Automatic sweater sewing method based on machine vision perception

A machine vision and sweater technology, applied in the direction of cloth feeding mechanism, sewing equipment, sewing machine components, etc., can solve the problems of insufficient detection and missed detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

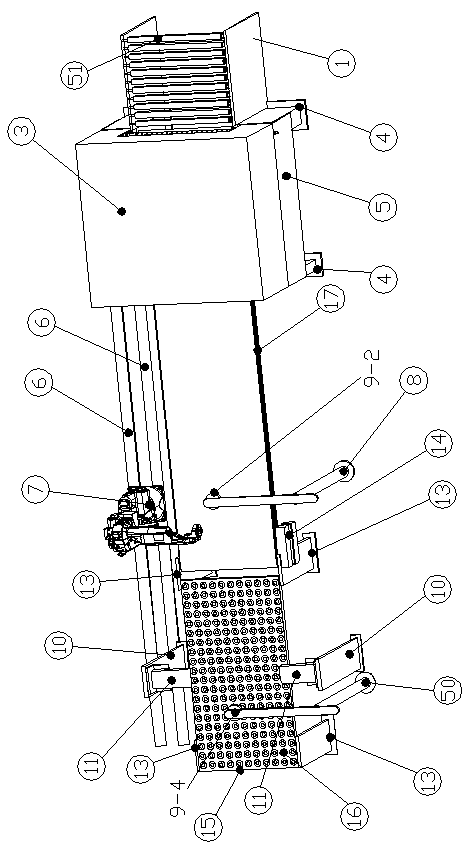

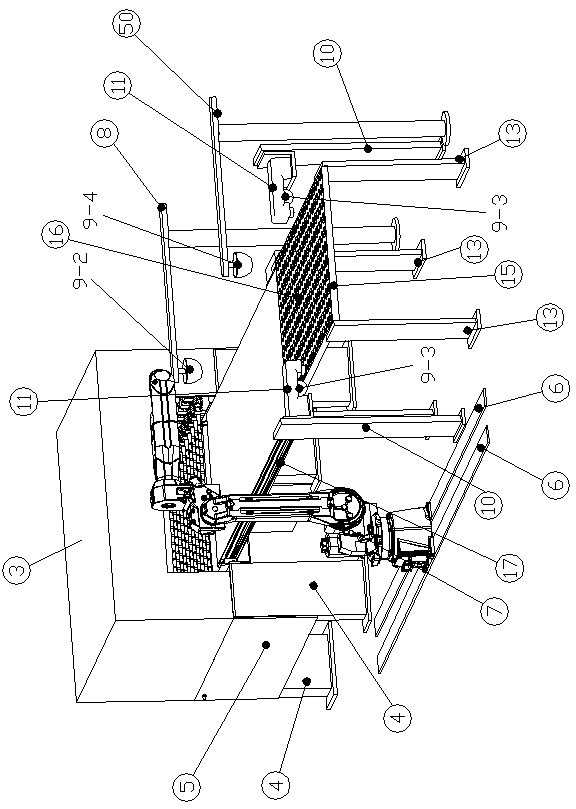

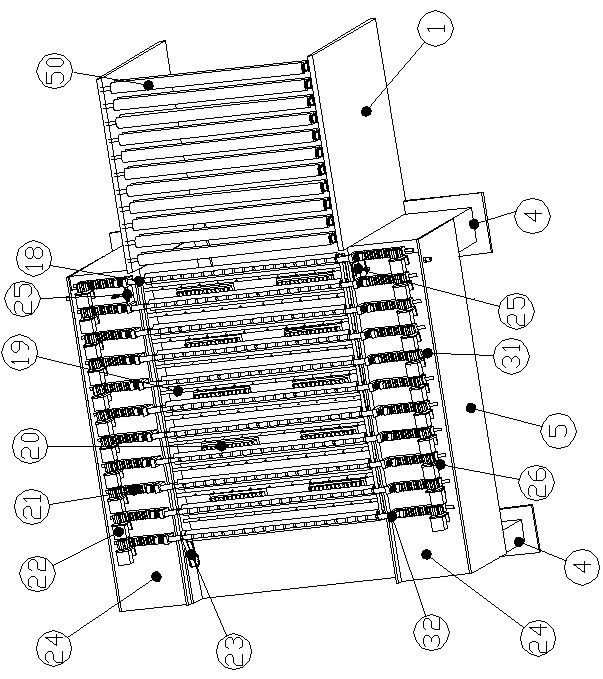

[0051] Such as Figure 1-Figure 9 As shown, the automatic sweater sewing method based on machine vision perception of the present invention, the automatic sweater sewing method adopts automatic sweater sewing equipment to operate; the automatic sweater sewing equipment includes an input flattening device, a stretch freezing device, a sewing preparation device, Suture device, handling robot 7 and control box 14;

[0052]The input flattening device, the stretching and freezing device, the suture preparation device and the suture device are sequentially connected from front to back, and the left side of the lower part of the suture preparation device and the suture device is provided with a track 6 along the front and rear direction, and the bottom of the handling robot is rollingly connected to the track 6 , the working part of the transport robot 7 extends above the suture preparation device and the suture device;

[0053] The control box 14 is provided with a control module a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com