Method for processing bottom cross beam or bottom side beam of container and system for producing the same

A processing method and technology of a production system, which are applied in the production system, the processing related to the bottom side beam, and the field of the container bottom beam, can solve the problems of unfavorable container bottom beam, increase the cost of human resources, reduce the cost of the bottom side, etc., and save circulation. Time, reduce duplication of labor, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

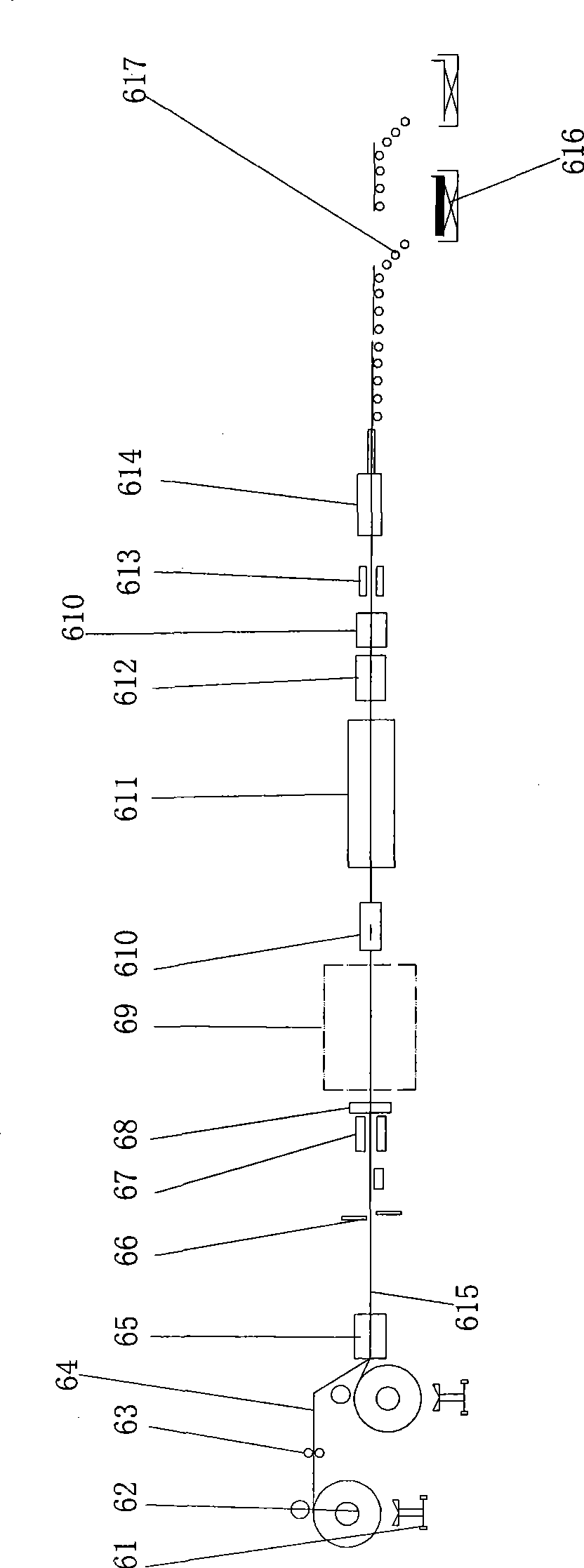

[0033] see figure 1 , the container bottom beam or bottom side beam of the present invention adopts the production system shown in the figure, and the production system has the following processing devices: double feeding trolleys 61, double uncoilers 62, pinching devices 63, transition frames 64, leveling machines 65. Shearing machine 66, burr machine 67, vertical roller device 68, roller machine 69, drying device 610, sanding machine 611, electrostatic spraying device 612, drying device 610, straightening device 613, CNC hydraulic punching and shearing machine 614 1. Stacking device 616, each processing device is sequentially arranged in the same working area to form an overall production line adjacent to each other and arranged in a straight line. The steel strip is discharged, and the steel strip is extended to the numerical control hydraulic punching and shearing machine in sequence along each device, and is punched and sheared by the numerical control hydraulic punching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com