Biodegradable shape memory stitched wire

The technology of a suture thread and a memory polymer is applied in the application field of medical surgical suture to achieve the effects of reducing economic burden, reducing inconvenience and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

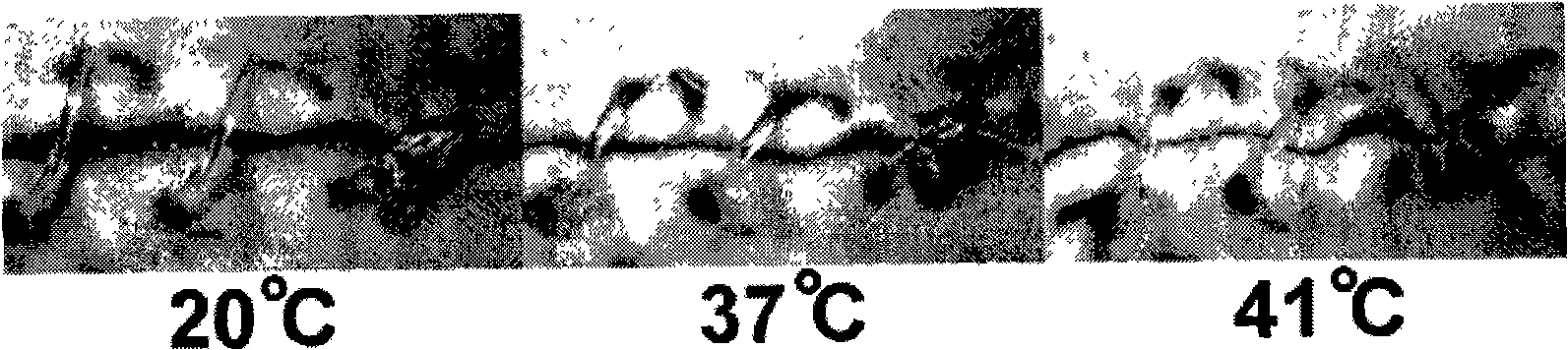

[0018] Embodiment 1: Preparation of a biodegradable shape memory suture thread. In this embodiment, the biodegradable shape memory suture thread is a molded solidified product of a biodegradable shape memory polymer. The biodegradable shape memory polymer used is one or a mixture of the following substances: poly-L-lactide-poly(glycolide / caprolactone) multi-block copolymer, aliphatic poly Ester-coupling agent-multifunctional monomer-adjuvant radiation crosslinking product, poly-L-lactic acid, ε-caprolactone polymer of dimethacrylate and n-butyl acrylate, rac-lactide and di Star blend of glycol, multi-block copolyester synthesized from ε-caprolactone and ethylene glycol monomethyl ether and chain extender based on carbonic anhydrase group, ε-caprolactone diol Oligomers and p-dioxanone homopolymers and diisocyanate polymers. The difference is that the biodegradable shape memory sutures made of different biodegradable shape memory polymer materials have different toughness and differ...

specific Embodiment approach 2

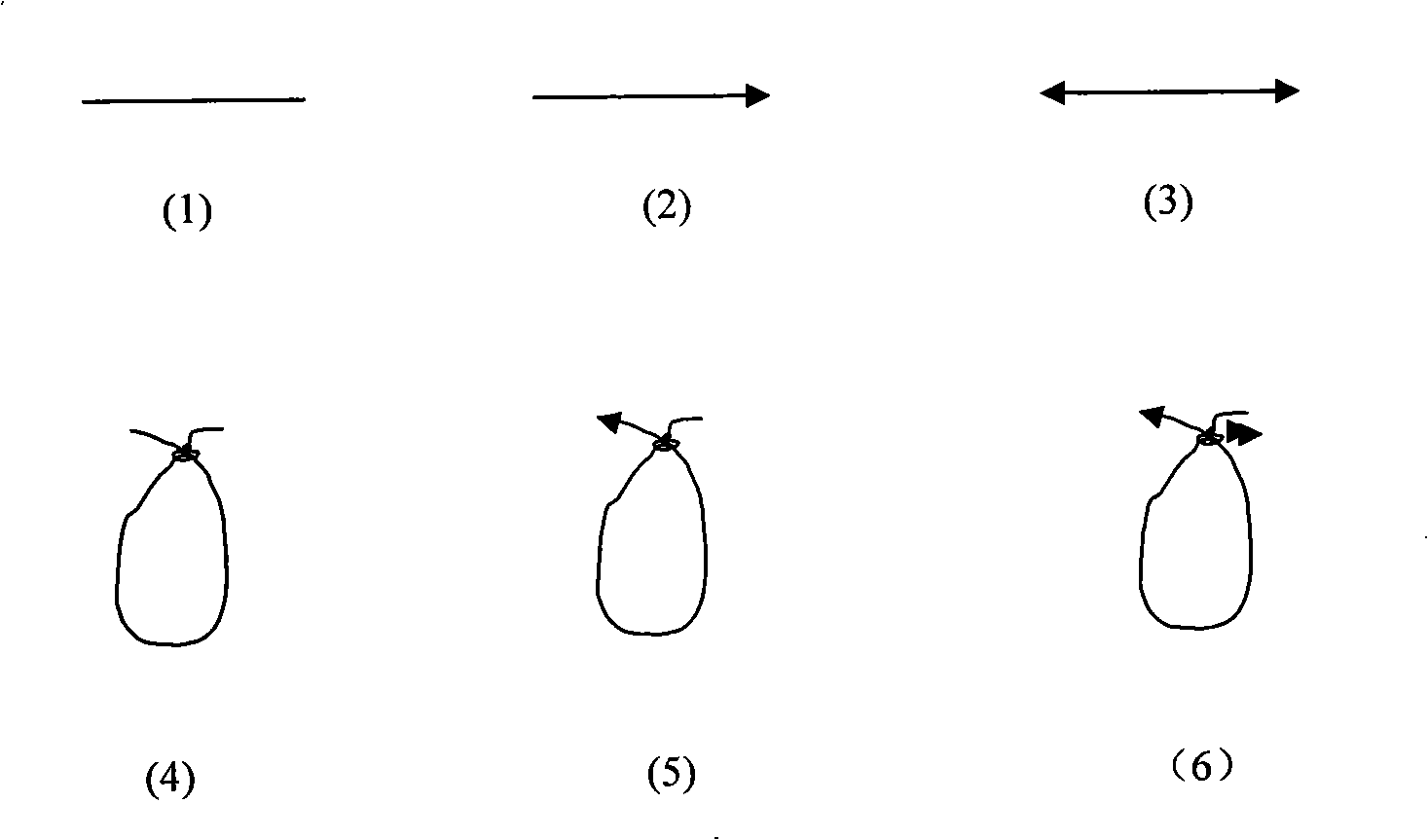

[0019] Embodiment 2: Preparation of a biodegradable shape memory suture. The difference between this embodiment and the first embodiment lies in the molding characteristics of the biodegradable shape memory suture. The molding method is one or more of the following methods: compression molding, injection (plastic) molding, compression molding, die-casting molding, blow molding, solid-phase hydrostatic extrusion molding, die drawing molding, sol -Gel filament picking molding, sol-gel spinning molding, melt stretching molding, directional free stretching molding, shrinkage stretching molding, solid state extrusion molding. The curing process of the biodegradable shape memory suture thread depends on the curing process of the corresponding biodegradable shape memory polymer. The shape of the biodegradable shape memory suture after solidification has two types: straight line and two ends twisted into suture kinks. The shape of each line can be specifically divided into uniform line ty...

specific Embodiment approach 3

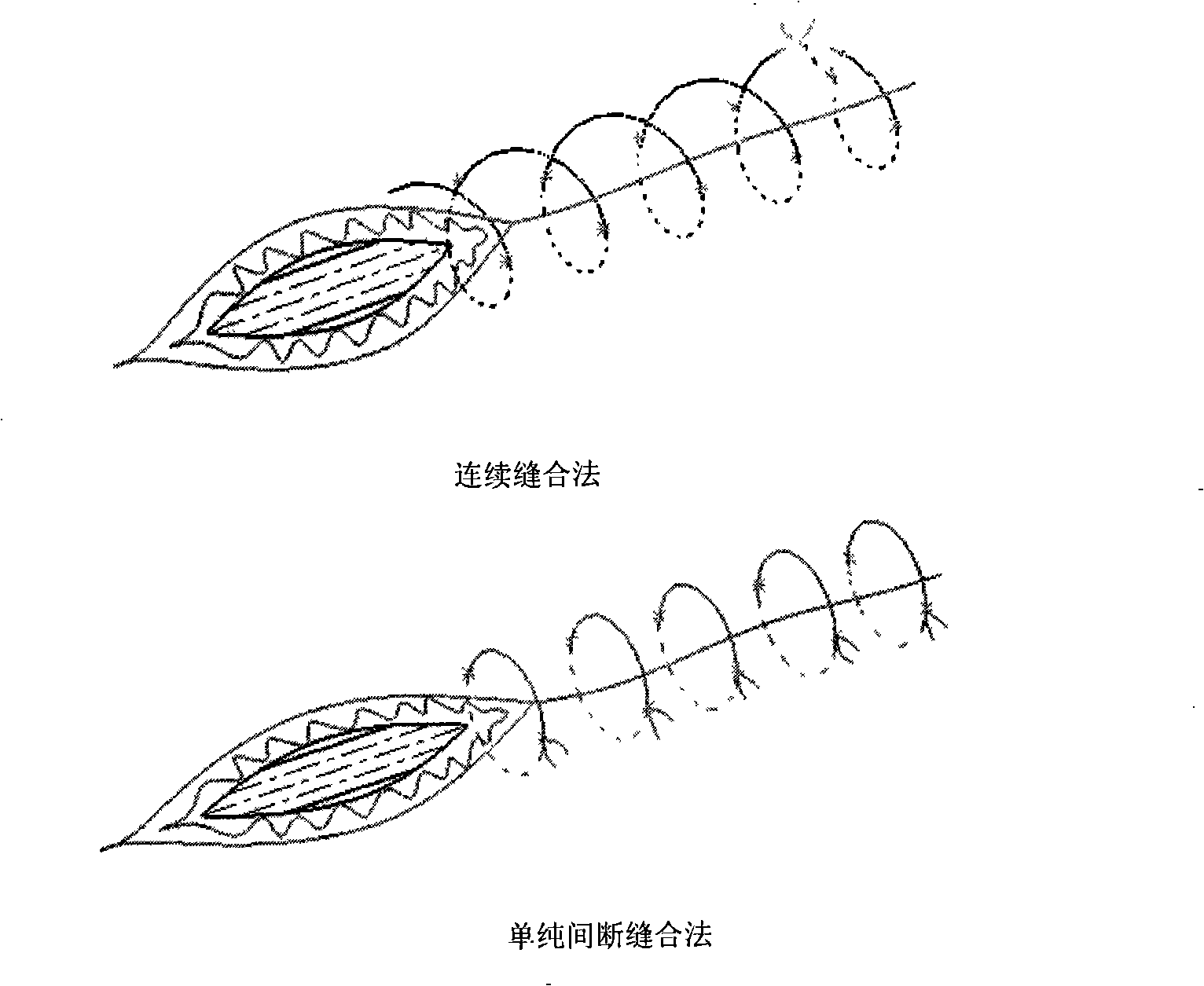

[0020] Specific embodiment three: application of biodegradable shape memory suture thread. Heat the biodegradable shape memory suture thread to soften, stretch it into an approximate linear shape under the action of external force, and then stretch it (straight-line shape is directly stretched); cooling, the suture will remain stretched; The elongated suture thread is used to sew the wound loosely; the suture thread is heated to return to the original shape until the wound is just ideally closed; after cooling, the recovery state of the suture thread is fixed, and the wound remains in the ideal closed state; as the wound heals , The biodegradable shape memory suture will dissolve at the designed time and be absorbed harmlessly by the body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com