Novel process for pavement patching

A technology of road surface repair and new technology, which is applied in the field of traffic road maintenance, can solve the problems of high price of seam filling machine and asphalt joint glue, low temperature of fractured end surface, and easily damaged road surface again, so as to reduce the cost of road surface maintenance, The effect of small impact on the climate environment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The best embodiment of the present invention is described below through specific embodiments.

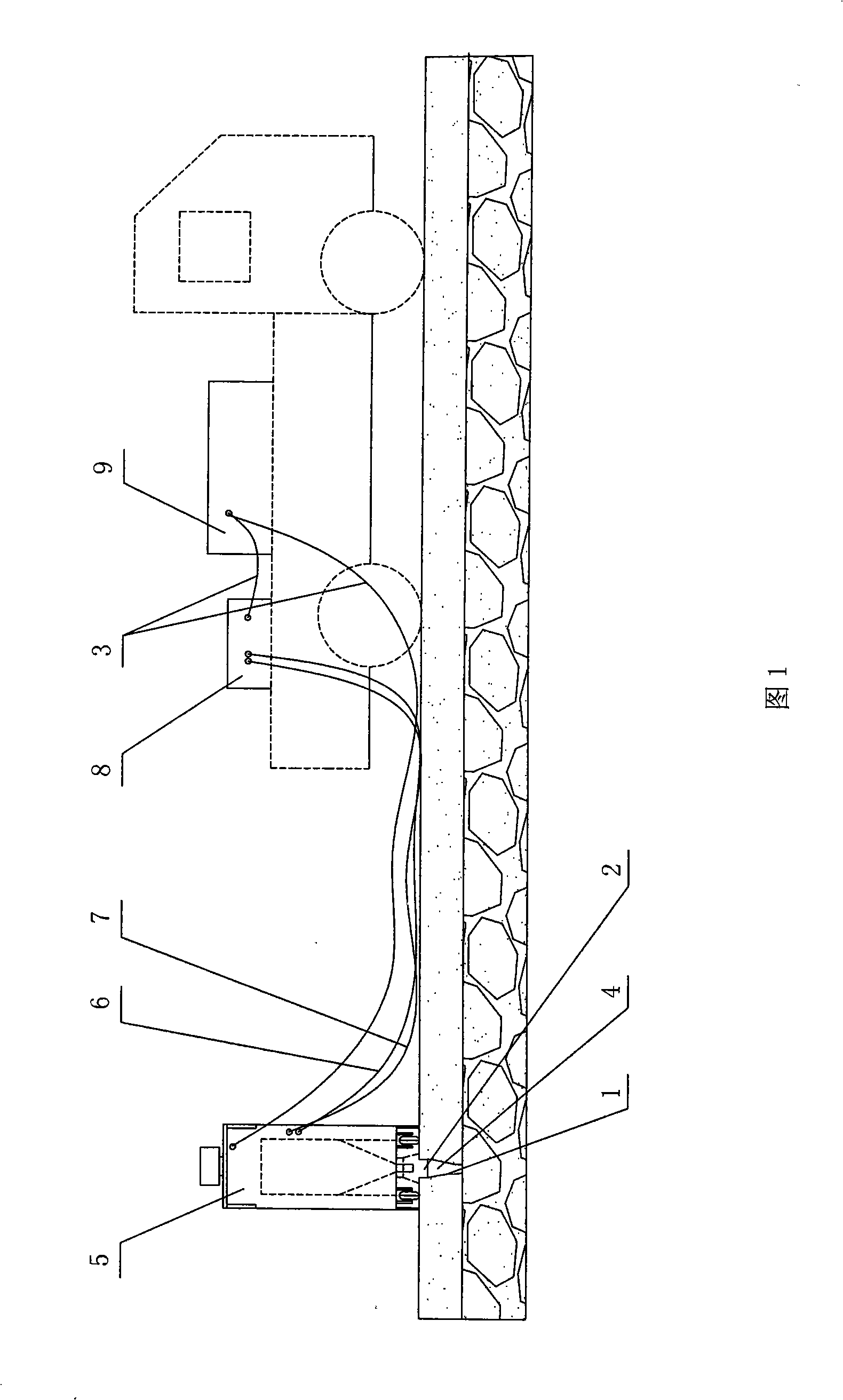

[0017] A new pavement repair process, which uses the principle of laser welding. The laser beam 8 generates a laser beam to heat the pavement crack 2 and the filled joint filling material 4 to 100-200°C, preferably 170°C. The asphalt melts into a liquid state, so that the crack end face 1 and the joint filling material 4 are melted into one body. During the heating process, the laser radiation heating point is continuously moved forward with the joint filling cart 5 for continuous operation to complete the joint filling operation.

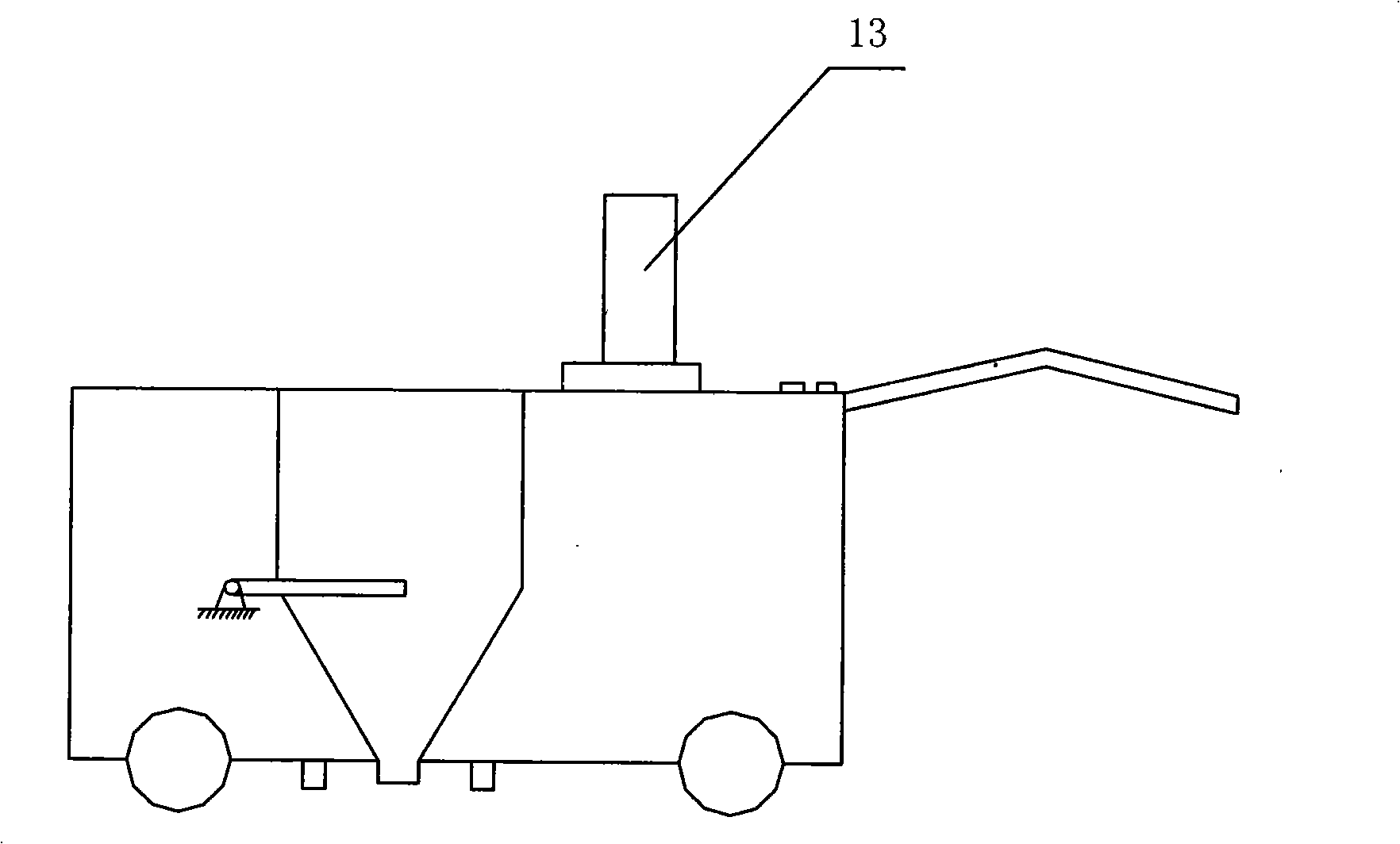

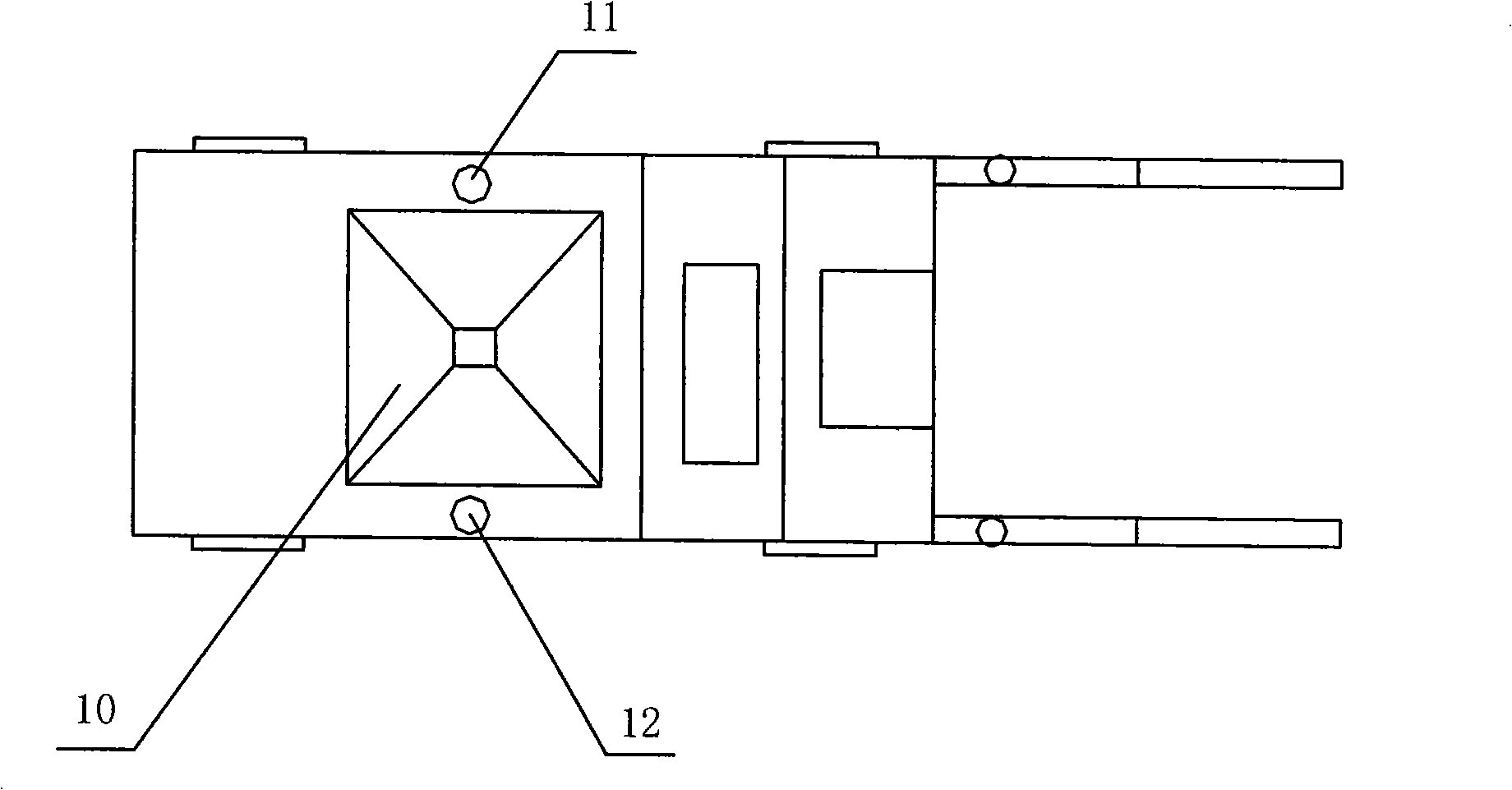

[0018] The laser filling machine is equipped with a generator 9, a laser 8, a laser transmission fiber, a filling cart 5, and a safety protection device. The generator 9 and the laser 8 are installed on the car. The laser beam output by the laser 8 is guided into the optical fiber, and the optical fiber output The laser beam is expanded to form a ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com