Movable traction type warehouse broken bag replacing machine

A package breaker and traction-type technology, which is applied in the field of mobile traction warehouse replacement package breaker, can solve the problems that the packaging machine is too large to be used in the warehouse, and the applicability of the equipment is disclosed, so as to achieve simple structure, improve practicability, and improve applicability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

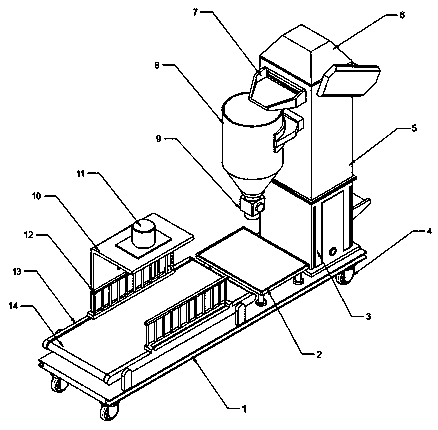

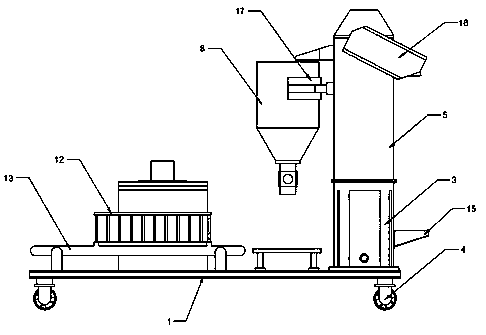

[0028] Figure 1-Figure 3 Shown is a movable traction-type warehouse breaker, including a base 1, a feeding box 5, a feed hopper 8 and a stitcher 11, the base 1 is provided with a material guide box 3, and the upper part of the material guide box 3 A loading box 5 is provided, and the loading box 5 passes through a fixer 17 and a feed hopper 8; idlers are arranged inside the loading box 5, and conveyor belts are arranged on the idlers, and the upper and lower parts of the loading box 5 are respectively arranged There are a material outlet and a material inlet, and the material outlet is connected to the upper part of the feed hopper 8 through the feed trough 7, and the feed trough 15 is arranged on the said feed inlet; the measuring scale 2 is arranged on the said base 1, And the measuring scale 2 one end is provided with the conveyor frame 13 of the conveyor belt 14; the base 1 side is provided with the fixed plate 10, and the fixed plate 10 top is provided with the stitcher ...

Embodiment 2

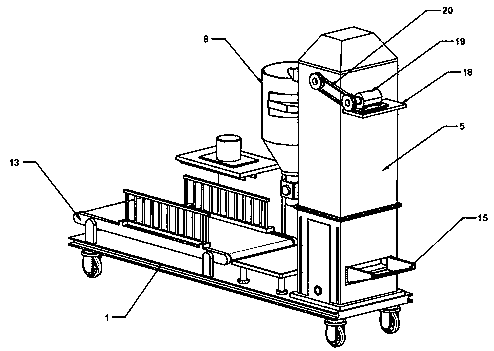

[0030] This embodiment further describes the loading box 5 on the basis of the existing embodiment 1, the loading box 5 is provided with a fixed platform 18, and the fixed platform 18 is provided with a driving motor 19, and the driving motor 19 The synchronous wheel is connected with the synchronous belt 20 and the idler roller; the drive motor 19 is used to drive the idler roller inside the feeding box 5 to further drive the conveyor belt for feeding, and the drive motor 19 is connected with the control box.

Embodiment 3

[0032] This embodiment is to further describe the upper material box 5 on the basis of the existing embodiment 1. The upper part of the upper material box 5 is provided with a sealing cover 6, and the sealing cover 6 is connected to the side of the upper material box 5 through the rotating shaft. The fixed ear is connected by rotation; the feeding hopper 8 is a conical cavity structure with an upper opening, and the lower part of the feeding hopper 8 is provided with a discharge pipe, and a numerical control valve 9 is provided on the discharge pipe, and the numerical control valve 9 is connected with the control box ; The feeding pipe of the feeding hopper 8 is provided with a numerical control valve 9, which can cooperate with the measuring scale 2 and the control box at the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com