Patents

Literature

153results about How to "Short turnaround time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

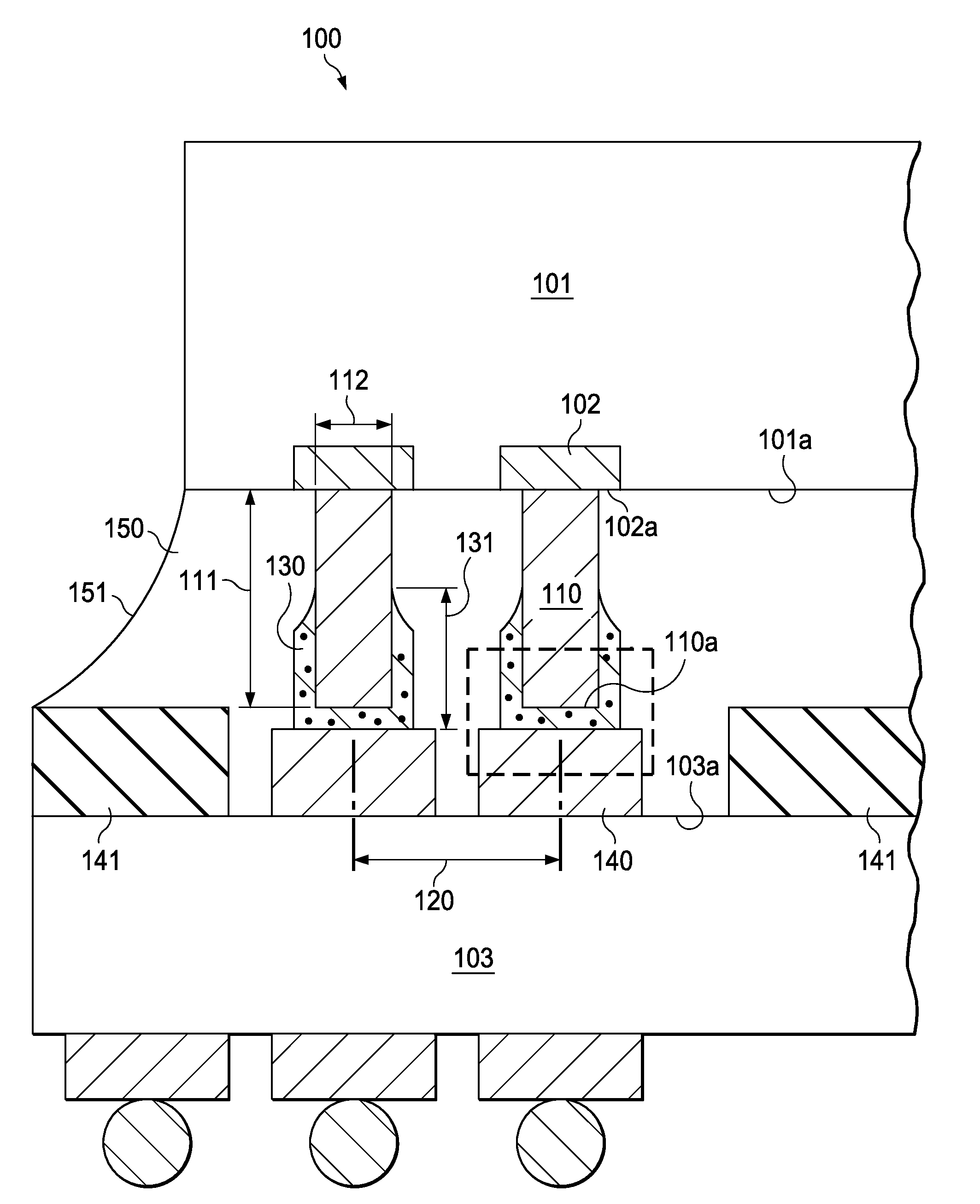

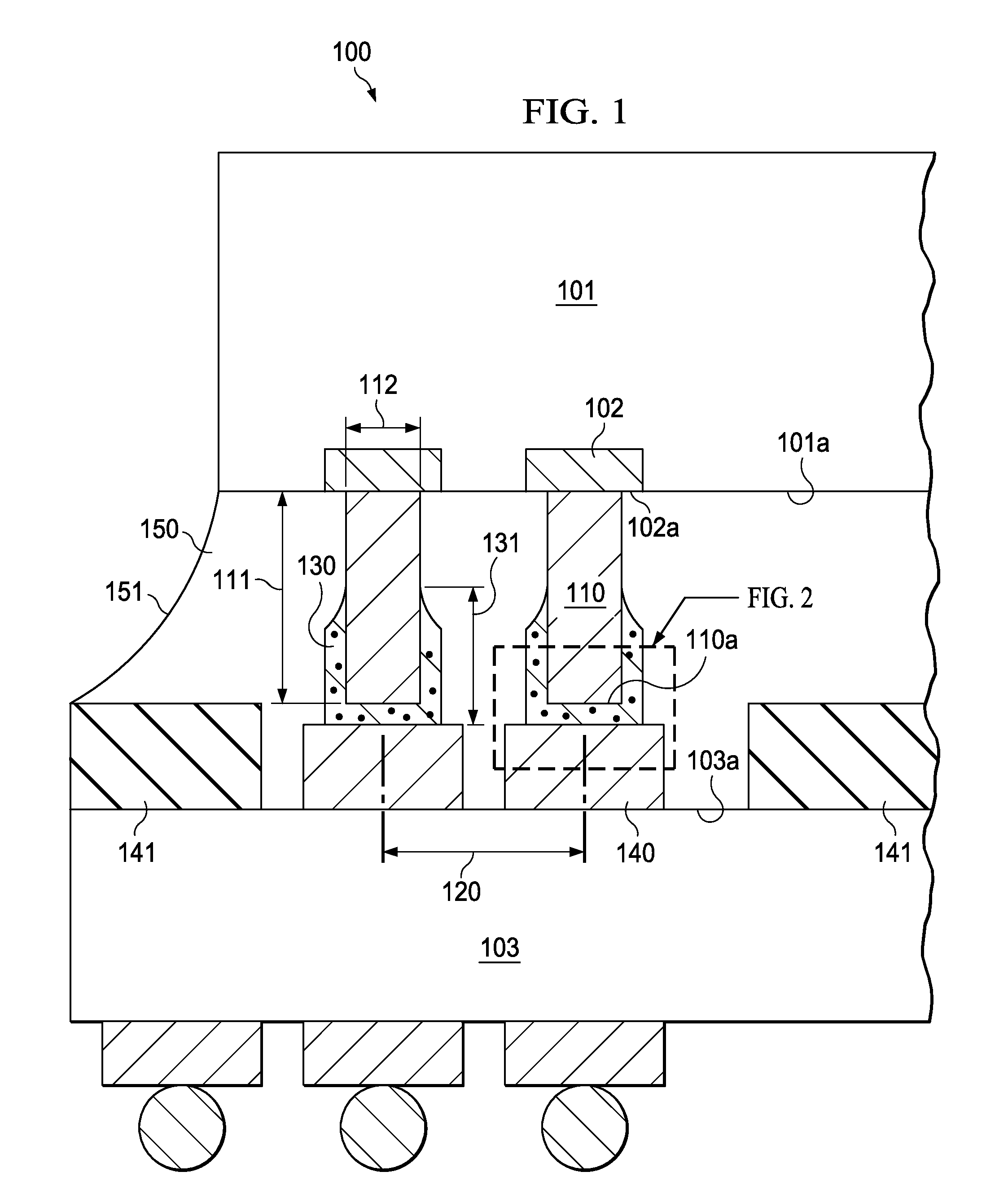

Method for low stress flip-chip assembly of fine-pitch semiconductor devices

ActiveUS7898083B2Short turnaround timeReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesMatrix embeddingFine pitch

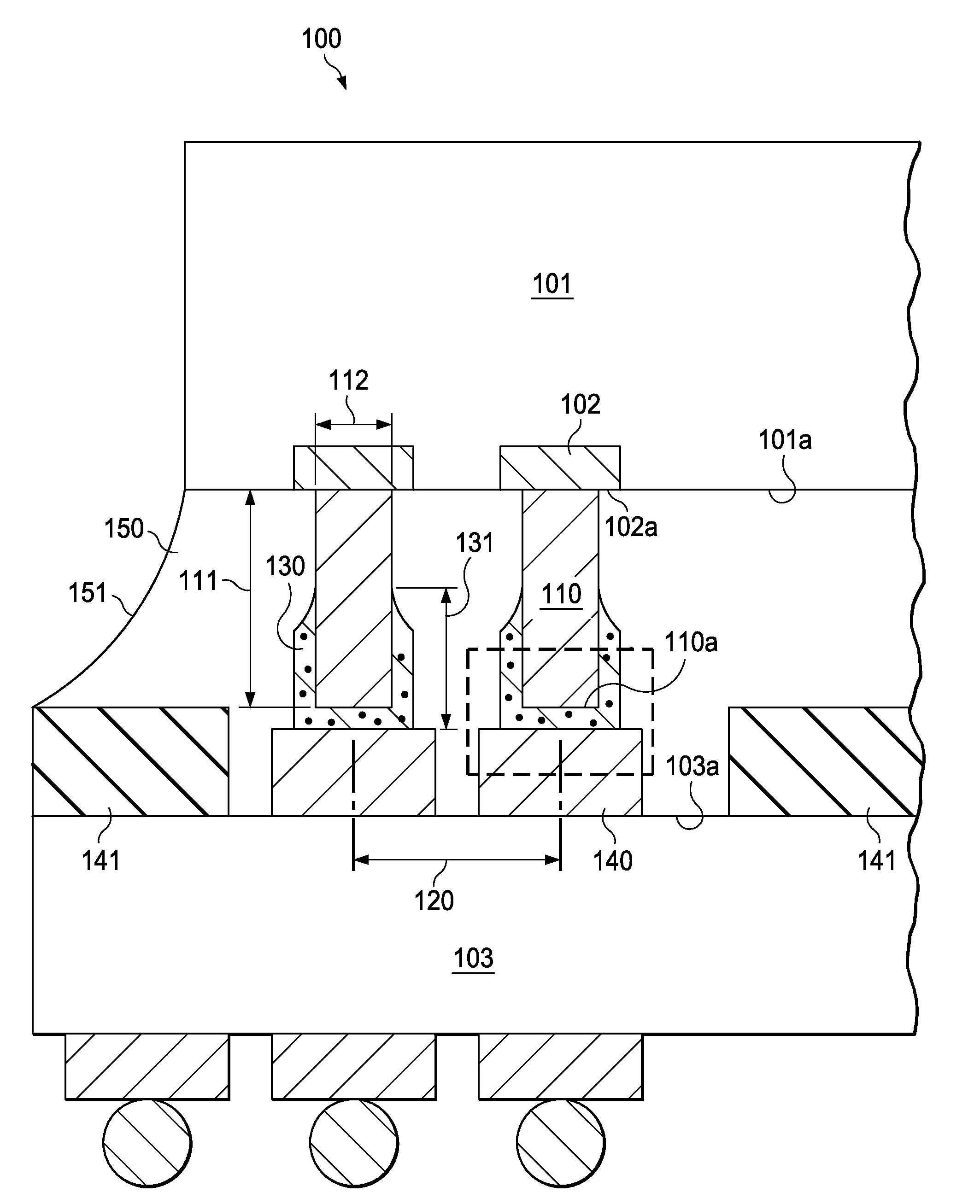

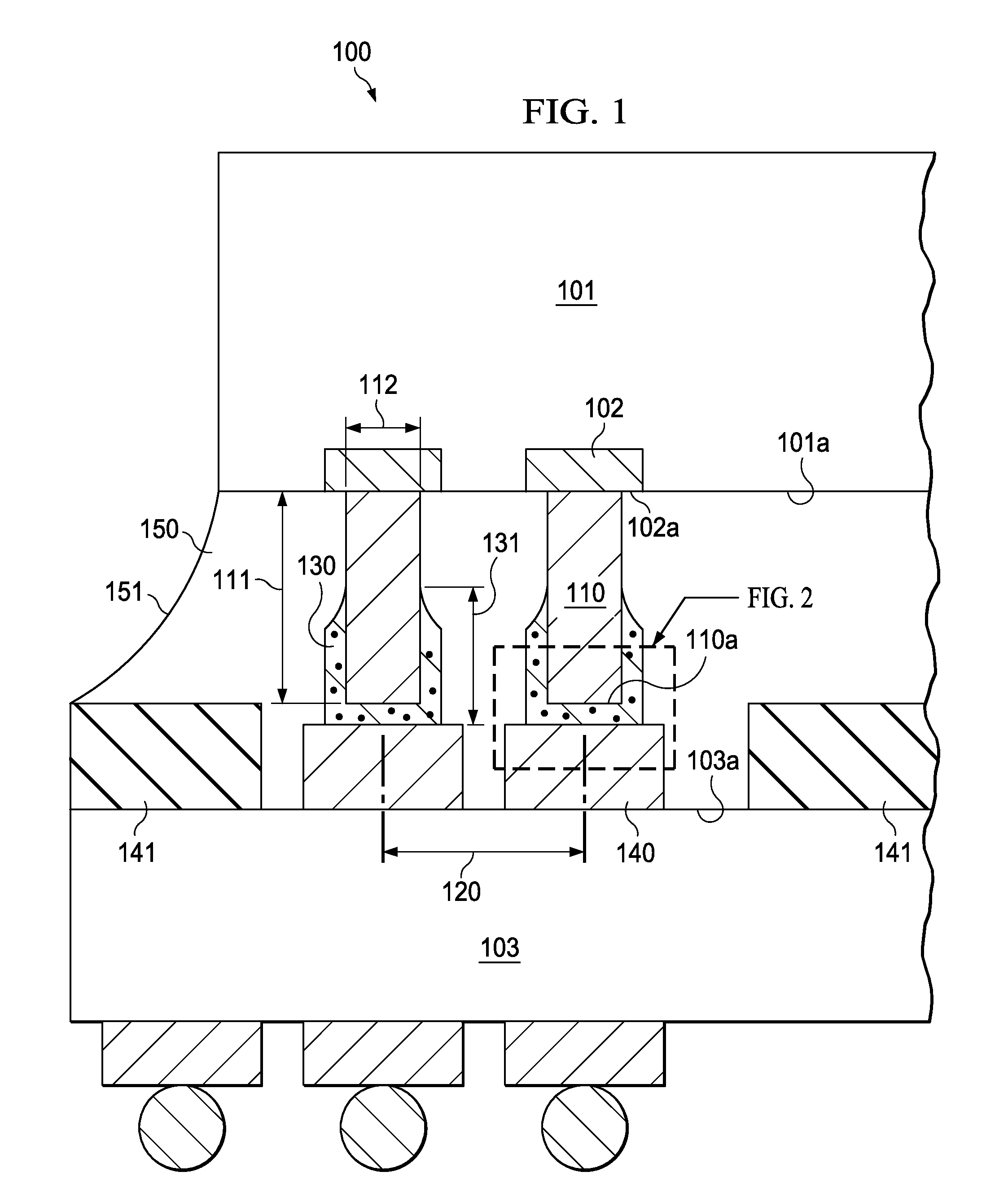

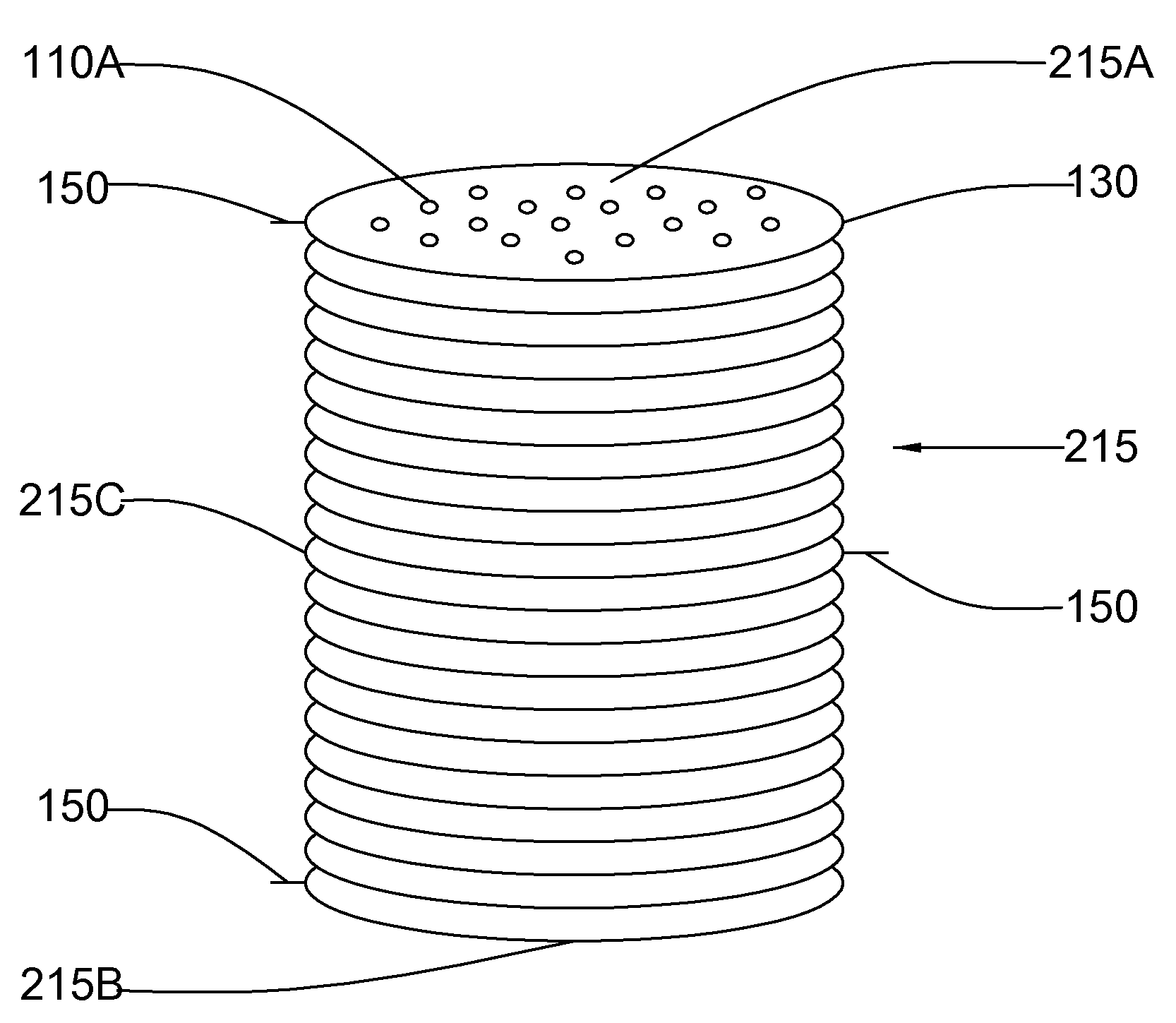

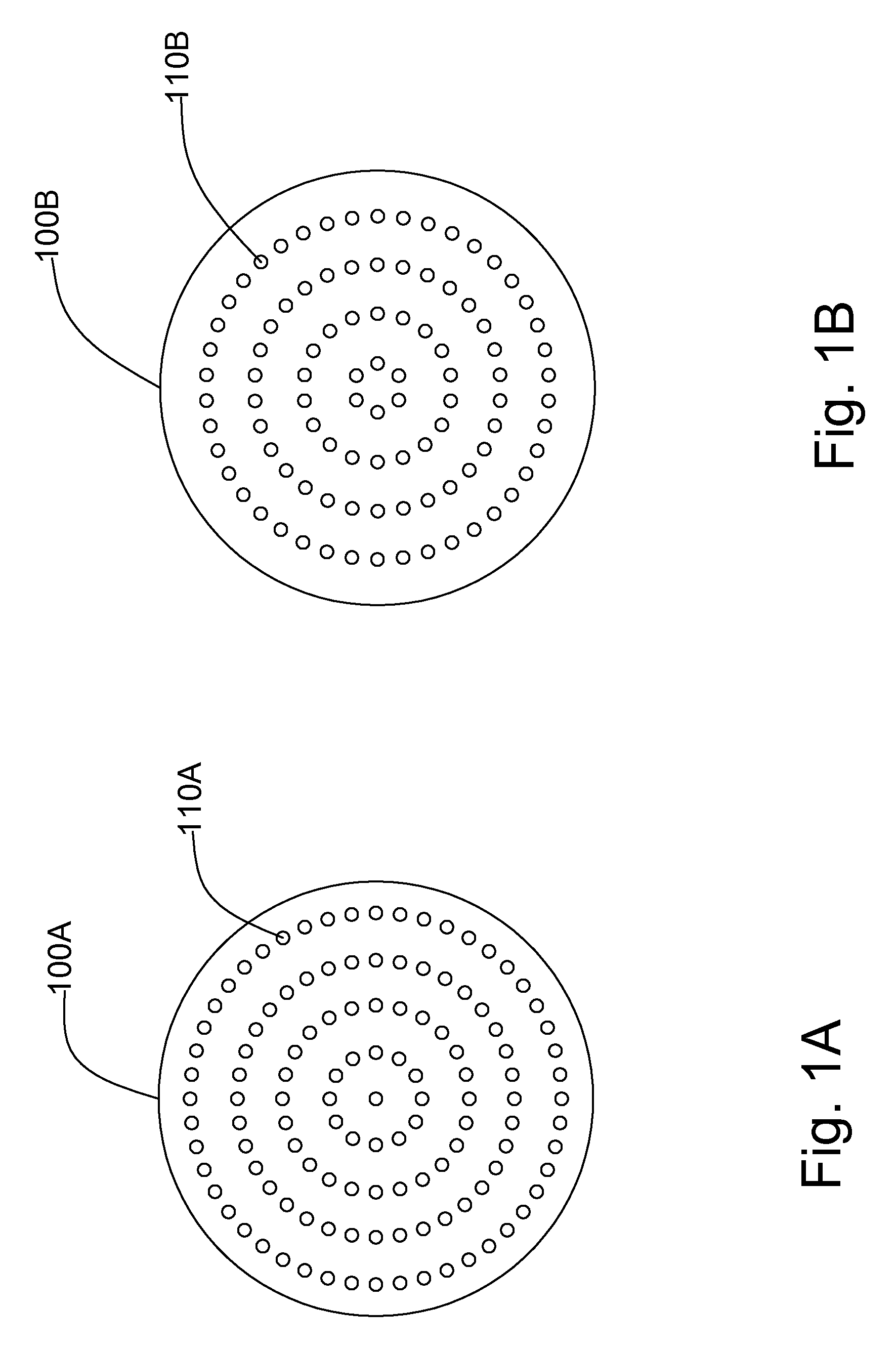

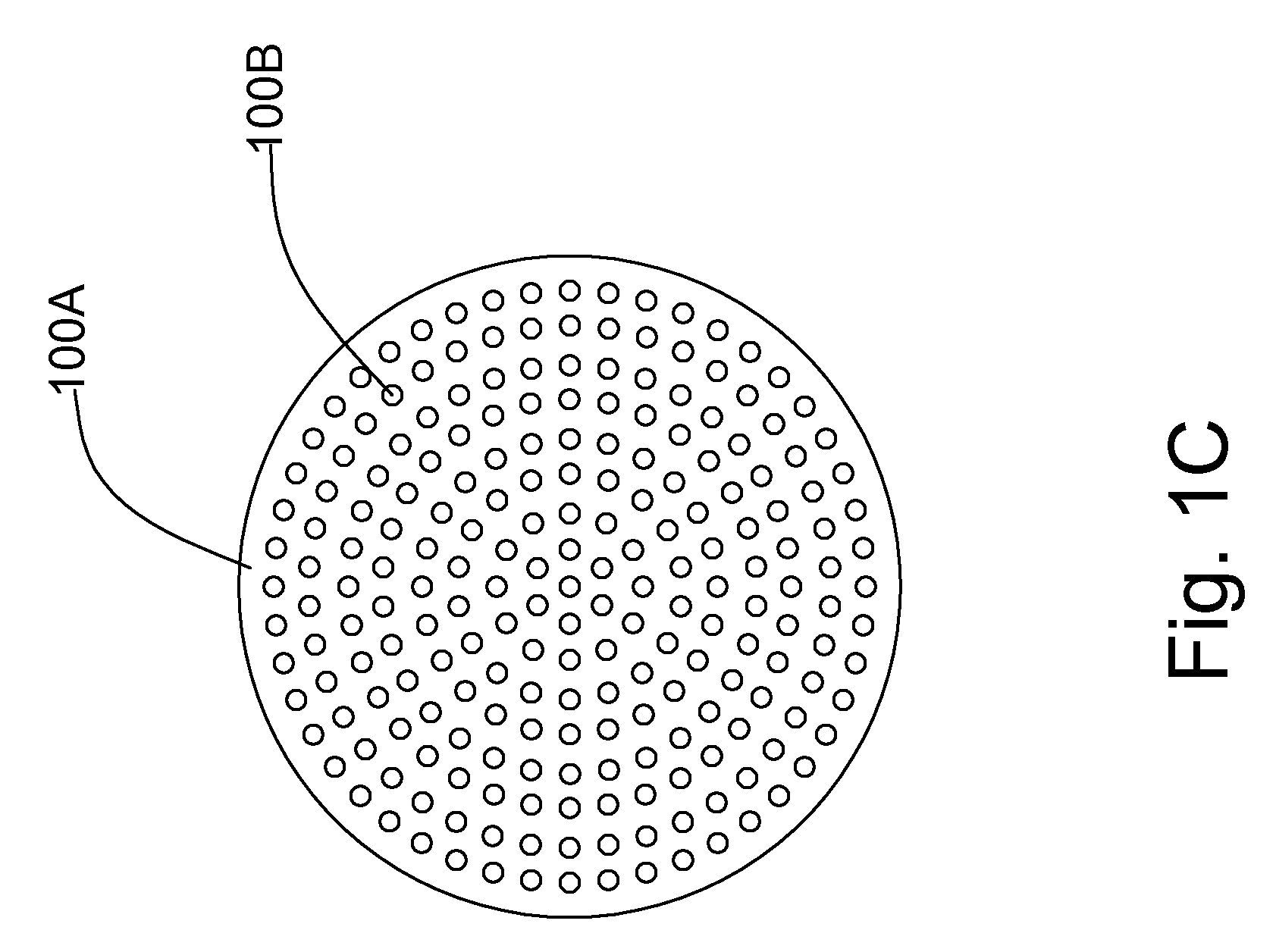

A device including a first body (101) with terminals (102) on a surface (101a), each terminal having a metallic connector (110), which is shaped as a column substantially perpendicular to the surface. Preferably, the connectors have an aspect ratio of height to diameter of 2 to 1 or greater, and a fine pitch center-to-center. The connector end (110a) remote from the terminal is covered by a film (130) of a sintered paste including a metallic matrix embedded in a first polymeric compound. Further a second body (103) having metallic pads (140) facing the respective terminals (102). Each connector film (130) is in contact with the respective pad (140), whereby the first body (101) is spaced from the second body (103) with the connector columns (110) as standoff. A second polymeric compound (150) is filling the space of the standoff.

Owner:TEXAS INSTR INC

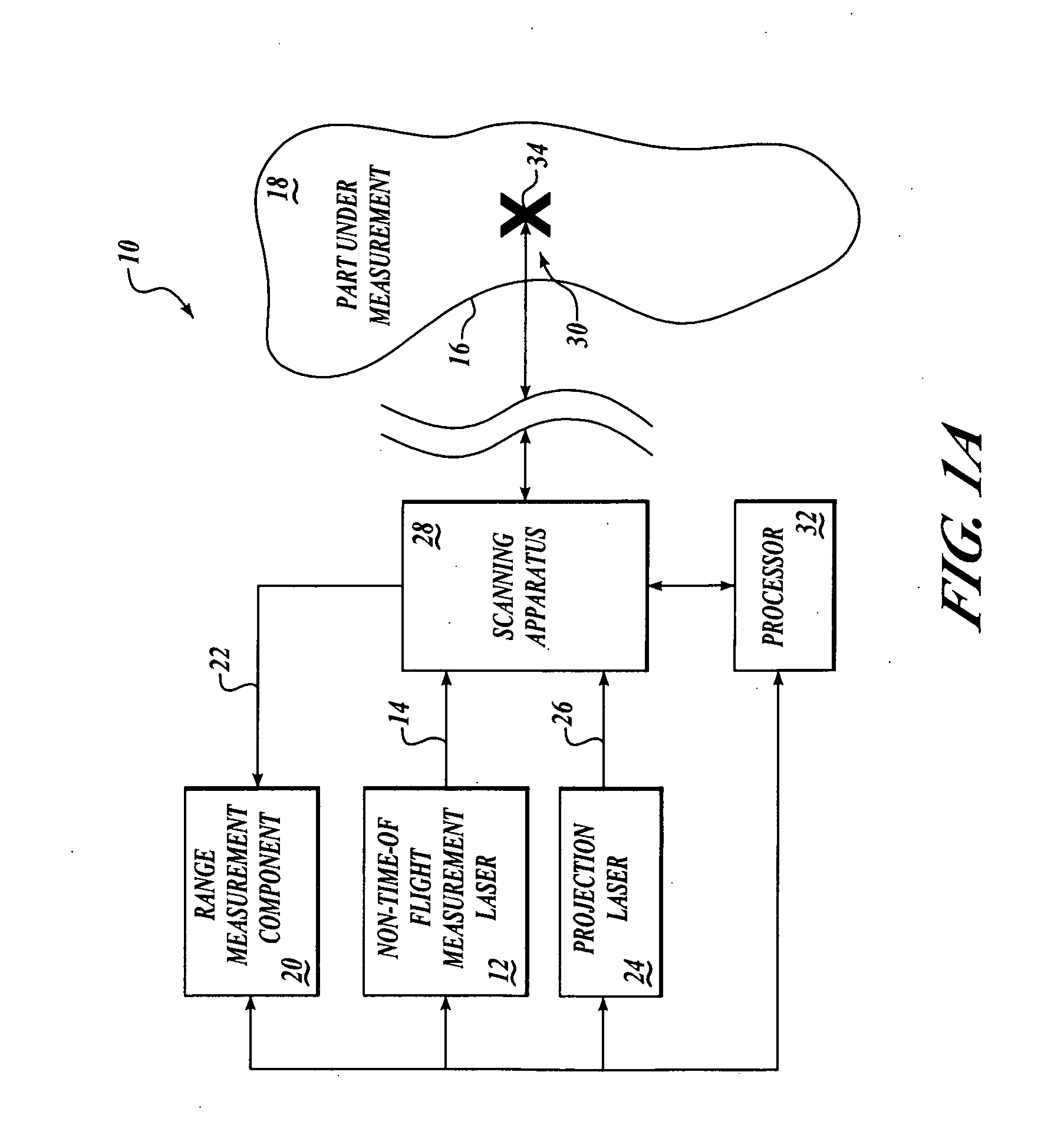

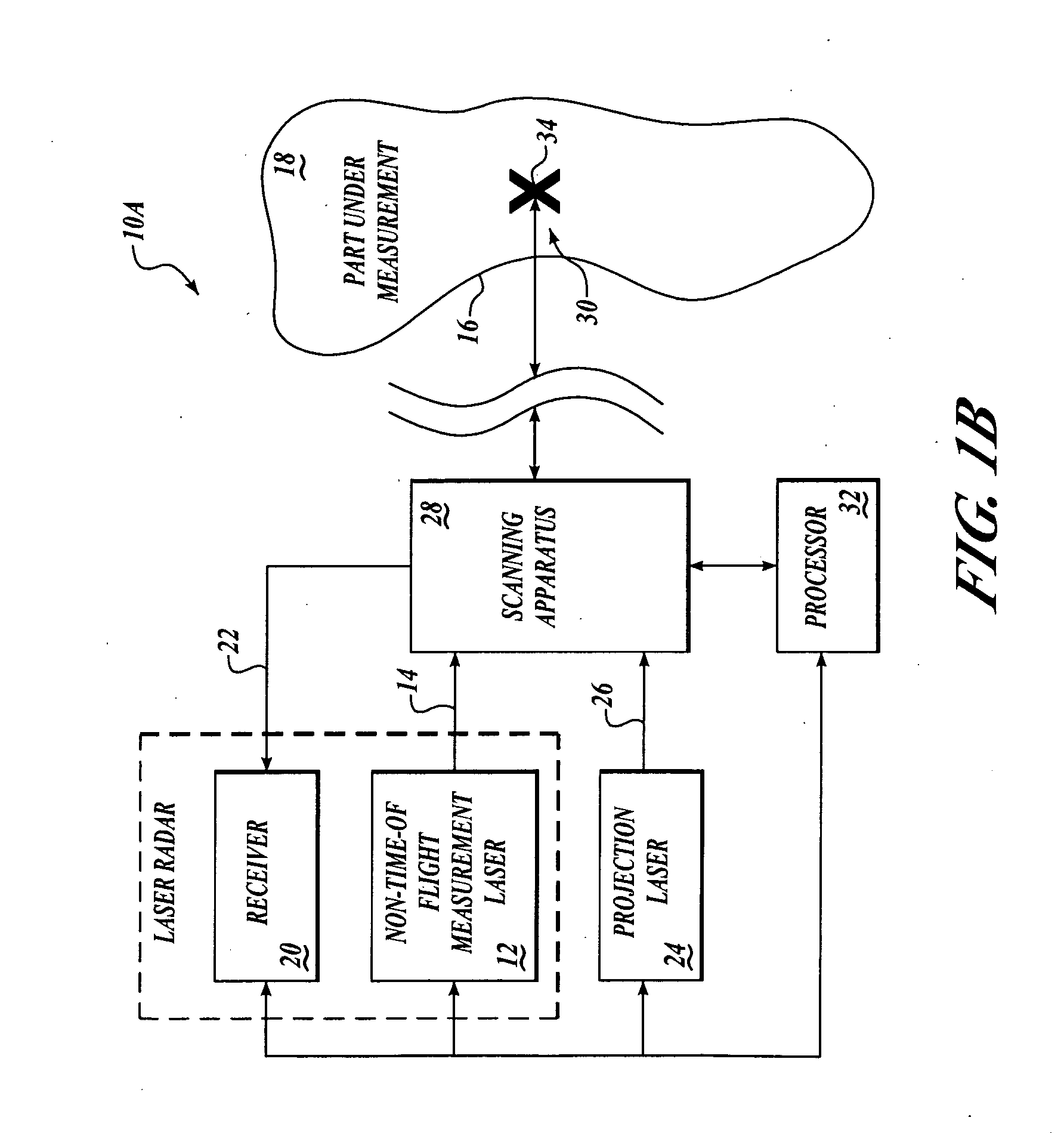

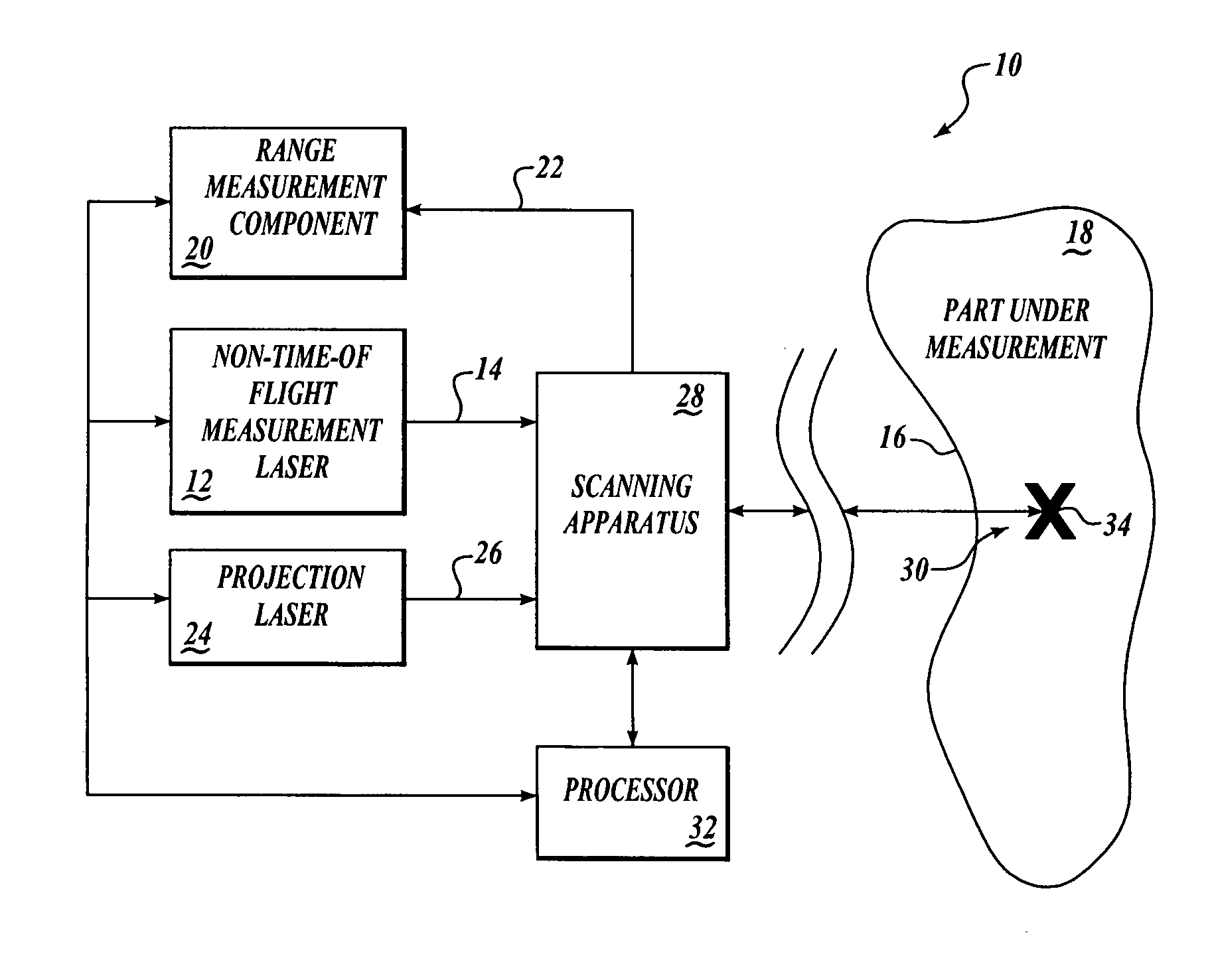

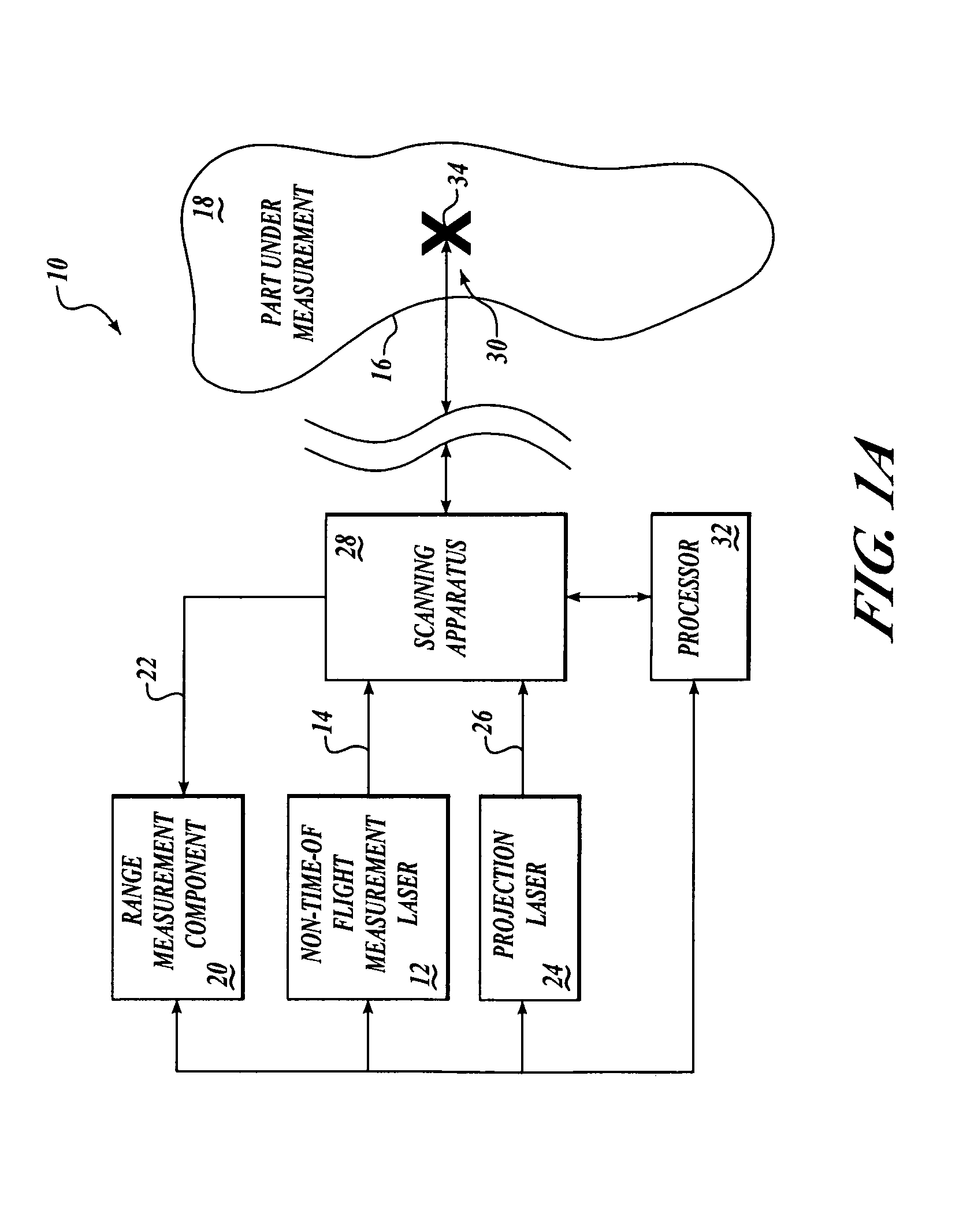

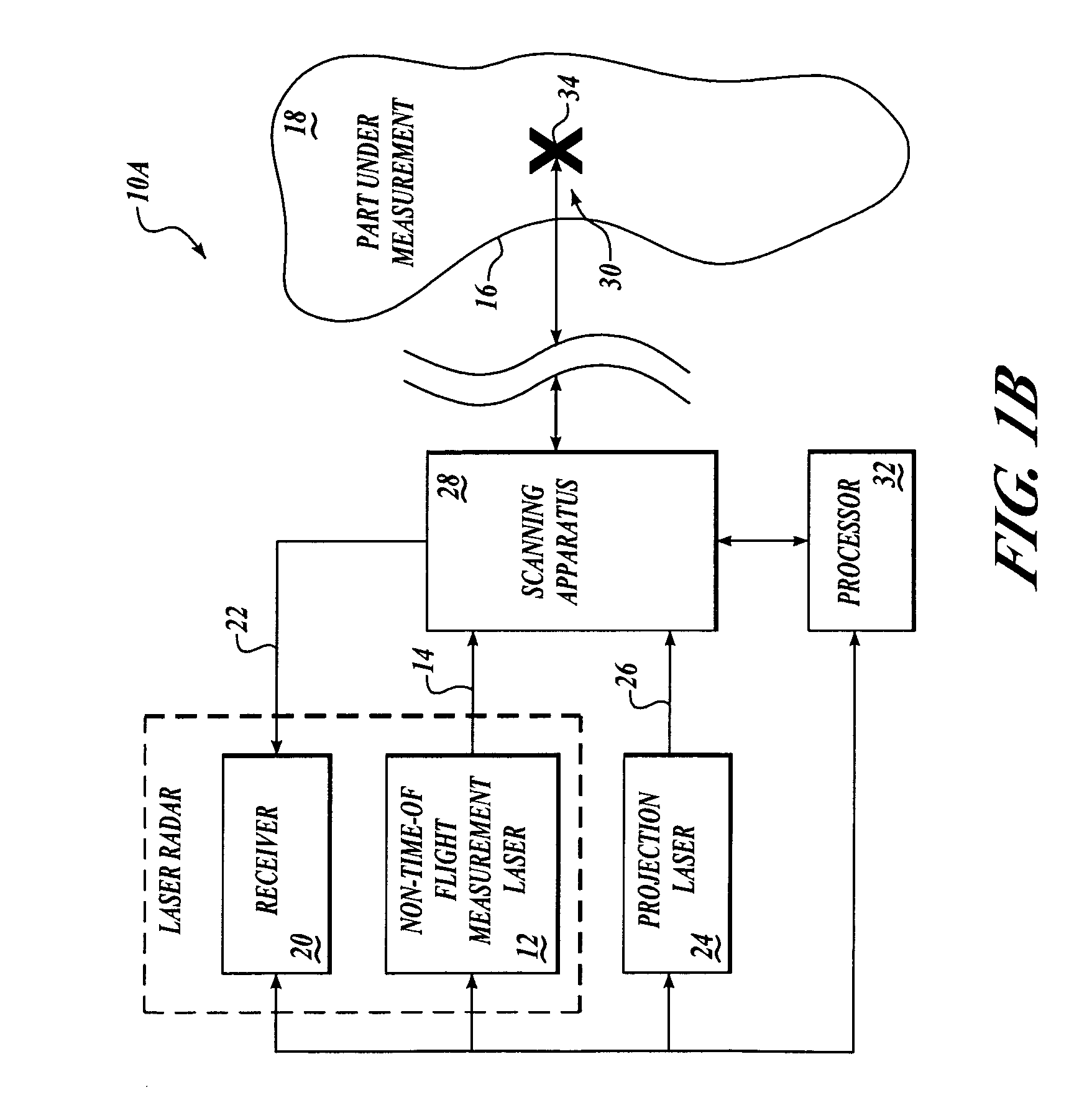

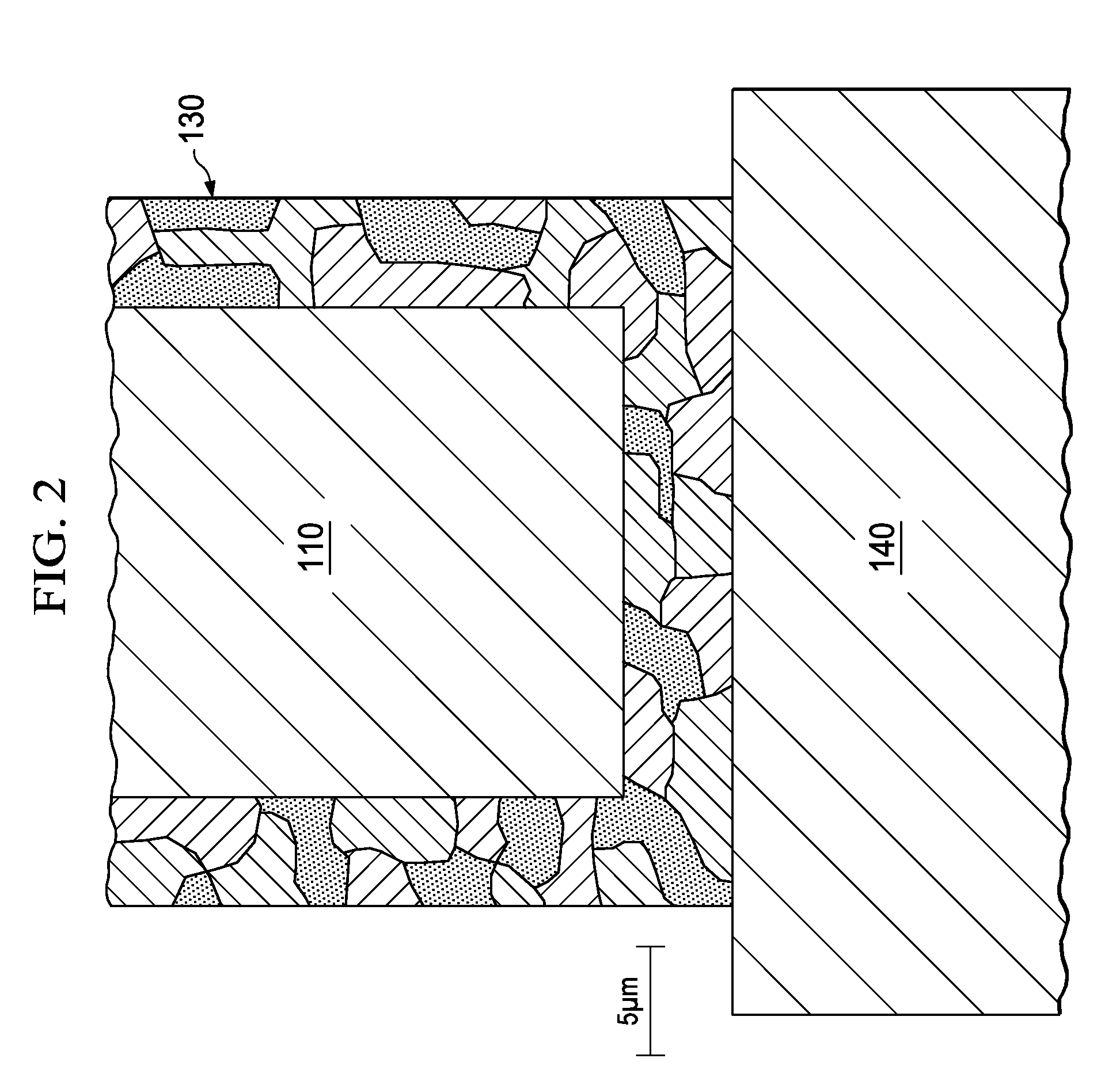

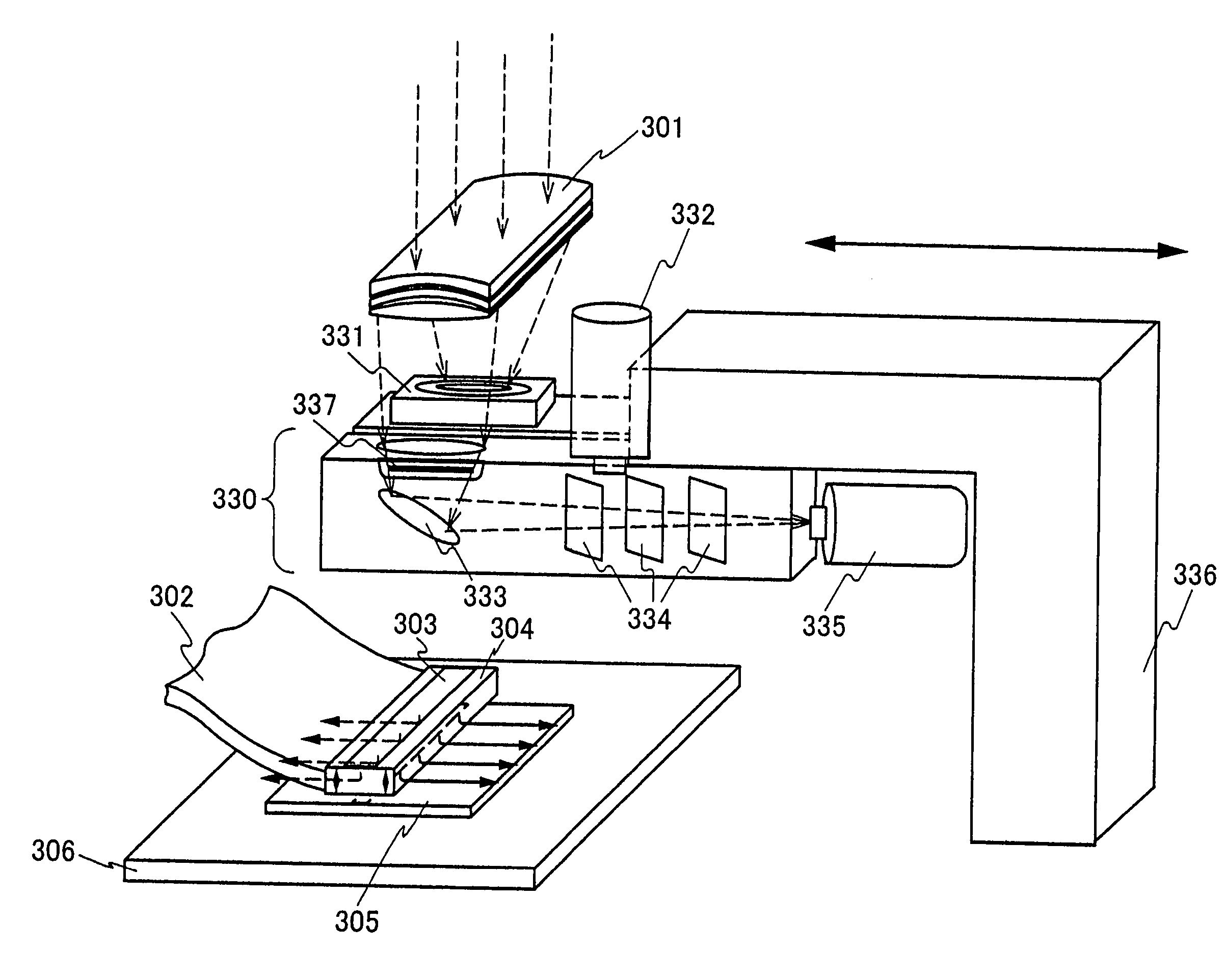

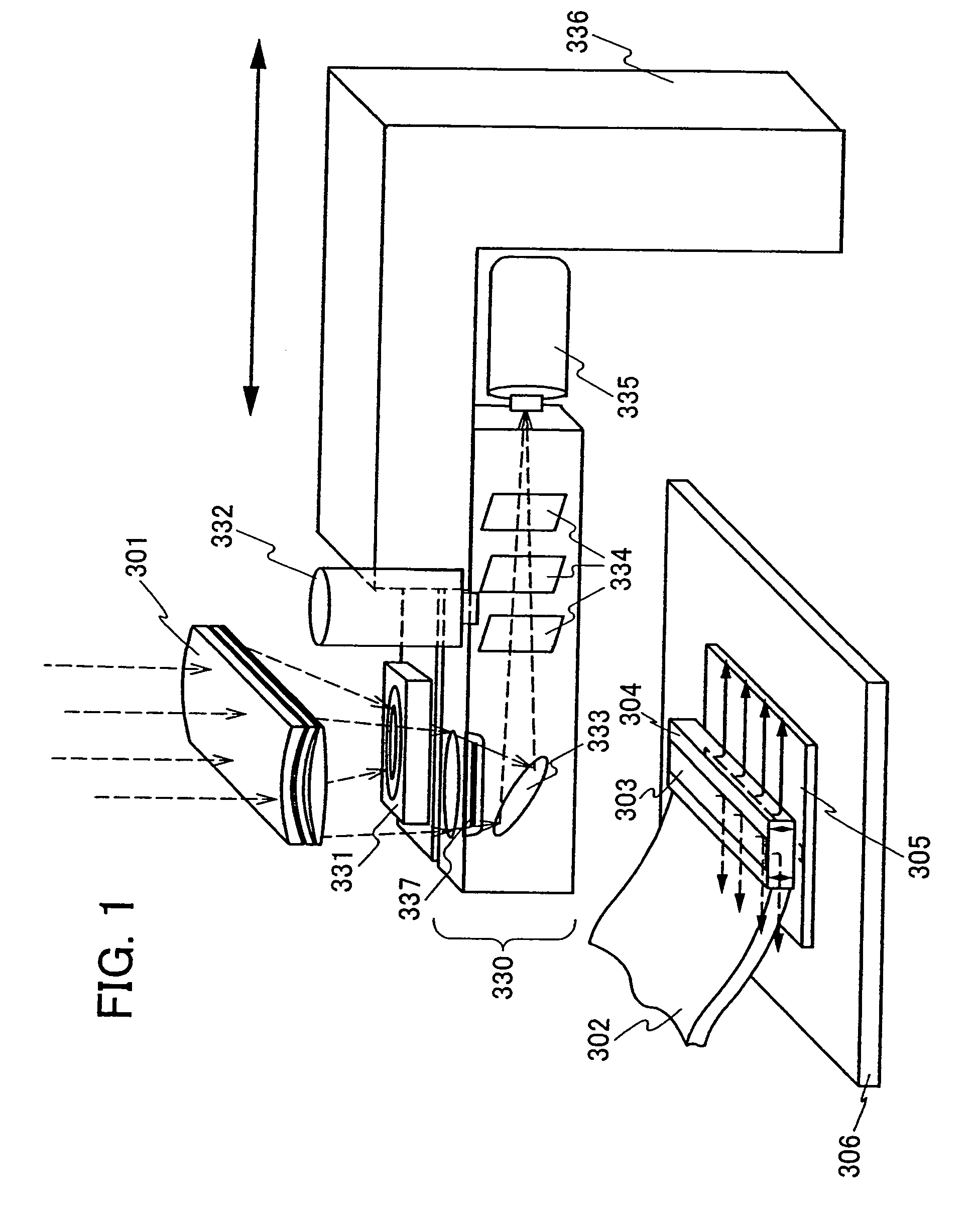

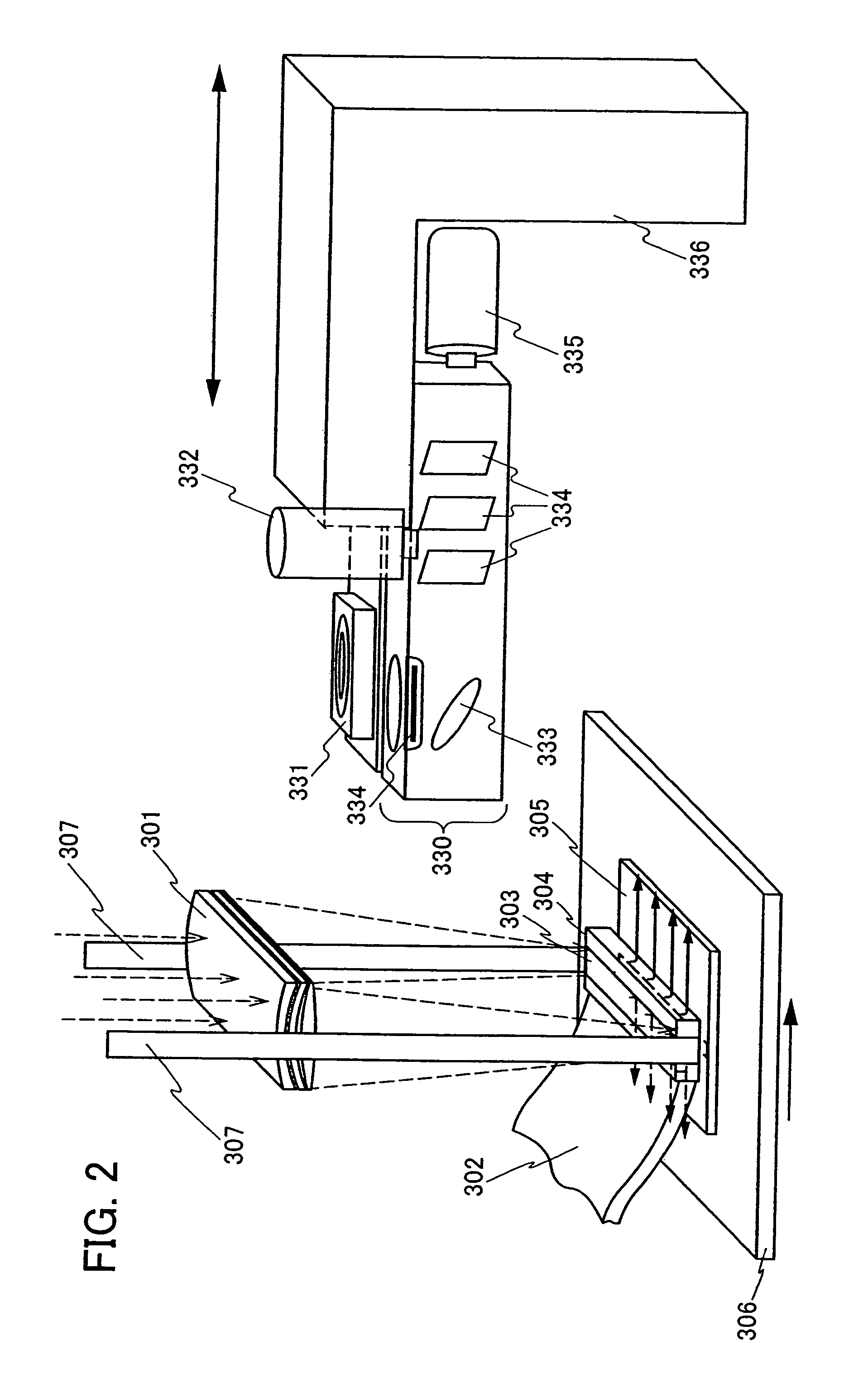

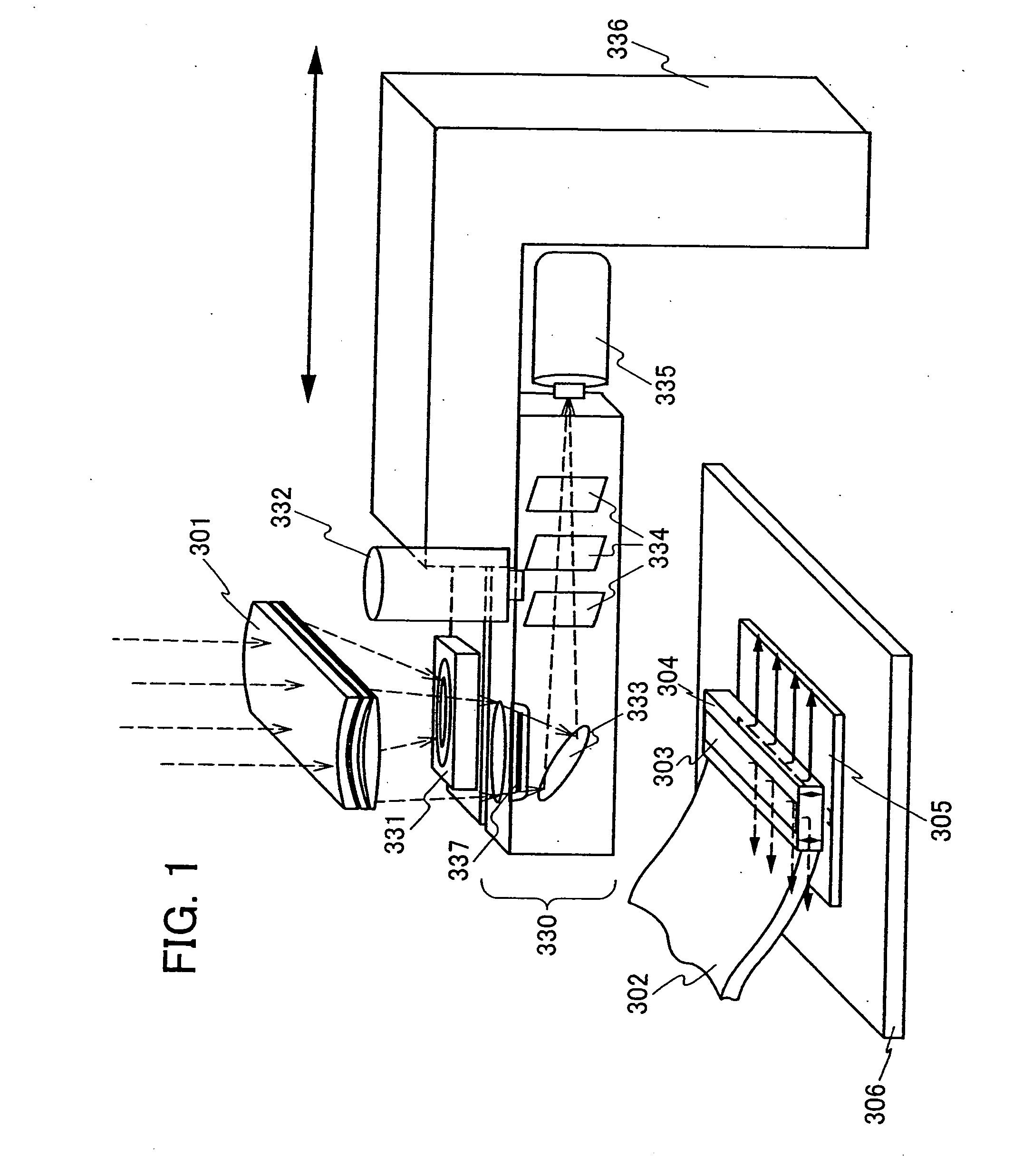

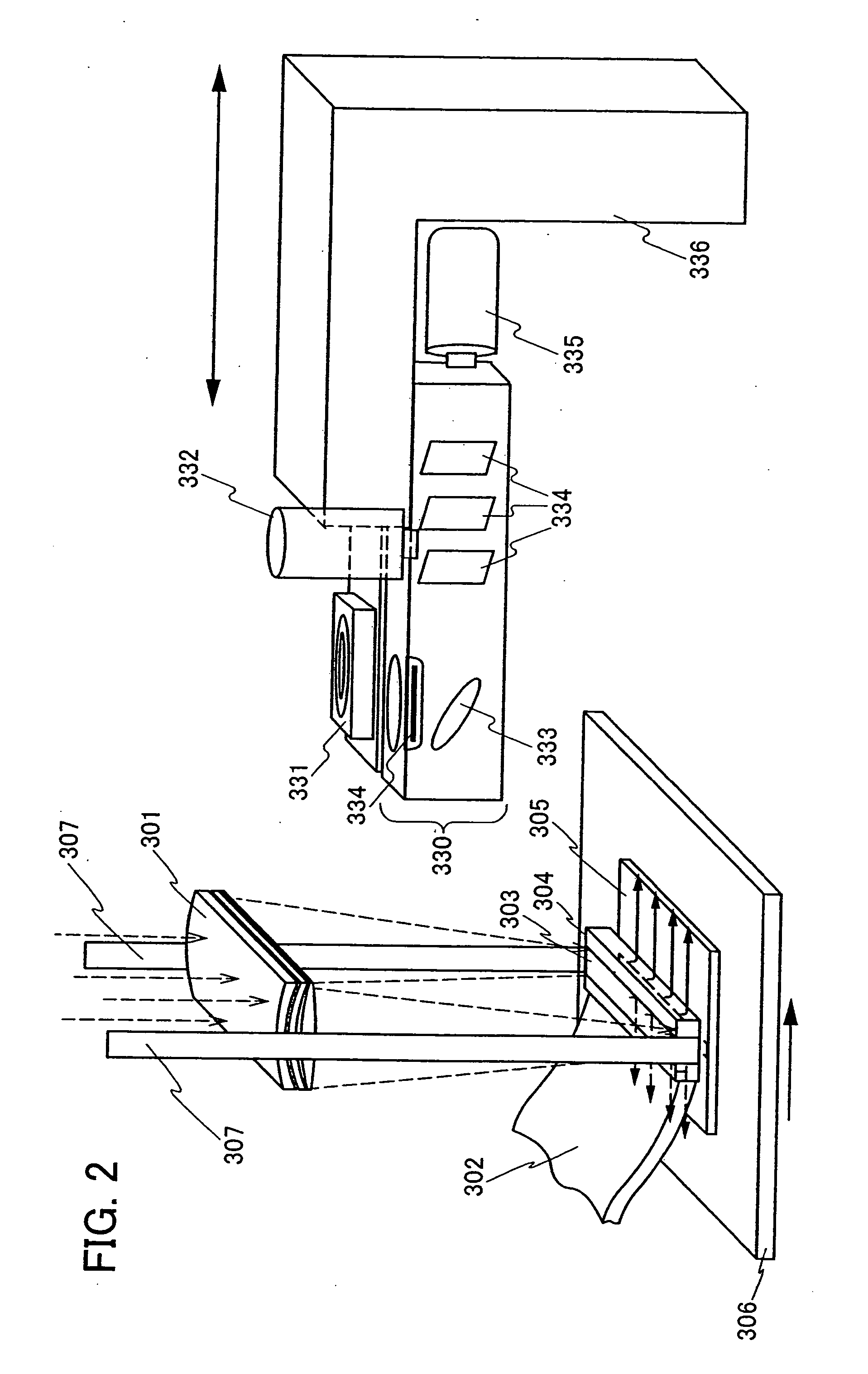

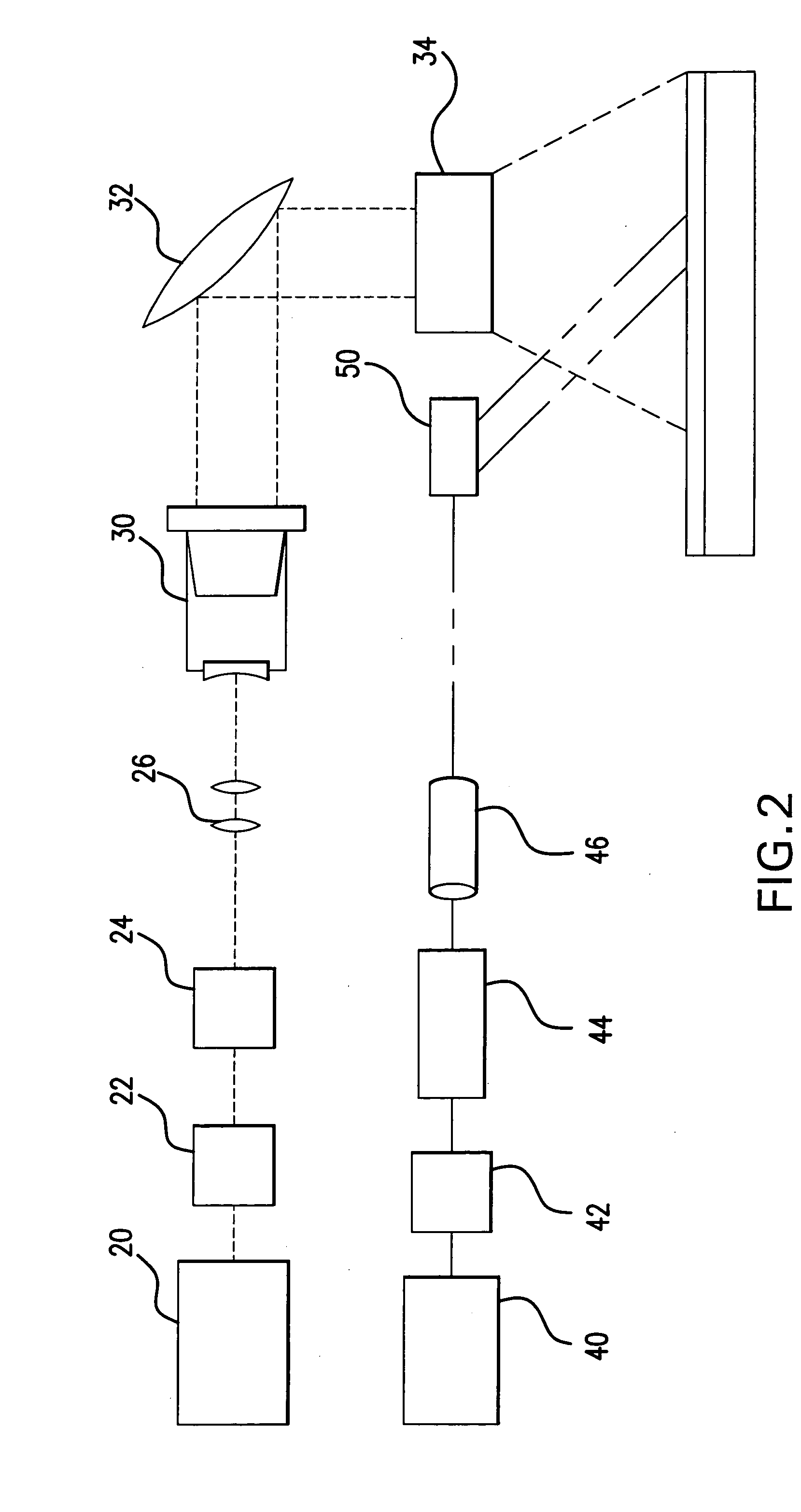

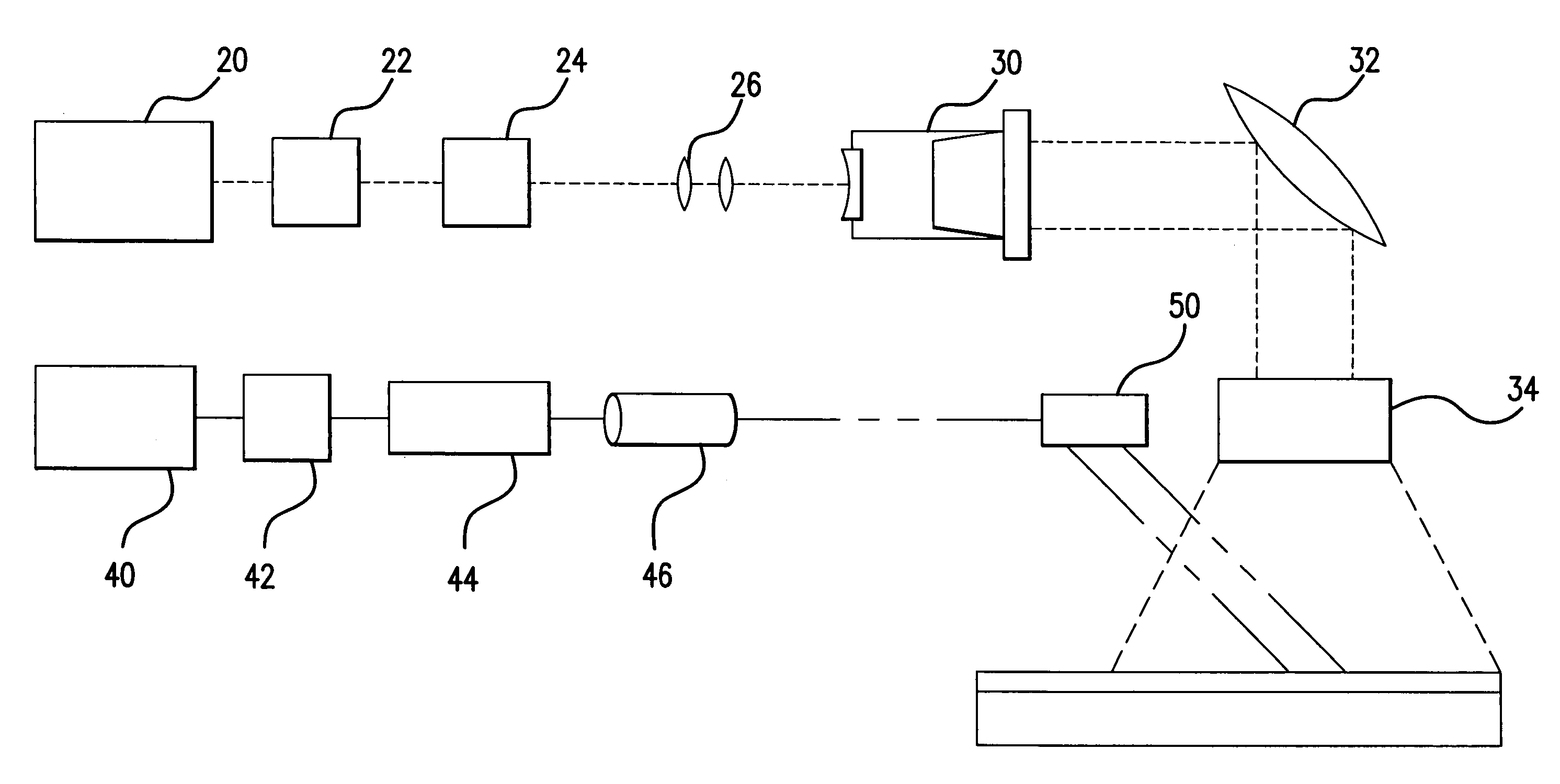

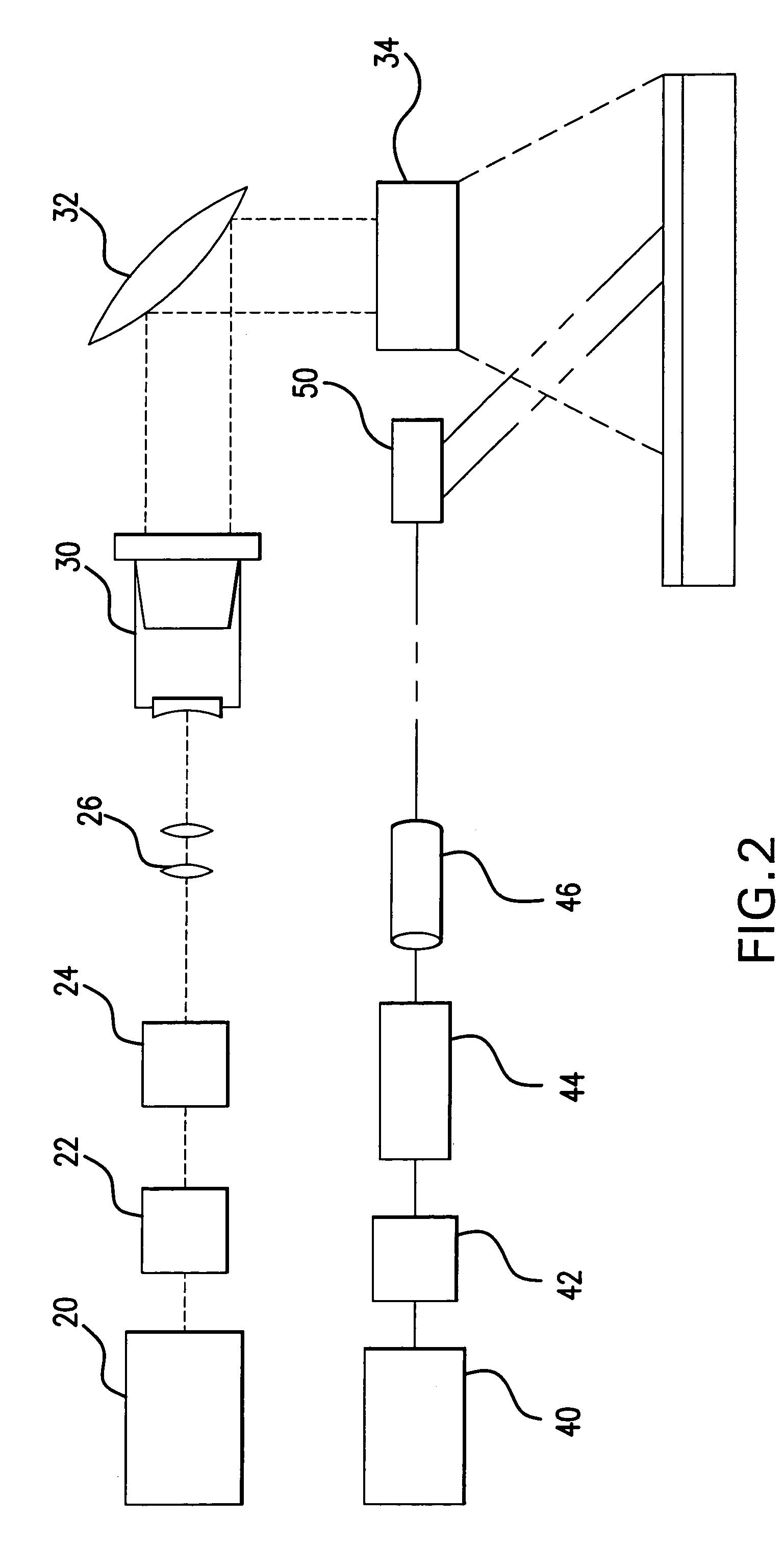

Method and apparatus for combining a targetless optical measurement function and optical projection of information

ActiveUS20060132803A1Low costEliminate errorsOptical rangefindersUsing optical meansLight beamOptical measurements

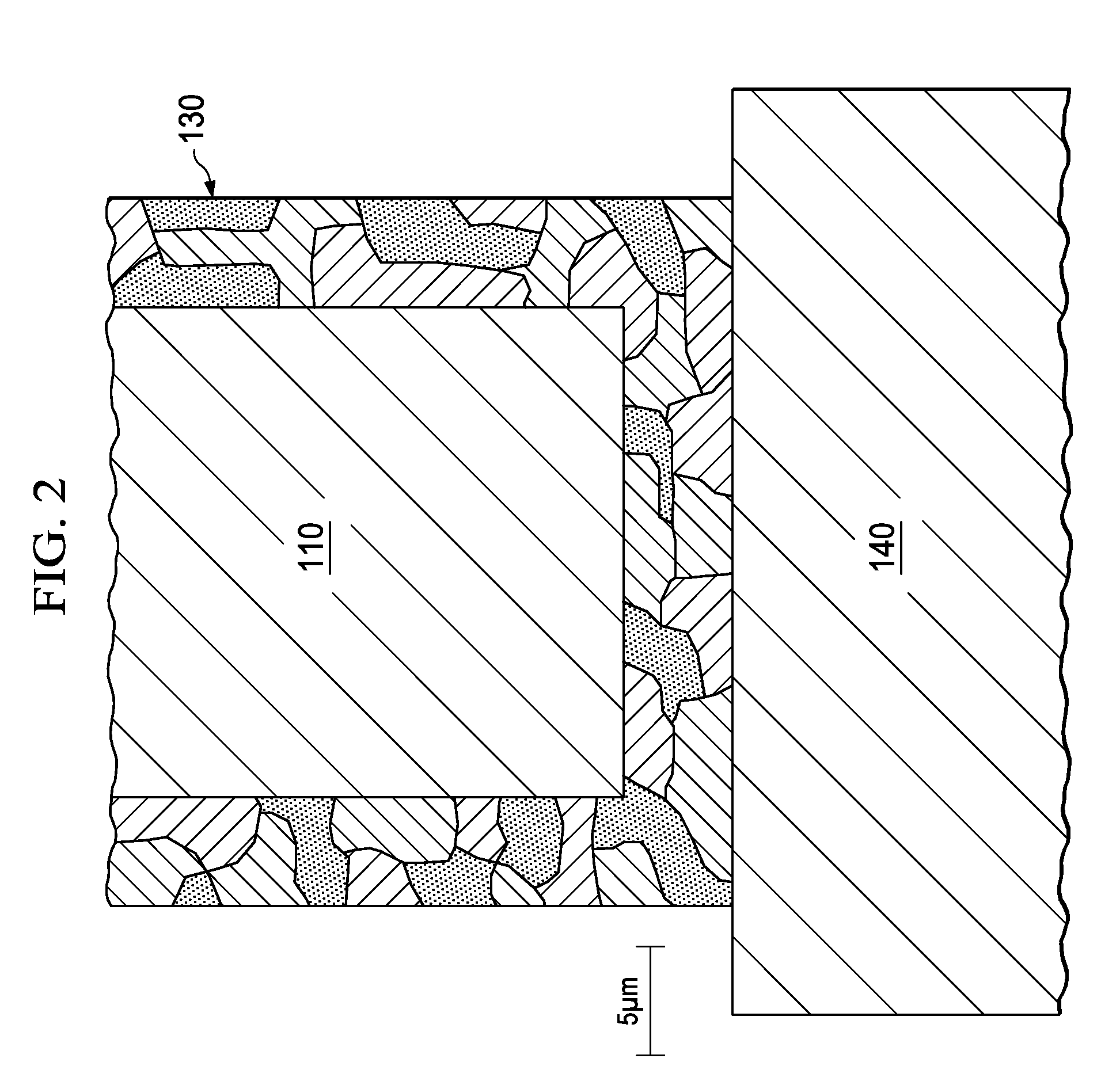

Systems and methods are provided for targetless optical measurement and optical information projection. A non-contact optical measurement device is provided for determining at least one of position and orientation of a workpiece. A projector is provided for projecting a part definition on the workpiece. Advantageously, beams from the non-contact optical measurement device and the projector pass through common optics.

Owner:THE BOEING CO

Method and apparatus for combining a targetless optical measurement function and optical projection of information

ActiveUS7701592B2Low costEliminate errorsOptical rangefindersUsing optical meansLight beamOptical measurements

Owner:THE BOEING CO

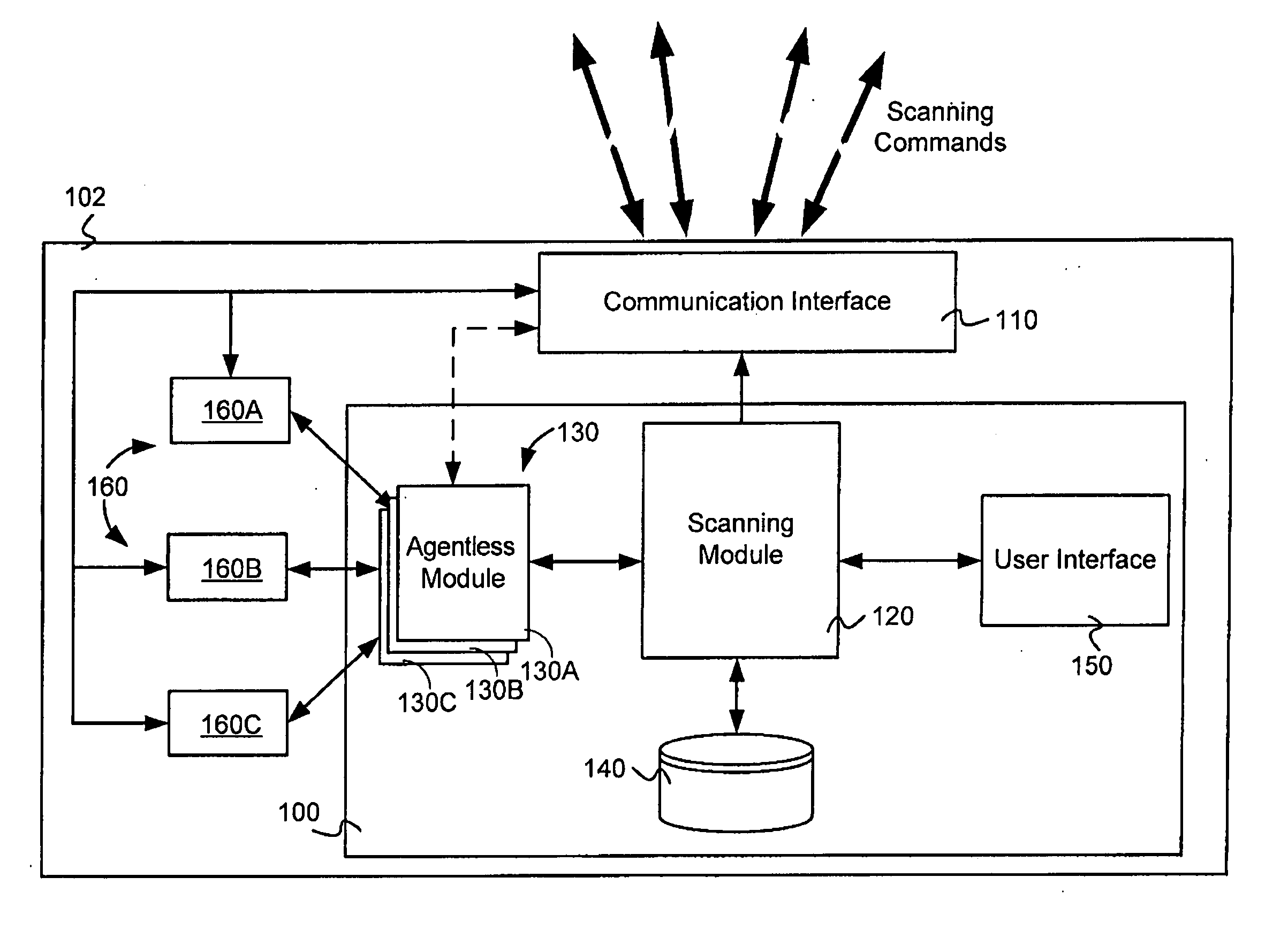

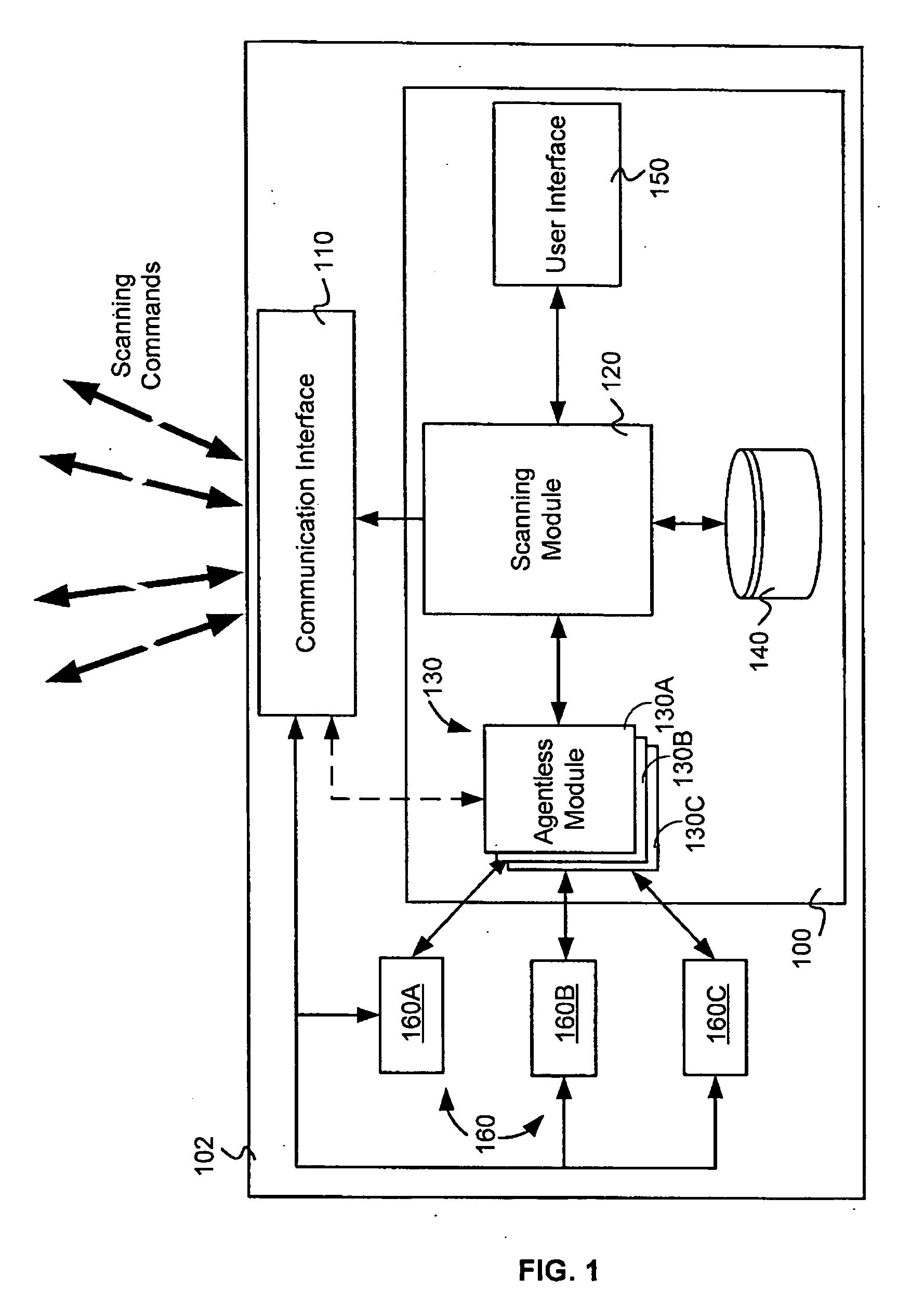

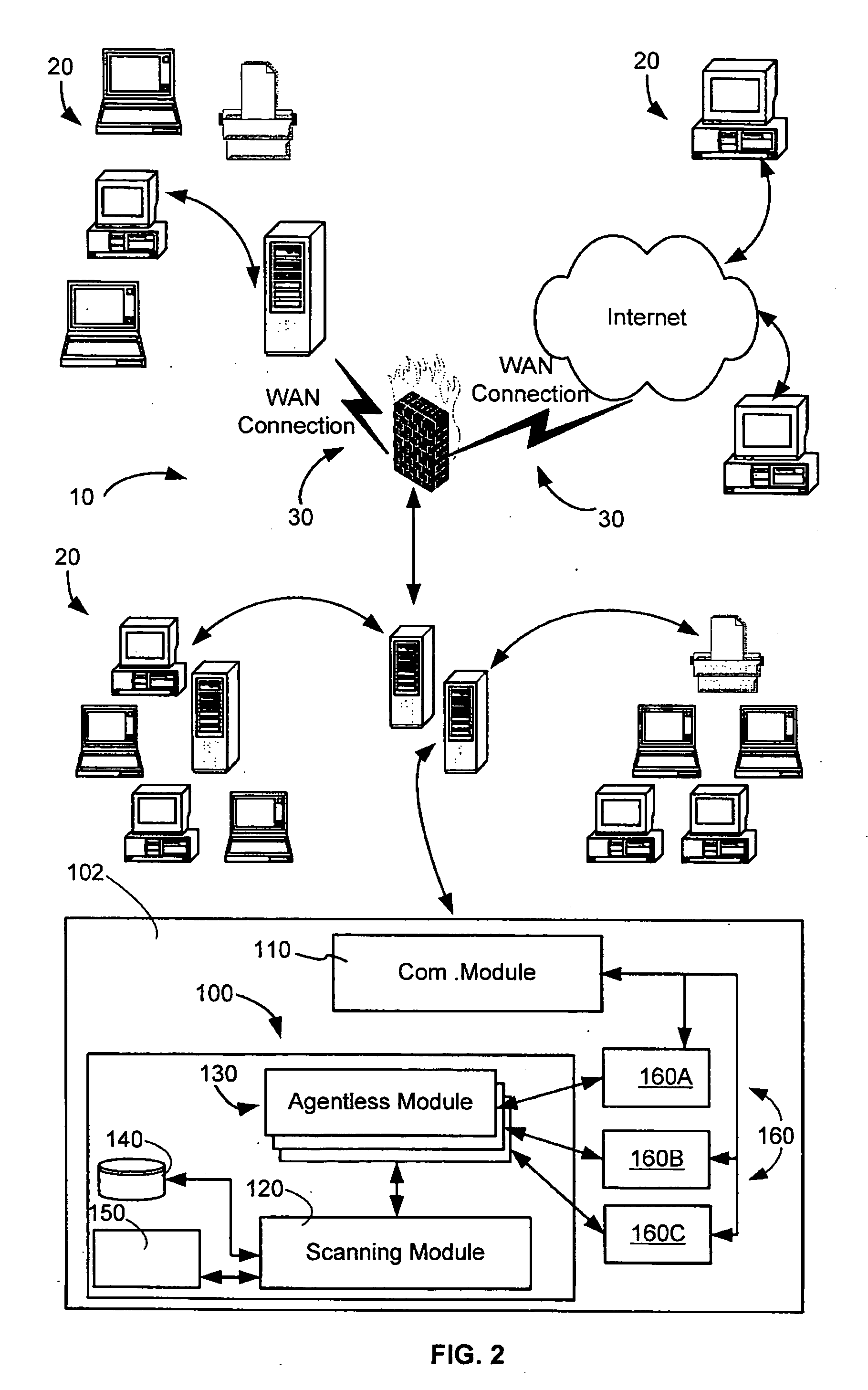

Method and device for scanning a plurality of computerized devices connected to a network

ActiveUS20060184682A1Efficient and robust scanningShort turnaround timeMemory loss protectionError detection/correctionRemote computerOperating system

Owner:PROMIIMER LTD

Method for low stress flip-chip assembly of fine-pitch semiconductor devices

ActiveUS20100148374A1Excellent ElectricalImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesMatrix embeddingSemiconductor

A device including a first body (101) with terminals (102) on a surface (101a), each terminal having a metallic connector (110), which is shaped as a column substantially perpendicular to the surface. Preferably, the connectors have an aspect ratio of height to diameter of 2 to 1 or greater, and a fine pitch center-to-center. The connector end (110a) remote from the terminal is covered by a film (130) of a sintered paste including a metallic matrix embedded in a first polymeric compound. Further a second body (103) having metallic pads (140) facing the respective terminals (102). Each connector film (130) is in contact with the respective pad (140), whereby the first body (101) is spaced from the second body (103) with the connector columns (110) as standoff. A second polymeric compound (150) is filling the space of the standoff.

Owner:TEXAS INSTR INC

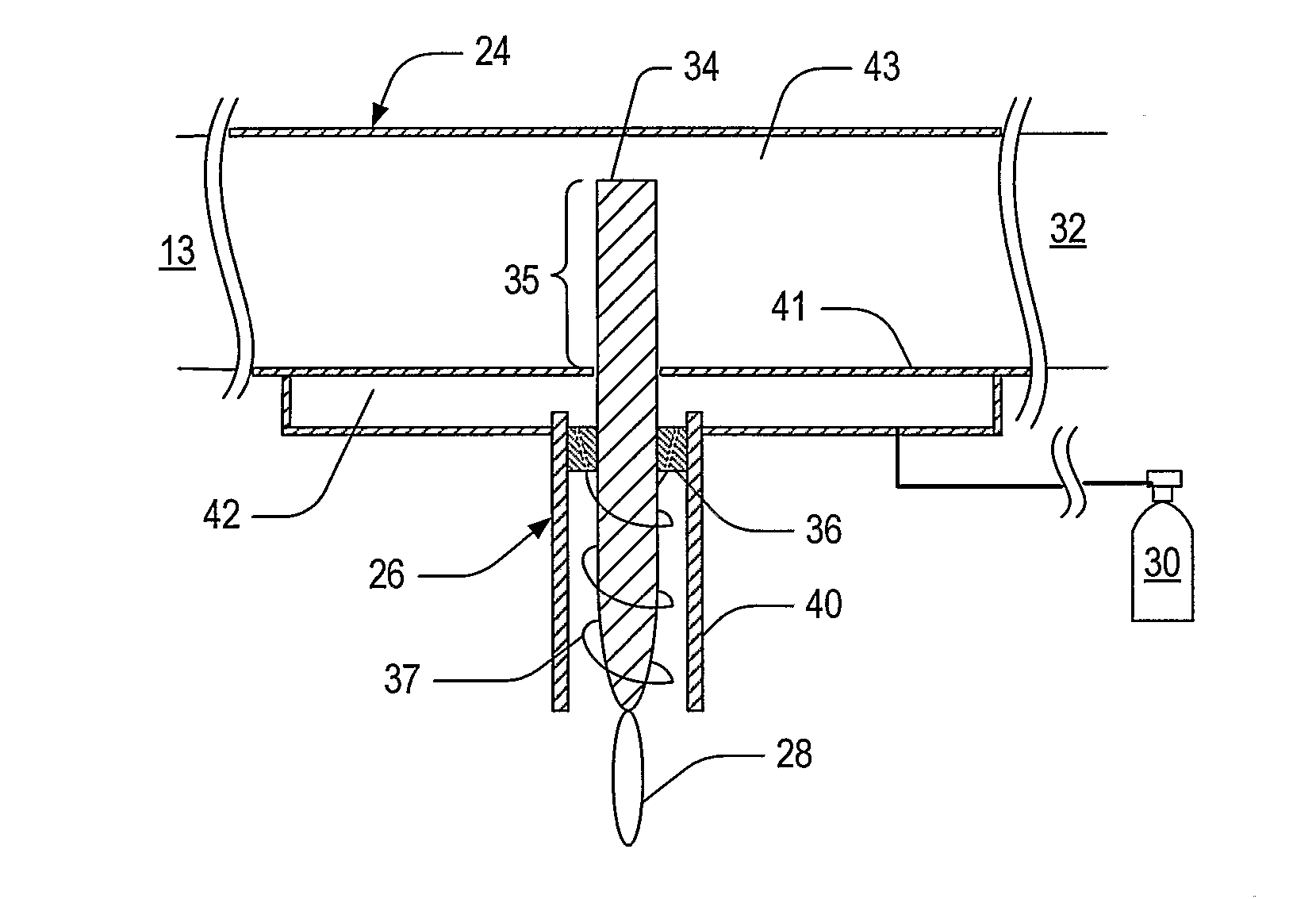

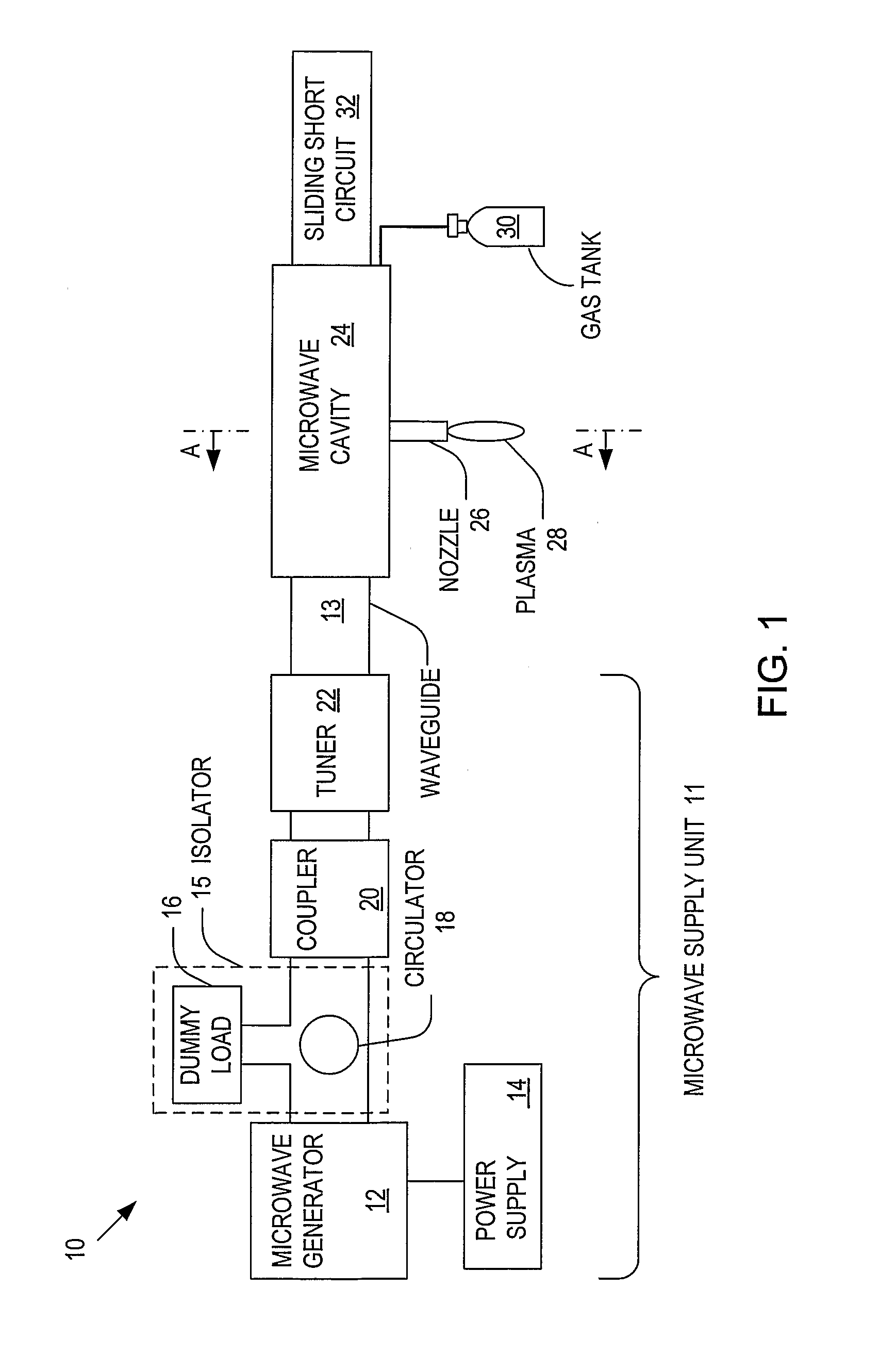

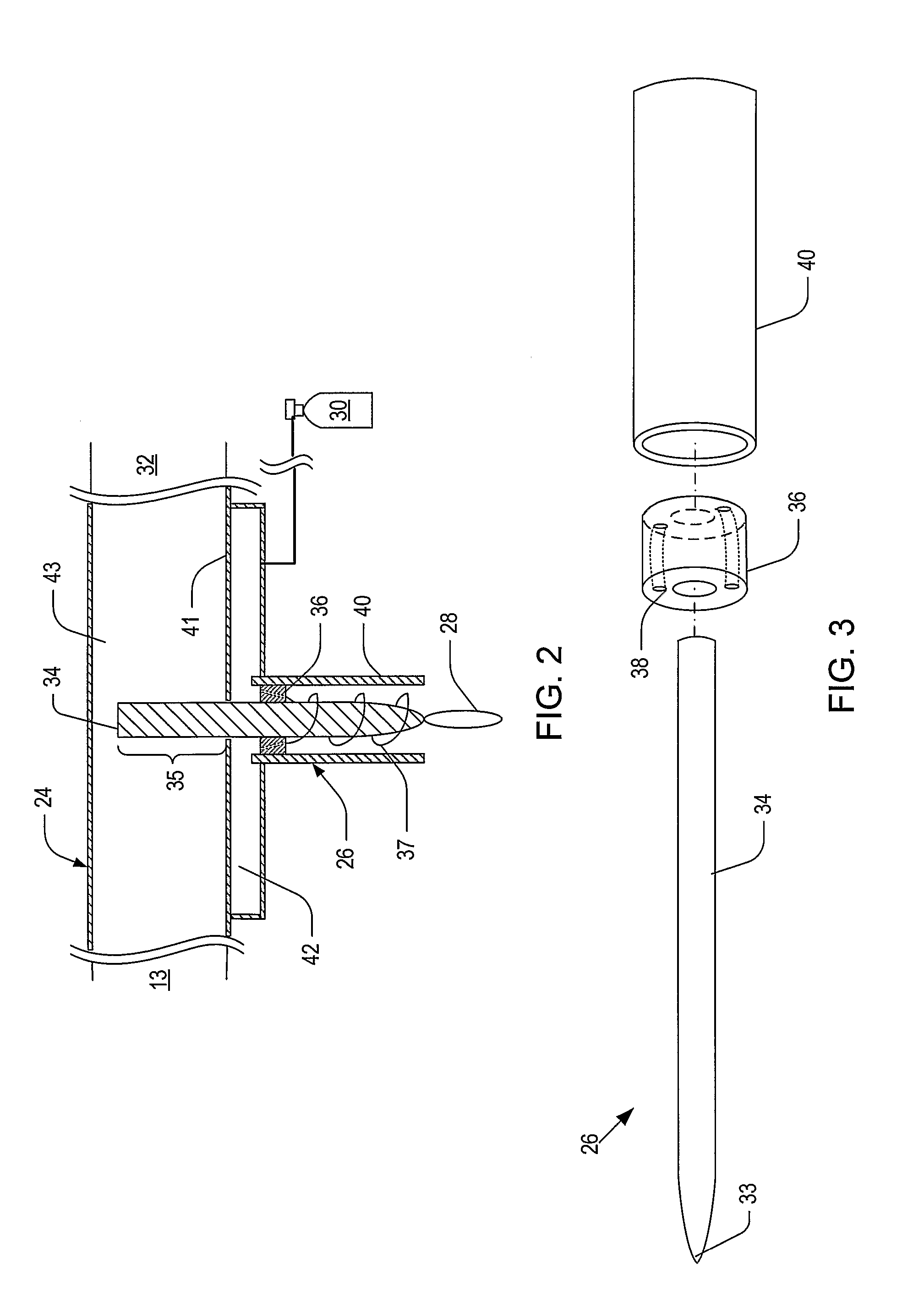

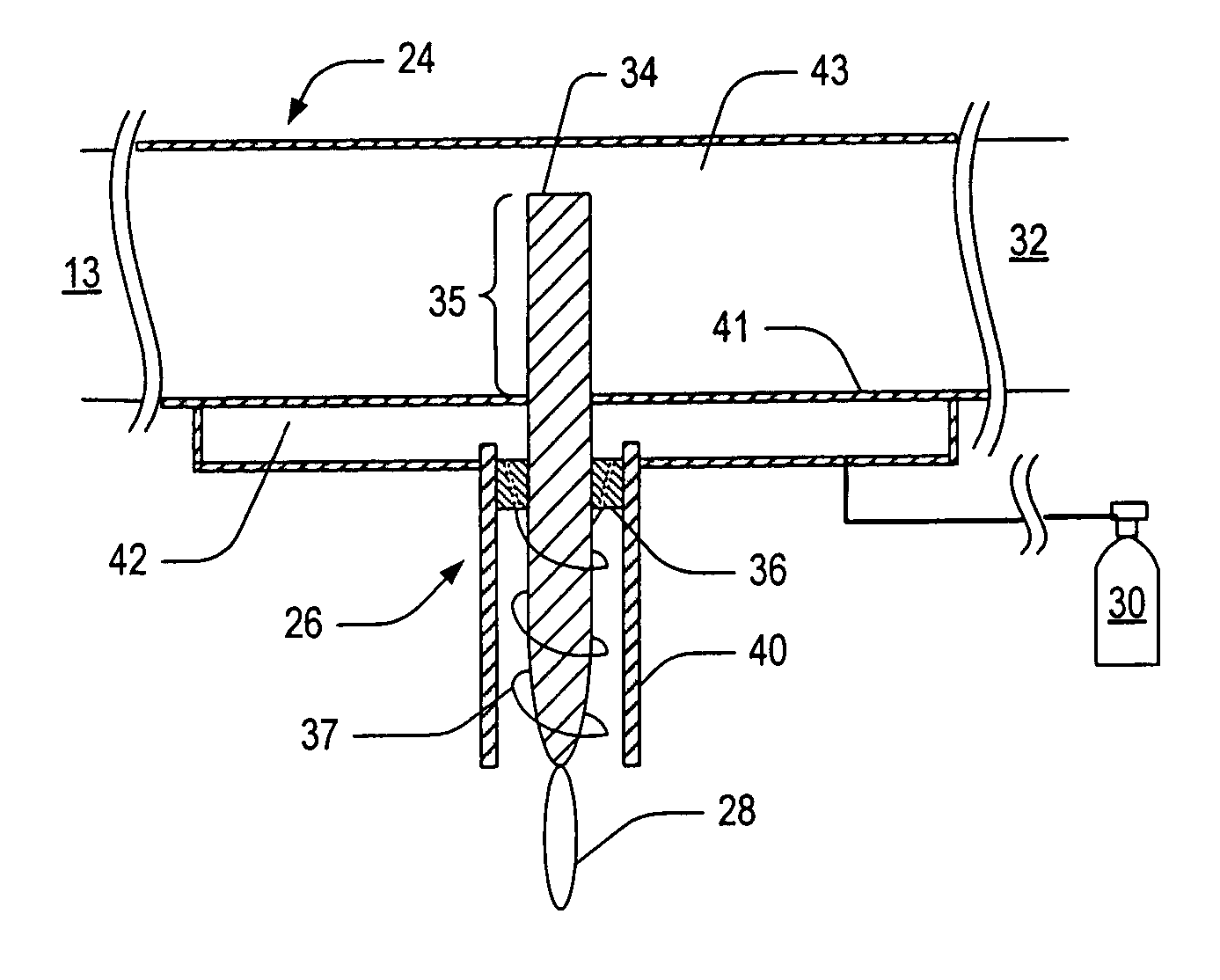

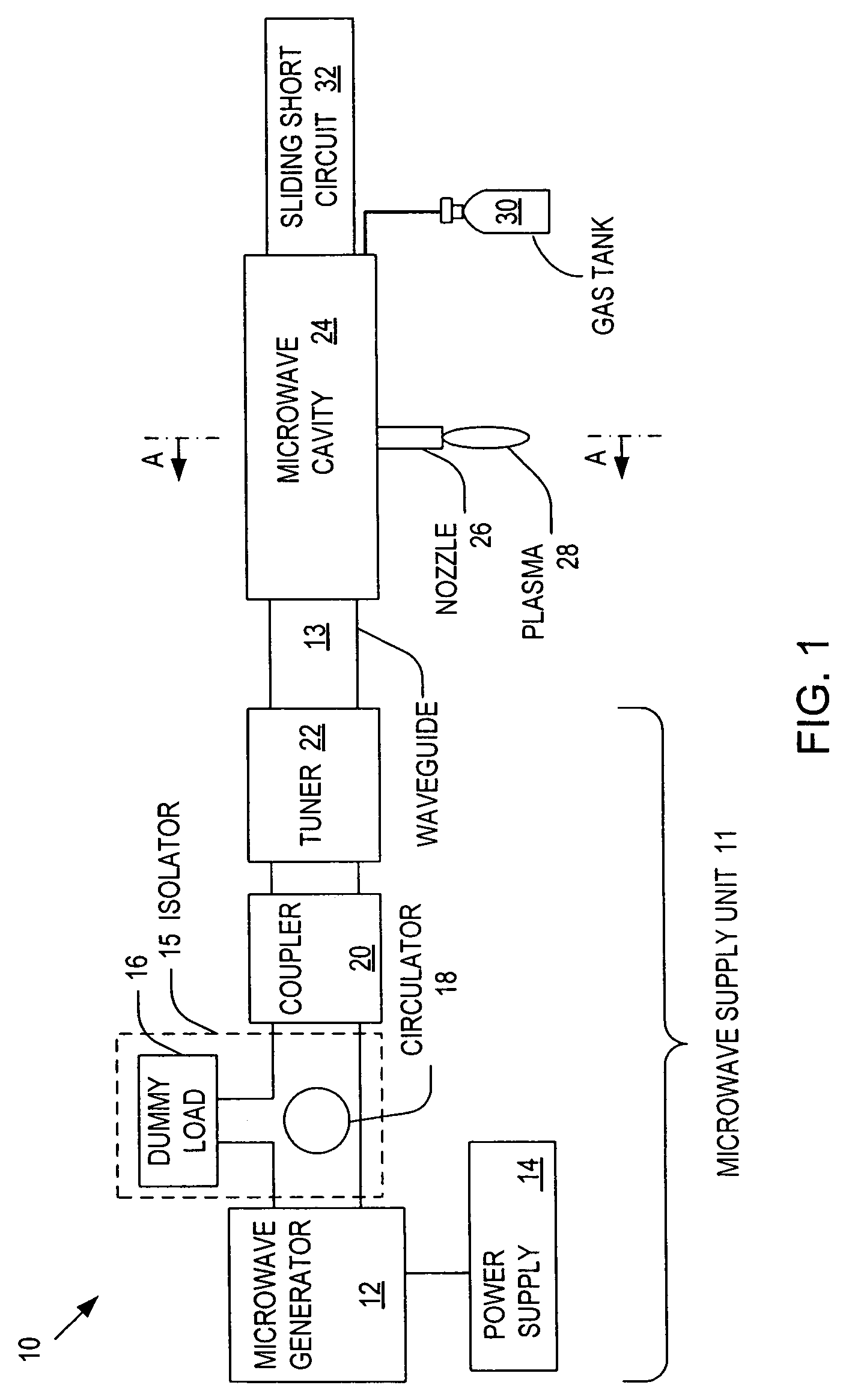

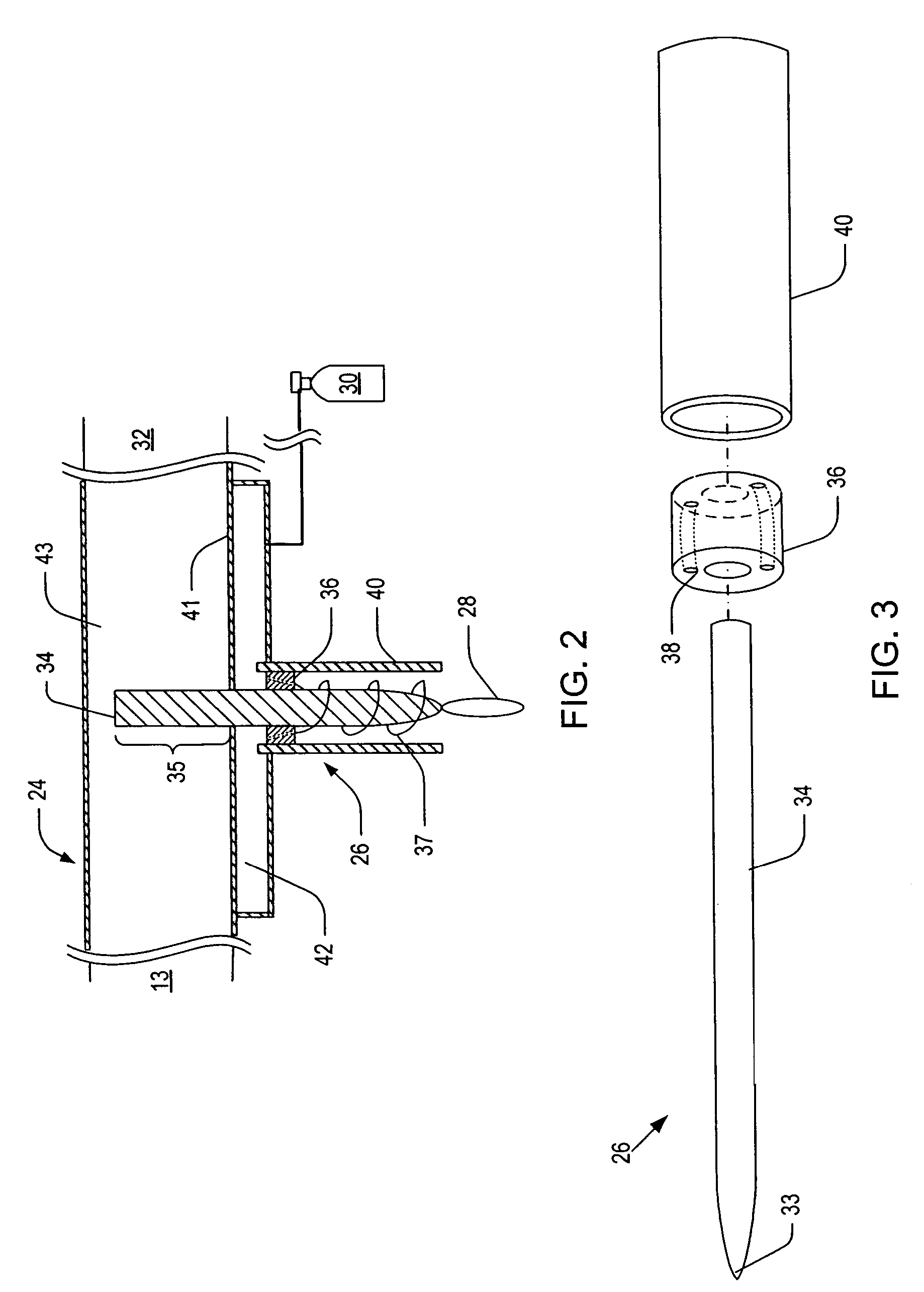

Microwave Plasma Nozzle With Enhanced Plume Stability And Heating Efficiency

ActiveUS20080017616A1Low per unit costShort turnaround timeElectric discharge tubesElectric arc lampsMicrowave cavityElectrical conductor

Systems and methods for generating relatively cool microwave plasma are disclosed. The present invention provides a microwave plasma nozzle that includes a gas flow tube through which a gas flows, and a rod-shaped conductor that is disposed in the gas flow tube and has a tapered tip near the outlet of the gas flow tube. A portion of the rod-shaped conductor extends into a microwave cavity to receive microwaves passing in the cavity. These received microwaves are focused at the tapered tip to heat the gas into plasma. The microwave plasma nozzle also includes a vortex guide between the rod-shaped conductor and the gas flow tube imparting a helical shaped flow direction around the rod-shaped conductor to the gas flowing through the tube. The microwave plasma nozzle further includes a mechanism for electronically exciting the gas and a shielding mechanism for reducing a microwave power loss through the gas flow tube.

Owner:RECARBON INC

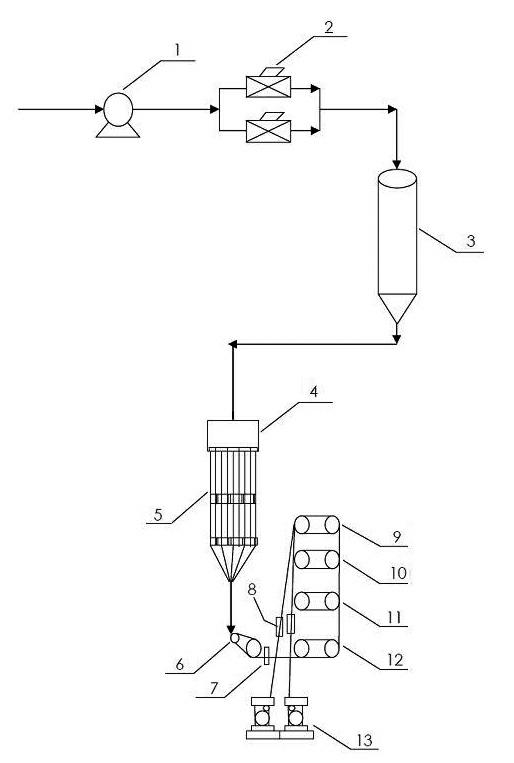

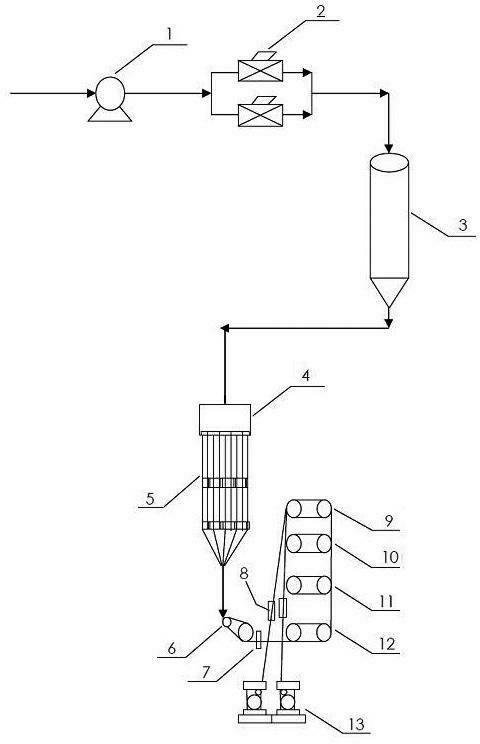

Process for producing polyester industrial yarns by liquid-phase tackified melts in multi-end direct spinning manner

ActiveCN102605444AShort turnaround timeReduce energy consumptionFilament forming substance formingNew-spun product collectionWinding machineYarn

The invention discloses a process for producing polyester industrial yarns by liquid-phase tackified melts in a multi-end direct spinning manner, which belongs to the technical field of polyester industrial yarns and includes the following steps: liquid-phase tackifying; obtaining high-viscosity polyester melts with intrinsic viscosity ranging from 0.90dl / g to 1.10dl / g by tackifying low-viscosity polyester melts in a liquid phase; double-end spinning; directly conveying the polyester melts after being subjected to liquid-phase tackifying to different spinning positions capable of spinning in 16-24 ends; drafting and thermal-forming; winding and forming; and utilization of a twin winding machine to perform high-speed winding of 16-24 spindle spinning cakes. In the process, 16-end direct spinning of high-strength or low-shrinkage polyester industrial yarns with a single end ranging from 800D to 1300D and 24-end direct spinning of low-denier polyester industrial yarns with a single end ranging from 100D to 500D can be realized on the same spinning position, and product production efficiency is high, performance is stable, production energy consumption and equipment investment cost are low.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

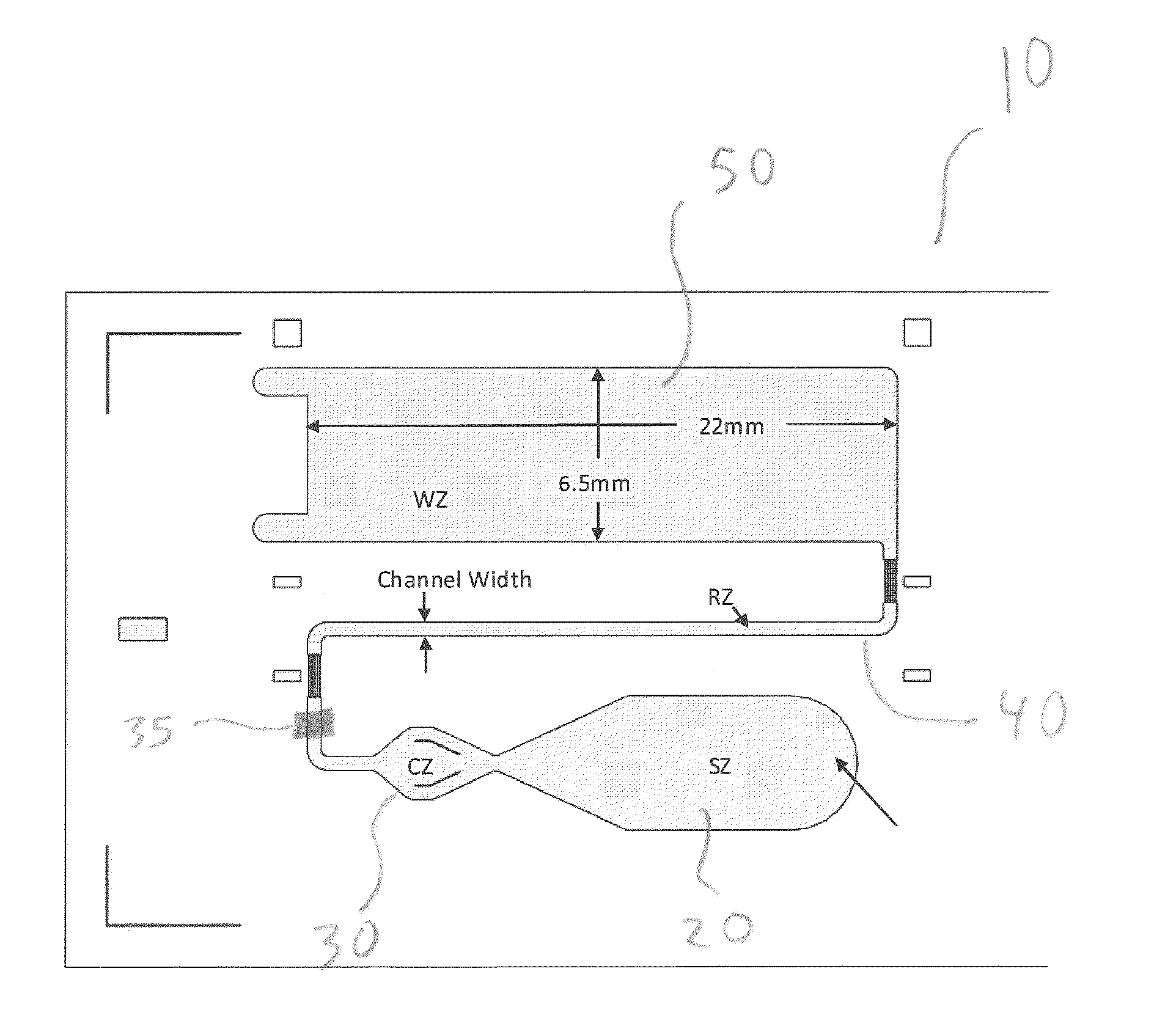

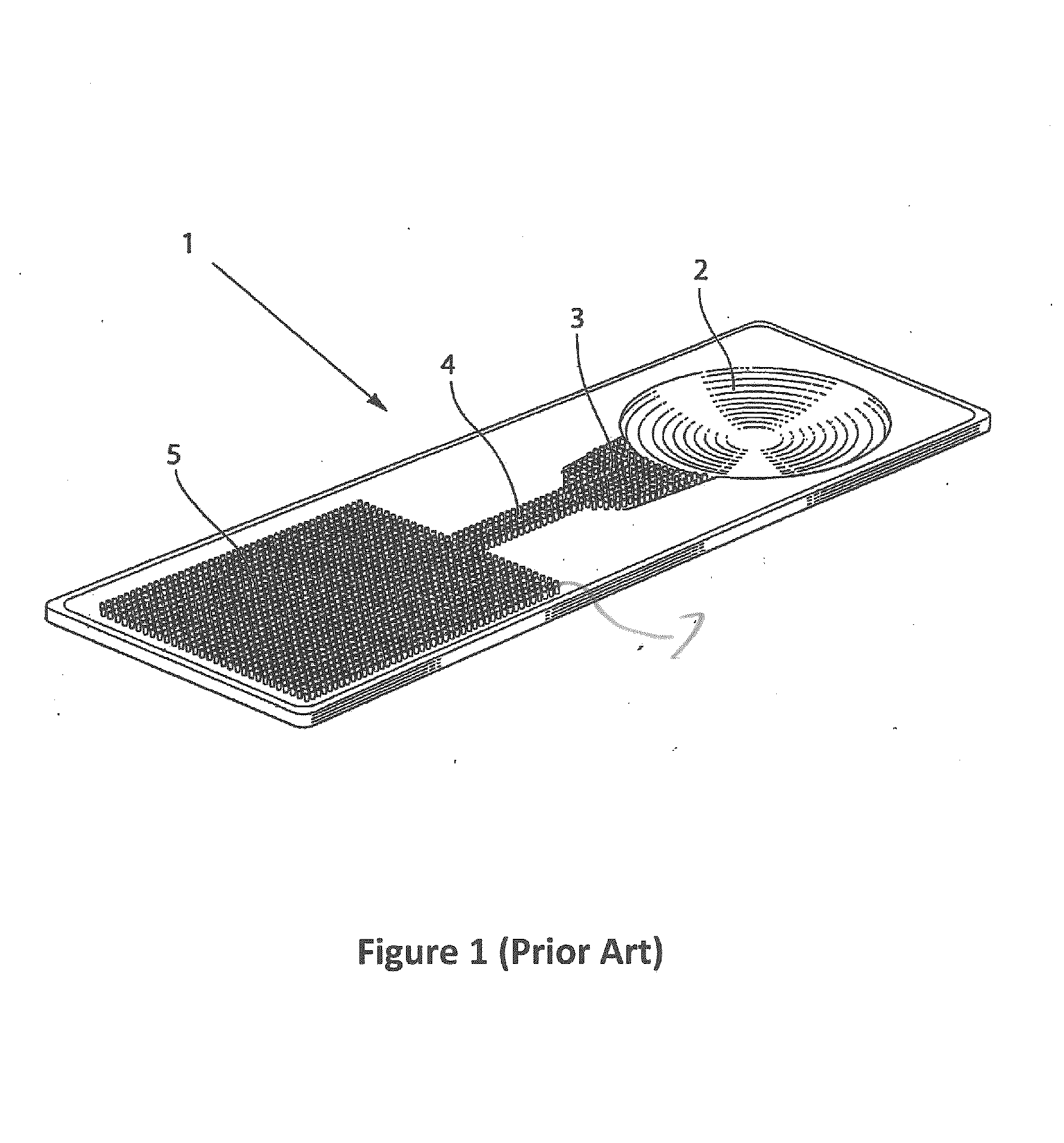

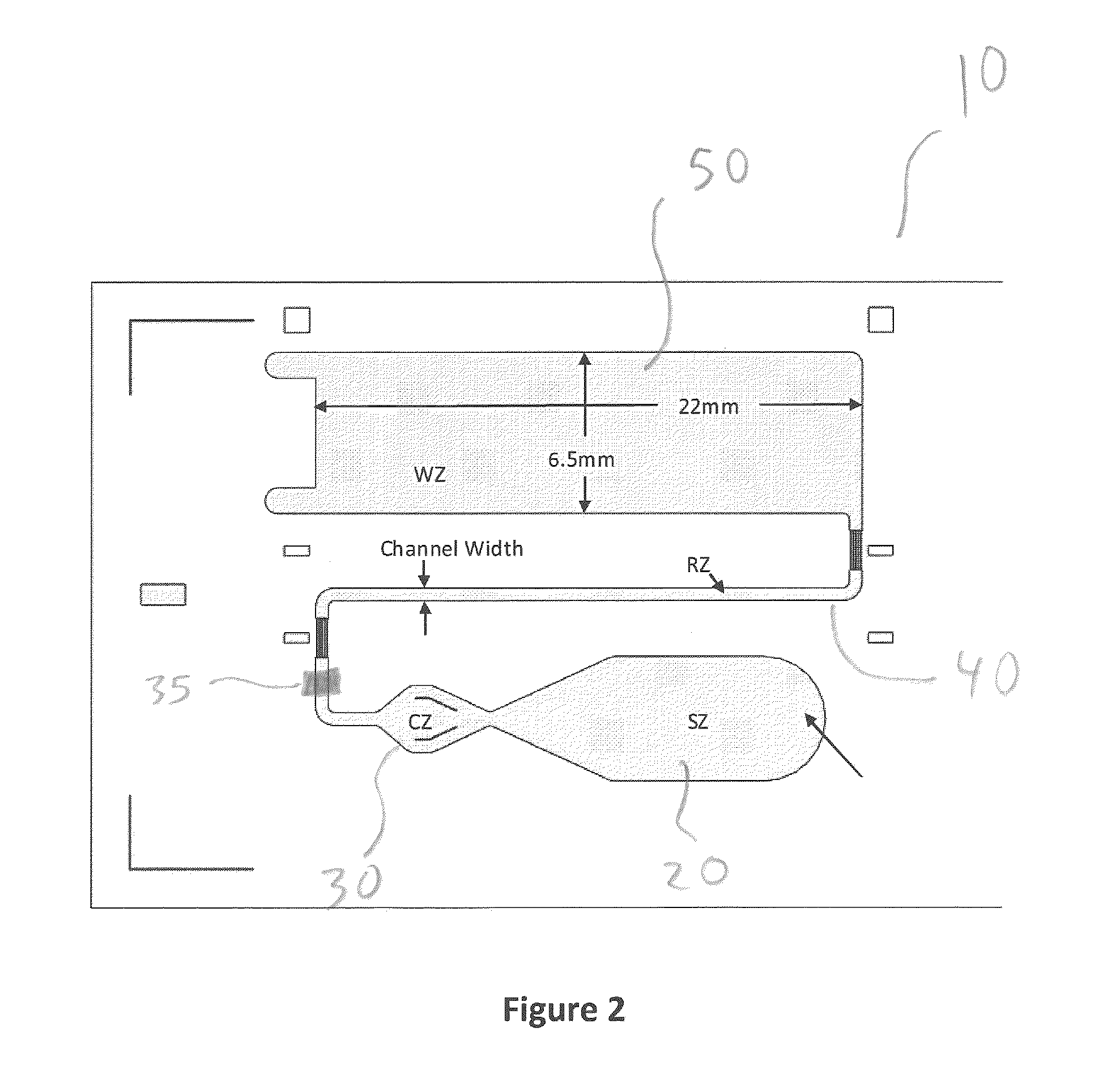

Controlling Fluid Flow Through An Assay Device

InactiveUS20130210036A1Reduce the pressure gradientExtended flow timeBioreactor/fermenter combinationsBiological substance pretreatmentsAssayMechanical engineering

An assay device includes: a detection zone which includes a first set of projections which are capable of generating capillary flow. A wicking zone (WZ) has a capacity to receive liquid sample flowing from the detection zone and includes a second set of projections which are capable of generating capillary flow. The WZ is rectangular in shape and the longer side of the rectangle extends in the direction of flow to thereby reduce the pressure gradient in the assay device which increases the total flow time of liquid sample compared to a WZ having equal length sides and same volume. At least a portion of the second set of projections have at least one dimension selected from a diameter, a center-to-center spacing, or a gap between projections that is different from the first set of projections, and is selected to increase the total flow time of the sample.

Owner:ORTHO-CLINICAL DIAGNOSTICS

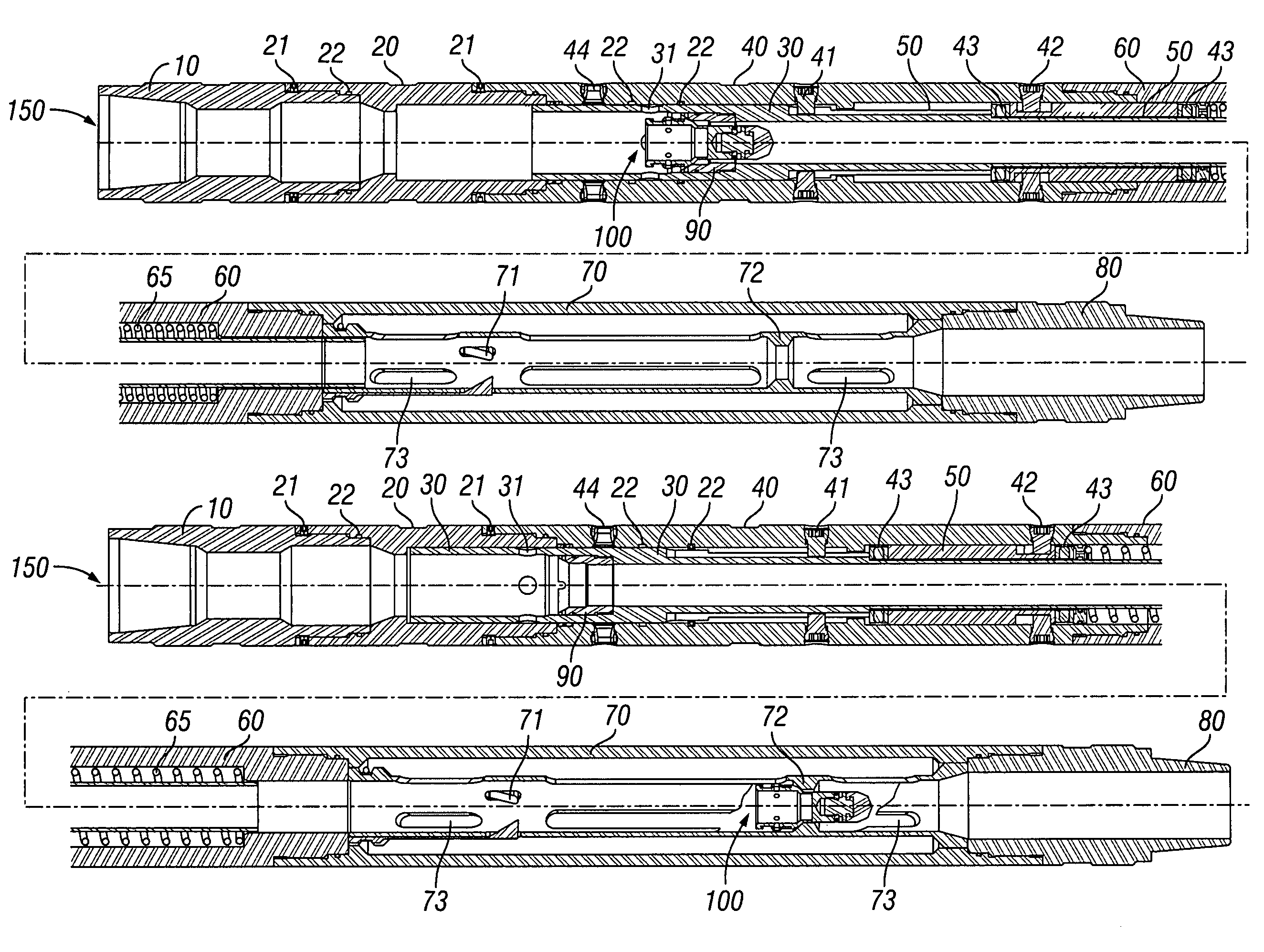

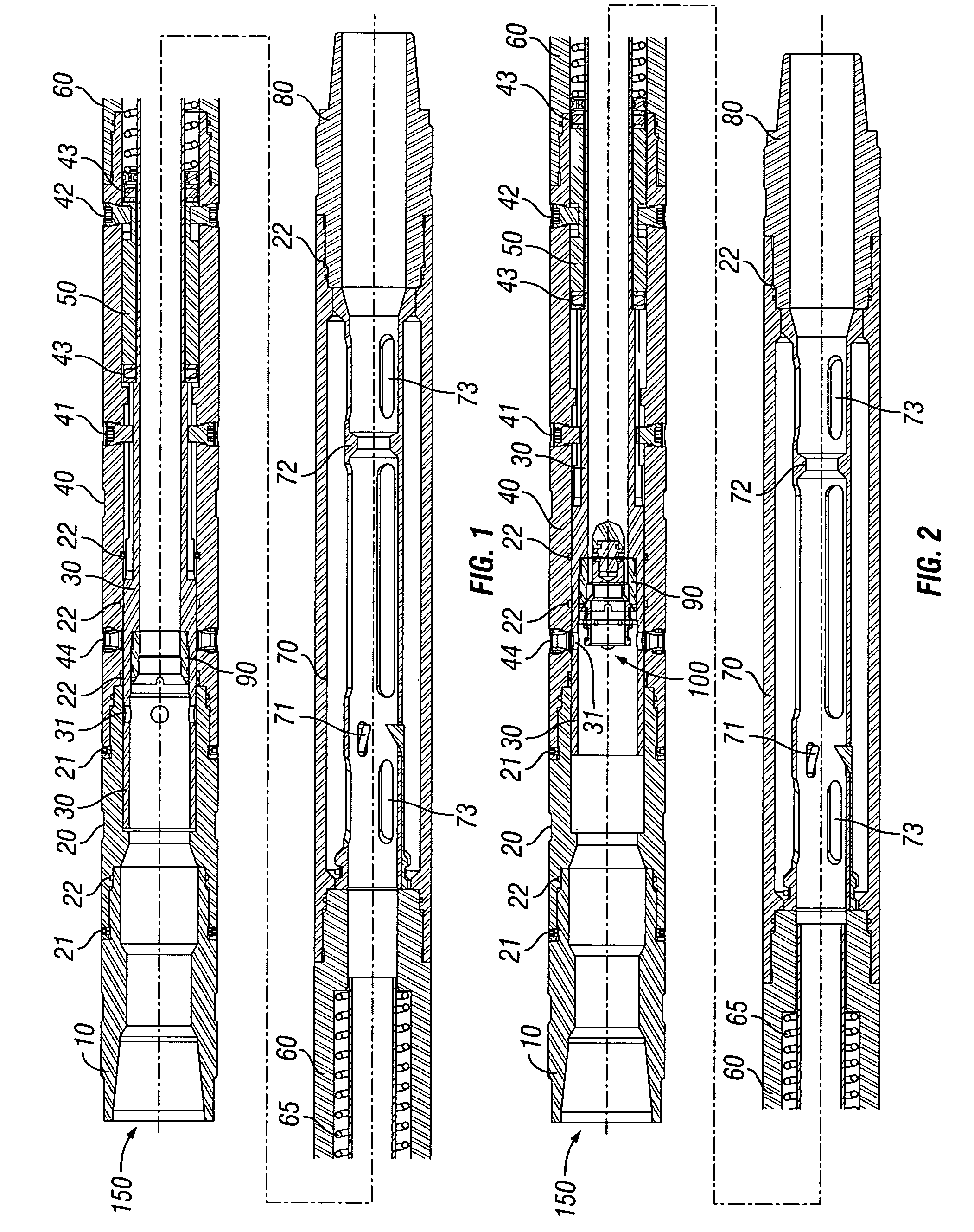

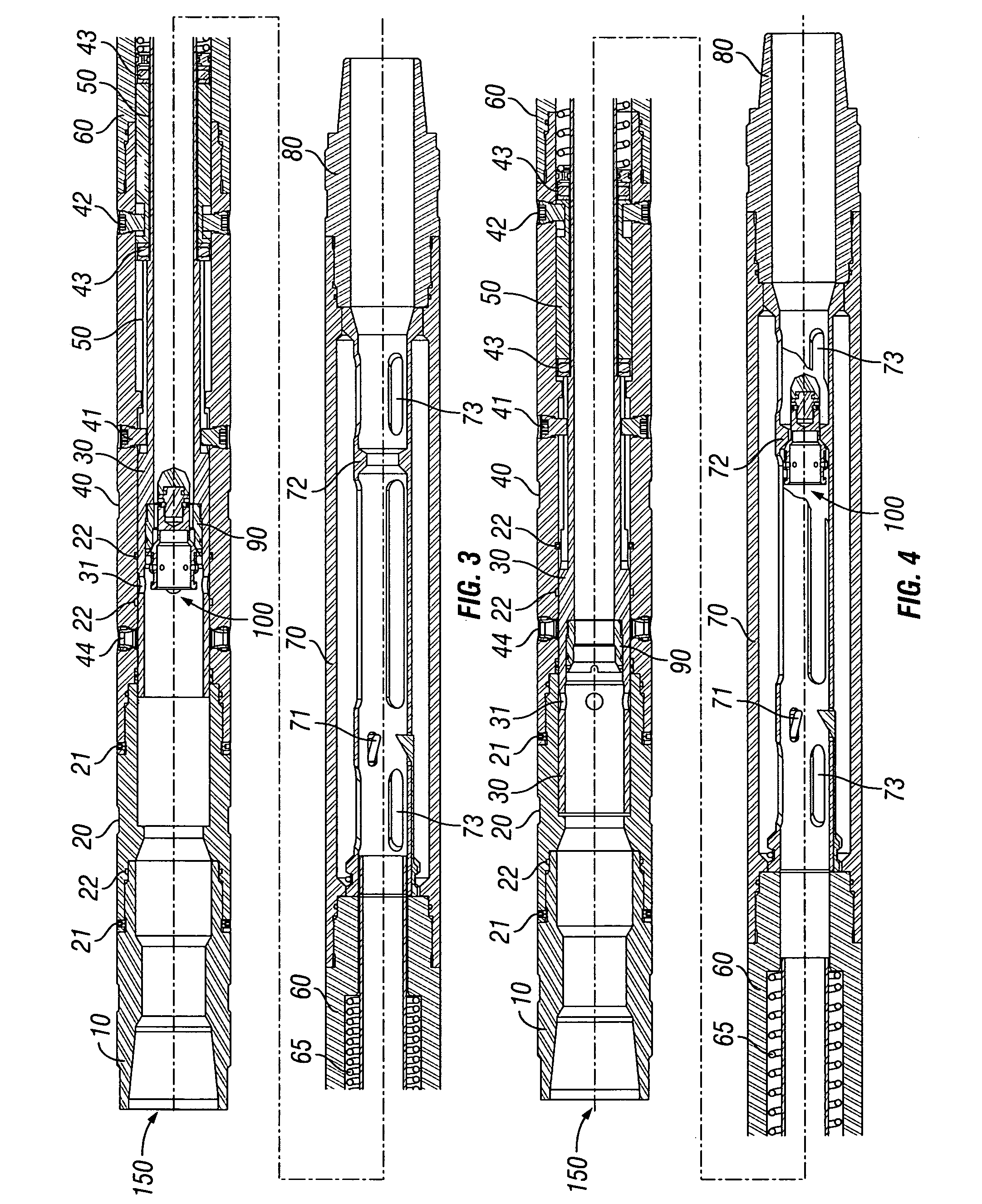

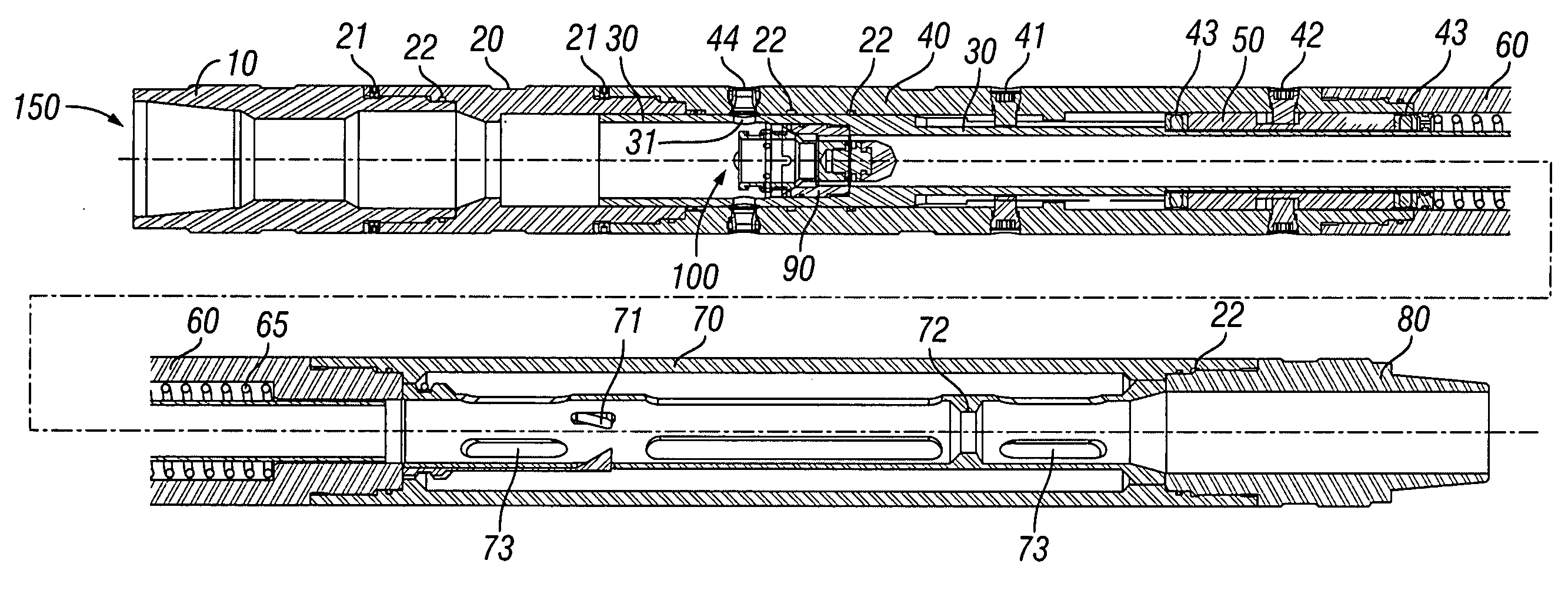

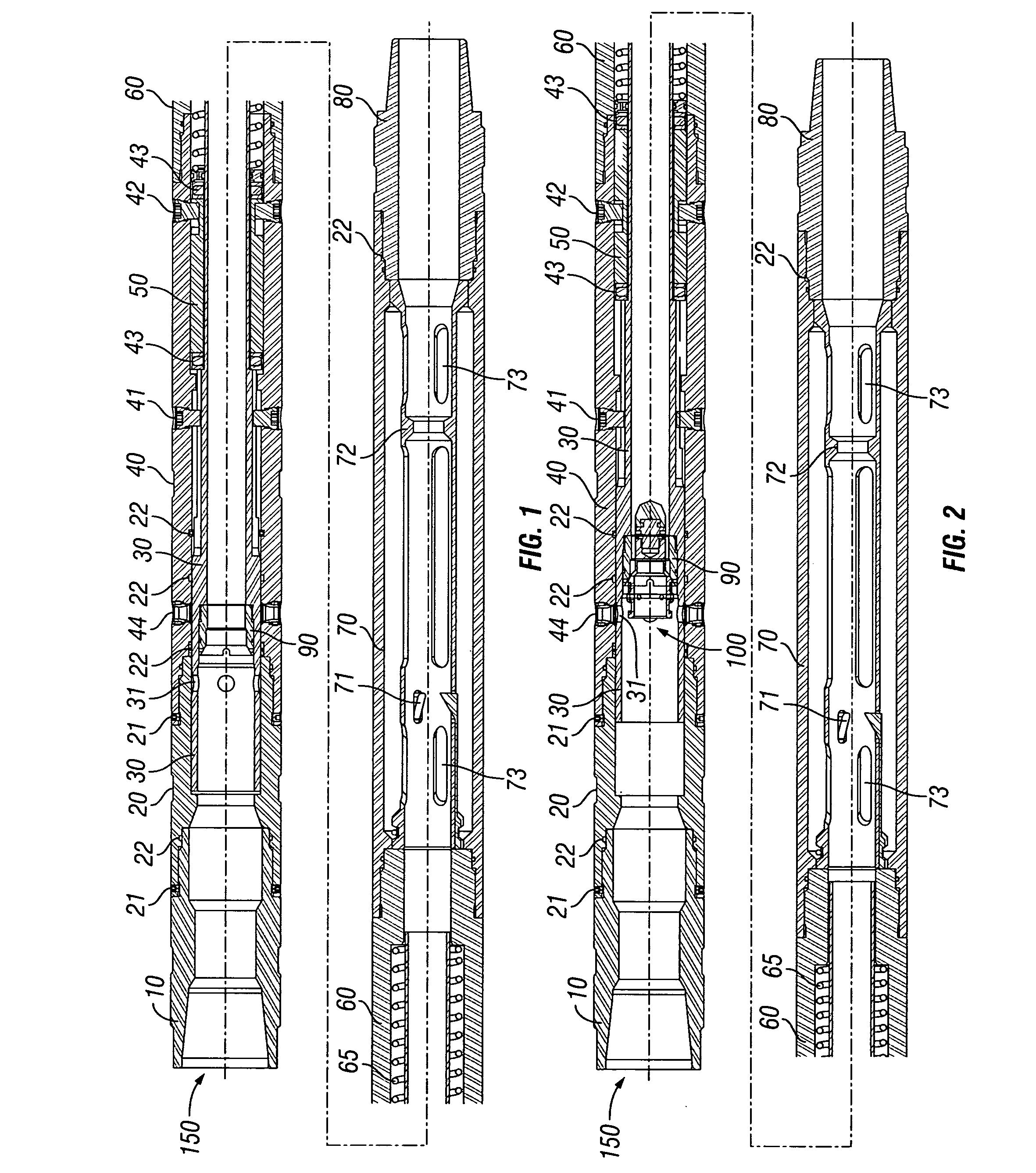

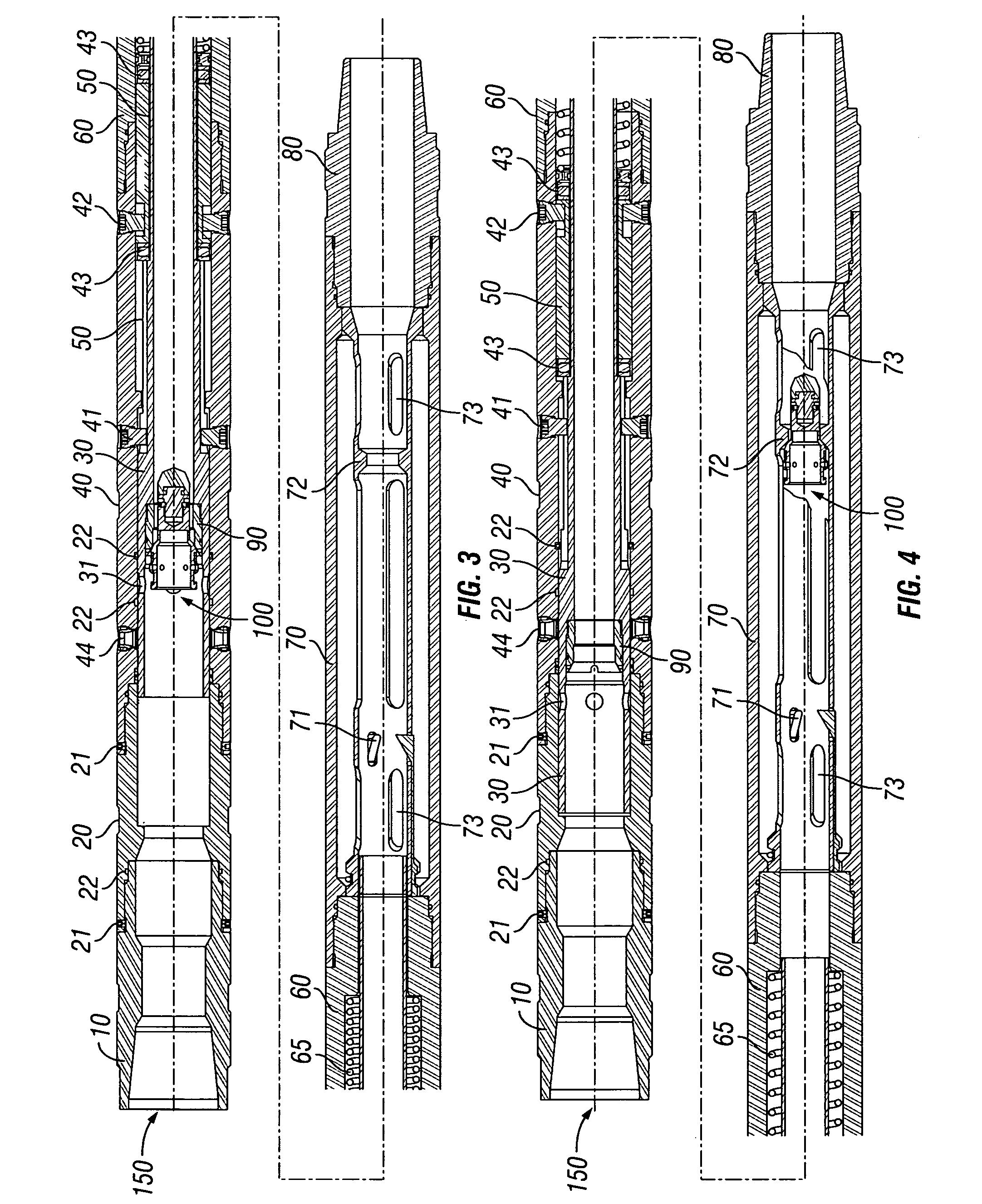

Multiple dart drop circulating tool

ActiveUS7520336B2Avoid flowShorten the timeConstructionsFluid removalIncreased fluid pressureBiomedical engineering

A downhole device used to divert fluid flow out of a work string. The downhole device may be located at any point along a work string at which it may be necessary to divert the fluid flow to the annulus. The downhole device may be activated and deactivated by inserting a single deformable dart into the work string. The device catches the dart blocking fluid flow through the work string. Increased fluid pressure activates the device, which diverts the fluid flow out of the work string into the annulus. A locating sleeve with a continuous j-track allows the device to be retained in activated position. The dart is adapted to deform under a predetermined amount of fluid pressure allowing the dart past the device and returning fluid flow through the work string. The downhole device may be activated multiple times without removing the downhole device from the wellbore.

Owner:BAKER HUGHES HLDG LLC

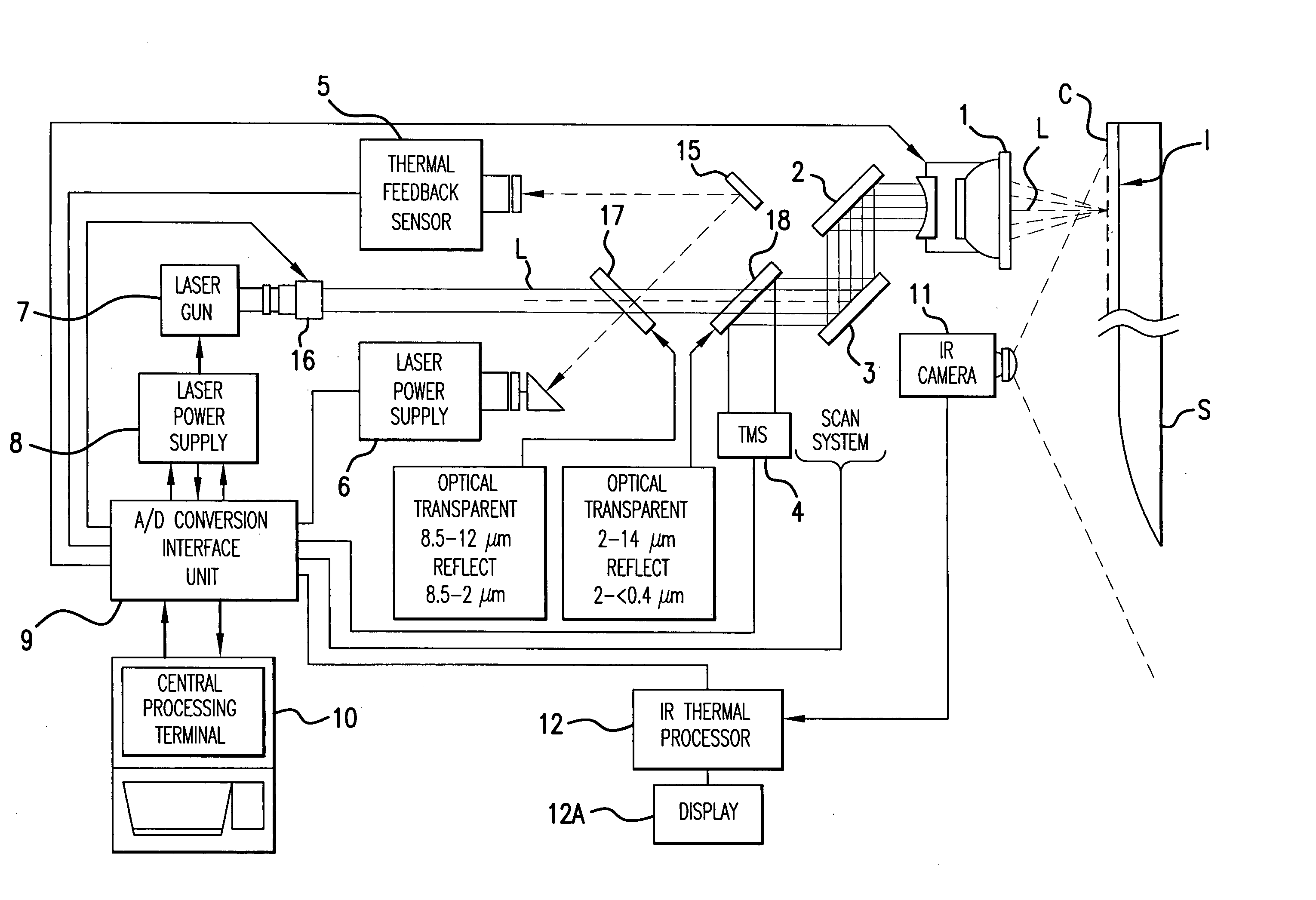

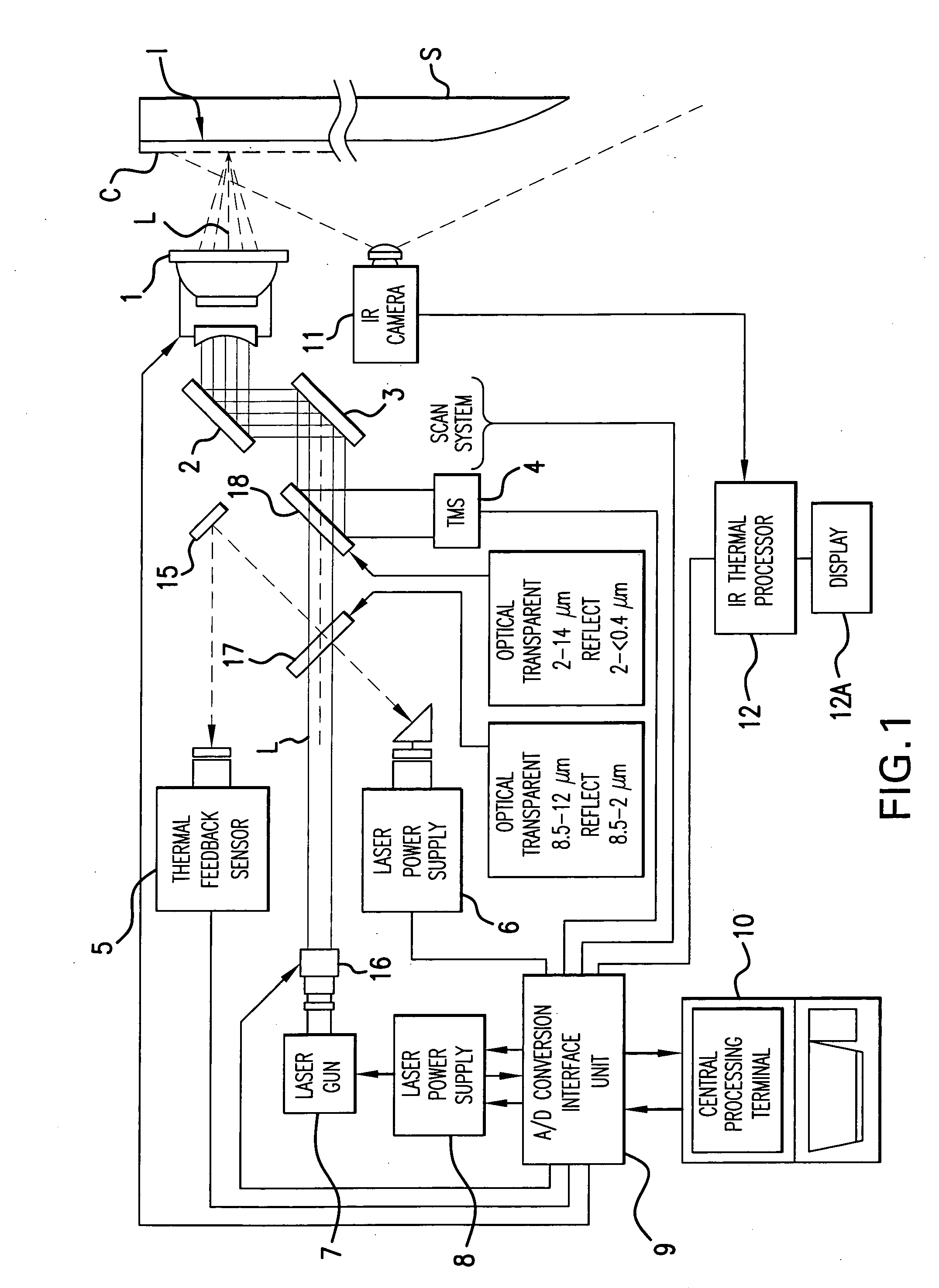

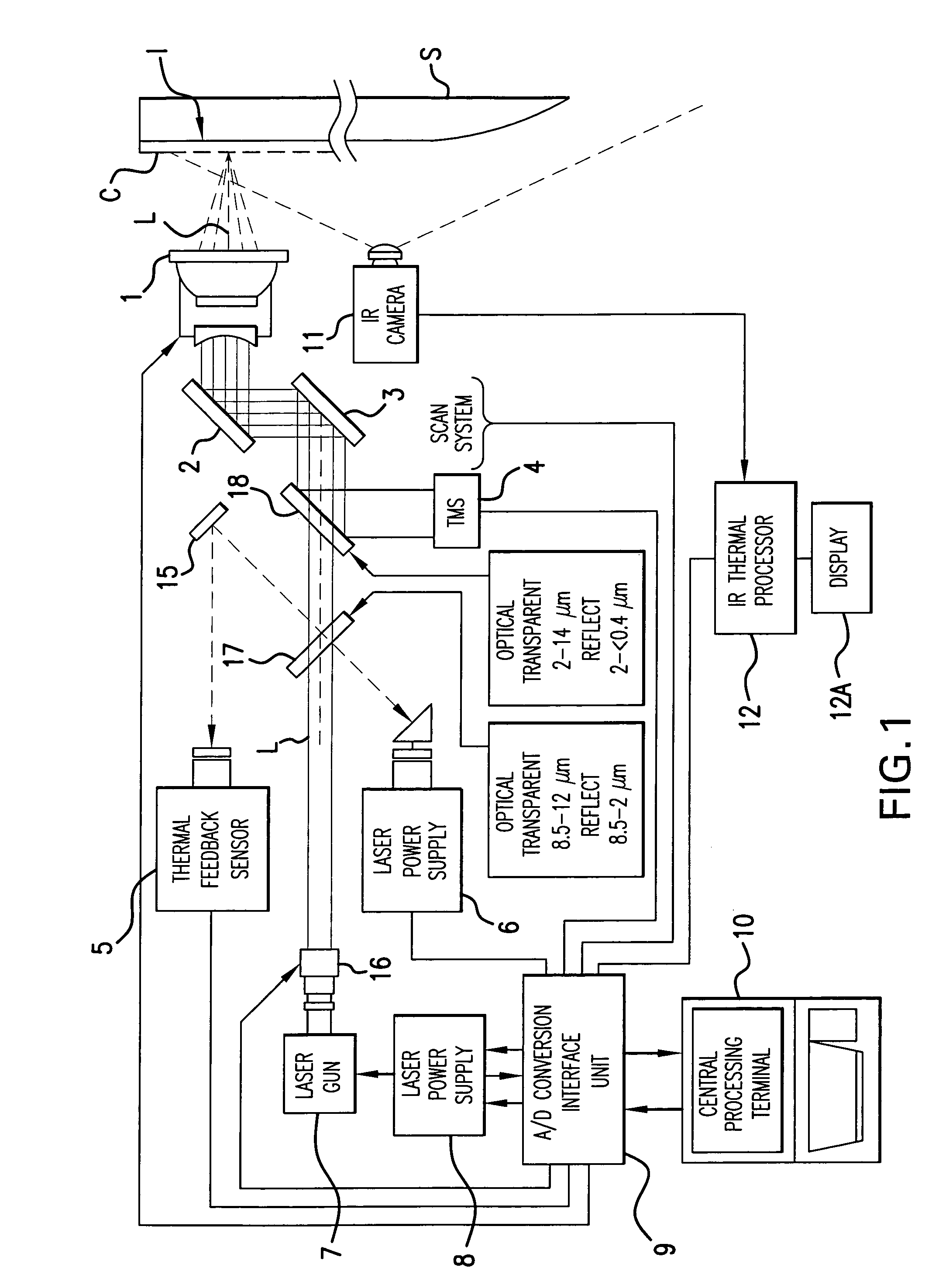

Laser irradiation apparatus

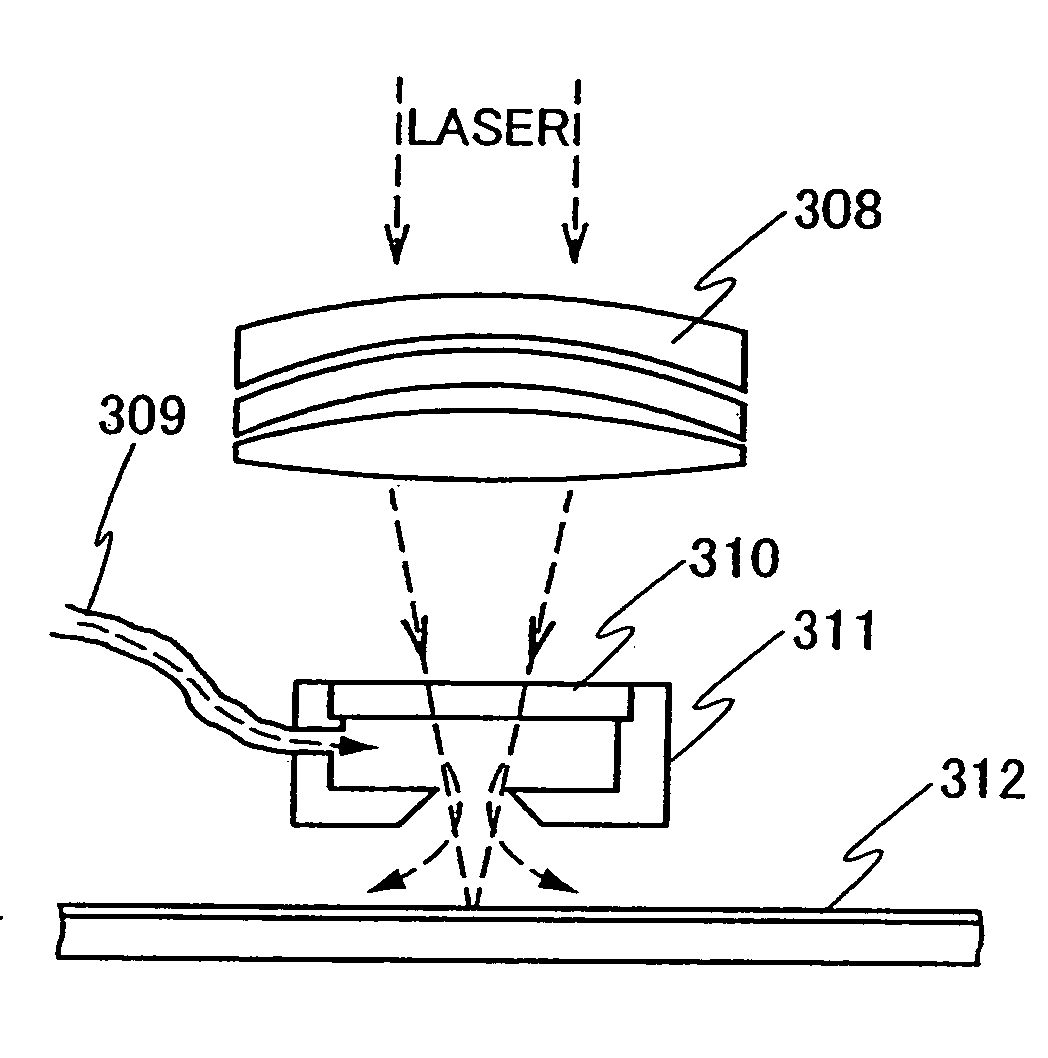

InactiveUS7714251B2Easy to measureShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsLaser light

Since the size of a plate for issuing gas used for a conventional laser irradiation apparatus is large and the distance between an optical system through which a laser light lastly passes and the plate is not enough, it is difficult to check the state of laser light delivered from the optical system which the laser light lastly passes through. A laser irradiation apparatus includes a laser oscillator, an optical system shaping laser light produced by the laser oscillator, a plate having an opening for issuing a gas, a stage provided below the blower, means for maintaining a constant distance between the blower and the stage above the stage, and means provided between the optical system and the blower for observing the laser light transmitted through the optical system are provided.

Owner:SEMICON ENERGY LAB CO LTD

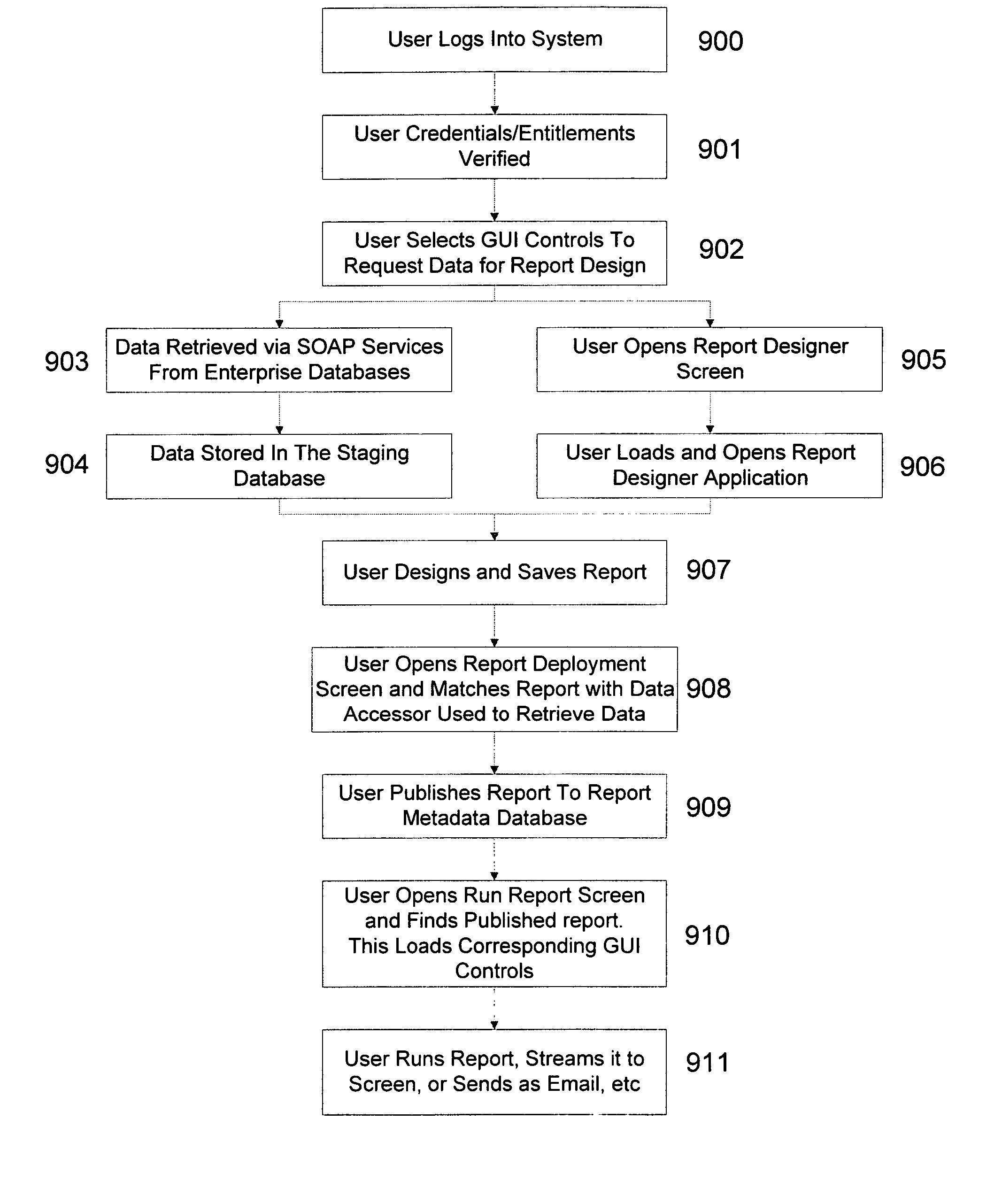

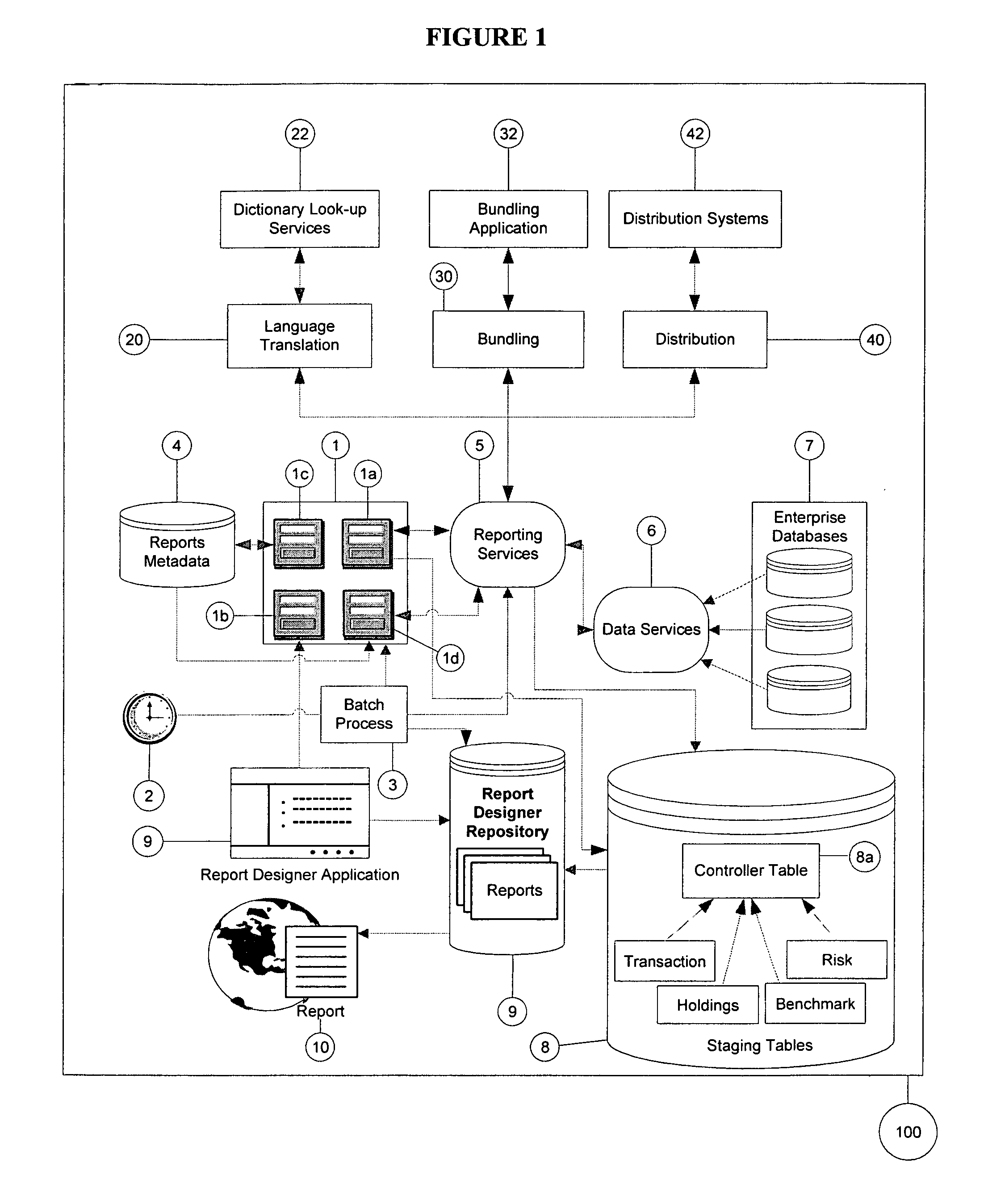

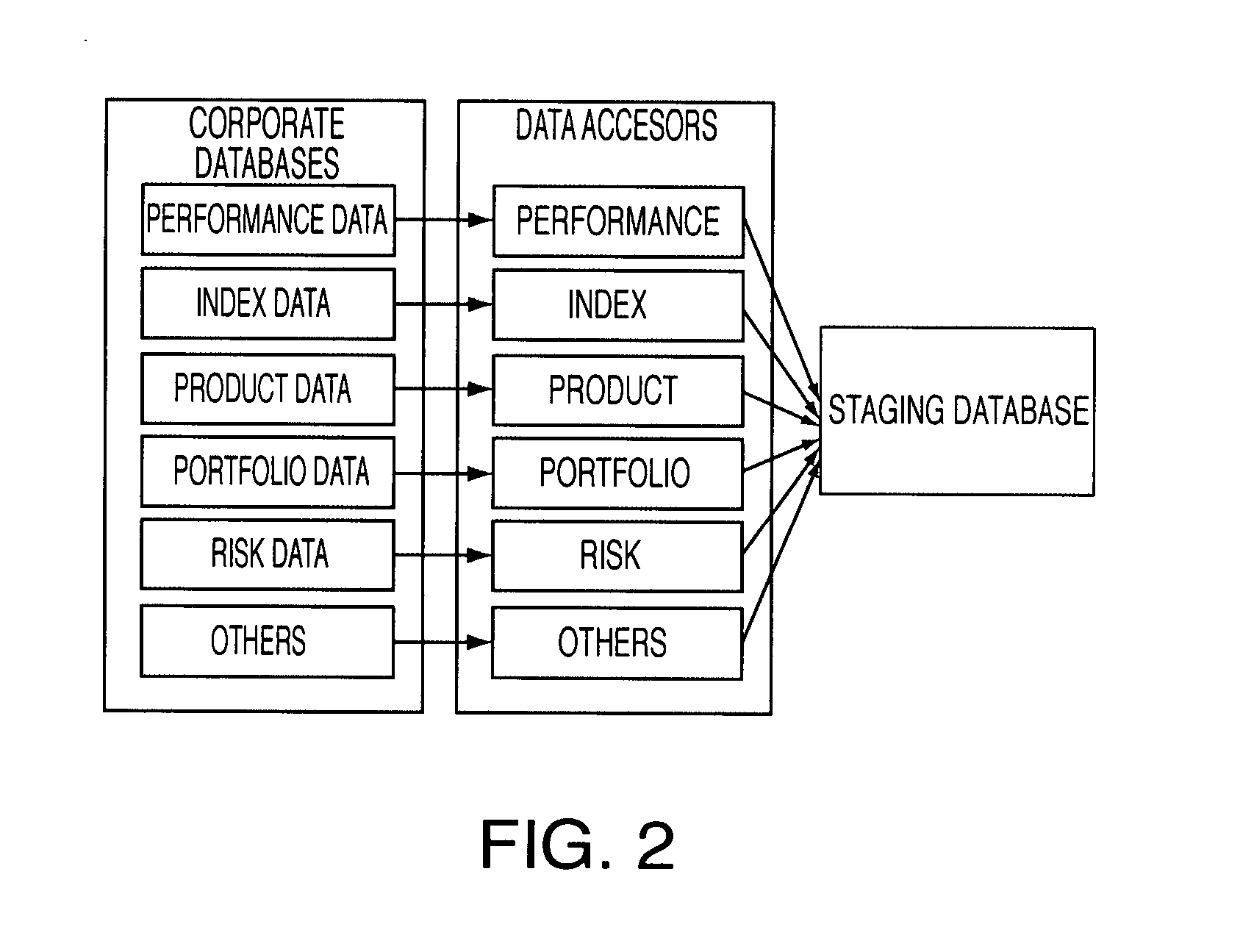

Dynamic Accessible Reporting Tool (DART)

ActiveUS20080091709A1Low costShort turnaround timeResourcesSpecial data processing applicationsData retrievalData source

A flexible metadata driven and workflow based report generation system is disclosed. The system comprises a Flexible Reporting GUI with four components that allow the user direct control in the creation of a report within a single application: a Data Generator for retrieving data, a Report Designer with a built-in report designer application, a Report Deployment element for deploying the report and an Report Run element for interactively running the report. The Flexible Reporting GUI allows a user to run a report with updated data stores, and to define the various parameters that affect the content of the generated report with great flexibility. Through the system of the invention, the user can be directly involved in all the report generation steps, through a user friendly interface, and a simplified environment. Moreover, the system in the invention provides improved solutions for updated data retrieval from protected data sources.

Owner:MORGAN STANLEY

Capacitive Deionization Using Hybrid Polar Electrodes

InactiveUS20090255815A1Reduce energy costsShort turnaround timeFatty/oily/floating substances removal devicesElectrostatic separatorsCapacitanceEngineering

Capacitive deionization (CDI) is a non-membrane and chemical-free technique for water purification, used-water recycling, and seawater desalination. Ionic contaminants in the waters are retained by a static electric field built within the critical component of CDI, which is known as flow through capacitor (FTC). Apparently, parameters enhancing the field strength of FTC and electrode efficiency are the keys to the performance of CDI. The FTC of the present invention is formed by a plurality of monopolar and a plurality of bipolar electrodes, and a plural number of perforated holes are disposed on the FTC electrodes in a pattern that allows certain water flow rate and residence time to yield the highest efficiency of electrode utilization.

Owner:GAINIA INTELLECTUAL ASSET SERVICES +1

Laser irradiation apparatus

InactiveUS20070117288A1Easy to measureShorten the timeSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsLaser light

Since the size of a plate for issuing gas used for a conventional laser irradiation apparatus is large and the distance between an optical system through which a laser light lastly passes and the plate is not enough, it is difficult to check the state of laser light delivered from the optical system which the laser light lastly passes through. A laser irradiation apparatus includes a laser oscillator, an optical system shaping laser light produced by the laser oscillator, a plate having an opening for issuing a gas, a stage provided below the blower, means for maintaining a constant distance between the blower and the stage above the stage, and means provided between the optical system and the blower for observing the laser light transmitted through the optical system are provided.

Owner:SEMICON ENERGY LAB CO LTD

Dual laser coating apparatus and process

ActiveUS20050266168A1Good for absorptionSufficient powerPretreated surfacesLiquid spraying apparatusSpectral linePowder coating

An apparatus for applying and fusing a powder coating to substrates of various composition uses two lasers to accurately heat the coating to the optimum temperature. A second laser has less power and heats a smaller area than the first laser. Temperature control is enhanced by the ability to superheterodyne two lasers at separate frequencies. This allows for better absorption of certain materials being fused by the laser. Another common problem associated with laser processing occurs as the polymer heats up. During the heating process the spectral lines are Doppler broadened and slightly shifted. This can affect the absorption of a laser of a fixed wavelength. With the present invention, the optimum laser frequency can be turned to a more optimum frequency for absorption still with sufficient power for fast efficient thermal processing.

Owner:PHOTOFUSION TECH

High frequency efficient breeding control technique of meat sheep

InactiveCN101361471AIncrease profitShort turnaround timeAnimal reproductionAnimal feeding stuffSheep breedVaginal Suppository

The invention discloses a mutton sheep breeding and regulating technology with high frequency and high efficiency. In China, the mutton sheep breeding and regulating technology with high frequency and high efficiency is applied relatively widely, but the situation of organically combining a plurality of technologies and the popularization thereof does not appear. The technology comprises an oestrus hormone-regulation proposal, a production system and a high-efficiency breeding technology; wherein, the oestrus hormone-regulation proposal relates to a progestogen vaginal suppository-PMSG method, the production system of twice producing one year or three producing two year is adopted, the high-efficiency and high frequency breeding technology adopts gonadotropin, grouping hybridization and nutritional regulation. The technology is applied to high-efficiency industry which leads the sheep industry to develop into industrialization.

Owner:黑龙江省农业科学院畜牧研究中心 +2

Microwave plasma nozzle with enhanced plume stability and heating efficiency

ActiveUS7164095B2Low per unit costShort turnaround timeArc welding apparatusPlasma welding apparatusMicrowave cavityElectrical conductor

Owner:NOXILIZER

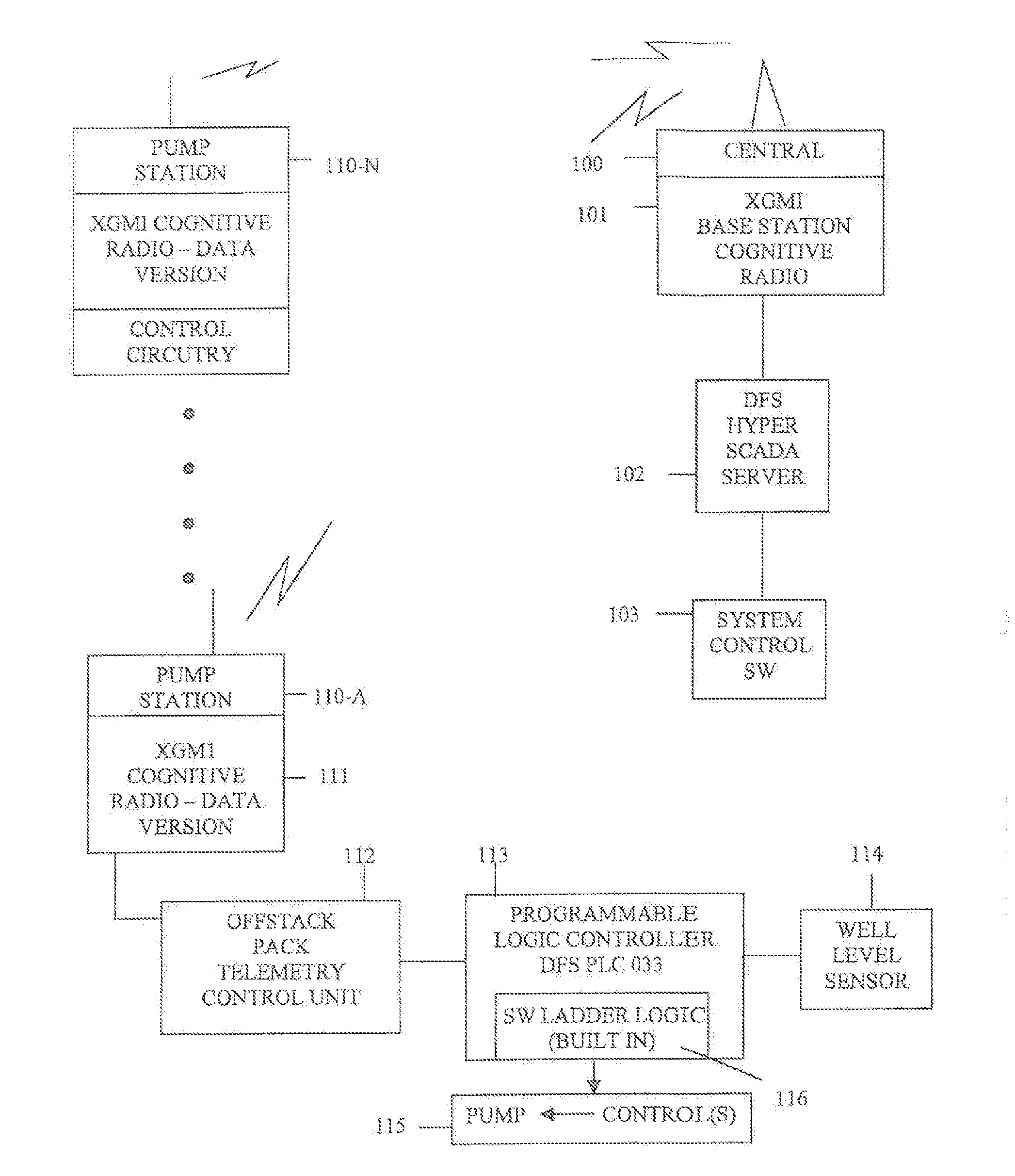

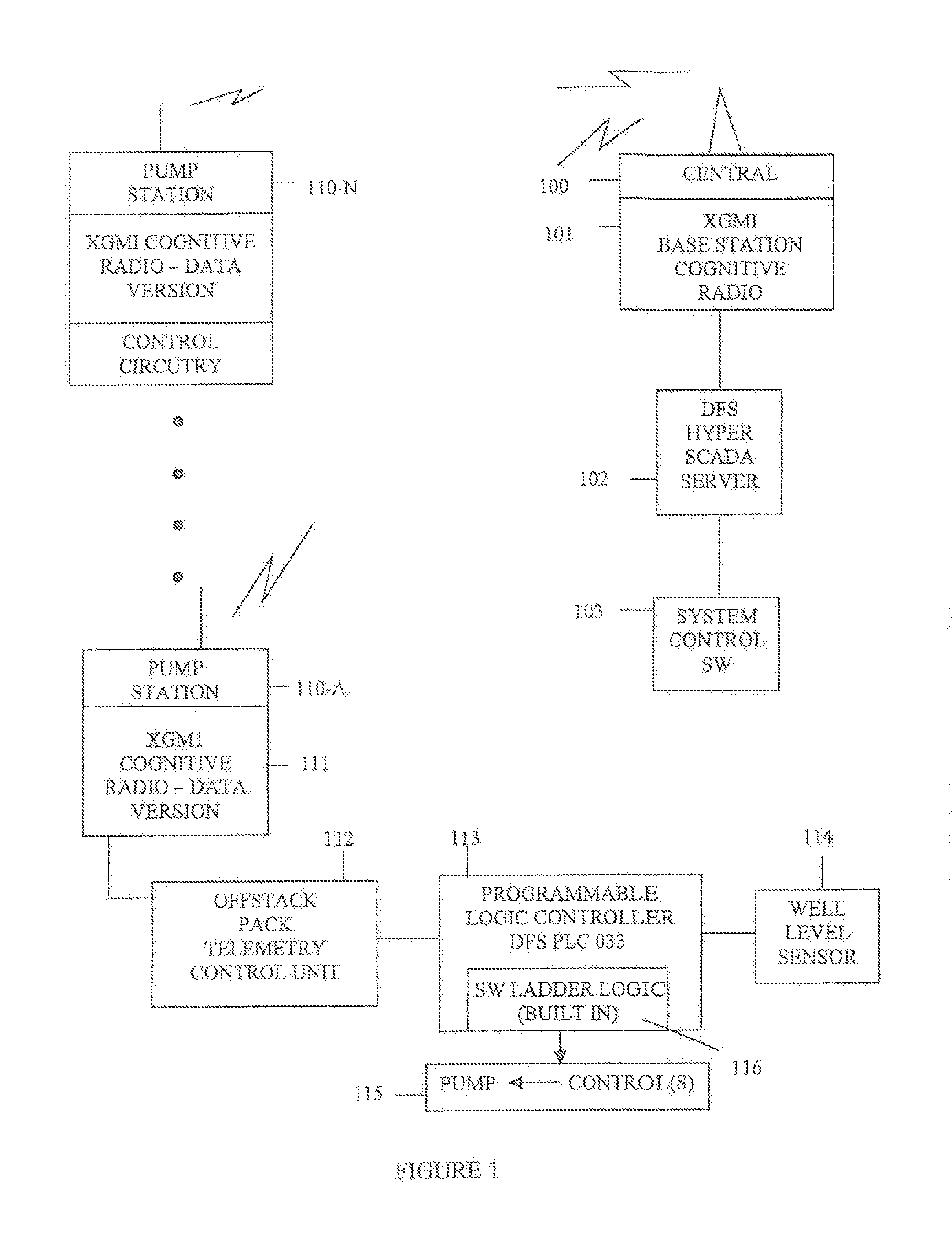

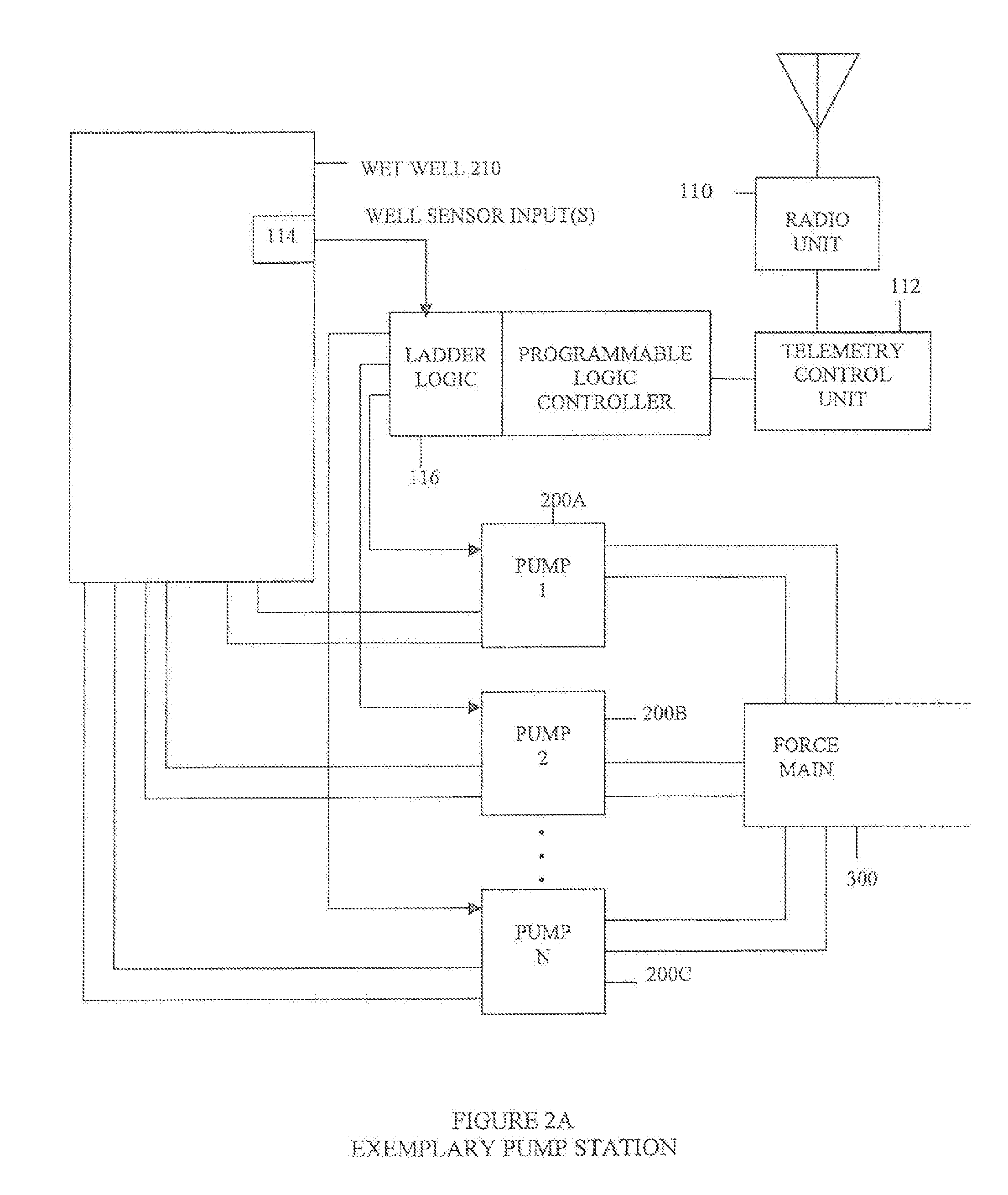

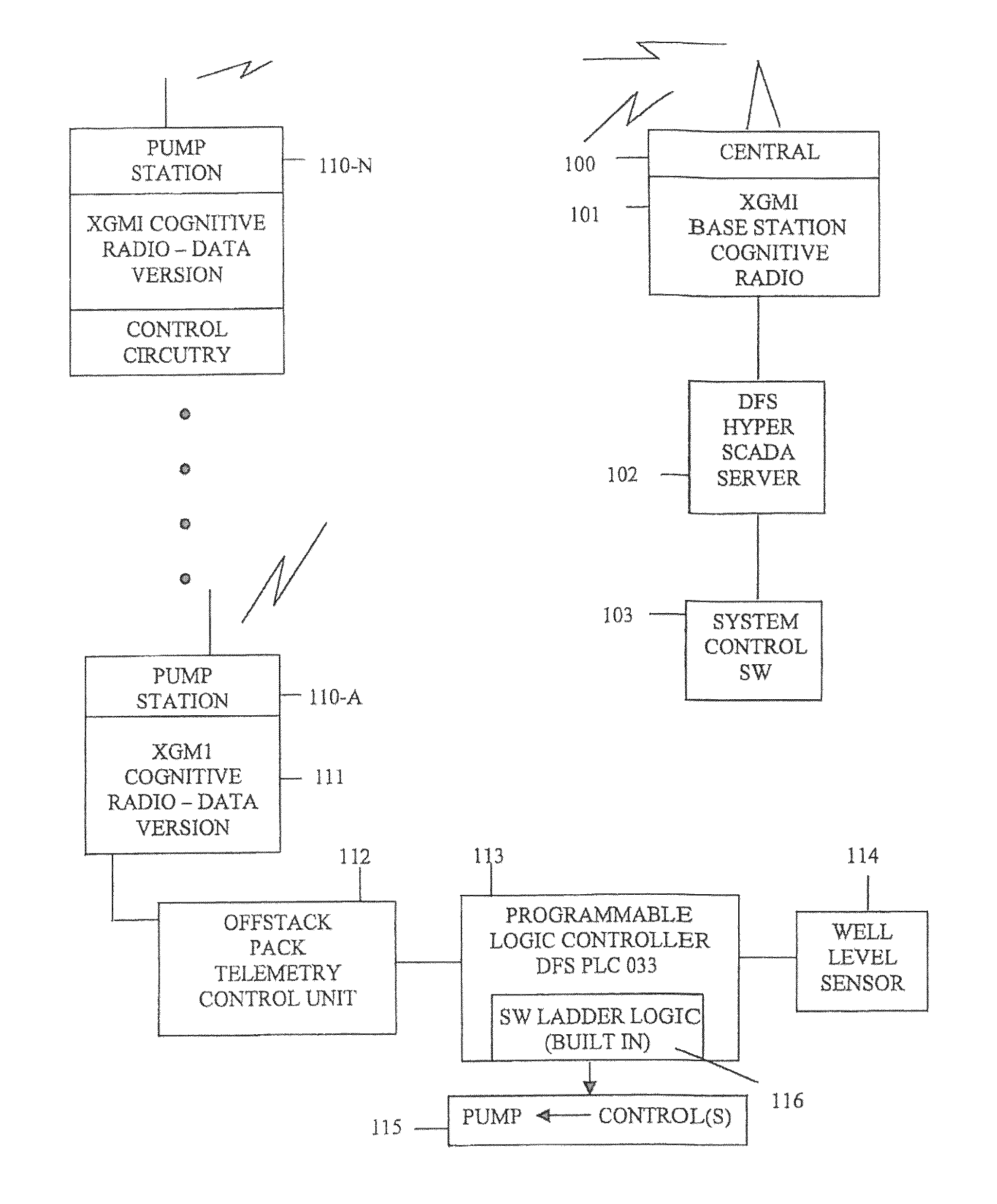

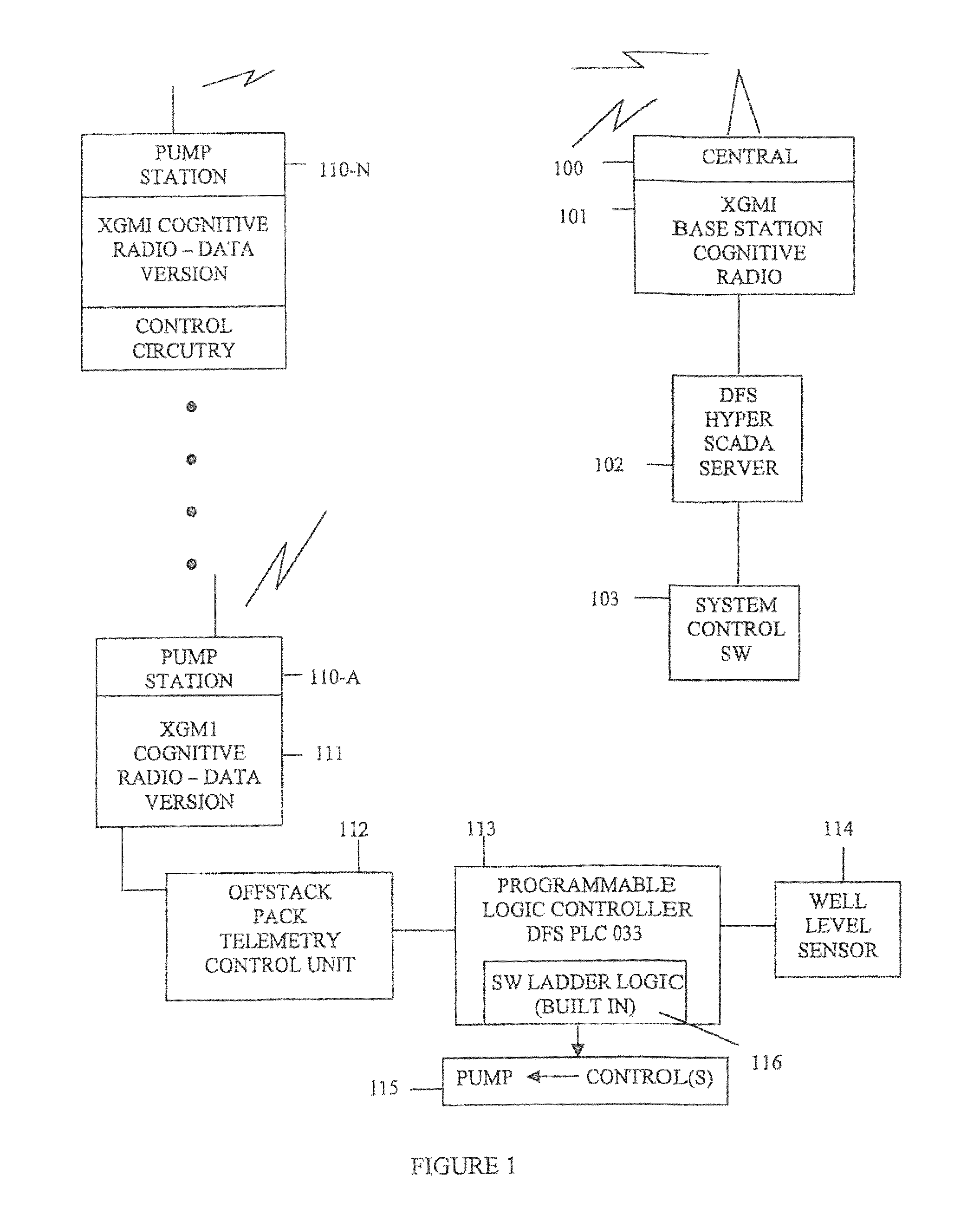

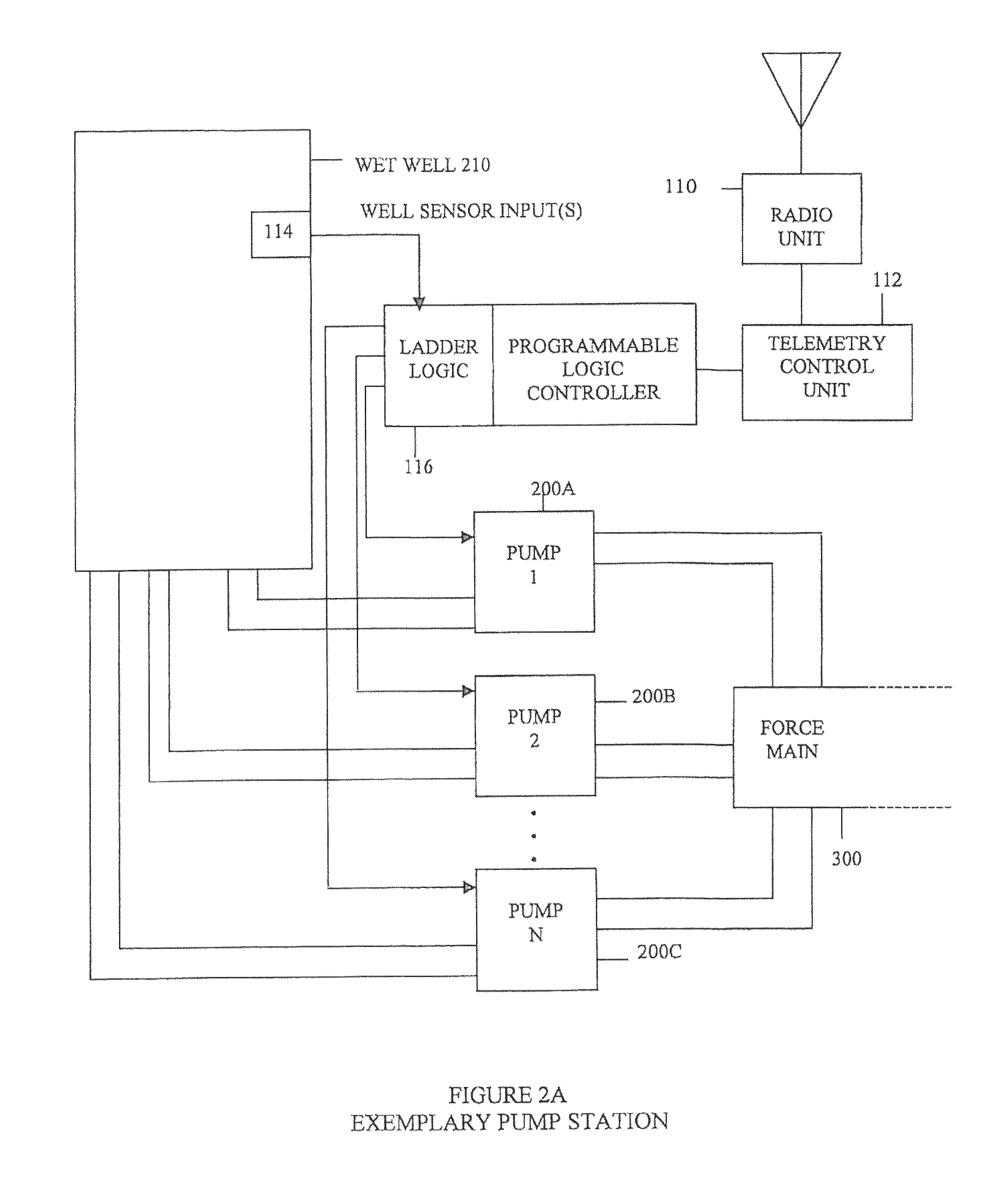

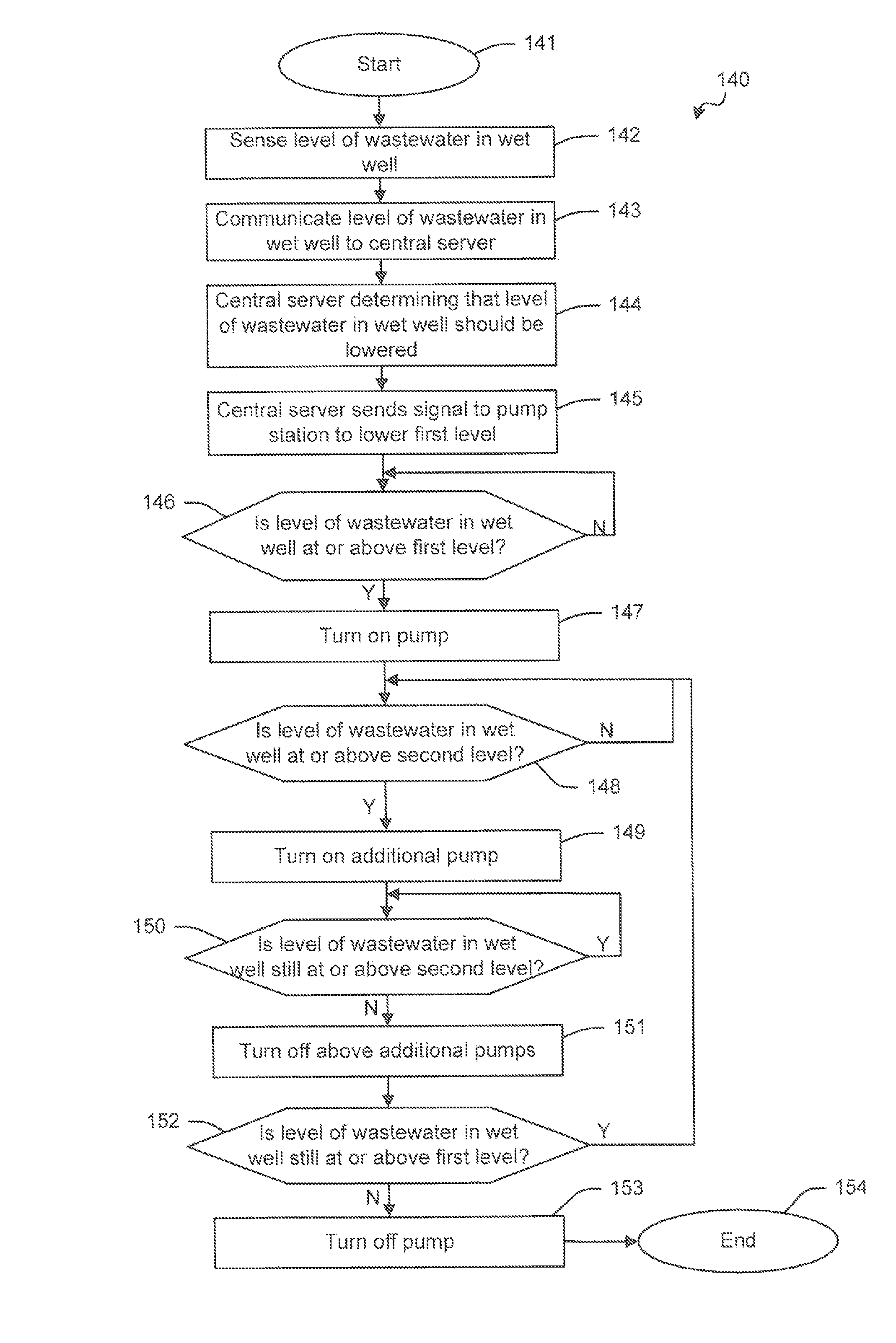

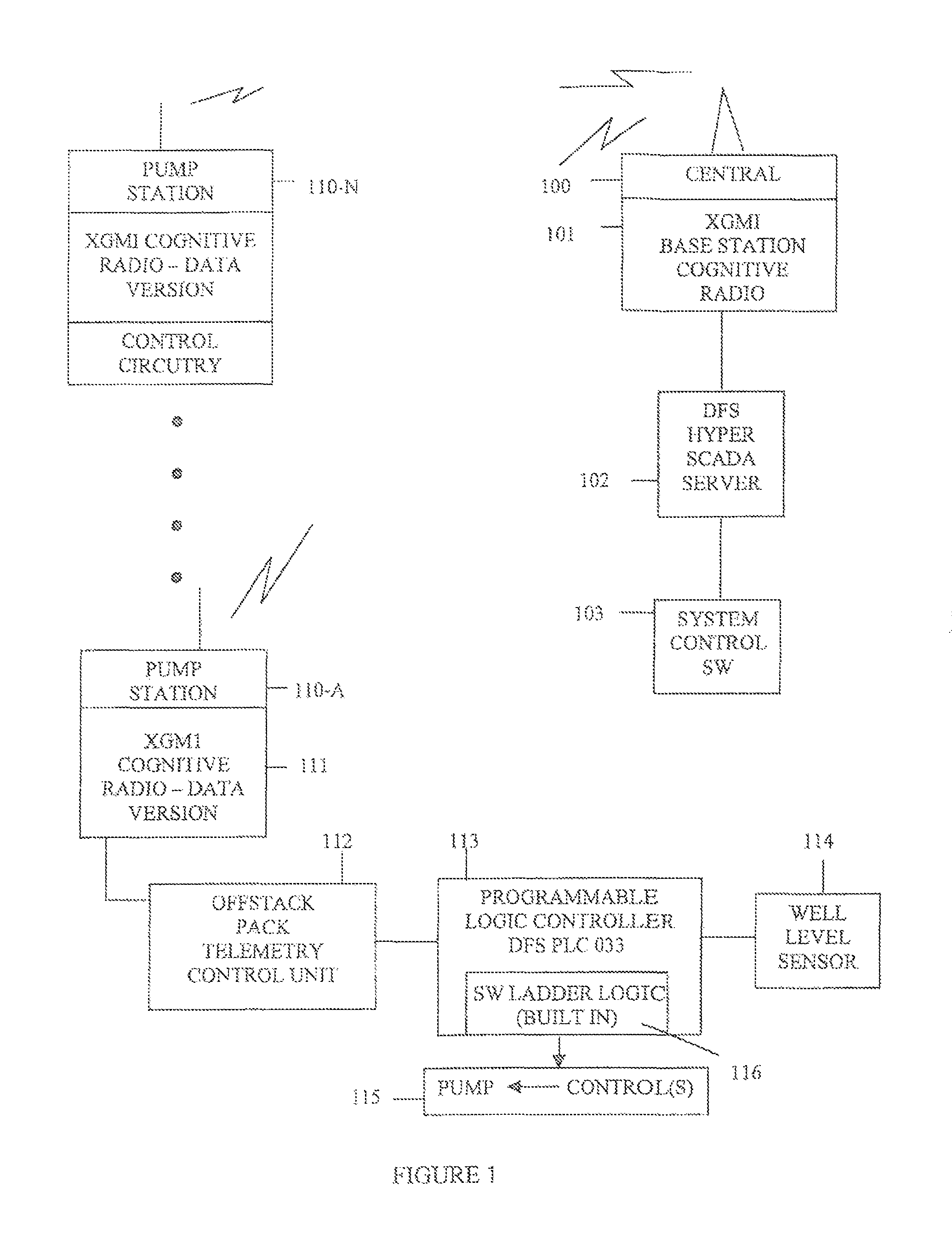

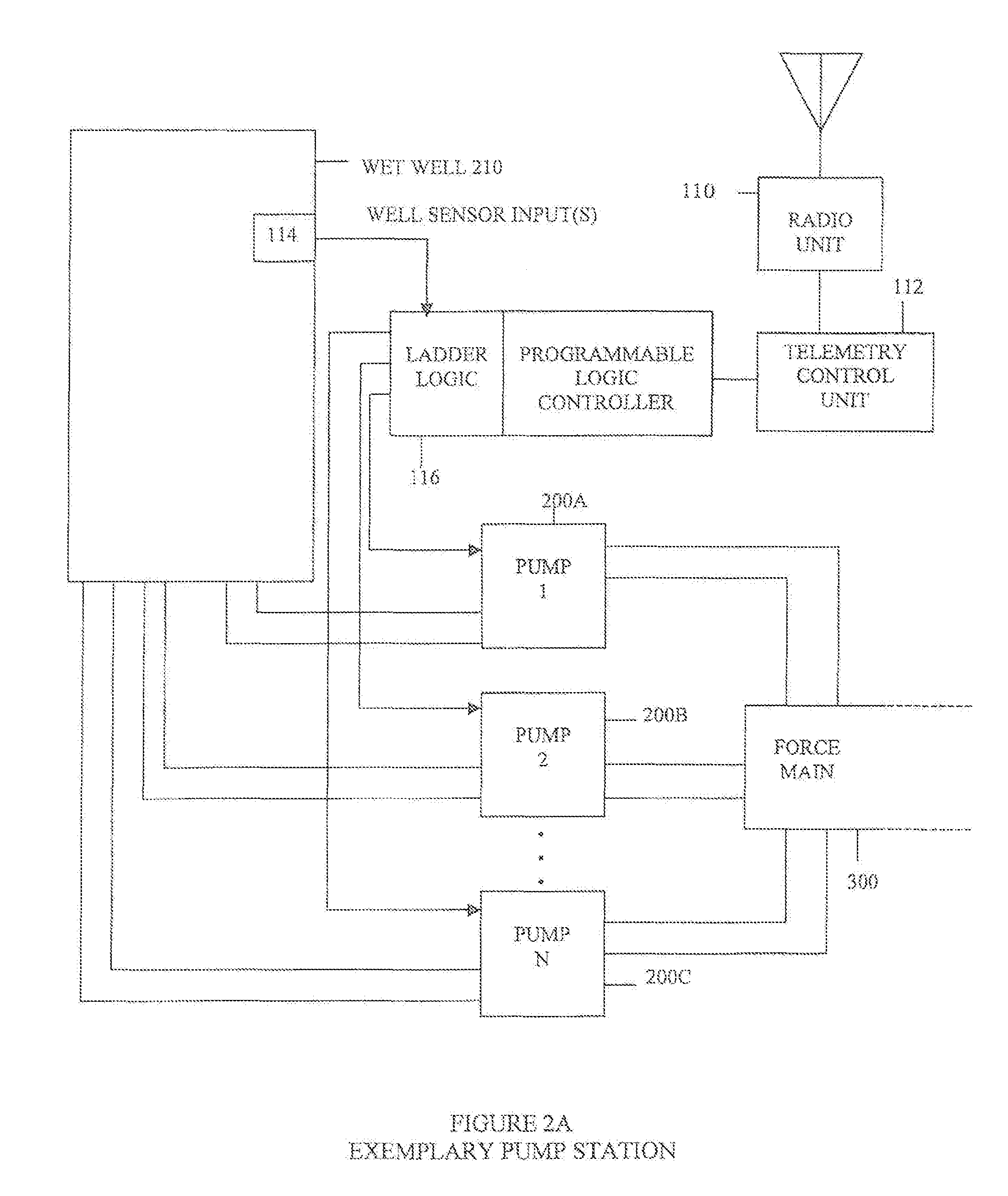

Fluid flow management system and associated methods

ActiveUS20120222994A1Efficient deliveryEasy to useTesting/calibration apparatusBiological treatment regulationFluid managementFlow management

A system is provided to control fluid flow in a wastewater treatment system. The wastewater treatment system may include a wastewater treatment plant and a main that connects a plurality of pump stations to the wastewater treatment plant. Each of the plurality of pump stations may include a wet well and a pump carried by the wet well to pump the wastewater. The system may include a central server and a sensor in communication with the central server to sense a level of wastewater within the wet well. The pump may be moved to an on position when the level of the wastewater in the wet well is at or above a first level. The level of wastewater within the wet well may be systematically manipulated responsive to the central server to control the fluid flow in the wastewater treatment system. The system advantageously enhances fluid management in a wastewater treatment system, increases life span of the wastewater treatment plant, and saves energy associated with running pumps at the pump stations of the wastewater treatment system.

Owner:DATA FLOW SYST

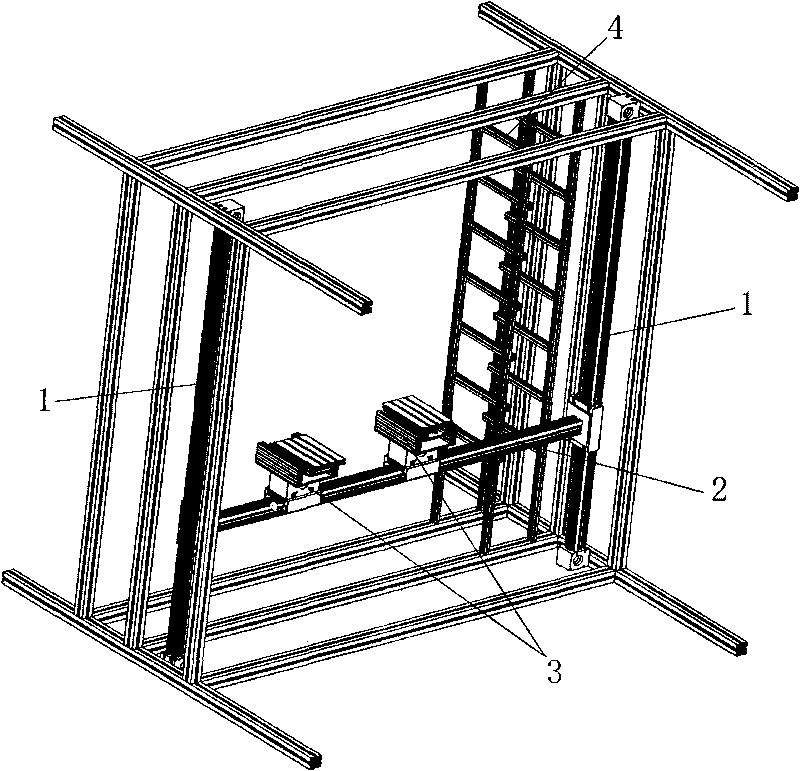

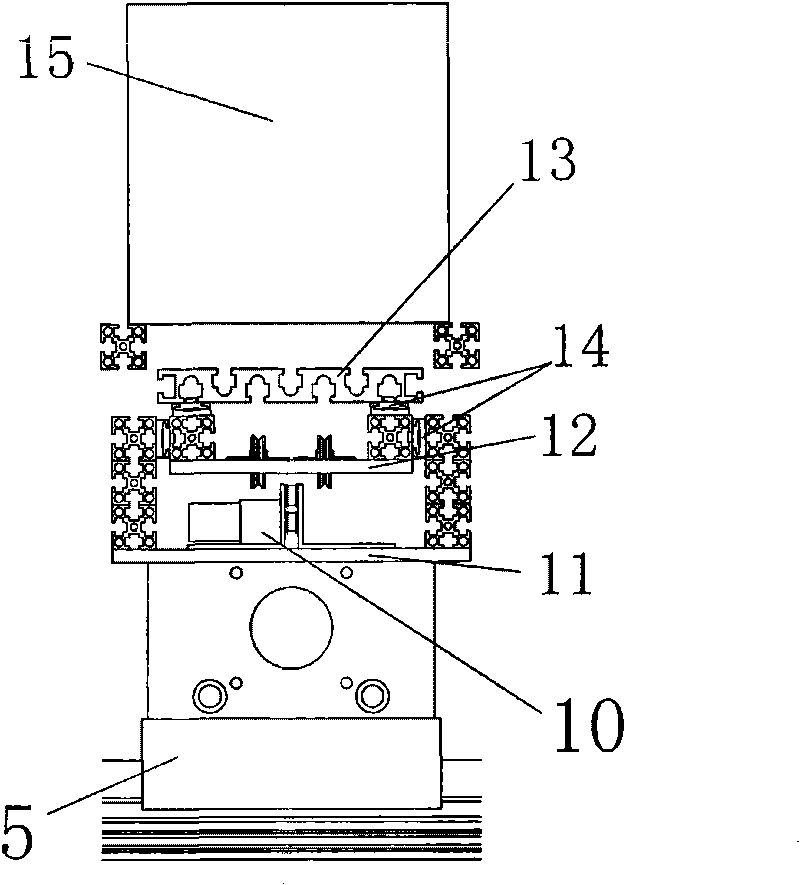

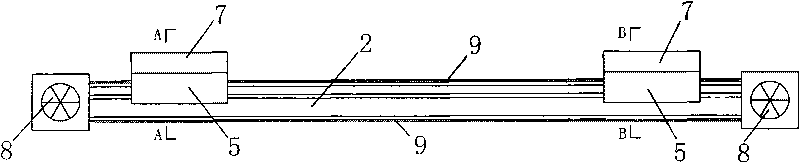

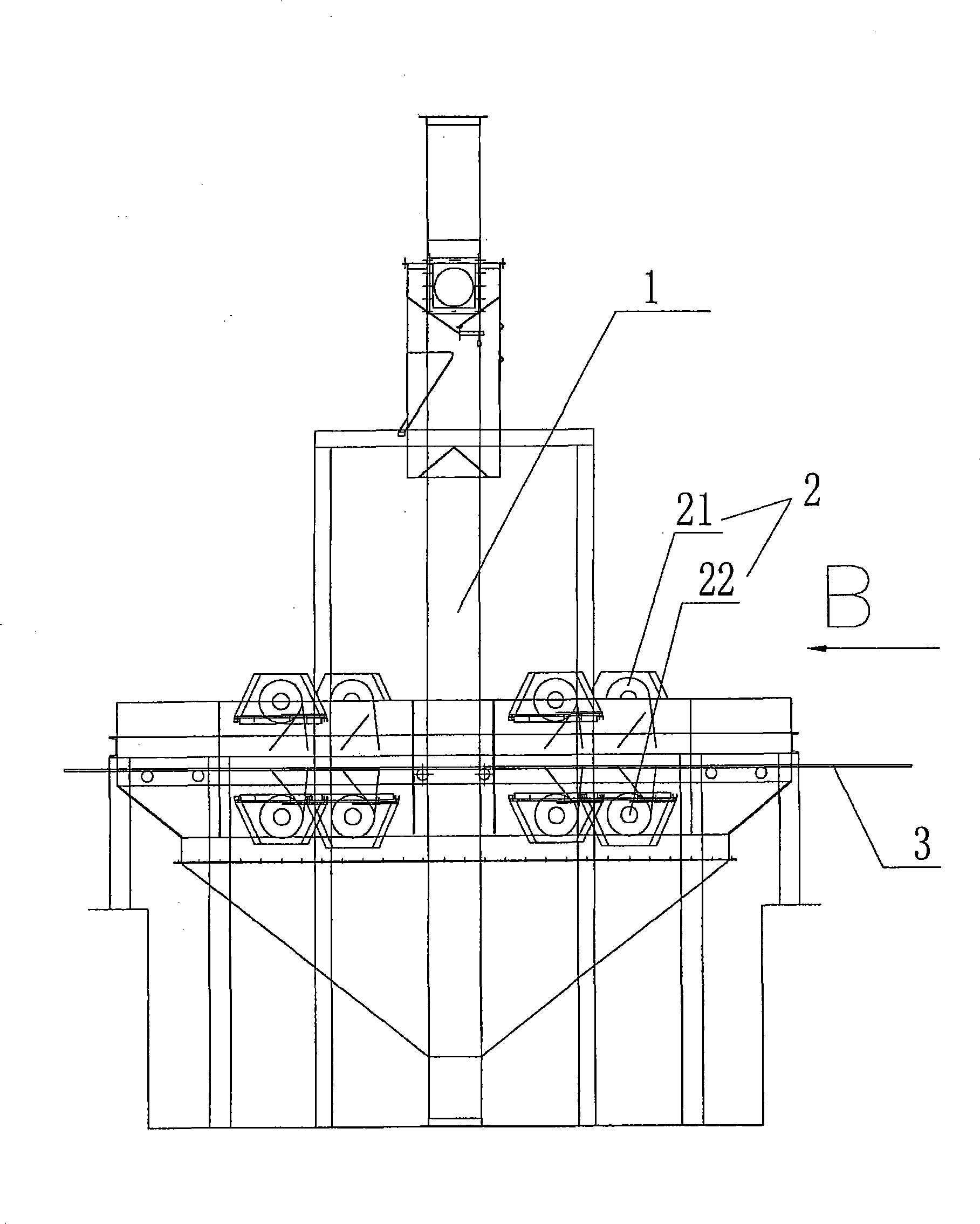

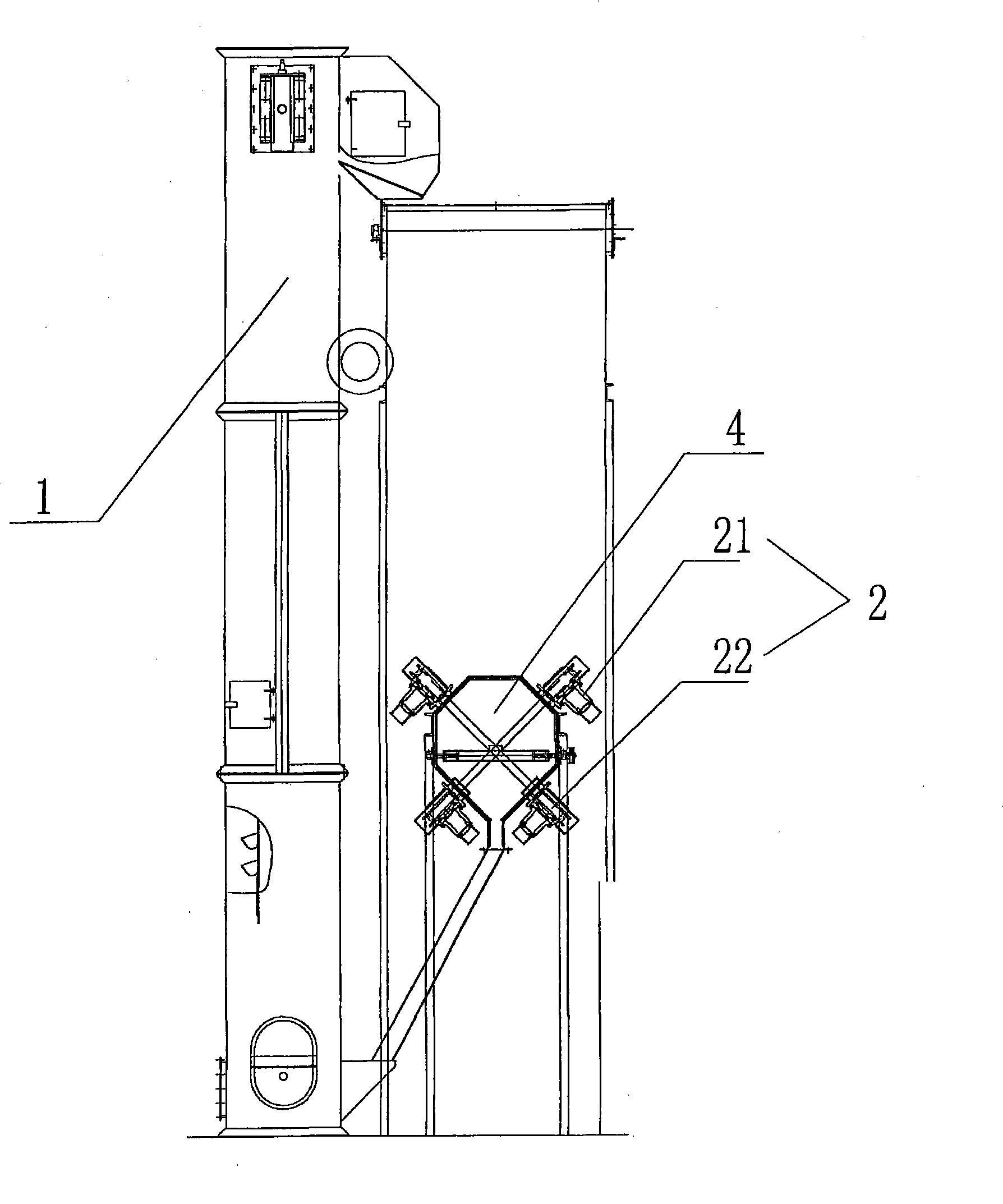

Double pallet fork rectangular coordinate robot stereoscopic warehouse

InactiveCN101712404AImprove operational efficiencyLots of homeworkLifting devicesStorage devicesKinematicsRectangular coordinates

The invention discloses a double pallet fork rectangular coordinate robot stereoscopic warehouse. The warehouse comprises multilayer goods shelves, a stacking crane kinematic system and a stock in / out mechanism, wherein the goods shelves are arranged in a single-roadway double-row goods shelves manner, the stacking crane kinematic system comprises vertical beams arranged on the two ends of the roadway, cross beams arranged between the vertical beams and a stacking crane, the two ends of each cross beam are separately latched on the vertical beams and slide vertically along the axial direction of the vertical beams, the cross beams are provided with over two stacking cranes and a crane driving mechanism, and the crane driving mechanism drives the stacking cranes to slide along the cross beams. The invention is also characterized in that the MCS structure in the current automatic stereoscopic warehouse can be changed and the number of the stacking cranes can be increased to significantly increase the overall operating efficiency of the warehouse and ensure the stability of the system in higher operating condition, thus the increase of the height of the stereoscopic warehouse can be realized.

Owner:于皓瑜

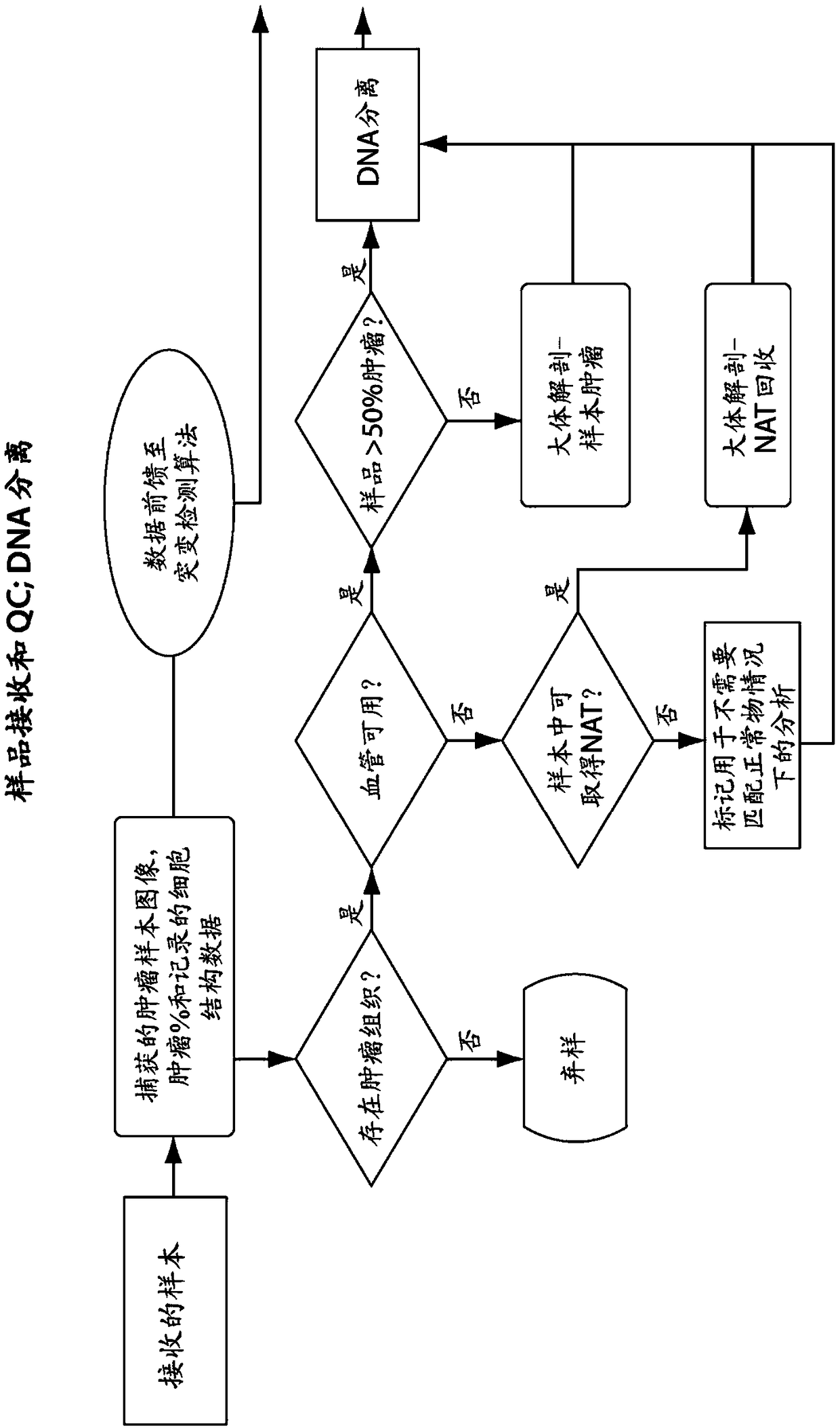

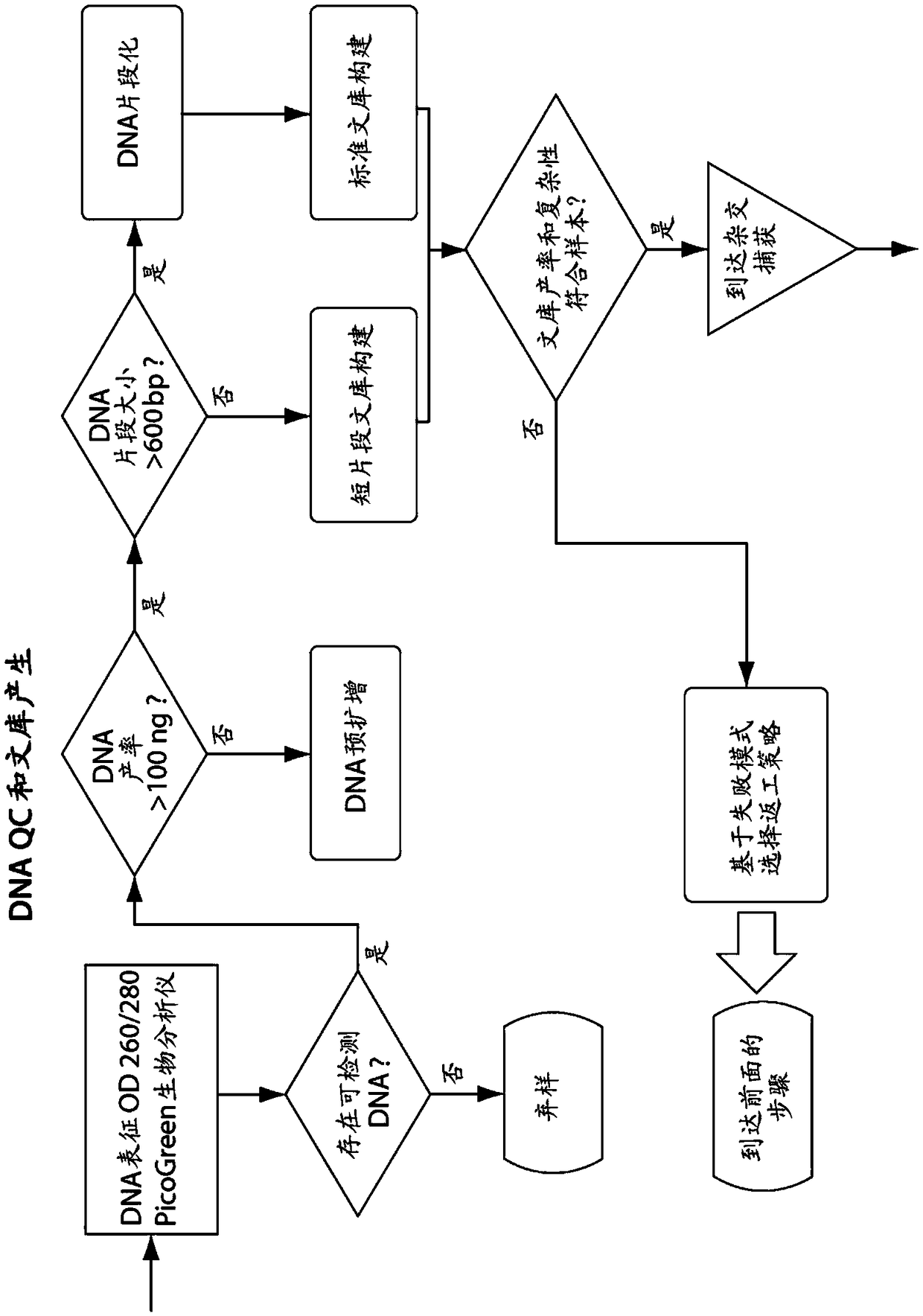

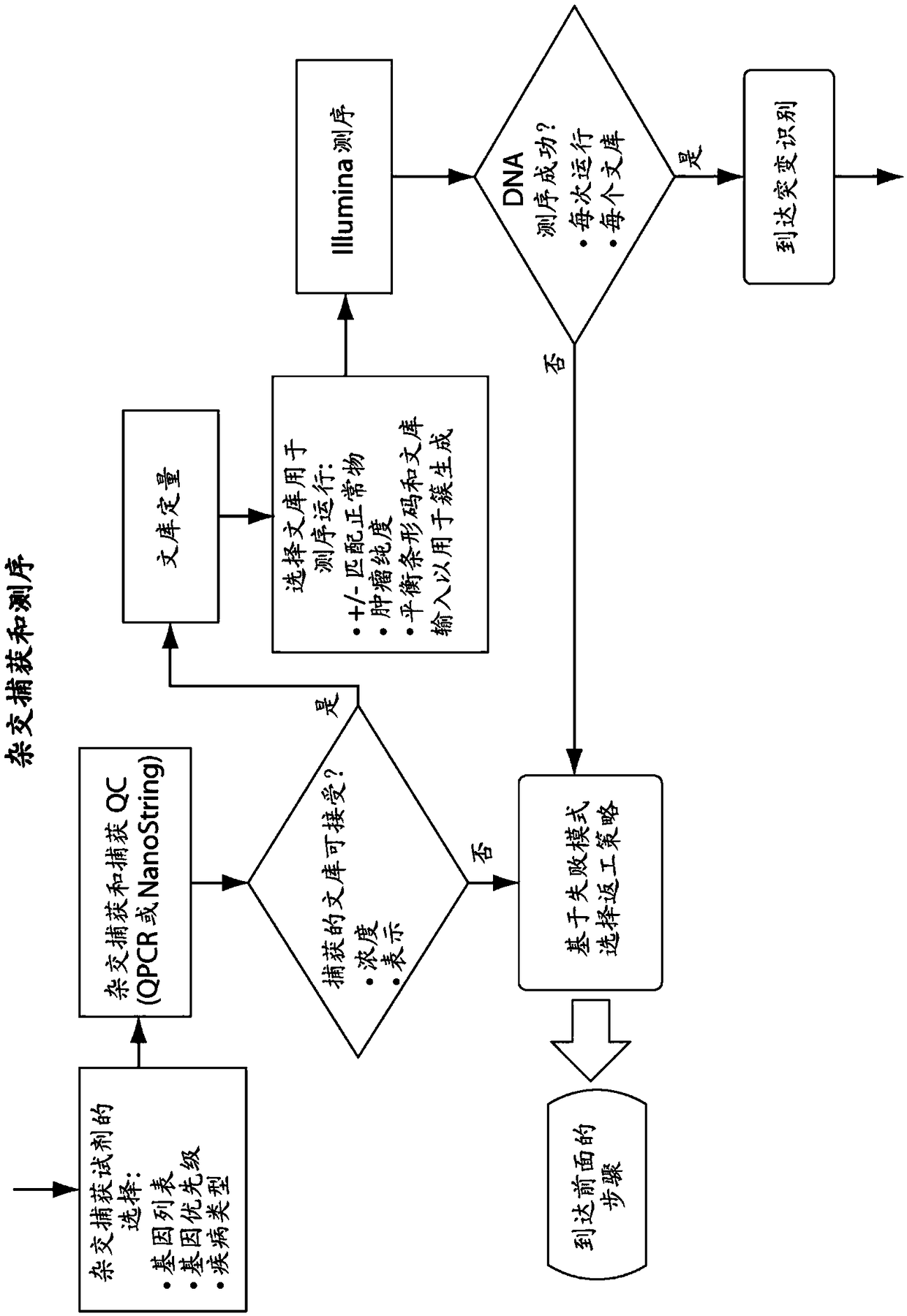

Methods and systems for evaluating tumor mutational burden

ActiveCN109196359AQuality improvementImprove efficiencyNucleotide librariesLibrary tagsTumor SampleOncology

Methods of evaluating tumor mutational burden in a sample, e.g., a tumor sample or a sample derived from a tumor, from a subject, are disclosed.

Owner:FOUND MEDICINE INC +1

Multiple dart drop circulating tool

ActiveUS20080169108A1Avoid flowShorten the timeConstructionsFluid removalIncreased fluid pressureBiomedical engineering

A downhole device used to divert fluid flow out of a work string. The downhole device may be located at any point along a work string at which it may be necessary to divert the fluid flow to the annulus. The downhole device may be activated and deactivated by inserting a single deformable dart into the work string. The device catches the dart blocking fluid flow through the work string. Increased fluid pressure activates the device, which diverts the fluid flow out of the work string into the annulus. A locating sleeve with a continuous j-track allows the device to be retained in activated position. The dart is adapted to deform under a predetermined amount of fluid pressure allowing the dart past the device and returning fluid flow through the work string. The downhole device may be activated multiple times without removing the downhole device from the wellbore.

Owner:BAKER HUGHES INC

Dual laser coating apparatus and process

ActiveUS7661387B2Promote absorptionEasy temperature controlPretreated surfacesLiquid spraying apparatusTemperature controlLaser coating

An apparatus for applying and fusing a powder coating to substrates of various composition uses two lasers to accurately heat the coating to the optimum temperature. A second laser has less power and heats a smaller area than the first laser. Temperature control is enhanced by the ability to superheterodyne two lasers at separate frequencies. This allows for better absorption of certain materials being fused by the laser. Another common problem associated with laser processing occurs as the polymer heats up. During the heating process the spectral lines are Doppler broadened and slightly shifted. This can affect the absorption of a laser of a fixed wavelength. With the present invention, the optimum laser frequency can be turned to a more optimum frequency for absorption still with sufficient power for fast efficient thermal processing.

Owner:PHOTOFUSION TECH

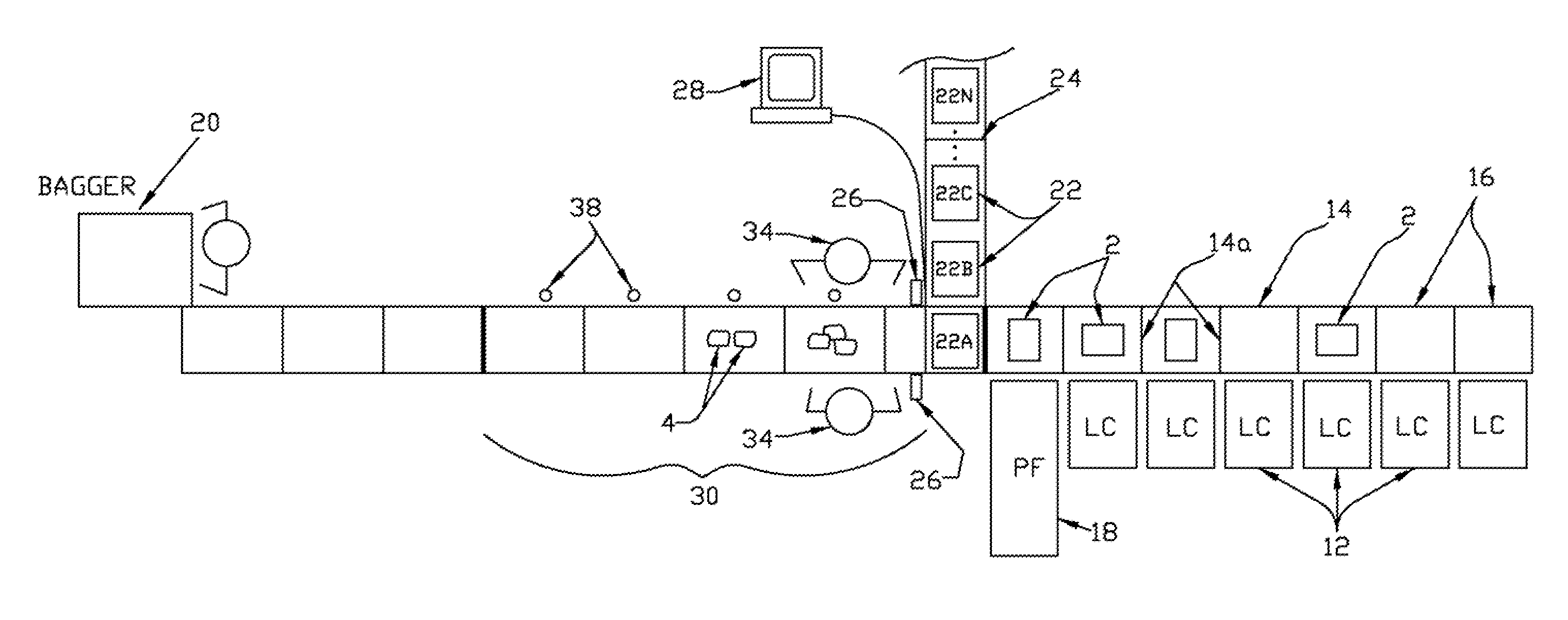

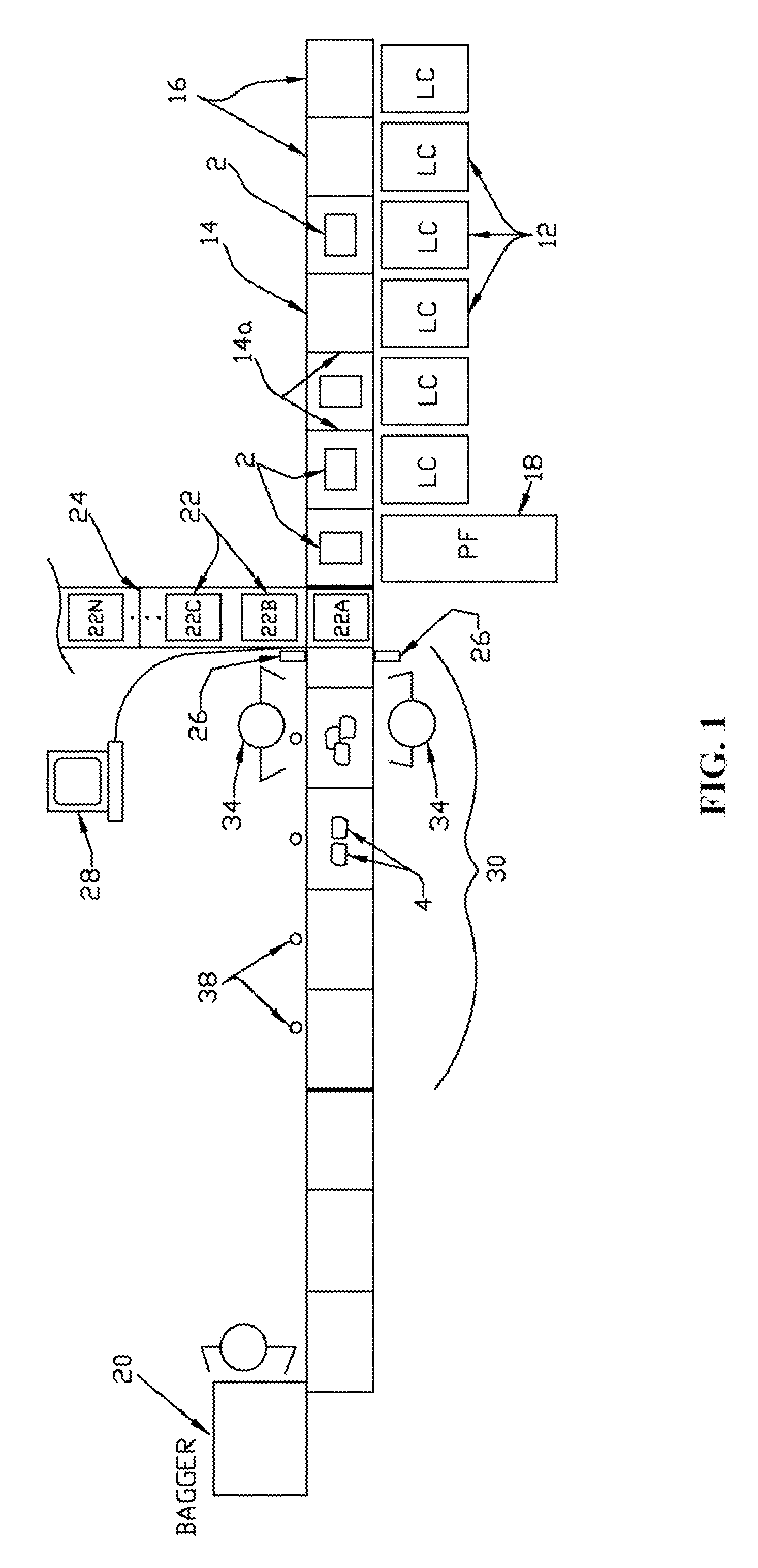

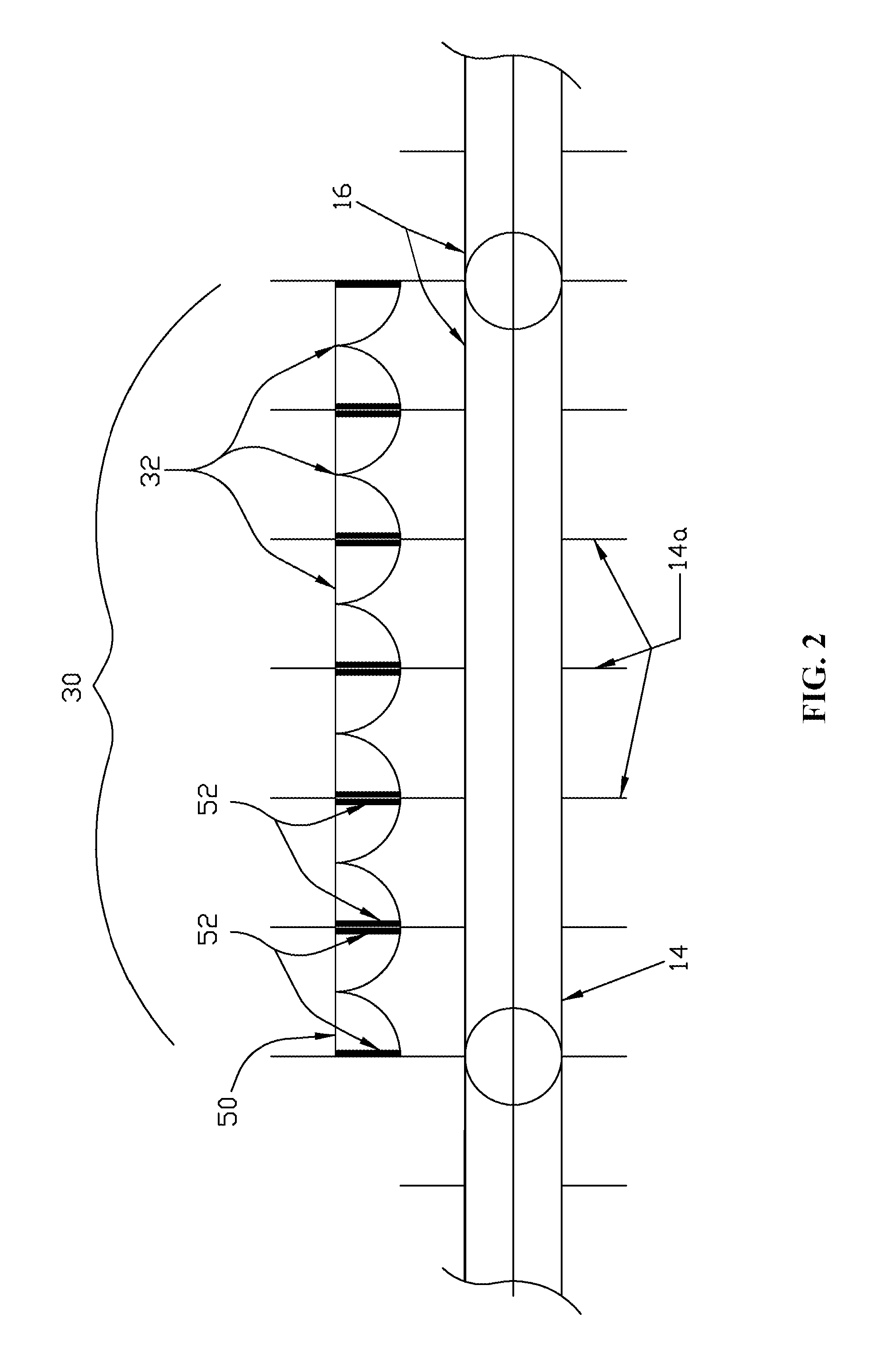

Order sorting system with selective document insertion

ActiveUS20150114798A1Improve throughputShort turnaround timeCharge manipulationPackagingProcess engineeringComputer science

An order sorting system for sorting and assembling a batch of purchaser orders, comprises a plurality of stationary dispensable item dispensers for dispensing dispensable items with on-demand printed literature and a dispensable items conveyor for conveying the dispensable items to a lower level of a sorting station. A tote conveyor conveys a plurality of purchased articles to the upper level of the sorting station. Stationary sorting bins are disposed along an upper level of the sorting station in alignment with the dispensable items conveyor. The purchased articles are moved onto the dispensable items conveyor, either manually or preferably the sorting bins each have a releasable bottom for dropping contents of the sorting bins onto the dispensable items conveyor.

Owner:PSI PERIPHERAL SOLUTIONS

Fluid flow management through a wastewater level manipulation system and associated methods

ActiveUS8983667B2Efficient deliveryEasy to useBiological treatment regulationPressure pumpsWater levelFluid management

A system is provided to control fluid flow in a wastewater treatment system through wastewater level manipulation. The wastewater treatment system may include a wastewater treatment plant connected to a plurality of pump stations by a main. Each of the plurality of pump stations may include a wet well with a pump therein. The system may include a central server in communication with a sensor to sense a level of wastewater within the wet well. The pump may be automatically moved to an on position when the level of the wastewater in the wet well is at or above a first level and may be automatically moved to an off position when the level of the wastewater in the respective wet well is at or below a pump cutoff level. The central server may systematically manipulate the first level to selectively set the level of wastewater within the wet well.

Owner:DATA FLOW SYST

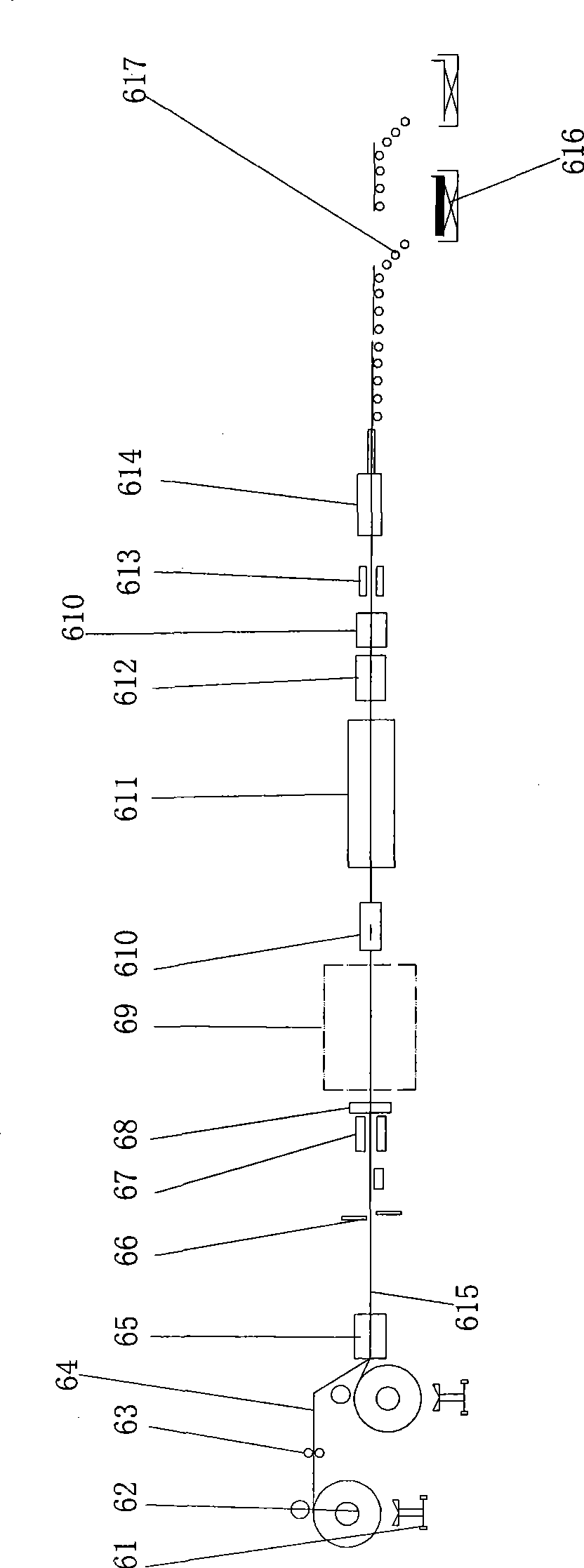

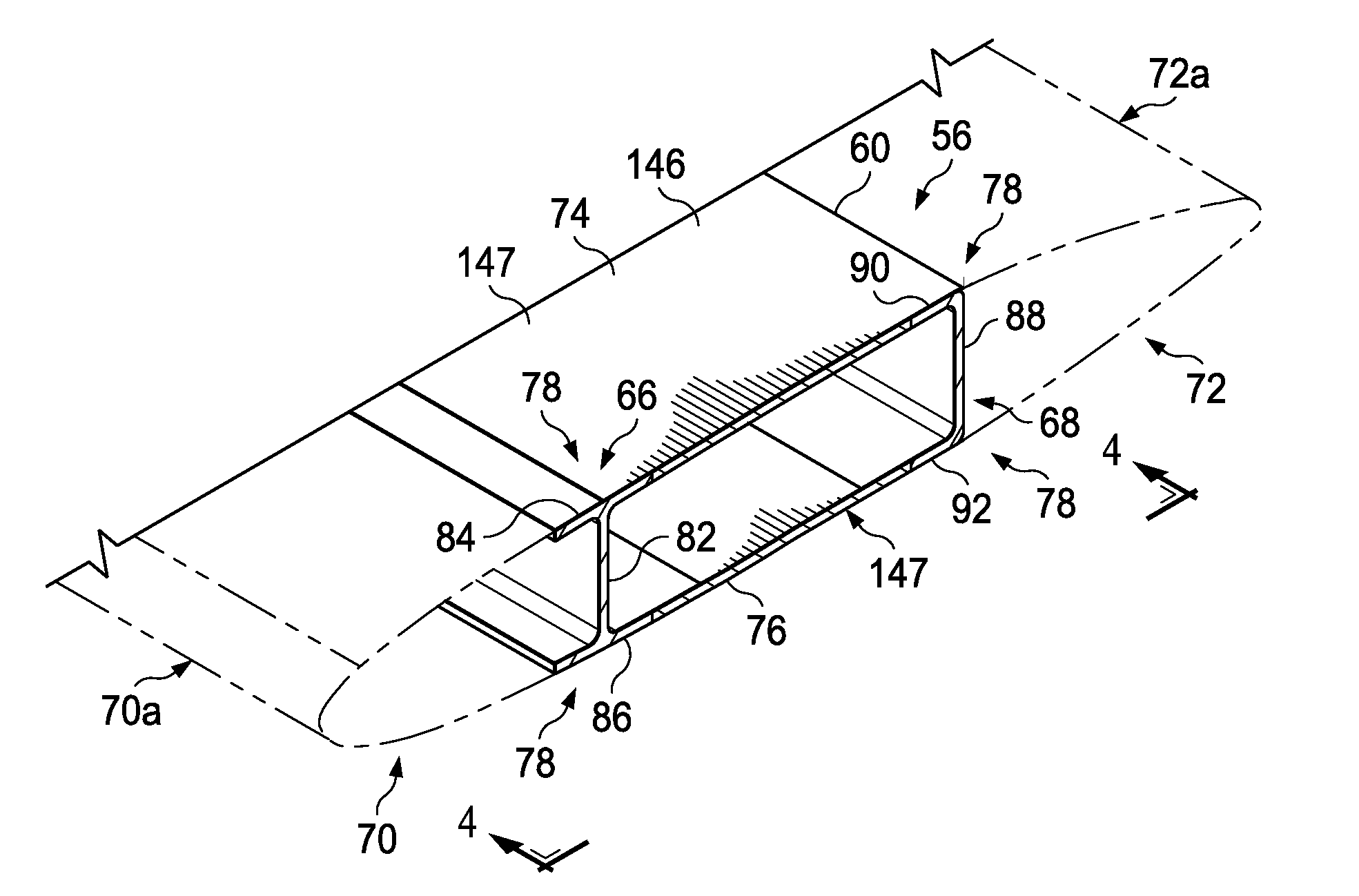

Method for processing bottom cross beam or bottom side beam of container and system for producing the same

ActiveCN101497165AShort turnaround timeIncrease productivityOther manufacturing equipments/toolsScrapCushioning

The invention discloses a method for processing bottom cross beams or bottom side beams of a container, which processes the bottom cross beams and the bottom side beams in the same working area through a plurality of steps sequentially. The steps mainly include material loading, decoiling, pinch conveying, leveling, head cropping, end cropping and butt joint, waste collecting, guiding, pinch conveying, looping pit cushioning, deburring, roll forming, leveling, high-pressure blow drying and high temperature drying, ball blasting, electric static spraying, drying, leveling, numerically controlled specified length tracing shearing, conveying, and formed workpiece piling and blanking. The processing method has the advantages of high production efficiency, cost conservation and the like. The invention also discloses a production system for the processing method.

Owner:TAICANG CIMC CONTAINER CO LTD

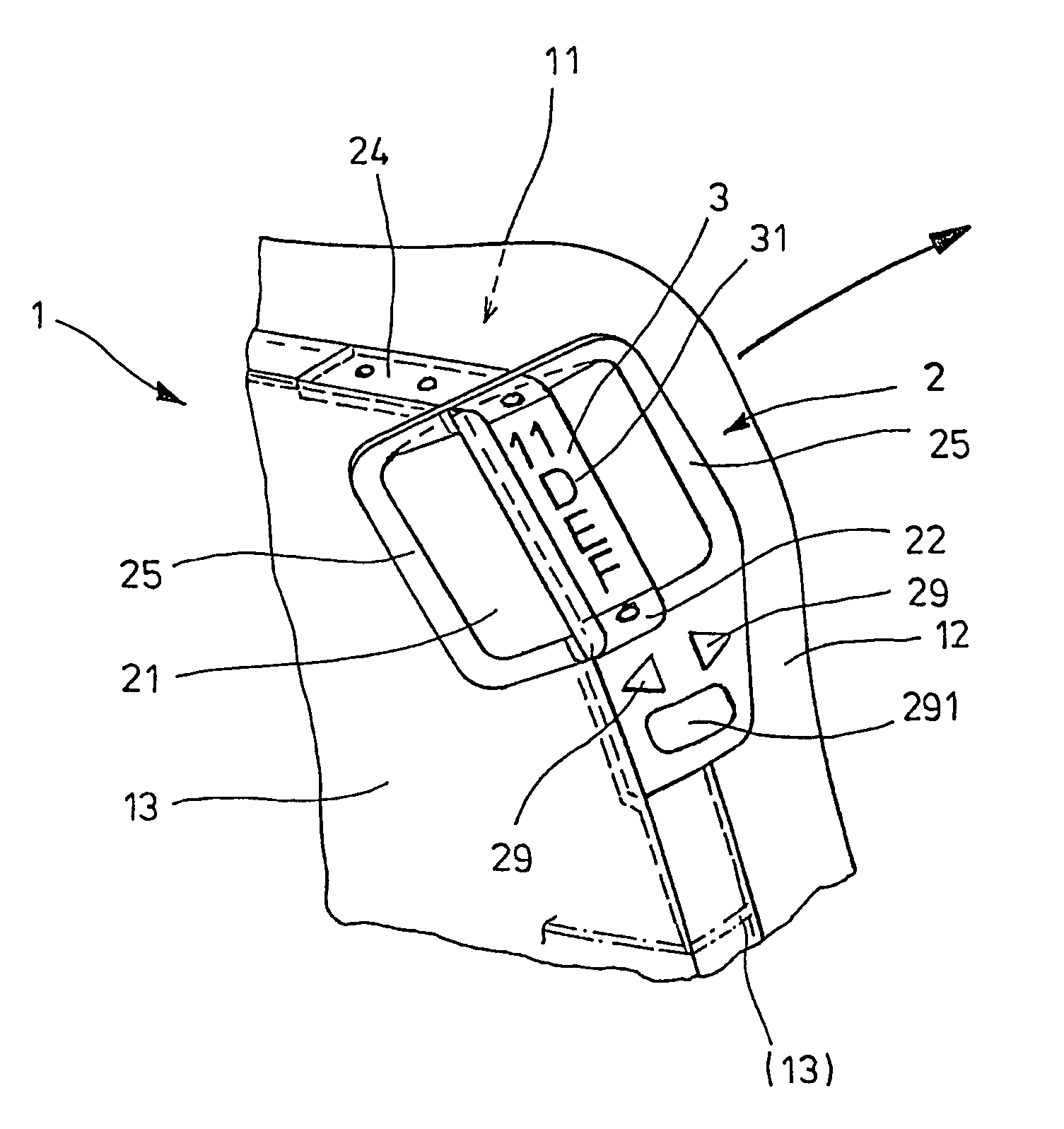

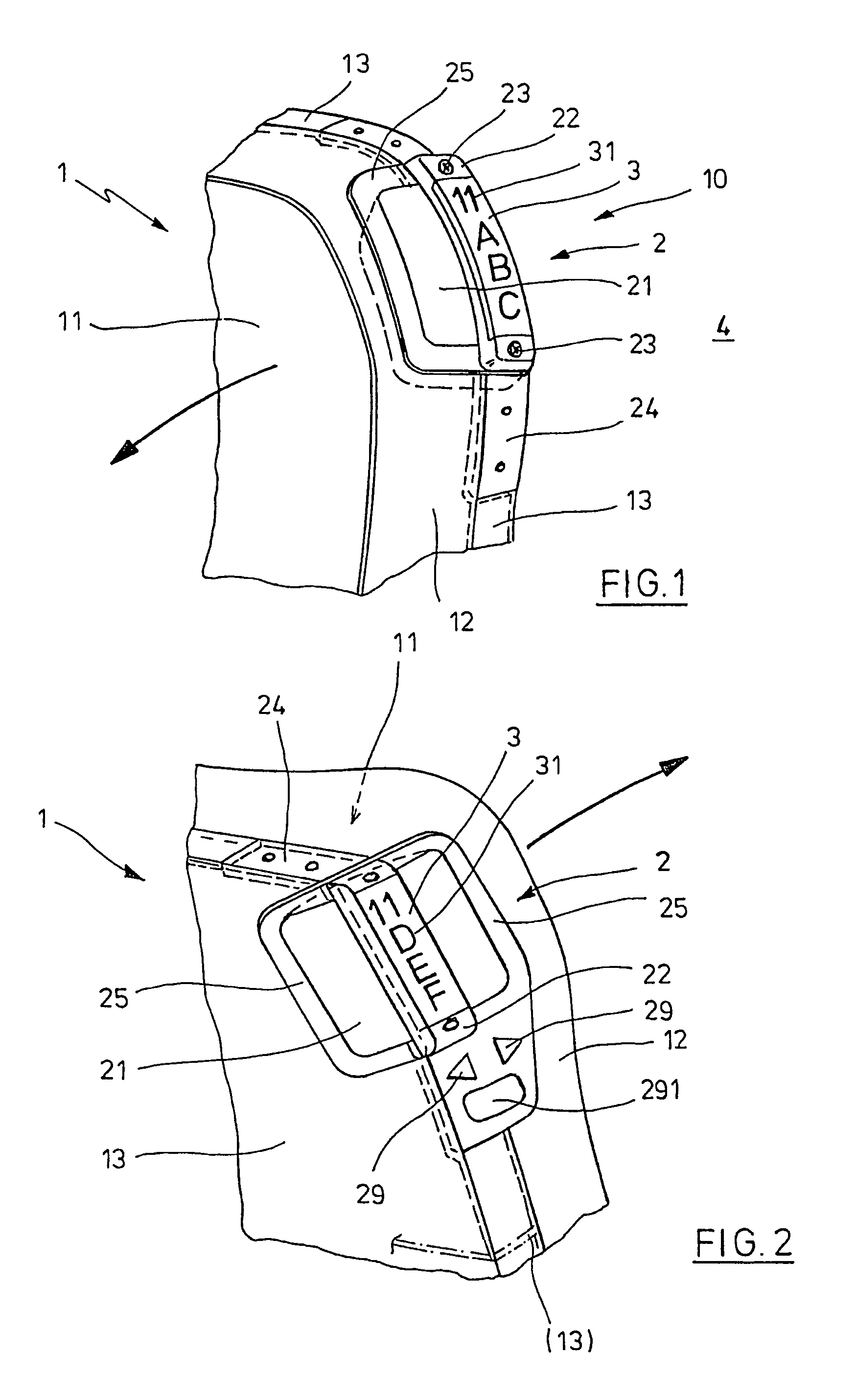

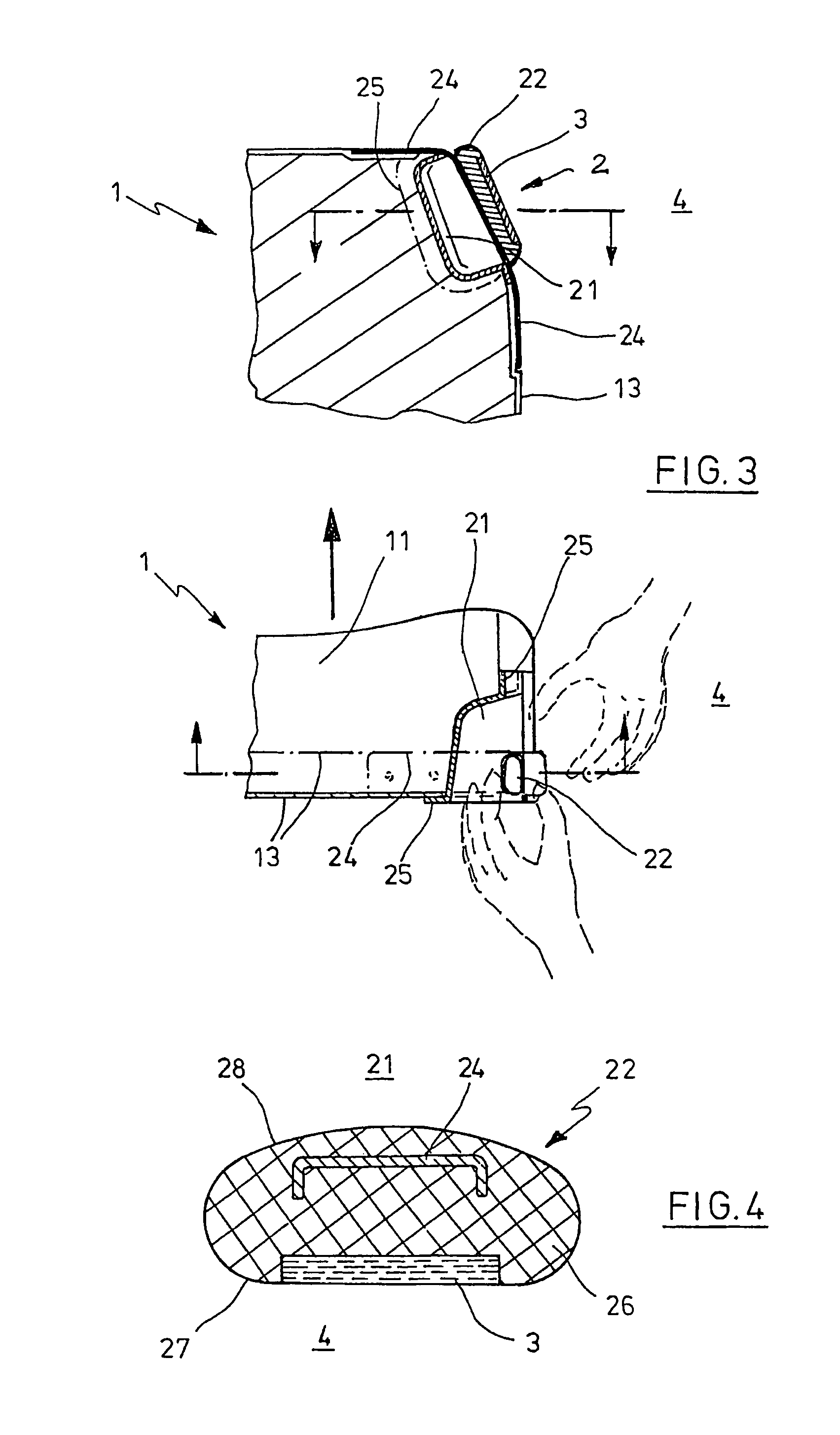

Arrangement of a safety and information device on at least one passenger seat in a passenger cabin of a commercial aircraft

InactiveUS7111808B2Safety of persons standing in the aislesImproving the passenger comfortVehicle arrangementsSeating arrangementsInformation functionInformation device

Owner:AIRBUS OPERATIONS GMBH

Fluid flow management system and associated methods

ActiveUS8600568B2Efficient deliveryEasy to useTesting/calibration apparatusLevel controlFluid managementFlow management

A system is provided to control fluid flow in a wastewater treatment system. The wastewater treatment system may include a wastewater treatment plant and a main that connects a plurality of pump stations to the wastewater treatment plant. Each of the plurality of pump stations may include a wet well and a pump carried by the wet well to pump the wastewater. The system may include a central server and a sensor in communication with the central server to sense a level of wastewater within the wet well. The pump may be moved to an on position when the level of the wastewater in the wet well is at or above a first level. The level of wastewater within the wet well may be systematically manipulated responsive to the central server to control the fluid flow in the wastewater treatment system. The system advantageously enhances fluid management in a wastewater treatment system, increases life span of the wastewater treatment plant, and saves energy associated with running pumps at the pump stations of the wastewater treatment system.

Owner:DATA FLOW SYST

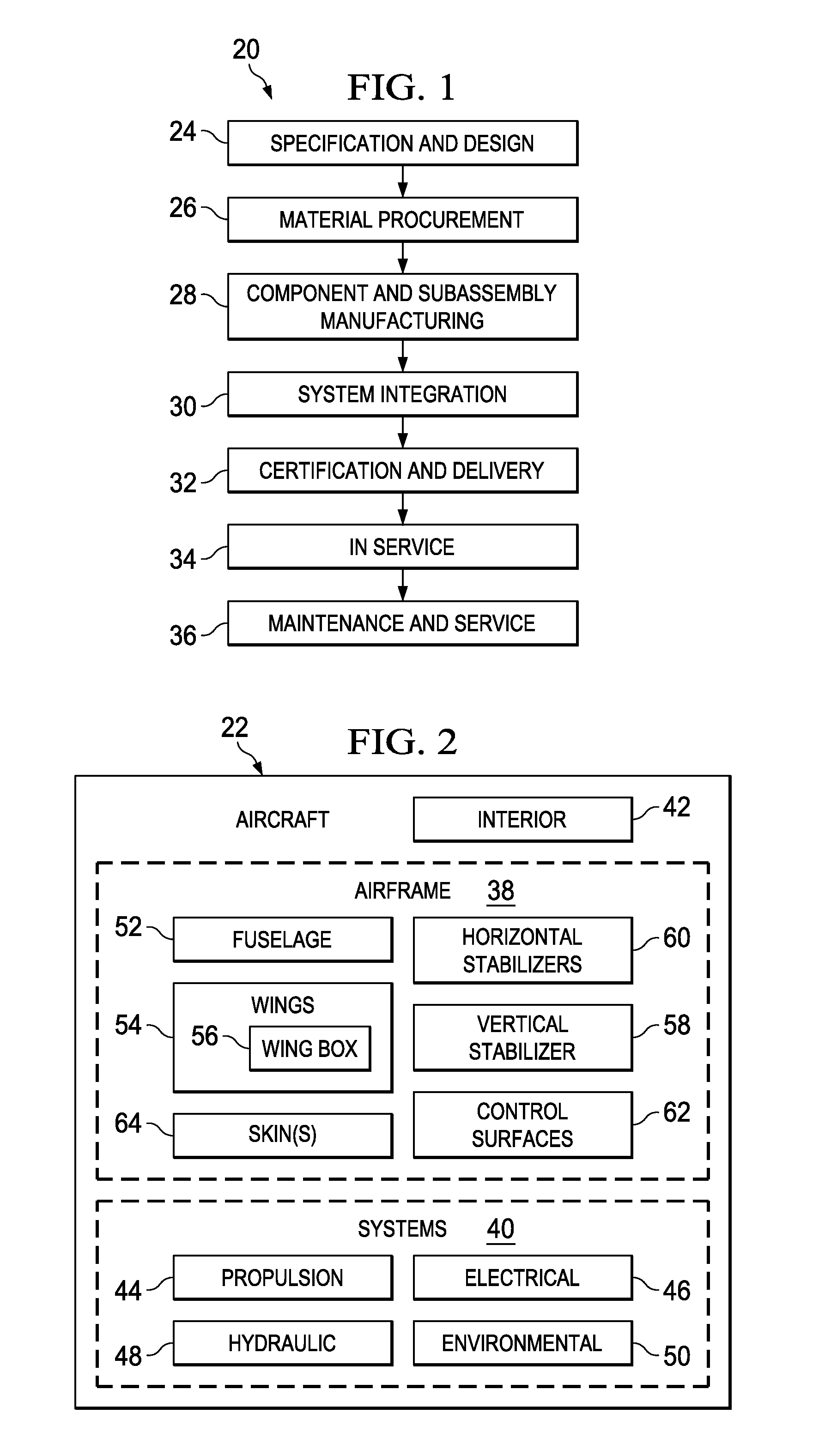

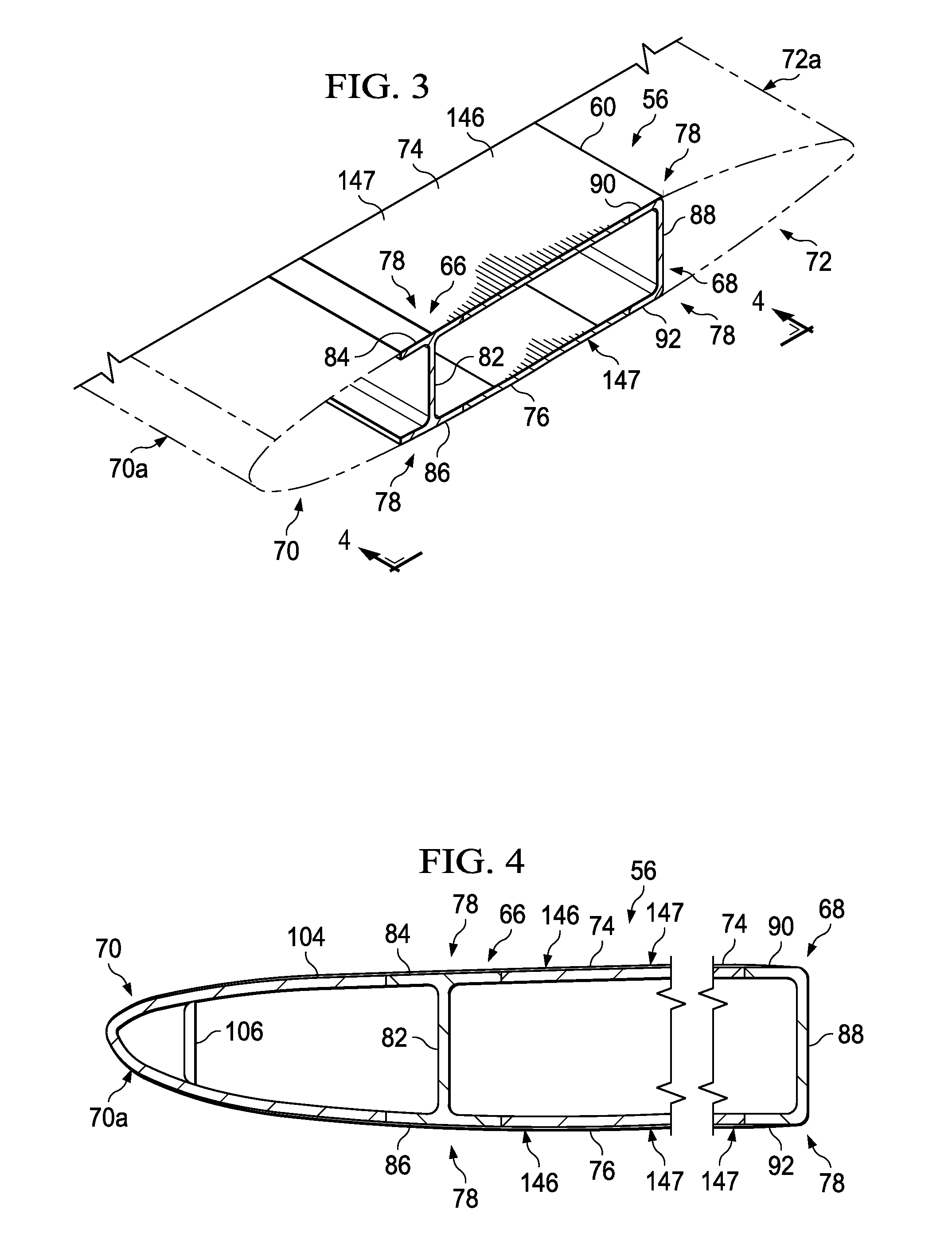

Bonded composite airfoil

ActiveUS9352822B2Quality improvementReduce and eliminate needAircraft stabilisationLaminationComposite skinEngineering

An airfoil includes at least one precured composite spar having a web and at least one flange integrated with an end of the web. A precured composite skin is attached to the spar by adhesive bonding the skin to the flange.

Owner:THE BOEING CO

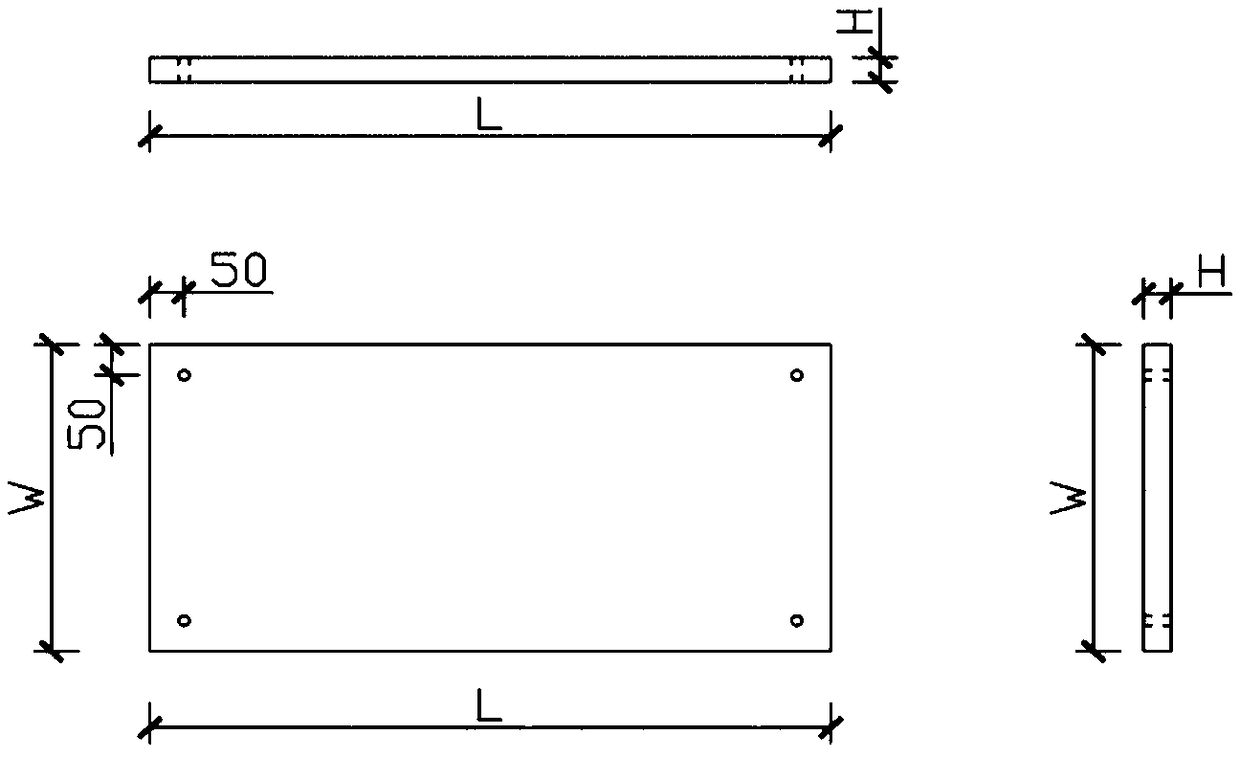

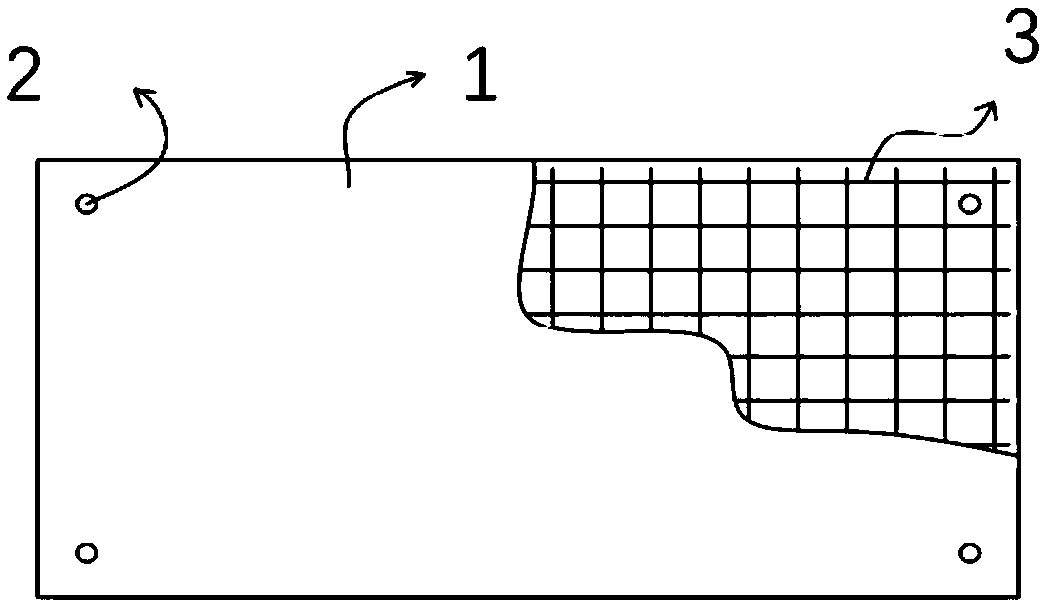

Ultra-high-flexibility concrete inorganic decorative board having pattern-contained surface and preparation method thereof

PendingCN109138310AImprove toughnessSmall shrinkageCovering/liningsCeramic shaping apparatusFlexural strengthCompressive strength

The invention, which relates to the technical field of building decoration materials, discloses an ultra-high-flexibility concrete inorganic decorative board having a pattern-contained surface. The ultra-high-flexibility concrete inorganic decorative board is made of ultra-high-flexibility concrete reinforcement bars by means of prefabrication, wherein the ultra-high-flexibility concrete reinforcement bars have the compressive strength greater than 100 MPa and the bending strength greater than 16 MPa. A decoration pattern is formed on the upper surface of the decorative board; and communicatedmounting bolt holes are formed in the four corners of the decorative board. The reinforcement bars are criss-cross webs; and the adjacent decorative boards are connected by using structural sealants.According to the invention, the inorganic decorative board that is prepared by using ultra-high-flexibility concrete based on vacuum defoaming has characteristics of high flexibility, diversified decorative effects, compact structure without pores, short mold turnover period, relatively low price, good fire-resistant performance, good staining-resistant and waterproof properties, and high durability and is suitable for development and application of green energy-saving decorative materials.

Owner:黄贺明

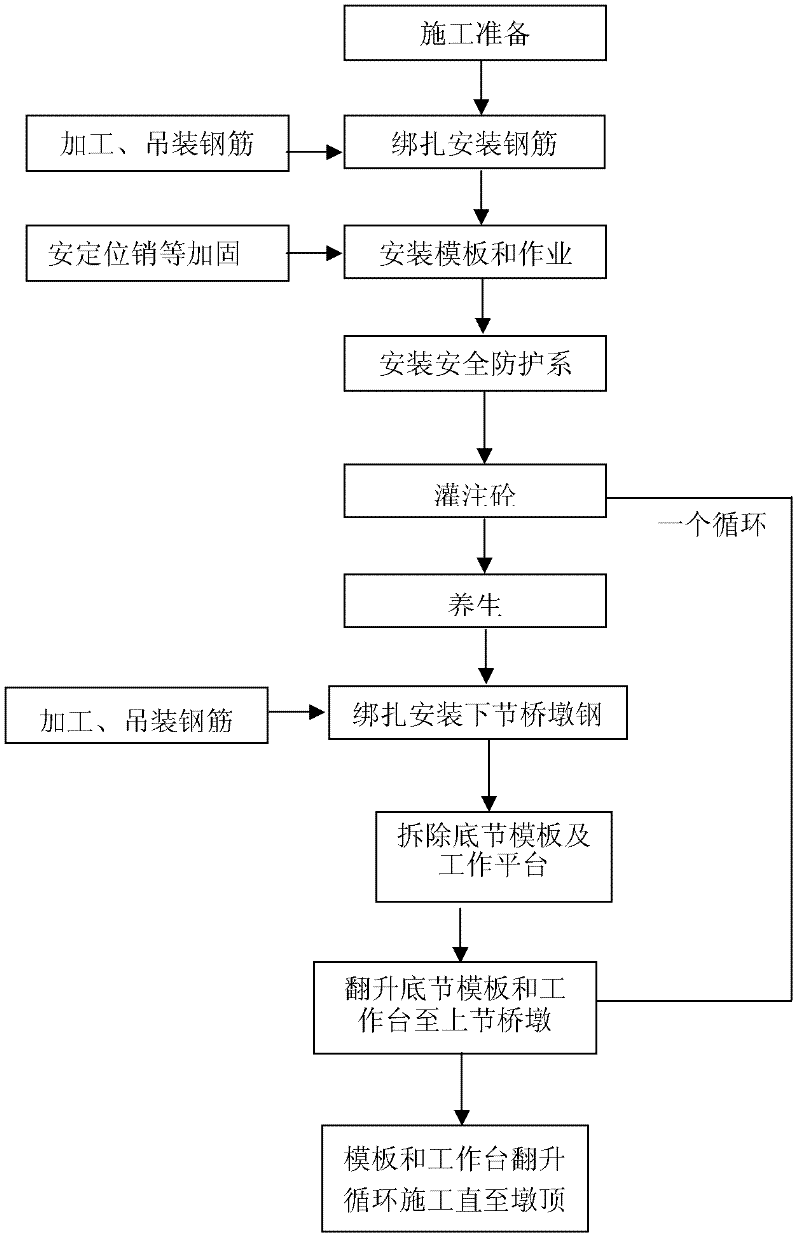

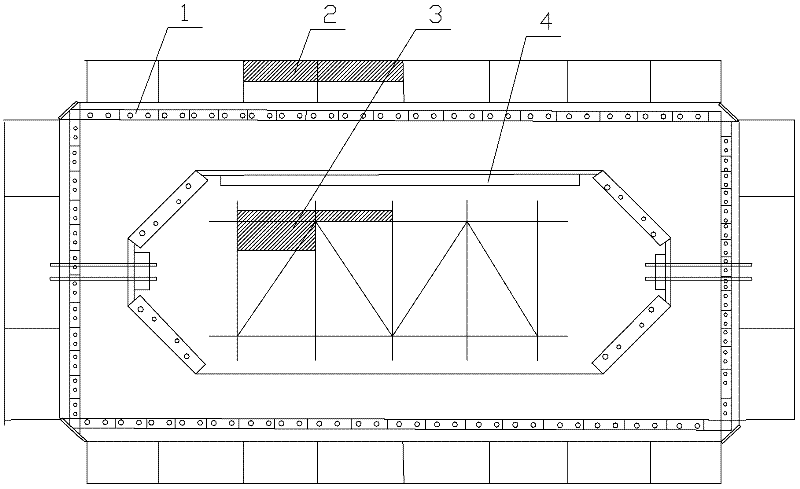

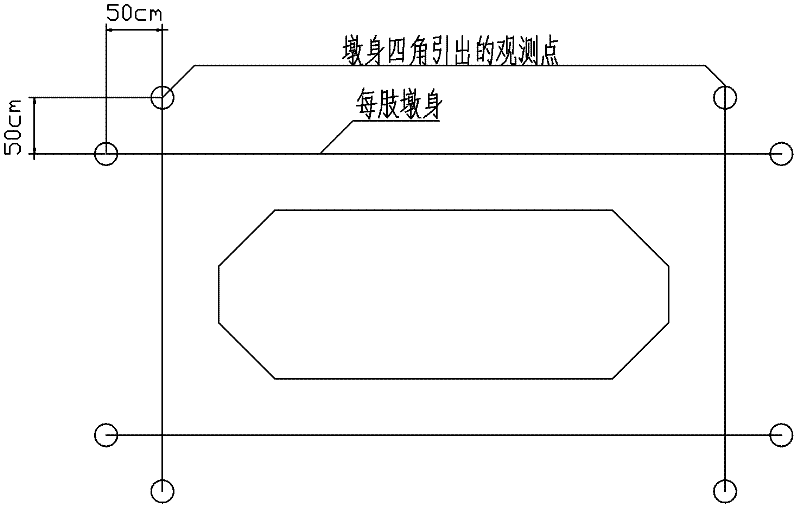

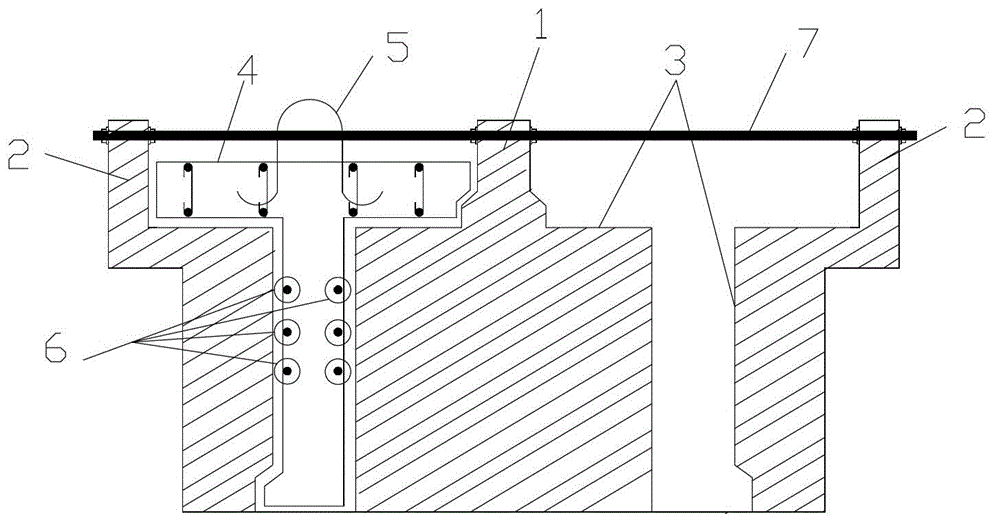

Method for constructing high pier

InactiveCN102409617AShort molding cycleShort turnaround timeBridge structural detailsBridge erection/assemblyEngineeringUltimate tensile strength

The invention discloses a method for constructing a high pier, which comprises the following steps of: 1) constructing a first section of pier through at least two upper and lower templates; 2) after concrete strength in a bottom template is more than or equal to 75 percent of design strength and concrete strength in the uppermost template is more than or equal to 2.5Mpa, detaching the bottom template and turning the bottom template above the uppermost template to serve as a second section of pier for installation, and finishing construction of the second section of pier; and 3) repeating the step 2) until construction of the whole pier is finished. Compared with a sliding formwork method, the method has the advantages that: the molding period is short, the pier is convenient to construct, and the method is convenient to operate; and compared with a creeping formwork method, the method has the advantages that: the molding period is short, a high scaffold is not needed to be erected, a few materials are occupied, and construction cost is low. The method has the advantages of sliding formwork and creeping formwork construction methods, the turnover period of the template is short, the construction period of each section of pier is short and is generally about five days, and the concrete joint of the pier has high quality.

Owner:TIANJIN 20 CONSTR

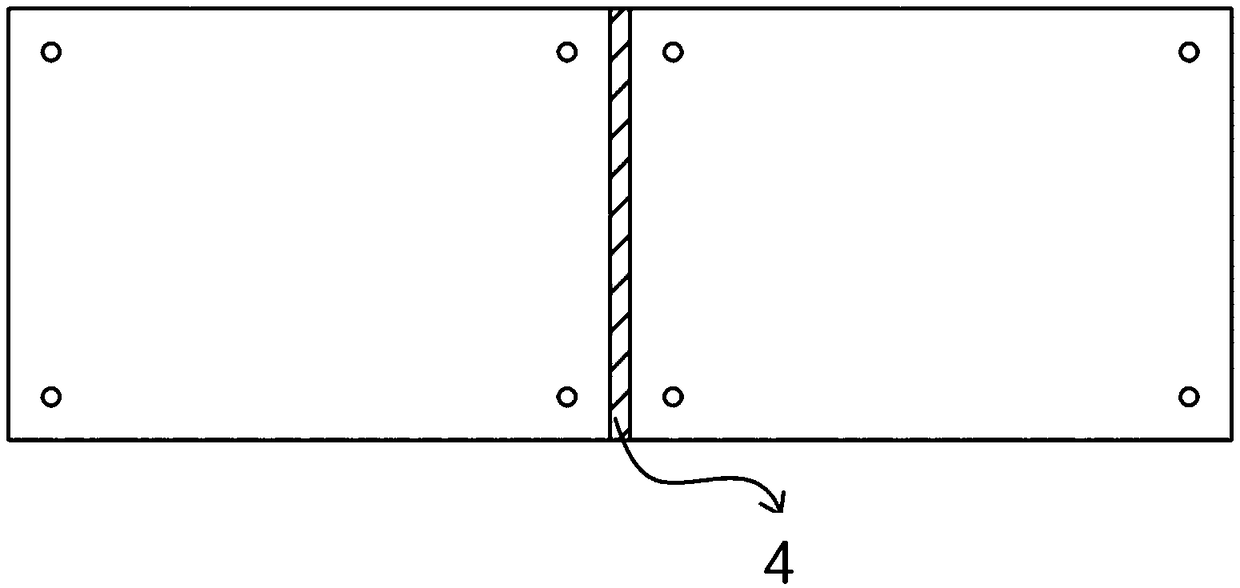

Construction method for bare concrete prefabricated stand board

InactiveCN103334588AHigh densitySmooth surface and good decorative effectBuilding material handlingReinforced concreteRebar

The invention relates to the field of concrete prefabricated members, in particular to a construction method for a bare concrete prefabricated stand board. The method comprises construction preparation, template manufacturing, steel bar framework manufacturing, concrete casting and vibrating, curing, demolding, piling and marking, and is characterized by comprising the following specific steps of: (1) making preparation for construction; (2) manufacturing a template; (3) manufacturing a steel bar framework; (4) coating an optical parting agent; (5) arranging a bracket; (6) inserting the steel bar framework into a mold; (7) assembling a steel mold; (8) fixing an embedded part and a hoisting ring; (9) performing self-checking and rechecking; (10) casting and vibrating concrete; (11) curing; (12) demolding and drawing; and (13) piling and marking. Compared with the prior art, the construction method has the beneficial effects of easiness and convenience in manufacturing, short turnover period, accurate geometric size, high construction speed, batch production and laminated assembly; due to the adoption of a prefabricating process, the engineering cost is reduced; and the construction method is particularly suitable for assembled reinforced concrete structures with high decorating requirements in large-sized stadiums.

Owner:ANSHAN NORTHEAST CONSTR ARCHITECTURAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com