Patents

Literature

157results about How to "Improve seam quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

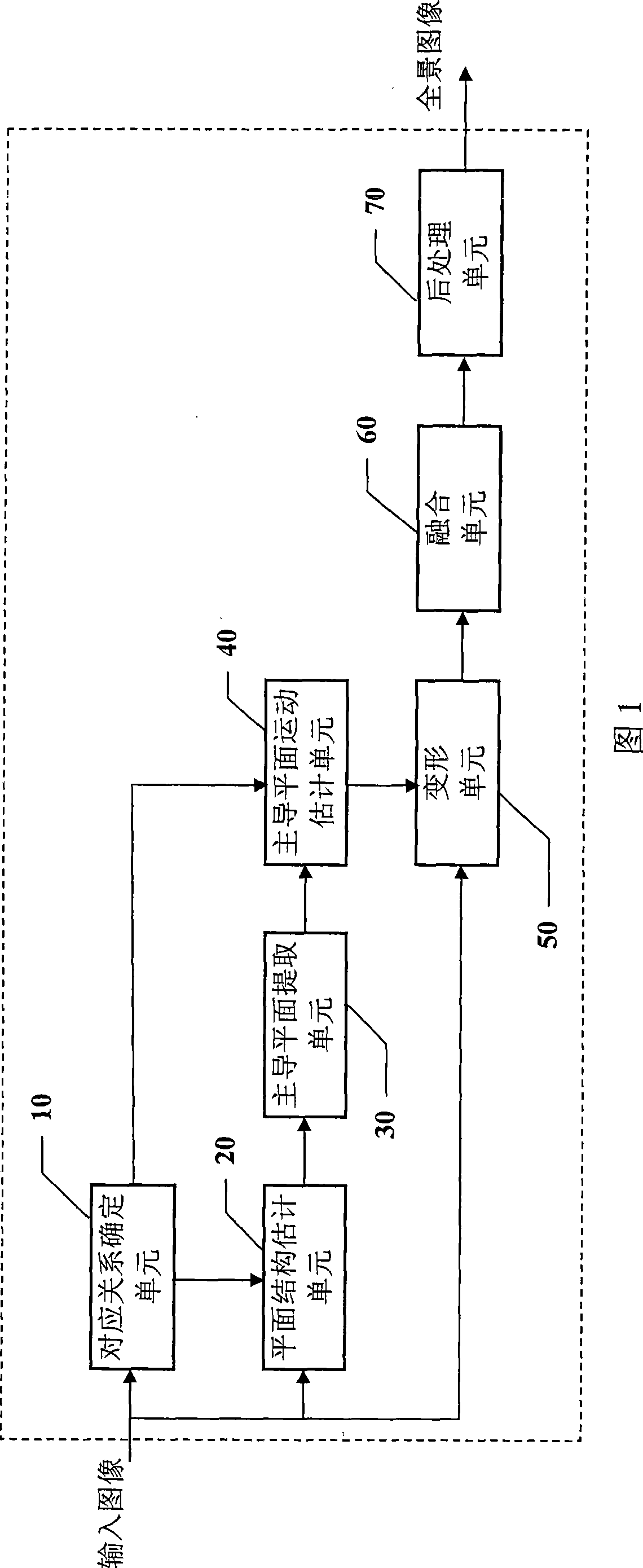

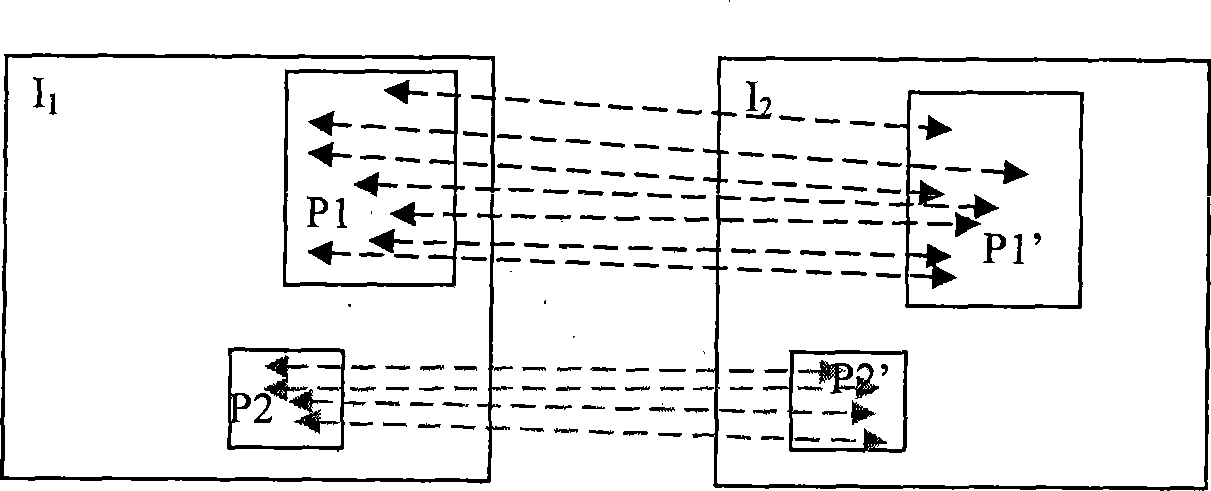

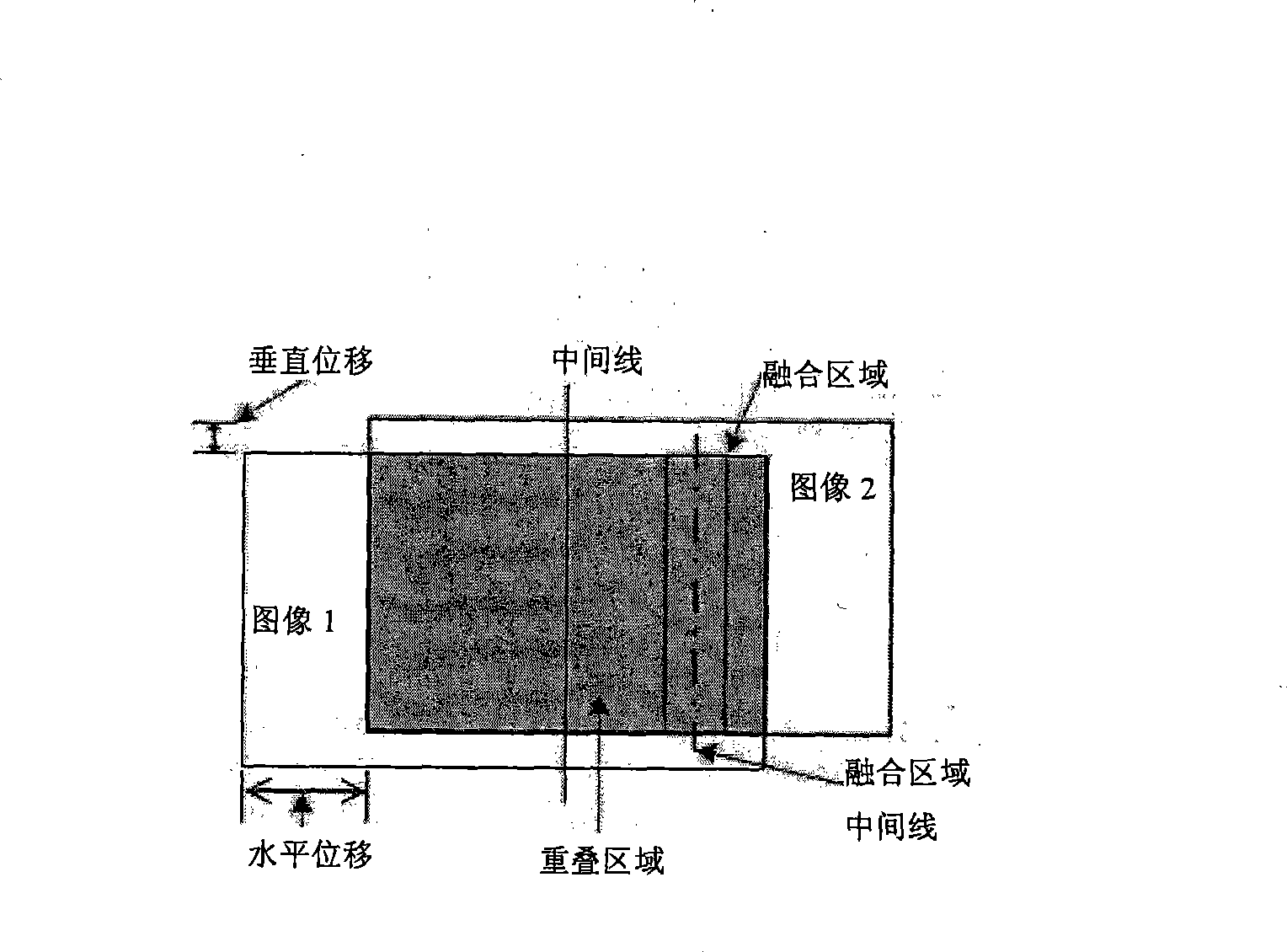

Apparatus and method for generating panorama image

ActiveCN101414379ASolve the problem of estimating depth of fieldImprove seam qualityImage enhancementComputer graphics (images)Computer vision

Owner:NEC (CHINA) CO LTD

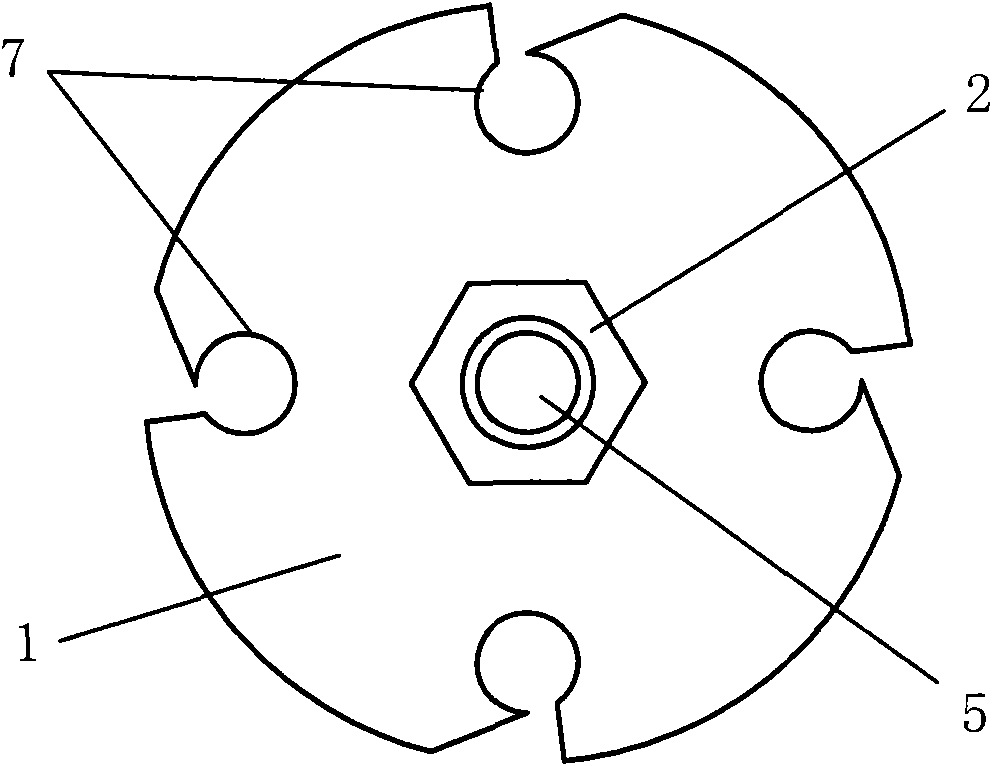

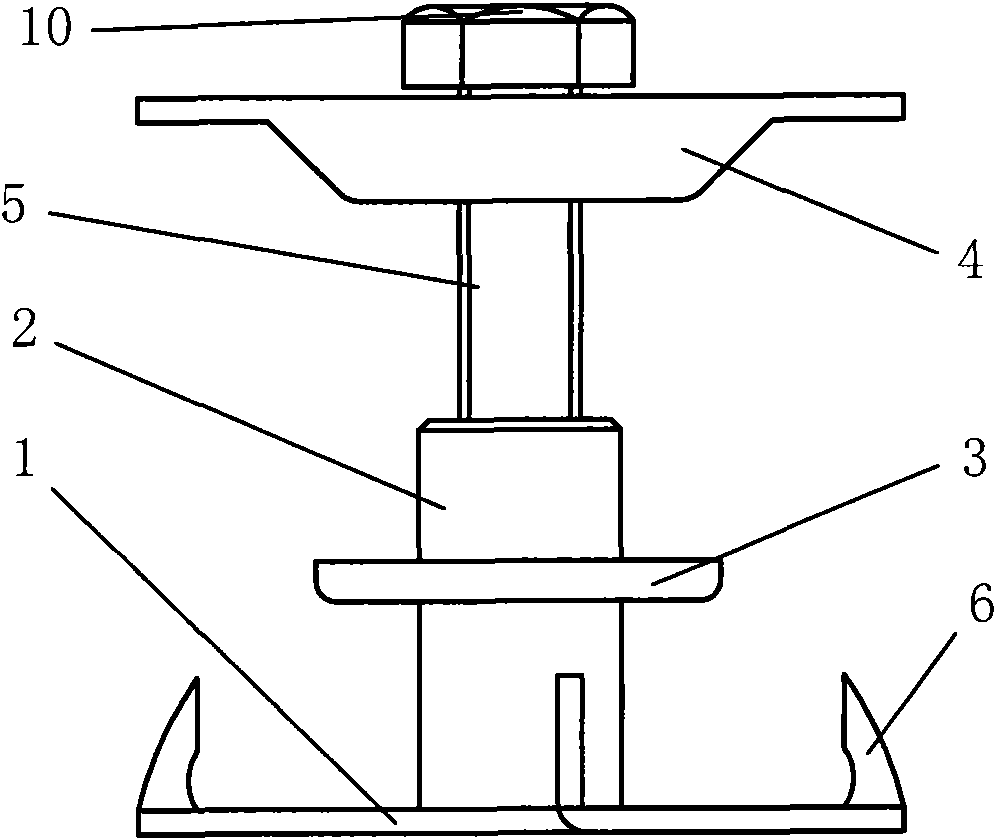

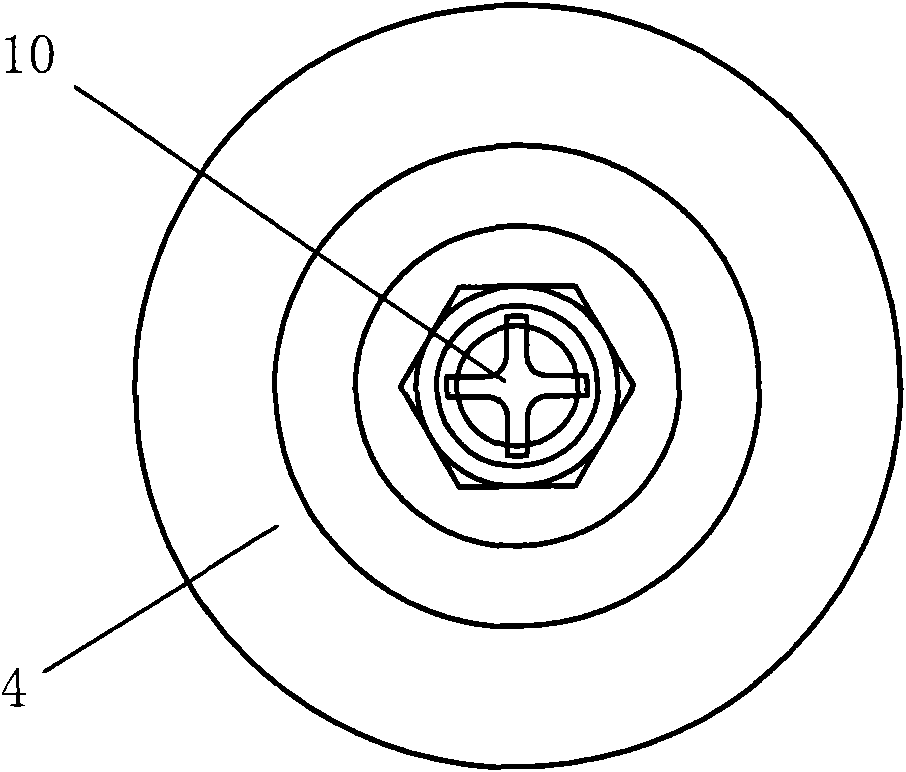

Connecting screw

InactiveCN101966881AReasonable structureSewing fastContainer/bottle contructionRigid containersEconomic benefitsPaperboard

The invention discloses a connecting screw, and belongs to the field of cargo packing. The connecting screw comprises a nut, a hexagonal screw, a toothed meson, a clamp spring meson and a pit meson, wherein the nut and the hexagonal screw are matched together; the toothed meson is assembled with the lower end of the nut together; the clamp spring meson is clamped on the nut; the pit meson is matched with the hexagonal screw together; the toothed meson is provided with 2 to 6 teeth and 2 to 6 mounting holes; the inner wall of the central hole of the toothed meson is provided with 2 to 6 lugs; and the clamp spring meson is provided with a plurality of trapezoidal clamping teeth. The connecting screw is used for sewing a paperboard packing box, has firm connection and high sewing speed, and is convenient to assemble and disassemble; the sewn product is attractive and high in quality; the connecting screw can relieve the labor intensity of workers, improve the work efficiency, reduce the labor amount, reduce the production cost of enterprises and improve the economic benefit, and is favorable for environmental protection; and the sewing process for the paperboard packing box produces epoch-making revolutionary change, and brings new vigor and vitality to the packing industry.

Owner:GUANGDONG HHS HEAVY DUTY PACKAGING GRP COMPANY

Method for beam welding of hardenable steels by means of short-time heat treatment

InactiveUS6365866B1Readily integrated into processCritical cooling timeHeat treatment process controlElectron beam welding apparatusEngineeringHeat treated

The invention concerns a method for beam welding of hardenable steels using a short-time heat treatment. A preferred area of application of the invention is motor vehicle and mechanical engineering. In the method according to the invention, the short-time heat treatment occurs first as the sole preheating in a defined manner, and then the beam welding begins after a defined cooling time, at the latest.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

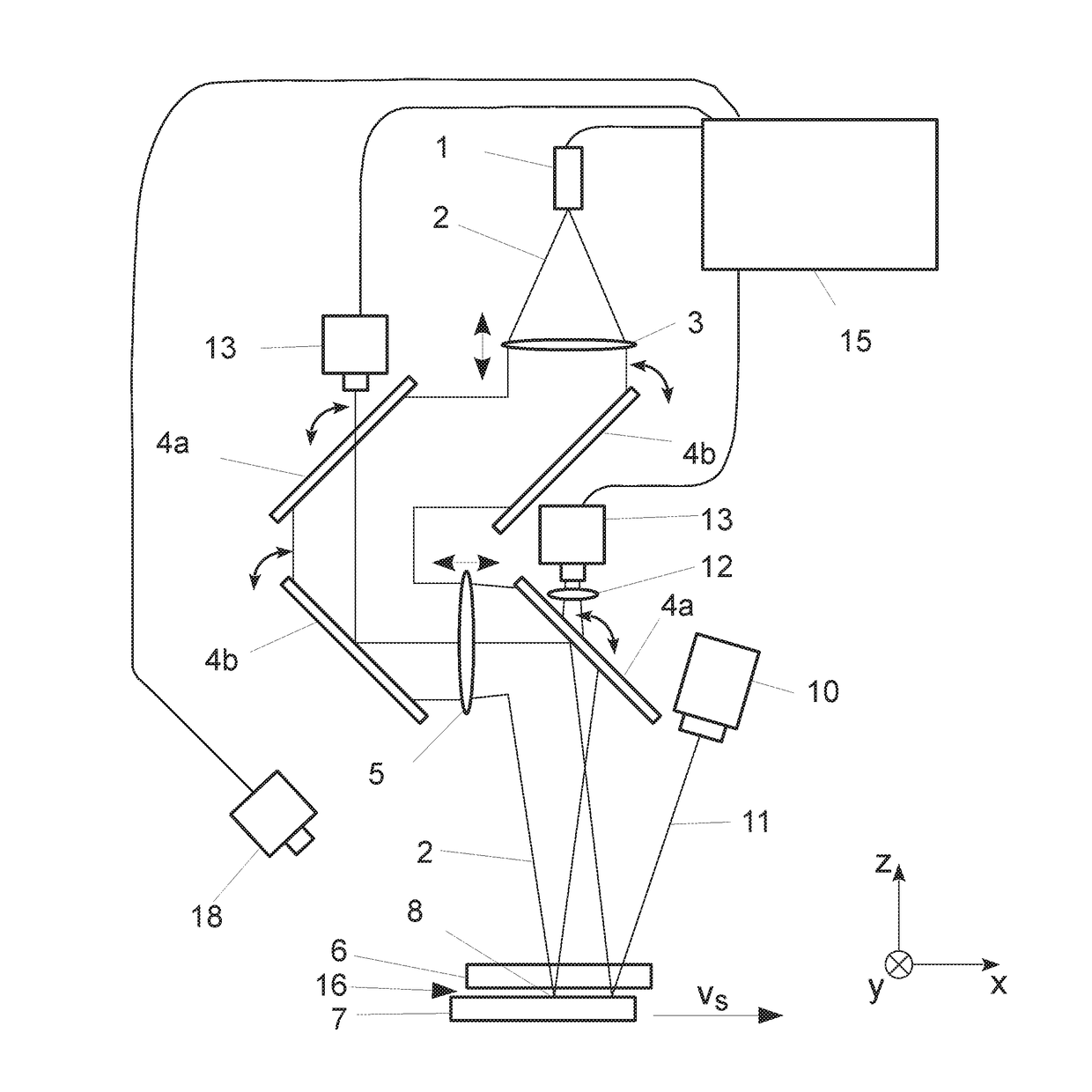

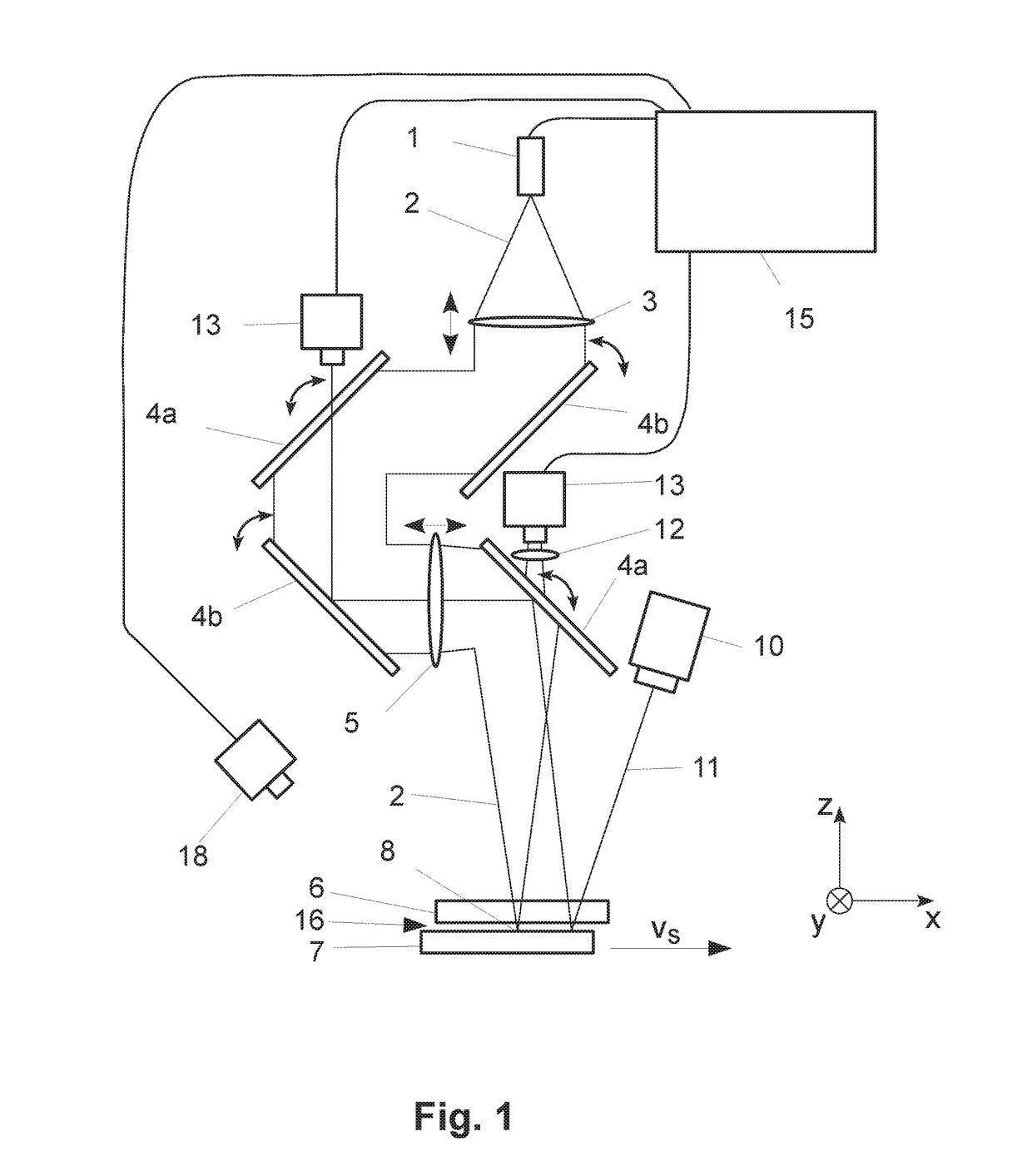

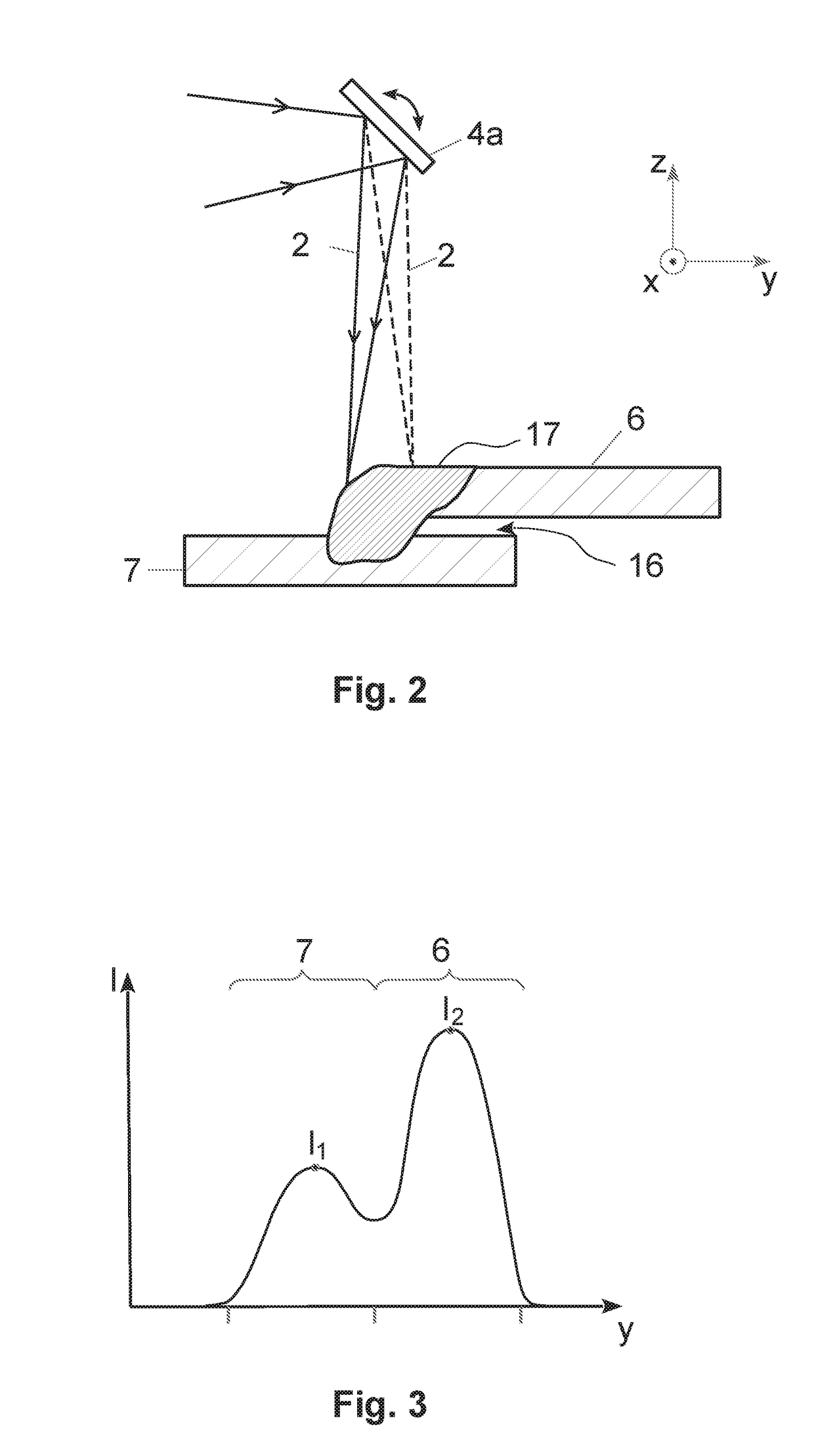

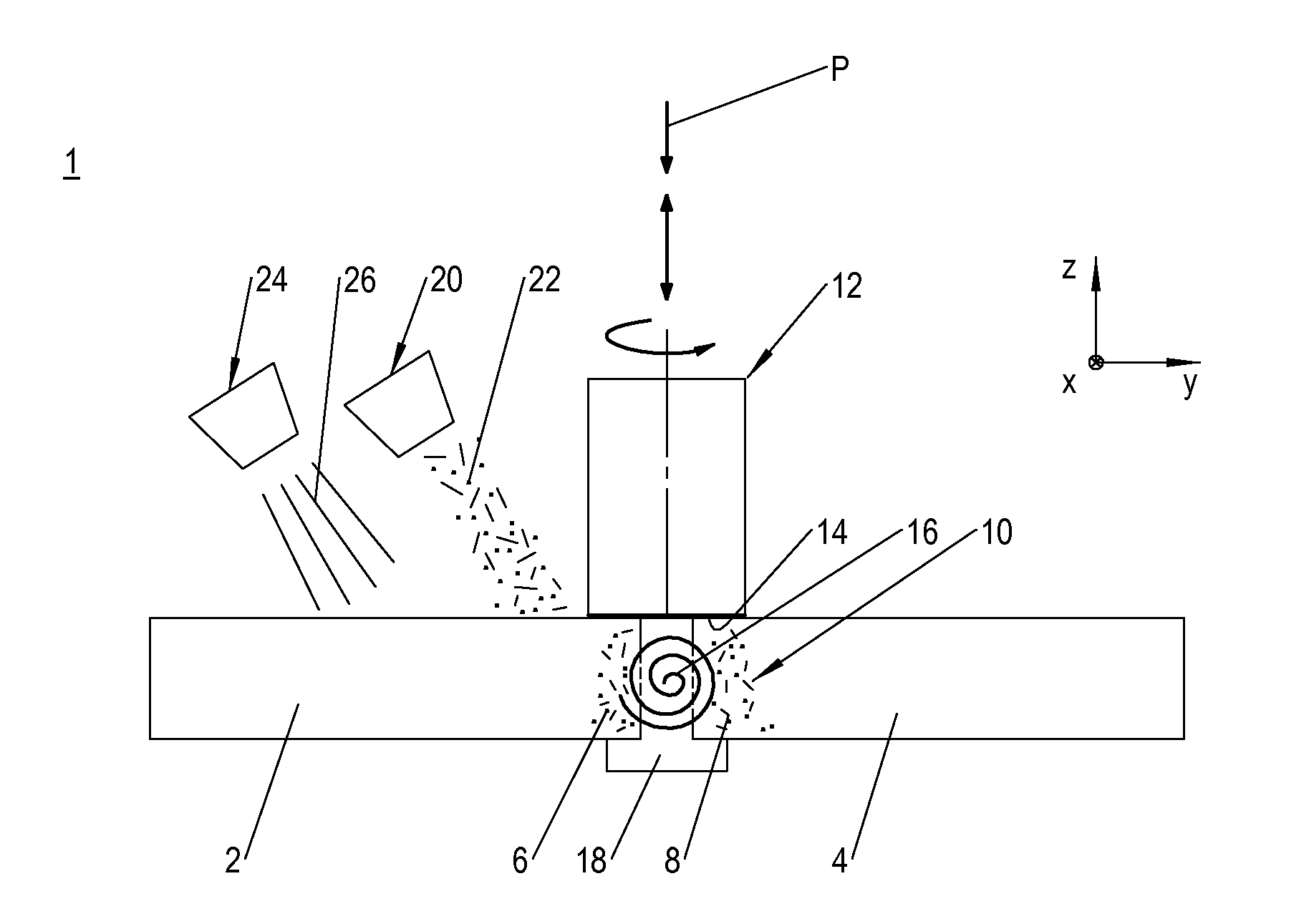

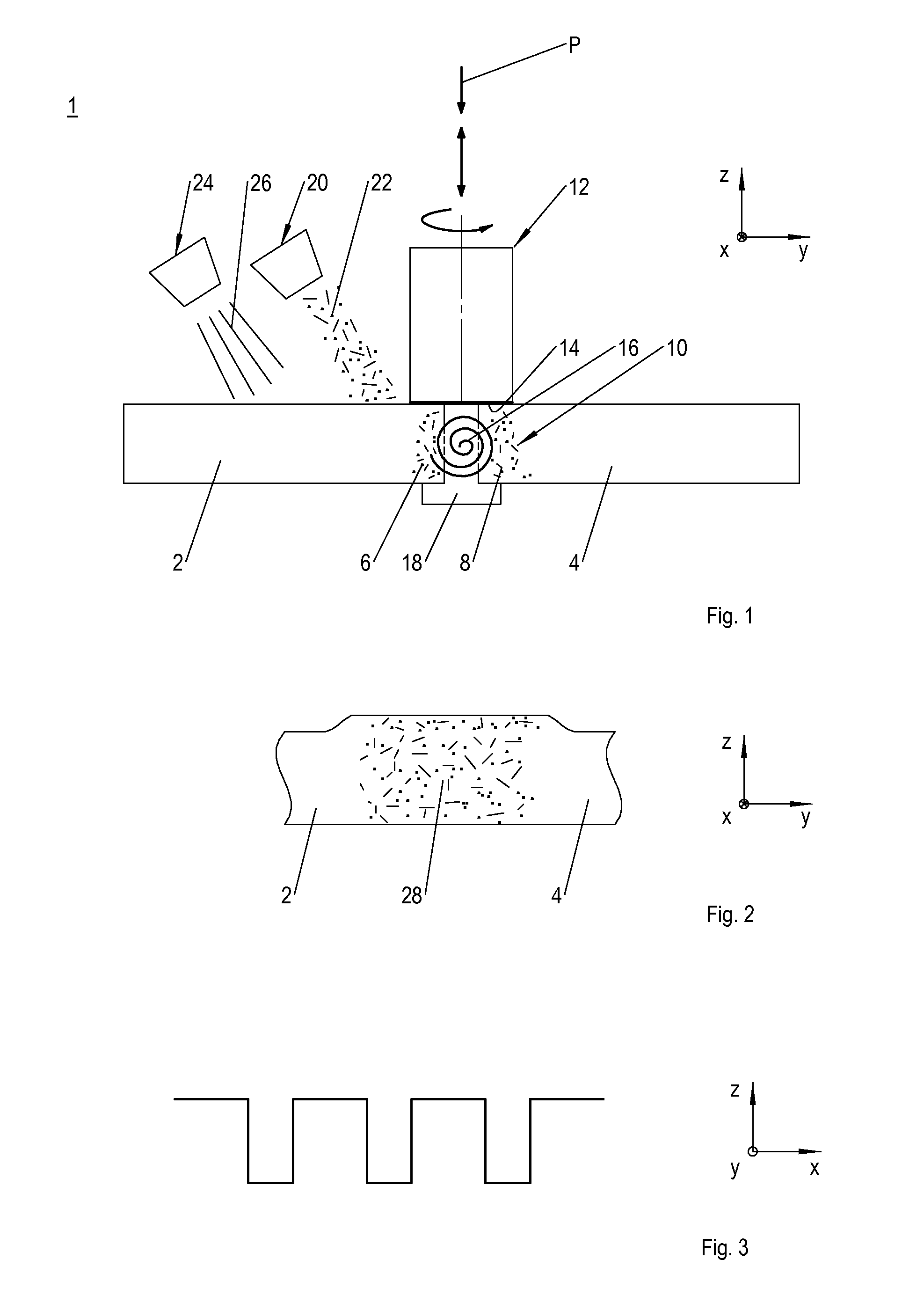

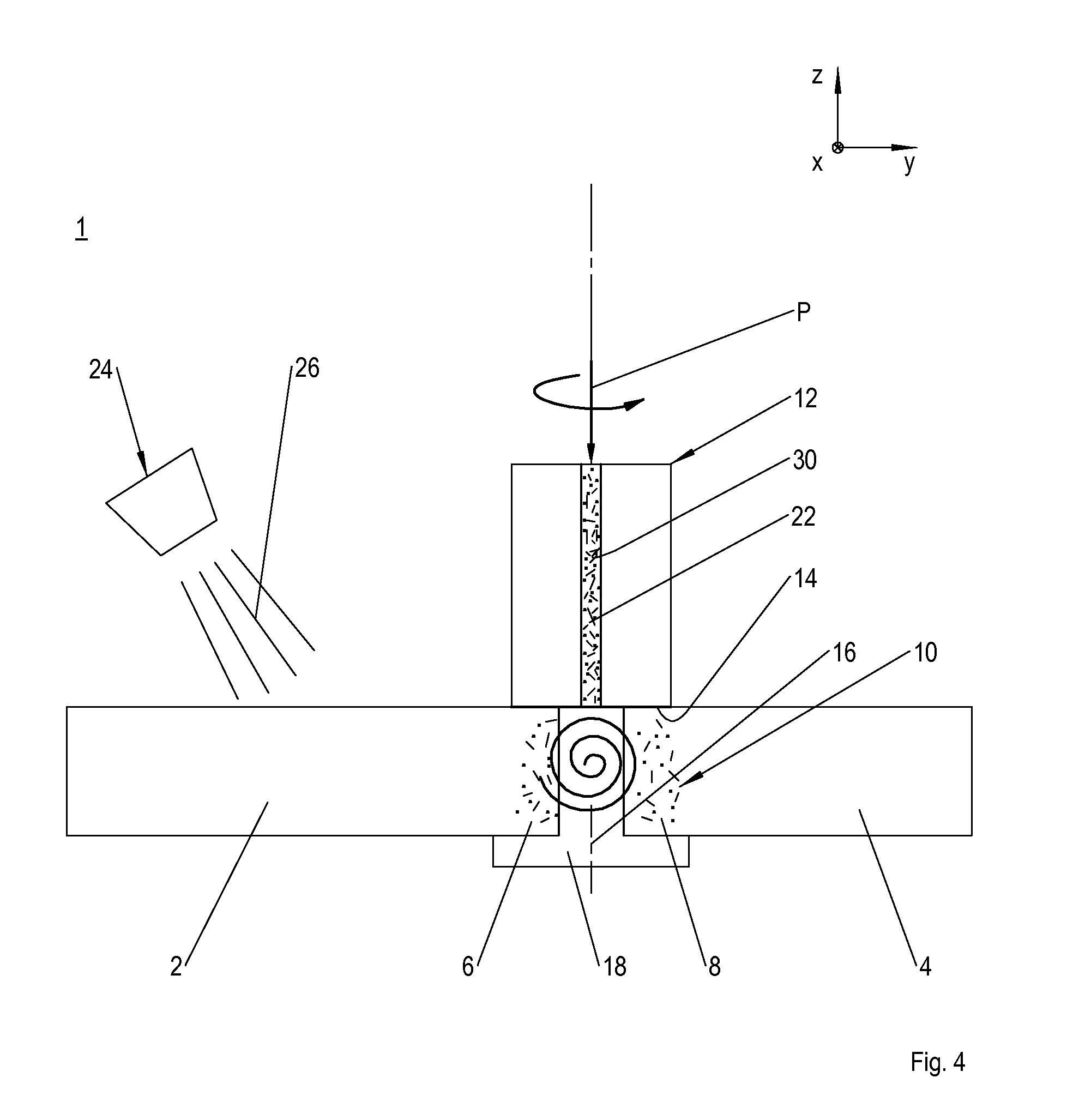

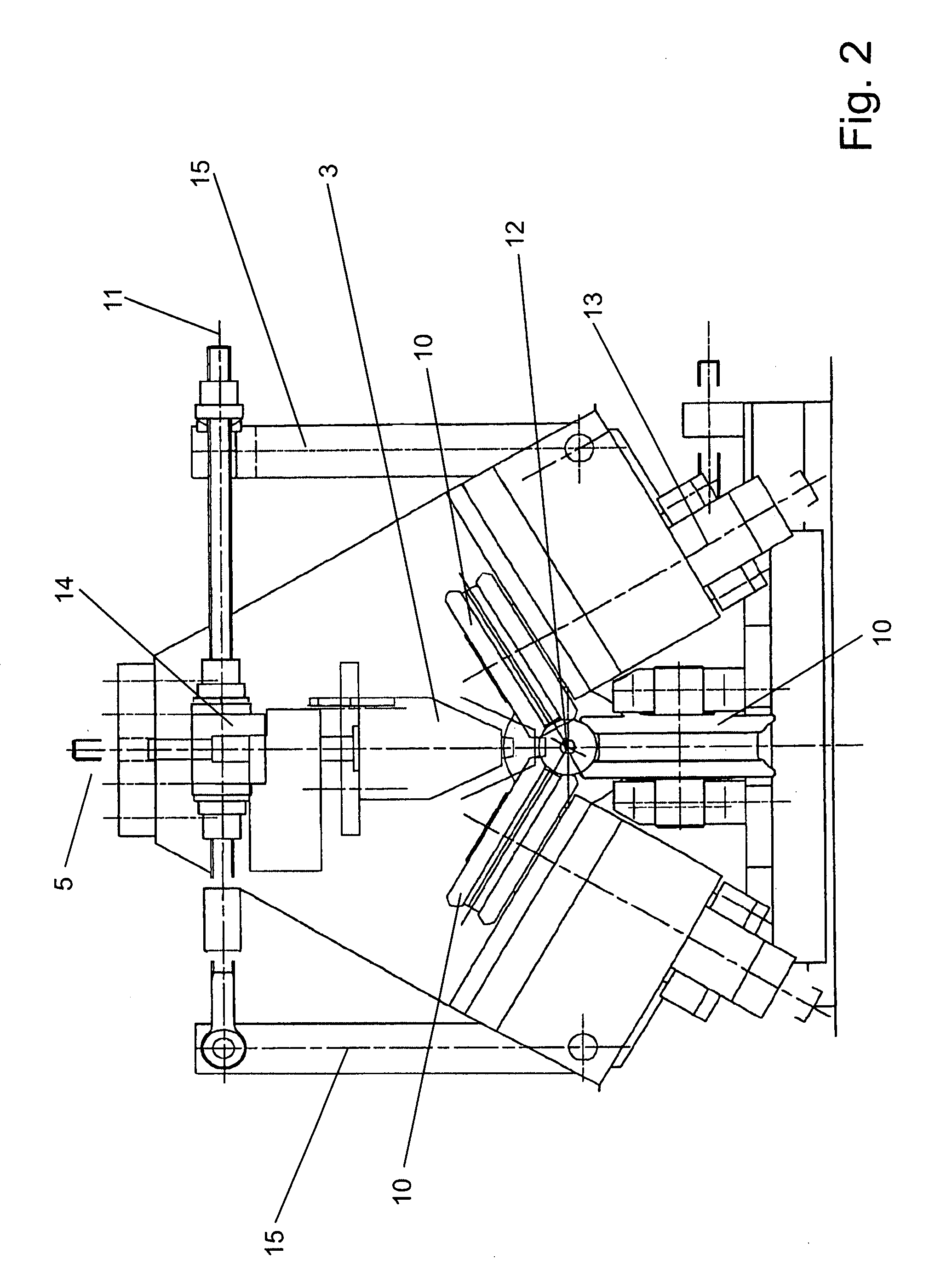

Method and Apparatus for Joining Workpieces at a Lap Joint

InactiveUS20170259373A1High degree of automationHigh constantWelding/soldering/cutting articlesLaser beam welding apparatusAngle of incidenceLap joint

A method and an apparatus for joining two workpieces by means of a processing beam by forming a weld seam along a lap joint, wherein a gap formed at the lap joint between the two workpieces is filled during welding. The processing beam performs a spatial oscillatory movement parallel and / or perpendicular to the joint during welding. The oscillation parameters of said oscillation, the feed rate, the power of the processing beam and the angle of incidence of the processing beam onto the surfaces of the workpieces are adjusted dynamically during the welding process such that the upper sheet is fused in line with demand and the melt flows from the upper sheet down to the lower sheet thus closing the gap. The gap height is measured permanently during welding and the process parameters are adjusted such that a reliable closing of the gap is made possible.

Owner:SCANSONIC MI

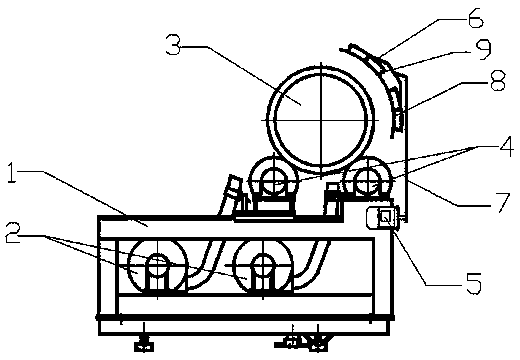

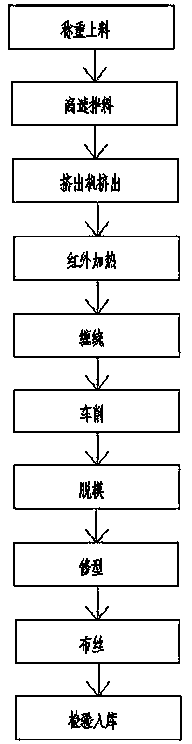

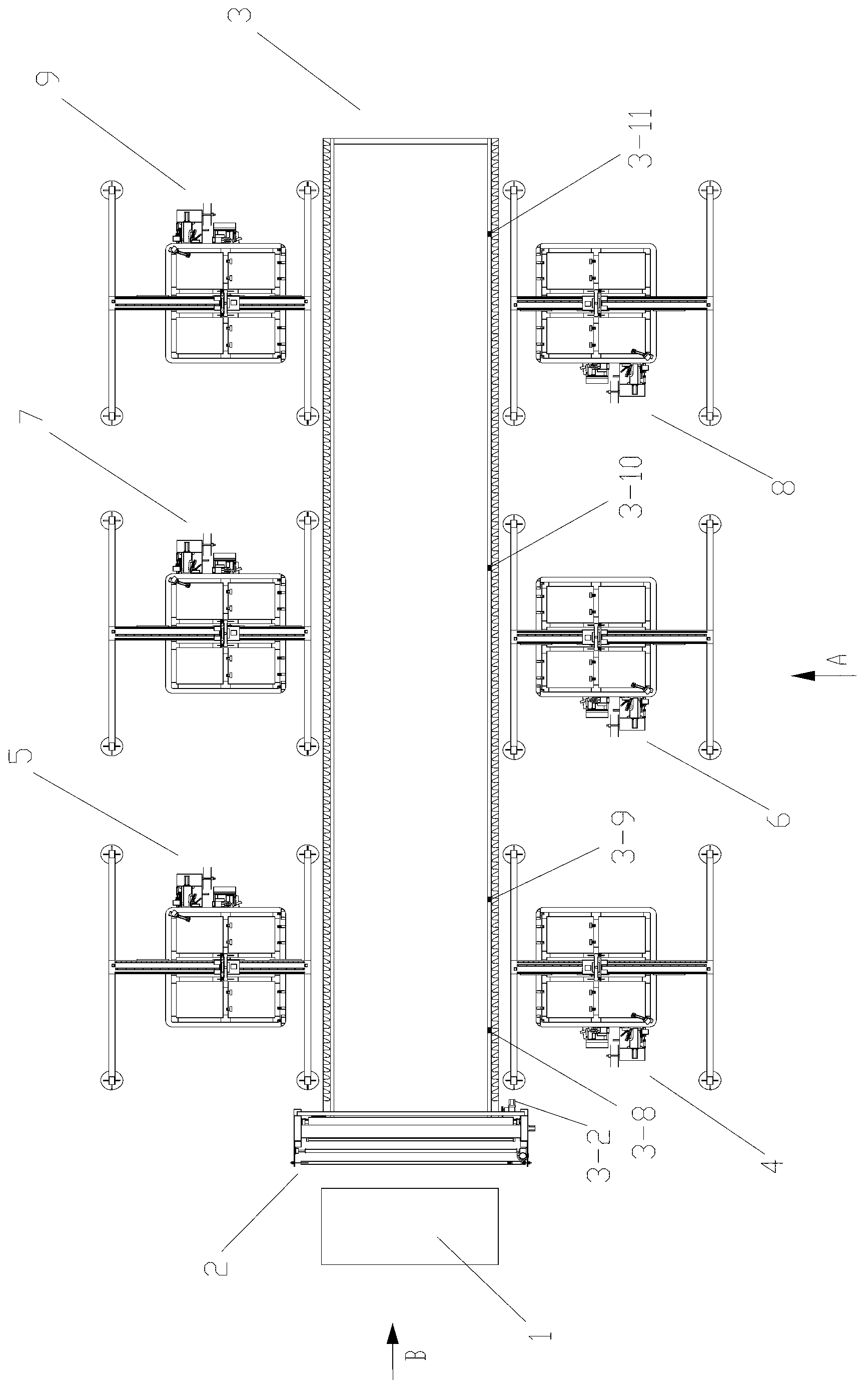

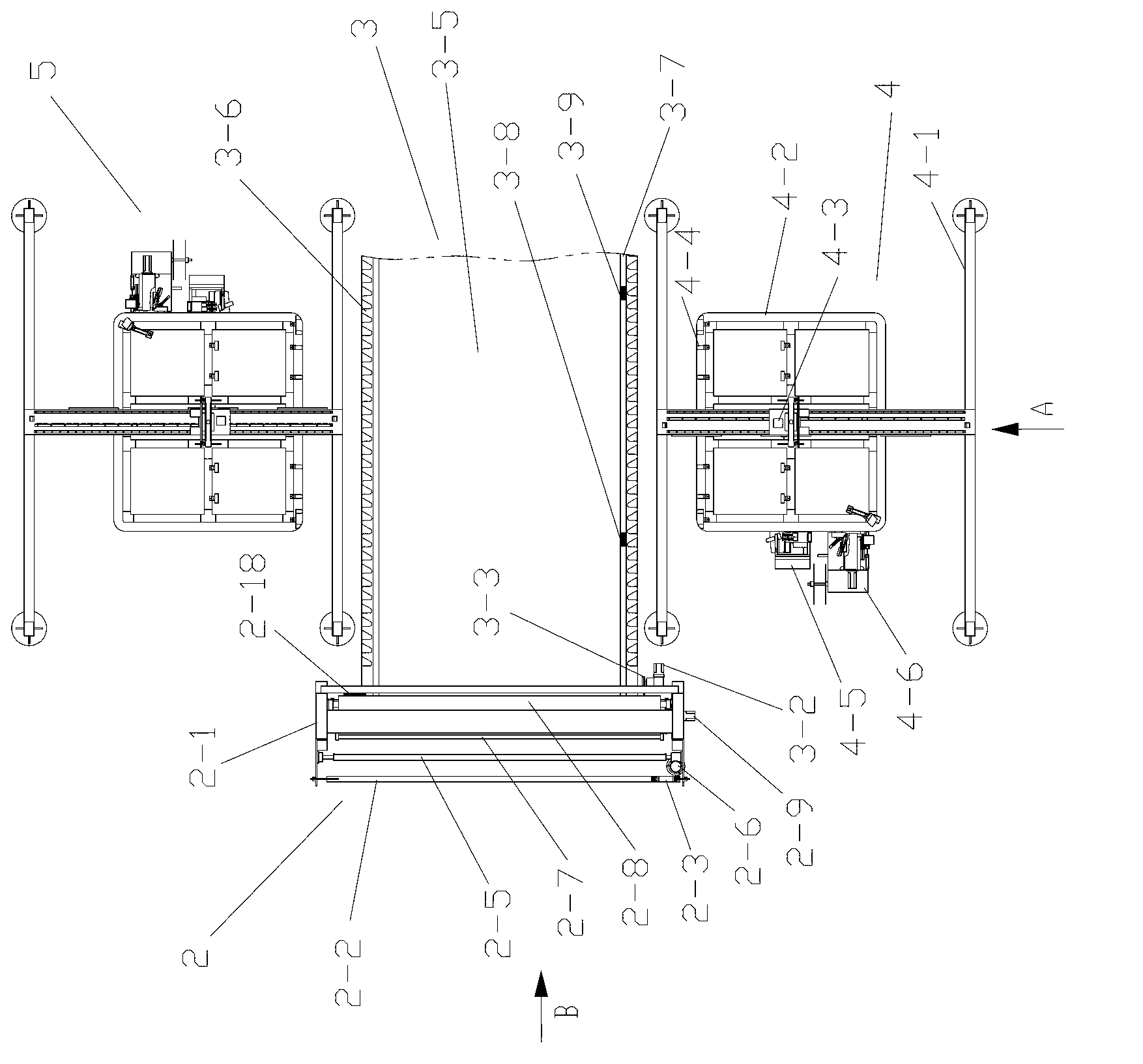

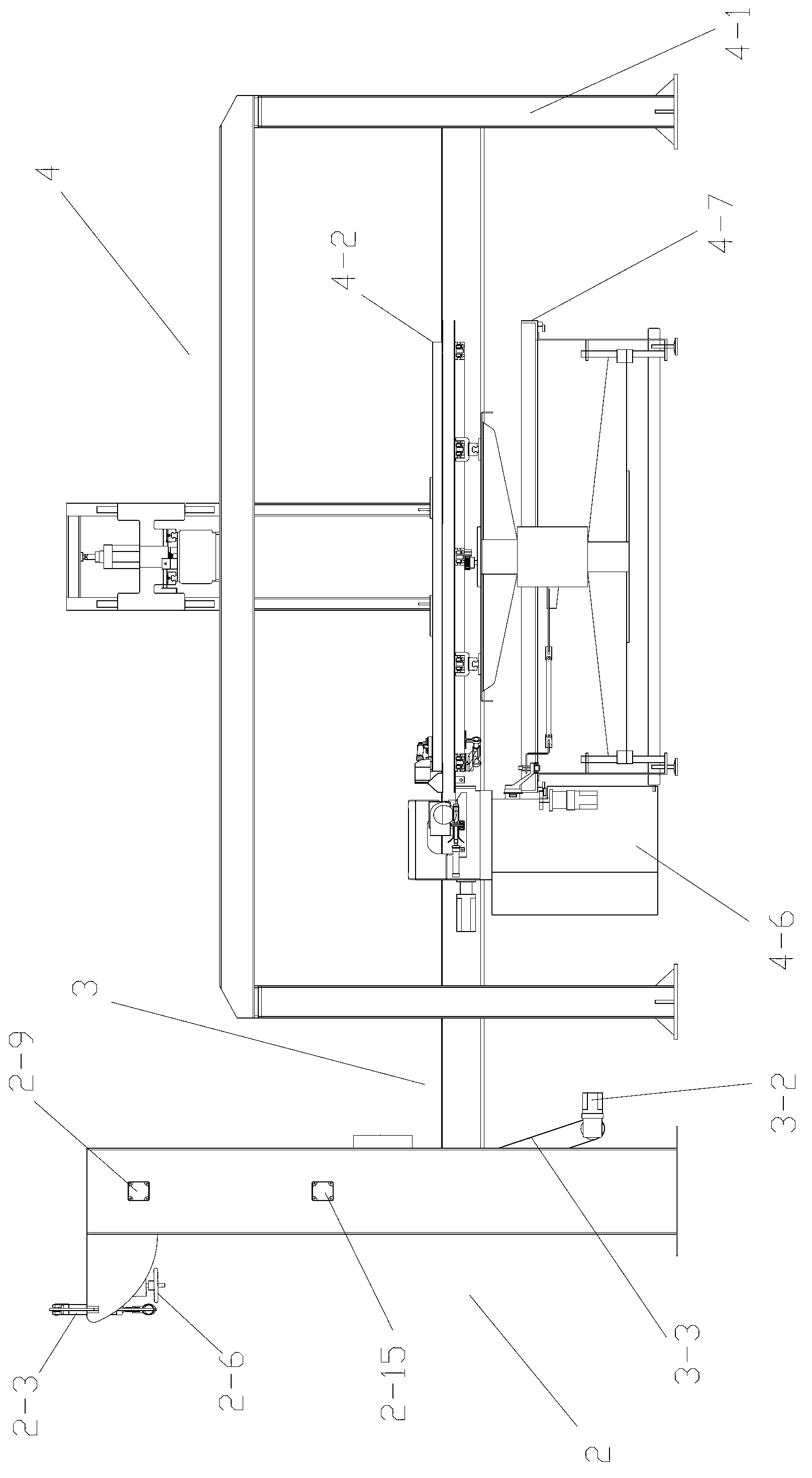

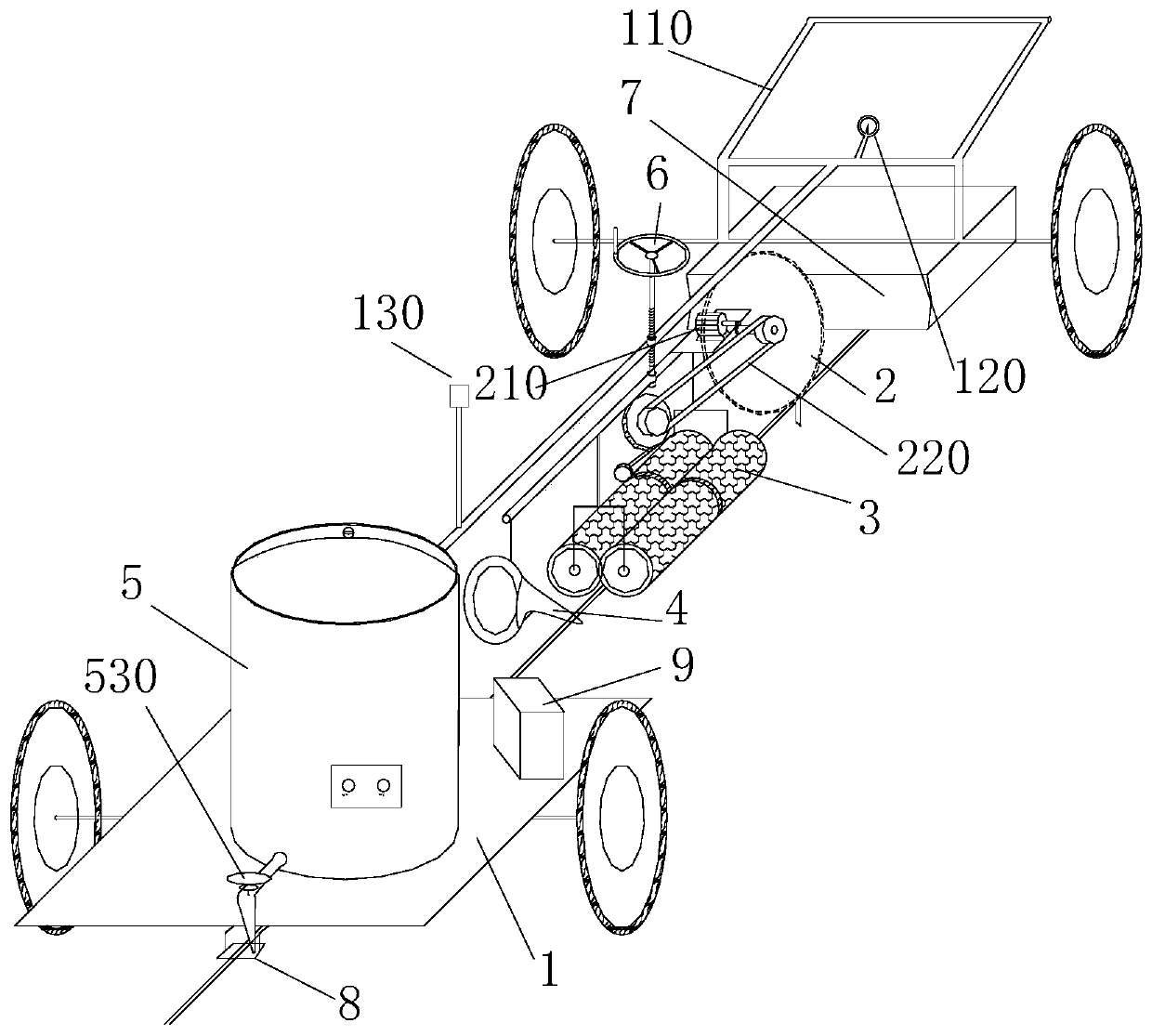

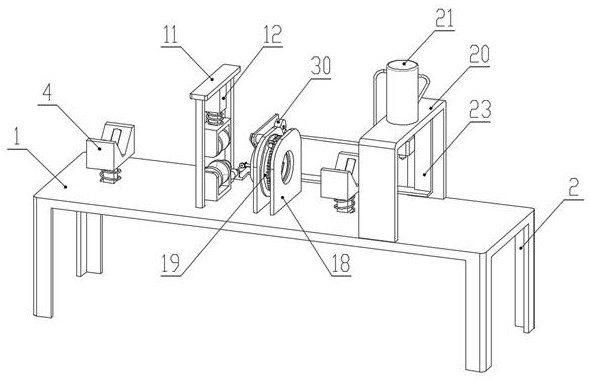

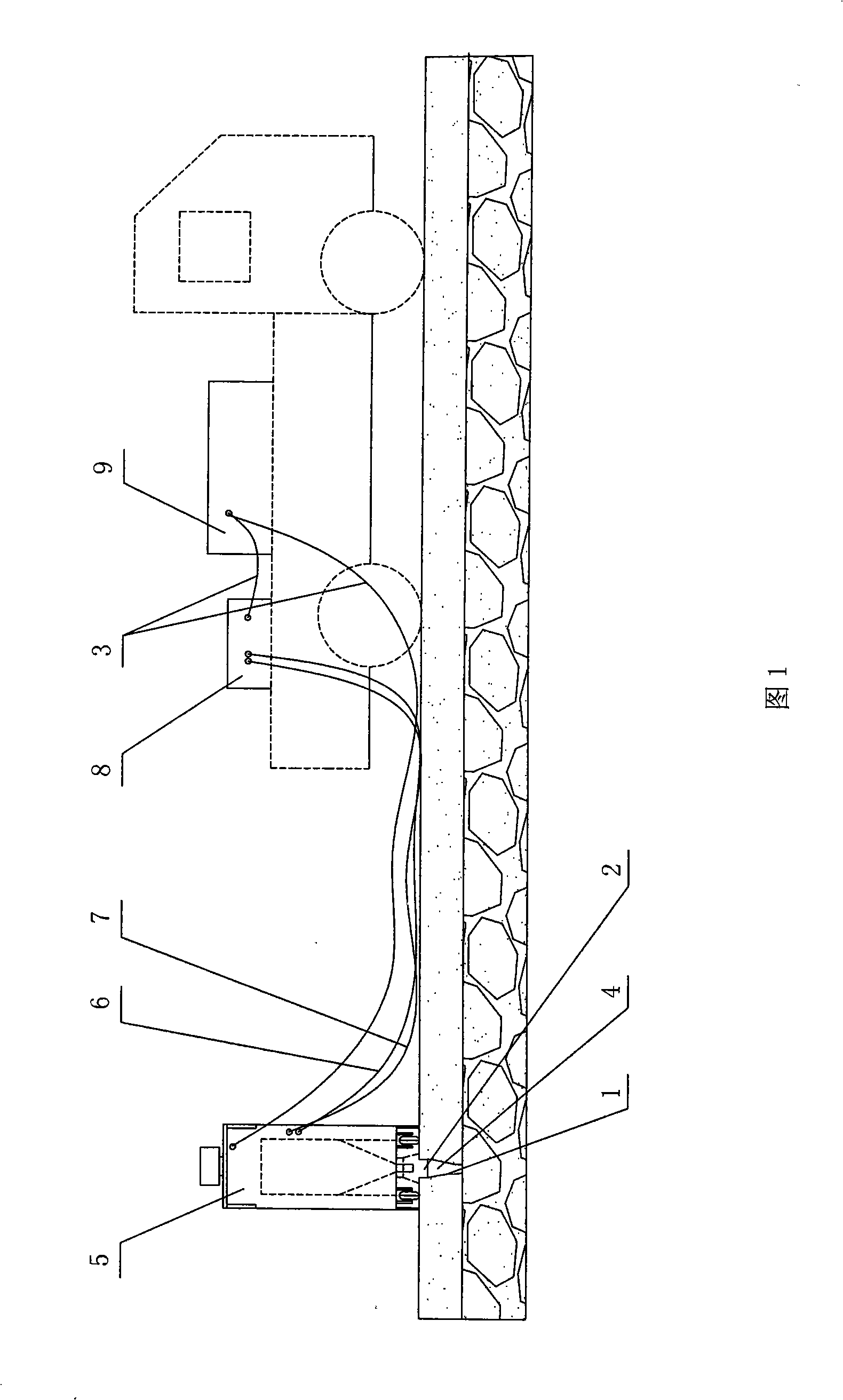

Production equipment and production technology for HDPE (high density polyethylene)spirally enwound structure-wall pipe (Krah pipe)

ActiveCN103963325AReduce manufacturing costImprove heating efficiencyTubular articlesElectric fusesProcess engineering

The invention discloses production equipment and a production technology for an HDPE (high density polyethylene) spirally enwound structure-wall pipe (Krah pipe).The equipment comprises a base trolley, cooling fans, a mold roller, rolling wheels, a servo motor, an infrared heating device and a rotating rod. The technology comprises material mixing, feeding, vacuum feeding, extrusion, enwinding, turning, demolding, modification, electric fuse distribution, inspection and storage. According to the production equipment and the production technology, infrared high-frequency heating is adopted, the heating efficiency is high, the cost is low, and the operation is simple and convenient; the ring stiffness is increased by above 30% due to addition of short-glass-fiber master batches; characteristics of HDPE are adopted, so that the comprehensive performance of the pipe is improved; the weld seam quality of the pipe is guaranteed, and the weld seam quality and the overall external pressure resistance of the pipe are also improved.

Owner:HUNAN QIANYUAN NEW MATERIAL

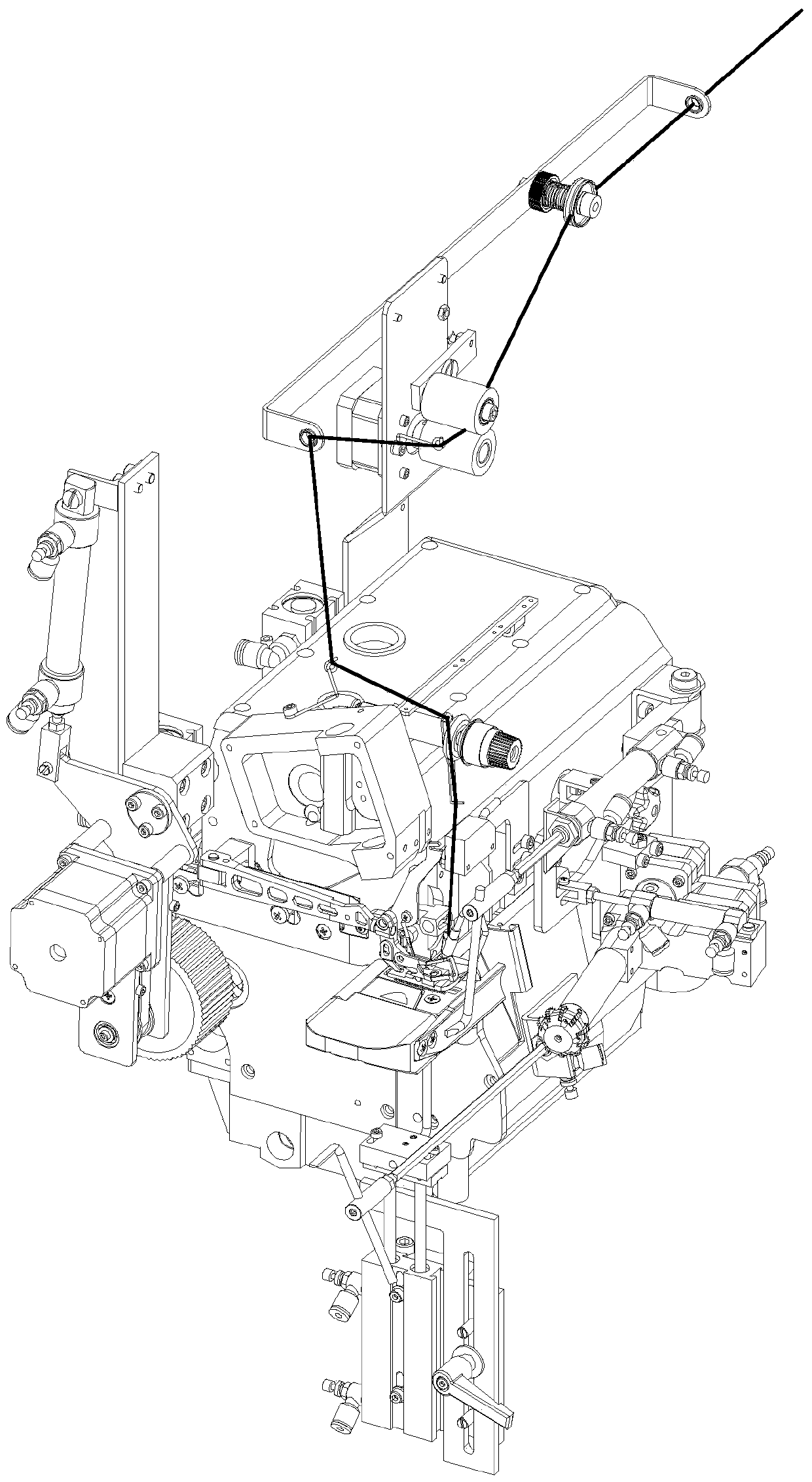

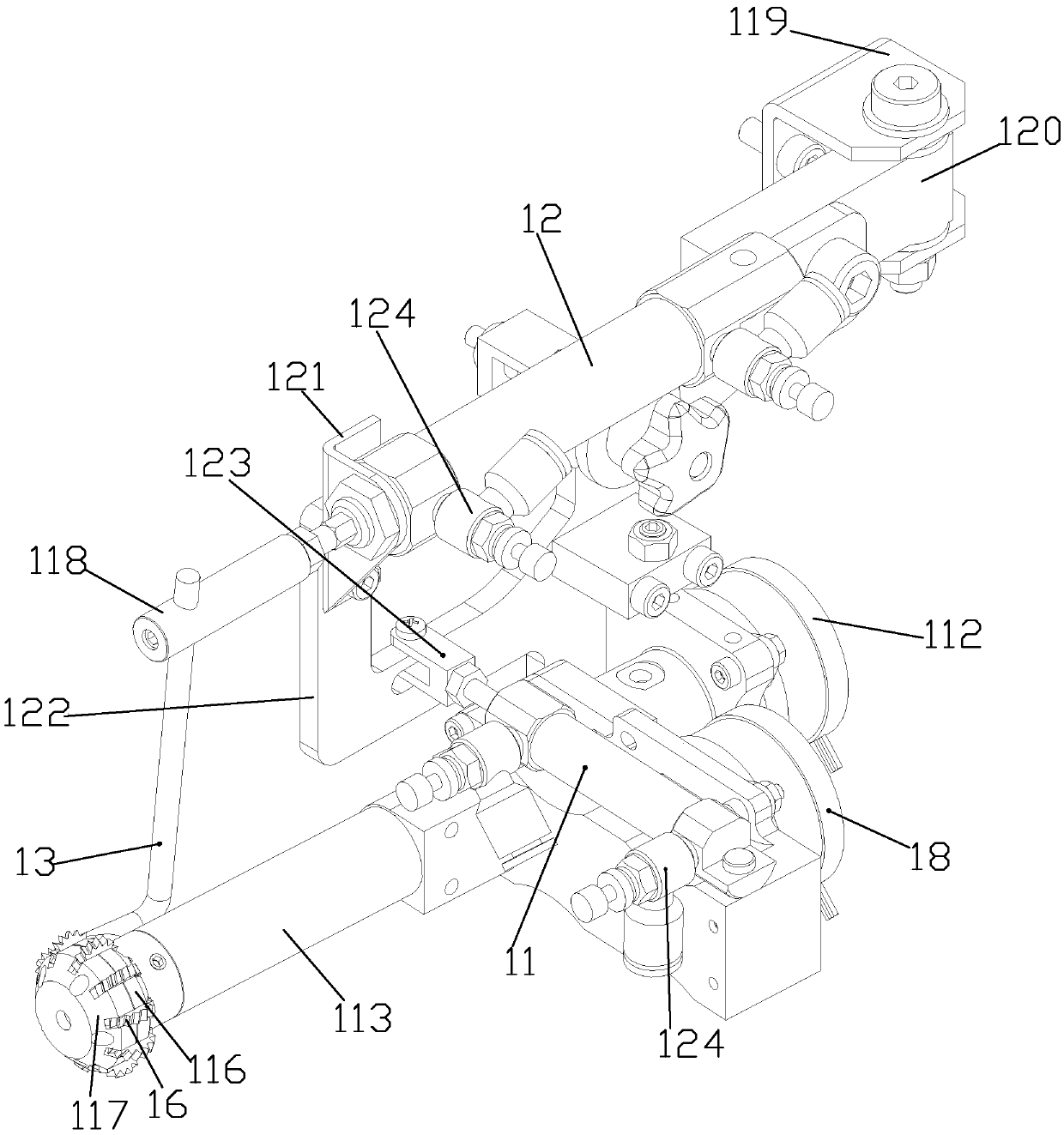

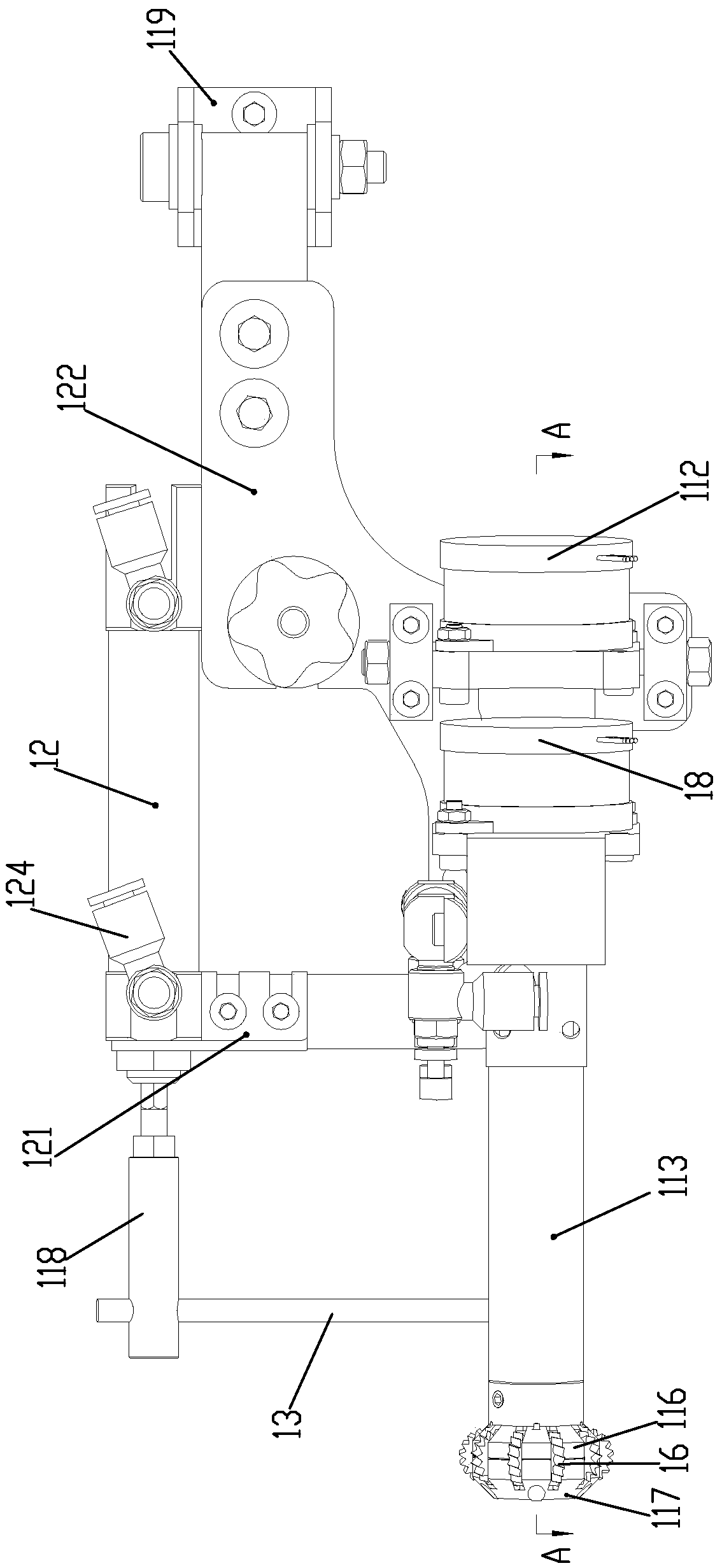

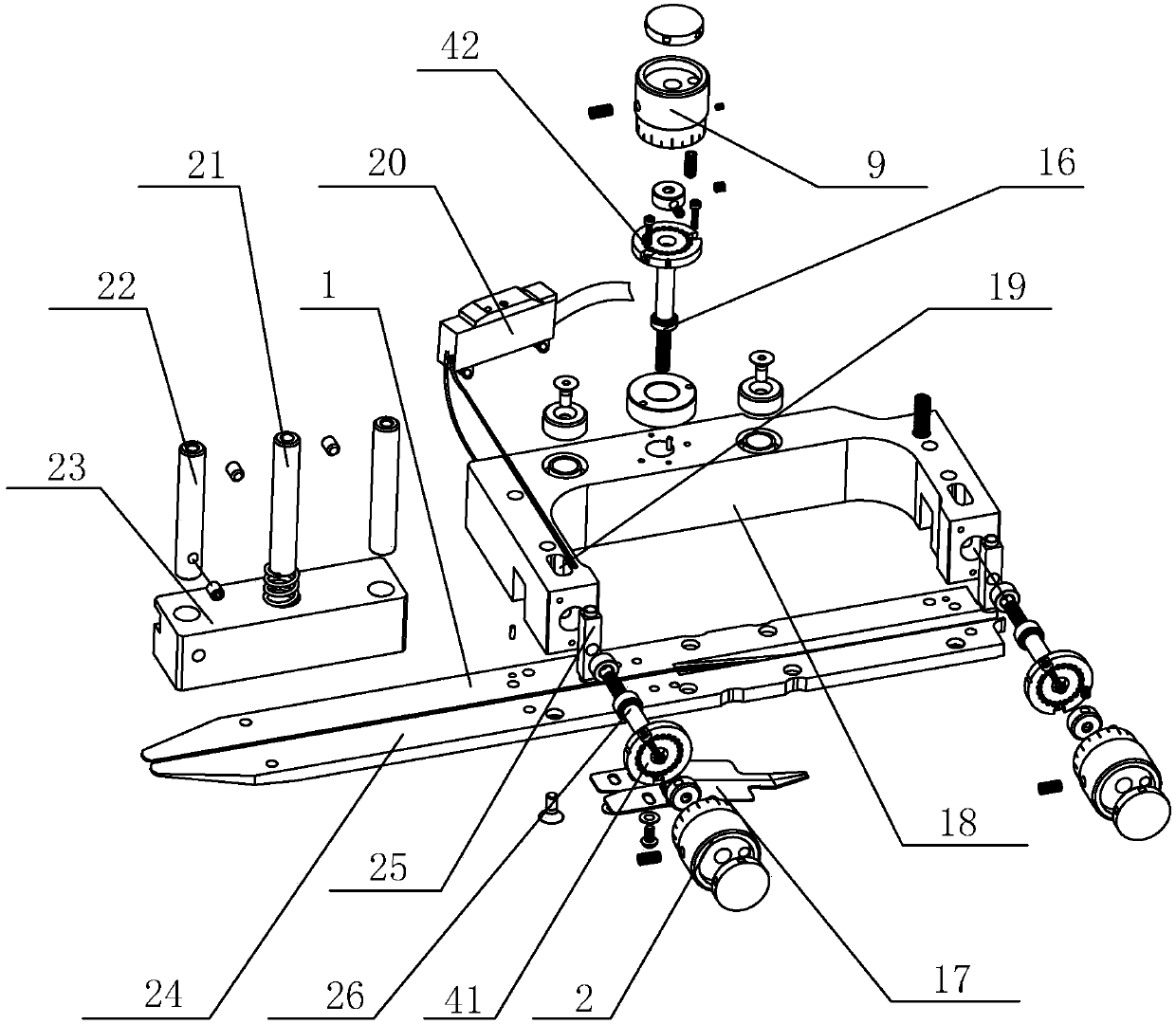

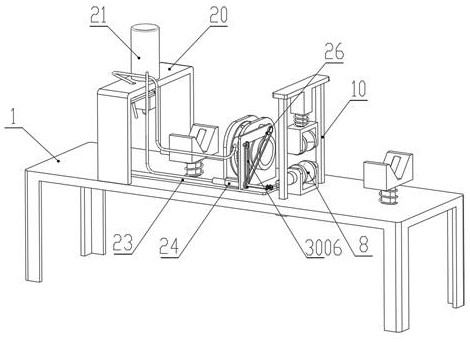

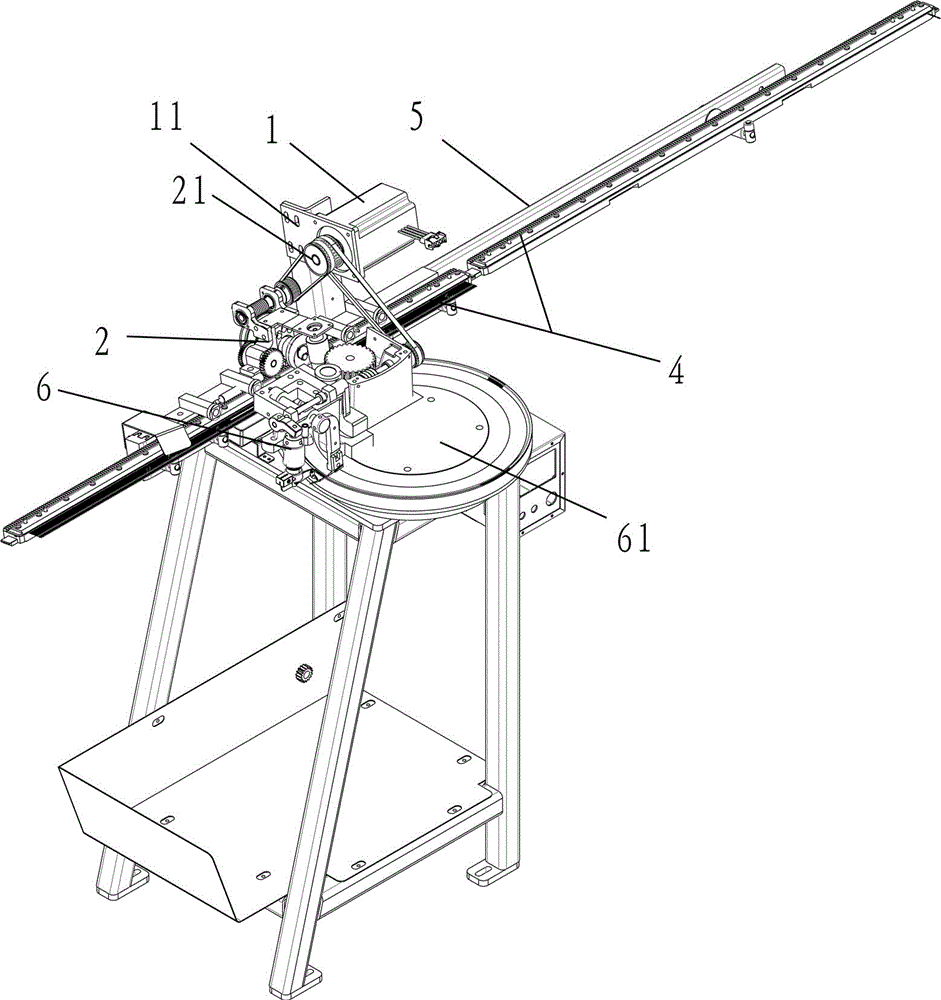

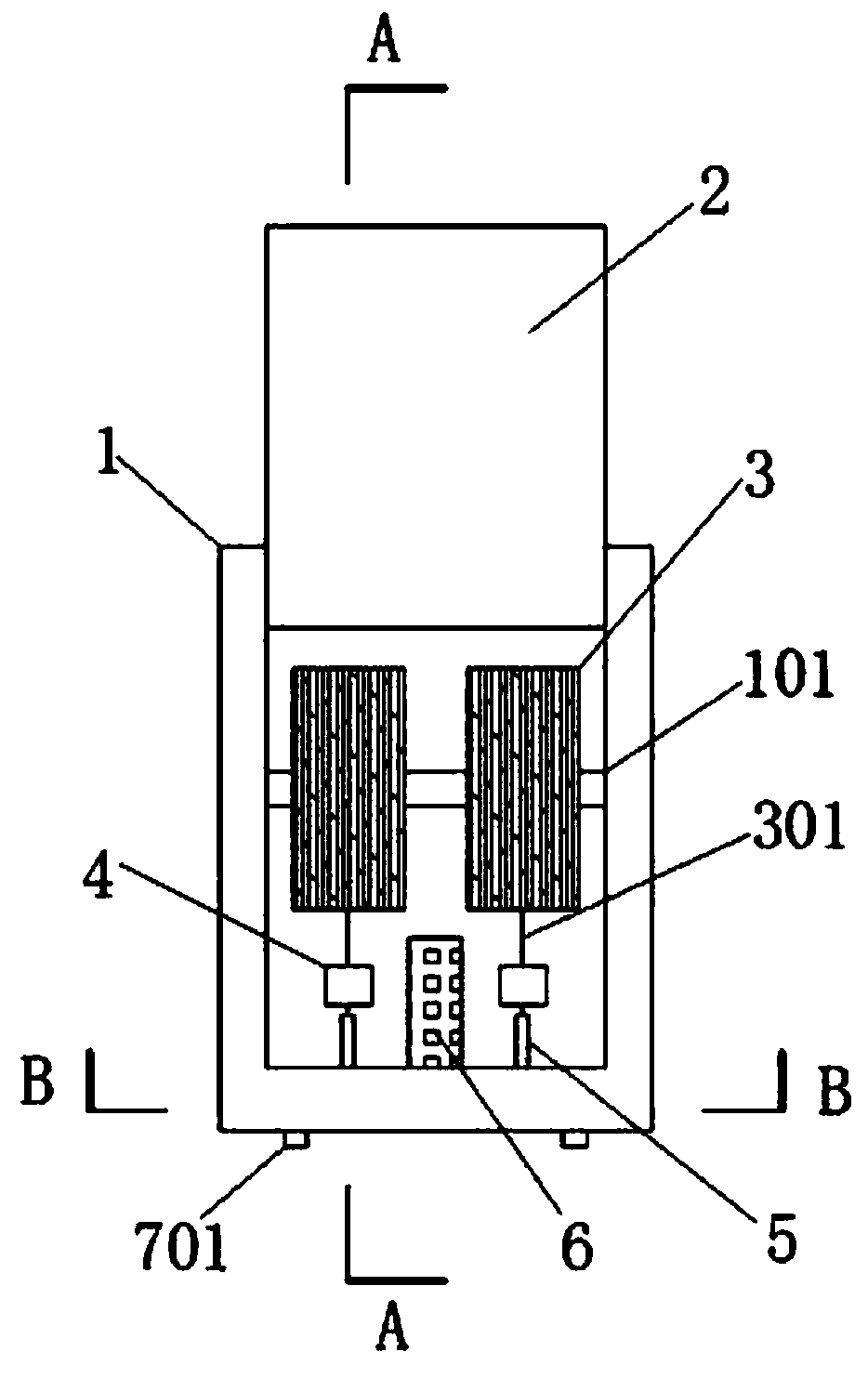

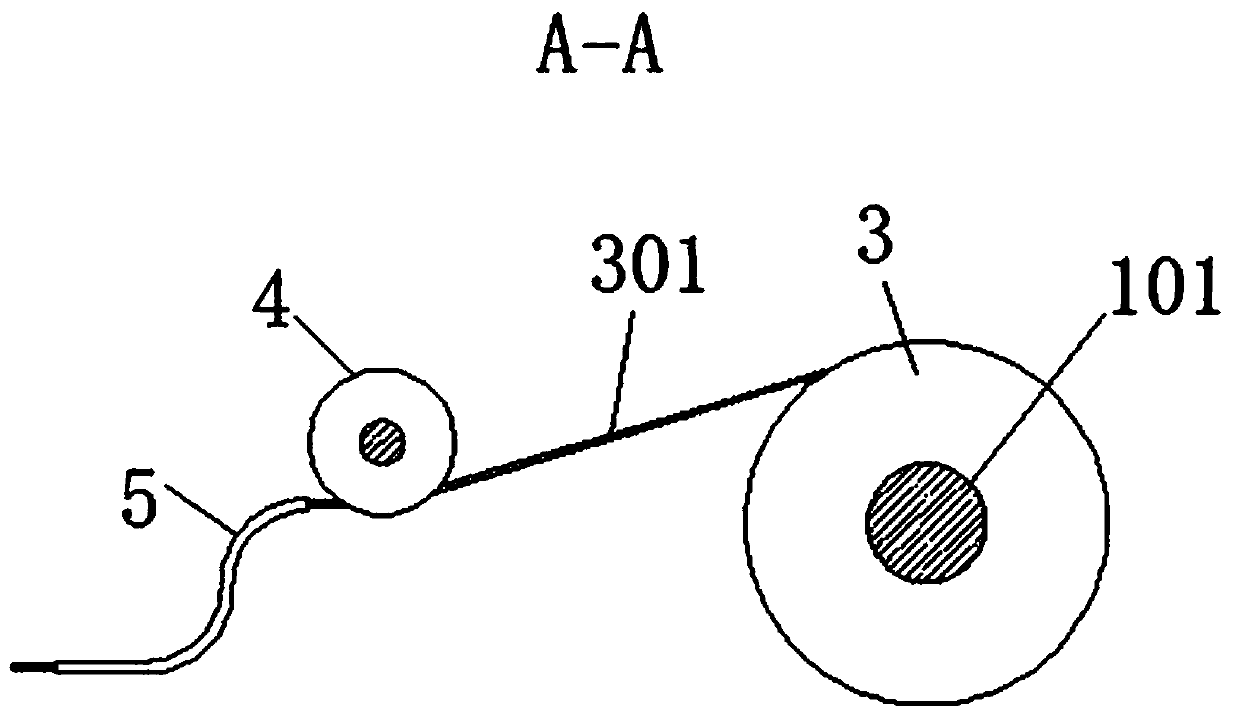

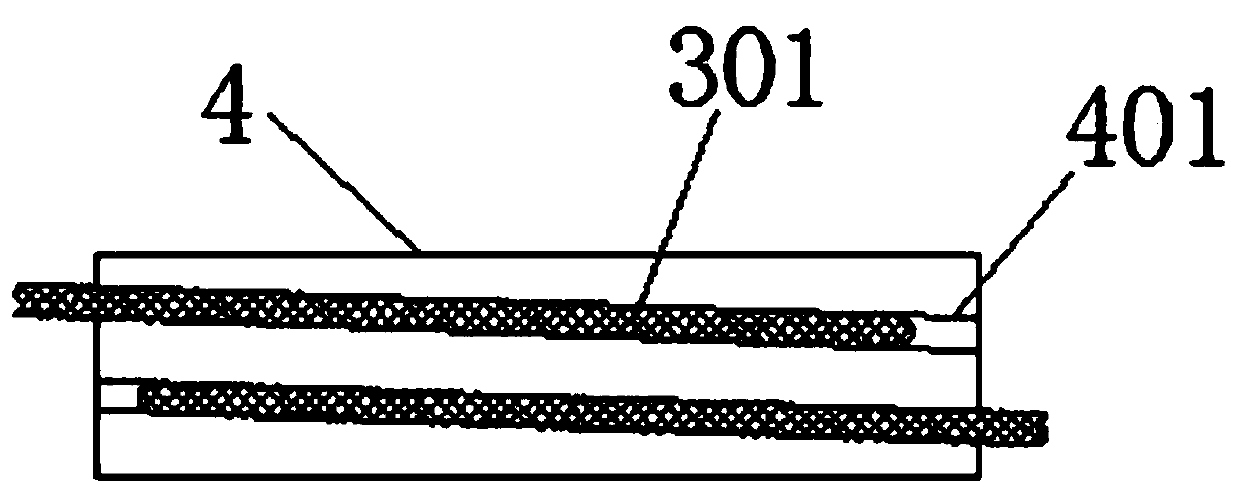

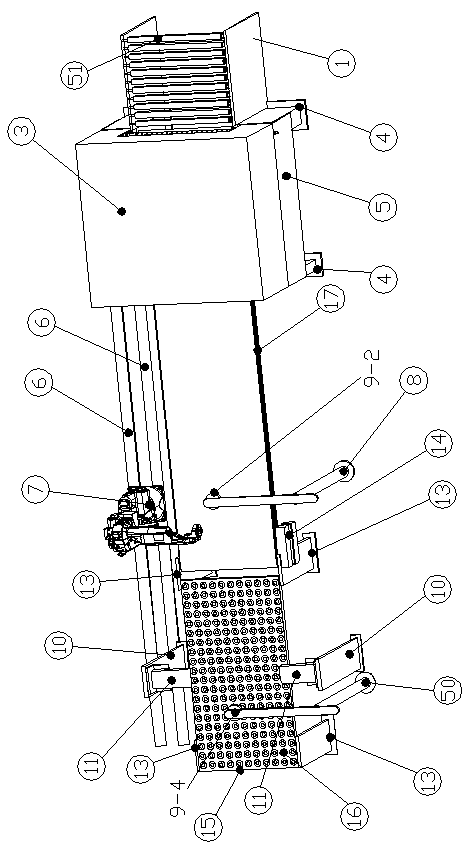

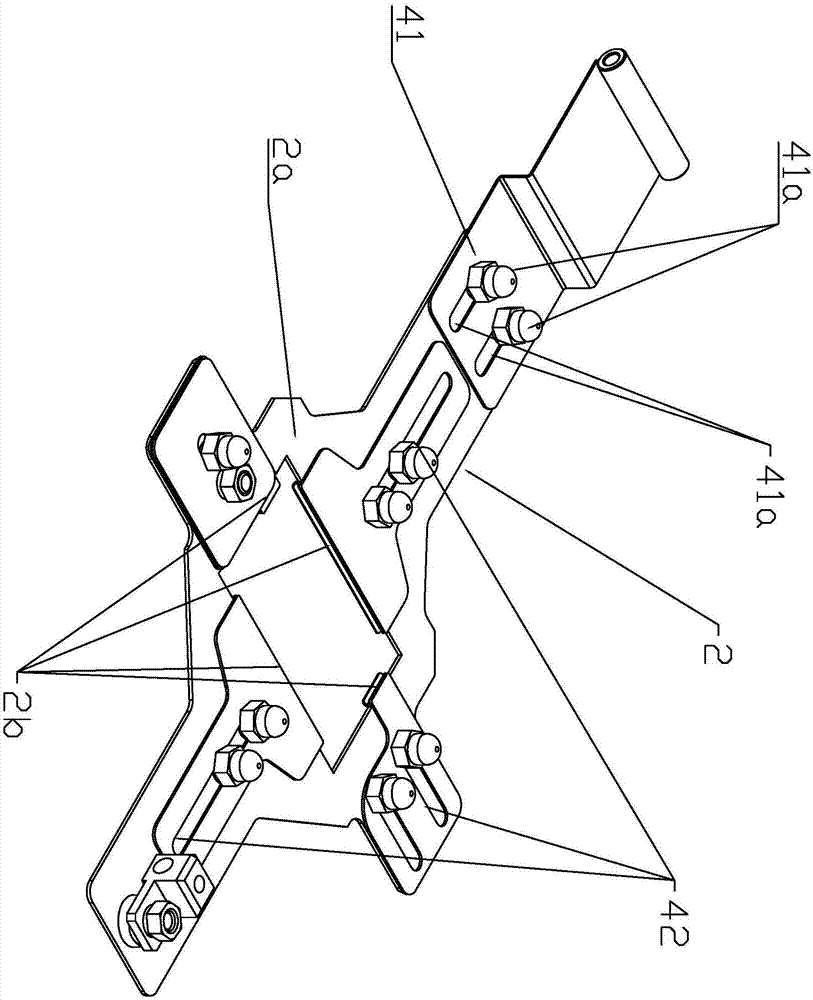

Automated production line for carpet flat seams

ActiveCN103015046ASimple structureGuaranteed uptimeWorkpiece carriersCombination sewing machinesProduction lineConveyor belt

The invention discloses an automated production line for carpet flat seams. The automated production line comprises a coiled carpet, a carpet feeding mechanism, a conveyor belt mechanism, and more than two automatic carpet flat seam stages, wherein the more than two automatic carpet flat seam stages are respectively arranged at two sides of the conveyor belt mechanism. The automated production line for carpet flat seams can automatically complete the technique processes of feeding of the coiled carpet, shearing into strips, automatic conveying, automatic capturing, shearing of residual corners of the carpet, automatic flat seam of straight lines and fillets of the carpet, and the like, multiple middle links on traditionally manually processing the flat seams of the carpet can be omitted, the fast and high-efficiency automatic streamlined production for carpet flat seams can be realized, the labor force can be liberated, and the production efficiency can be improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

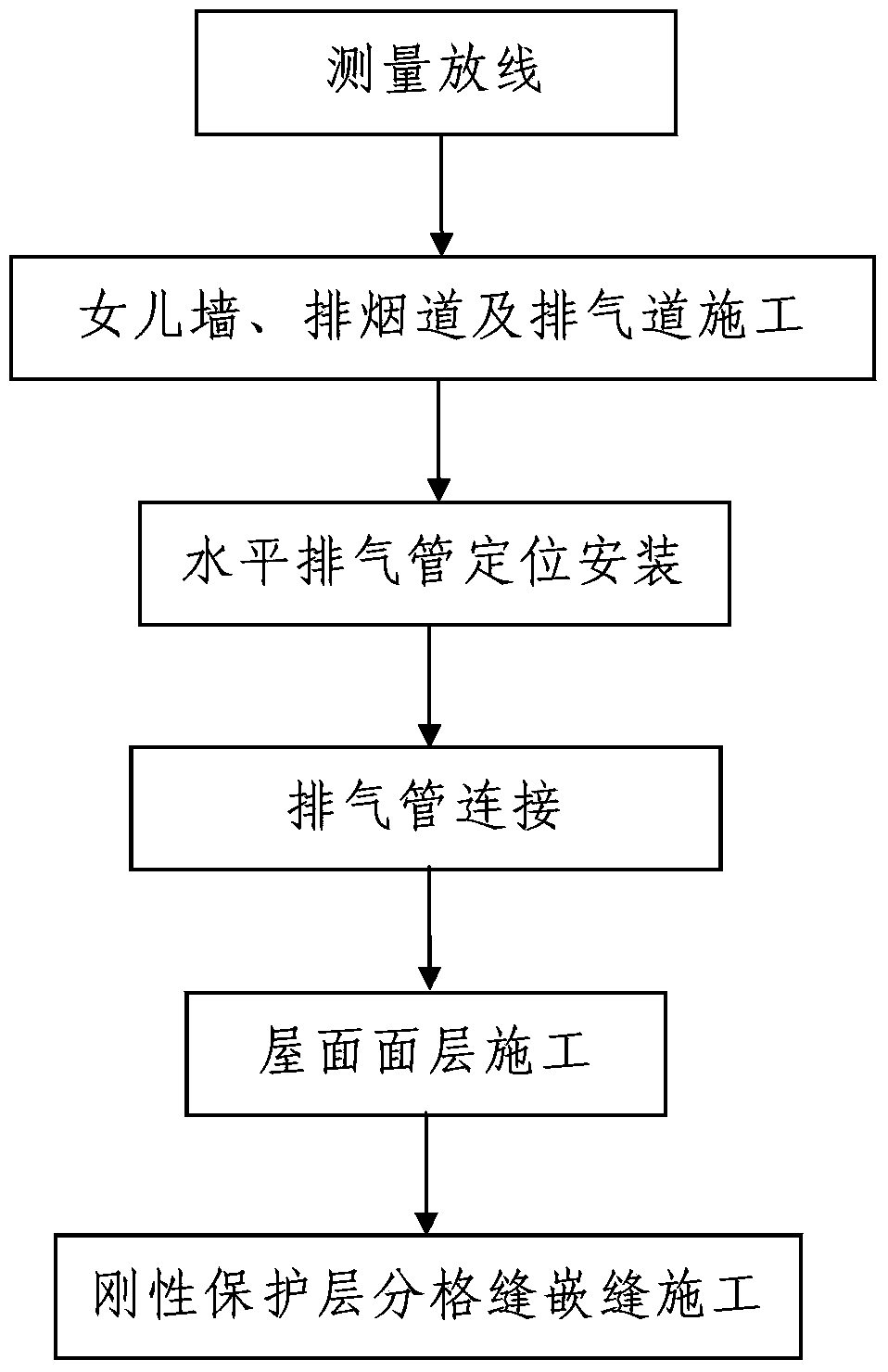

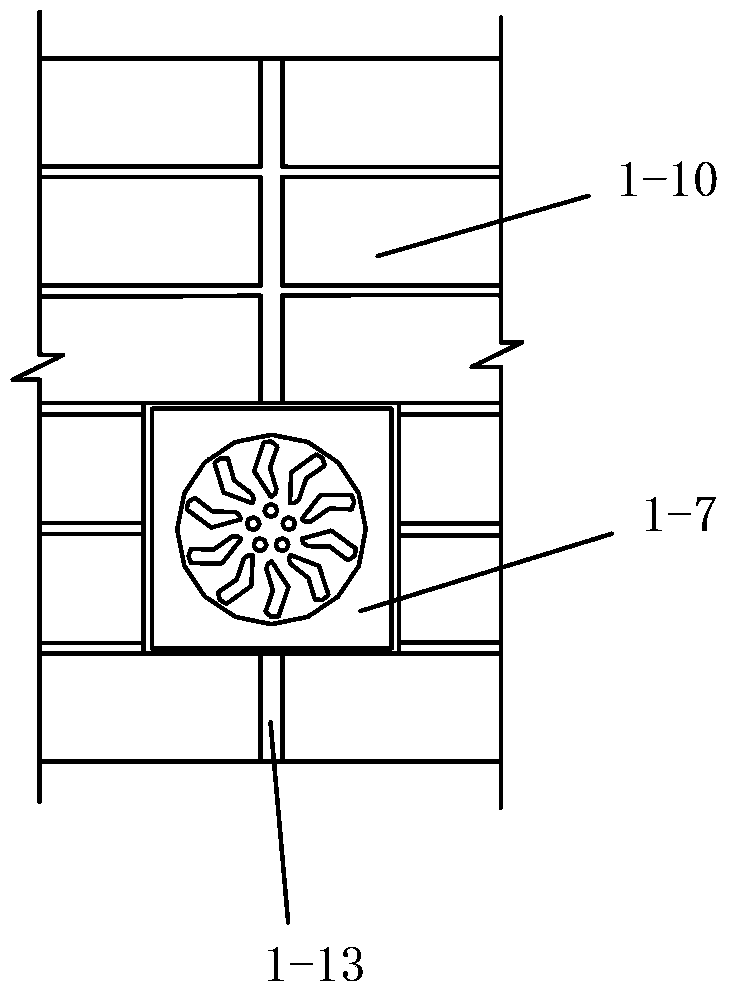

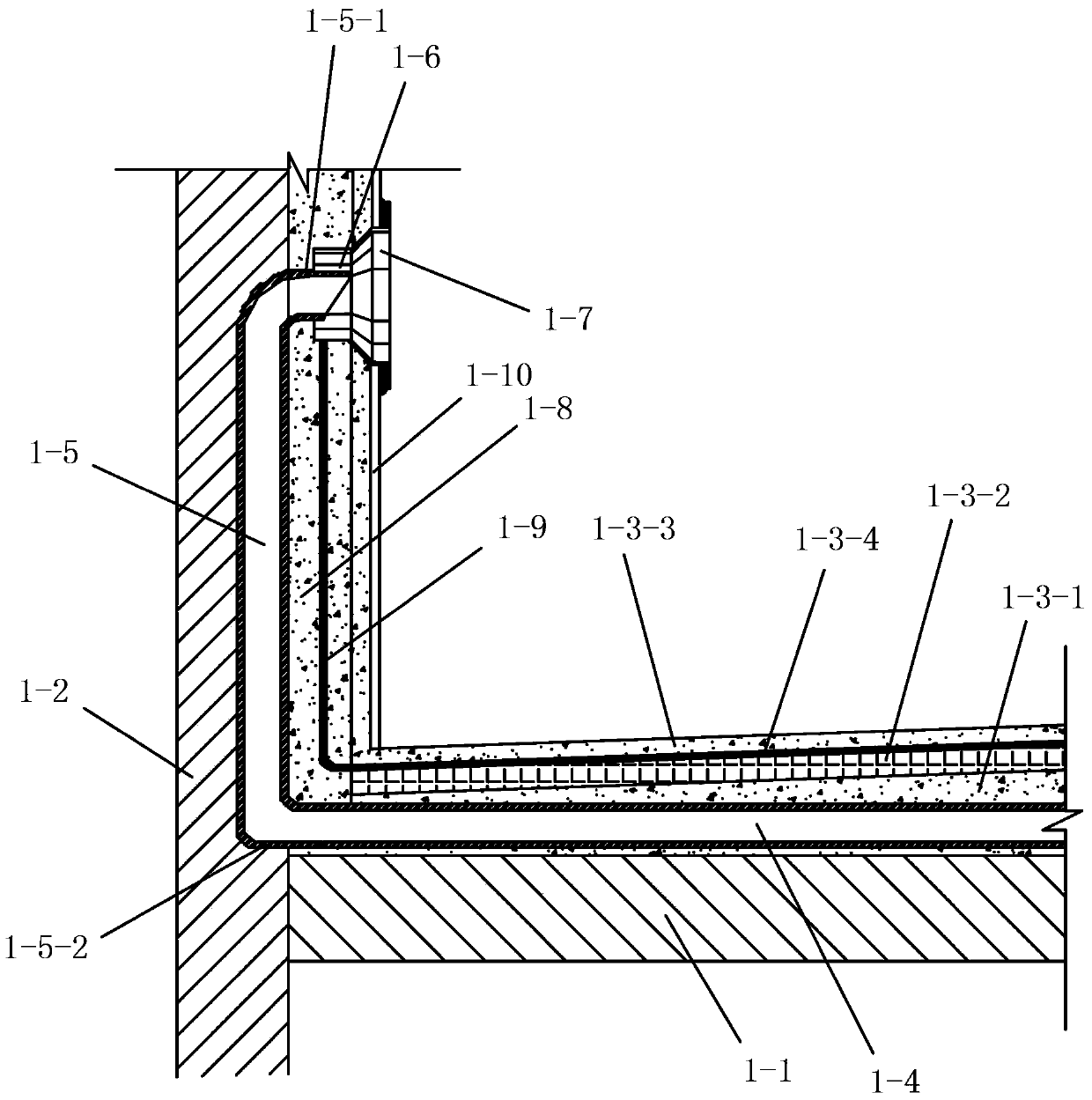

Building roof construction process

InactiveCN103362254ASimple stepsReasonable designLighting and heating apparatusBuild-up roofsInsulation layerSurface layer

The invention discloses a building roof construction process. A construction roof comprises a roof structure plate, a parapet wall and a roof surface layer, wherein the parapet wall is arranged above the roof structure plate, the roof surface layer is paved on the roof structure plate, a roof exhaust system is arranged on the construction roof and comprises a plurality of first horizontal exhaust pipes, the first horizontal exhaust pipes are respectively laid in a slope finding layer or a heat insulation layer in the roof surface layer, two ends of each first horizontal exhaust pipe are respectively connected with a vertical exhaust pipe, and the vertical exhaust pipes are embedded in the side walls of the parapet wall and a discharge flue or the side wall of an exhaust passage. The construction process of a construction roof comprises the steps of 1, surveying and setting out; 2, parapet wall, discharge flue and exhaust passage construction; 3, horizontal exhaust pipe positioning installation; 4, exhaust pipe connection; 5, roof surface layer construction; and 6, rigid protecting layer mesh division and caulking construction. The construction process has the advantages that the steps are simple, the operability is high, the realization is convenient, in addition, the work efficiency is high, the construction effect is good, and the construction quality of the construction forming building roof can be effectively ensured.

Owner:陕西建工集团有限公司 +1

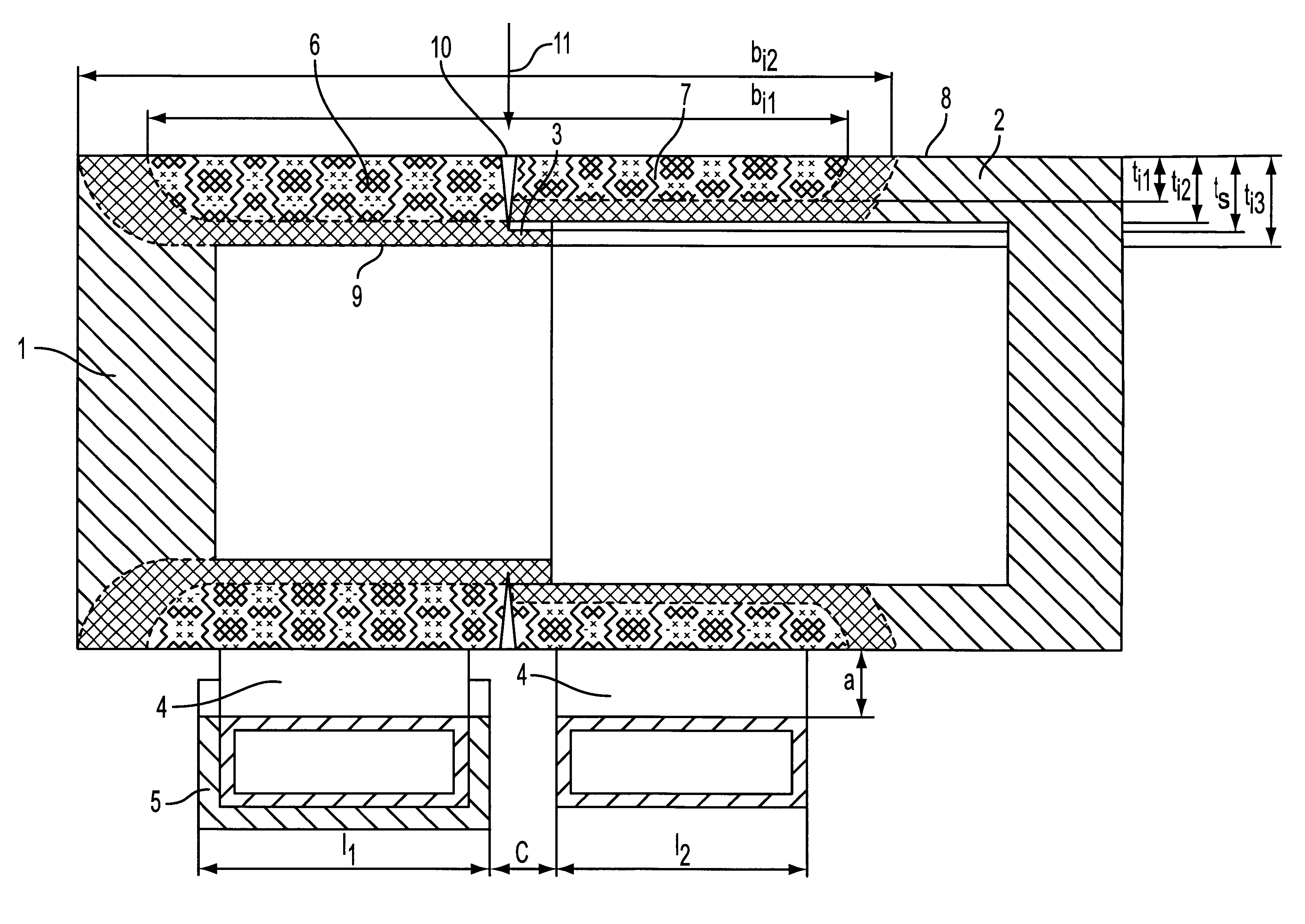

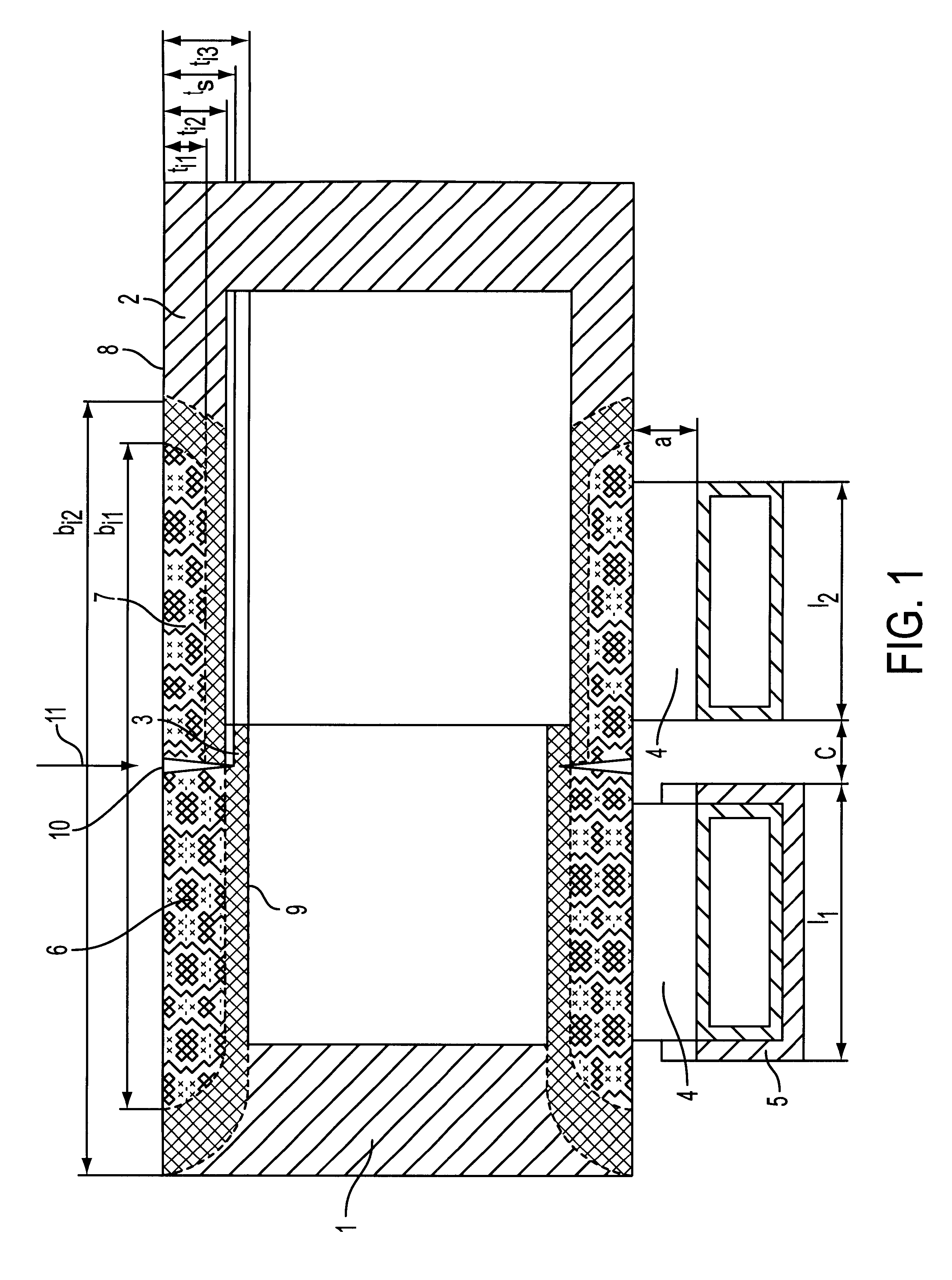

Method and device for bonding parts to be joined, as well as component

ActiveUS20120328837A1Short cycleWeight optimizationLayered productsDomestic articlesButt jointEngineering

A method is provided for producing a bonded joint between fiber-reinforced thermoplastic parts to be joined, in which fiber-containing plastic material is mixed into the joining zone while friction stir welding the parts to be joined in the form of a butt joint. A device for carrying out such a method for a joined component is also provided.

Owner:AIRBUS OPERATIONS GMBH

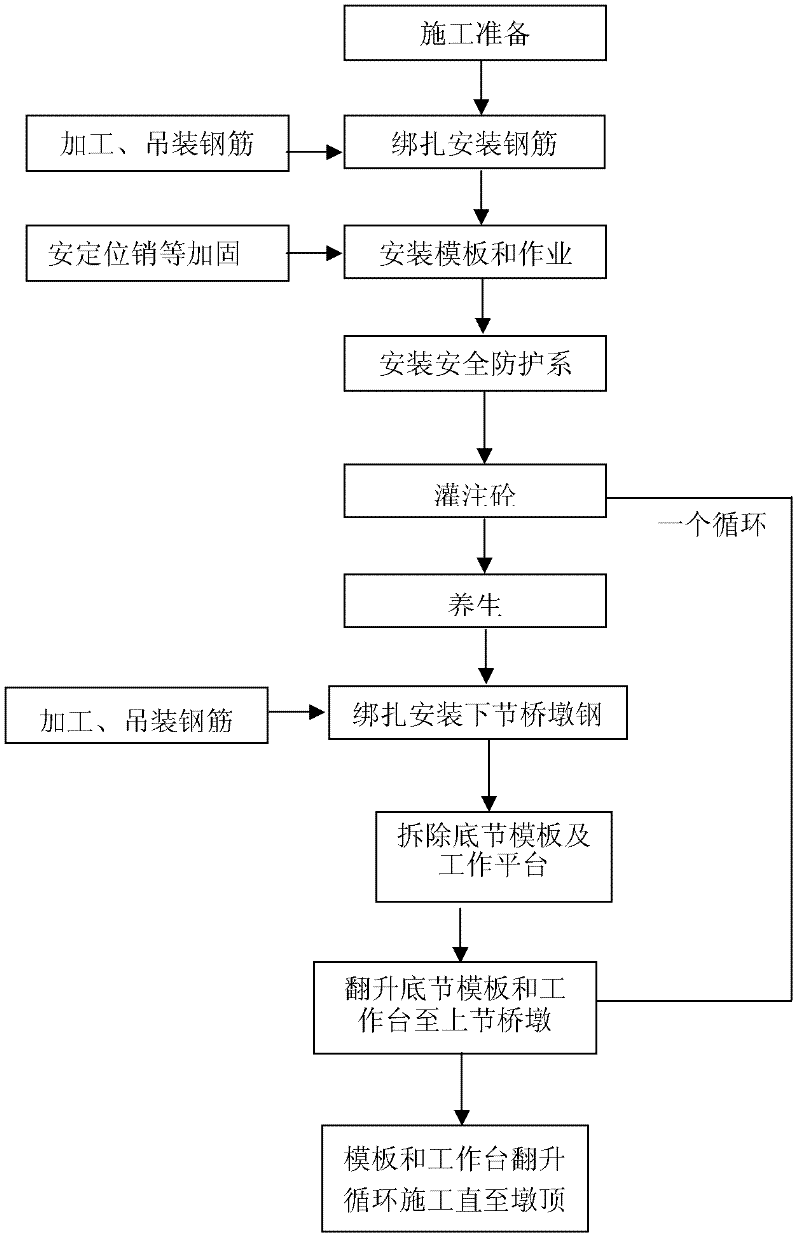

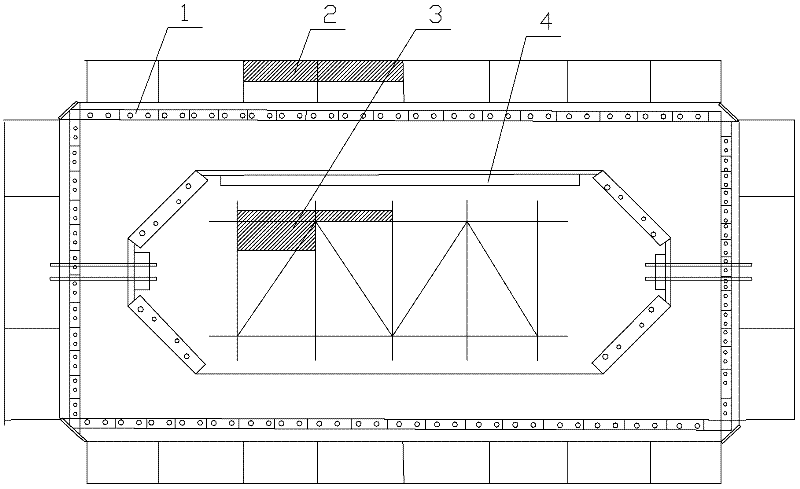

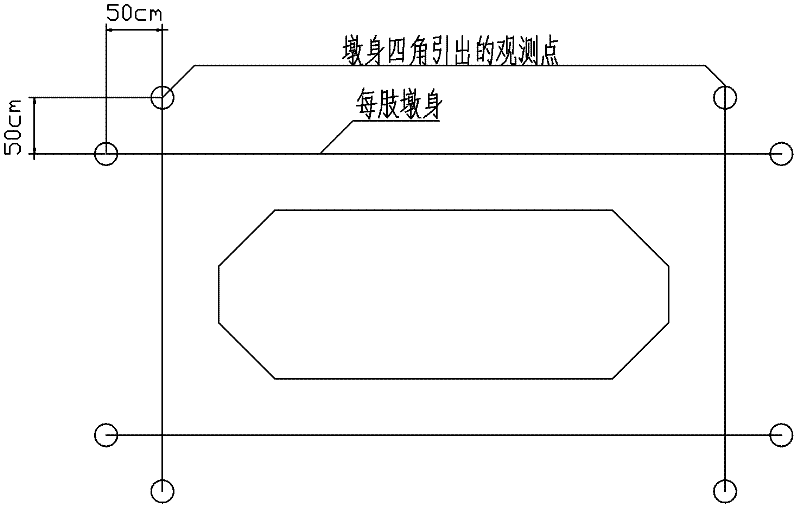

Method for constructing high pier

InactiveCN102409617AShort molding cycleShort turnaround timeBridge structural detailsBridge erection/assemblyEngineeringUltimate tensile strength

The invention discloses a method for constructing a high pier, which comprises the following steps of: 1) constructing a first section of pier through at least two upper and lower templates; 2) after concrete strength in a bottom template is more than or equal to 75 percent of design strength and concrete strength in the uppermost template is more than or equal to 2.5Mpa, detaching the bottom template and turning the bottom template above the uppermost template to serve as a second section of pier for installation, and finishing construction of the second section of pier; and 3) repeating the step 2) until construction of the whole pier is finished. Compared with a sliding formwork method, the method has the advantages that: the molding period is short, the pier is convenient to construct, and the method is convenient to operate; and compared with a creeping formwork method, the method has the advantages that: the molding period is short, a high scaffold is not needed to be erected, a few materials are occupied, and construction cost is low. The method has the advantages of sliding formwork and creeping formwork construction methods, the turnover period of the template is short, the construction period of each section of pier is short and is generally about five days, and the concrete joint of the pier has high quality.

Owner:TIANJIN 20 CONSTR

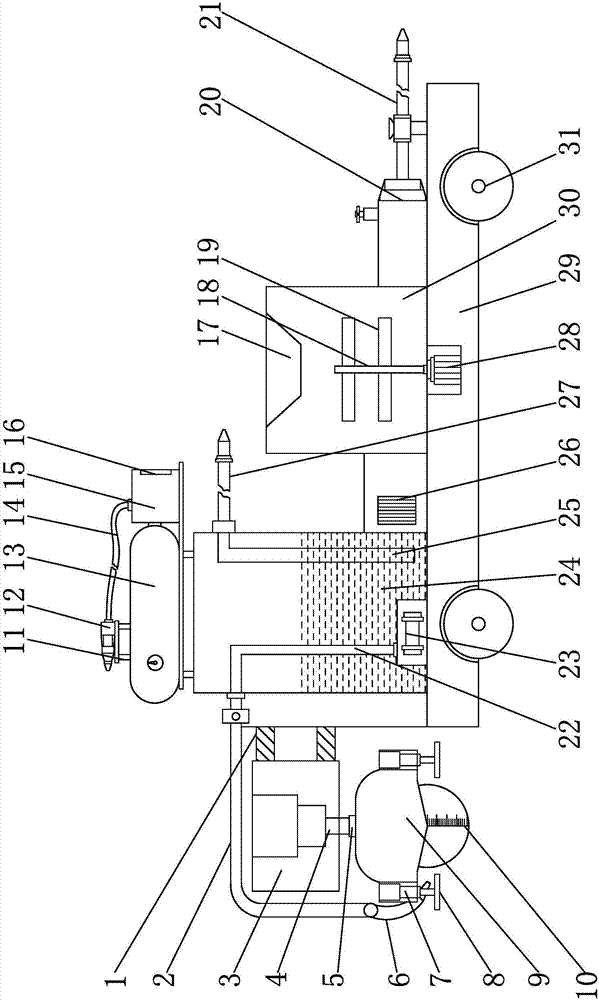

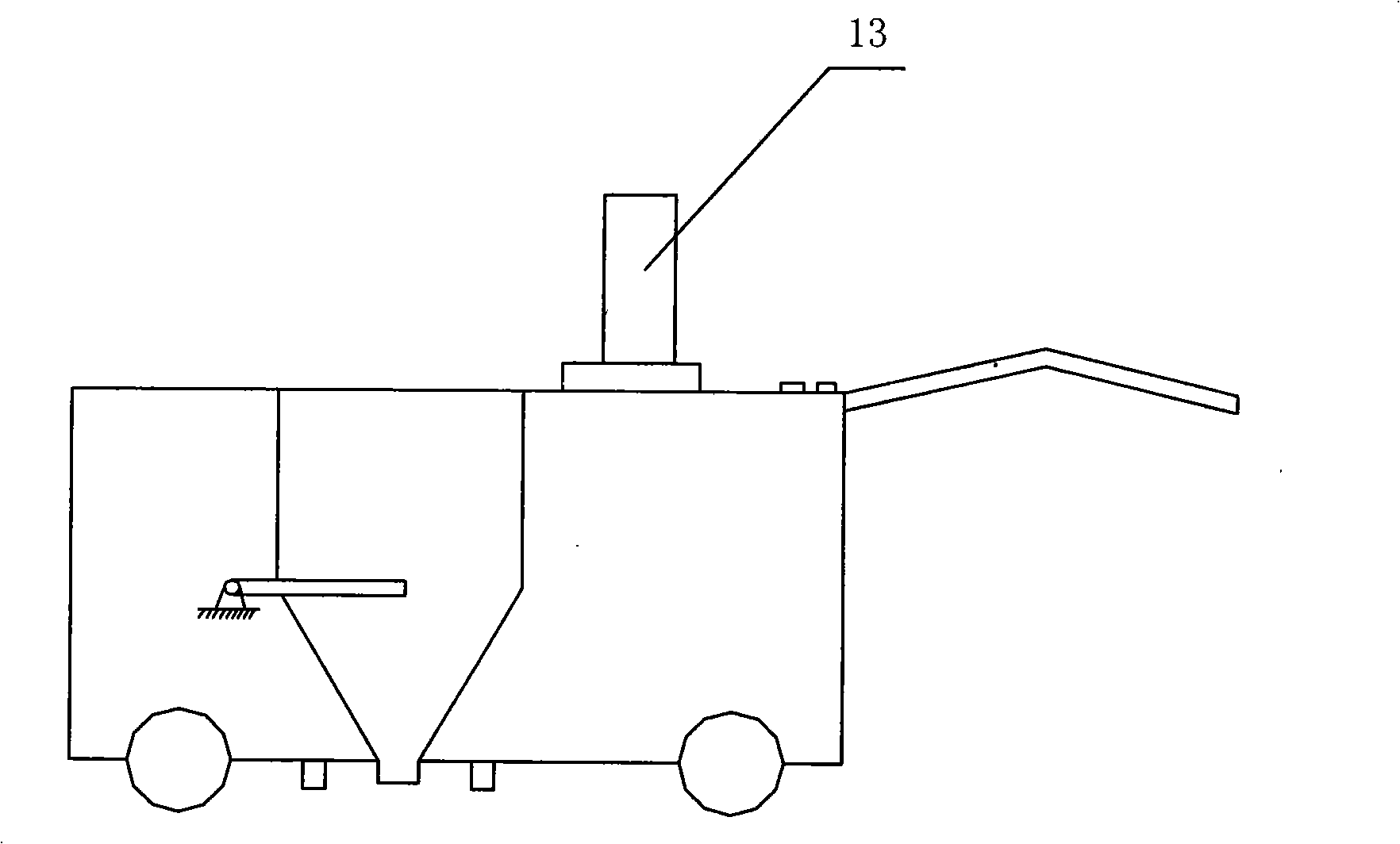

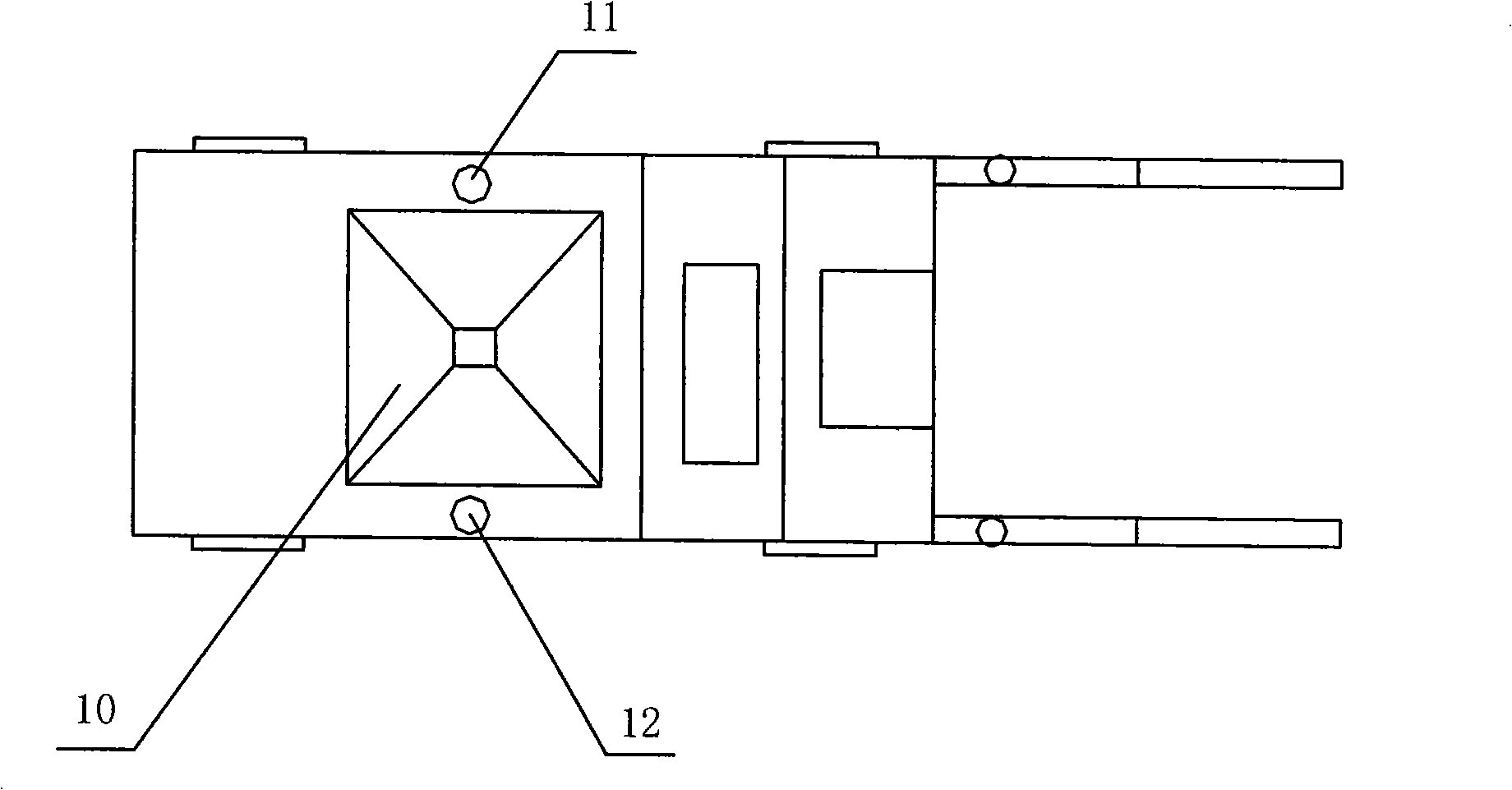

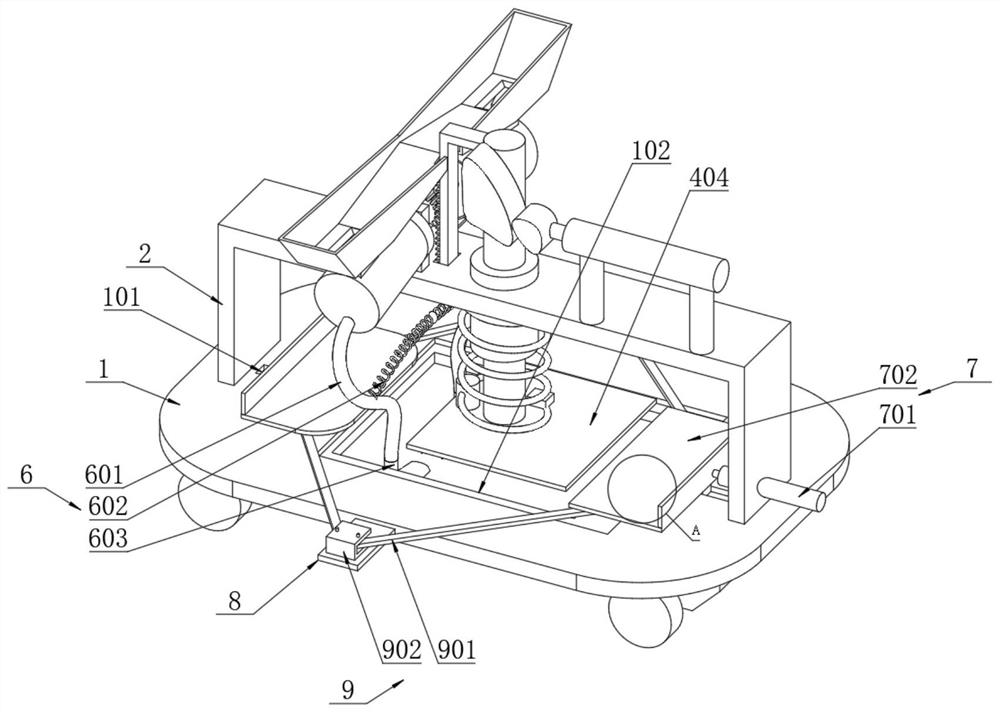

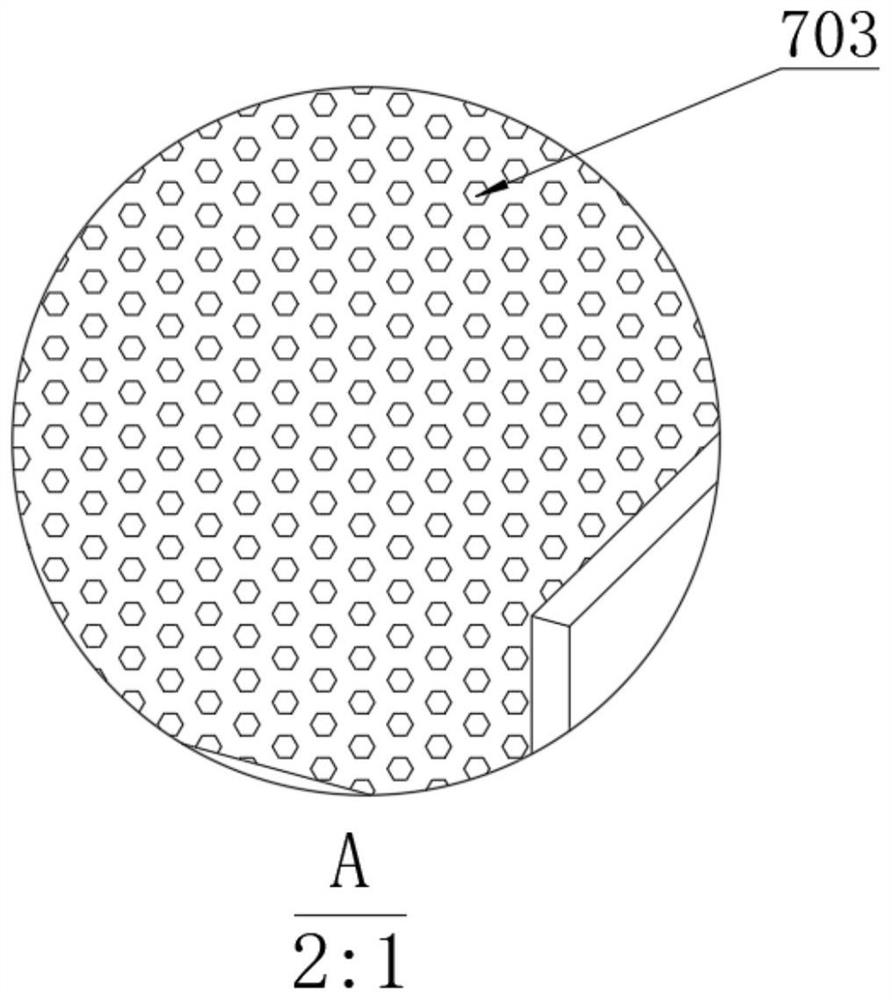

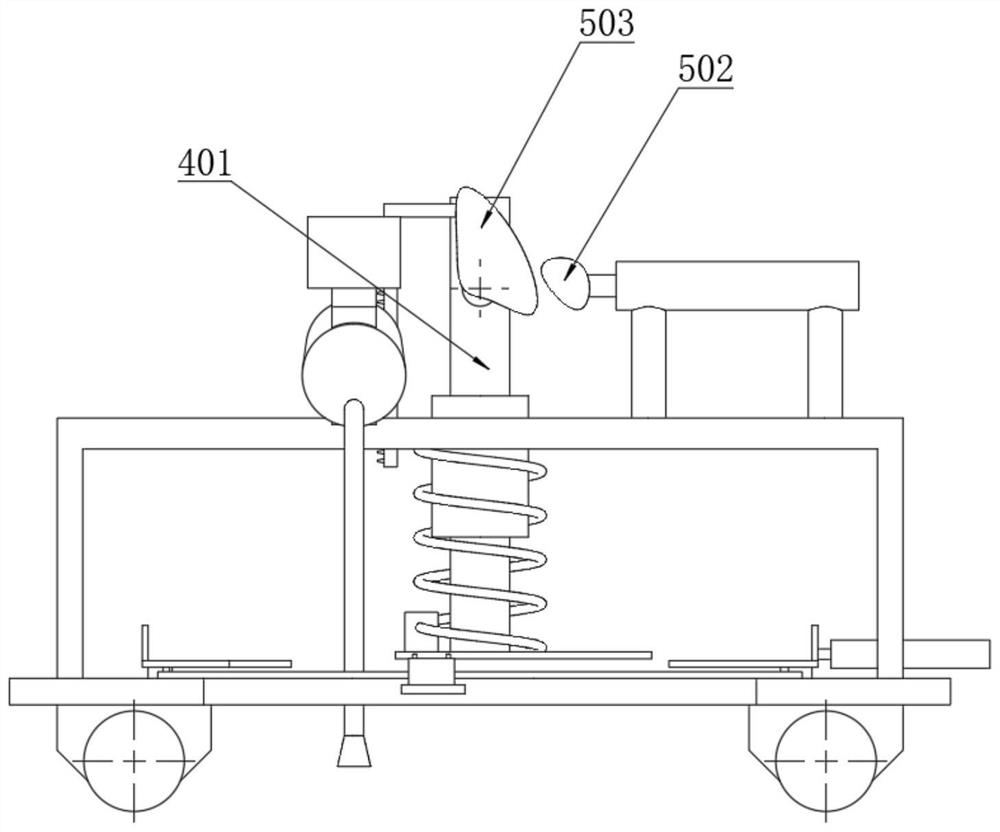

Concrete pavement crack clearing and filling integrated device and construction method

The invention relates to a concrete pavement crack clearing and filling integrated device. The device comprises a movable trolley, an inner crack impurity removing device, a cleaning and brushing device, an air blowing and drying device, a crack filling device, a lifting component and a sludge residue collecting device, wherein the air blowing and drying device, the crack filling device and the lifting component are all arranged on the movable trolley, and the inner crack impurity removing device and the cleaning and brushing device are arranged on the lifting component. The sludge residue collecting device is arranged on the moving trolley and is used for collecting sludge which is cleaned out from cracks by the inner crack impurity removing device. The method has the beneficial effects that crack cleaning and filling can be completed at the same time, cleaned sludge can be collected, walls of cracks the can be dried and the filling depth can be controlled according to different seasons, thus achieving high working efficiency and good quality in crack filling.

Owner:CHINA FIRST METALLURGICAL GROUP

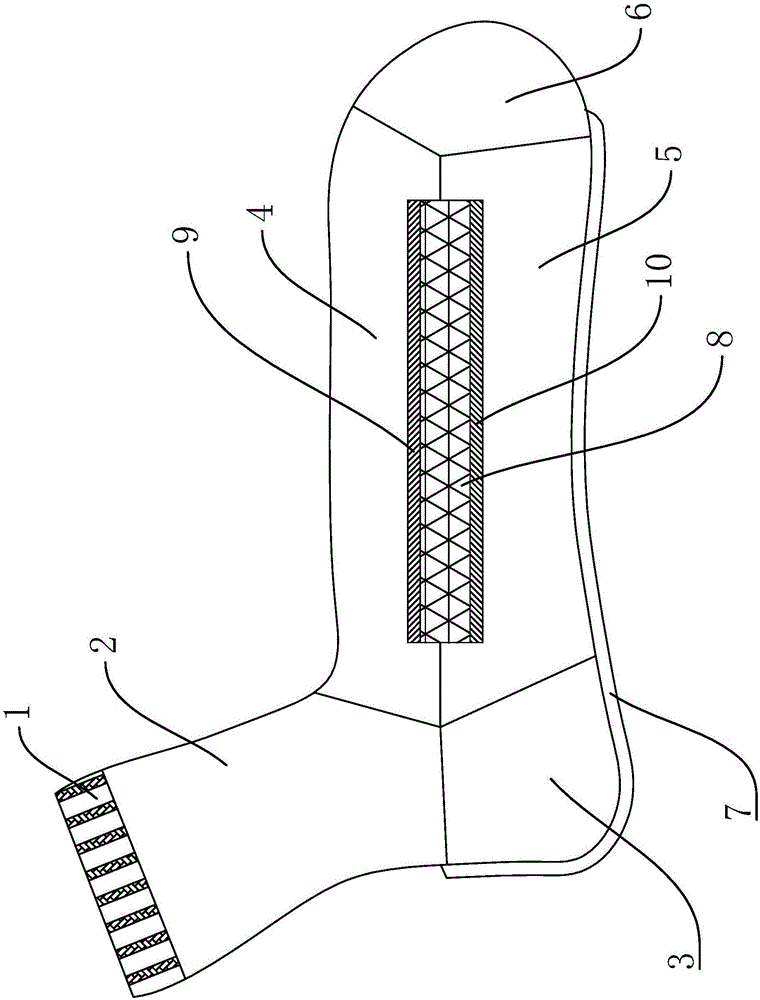

Fully-computerized glove overlock machine

ActiveCN105506868APrevent movementImprove seam qualityProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention relates to a fully-computerized glove overlock machine which comprises a glove overlock machine body and a control system. An automatic positioning device, a driving device, an expanding device and a rubber string conveying device are mounted on the glove overlock machine body and all controlled by the control system. The fully-computerized glove overlock machine has the advantages that full computer control of positioning, driving, expanding, rubber string conveying and the like is realized, high labor precision is achieved while labor efficiency is greatly improved, and glove overlock quality is guaranteed.

Owner:ZHEJIANG HAISEN KNITTING MACHINE TECHN

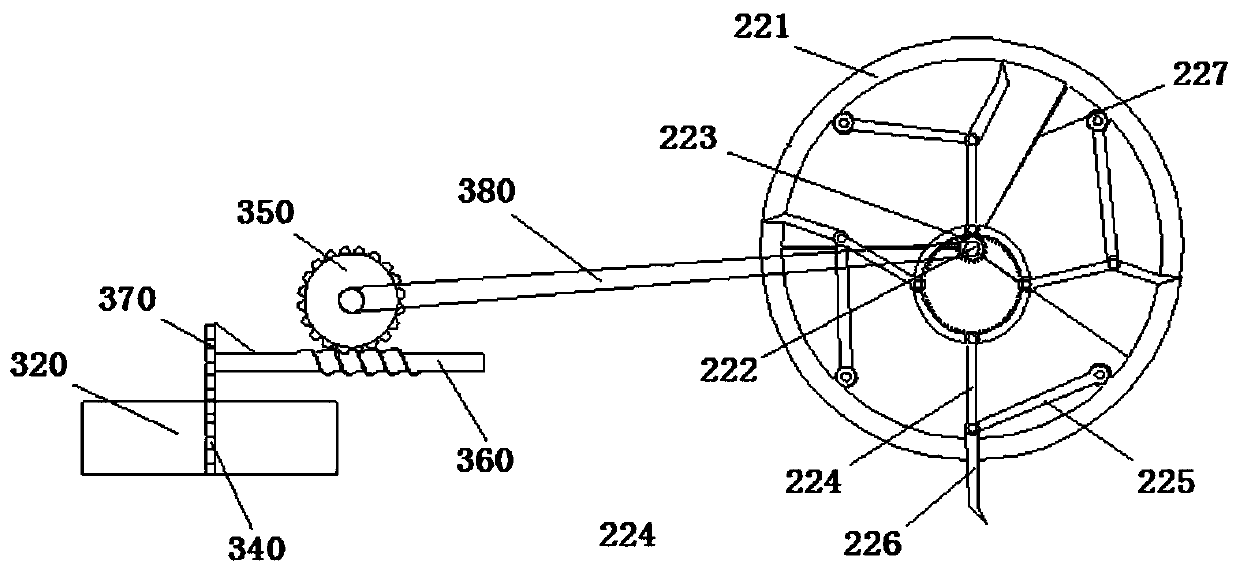

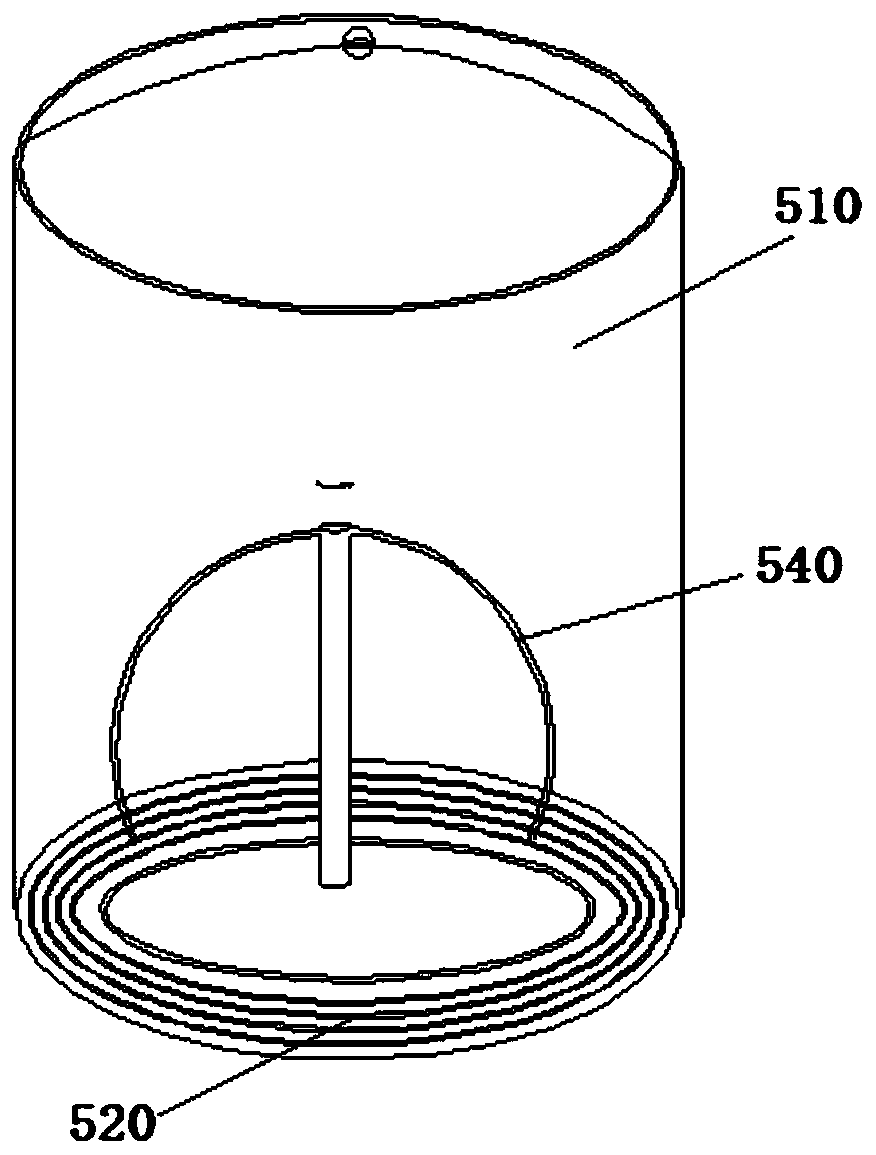

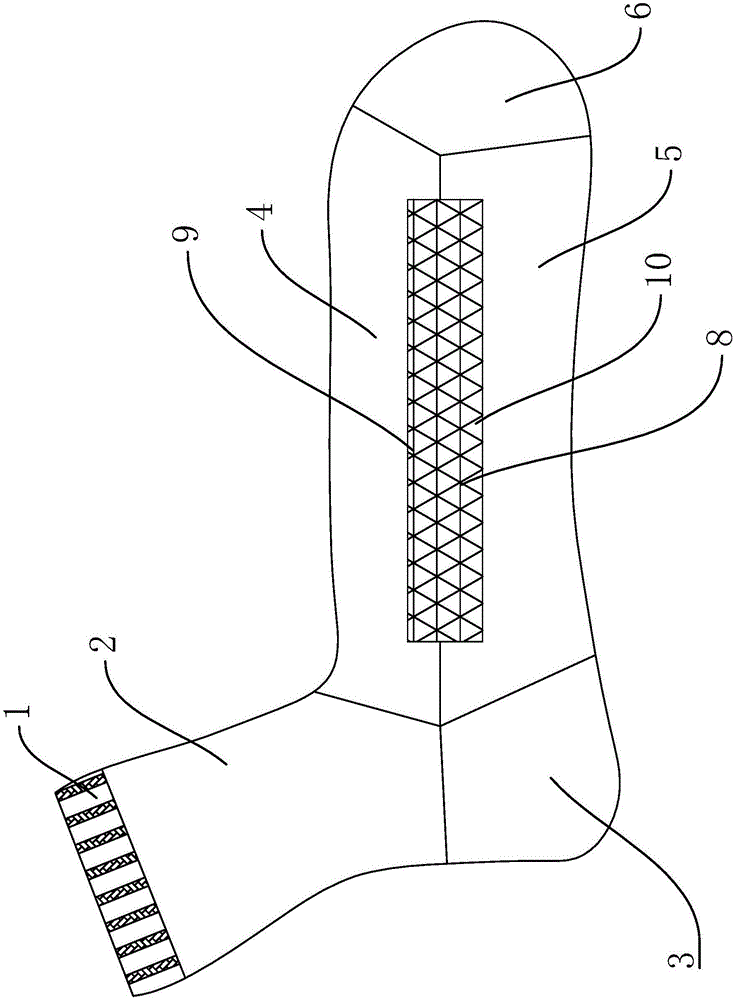

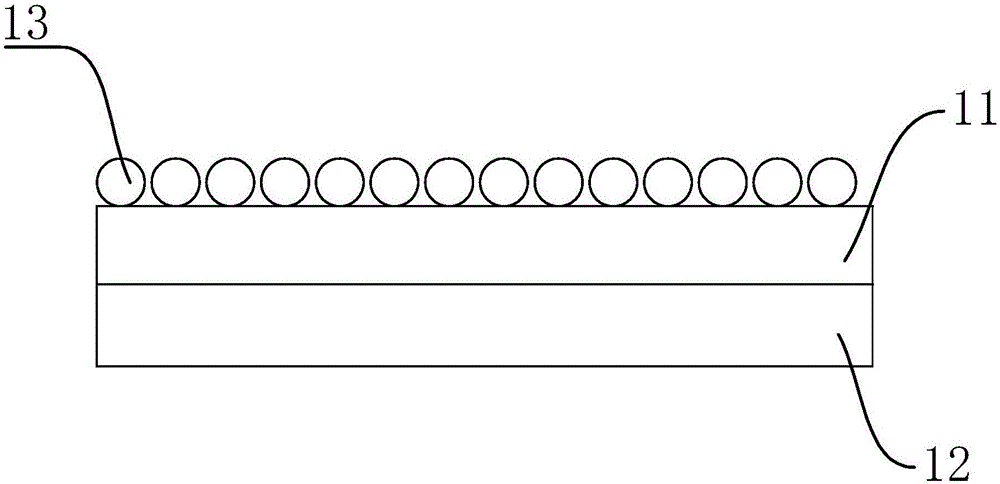

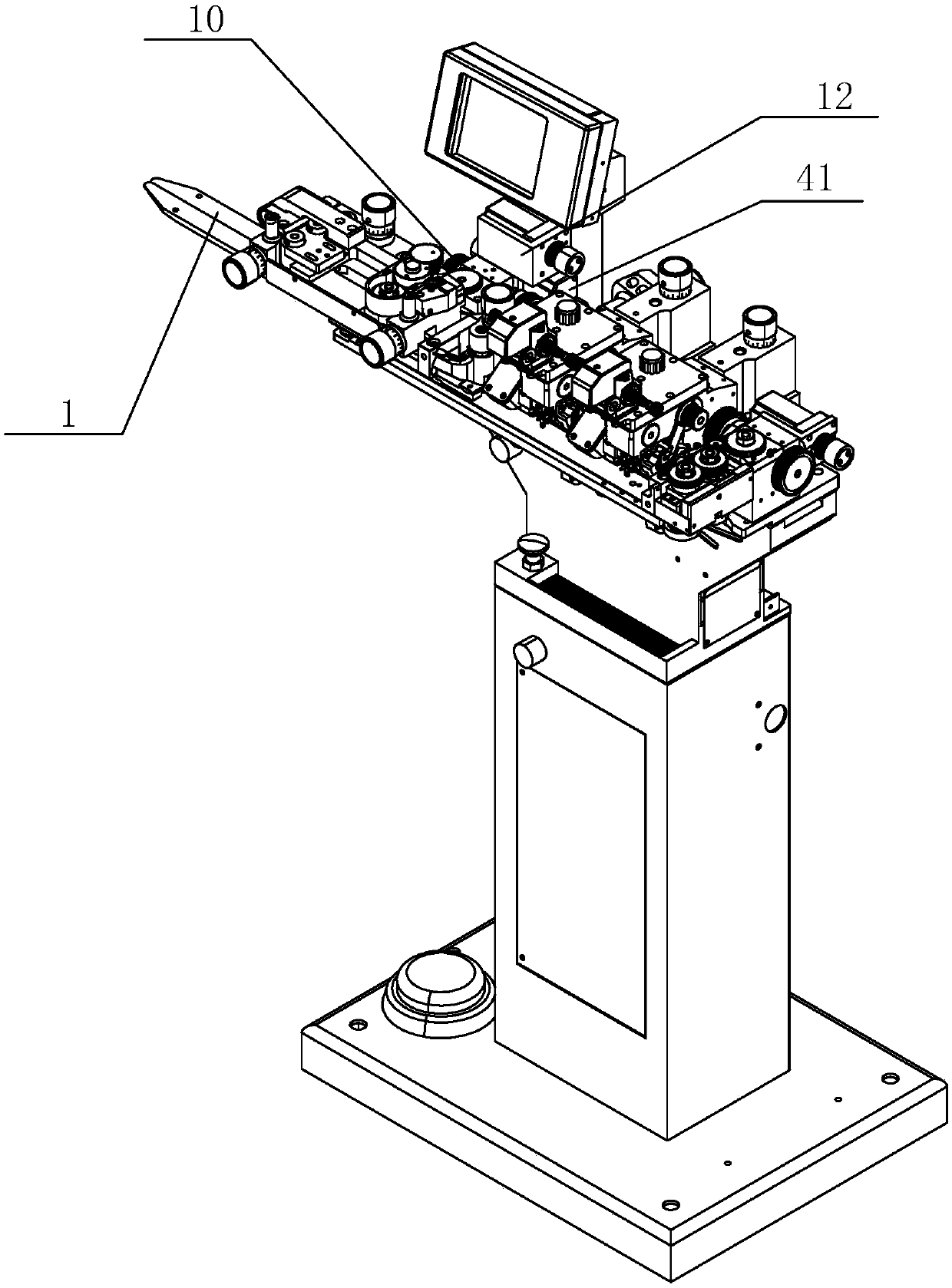

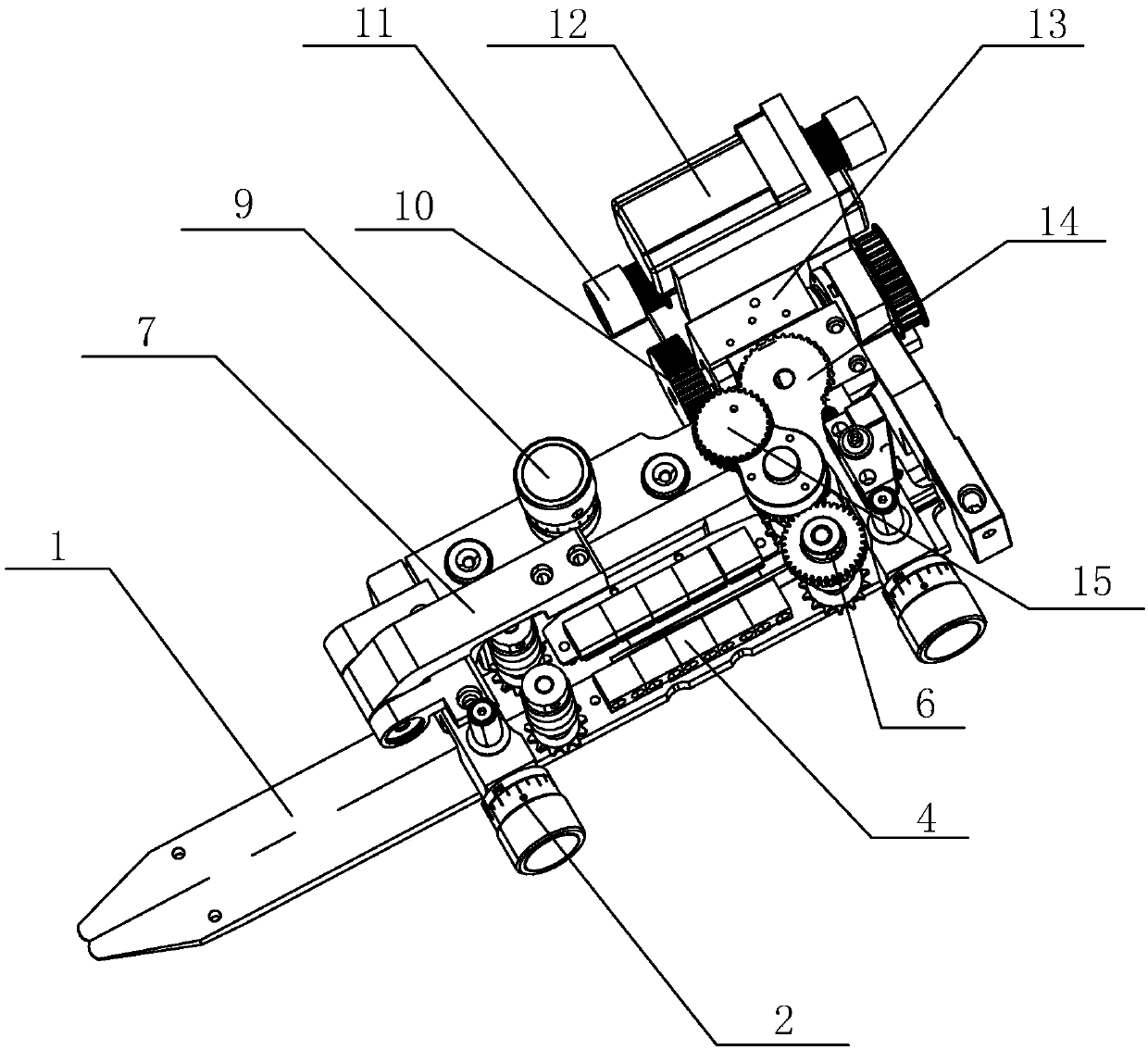

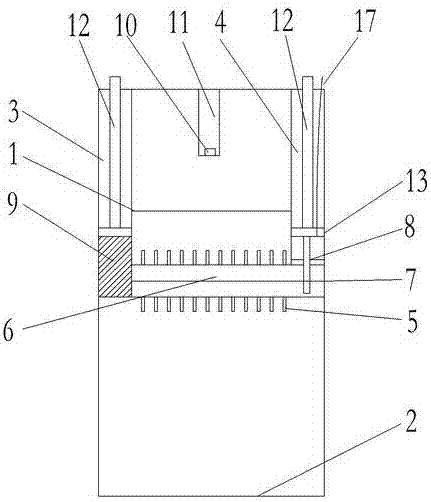

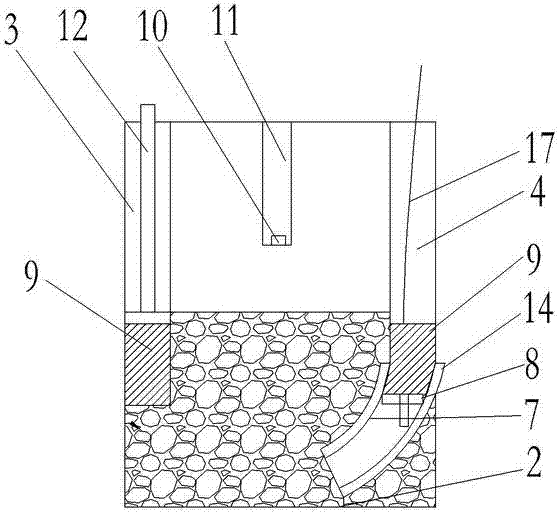

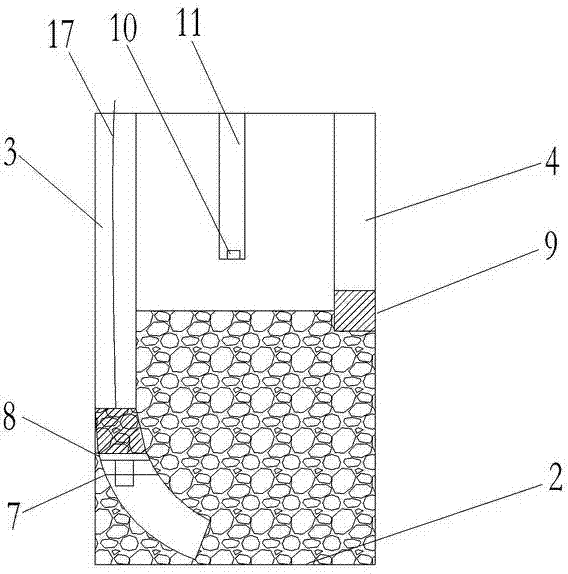

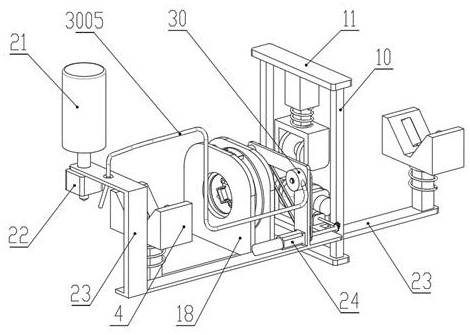

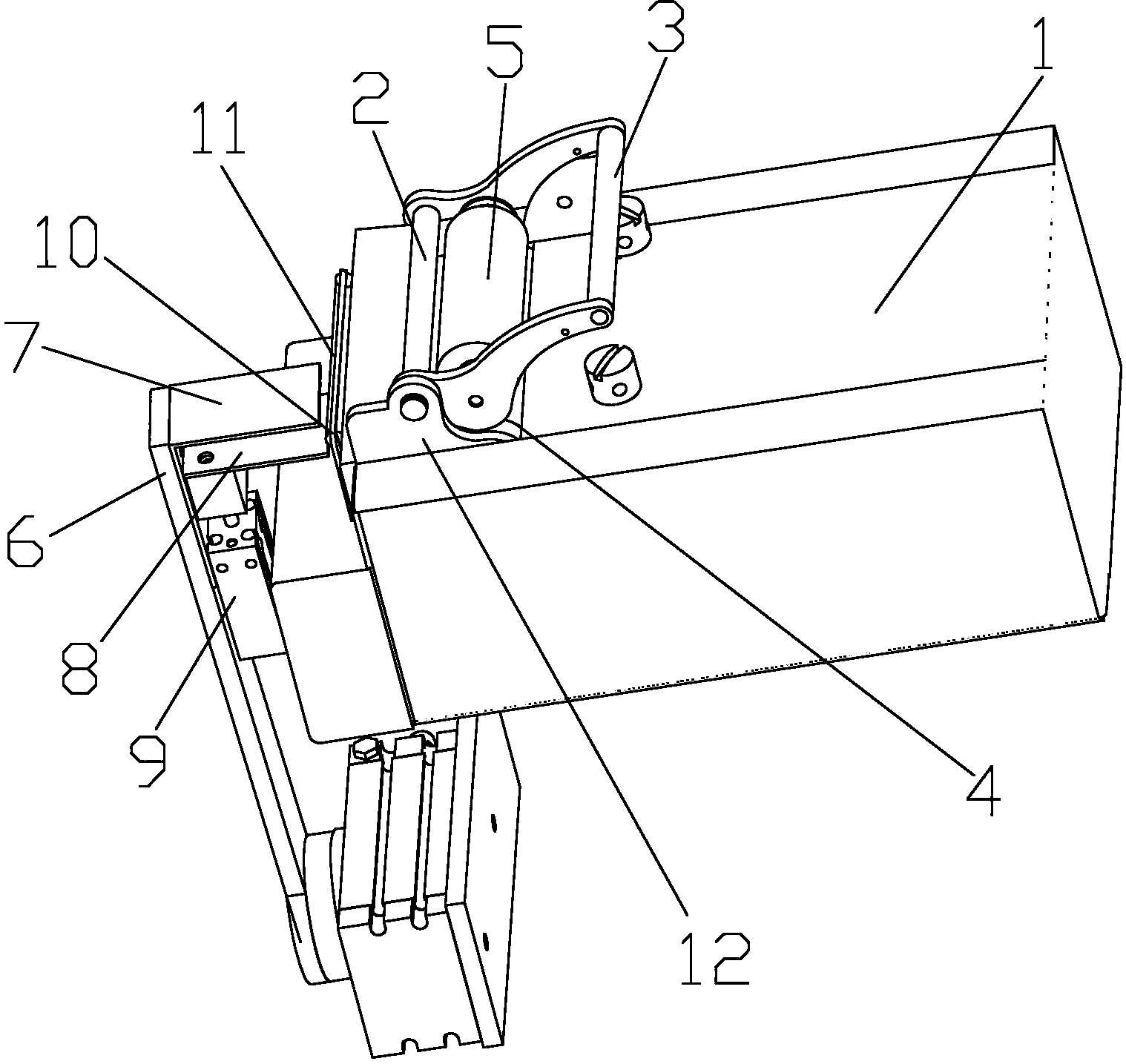

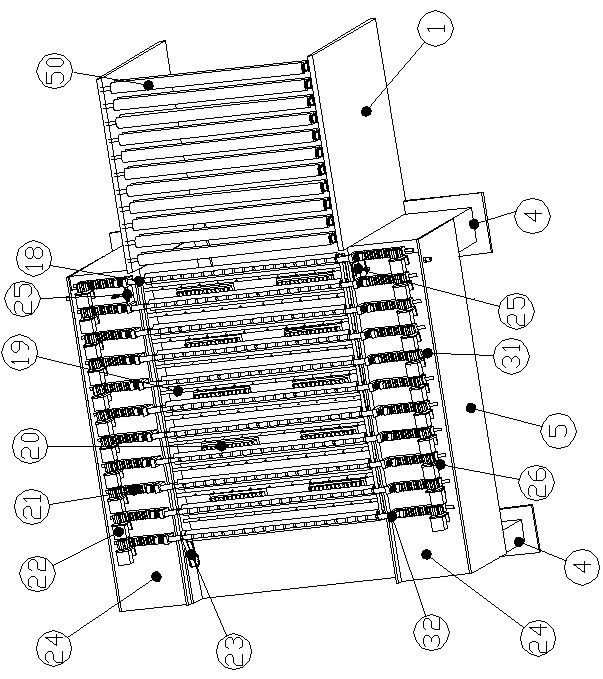

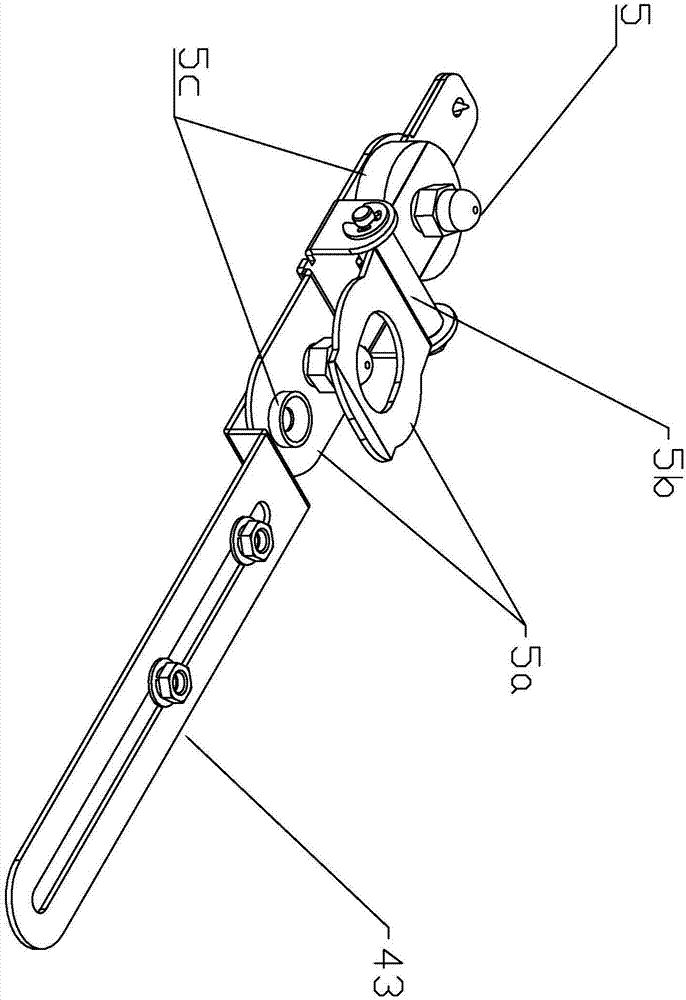

Hollow fiber cool healthcare socks and full-automatic linking machine

The invention provides a pair of hollow fiber cool healthcare socks and a full-automatic linking machine, and belongs to the technical field of textiles. Each hollow fiber cool healthcare sock comprises a sock body; the sock body is formed by weaving blended yarns; the blended yarns include yarns prepared from porous polyester fibers and special fibers by adopting hollow spinning; the sock body comprises a sock opening, a sock leg, a sock heel, the sock body and a sock toe; the front end of the sock body is the sock toe; the turning joint of the sock leg and the sock body is the sock heel; the upper end of the sock leg is the sock opening; the sock body comprises a sock surface and a sock bottom; the sock toe and the sock surface are linked by adopting the full-automatic linking machine; the sock bottom is embedded with viscose fibers; the full-automatic linking machine comprises a machine frame; the machine frame comprises a base and a working table; and a first conveying mechanism, a second conveying mechanism, a guide hole mechanism, a trimming mechanism, a first machine head, a yarn frame and a second machine head are arranged on the working table. The healthcare socks are good in moisture absorbing and sweat releasing property, have a cool feeling, are high in comfort level, and are suitable to be worn in summer.

Owner:海宁威尔斯针织股份有限公司

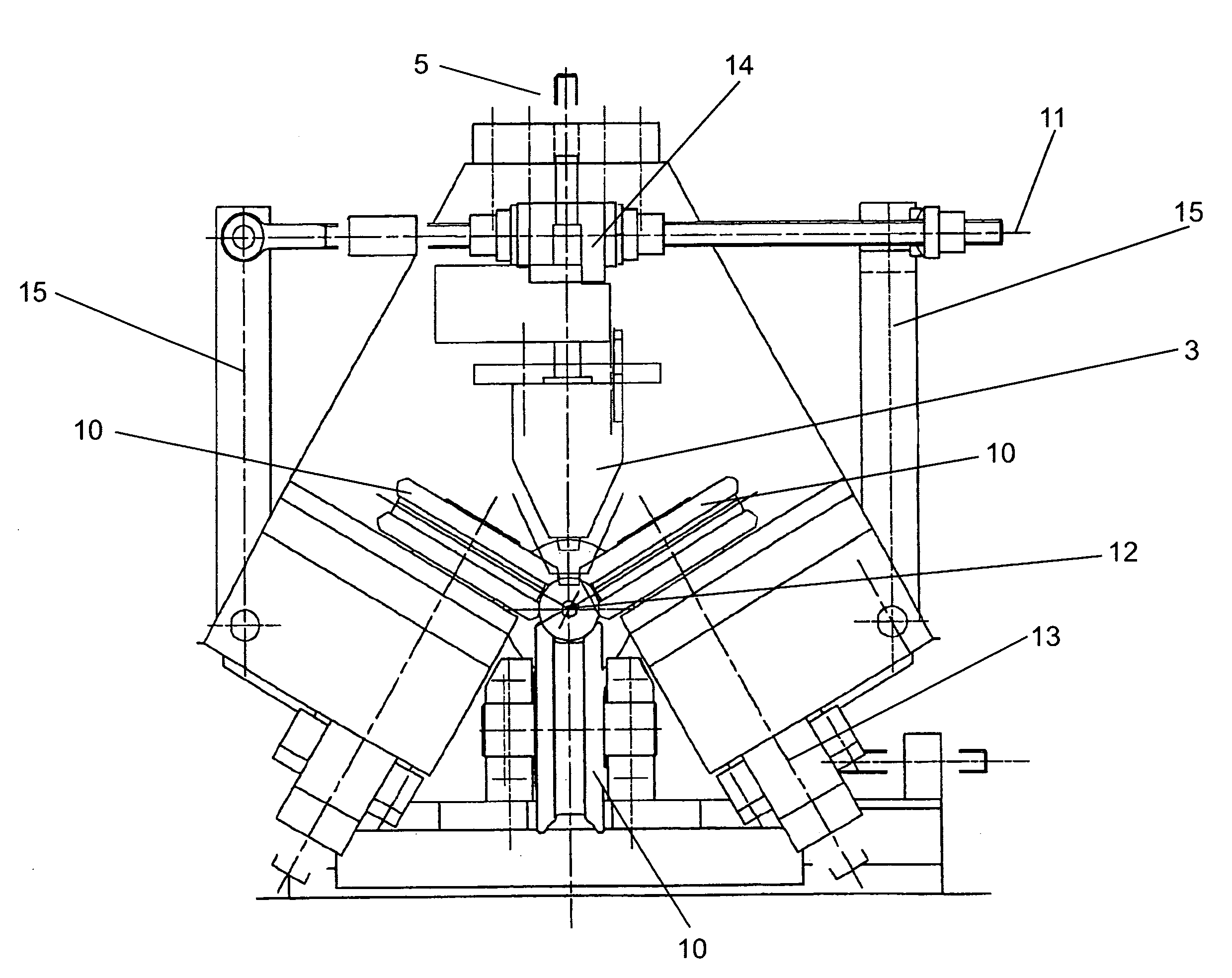

Efficient sock butend sewing machine rivaling manual butend sewing

ActiveCN107761262AReduce widthLow failure rateWork-feeding meansCombination sewing machinesIndustrial engineeringSewing machine

The invention discloses an efficient sock butend sewing machine rivaling manual butend sewing. The efficient sock butend sewing machine comprises a butend sewing motor for driving the sock butend sewing machine and a conveying motor for driving a sock conveying system; the efficient sock butend sewing machine is characterized in that the sock conveying system comprises a front-section conveying system body, a rear-section conveying system body, a butend sewing machine body, two machine heads and two lifting systems, wherein the butend sewing machine body, the two machines head and the two lifting systems are arranged on a mounting platform board. According to the efficient sock butend sewing machine rivaling manual butend sewing, the sewing width is small, the sewing speed ratio is adjustable, and the two machine heads share one center shaft, so that sewing lines of secondary sewing are highly consistent in coaxality.

Owner:ZHEJIANG ROSSO EQUIP MFG

Method for artificial building of hot dry rock heat storage layer

The invention discloses a method for artificial building of a hot dry rock heat storage layer. Heat storage layer joint forming is conducted through the layered segment blasting joint forming mode. A plurality of cavities with certain widths are formed in a horizontal well segment at equal intervals through a high-pressure pulse jet flow drill tool, liquid explosives are injected into a horizontal well, and then an electromagnetic initiator is put down from an injection well. Then rock powder is backfilled to a production well and the injection well correspondingly, and the well hole sealing effect is achieved. Meanwhile, a microseismic monitoring device is put down from a monitoring well to monitor the blasting joint forming effect. After blasting is implemented, when cracks are sufficiently developed, blasting operation can be implemented again. When artificial crack swarms meet the design requirements, blasting operation can be stopped. According to the method for artificial building of the hot dry rock heat storage layer, the joint forming quality can be improved, the large-size artificial crack swarms are formed, meanwhile large hydraulic fracturing is not needed, increasing of the utilization rate of a hot dry rock layer is facilitated, and conditions are provided for achievement of commercial use of hot dry rocks.

Owner:JILIN UNIV

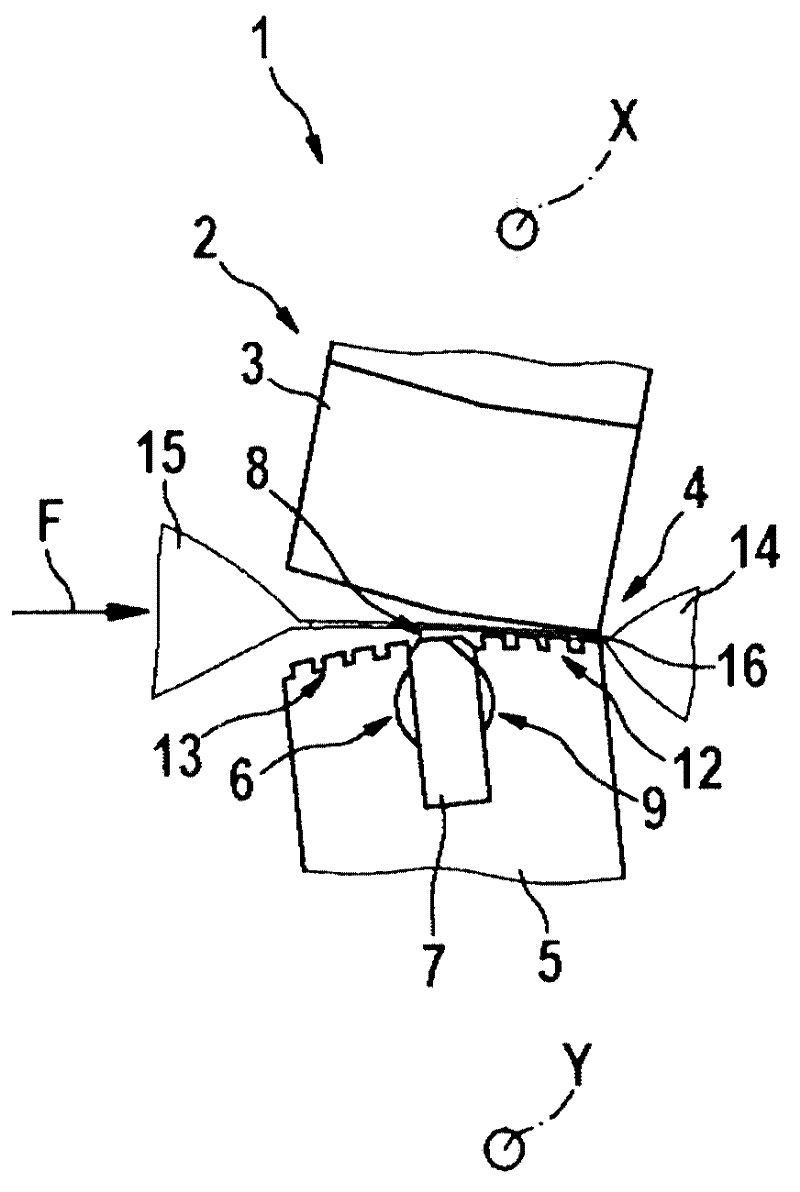

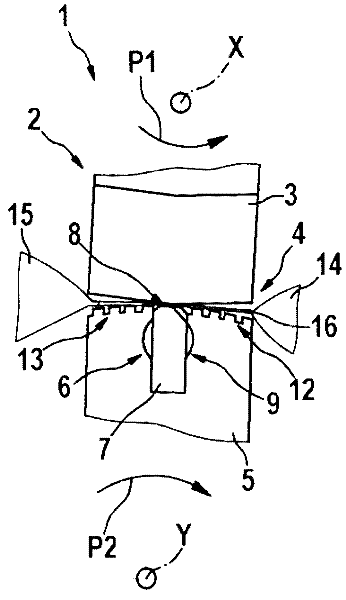

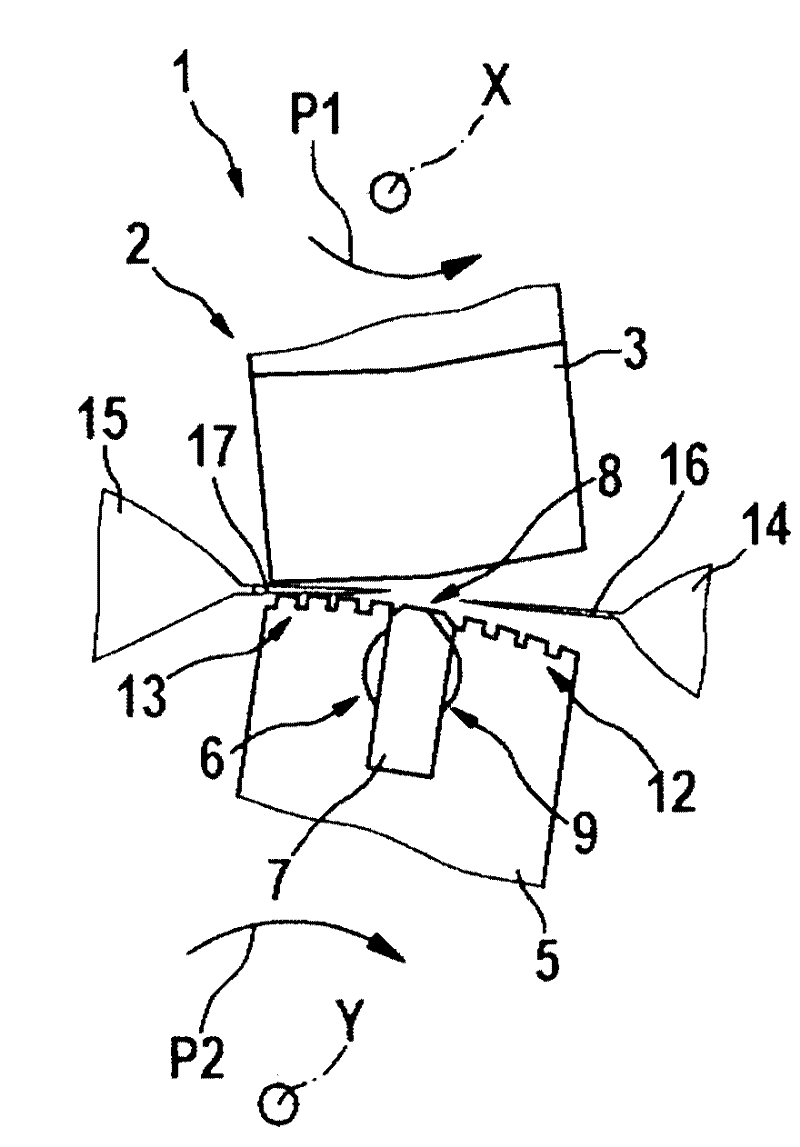

Device and method for welding and separating packaging materials for a package

InactiveCN102548735AExtended service lifeReduced conversion timeWrapper twisting/gatheringEngineeringUltrasonic welding

The invention relates to a device for welding and separating a packaging material (4) for a package, comprising an ultrasonic welding device (2) with a sonotrode (3) and an anvil (5) for sealing the packaging material (4), wherein the sonotrode (3) is rotatable about a first axis of rotation (X) and the anvil (5) is rotatable about a second axis of rotation (Y), and a cutting device (6) with at least one blade (7) for separating the packaging material (4), which device is arranged in the anvil (5), wherein the at least one blade (7) is arranged on the anvil (5) in such a way that a minimum distance (S) between the sonotrode (3) and a cutting edge (8) of the blade (7) is maintained, and so the packaging material (4) can be severed without any contact between the sonotrode (3) and the blade (7).

Owner:ROBERT BOSCH GMBH

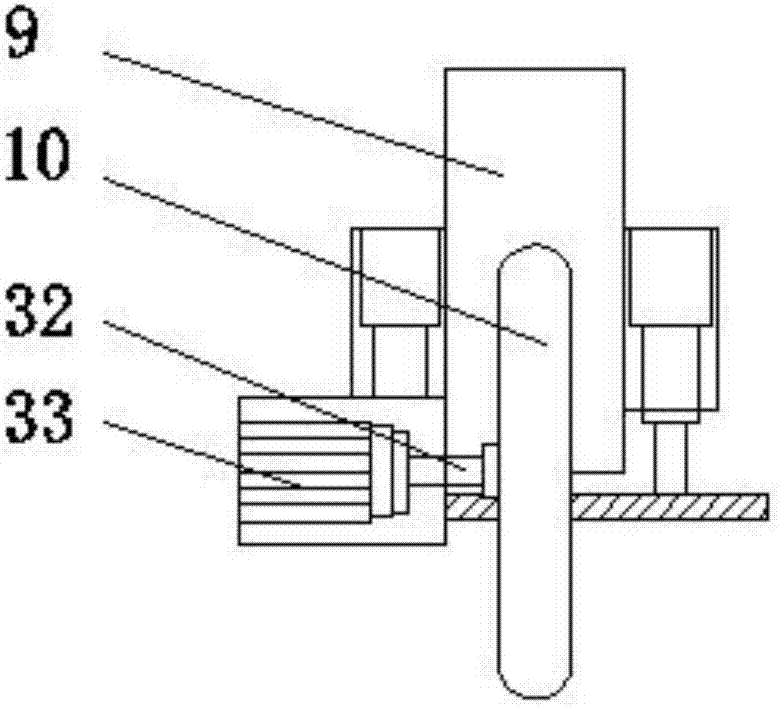

Automatic laser cutting device facilitating clamping and positioning and used for pipe fitting machining

ActiveCN114473254AEasy to clamp and positionFacilitates automatic rotary cuttingWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingStructural engineering

The invention discloses an automatic laser cutting device convenient for clamping and positioning for pipe fitting processing, which comprises a cutting platform, supporting legs are fixedly connected to the periphery of the lower end face of the cutting platform, telescopic columns are slidably connected to the left side and the right side of the upper end face of the cutting platform, and supporting blocks are fixedly connected to the upper end faces of the telescopic columns. A reset spring is connected to the side face of the telescopic column, and first roller columns are connected to the two sides of the interior of the supporting block through shafts. According to the laser cutting device, a pipe fitting can be conveniently, rapidly and conveniently clamped and positioned, so that the operation convenience of the laser cutting device can be effectively improved, the pipe fitting can be conveniently and automatically rotated and cut, the joint cutting quality of the pipe fitting is improved, the pipe fitting can be conveniently and automatically conveyed, the cutting machining efficiency of the pipe fitting is improved, and the labor intensity of workers is reduced. And moreover, water spraying cooling and smoke removal can be conveniently carried out on a notch of the pipe fitting, so that environmental pollution is avoided.

Owner:徐州市富昌制药机械有限公司

Joint cutting and filling integrated machine for road building

InactiveCN107090765AImprove work efficiencySmall footprintRoads maintainenceEngineeringMechanical engineering

The invention discloses a joint cutting and filling integrated machine for road building. The joint cutting and filling integrated machine comprises a cutting blade, a water tank, a bearing base plate and a mixing burdening tank. Four corners at the bottom end of the bearing base plate are each provided with a roller, the water tank is installed at one end of the top of the bearing base plate, and the mixing burdening tank is installed at the other end of the top of the bearing base plate; a pressurization device is installed between the mixing burdening tank and the water tank, a connecting frame is installed on the bearing base plate of the side, away from the pressurization device, of the water tank, and a fixing block is installed at the top end of the side, away from the water tank, of the connecting frame; and a booster pump is installed on the bearing base plate of the side, away from the pressurization device, of the mixing burdening tank, and a jetting gun is installed on the side, away from the mixing burdening tank, of the booster pump. The joint cutting and filling integrated machine for road building can achieve the road joint cutting and filling integrated automatic operating function and has the advantages that joint cutting and filling do not need labor, joint cutting precision is high, joint cutting quality is high, road quality is good, and working efficiency is high.

Owner:福建省龙祥建设集团有限公司

Novel process for pavement patching

The invention relates to a new method for patching pavement. Crack in pavement and fillers filled therein are heated firstly to melt asphalt thereof into liquid state so that the two end surfaces of the crack and the fillers are melted integrally with a heating temperature of 100-200 DEG C. The invention solves the problem that the traditional pavement patching glue and the end surfaces of the crack are not firmly spliced, and has the advantages of simple and convenient operation, good crack pouring quality, low cost, and energy-saving as well as environmental protection.

Owner:关莹 +2

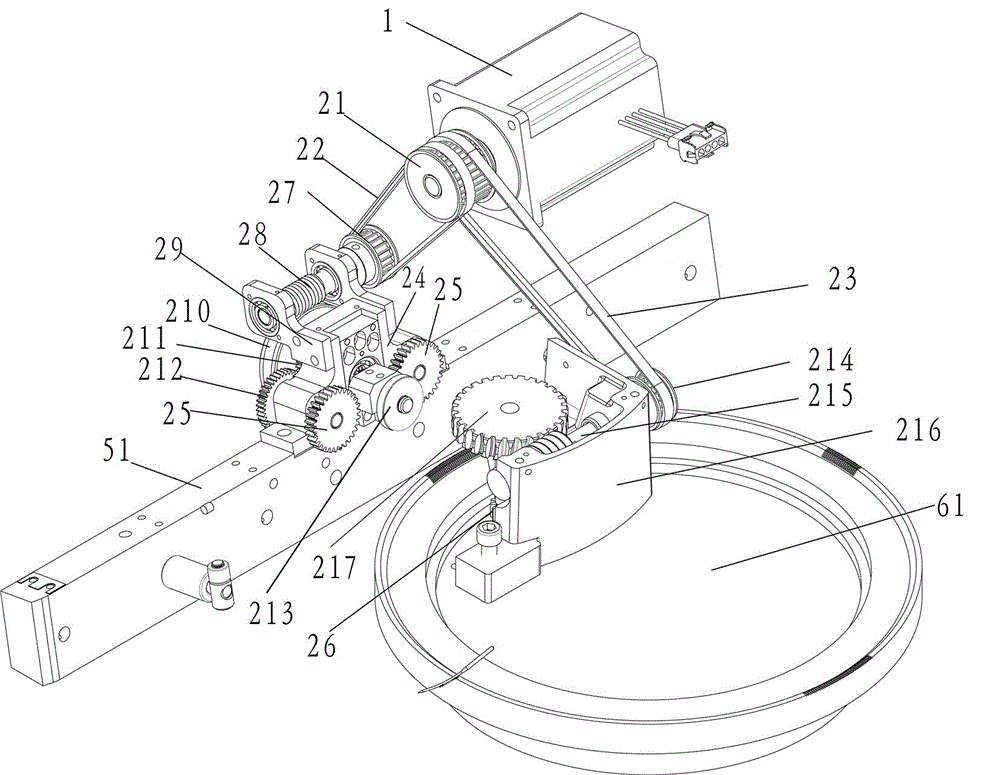

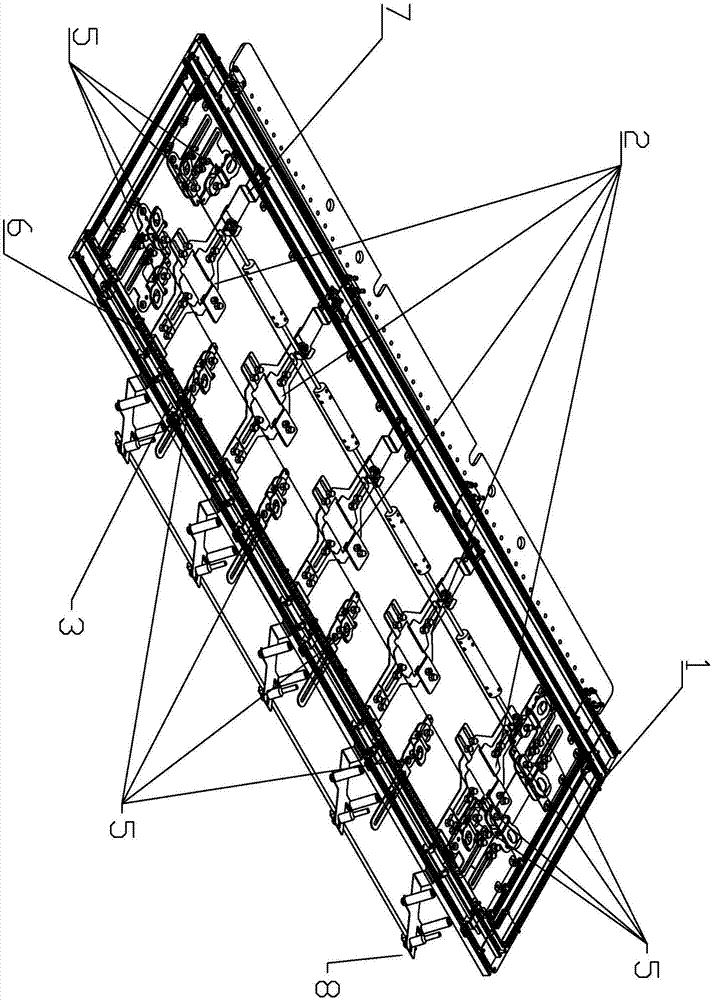

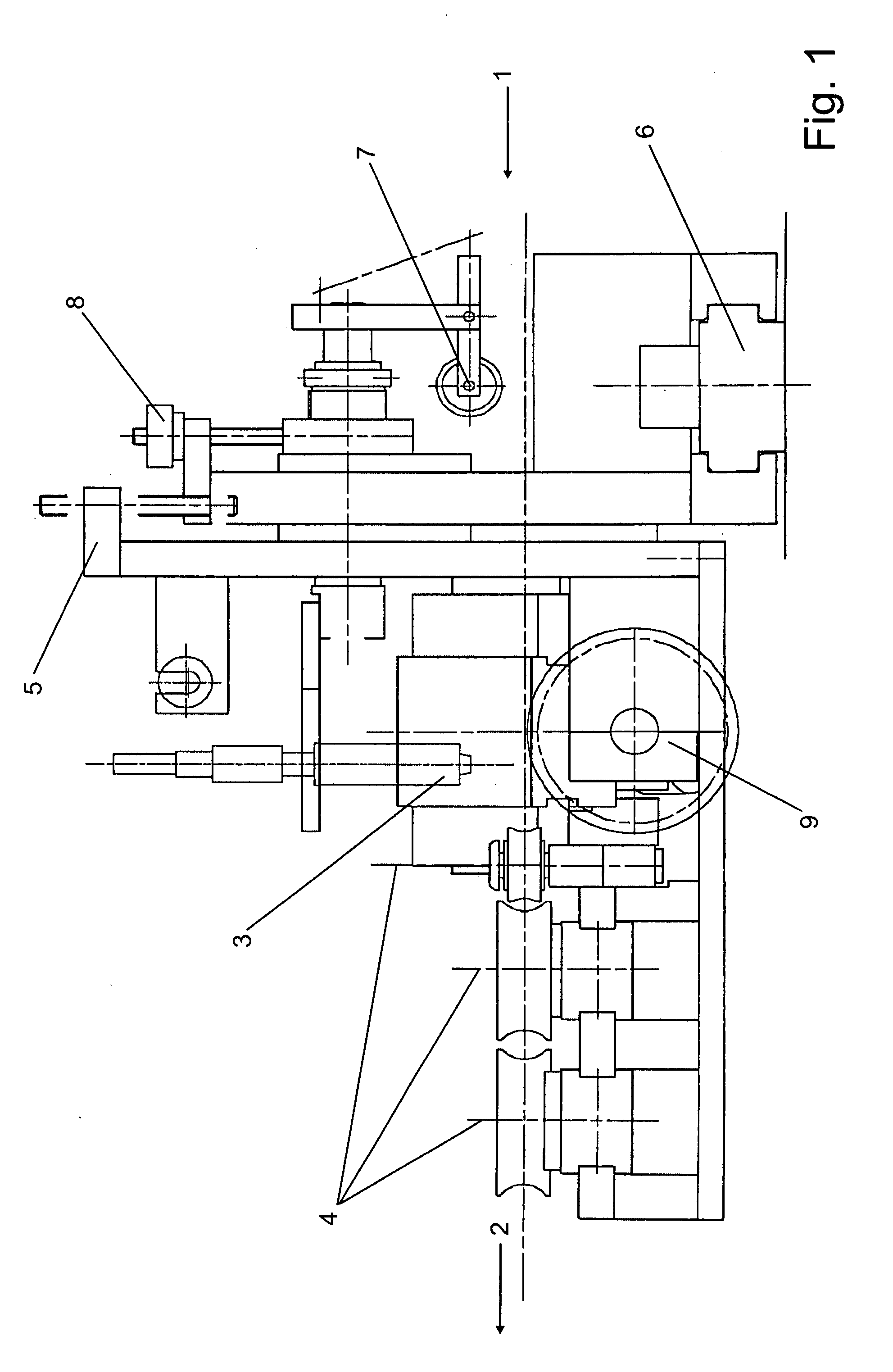

Different stitch length conversion device in sewing system

The invention discloses a different stitch length conversion device in a sewing system. The different stitch length conversion device comprises a main motor, a speed ratio conversion device and a disc sewing machine. The speed ratio conversion device comprises a main driving wheel, a motor shaft of the main motor is sleeved with the main driving wheel, and the main driving wheel is sleeved with a first conveying belt and a second conveying belt. The speed ratio conversion device further comprises a needle rake moving device and a disc moving device, the needle rake moving device is sleeved with the other end of the first conveying belt, and the disc moving device is sleeved with the other end of the second conveying belt. A third gear driving a collar moving needle rake is arranged on the needle rake moving device. The disc moving device is fixed to a disc of the disc sewing machine, and a fourth gear driving the disc to rotate is arranged on the disc moving device. A collar moving needle on the collar moving needle rake and a needle on the disc can do synchronous movement through the first conveying belt and the second conveying belt arranged on the driving belt wheel in a sleeving mode, and conversion from linear stitch length to disc stitch length is achieved.

Owner:NINGBO CIXING

Method for laser cutting of 0.5 mm stainless steel

InactiveCN112222639AImprove cleanlinessQuality improvementWelding/soldering/cutting articlesLaser beam welding apparatusLaser cuttingSS - Stainless steel

The invention relates to a method for laser cutting of a 0.5 mm stainless steel. The method comprises the following steps: (1) removing greasy dirt and dust on the surface of stainless steel, and keeping the surface of the stainless steel smooth; and (2) cutting a 0.5 mm stainless steel panel by a ProCutter laser cutting gun, wherein the technological parameters are as follows: the cutting speed is 14-16 m / min; the laser power is 1-2kW; the gas pressure is 1-2 MPa; the defocusing amount is -1-0 mm; the working distance is 0.6 to 1.0 mm; the diameter of a cutting nozzle is 0.8 to 1.2 mm; and the cutting gas is nitrogen. The method is stable in process, has repeatability, is safe, stable and reliable, and a kerf is smooth, level, free of adhering slag and good in quality.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

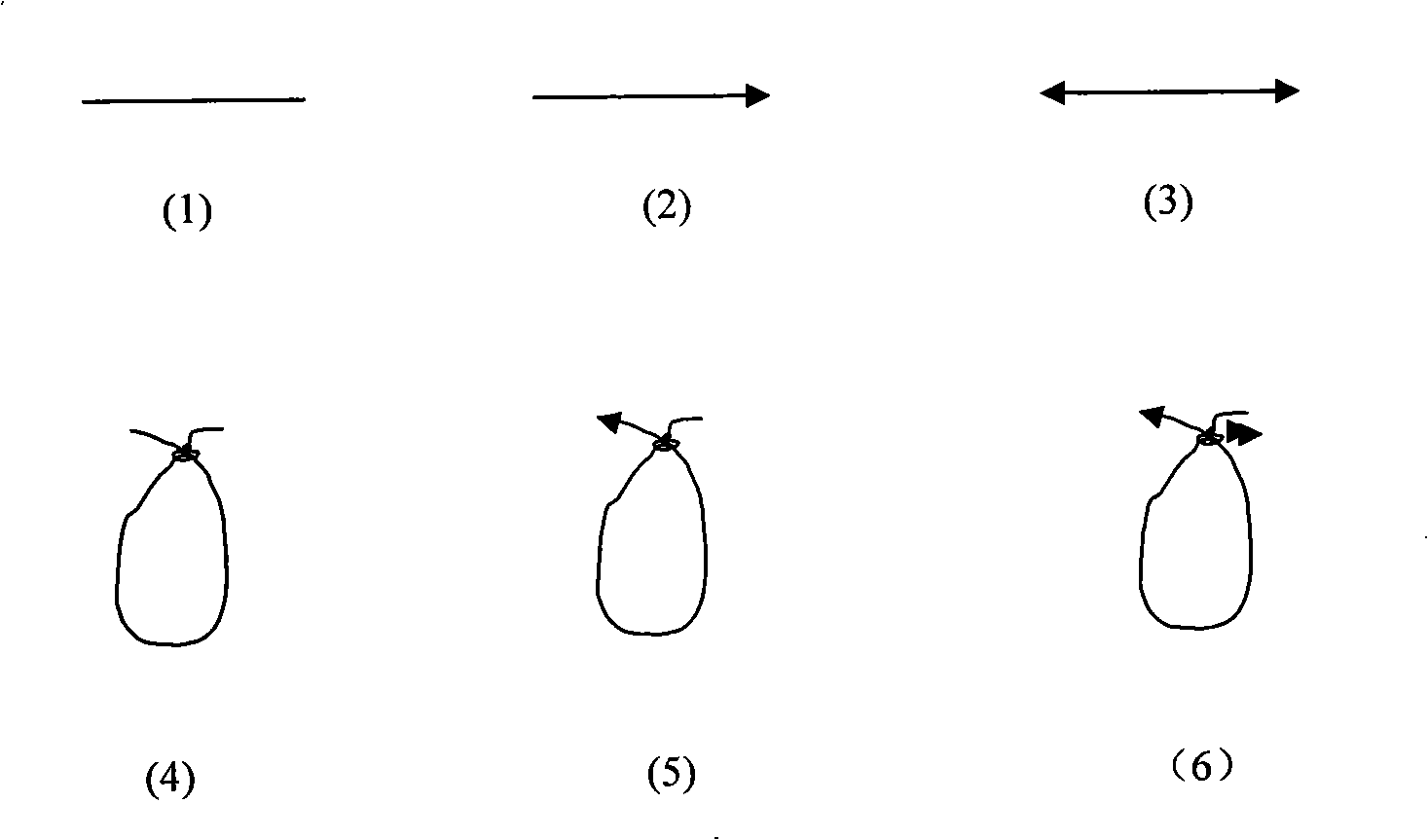

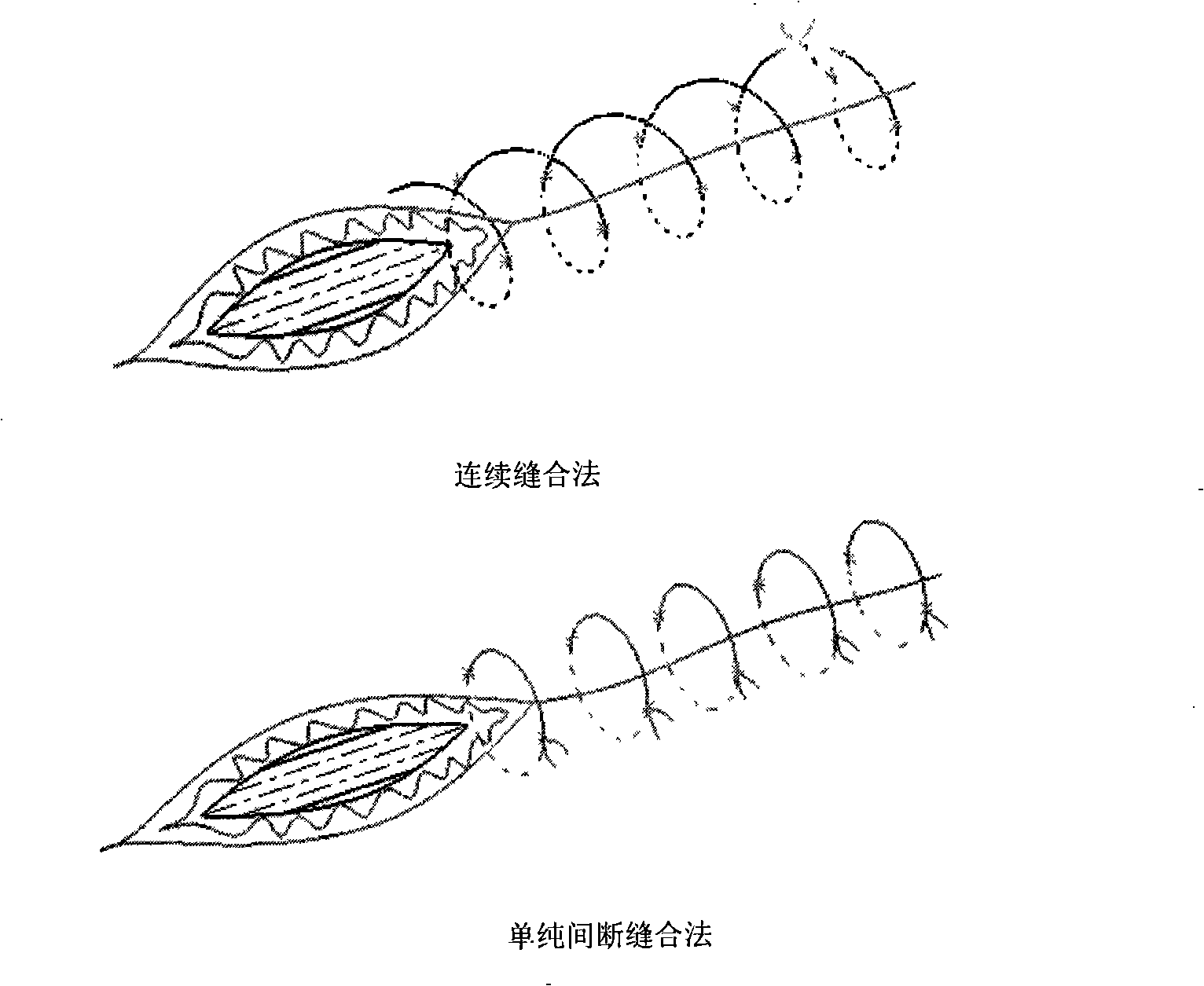

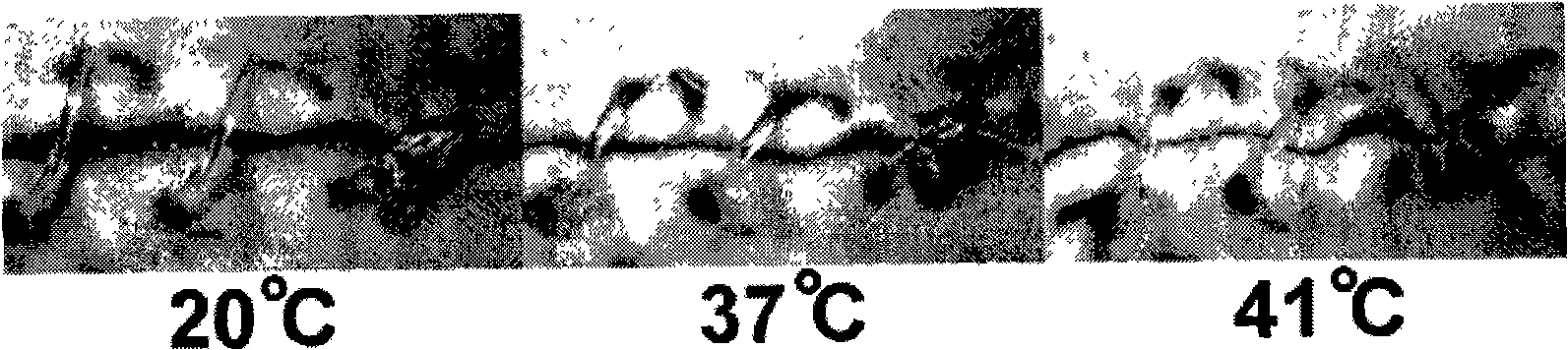

Biodegradable shape memory stitched wire

The invention relates to the preparation and the application of a biodegradable shape memory suture which can not only accurately control the wound closure tightness, but also solve the problem that the operational space for the wound in the body is restricted; at the same time, the cost of treatment is significantly reduced and no stitch removal is needed after the operation. Taking a biodegradable shape memory polymer as the raw material, the suture with required specification is obtained through molding and curing process. The using method of the suture mainly lies in the temperature control: before the suturing, the suture is heated to softening temperature and then stretched to suture the wound; after the suturing, the suture is heated again and restored to the initial shape, and then the suture gradually contracts and tightens until the wound is closed ideally; finally the suture is absorbed by the body gradually along with the time without any harm caused to the human body. The biodegradable shape memory suture can be widely used in human and animal surgery wound suture.

Owner:冷劲松

Nursing surgical suture fixing device capable of keeping humidity of surgical sutures

InactiveCN111358516AMaintain humiditySolve Humidity ProblemsSuture equipmentsSurgical needlesOperating theatresSurgical suture

The invention relates to the technical field of medical instruments, and discloses a nursing surgical suture fixing device capable of keeping the humidity of surgical sutures. The device comprises a box body; the box body includes a fixed shaft, a first fixed column, a first sliding rail, a sliding groove, a suture exit hole, a second sliding rail and a second fixed column; the lower part of an L-shaped rod is connected with a connecting rod; a first spring is connected between the first fixed column and a first slider; the lower part of the connecting rod is connected with a blade; a second spring is connected between the second fixed column and a second slider; the outer side of the second slider is connected with a longitudinal rod; and the lower end of a fixed block is connected with asponge. The second slider is driven by a transverse rod to move down; when restoring, the second slider moves along a right track of the second sliding rail; elastic deformation of the sponge is restored to push rotating wheels to rotate; and a surgical suture rotationally conveyed on each rotating wheel slides out through a suture conduit under the action of gravity. Such structure solves the problems that an existing surgical suture fixing device for operating room nursing cannot automatically feed sutures and the surgical sutures are wasted too much.

Owner:JILIN UNIV

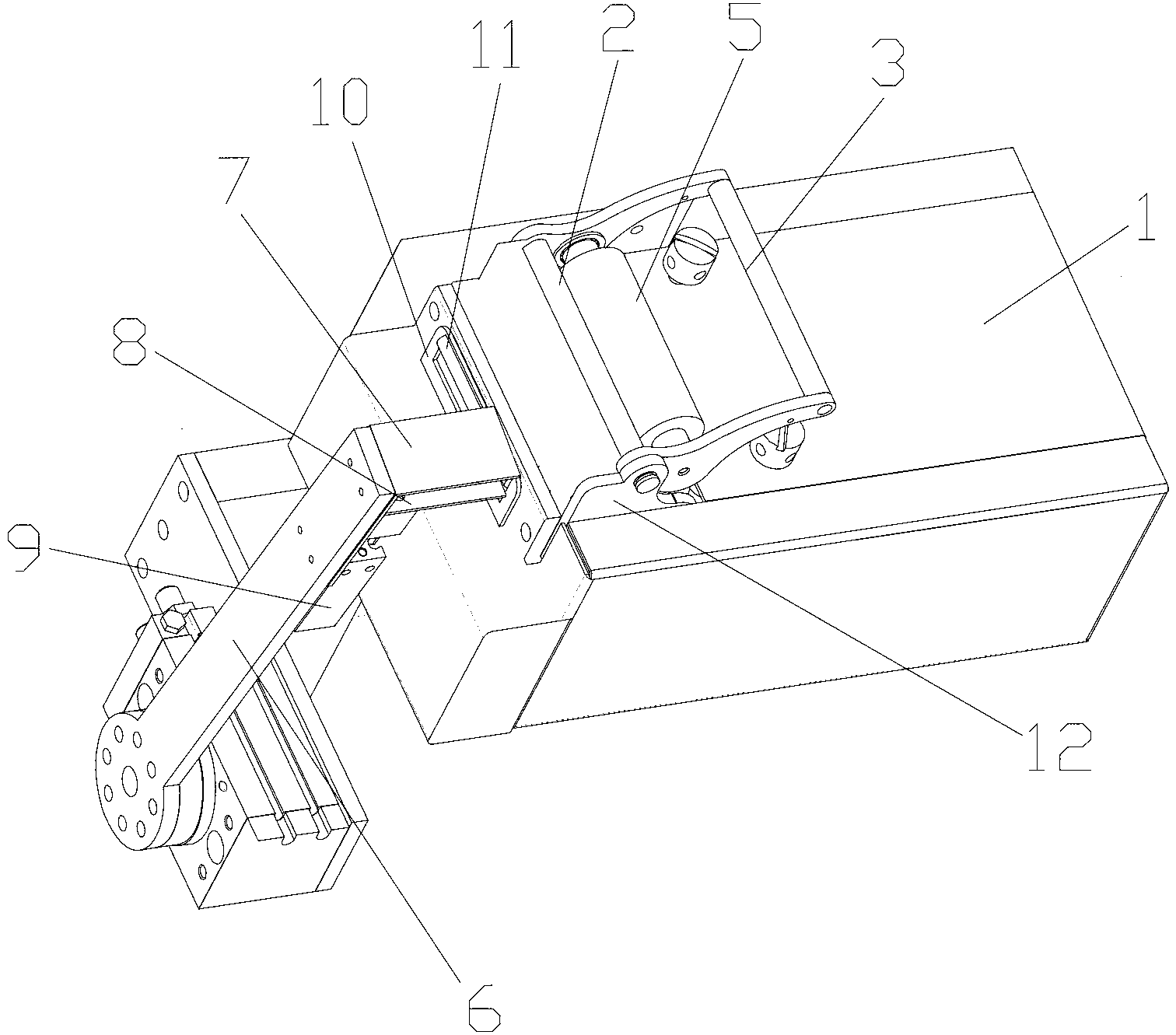

Automatic folding device

InactiveCN103318697AImprove seam qualityQuality improvementFolding thin materialsUltimate tensile strengthAutomation

The invention discloses an automatic folding device. The automatic folding device comprises a pressing mechanism and a folding mechanism which are arranged on a frame. A fabric is sent to the folding mechanism for being folded after the fabric passed through the pressing mechanism. According to the automatic folding device, the pressing mechanism and the folding mechanism are additionally arranged, and the fabric is placed on the pressing mechanism and then is sent to the folding mechanism for being folded when the fabric needs to be folded, so that the mechanical automation replaces the manual operation, the labor intensity of operators is reduced, and the production efficiency and the fabric sewing quality are improved. The automatic folding device is applicable to large-scale popularization and application.

Owner:SUZHOU JUKANG SEWING ROBOT

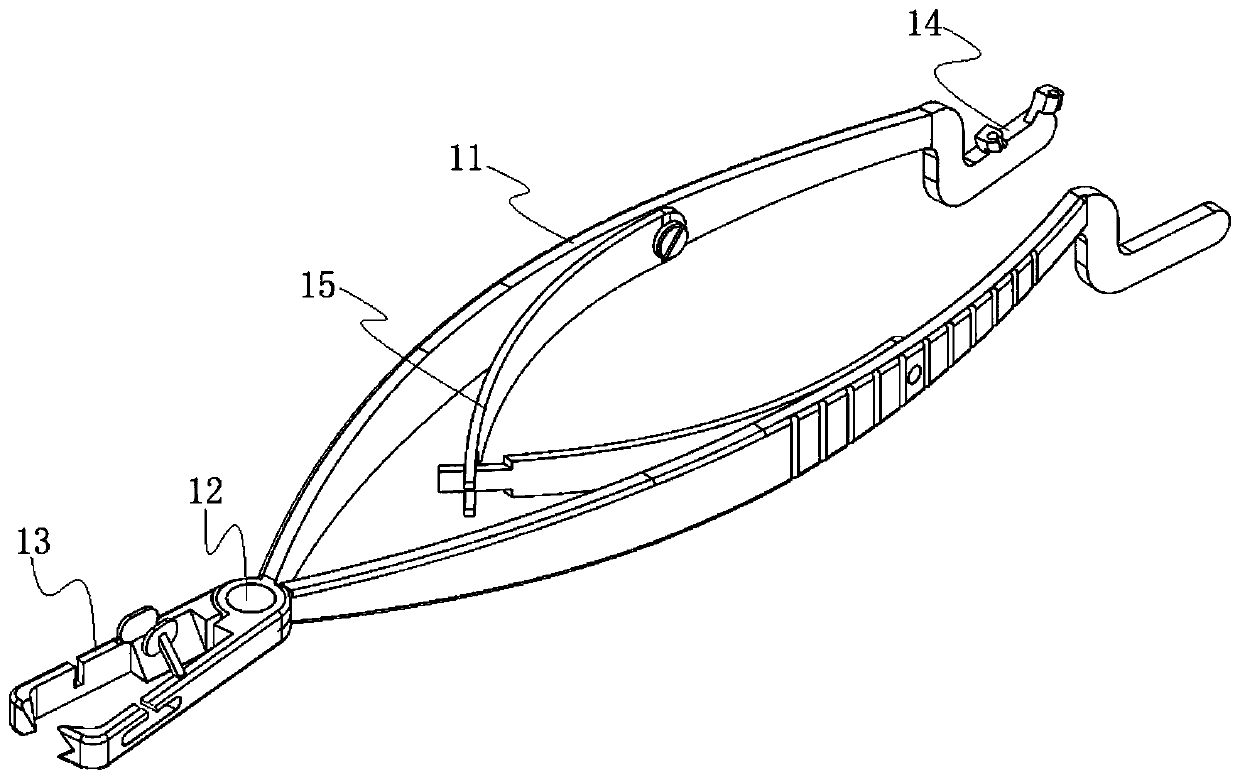

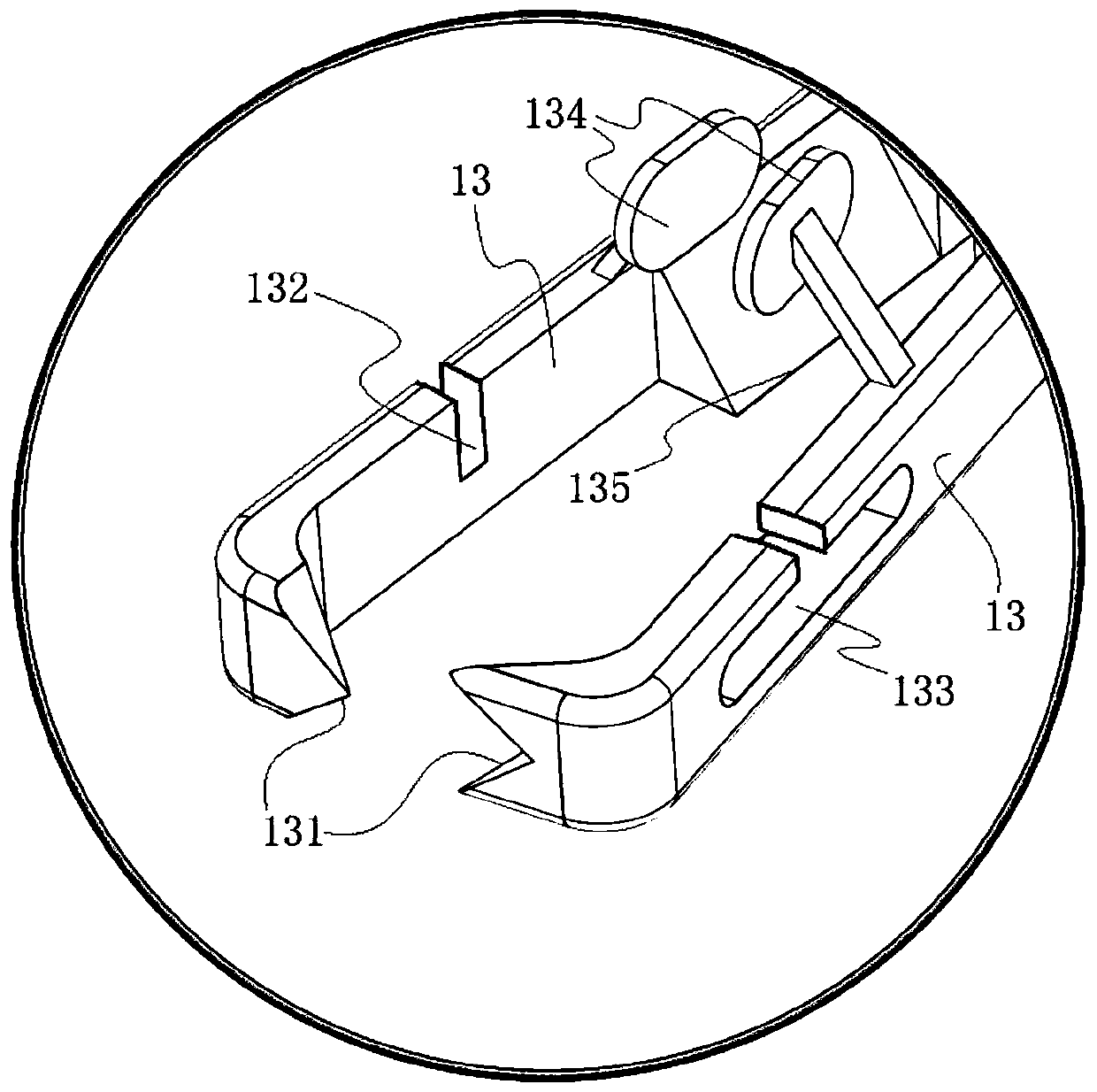

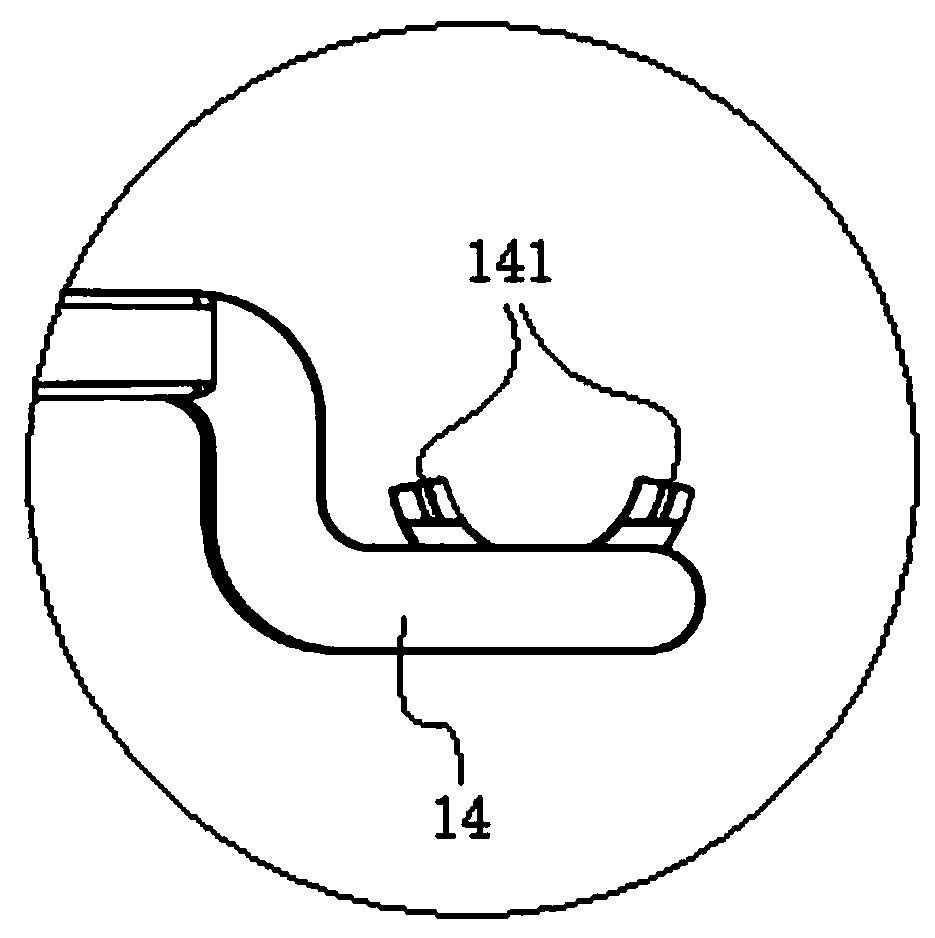

Skin suturing pliers

ActiveCN111317525AImprove stitching effectEasy thread cuttingSuture equipmentsSuturing needleWound suturing

The invention discloses a pair of skin suturing pliers, which comprises clamping handles, first pliers arms and second pliers arms, wherein one end of each of the two groups of clamping handles is hinged and connected; the first pliers arms and the second pliers arms are independently rigid extension segments of two groups of clamping handles on the other side of a hinging point, and rigid extension segments of the free ends of two groups of clamping handles; the free ends of the first pliers arms can form clamping pliers heads; two groups of first pliers arms are independently provided with aneedle entering guide hole and a needle leaving guide hole, which are used for conventional suturing; the needle entering guide hole and the needle leaving guide hole are through in an alignment wayunder a state that the first pliers arms are clamped; the inner side of each second pliers arm is a clamping surface; the upper side surfaces of one group of second pliers arms are convexly provided with two groups of needle guiding seats used for beatification suturing; and each needle guiding seat is provided with a needle guiding hole used for a suturing needle to pass. According to the pair ofskin suturing pliers, conventional skin suturing and intracutaneous beatification suturing can be realized, a surgeon can independently finish a suturing and thread shearing operation and the accurate needling entering of intracutaneous suturing during operation wound suturing, suturing time is greatly shortened, and suturing quality is improved.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

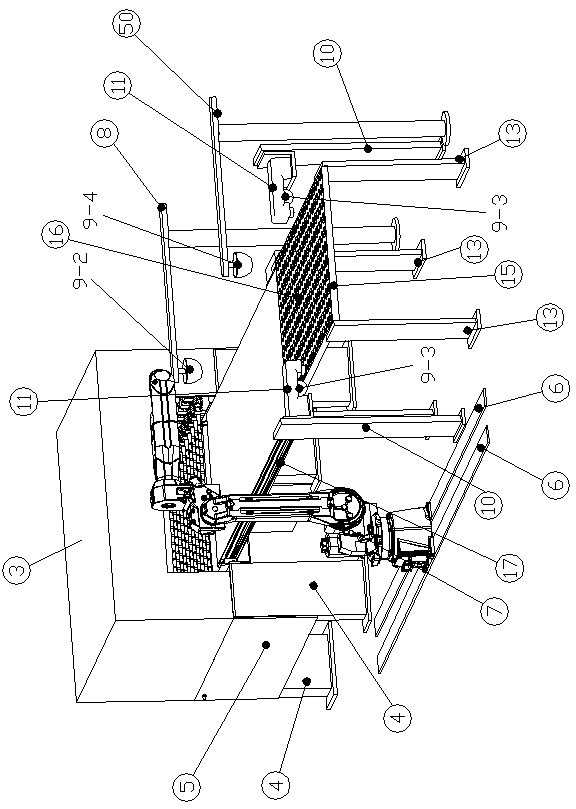

Automatic sweater sewing method based on machine vision perception

ActiveCN109457398AFacilitate automatic sewingRealize automatic stitchingProgramme-controlled sewing machinesWork-feeding meansMachine visionEngineering

An automatic sweater sewing method based on machine vision perception comprises the following steps of: (1) starting automatic sweater sewing equipment; (2) conveying a sweater weaving piece into a stretching and freezing device from front to back from an input flattening device; (3) stretching the sweater weaving piece and freezing the sweater weaving piece into a rigid body convenient for sewingin the stretching and freezing device; (4) conveying the sweater weaving piece which is stretched and frozen into the rigid body to a sewing preparation device; and (5) finishing turning, carrying, sewing auxiliary pushing and sorting of the frozen sweater weaving piece by a carrying robot, and sewing an upper sweater weaving piece and lower sweater weaving piece which are correspondingly arranged up and down by using a sewing device. The method can replace prior manual sweater sewing, improves the processing efficiency, achieves the improvement of the sewing quality, achieves the stable consistency of products in batch production, and further improves the added value of the products; and the method has certain significance for promoting the development of equipment in the sweater weavingindustry in China.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Hook-and-loop tape sewing universal fixture

ActiveCN107503049AImprove accuracyImprove efficiencyWork-feeding meansNumerical controlBiomedical engineering

The invention discloses a hook-and-loop tape sewing universal fixture, and relates to the field of sewing processing. The hook-and-loop tape sewing universal fixture is characterized in that a processing plane is enclosed in a fixture frame; clamping mechanisms are used for fixing to-be-sewn cloth into the processing plane; the clamping mechanisms are mounted in the fixture frame in such a manner that the clamping mechanisms can be continuously repositioned. The hook-and-loop tape sewing universal fixture has the advantages that the fixture frame can be fixed onto sewing equipment such as numerical-control sewing centers; the to-be-sewn cloth can be fixed by the aid of the clamping mechanisms instead of manual or gluing modes, accordingly, the fixing accuracy can be improved, potential safety hazards can be prevented, and the efficiency can be improved; the clamping mechanisms can be continuously repositioned relative to the fixture frame, and accordingly the to-be-sewn cloth can be positioned at required processing locations of the sewing equipment; the clamping mechanisms are continuously repositioned, and accordingly the positioning precision and the sewing quality of products can be improved.

Owner:SHENZHEN YANO TECH

Guiding and shaping system

InactiveUS20090277879A1Easy to usePrevent burstArc welding apparatusResistance welding apparatusEngineeringMechanical engineering

A guiding and shaping system for producing welded pipes made from metallic strip material. The guiding and shaping system comprises several pairs of rolls that are disposed one behind another in the direction of travel of the workpiece and are used for increasingly cold-working and bending the edges of the workpiece as the workpiece advances. First pairs of rolls grip the top side and bottom side of the workpiece while pairs of rolls that grip the external faces of the bent edges and form the shape of a pipe are provided in the region where the bent edges form undercuts. The guiding and shaping system further comprises a welding device. The workpiece is supported by floatingly mounted lateral rolls until cooling off following the welding process.

Owner:WUPPERMANN EDELSTAHLTECHN

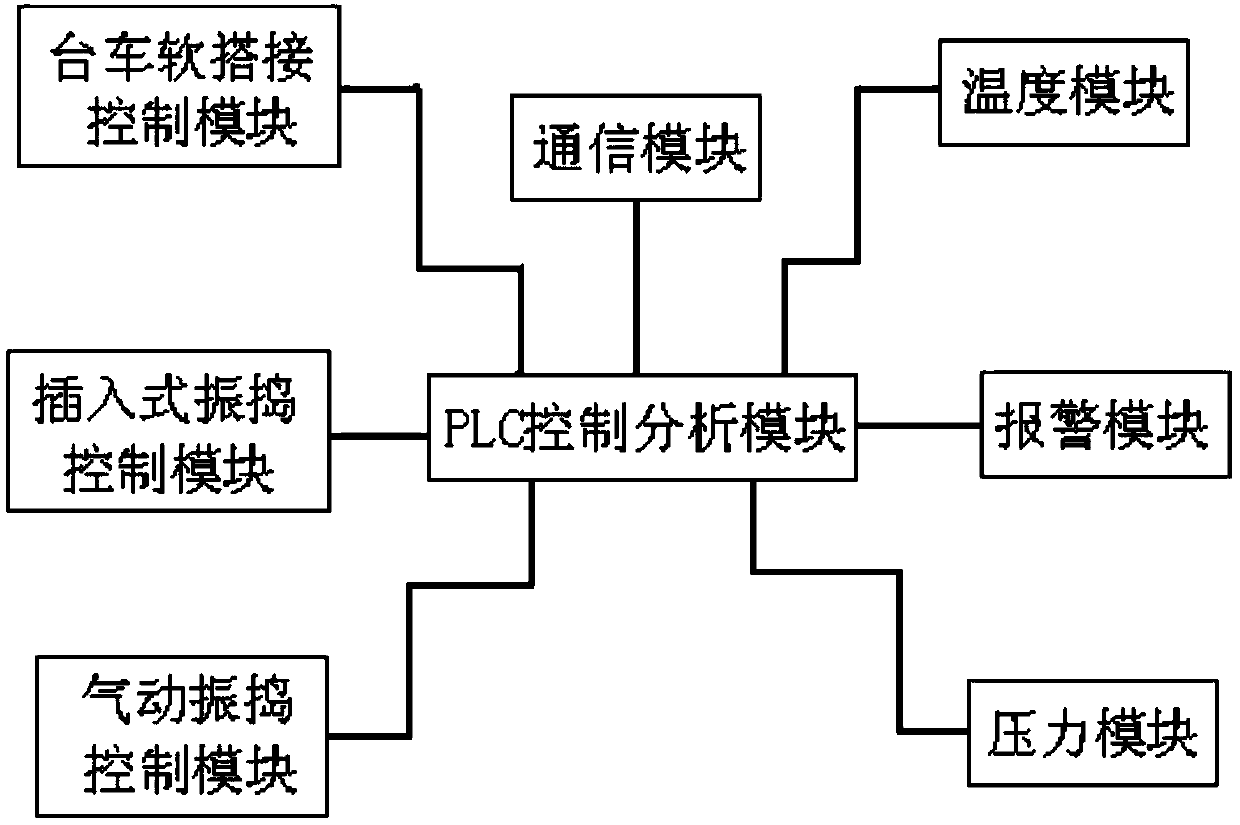

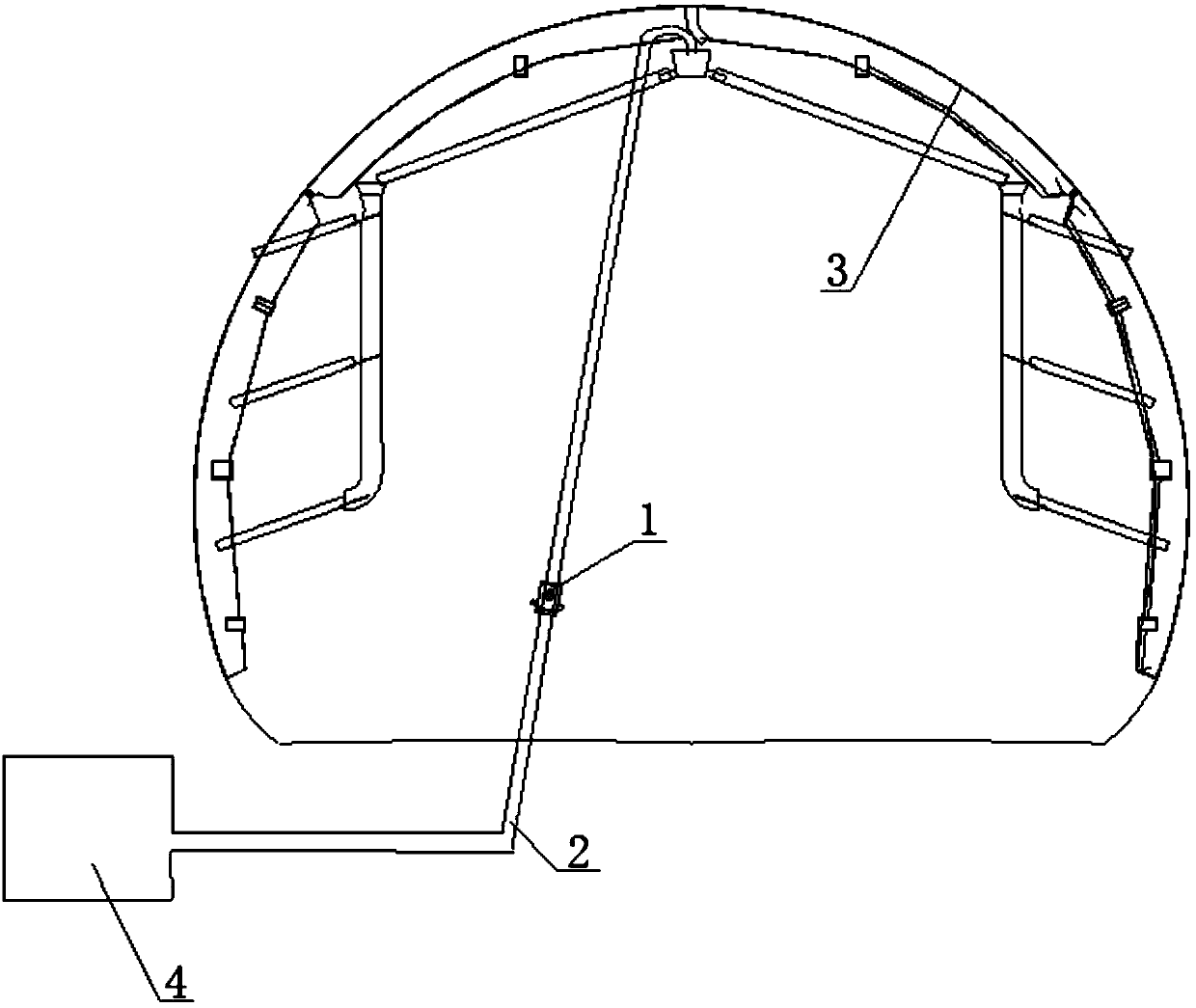

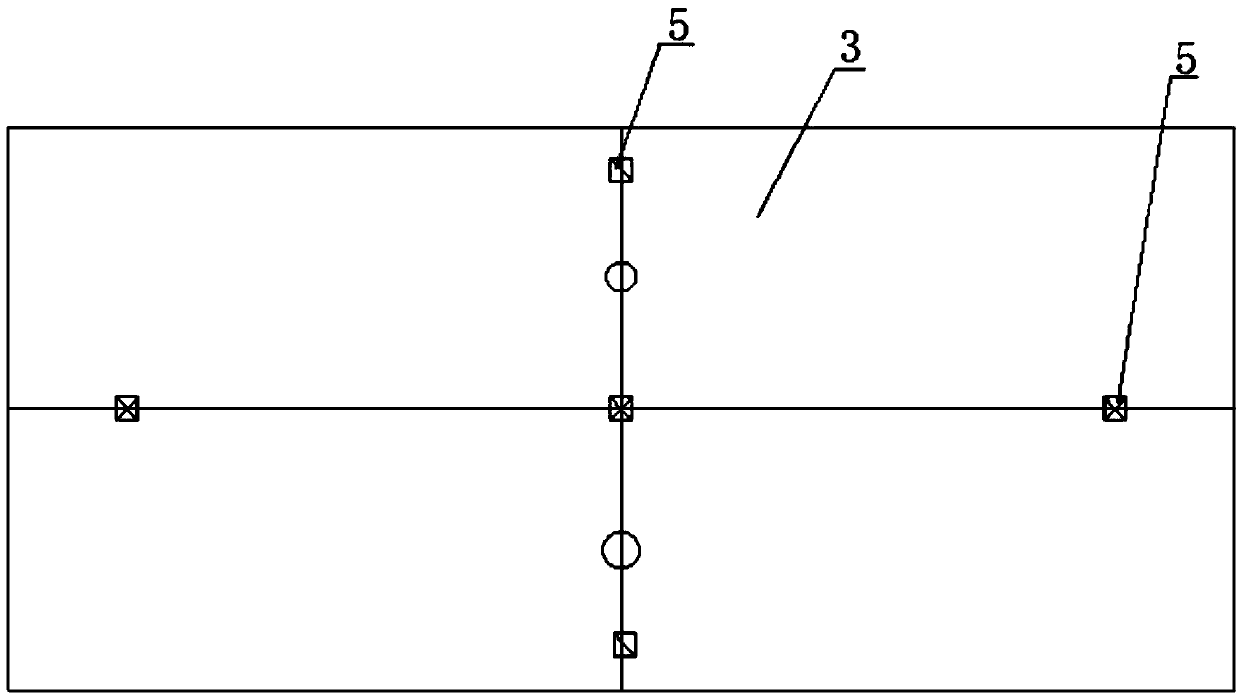

Tunnel secondary lining concrete pouring control system and method

ActiveCN109611123AIntuitive pouring processReliable dataUnderground chambersProgramme control in sequence/logic controllersVibration controlControl system

The invention discloses a tunnel secondary lining concrete pouring control system and method. The system comprises a trolley soft lap joint control module, a communication module, a PLC control analysis module, an alarm module, a pneumatic vibration control module, a plug-in vibration control module, a temperature module and a pressure module. The method comprises the following steps: S1, the pneumatic vibration control module and the PLC control analysis module control pneumatic vibration; S2, the plug-in vibration control module and the PLC control analysis module control plug-in vibration;and S3, the PLC control analysis module compares the estimated concrete pouring square value with the concrete flow data, when the concrete flow data is larger than the estimated concrete pouring square value, the PLC control analysis module sends an instruction to the alarm module, the alarm module sends an alarm signal, and concrete pouring is stopped. Automatic vibration in a tunnel secondary lining vault is achieved, and the phenomena of void separation, nonuniformity, honeycomb pitted surface and incompactness caused by local concrete blocking of the secondary lining vault are prevented.

Owner:NO 4 ENG CO LTD OF CHINA RAILWAY 11 BUREAU GRP +1

Quick repairing device for roads

The invention relates to a quick repairing device for roads. The quick repairing device comprises a moving base, scraper mechanisms and connecting rod mechanisms, wherein a U-shaped beam is mounted onthe top face of the moving base; material mixing mechanisms and a top-pressing mechanism; when doing a press-down action, a beating mechanism is linked with the material mixing mechanisms to ensure that tar in the material mixing mechanisms is mixed and stirred to obtain a mixture and the mixture is discharged downwards; a front group and a back group of the material mixing mechanisms are arranged; discharging mechanisms for discharging the tar materials downwards are also arranged on the two groups of material mixing mechanisms; the two scraper mechanisms are arranged; and because the beating mechanism has a thick column structure, the tar poured into cracks of the road can be tamped preferably, so that the seaming quality is improved; by adopting a linkage way, the left group and the right group of scraper mechanisms are arranged; when the scraper mechanisms operate inwards, the tar-like materials which are attached with the bottom of a beating plate due to beating of the tar can bescrapped downwards, and the phenomenon that pits are reserved on a tar connection part required for beating because of staying of adhesive materials when the tar surface is beaten again by adopting the beating plate is avoided; and the construction quality is improved.

Owner:NANJING FREETECH ROAD MAINTENANCE VEHICLE MFG CORP

Metal-protective gas-joint with changeable polarity

InactiveUS7244904B2Improve processing stabilityImprove seam qualityArc welding apparatusWelding/cutting media/materialsCarbon Dioxide / HeliumShielding gas

A method of gas-shielded metal arc joining using a consumable electrode having an alternating polarity (GMA-AC). A shielding gas containing helium is used to improve process stability and working speed.

Owner:LINDE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com