Method for prefabricating and assembling large cantilever cover beam

A technology for prefabricating and assembling beams, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of transportation, hoisting difficulties, large crane occupation, design width of viaducts and tonnage increase, etc. The effect of processing, low investment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

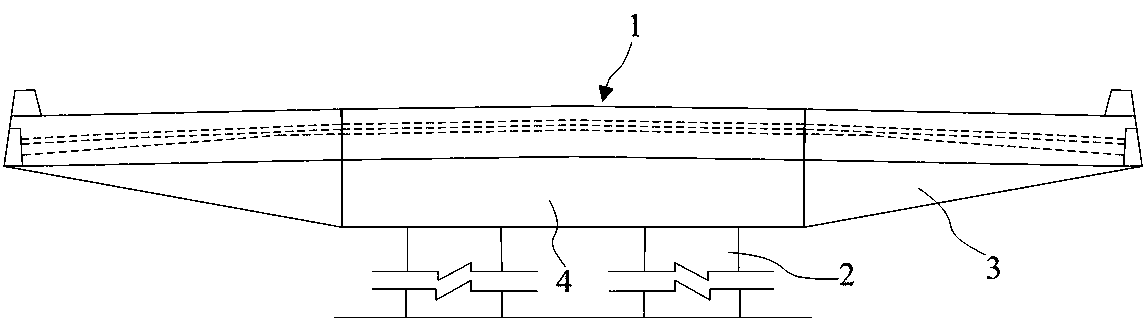

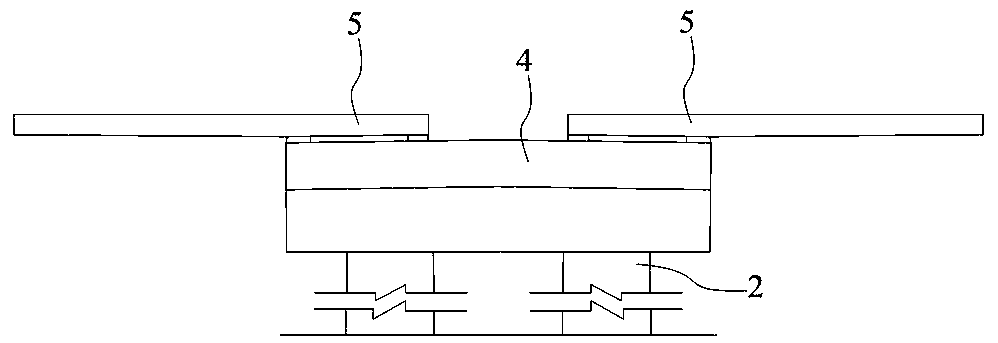

[0022] Example: such as figure 1 , 5 As shown, this embodiment specifically relates to a prefabricated and assembled method for a large cantilever cover beam, which is used for lifting and splicing a large-tonnage cover beam 1 to the top of a column 2; the cover beam 1 is prefabricated into two cantilever sections of the cover beam 3 and a section of cover beam middle section 4.

[0023] Such as Figures 1 to 6 As shown, the prefabricated assembly method of the large cantilever cover beam in this embodiment specifically includes the following steps:

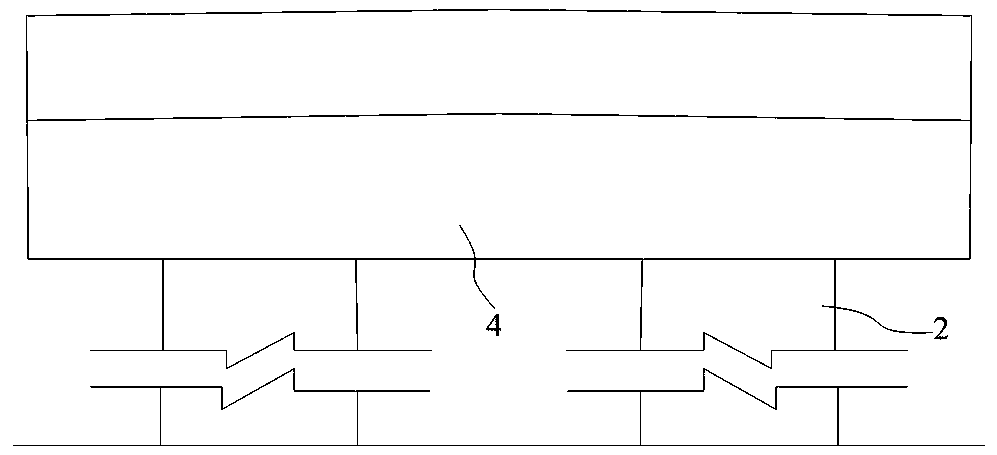

[0024] (1) Hoist and install the middle section 4 of the cover beam to the top of the column 2. Such as figure 2 As shown, during the hoisting process, a crane is used for hoisting, and the middle section 4 of the cover beam is in a horizontal state. The top of the column 2 is provided with a pre-embedded steel bar, and the middle section of the cover beam is provided with a sleeve. In the process of installing the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com