Device and method for welding and separating packaging materials for a package

A packaging material and cutting device technology, applied in the field of devices and methods for welding and dividing packaging materials used for packaging, can solve problems such as wear and tear, and achieve the effect of high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

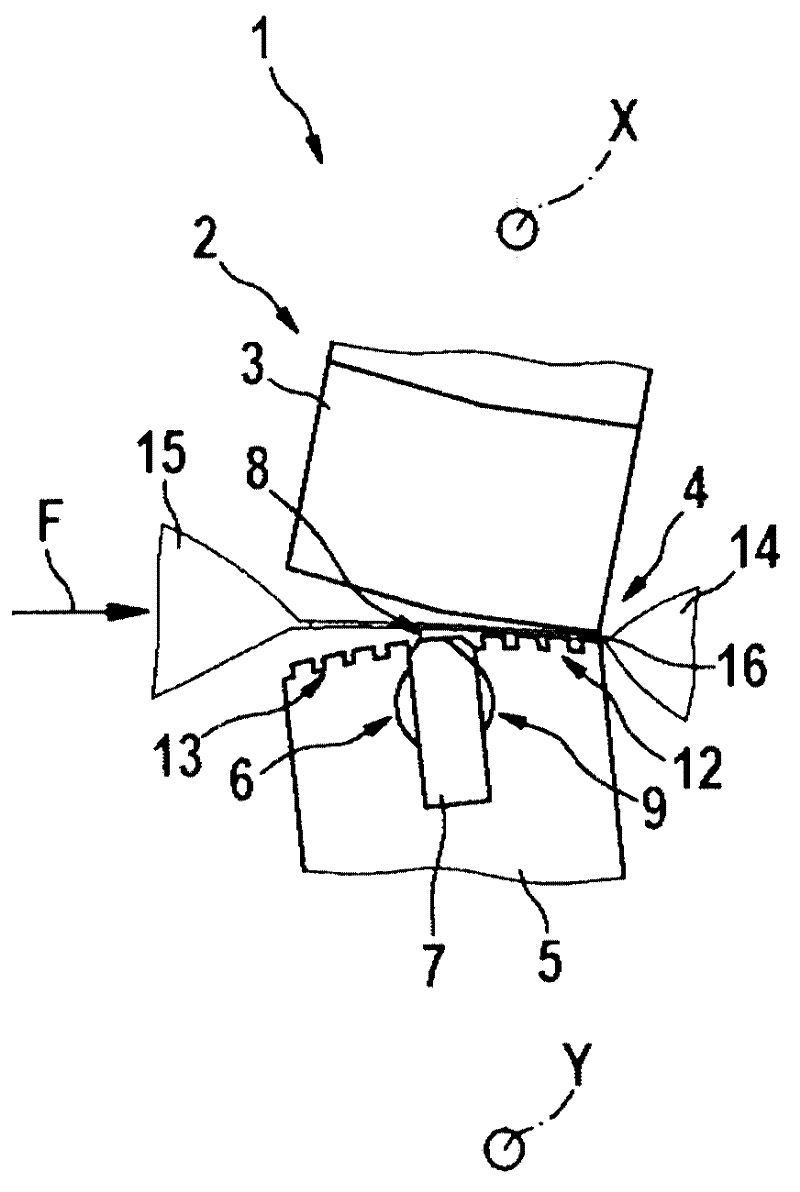

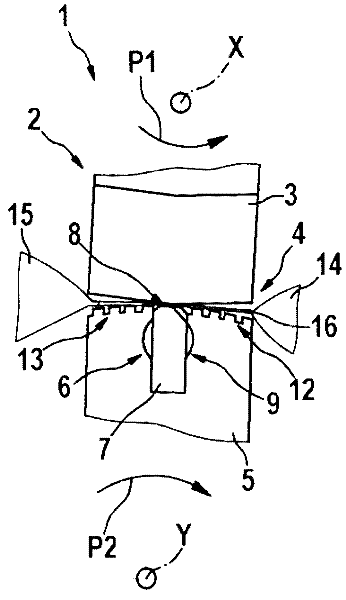

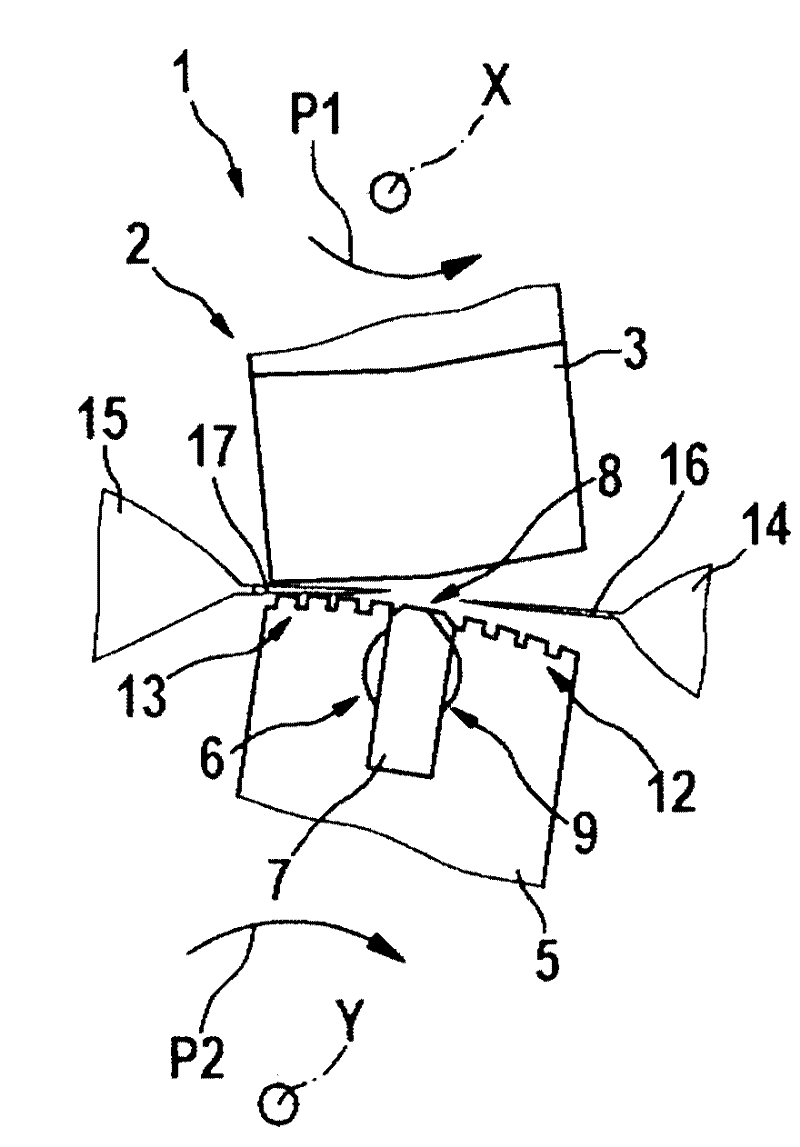

[0019] Refer below Figures 1 to 4 An apparatus 1 for welding and dividing packaging materials for packaging according to a preferred embodiment of the present invention is described in detail.

[0020] Such as figure 1 As shown, the device 1 for welding and dividing packaging materials comprises an ultrasonic welding device 2 with a sonotrode 3 and an anvil 5, the packaging materials 4 forming the preceding packaging 14 and the following packaging 15 are transported in the conveying direction indicated by the arrow F passes between the sonotrode and the anvil. The sonotrode 3 is rotatable about a first axis of rotation X and the anvil 5 is rotatable about a second axis Y.

[0021] Arranged inside the anvil 5 is a cutting device 6 with a knife 7 and an adjusting device 9 , by means of which the knife 7 is fixed and adjusted in the radial direction of the anvil 5 . The cutting device 6 is arranged between the first sealing region 12 and the second sealing region 13 of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com