Adhesive-free carpet tile installation construction method and device used and carpet tile structure

A construction method and carpet block technology, which are applied to building structures, floors, buildings, etc., can solve the problems of inconvenient disassembly and maintenance, troublesome installation and alignment, and large amount of adhesive, and achieve convenient and fast installation and disassembly. Save construction period and labor costs, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

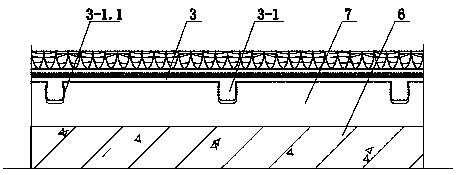

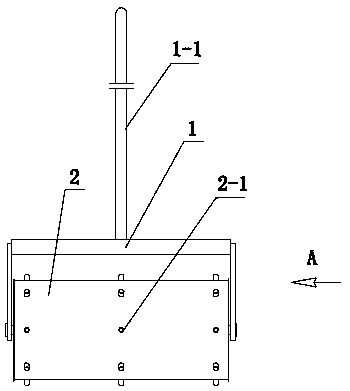

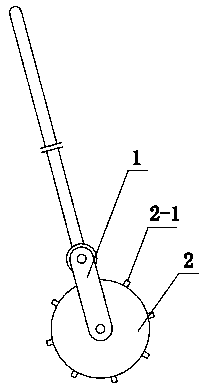

[0022] See attached picture,

[0023] A method for installing an adhesive-free carpet block, which is realized by the following steps:

[0024] Step 1. Set the cement mortar or self-leveling cement leveling installation layer on the carpeted floor. The cement mortar or self-leveling cement leveling installation layer is required to have a certain thickness and flatness. The cement mortar or self-leveling cement leveling installation layer is cured and solidified ;

[0025] Step 2. After the initial setting of the cement mortar or self-leveling cement leveling installation layer in step 1, a set of fixed blind holes with a design depth are regularly pressed out on the cement mortar or self-leveling cement leveling installation layer, and the cement mortar or self-leveling cement is continued. The leveling and installation layer is cured until it is completely solidified;

[0026] Step 3. On the fully solidified cement mortar or self-leveling cement leveling installation layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com