Construction method for bare concrete prefabricated stand board

A technology of fair-faced concrete and construction methods, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of long construction period, failure to achieve the surface decoration effect of fair-faced concrete, and failure to meet the construction period, etc., and achieve short turnover period , good decorative effect and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described step by step:

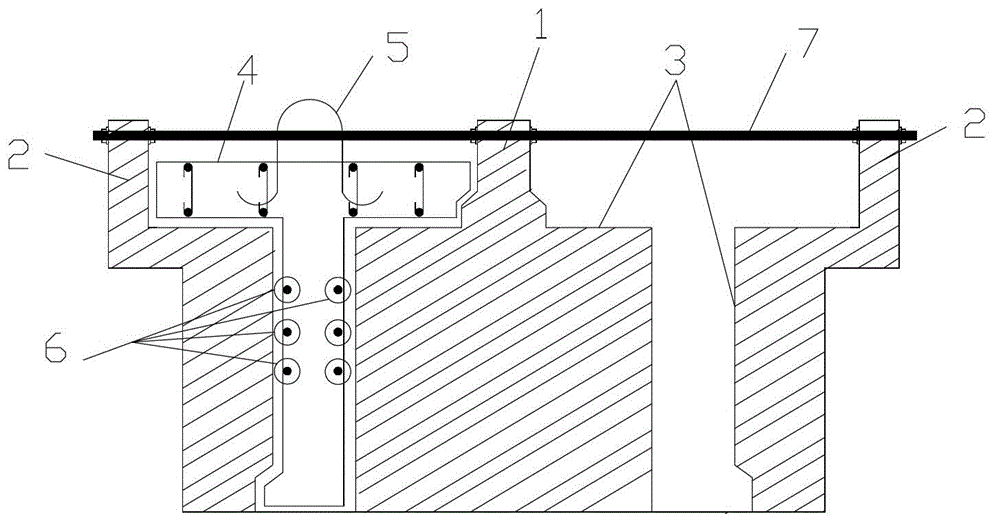

[0029] Such as figure 1 , is a schematic diagram of the mold state during the construction of the stand plate embodiment of the present invention. The formwork 1 is a steel integral formwork, wherein the main bearing frame of the bottom formwork is a 240mm channel steel, the surface formwork adopts a 6mm steel plate, and the side formwork 2 is on an 80mm channel steel frame. Combination of 6mm steel plate and 80mm angle steel welded body; in the process of making the template, the allowable error of each dimension is ±2mm; the upper and lower parts of the template are controlled by screw rods 7, and the distance between adjacent screw rods 7 is 1~1.2m; In the formwork, paint the light release agent on 3 places on the inner surface of the mold; place the plastic bracket 6 at the position of the main reinforcement at the 4 places of the steel skele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com