Cast-in-situ hollow board

A hollow slab and cast-in-place concrete technology, which is applied to floors, building components, buildings, etc., can solve problems such as the inability to effectively ensure that the width of the floor is consistent with the design width, affect the construction quality of the floor, and cannot arrange hollow carcass. Achieve the effects of guaranteed pouring quality, low cost and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

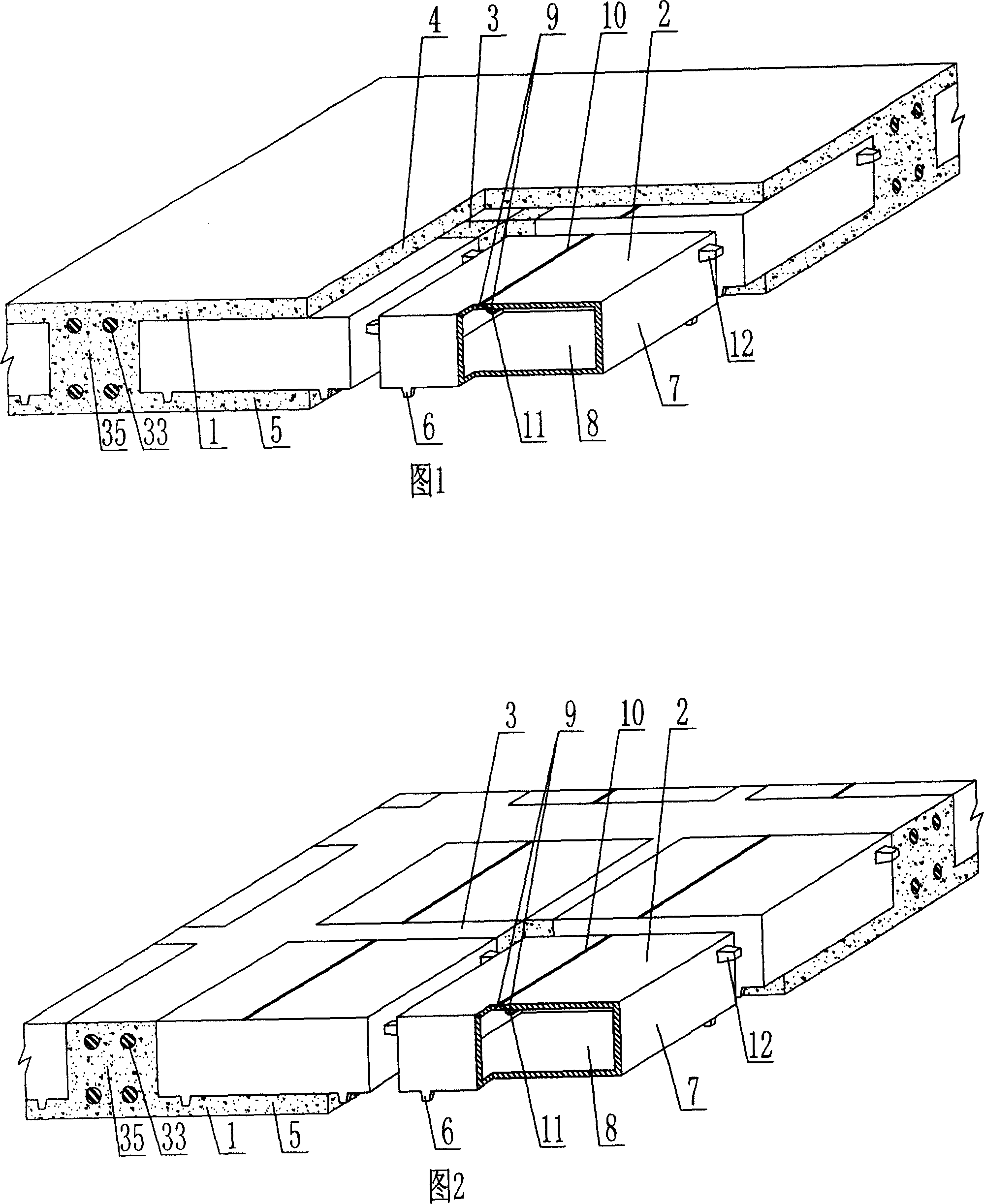

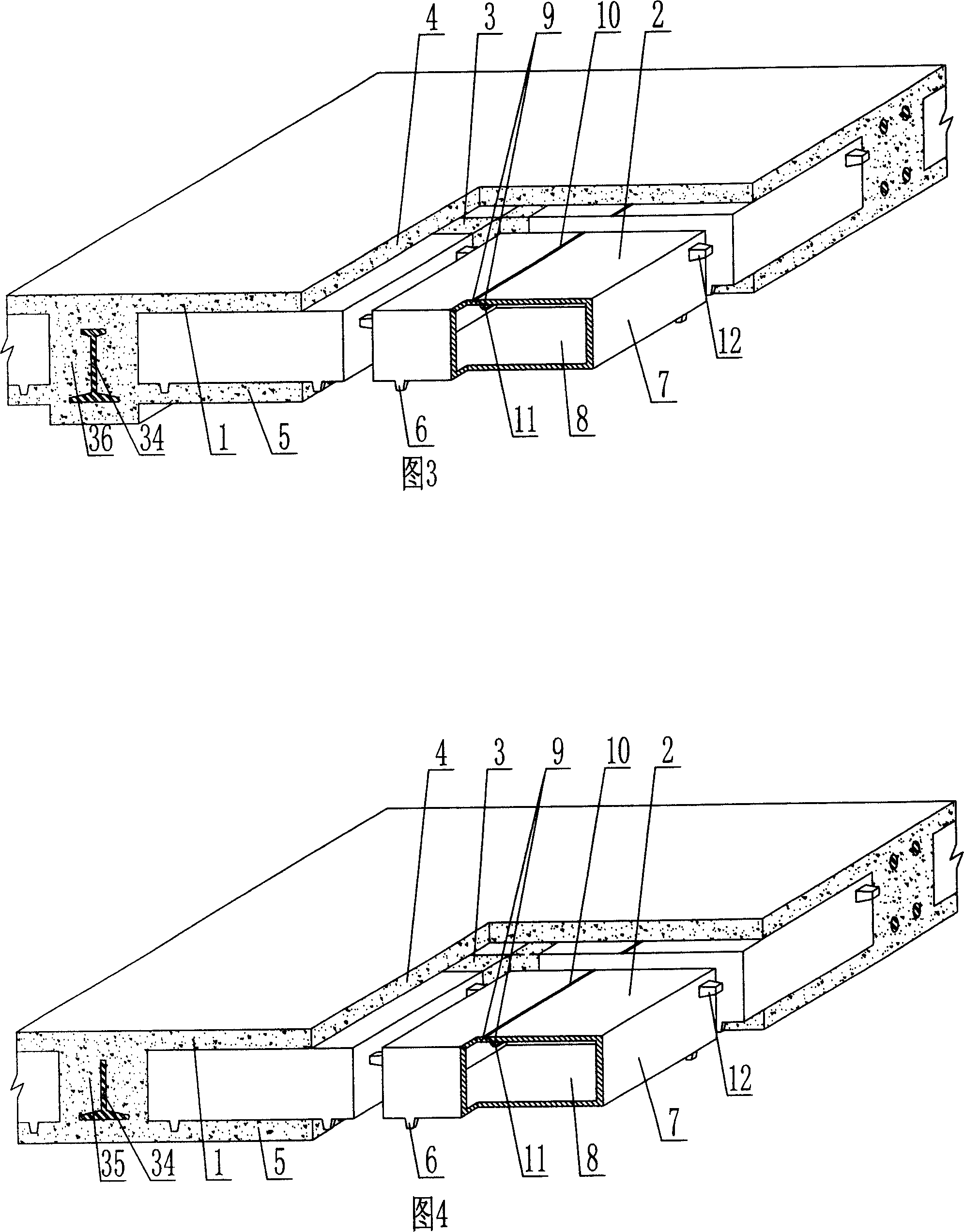

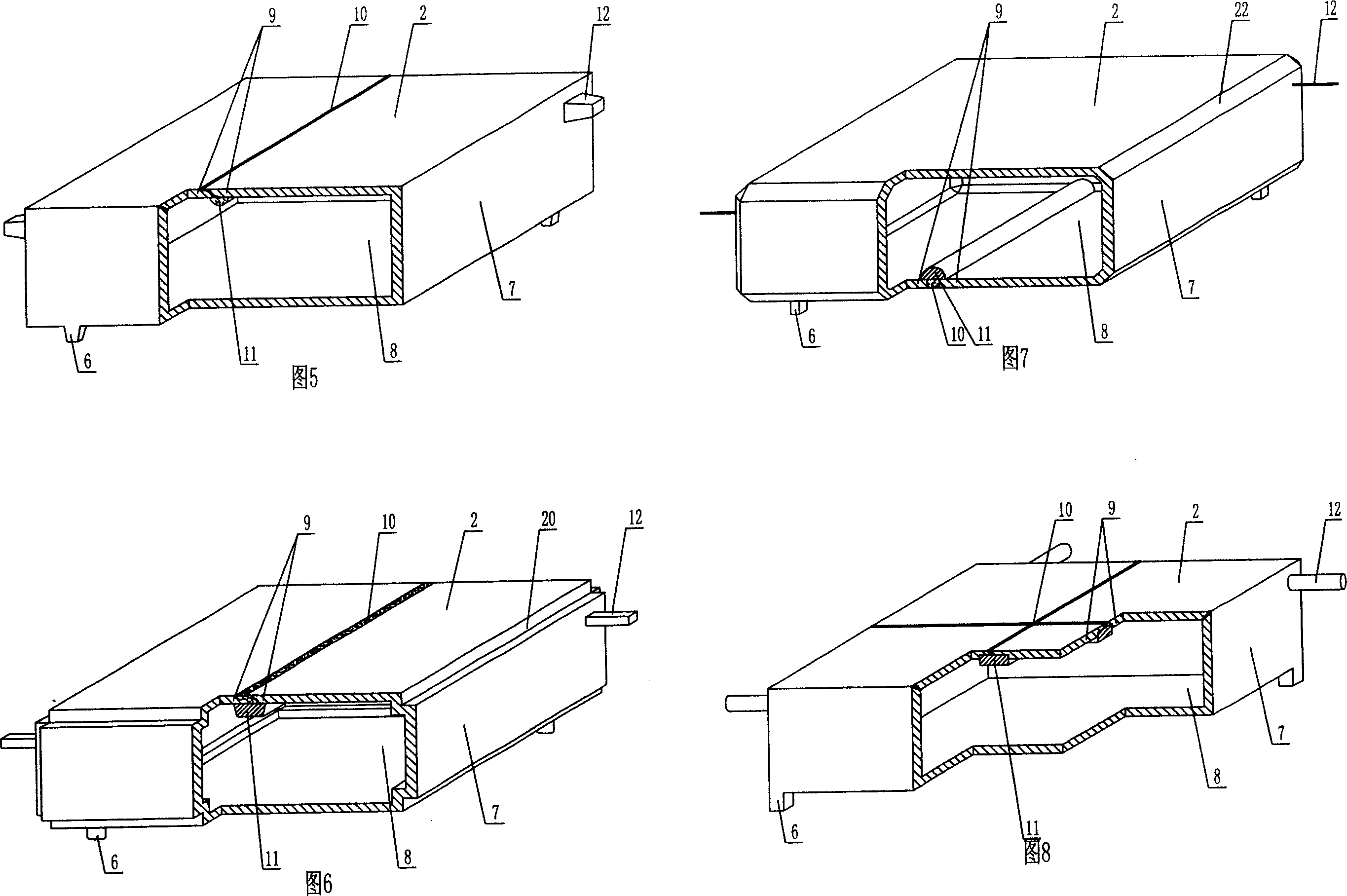

[0085] As shown in the accompanying drawings, the present invention comprises a reinforced concrete 1 and a hollow carcass 2, the hollow carcass 2 is wrapped in the reinforced concrete 1, the hollow carcass 2 are arranged alternately, and there are cast-in-situ reinforced concrete ribs 3 between them. It is an upper plate 4 of cast-in-place reinforced concrete, under which is a lower plate 5 of cast-in-place reinforced concrete. The hollow carcass 2 is provided with supporting feet 6. The supporting feet 6 are arranged on the outer wall 7 of the bottom surface of the hollow carcass 2. The outer wall 7 encloses The hollow carcass 2 formed with a cavity 8 is characterized in that the outer wall 7 of the hollow carcass 2 has a cementing belt 10 joined to the edge of the slurry body 9 of the outer wall 7, and the cementing belt 10 is located in the cavity 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com