High-pressure bin type perfusion system

A high-pressure chamber and high-viscosity technology, which is applied in roads, constructions, road repairs, etc., can solve problems such as difficulty in ejection and blockage of material pipelines, and achieve the effects of low labor intensity, energy saving, and high-efficiency sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

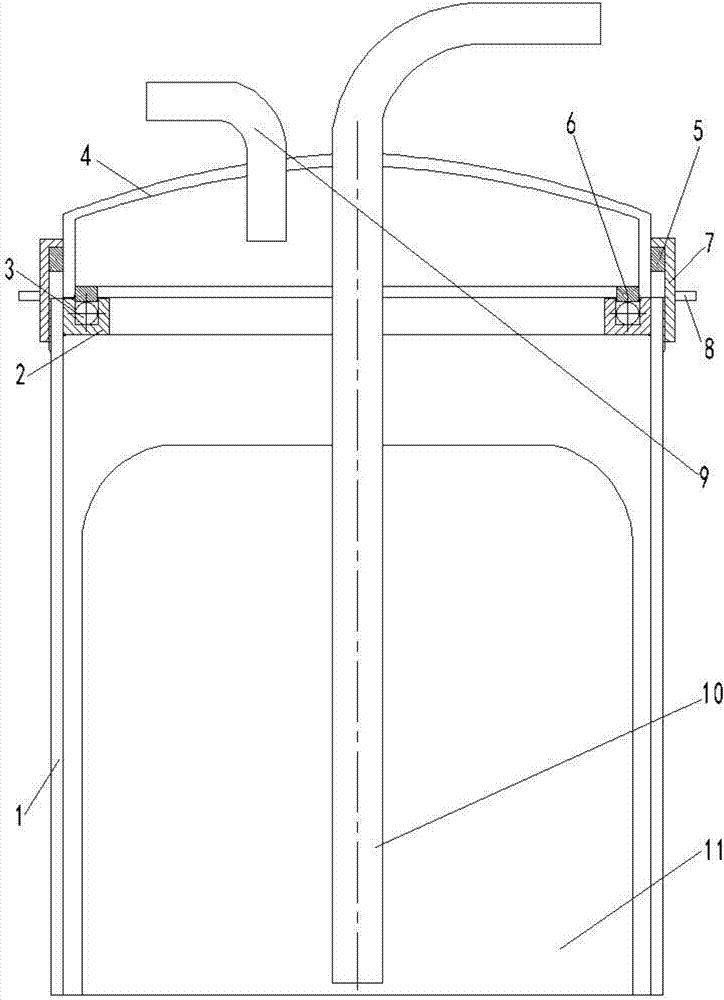

[0018] exist figure 1 Among them, the high-pressure chamber type perfusion system of the present invention includes a high-pressure chamber body 1 with threads on the outer surface of the upper part, an annular groove body 2 installed on the inner surface of the upper part of the high-pressure chamber body, and an O-shaped rubber sealing ring 3 installed in the annular groove body, The cover body 4 located on the upper part of the high-pressure chamber body, the stop ring 5 installed on the outer side of the cover body, the O-shaped rubber sealing ring installed on the inner side surface of the lower part of the cover body is embedded in the pressure ring 6, which is used to press against the stop ring and has internal threads The connecting body 7, several horizontal turning handles 8 installed on the outside of the connecting body, the high-pressure gas inlet pipe 9 installed on the upper part of the cover, the high-viscosity rubber installed on the cover and extending into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com