Furniture plate disassembling method

A panel and furniture technology, which is applied in the field of dismantling and manufacturing furniture panels in the furniture industry, can solve the problems of low disassembly efficiency and production efficiency, high technical ability requirements for production personnel, and high labor costs, and achieve the reduction of technical ability requirements, The effect of reducing manual labor and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

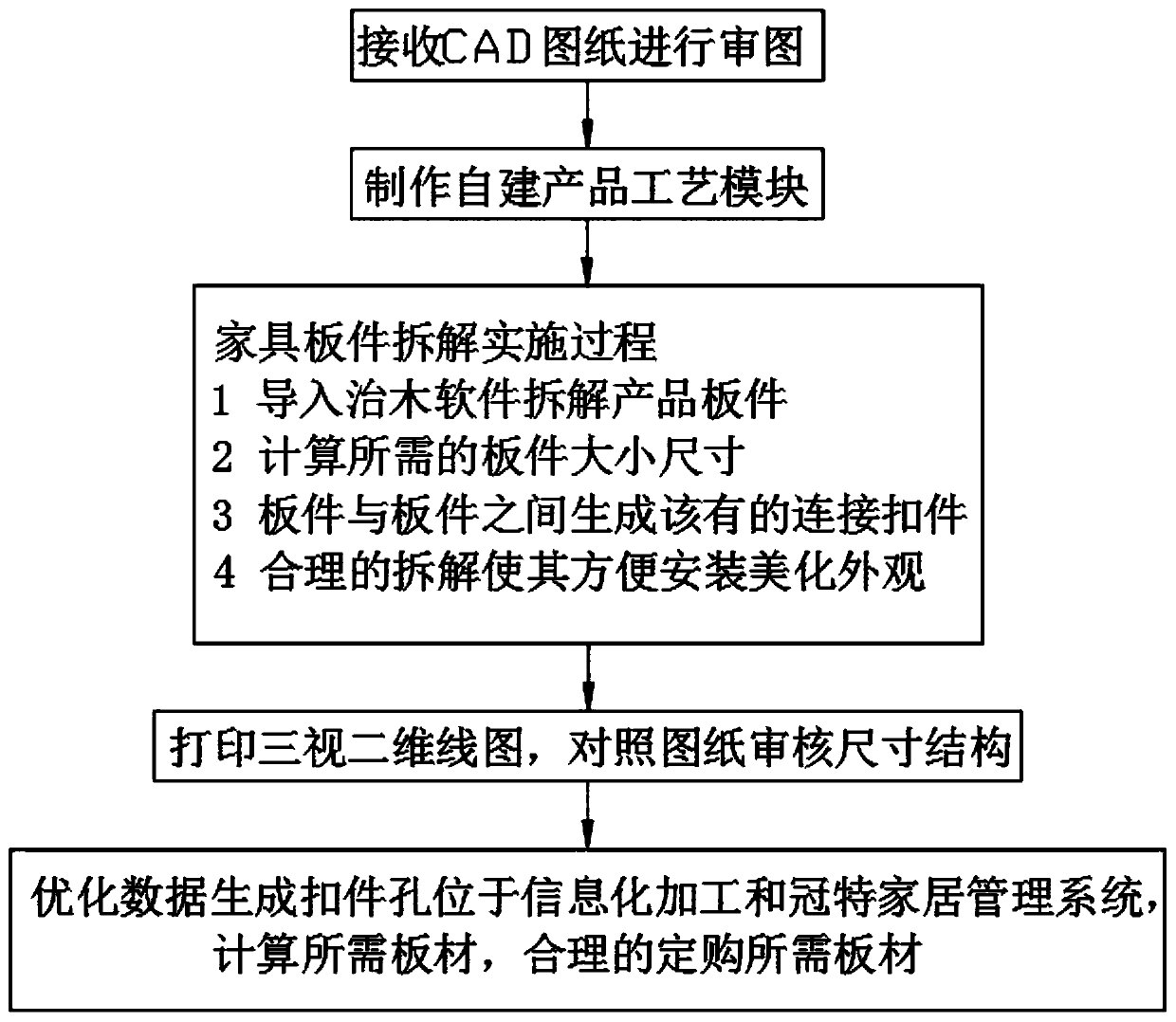

[0057] A method for disassembling furniture panels, comprising the following steps:

[0058] Step 1. Receive CAD drawings for drawing review, obtain the patterns designed by the furniture products that have been sold at the front end, and analyze the drawings in detail to effectively avoid errors in the product physical design process;

[0059] Step 2. Make a self-built product process module, and select the hanging cabinet series for the process module;

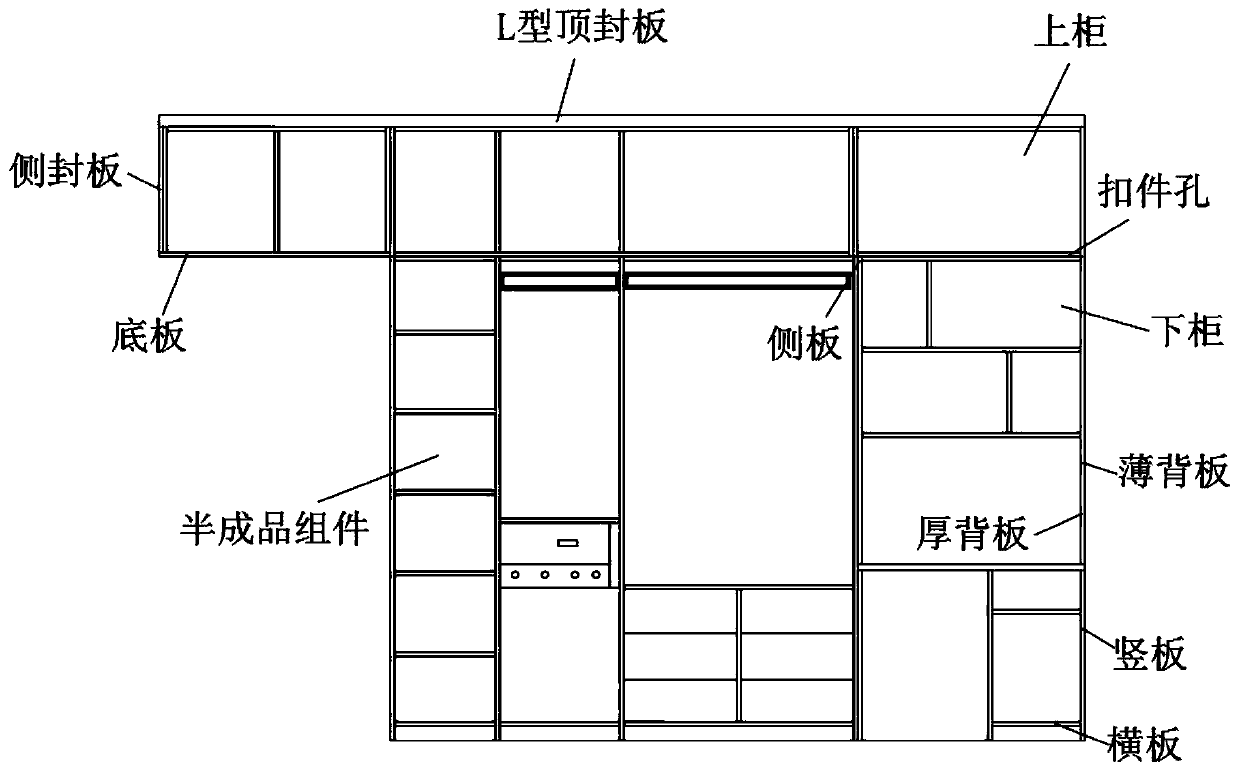

[0060] Step 3: Formulate the implementation process of dismantling furniture panels: Import wood management software to disassemble product panels, calculate the required panel size, generate necessary connecting fasteners between panels, and disassemble reasonably Make it easy to install and beautify the appearance;

[0061] Step 4. Print the three-dimensional two-dimensional line diagram, review the size structure against the drawings, and effectively avoid dimensional errors in the later production of products;

[0062]...

Embodiment 2

[0068] A method for disassembling furniture panels, comprising the following steps:

[0069] Step 1. Receive CAD drawings for drawing review, obtain the patterns designed by the furniture products that have been sold at the front end, and analyze the drawings in detail to effectively avoid errors in the product physical design process;

[0070] Step 2. Make a self-built product process module, and select the tatami series for the process module;

[0071] Step 3: Formulate the implementation process of dismantling furniture panels: Import wood management software to disassemble product panels, calculate the required panel size, generate necessary connecting fasteners between panels, and disassemble reasonably Make it easy to install and beautify the appearance;

[0072] Step 4. Print the three-dimensional two-dimensional line diagram, review the size structure against the drawings, and effectively avoid dimensional errors in the later production of products;

[0073] Step 5. ...

Embodiment 3

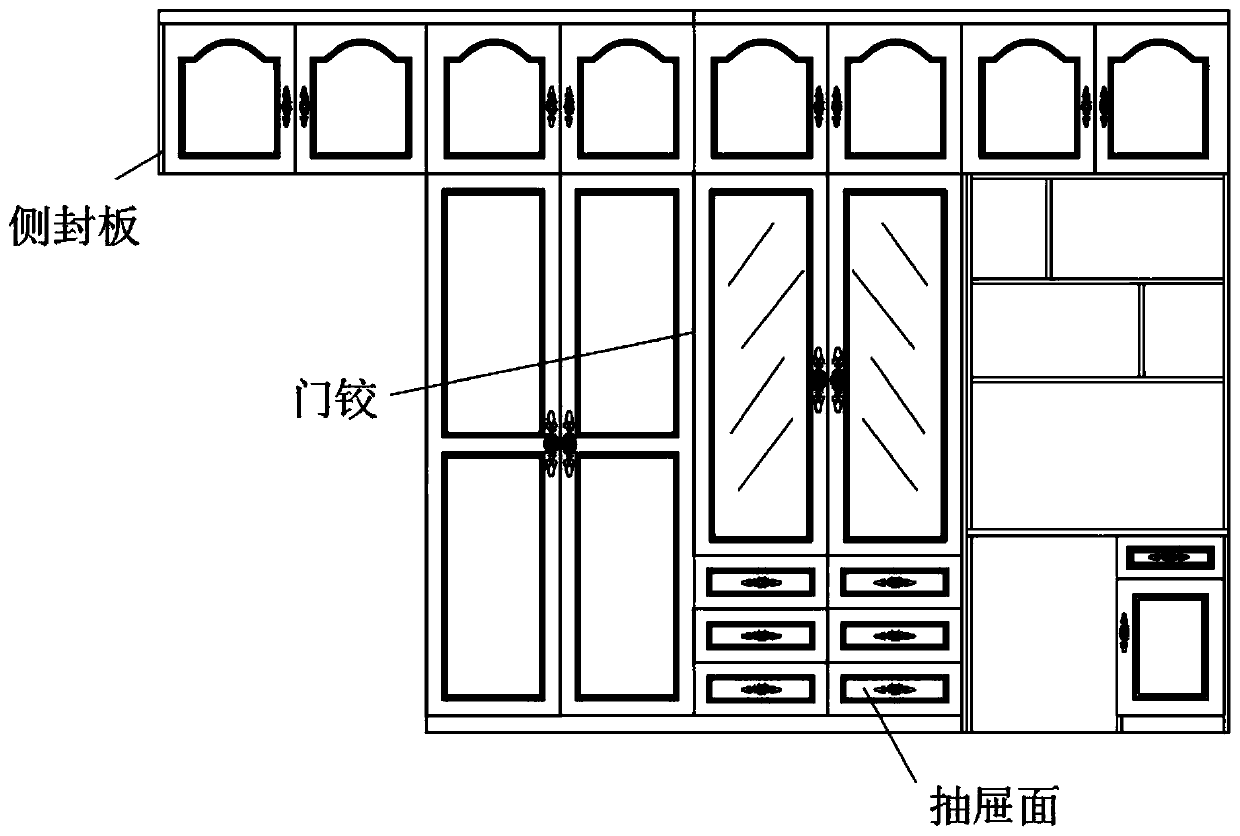

[0077] A method for disassembling furniture panels, comprising the following steps:

[0078] Step 1. Receive CAD drawings for drawing review, obtain the patterns designed by the furniture products that have been sold at the front end, and analyze the drawings in detail to effectively avoid errors in the product physical design process;

[0079] Step 2. Make a self-built product process module, and select the card slot vertical wardrobe series for the process module;

[0080] Step 3: Formulate the implementation process of dismantling furniture panels: Import wood management software to disassemble product panels, calculate the required panel size, generate necessary connecting fasteners between panels, and disassemble reasonably Make it easy to install and beautify the appearance;

[0081] Step 4. Print the three-dimensional two-dimensional line diagram, review the size structure against the drawings, and effectively avoid dimensional errors in the later production of product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com