Connecting screw

A screw and nut technology, applied in the field of connecting screws, can solve the problems of low quality of cardboard boxes, unsightly appearance, low work efficiency, etc., and achieve the effects of reducing labor consumption, being beneficial to environmental protection, and fast disassembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

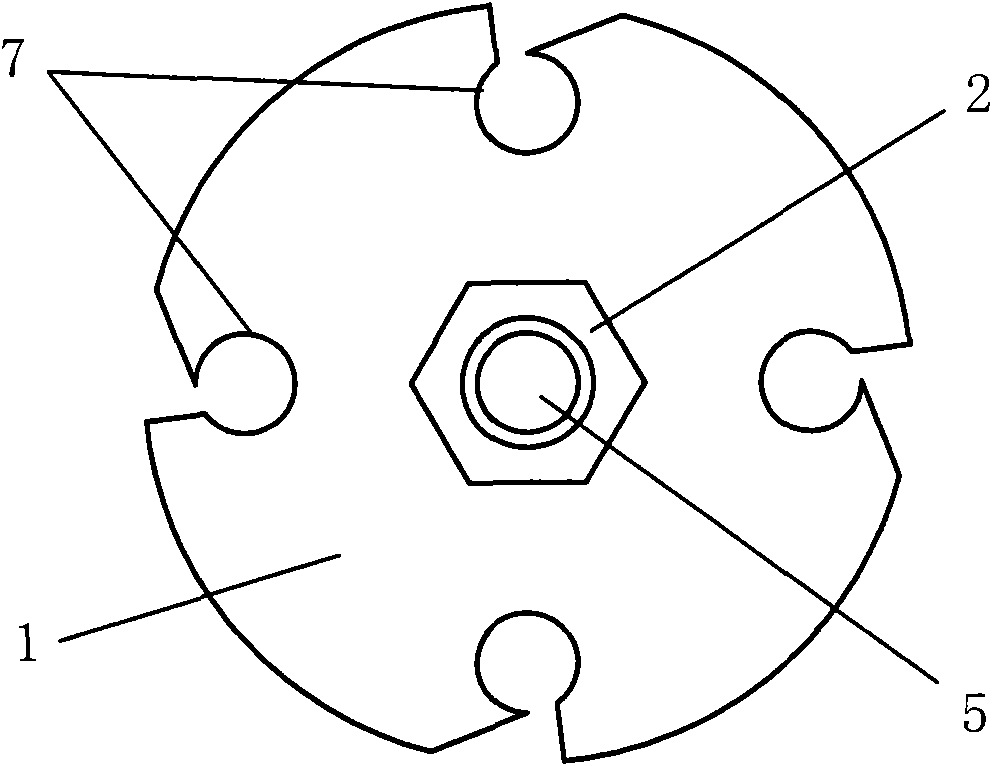

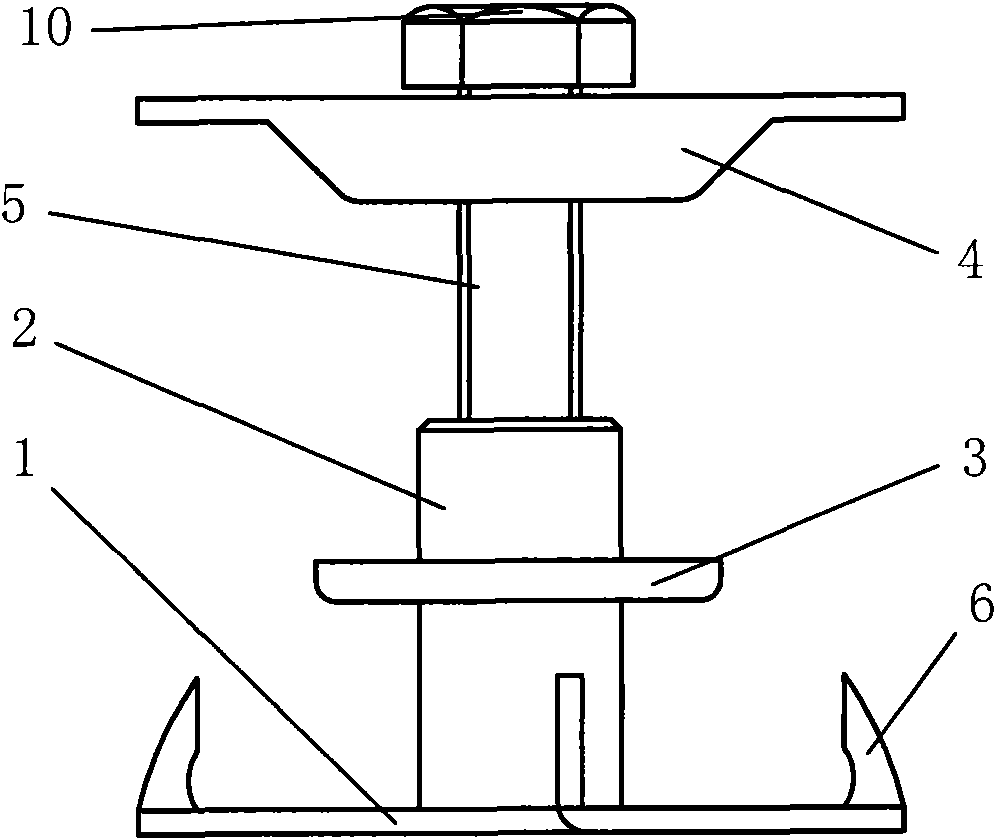

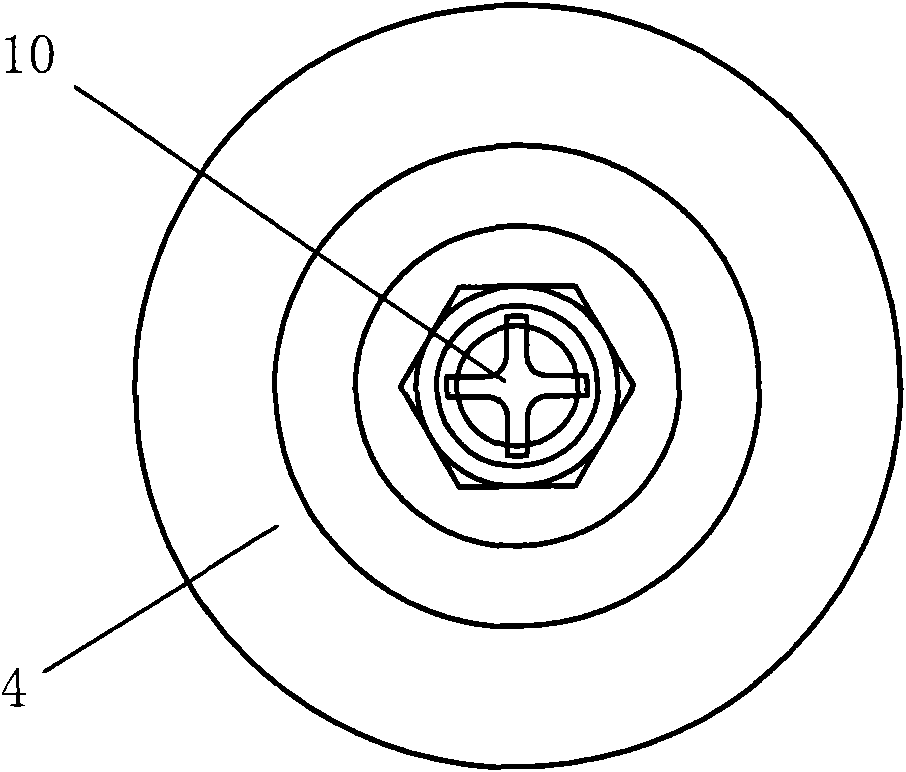

[0017] see Figure 1 to Figure 4 , a connecting screw described in this embodiment, including a nut 2 and a hexagonal screw 5, the nut 2 and the hexagonal screw 5 are fitted together, the connecting screw also includes a toothed meson 1, a spring meson 3 and a pot-shaped meson 4, The toothed meson 1 is assembled with the lower end of the nut 2, the circlip meson 3 is stuck on the nut 2, and the pot-shaped meson 4 is matched with the hexagonal screw 5. The toothed meson 1 is designed with 4 teeth 6 for tightly connecting the cardboard and 4 mounting holes 7 for convenient disassembly of the toothed meson 1 and the nut 2 . Four protrusions 8 for tightly riveting the lower end of the nut are designed on the inner wall of the central hole of the toothed meson 1 . A plurality of trapezoidal locking teeth 9 for tightly engaging with the outer wall of the nut are designed on the snap ring meson 3 . On the inner wall of the center hole of the pot-shaped meson 4, an internal thread f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com