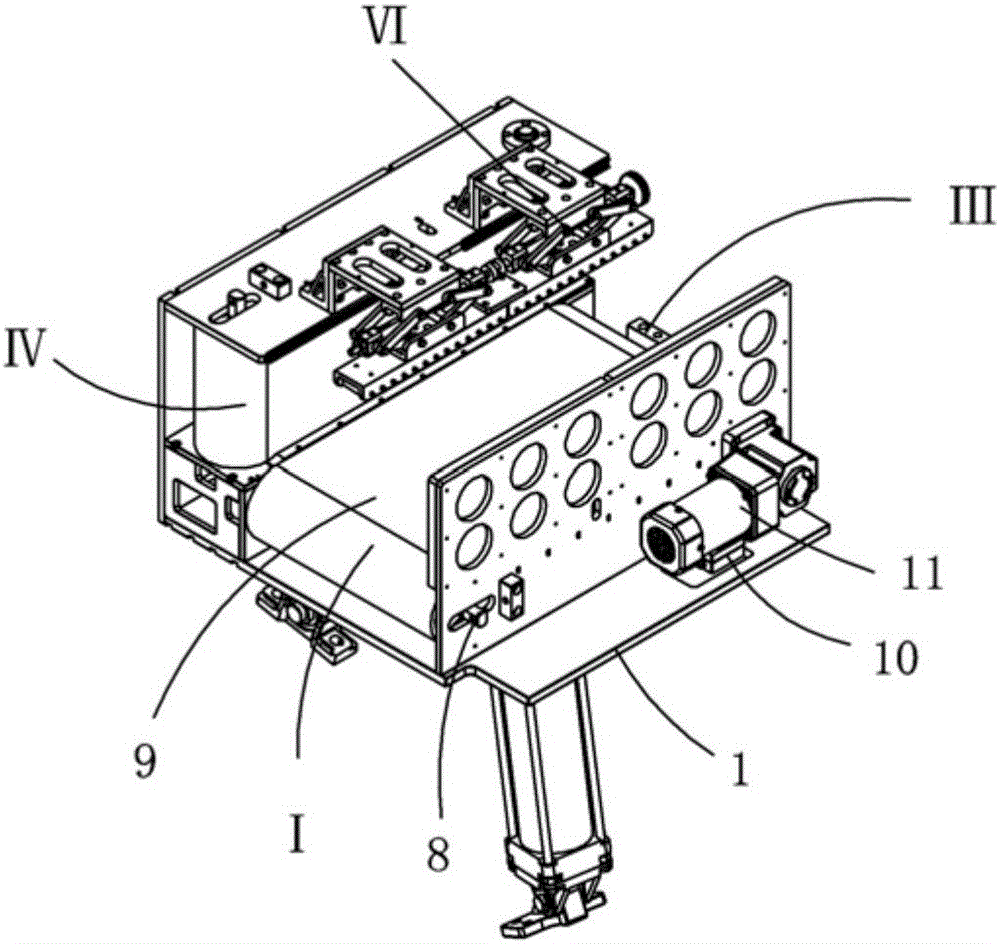

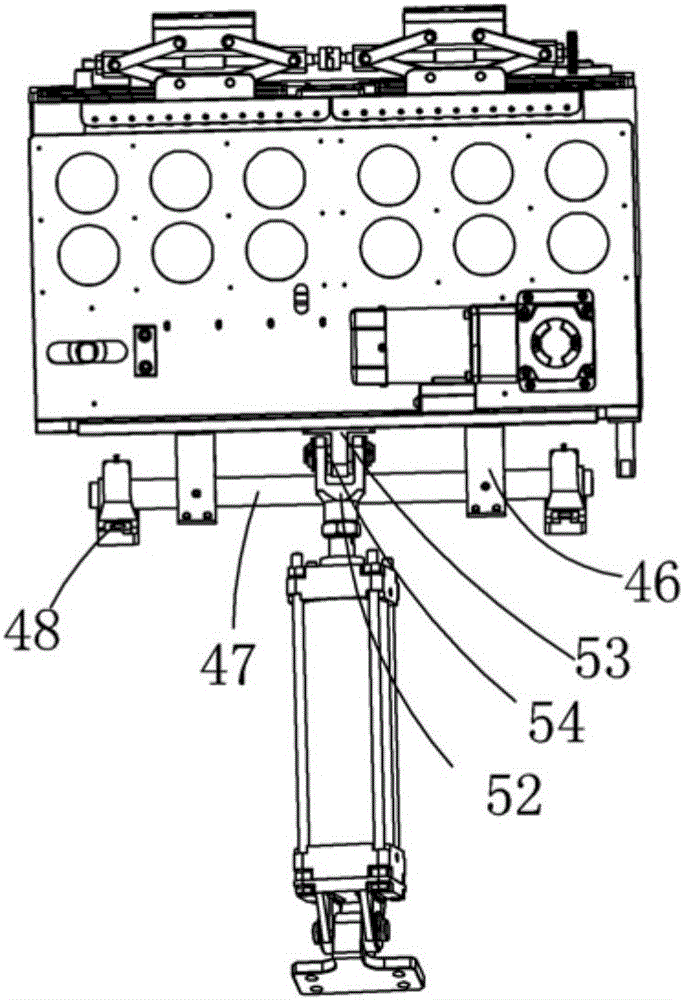

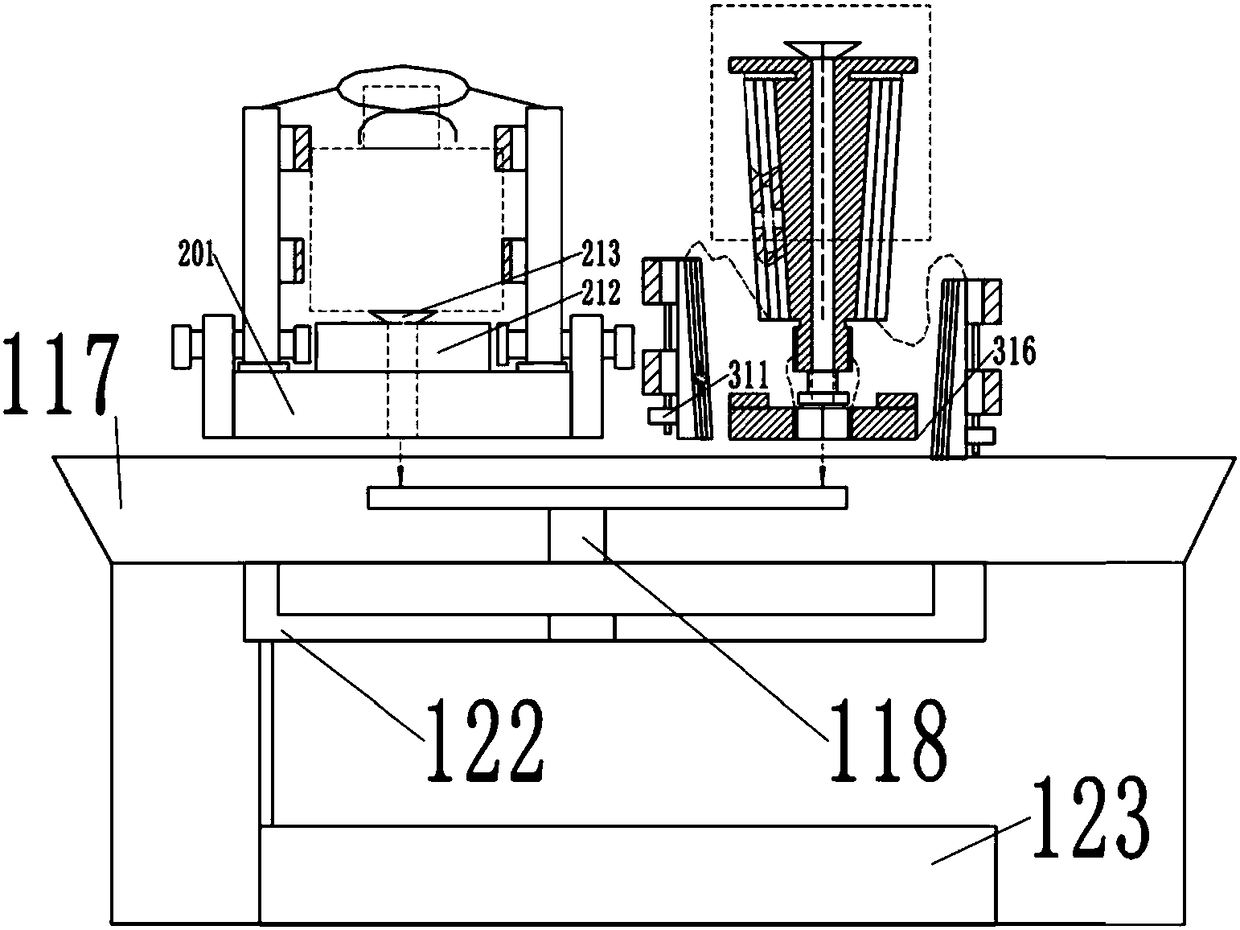

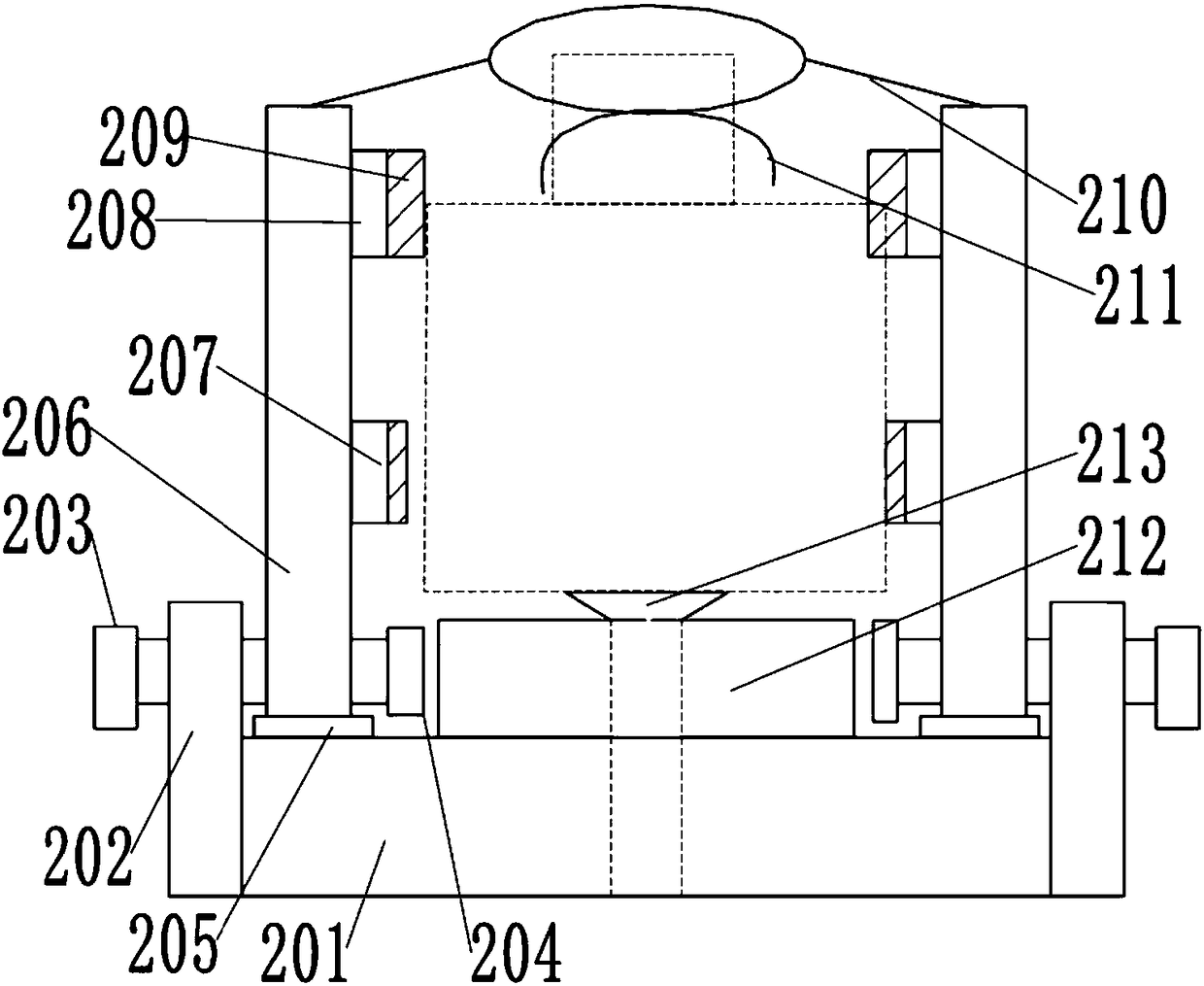

Rotary body container processing center

InactiveCN108311969AAvoid shakingGrinding high speedRevolution surface grinding machinesGrinding work supportsEngineeringOutput device

The invention relates to a rotary body container processing center. The rotary body container processing center comprises a frame, a welding device arranged on the frame, an input device arranged on the left side of the frame and an output device arranged on the right side of the frame. An input manipulator is arranged between the input device and the frame, a discharging manipulator is arranged between the output device and the frame, and the input manipulator and the discharging manipulator are of the same structure. The welding device comprises a rotary processing machine head arranged above the frame, a working head arranged on the rotary processing machine head, a grinding disc arranged at the lower end of the working head and used for grinding a container, a processing table-board arranged below the grinding disc, a rotary station workbench arranged at the middle part of the processing table-board and positioned below the grinding disc, an inner cavity grinding station arranged on the rotary station workbench and used for sucking the outer bottom of the container under the negative pressure and an outer wall grinding station arranged on the rotary station workbench and used for sucking the bottom of the inner cavity of the container under the negative pressure. The rotary body container processing center is reasonable in design, compact in structure and convenient to use.

Owner:WENZHOU UNIV OUJIANG COLLEGE

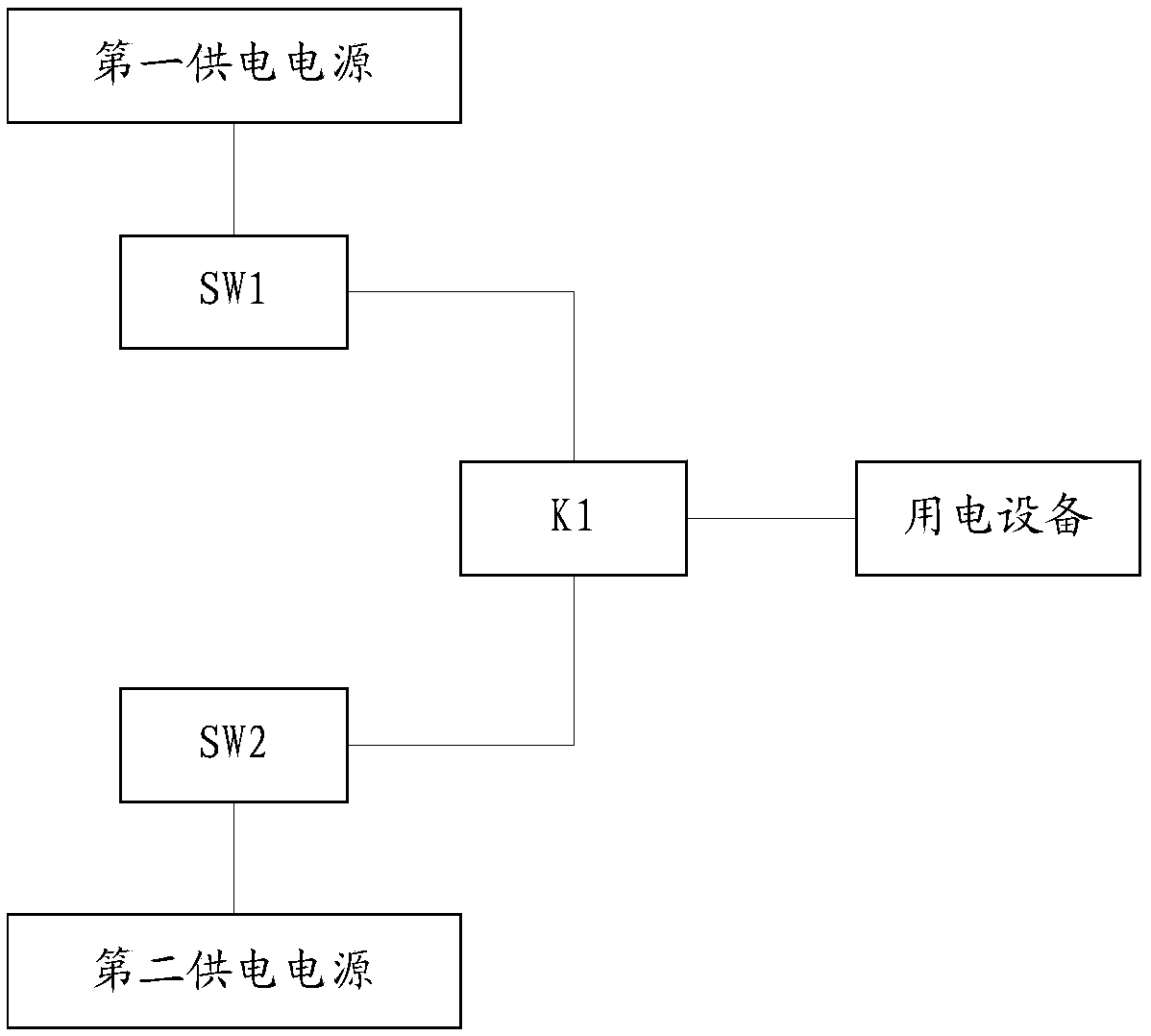

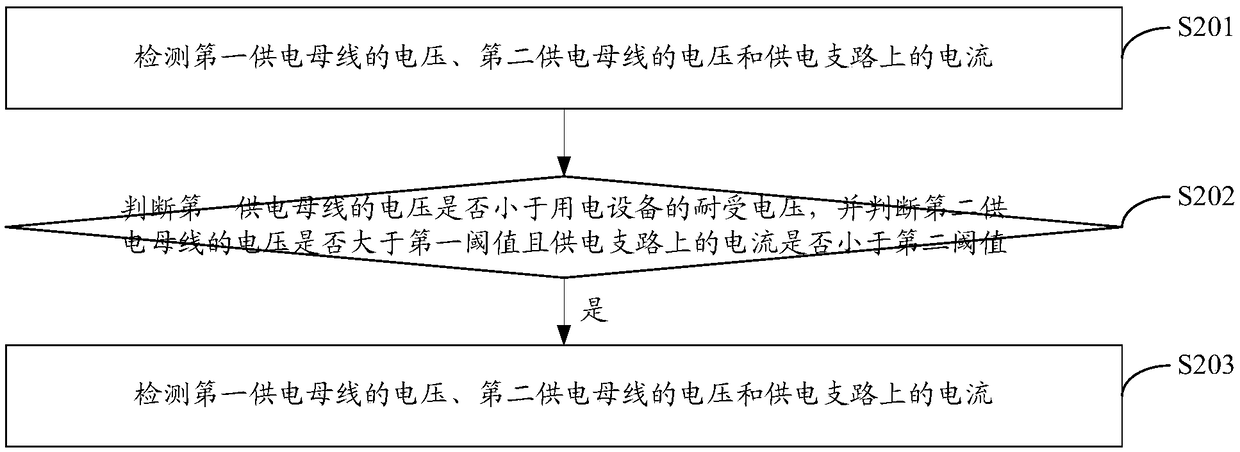

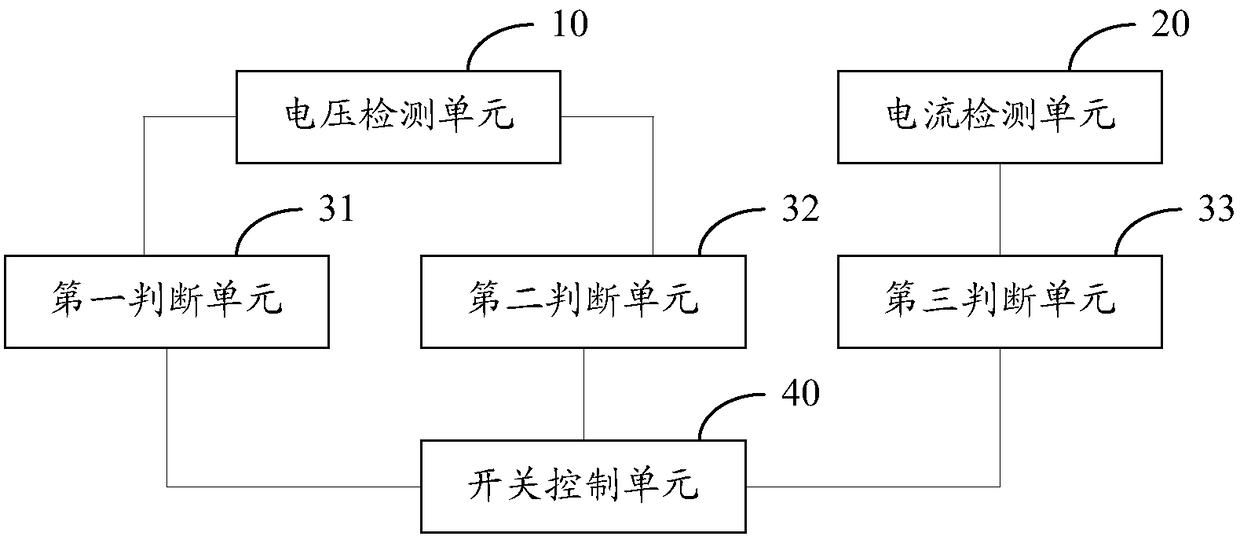

Backup power supply switch-in method and device

ActiveCN109412256AGuaranteed to workRealize automatic inputPower network operation systems integrationInformation technology support systemPower flowLow voltage

The invention discloses a backup power supply switch-in method and device, and the method and device are applied to power supply loops of high-voltage equipment. The method comprises the steps of: detecting voltage of a first power supply bus, voltage of a second power supply bus and current on a power supply branch; when a first branch switch and a first bus switch are switched on and a second branch switch and a second bus switch are switched off, judging whether the voltage of the first power supply bus is smaller than withstand voltage of electric equipment or not, whether the voltage of the second power supply bus is greater than a first threshold value or not and whether the current on the power supply branch is smaller than a second threshold value or not; when the voltage of the first power supply bus is smaller than the withstand voltage, if the voltage of the second power supply bus is greater than the first threshold value and the current on the power supply branch is smaller than the second threshold value, switching off the first branch switch and the first bus switch; and switching on the second bus switch and the first branch switch. According to the method and device, automatic switch-in of backup power supplies is realized, the electric equipment is prevented from halt due to too low voltage of the power supplies, and continuous power supply requirements of chemical enterprises are satisfied.

Owner:CHINA COAL ORDOS ENERGY CHEM COP LTD

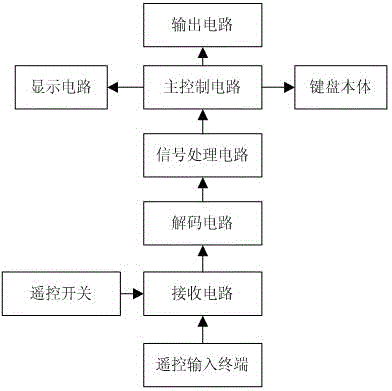

Input control system for computer keyboard

InactiveCN105068666AAdd character input methodFlexible and efficient to useInput/output for user-computer interactionKey pressingSignal processing circuits

The invention discloses an input control system for a computer keyboard. The system comprises: a remote control input terminal used for inputting a key character, encoding the key character into a remote control signal and sending the remote control signal; a keyboard body comprising a keyboard array and a control mechanism, wherein the control mechanism comprises a remote control switch, a receiving circuit, a decoding circuit, a signal processing circuit, a main control circuit and an output circuit; the remote control switch used for a working state; the receiving circuit used for receiving the remote control signal; the decoding circuit used for decoding the received remote control signal to obtain a digital signal; the signal processing circuit used for performing filtration processing on the digital signal; the main control circuit used for analyzing the digital signal to obtain the key character and generating a character instruction according to the key character; and the output circuit used for executing the character instruction to output the character. According to the system, a character input mode of the computer keyboard is added, so that the computer keyboard is more flexible and efficient to use.

Owner:WUXI EPIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com