Method for constructing high pier

A construction method and high pier technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of high construction cost, long construction period, and large material occupation, and achieve low construction cost, short construction period, and less material occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

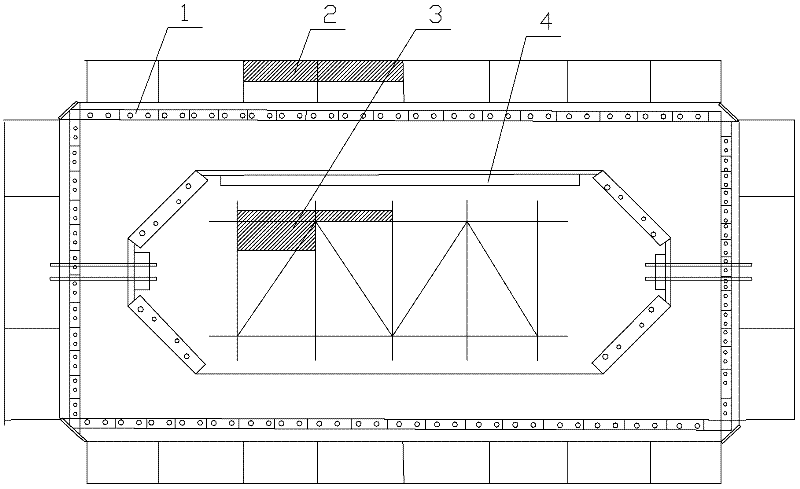

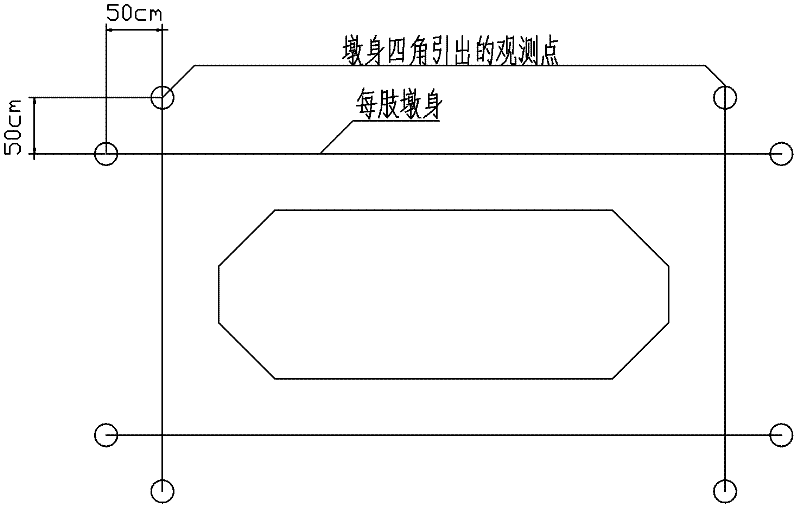

[0016] see Figure 1 ~ Figure 3 .

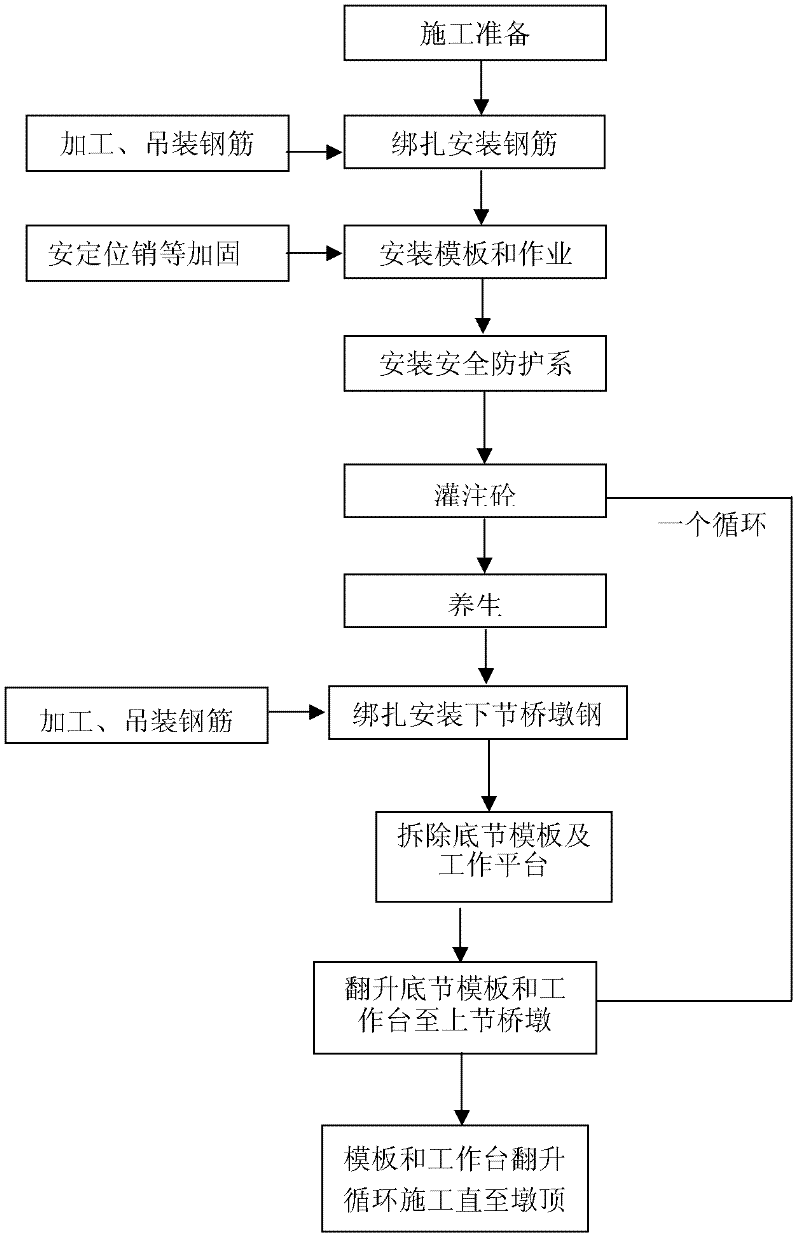

[0017] A construction method for a high bridge pier, comprising the steps of:

[0018] 1) Construction preparation

[0019] Before construction, personnel, machinery and equipment, site and other preparations should be made. After the formwork is manufactured in the factory, it should be inspected and tested to see if it meets the design requirements and numbered. After the formwork is transported to the construction site, a trial assembly is required.

[0020] 2) Binding and installing the steel bars of the first pier

[0021] 3) Assembly of the first pier formwork

[0022] The formwork for the first pier section uses at least two formwork sections, upper and lower, and is lifted by tower cranes and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com