Rotary body container processing center

A machining center and rotary body technology, applied in metal processing equipment, manufacturing tools, grinding workpiece supports, etc., can solve the problems of rough surface of crystal glass ornaments, high labor intensity of workers, and limited processing capacity, so as to improve grinding efficiency and Quality, compactness and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

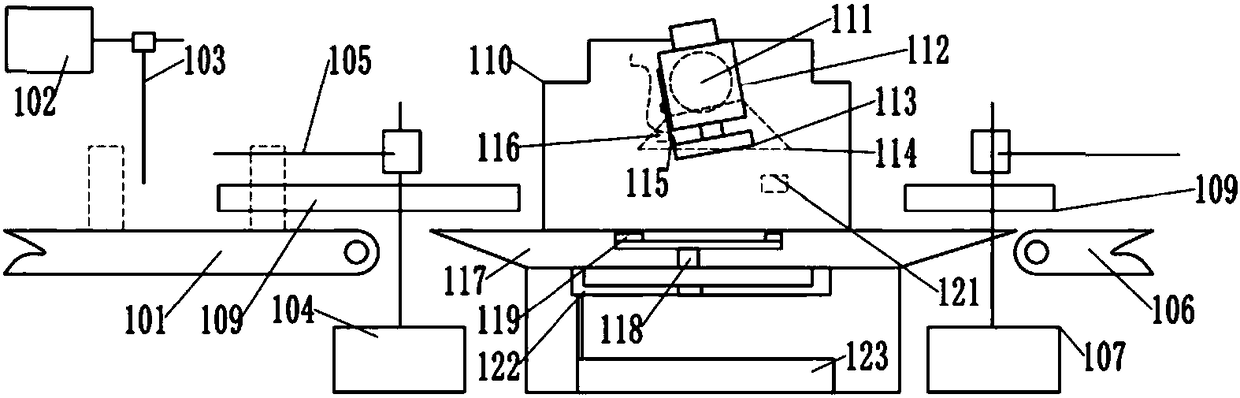

[0047] Such as Figure 1-4 As shown, the rotary container processing center of this embodiment includes a frame 110, a welding device arranged on the frame 110, an input device arranged on the left side of the frame 110, and an output device arranged on the right side of the frame 110 ;

[0048] An input manipulator is provided between the input device and the frame 110, and a discharge manipulator 107 is provided between the output device and the frame 110. The input manipulator and the discharge manipulator 107 have the same structure;

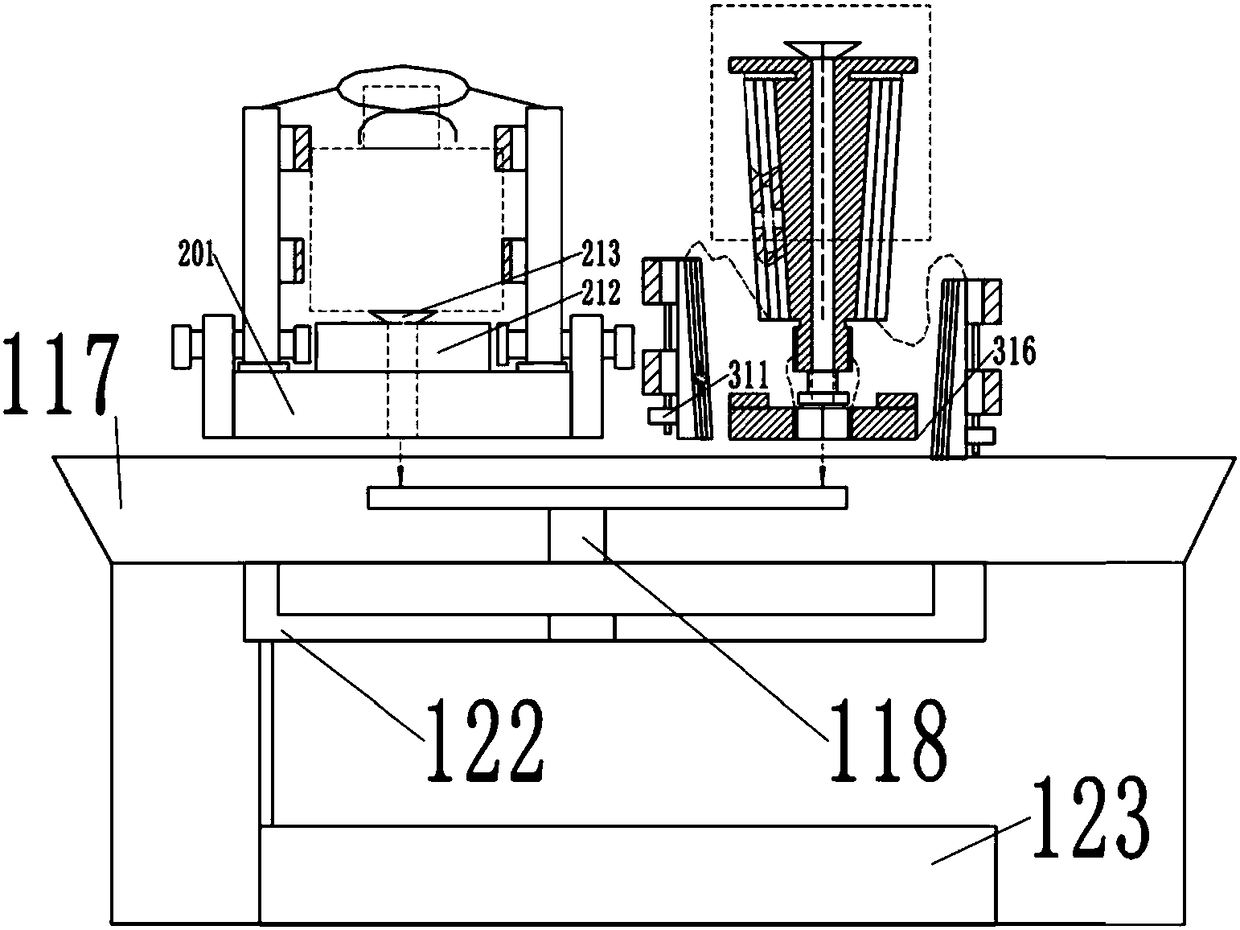

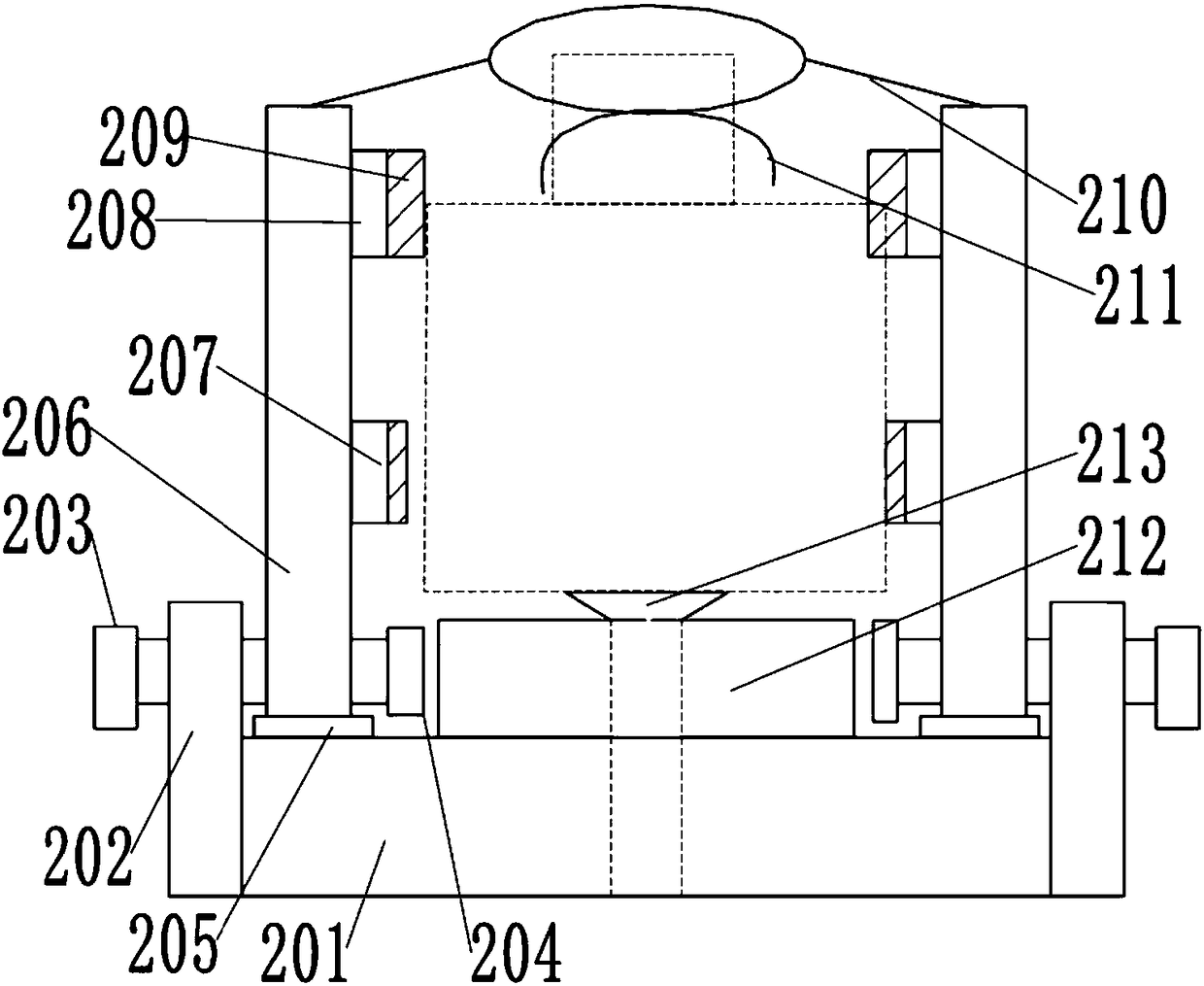

[0049] The welding device comprises a rotary processing head 111 arranged above the frame 110, a working head 112 arranged on the rotating processing head 111, a grinding disc 113 arranged at the lower end of the working head 112 and used for grinding the container, and a grinding disc 113 arranged below the grinding disc 113. Processing table top 117, be arranged on processing table top 117 middle part and be positioned at the rotary stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com